66d9cb0e5c30011a0e3337f391e2c557.ppt

- Количество слайдов: 90

Introduction & Agenda • • 3 Why we need VFDs What is a VFD Savings Where VFDs are used How VFDs are used Motor Questions Honeywell VFD Product Line Tools

Introduction & Agenda • • 3 Why we need VFDs What is a VFD Savings Where VFDs are used How VFDs are used Motor Questions Honeywell VFD Product Line Tools

Why Do We Need VFDs? Green Smart 4 Energy Savings

Why Do We Need VFDs? Green Smart 4 Energy Savings

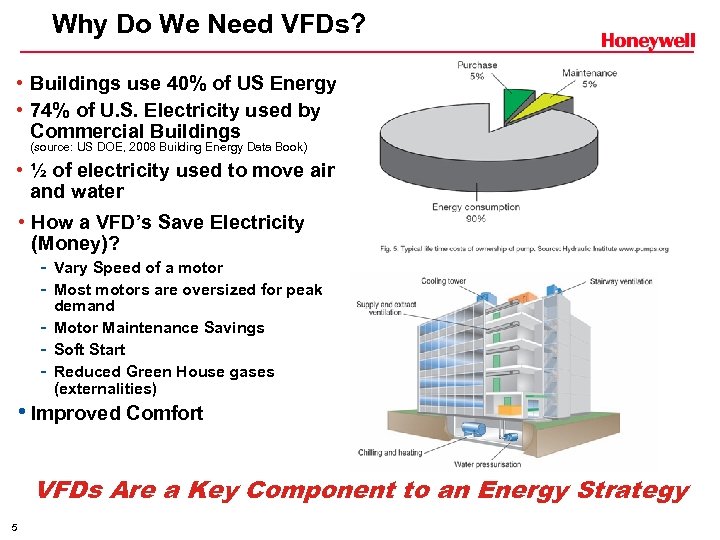

Why Do We Need VFDs? • Buildings use 40% of US Energy • 74% of U. S. Electricity used by Commercial Buildings (source: US DOE, 2008 Building Energy Data Book) • ½ of electricity used to move air and water • How a VFD’s Save Electricity (Money)? - Vary Speed of a motor - Most motors are oversized for peak - demand Motor Maintenance Savings Soft Start Reduced Green House gases (externalities) • Improved Comfort VFDs Are a Key Component to an Energy Strategy 5

Why Do We Need VFDs? • Buildings use 40% of US Energy • 74% of U. S. Electricity used by Commercial Buildings (source: US DOE, 2008 Building Energy Data Book) • ½ of electricity used to move air and water • How a VFD’s Save Electricity (Money)? - Vary Speed of a motor - Most motors are oversized for peak - demand Motor Maintenance Savings Soft Start Reduced Green House gases (externalities) • Improved Comfort VFDs Are a Key Component to an Energy Strategy 5

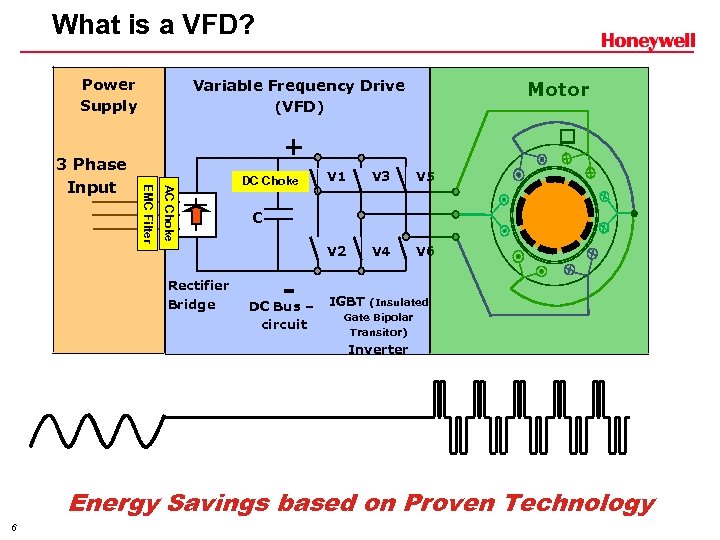

What is a VFD? Power Supply Motor + Rectifier Bridge DC Choke V 1 V 3 V 5 V 2 AC Choke EMC Filter 3 Phase Input Variable Frequency Drive (VFD) V 4 V 6 C - DC Bus – circuit IGBT (Insulated Gate Bipolar Transitor) Inverter Energy Savings based on Proven Technology 6

What is a VFD? Power Supply Motor + Rectifier Bridge DC Choke V 1 V 3 V 5 V 2 AC Choke EMC Filter 3 Phase Input Variable Frequency Drive (VFD) V 4 V 6 C - DC Bus – circuit IGBT (Insulated Gate Bipolar Transitor) Inverter Energy Savings based on Proven Technology 6

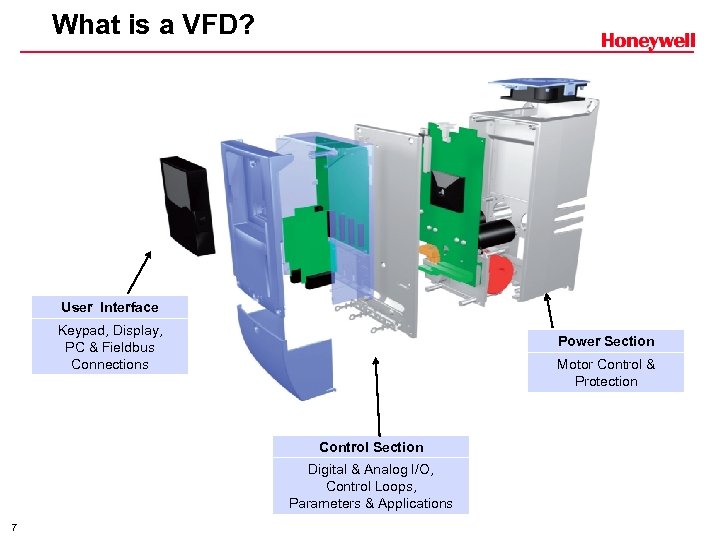

What is a VFD? User Interface Keypad, Display, PC & Fieldbus Connections Power Section Motor Control & Protection Control Section Digital & Analog I/O, Control Loops, Parameters & Applications 7

What is a VFD? User Interface Keypad, Display, PC & Fieldbus Connections Power Section Motor Control & Protection Control Section Digital & Analog I/O, Control Loops, Parameters & Applications 7

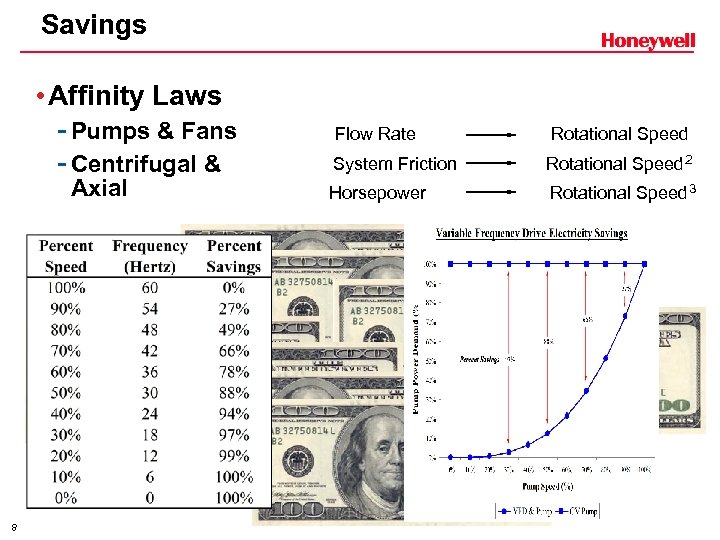

Savings • Affinity Laws - Pumps & Fans - Centrifugal & Axial 8 Flow Rate Rotational Speed System Friction Rotational Speed 2 Horsepower Rotational Speed 3

Savings • Affinity Laws - Pumps & Fans - Centrifugal & Axial 8 Flow Rate Rotational Speed System Friction Rotational Speed 2 Horsepower Rotational Speed 3

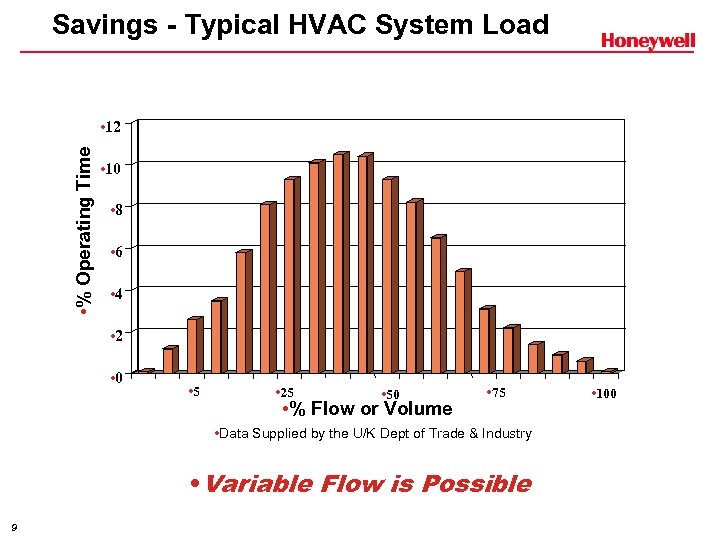

Savings - Typical HVAC System Load • % Operating Time • 12 • 10 • 8 • 6 • 4 • 2 • 0 • 5 • 25 • 50 • % Flow or Volume • 75 • Data Supplied by the U/K Dept of Trade & Industry • Variable Flow is Possible 9 • 100

Savings - Typical HVAC System Load • % Operating Time • 12 • 10 • 8 • 6 • 4 • 2 • 0 • 5 • 25 • 50 • % Flow or Volume • 75 • Data Supplied by the U/K Dept of Trade & Industry • Variable Flow is Possible 9 • 100

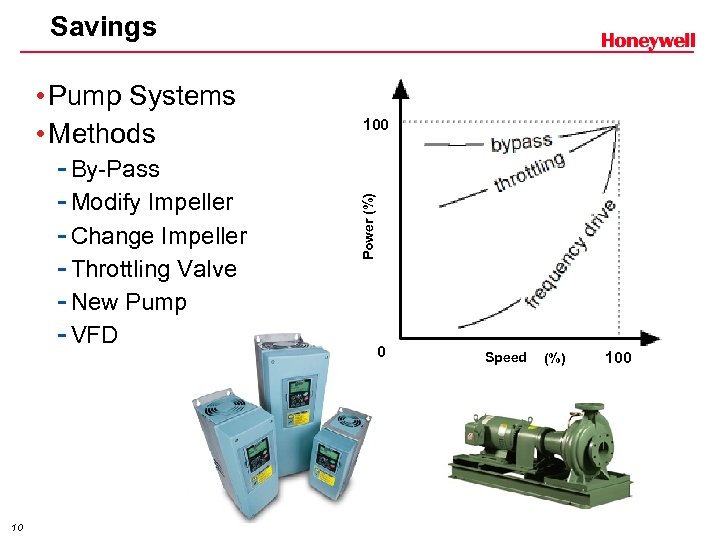

Savings 10 100 Power (%) • Pump Systems • Methods - By-Pass - Modify Impeller - Change Impeller - Throttling Valve - New Pump - VFD 0 Speed Flow Rate (%) 100

Savings 10 100 Power (%) • Pump Systems • Methods - By-Pass - Modify Impeller - Change Impeller - Throttling Valve - New Pump - VFD 0 Speed Flow Rate (%) 100

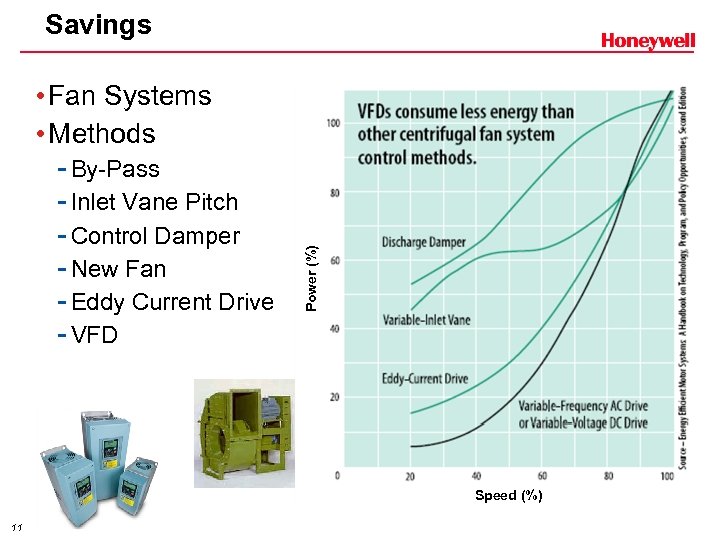

• Fan Systems • Methods - By-Pass - Inlet Vane Pitch - Control Damper - New Fan - Eddy Current Drive - VFD Power (%) Savings Speed (%) 11

• Fan Systems • Methods - By-Pass - Inlet Vane Pitch - Control Damper - New Fan - Eddy Current Drive - VFD Power (%) Savings Speed (%) 11

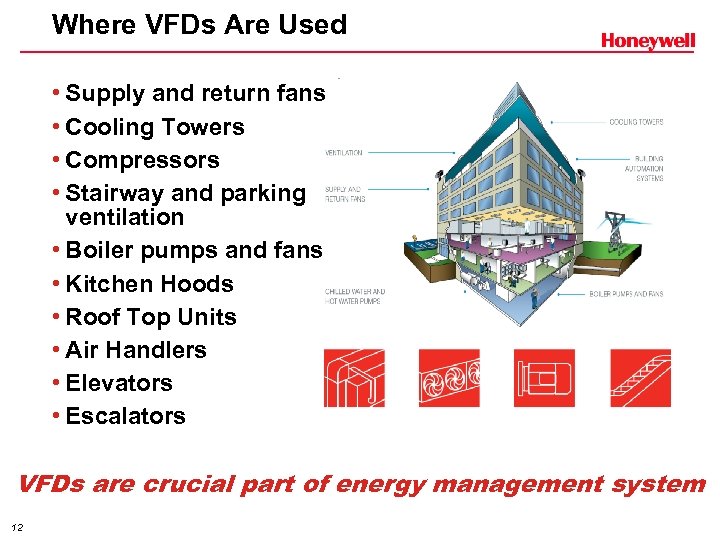

Where VFDs Are Used • Supply and return fans • Cooling Towers • Compressors • Stairway and parking ventilation • Boiler pumps and fans • Kitchen Hoods • Roof Top Units • Air Handlers • Elevators • Escalators VFDs are crucial part of energy management system 12

Where VFDs Are Used • Supply and return fans • Cooling Towers • Compressors • Stairway and parking ventilation • Boiler pumps and fans • Kitchen Hoods • Roof Top Units • Air Handlers • Elevators • Escalators VFDs are crucial part of energy management system 12

Where VFDs are Used – Fans and Pumps 13

Where VFDs are Used – Fans and Pumps 13

Where VFDs are Used - Packaged Equipment 14

Where VFDs are Used - Packaged Equipment 14

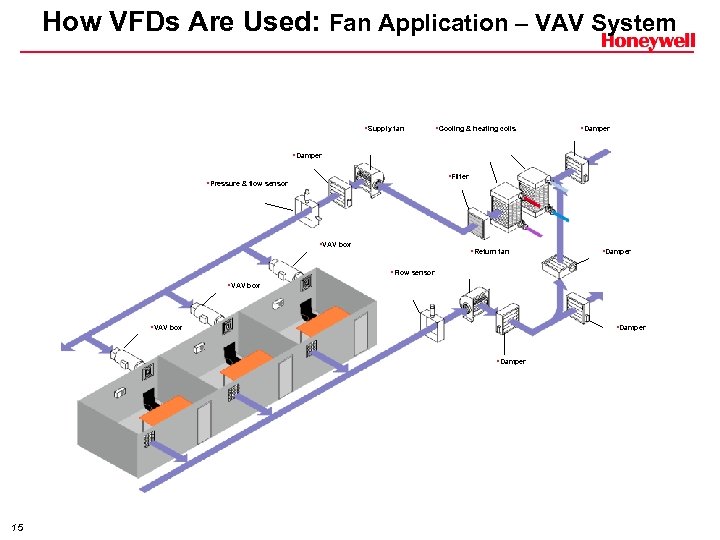

How VFDs Are Used: Fan Application – VAV System • Supply fan • Cooling & heating coils • Damper • Filter • Pressure & flow sensor • VAV box • Return fan • Damper • Flow sensor • VAV box • Damper 15

How VFDs Are Used: Fan Application – VAV System • Supply fan • Cooling & heating coils • Damper • Filter • Pressure & flow sensor • VAV box • Return fan • Damper • Flow sensor • VAV box • Damper 15

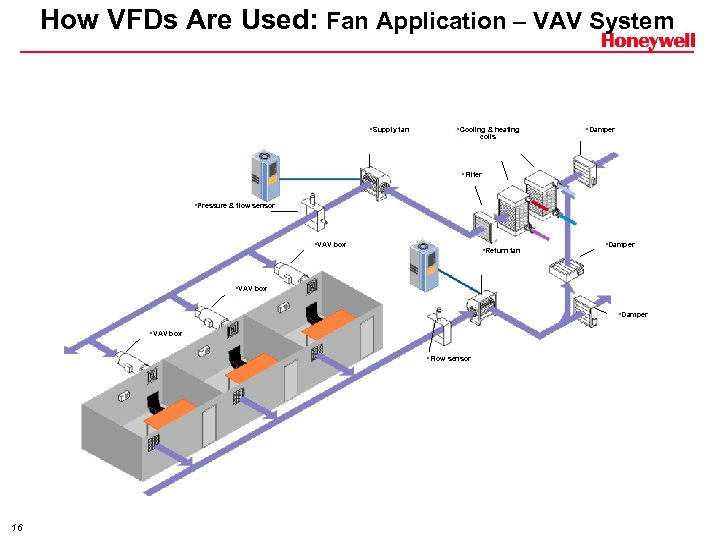

How VFDs Are Used: Fan Application – VAV System • Supply fan • Cooling & heating coils • Damper • Filter • Pressure & flow sensor • VAV box • Return fan • Damper • VAV box • Damper • VAV box • Flow sensor 16

How VFDs Are Used: Fan Application – VAV System • Supply fan • Cooling & heating coils • Damper • Filter • Pressure & flow sensor • VAV box • Return fan • Damper • VAV box • Damper • VAV box • Flow sensor 16

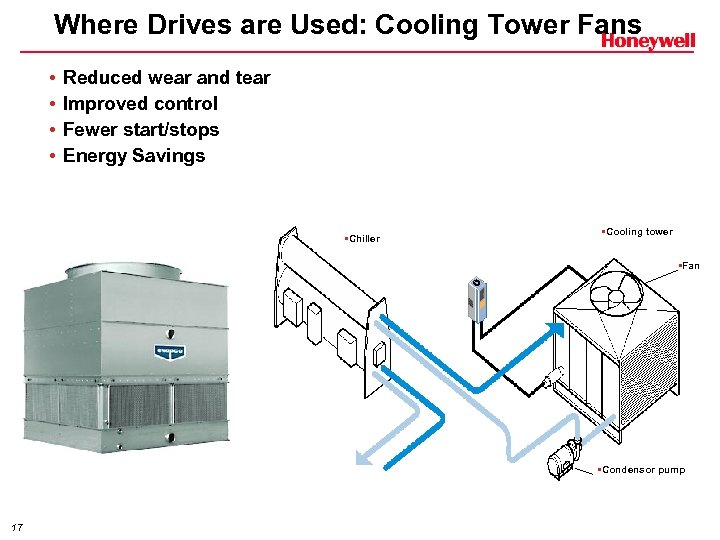

Where Drives are Used: Cooling Tower Fans • • Reduced wear and tear Improved control Fewer start/stops Energy Savings • Chiller • Cooling tower • Fan • Condensor pump 17

Where Drives are Used: Cooling Tower Fans • • Reduced wear and tear Improved control Fewer start/stops Energy Savings • Chiller • Cooling tower • Fan • Condensor pump 17

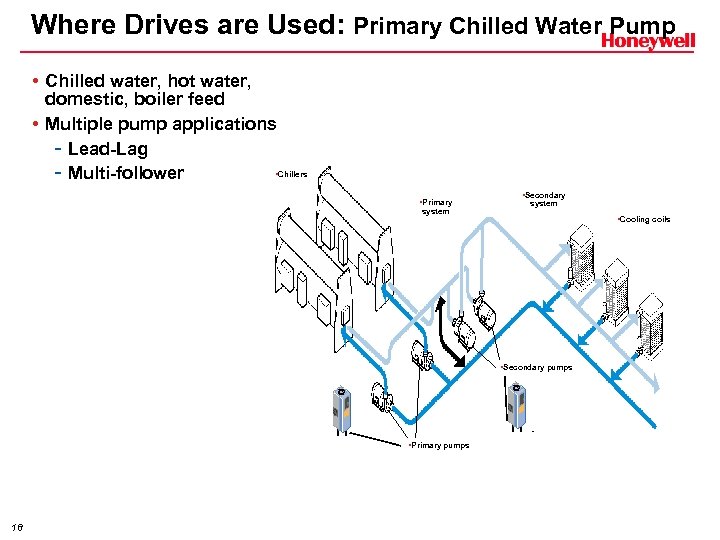

Where Drives are Used: Primary Chilled Water Pump • Chilled water, hot water, domestic, boiler feed • Multiple pump applications - Lead-Lag • Chillers - Multi-follower • Primary system • Secondary system • Cooling coils • Secondary pumps • Primary pumps 18

Where Drives are Used: Primary Chilled Water Pump • Chilled water, hot water, domestic, boiler feed • Multiple pump applications - Lead-Lag • Chillers - Multi-follower • Primary system • Secondary system • Cooling coils • Secondary pumps • Primary pumps 18

VFD • PID Application 19

VFD • PID Application 19

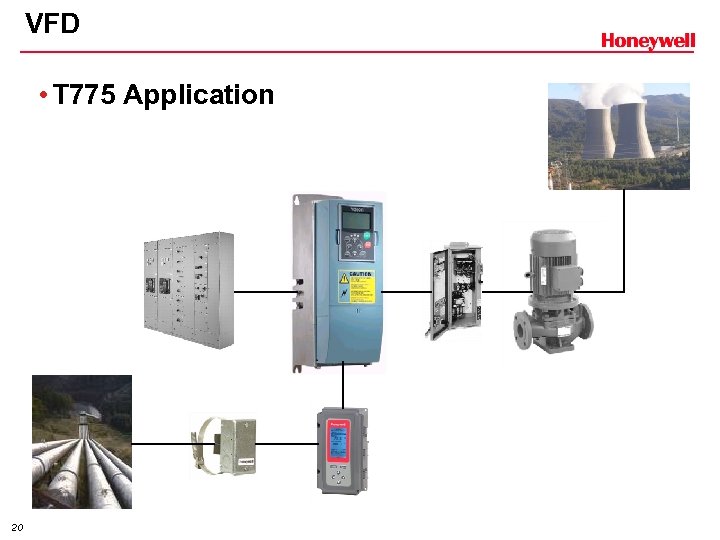

VFD • T 775 Application 20

VFD • T 775 Application 20

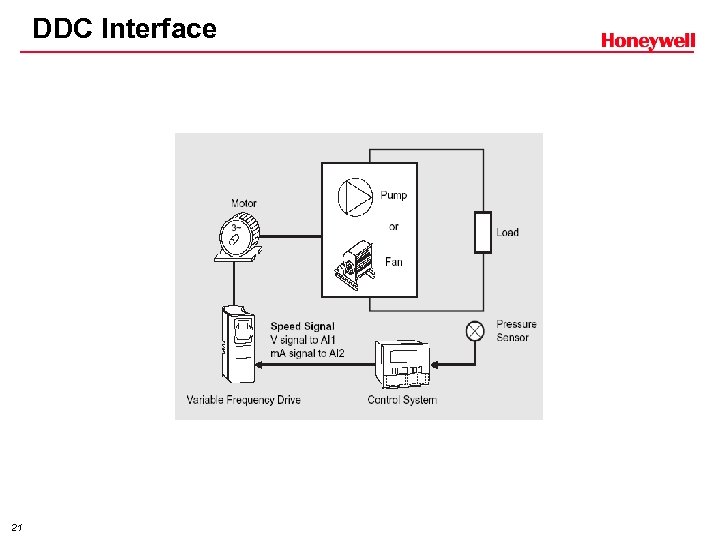

DDC Interface 21

DDC Interface 21

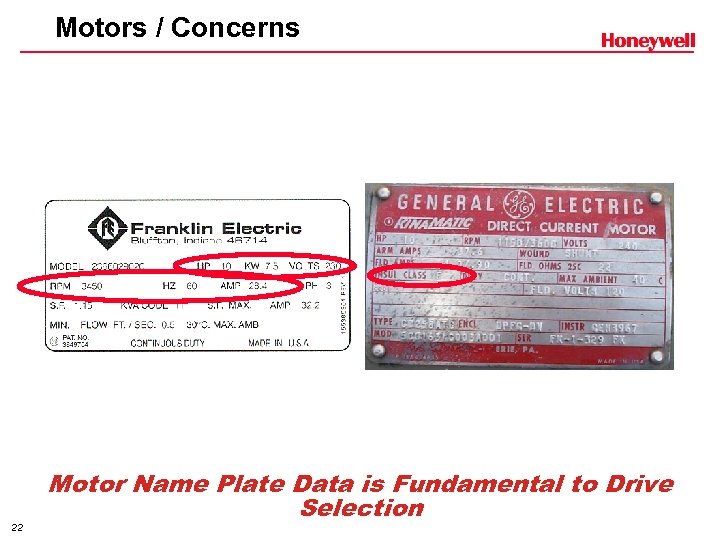

Motors / Concerns 22 Motor Name Plate Data is Fundamental to Drive Selection

Motors / Concerns 22 Motor Name Plate Data is Fundamental to Drive Selection

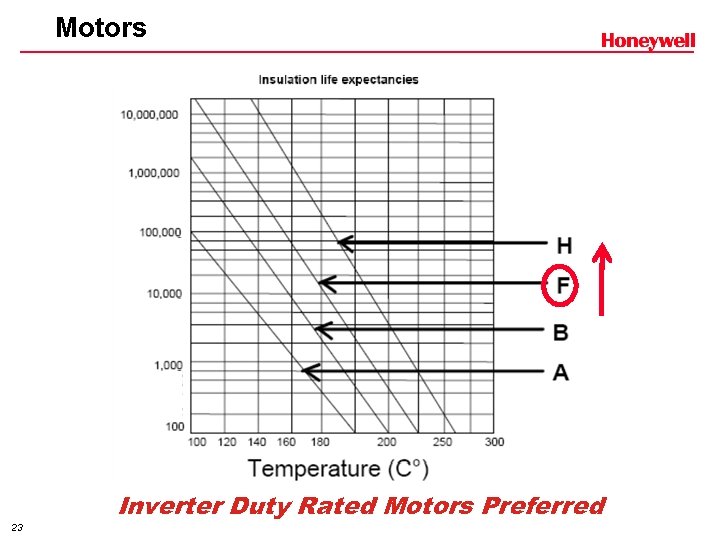

Motors Inverter Duty Rated Motors Preferred 23

Motors Inverter Duty Rated Motors Preferred 23

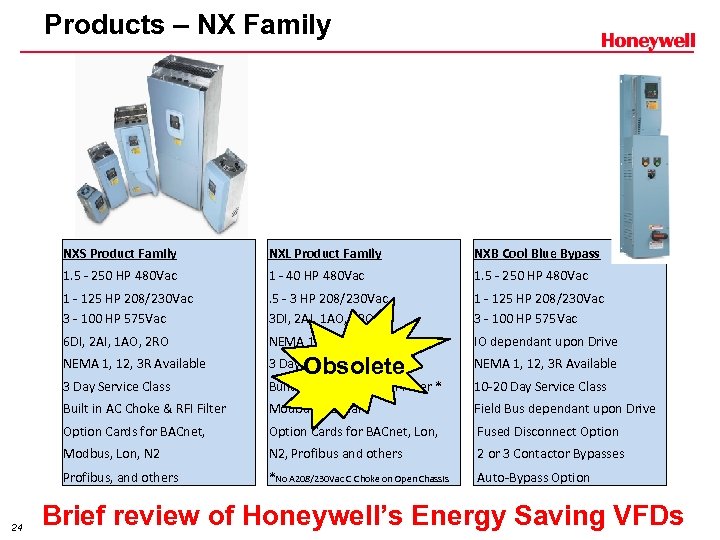

Products – NX Family NXS Product Family NXB Cool Blue Bypass 1. 5 - 250 HP 480 Vac 1 - 40 HP 480 Vac 1. 5 - 250 HP 480 Vac 1 - 125 HP 208/230 Vac 3 - 100 HP 575 Vac . 5 - 3 HP 208/230 Vac 3 DI, 2 AI, 1 AO, 2 RO 1 - 125 HP 208/230 Vac 3 - 100 HP 575 Vac 6 DI, 2 AI, 1 AO, 2 RO NEMA 1, 12, 3 R IO dependant upon Drive NEMA 1, 12, 3 R Available 3 Day Service Class NEMA 1, 12, 3 R Available 3 Day Service Class Built in AC Choke & RFI Filter * 10 -20 Day Service Class Built in AC Choke & RFI Filter Modbus Standard Field Bus dependant upon Drive Option Cards for BACnet, Lon, Fused Disconnect Option Modbus, Lon, N 2, Profibus and others 2 or 3 Contactor Bypasses Profibus, and others 24 NXL Product Family *No A 208/230 Vac C Choke on Open Chassis Auto-Bypass Option Obsolete Brief review of Honeywell’s Energy Saving VFDs

Products – NX Family NXS Product Family NXB Cool Blue Bypass 1. 5 - 250 HP 480 Vac 1 - 40 HP 480 Vac 1. 5 - 250 HP 480 Vac 1 - 125 HP 208/230 Vac 3 - 100 HP 575 Vac . 5 - 3 HP 208/230 Vac 3 DI, 2 AI, 1 AO, 2 RO 1 - 125 HP 208/230 Vac 3 - 100 HP 575 Vac 6 DI, 2 AI, 1 AO, 2 RO NEMA 1, 12, 3 R IO dependant upon Drive NEMA 1, 12, 3 R Available 3 Day Service Class NEMA 1, 12, 3 R Available 3 Day Service Class Built in AC Choke & RFI Filter * 10 -20 Day Service Class Built in AC Choke & RFI Filter Modbus Standard Field Bus dependant upon Drive Option Cards for BACnet, Lon, Fused Disconnect Option Modbus, Lon, N 2, Profibus and others 2 or 3 Contactor Bypasses Profibus, and others 24 NXL Product Family *No A 208/230 Vac C Choke on Open Chassis Auto-Bypass Option Obsolete Brief review of Honeywell’s Energy Saving VFDs

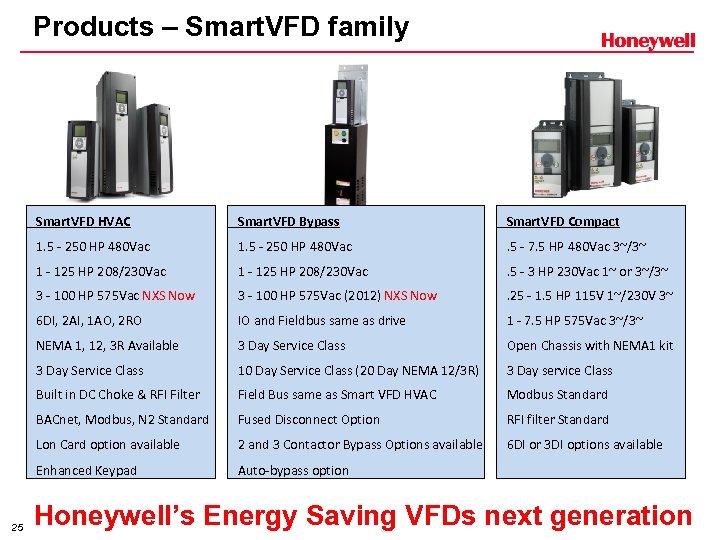

Products – Smart. VFD family Smart. VFD HVAC 1. 5 - 250 HP 480 Vac Smart. VFD Bypass 1. 5 - 250 HP 480 Vac Smart. VFD Compact . 5 - 7. 5 HP 480 Vac 3~/3~ 1 - 125 HP 208/230 Vac . 5 - 3 HP 230 Vac 1~ or 3~/3~ 3 - 100 HP 575 Vac NXS Now 3 - 100 HP 575 Vac (2012) NXS Now . 25 - 1. 5 HP 115 V 1~/230 V 3~ 6 DI, 2 AI, 1 AO, 2 RO IO and Fieldbus same as drive 1 - 7. 5 HP 575 Vac 3~/3~ NEMA 1, 12, 3 R Available 3 Day Service Class Open Chassis with NEMA 1 kit 3 Day Service Class 10 Day Service Class (20 Day NEMA 12/3 R) 3 Day service Class Built in DC Choke & RFI Filter Field Bus same as Smart VFD HVAC BACnet, Modbus, N 2 Standard Fused Disconnect Option Modbus Standard RFI filter Standard Lon Card option available Enhanced Keypad 25 2 and 3 Contactor Bypass Options available 6 DI or 3 DI options available Auto-bypass option Honeywell’s Energy Saving VFDs next generation

Products – Smart. VFD family Smart. VFD HVAC 1. 5 - 250 HP 480 Vac Smart. VFD Bypass 1. 5 - 250 HP 480 Vac Smart. VFD Compact . 5 - 7. 5 HP 480 Vac 3~/3~ 1 - 125 HP 208/230 Vac . 5 - 3 HP 230 Vac 1~ or 3~/3~ 3 - 100 HP 575 Vac NXS Now 3 - 100 HP 575 Vac (2012) NXS Now . 25 - 1. 5 HP 115 V 1~/230 V 3~ 6 DI, 2 AI, 1 AO, 2 RO IO and Fieldbus same as drive 1 - 7. 5 HP 575 Vac 3~/3~ NEMA 1, 12, 3 R Available 3 Day Service Class Open Chassis with NEMA 1 kit 3 Day Service Class 10 Day Service Class (20 Day NEMA 12/3 R) 3 Day service Class Built in DC Choke & RFI Filter Field Bus same as Smart VFD HVAC BACnet, Modbus, N 2 Standard Fused Disconnect Option Modbus Standard RFI filter Standard Lon Card option available Enhanced Keypad 25 2 and 3 Contactor Bypass Options available 6 DI or 3 DI options available Auto-bypass option Honeywell’s Energy Saving VFDs next generation

Smart. VFD HVAC • • • Intuitive Interface Easy Commissioning Standard Communication Reliable Protection Effective Operation/Monitoring The Smart. VFD for Smart Buildings 26

Smart. VFD HVAC • • • Intuitive Interface Easy Commissioning Standard Communication Reliable Protection Effective Operation/Monitoring The Smart. VFD for Smart Buildings 26

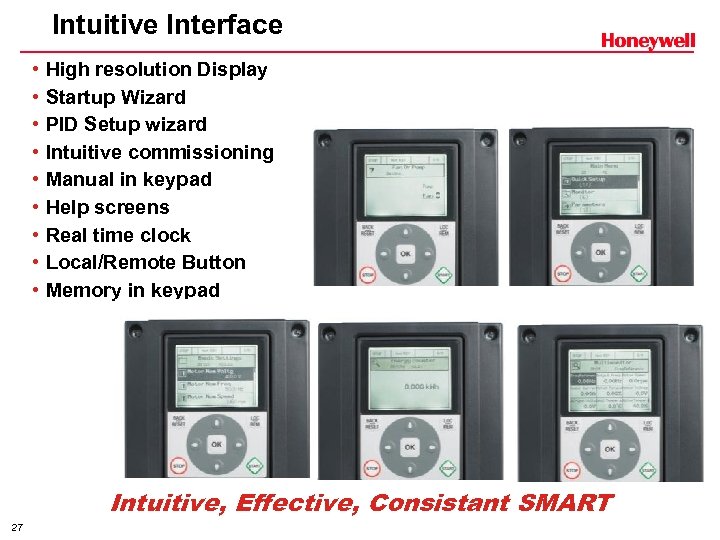

Intuitive Interface • • • High resolution Display Startup Wizard PID Setup wizard Intuitive commissioning Manual in keypad Help screens Real time clock Local/Remote Button Memory in keypad Intuitive, Effective, Consistant SMART 27

Intuitive Interface • • • High resolution Display Startup Wizard PID Setup wizard Intuitive commissioning Manual in keypad Help screens Real time clock Local/Remote Button Memory in keypad Intuitive, Effective, Consistant SMART 27

Built-In Protection • DC Choke - Built in resistors for upfront protection - Meets EN 61800 -3 -12 • Conformal Coated/ Varnished boards • C 2 class EMC filter standard • Built in Fan - NEMA 12 extra fan Harmonic, RFI, Environmental Protection 28

Built-In Protection • DC Choke - Built in resistors for upfront protection - Meets EN 61800 -3 -12 • Conformal Coated/ Varnished boards • C 2 class EMC filter standard • Built in Fan - NEMA 12 extra fan Harmonic, RFI, Environmental Protection 28

SMART Software • Power loss ride through • Fire mode • Memory in keypad • Pump and Fan Cascade • Ramp Time Optimizer • Maintenance Counters • Pump Soft Fill • 2 PID Controllers • Fault Reset • Motor Pre-heat The Smart. VFD for Smart Buildings 29

SMART Software • Power loss ride through • Fire mode • Memory in keypad • Pump and Fan Cascade • Ramp Time Optimizer • Maintenance Counters • Pump Soft Fill • 2 PID Controllers • Fault Reset • Motor Pre-heat The Smart. VFD for Smart Buildings 29

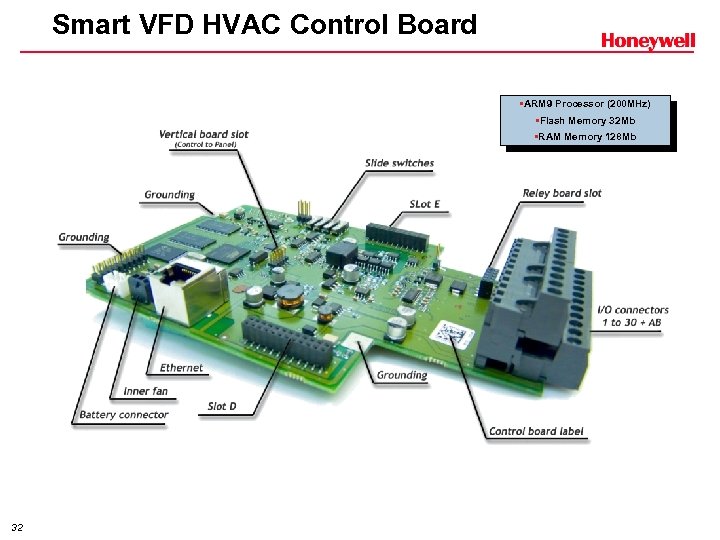

Smart VFD HVAC Control Board • ARM 9 Processor (200 MHz) • Flash Memory 32 Mb • RAM Memory 128 Mb 32

Smart VFD HVAC Control Board • ARM 9 Processor (200 MHz) • Flash Memory 32 Mb • RAM Memory 128 Mb 32

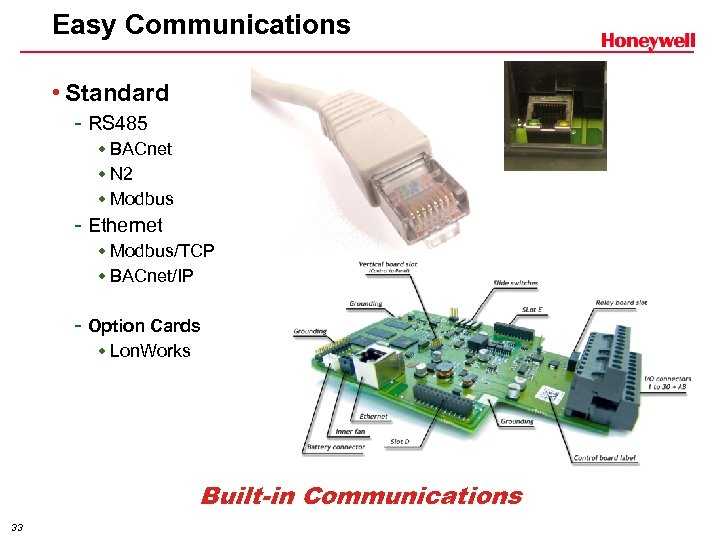

Easy Communications • Standard - RS 485 w BACnet w N 2 w Modbus - Ethernet w Modbus/TCP w BACnet/IP - Option Cards w Lon. Works Built-in Communications 33

Easy Communications • Standard - RS 485 w BACnet w N 2 w Modbus - Ethernet w Modbus/TCP w BACnet/IP - Option Cards w Lon. Works Built-in Communications 33

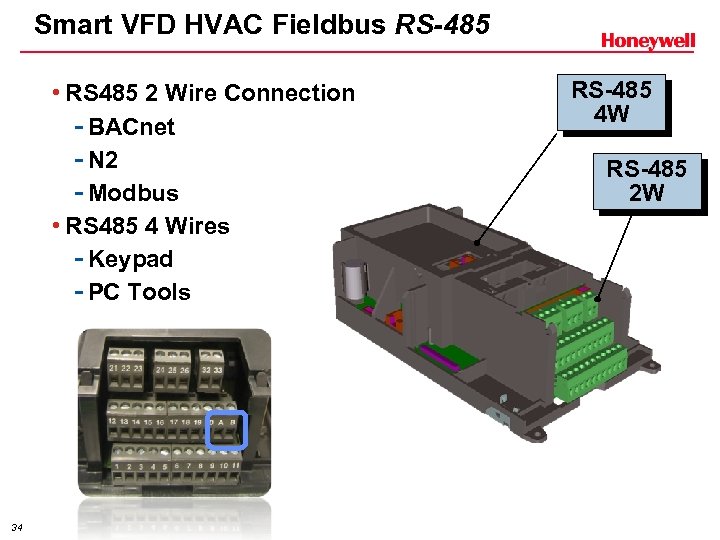

Smart VFD HVAC Fieldbus RS-485 • RS 485 2 Wire Connection - BACnet - N 2 - Modbus • RS 485 4 Wires - Keypad - PC Tools 34 RS-485 4 W RS-485 2 W

Smart VFD HVAC Fieldbus RS-485 • RS 485 2 Wire Connection - BACnet - N 2 - Modbus • RS 485 4 Wires - Keypad - PC Tools 34 RS-485 4 W RS-485 2 W

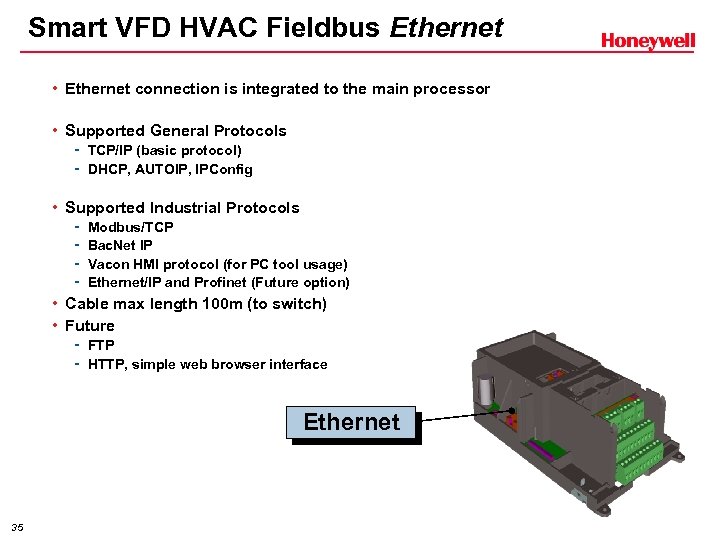

Smart VFD HVAC Fieldbus Ethernet • Ethernet connection is integrated to the main processor • Supported General Protocols - TCP/IP (basic protocol) - DHCP, AUTOIP, IPConfig • Supported Industrial Protocols - Modbus/TCP - Bac. Net IP - Vacon HMI protocol (for PC tool usage) - Ethernet/IP and Profinet (Future option) • Cable max length 100 m (to switch) • Future - FTP - HTTP, simple web browser interface Ethernet 35

Smart VFD HVAC Fieldbus Ethernet • Ethernet connection is integrated to the main processor • Supported General Protocols - TCP/IP (basic protocol) - DHCP, AUTOIP, IPConfig • Supported Industrial Protocols - Modbus/TCP - Bac. Net IP - Vacon HMI protocol (for PC tool usage) - Ethernet/IP and Profinet (Future option) • Cable max length 100 m (to switch) • Future - FTP - HTTP, simple web browser interface Ethernet 35

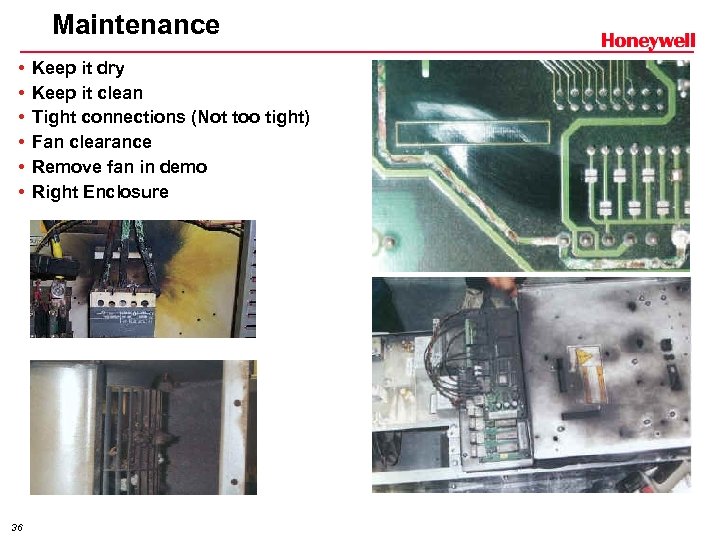

Maintenance • • • 36 Keep it dry Keep it clean Tight connections (Not too tight) Fan clearance Remove fan in demo Right Enclosure

Maintenance • • • 36 Keep it dry Keep it clean Tight connections (Not too tight) Fan clearance Remove fan in demo Right Enclosure

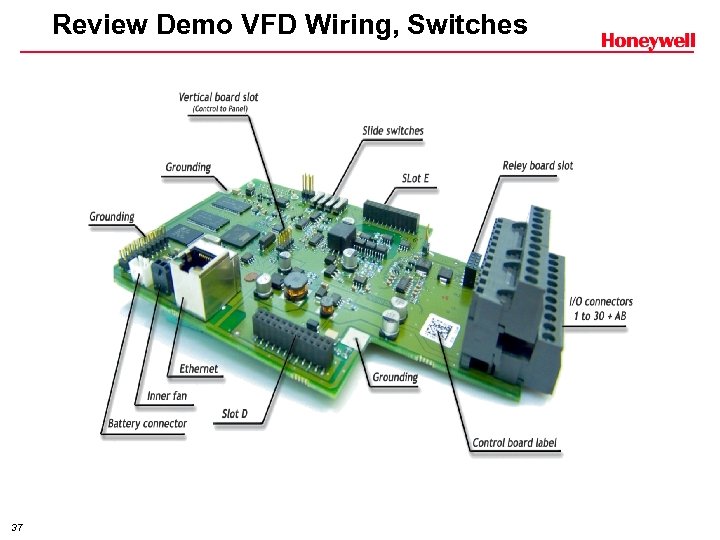

Review Demo VFD Wiring, Switches 37

Review Demo VFD Wiring, Switches 37

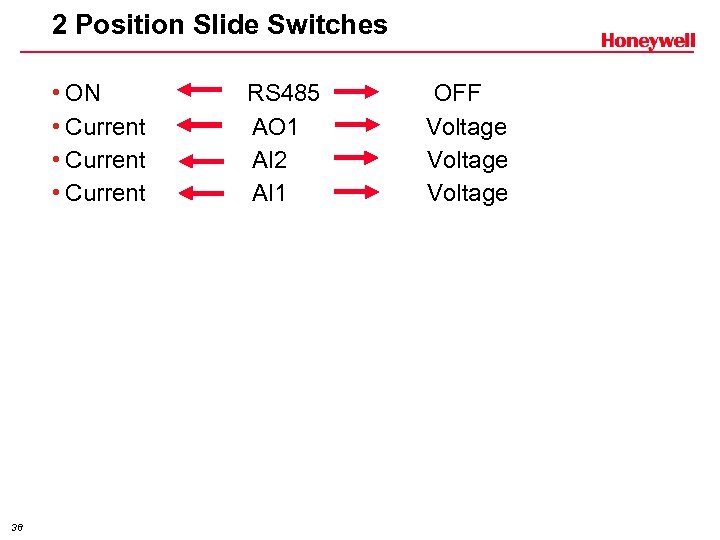

2 Position Slide Switches • ON • Current 38 RS 485 AO 1 AI 2 AI 1 OFF Voltage

2 Position Slide Switches • ON • Current 38 RS 485 AO 1 AI 2 AI 1 OFF Voltage

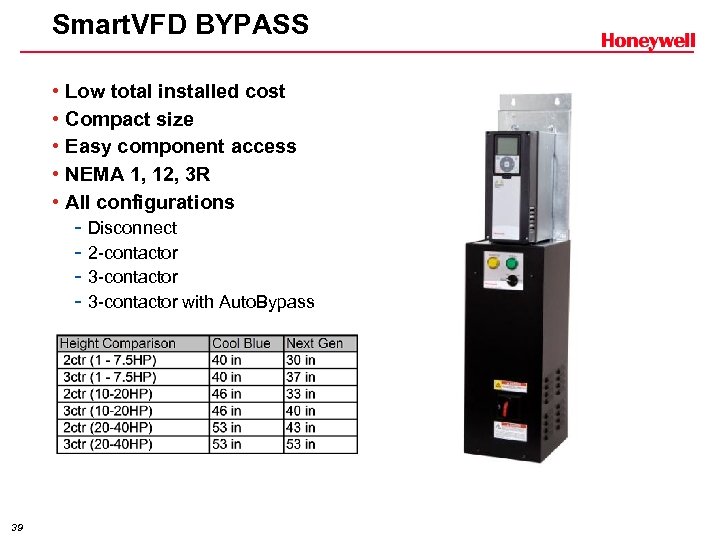

Smart. VFD BYPASS • • • Low total installed cost Compact size Easy component access NEMA 1, 12, 3 R All configurations - Disconnect - 2 -contactor - 3 -contactor with Auto. Bypass 39

Smart. VFD BYPASS • • • Low total installed cost Compact size Easy component access NEMA 1, 12, 3 R All configurations - Disconnect - 2 -contactor - 3 -contactor with Auto. Bypass 39

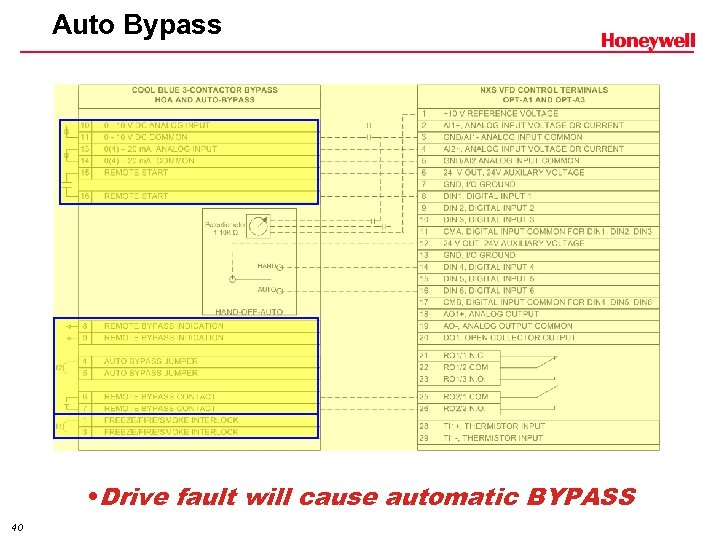

Auto Bypass • Drive fault will cause automatic BYPASS 40

Auto Bypass • Drive fault will cause automatic BYPASS 40

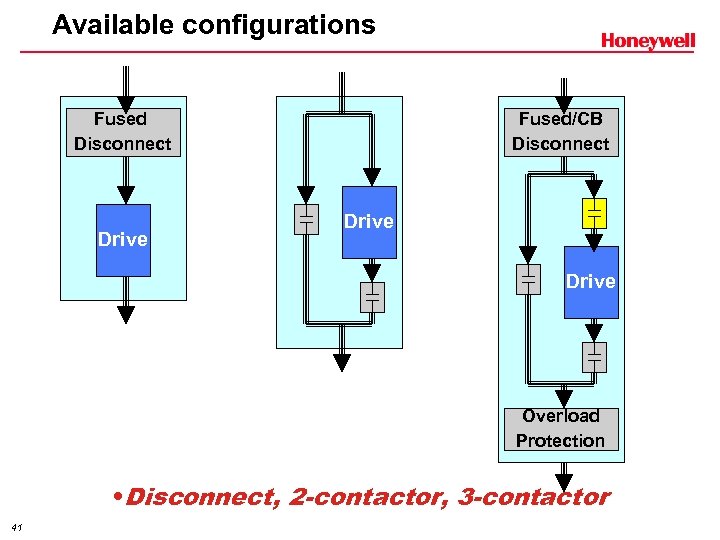

Available configurations Fused Disconnect Drive Fused/CB Disconnect Drive Overload Protection • Disconnect, 2 -contactor, 3 -contactor 41

Available configurations Fused Disconnect Drive Fused/CB Disconnect Drive Overload Protection • Disconnect, 2 -contactor, 3 -contactor 41

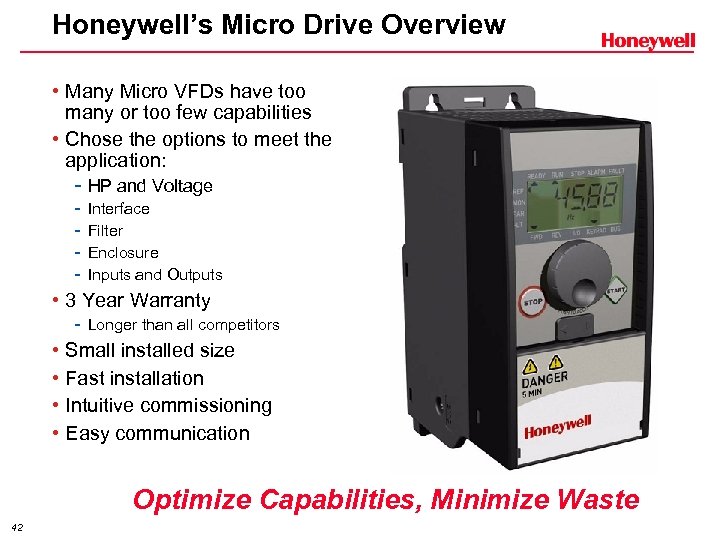

Honeywell’s Micro Drive Overview • Many Micro VFDs have too many or too few capabilities • Chose the options to meet the application: - HP and Voltage • • • - Interface - Filter - Enclosure - Inputs and Outputs 3 Year Warranty - Longer than all competitors Small installed size Fast installation Intuitive commissioning Easy communication Optimize Capabilities, Minimize Waste 42

Honeywell’s Micro Drive Overview • Many Micro VFDs have too many or too few capabilities • Chose the options to meet the application: - HP and Voltage • • • - Interface - Filter - Enclosure - Inputs and Outputs 3 Year Warranty - Longer than all competitors Small installed size Fast installation Intuitive commissioning Easy communication Optimize Capabilities, Minimize Waste 42

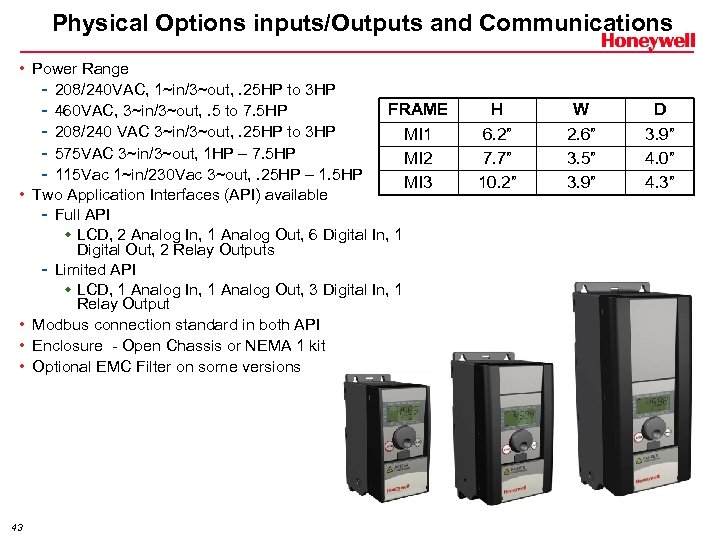

Physical Options inputs/Outputs and Communications • Power Range - 208/240 VAC, 1~in/3~out, . 25 HP to 3 HP FRAME - 460 VAC, 3~in/3~out, . 5 to 7. 5 HP - 208/240 VAC 3~in/3~out, . 25 HP to 3 HP MI 1 - 575 VAC 3~in/3~out, 1 HP – 7. 5 HP MI 2 - 115 Vac 1~in/230 Vac 3~out, . 25 HP – 1. 5 HP MI 3 • Two Application Interfaces (API) available - Full API w LCD, 2 Analog In, 1 Analog Out, 6 Digital In, 1 Digital Out, 2 Relay Outputs - Limited API w LCD, 1 Analog In, 1 Analog Out, 3 Digital In, 1 Relay Output • Modbus connection standard in both API • Enclosure - Open Chassis or NEMA 1 kit • Optional EMC Filter on some versions 43 H 6. 2” 7. 7” 10. 2” W 2. 6” 3. 5” 3. 9” D 3. 9” 4. 0” 4. 3”

Physical Options inputs/Outputs and Communications • Power Range - 208/240 VAC, 1~in/3~out, . 25 HP to 3 HP FRAME - 460 VAC, 3~in/3~out, . 5 to 7. 5 HP - 208/240 VAC 3~in/3~out, . 25 HP to 3 HP MI 1 - 575 VAC 3~in/3~out, 1 HP – 7. 5 HP MI 2 - 115 Vac 1~in/230 Vac 3~out, . 25 HP – 1. 5 HP MI 3 • Two Application Interfaces (API) available - Full API w LCD, 2 Analog In, 1 Analog Out, 6 Digital In, 1 Digital Out, 2 Relay Outputs - Limited API w LCD, 1 Analog In, 1 Analog Out, 3 Digital In, 1 Relay Output • Modbus connection standard in both API • Enclosure - Open Chassis or NEMA 1 kit • Optional EMC Filter on some versions 43 H 6. 2” 7. 7” 10. 2” W 2. 6” 3. 5” 3. 9” D 3. 9” 4. 0” 4. 3”

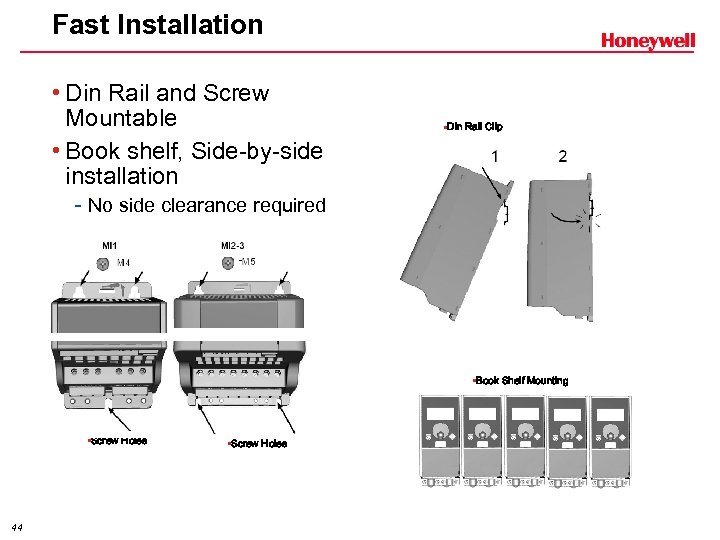

Fast Installation • Din Rail and Screw Mountable • Book shelf, Side-by-side installation - No side clearance required • Din Rail Clip • Book Shelf Mounting • Screw Holes 44 • Screw Holes

Fast Installation • Din Rail and Screw Mountable • Book shelf, Side-by-side installation - No side clearance required • Din Rail Clip • Book Shelf Mounting • Screw Holes 44 • Screw Holes

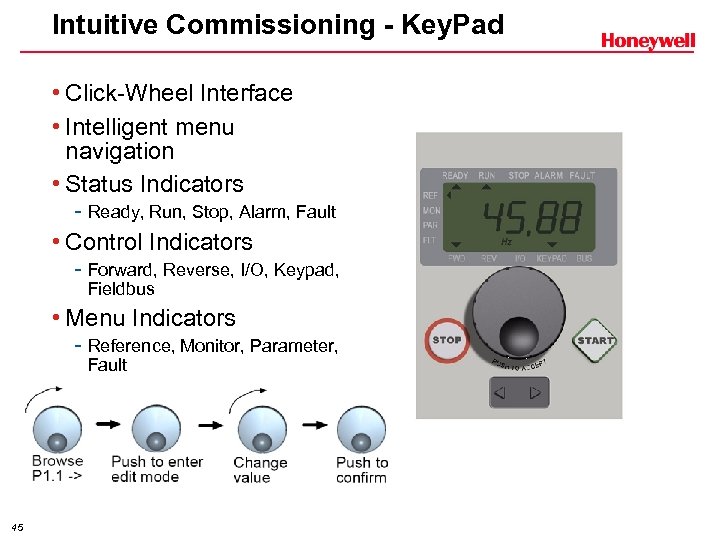

Intuitive Commissioning - Key. Pad • Click-Wheel Interface • Intelligent menu navigation • Status Indicators - Ready, Run, Stop, Alarm, Fault • Control Indicators - Forward, Reverse, I/O, Keypad, Fieldbus • Menu Indicators - Reference, Monitor, Parameter, Fault 45

Intuitive Commissioning - Key. Pad • Click-Wheel Interface • Intelligent menu navigation • Status Indicators - Ready, Run, Stop, Alarm, Fault • Control Indicators - Forward, Reverse, I/O, Keypad, Fieldbus • Menu Indicators - Reference, Monitor, Parameter, Fault 45

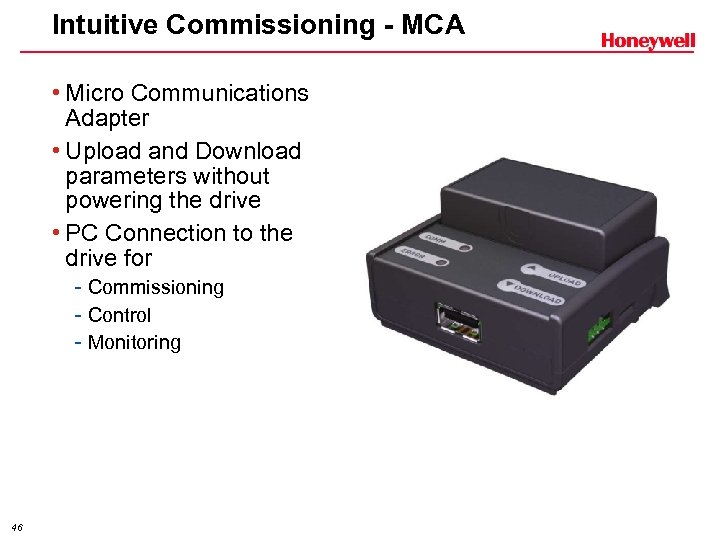

Intuitive Commissioning - MCA • Micro Communications Adapter • Upload and Download parameters without powering the drive • PC Connection to the drive for - Commissioning - Control - Monitoring 46

Intuitive Commissioning - MCA • Micro Communications Adapter • Upload and Download parameters without powering the drive • PC Connection to the drive for - Commissioning - Control - Monitoring 46

Honeywell Warranty Process Review • 2 Year Standard Warranty • 3 Year Warranty with Commissioning Training • Warranty period is from date of purchase • Process: - Call HON technical support for trouble - shooting help No resolution, Warranty coordinator will issue RGA PO needed for advanced replacement Under warranty – Credit Adv Rep PO Warranties covered if the process is followed and product is not abused Critical to Call Hot Line ~ No Return Goods 47

Honeywell Warranty Process Review • 2 Year Standard Warranty • 3 Year Warranty with Commissioning Training • Warranty period is from date of purchase • Process: - Call HON technical support for trouble - shooting help No resolution, Warranty coordinator will issue RGA PO needed for advanced replacement Under warranty – Credit Adv Rep PO Warranties covered if the process is followed and product is not abused Critical to Call Hot Line ~ No Return Goods 47

Tools • Beyondinnovation. honeywell. com - Pricing tools - Product manuals - Sales brochures - Instruction sheets - Submittal documents - Marketing materials • Specify. honeywell. com - CE spec information • Customer. honeywell. com/vfd - Under Software: - PC commissioning and control tool - Firmware updates - Energy savings calculators • Technical Support Hotline - (888) 516 -9347, option 4 48

Tools • Beyondinnovation. honeywell. com - Pricing tools - Product manuals - Sales brochures - Instruction sheets - Submittal documents - Marketing materials • Specify. honeywell. com - CE spec information • Customer. honeywell. com/vfd - Under Software: - PC commissioning and control tool - Firmware updates - Energy savings calculators • Technical Support Hotline - (888) 516 -9347, option 4 48

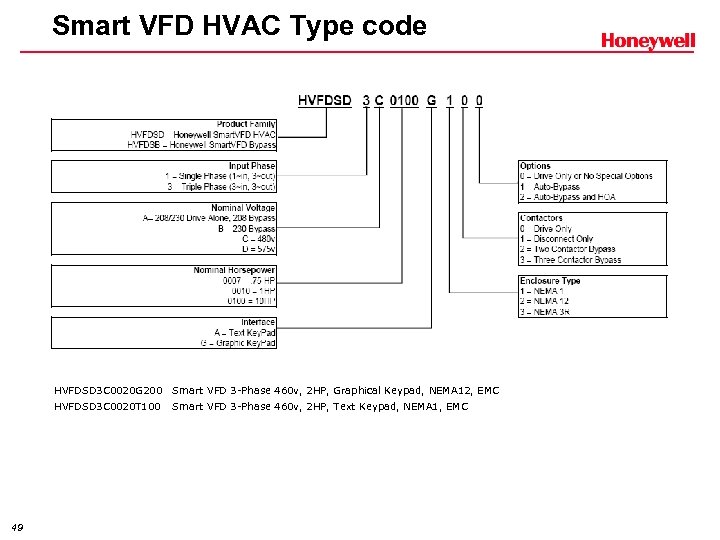

Smart VFD HVAC Type code HVFDSD 3 C 0020 G 200 HVFDSD 3 C 0020 T 100 49 Smart VFD 3 -Phase 460 v, 2 HP, Graphical Keypad, NEMA 12, EMC Smart VFD 3 -Phase 460 v, 2 HP, Text Keypad, NEMA 1, EMC

Smart VFD HVAC Type code HVFDSD 3 C 0020 G 200 HVFDSD 3 C 0020 T 100 49 Smart VFD 3 -Phase 460 v, 2 HP, Graphical Keypad, NEMA 12, EMC Smart VFD 3 -Phase 460 v, 2 HP, Text Keypad, NEMA 1, EMC

How to Select the Drive - Questions to ask ØNEMA rating? How harsh is the environment? ØFiltering requirements? ØFull load current (A) and HP of motor ? ØPower supply voltage? ØSingle phase or 3 phase input? ØDoes the application need a bypass? ØIs there a disconnect on site? 50

How to Select the Drive - Questions to ask ØNEMA rating? How harsh is the environment? ØFiltering requirements? ØFull load current (A) and HP of motor ? ØPower supply voltage? ØSingle phase or 3 phase input? ØDoes the application need a bypass? ØIs there a disconnect on site? 50

Tools - Product Selection 51

Tools - Product Selection 51

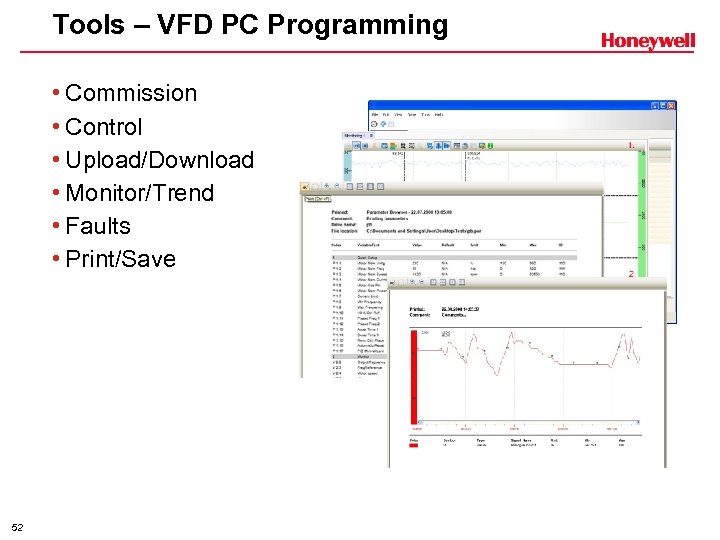

Tools – VFD PC Programming • Commission • Control • Upload/Download • Monitor/Trend • Faults • Print/Save 52

Tools – VFD PC Programming • Commission • Control • Upload/Download • Monitor/Trend • Faults • Print/Save 52

Take-off Service • Complete schedule and quote creation from blueprints and specs - We ask that drawings are submit in PDF or TIFF format via email (no downloads via database) • Partial jobs are OK • Cross-reference service • Contact Info: - Takeoff. Service@Honeywell. com - Tel: (888) 664 -4092 - Fax: (877) 880 -3386 Information OUT 54 ∝ Information IN

Take-off Service • Complete schedule and quote creation from blueprints and specs - We ask that drawings are submit in PDF or TIFF format via email (no downloads via database) • Partial jobs are OK • Cross-reference service • Contact Info: - Takeoff. Service@Honeywell. com - Tel: (888) 664 -4092 - Fax: (877) 880 -3386 Information OUT 54 ∝ Information IN

Questions http//. customer. honeywell. com/VFD Beyondinnovation. honeywell. com Technical Support – 888 516 9347 option 4 55

Questions http//. customer. honeywell. com/VFD Beyondinnovation. honeywell. com Technical Support – 888 516 9347 option 4 55

Summary Questions • • • 56 If I reduce power to a motor by _____% I will save 58% in energy. Honeywell drives come standard with DC chokes and RFI filters. T or F What’s the DC choke’s function? The keypad is portable and can hold 3 programs. T or F Smart drives can be integrated into a Lon system. T or F When sizing a vfd the hp is more important than amperage. T or F Three reasons to buy a vfd? Honeywell vfd’s have a 1 year warranty. T or F It’s safe to open the vfd control compartment if the vfd is off. T or F Will the drive tell you the time and date? Can I start and stop the drive from the internal timeclock?

Summary Questions • • • 56 If I reduce power to a motor by _____% I will save 58% in energy. Honeywell drives come standard with DC chokes and RFI filters. T or F What’s the DC choke’s function? The keypad is portable and can hold 3 programs. T or F Smart drives can be integrated into a Lon system. T or F When sizing a vfd the hp is more important than amperage. T or F Three reasons to buy a vfd? Honeywell vfd’s have a 1 year warranty. T or F It’s safe to open the vfd control compartment if the vfd is off. T or F Will the drive tell you the time and date? Can I start and stop the drive from the internal timeclock?

LAB 1 Start up Wizard & Keypad basics

LAB 1 Start up Wizard & Keypad basics

Start up Wizard Lab • Run the Start-Up Wizard - Change the date and time to 8: 33 AM, June 6, 2012 - RPM 1880 - Nominal Current 6 Amps • Test out the drive with the demo unit - Flip DIN 1 – start forward - Move AL 1 – ramp up the motor - Toggle Din 3 – what happens? - Toggle Din 6 – what happens? • Reset factory defaults and let other person have a try 58

Start up Wizard Lab • Run the Start-Up Wizard - Change the date and time to 8: 33 AM, June 6, 2012 - RPM 1880 - Nominal Current 6 Amps • Test out the drive with the demo unit - Flip DIN 1 – start forward - Move AL 1 – ramp up the motor - Toggle Din 3 – what happens? - Toggle Din 6 – what happens? • Reset factory defaults and let other person have a try 58

LAB 2 Monitoring

LAB 2 Monitoring

Monitoring Lab • Return to Main menu • Enter Monitor Menu • Select motor Torque in the Multi-monitor screen and select OK • Scroll up to Energy Counter and hit enter • Run the demo, DI 1, Turn Analog knob, and notice the values change. • Change whatever other values you would like scrolling up and down through monitor values 60

Monitoring Lab • Return to Main menu • Enter Monitor Menu • Select motor Torque in the Multi-monitor screen and select OK • Scroll up to Energy Counter and hit enter • Run the demo, DI 1, Turn Analog knob, and notice the values change. • Change whatever other values you would like scrolling up and down through monitor values 60

LAB 3 Fault Review

LAB 3 Fault Review

Smart VFD HVAC Faults in General • Active faults - Max 10 Active faults simultaniously • Faulthistory - Max 40 faults in history • Different fault types: - FAULT = Stops the Motor if not programmed otherwise - ALARM = Tells about unwanted conditions. No affect on motor - INFO = Might need resetting but wont have an affect on the motor 62

Smart VFD HVAC Faults in General • Active faults - Max 10 Active faults simultaniously • Faulthistory - Max 40 faults in history • Different fault types: - FAULT = Stops the Motor if not programmed otherwise - ALARM = Tells about unwanted conditions. No affect on motor - INFO = Might need resetting but wont have an affect on the motor 62

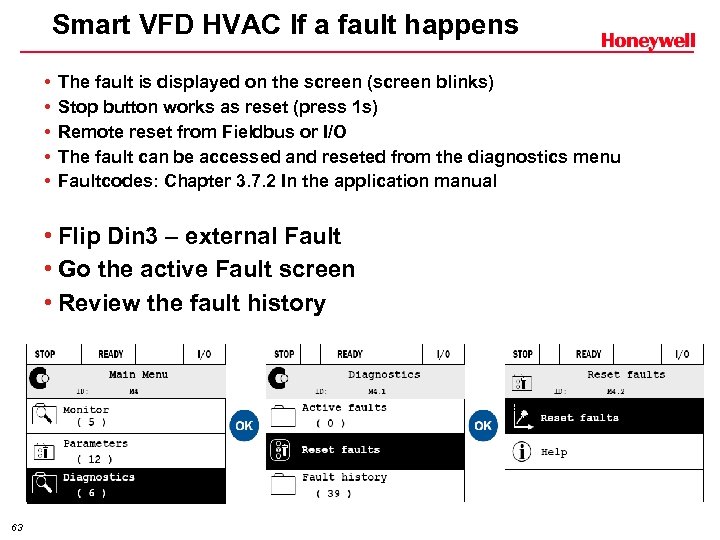

Smart VFD HVAC If a fault happens • • • The fault is displayed on the screen (screen blinks) Stop button works as reset (press 1 s) Remote reset from Fieldbus or I/O The fault can be accessed and reseted from the diagnostics menu Faultcodes: Chapter 3. 7. 2 In the application manual • Flip Din 3 – external Fault • Go the active Fault screen • Review the fault history 63

Smart VFD HVAC If a fault happens • • • The fault is displayed on the screen (screen blinks) Stop button works as reset (press 1 s) Remote reset from Fieldbus or I/O The fault can be accessed and reseted from the diagnostics menu Faultcodes: Chapter 3. 7. 2 In the application manual • Flip Din 3 – external Fault • Go the active Fault screen • Review the fault history 63

LAB 4 Other Parameters

LAB 4 Other Parameters

Quick Setup • Change Min Frequency to 10 hz - Turn on drive to minimum and confirm • Change acceleration and deceleration time to 2 minutes – run and test • Change acceleration and deceleration time to 2 seconds – run and test • Change Preset Frequency 1 to 25 Hz Flip DIN 4 to test • Change Preset Frequency 2 to 30 Hz Flip DIN 5 to test • Change I/O A Control reference to AI 2 - test • In User Settings save parameters to the keypad - Then download from the keypad. 65

Quick Setup • Change Min Frequency to 10 hz - Turn on drive to minimum and confirm • Change acceleration and deceleration time to 2 minutes – run and test • Change acceleration and deceleration time to 2 seconds – run and test • Change Preset Frequency 1 to 25 Hz Flip DIN 4 to test • Change Preset Frequency 2 to 30 Hz Flip DIN 5 to test • Change I/O A Control reference to AI 2 - test • In User Settings save parameters to the keypad - Then download from the keypad. 65

Other Parameters • Auto-Restart - Enable external fault auto restart – 4 times - Test using the external fault functionality - Place the Auto-restart parameter in favorites - Confirm the parameter is in the favorites menu • Motor Control - Change the Switching Frequency to 5 k. Hz w Can affect the noise of the motor 66

Other Parameters • Auto-Restart - Enable external fault auto restart – 4 times - Test using the external fault functionality - Place the Auto-restart parameter in favorites - Confirm the parameter is in the favorites menu • Motor Control - Change the Switching Frequency to 5 k. Hz w Can affect the noise of the motor 66

Prohibit Frequencies • Complete this lab as a team • Prohibit frequency • Set range 1 low at 30 and high at 35 • Set range 2 low at 45 and high at 50 • Start vfd, twist pot slowly to observe • Save your program to the keypad and download your program from the keypad (M 6) 67

Prohibit Frequencies • Complete this lab as a team • Prohibit frequency • Set range 1 low at 30 and high at 35 • Set range 2 low at 45 and high at 50 • Start vfd, twist pot slowly to observe • Save your program to the keypad and download your program from the keypad (M 6) 67

Motor Pre-Heat • Complete this lab individually • Motor Preheat Function • Turn DIN 1 OFF • Go to M 3. 1. 2. 3 PREHEAT FUNCTION • Select TEMP LIMIT, enter 40 / 38 degrees C, Hit BACK • Select ADD TO FAVORITES, Hit OK • Note DO 1 is energized and display reads HEATING • Go to 2. 2. 11 (BASIC MONITORING) • Note UNIT TEMPERATURE • Go to M 7 Favorites, Select PREHEAT TEMP LIMIT • Enter a temperature 5 / 7 degress C below Unit Temp • Note DO 1 is De-energized, Hit BACK • Select REM FROM FAVORITES to remove from Favorites list 68

Motor Pre-Heat • Complete this lab individually • Motor Preheat Function • Turn DIN 1 OFF • Go to M 3. 1. 2. 3 PREHEAT FUNCTION • Select TEMP LIMIT, enter 40 / 38 degrees C, Hit BACK • Select ADD TO FAVORITES, Hit OK • Note DO 1 is energized and display reads HEATING • Go to 2. 2. 11 (BASIC MONITORING) • Note UNIT TEMPERATURE • Go to M 7 Favorites, Select PREHEAT TEMP LIMIT • Enter a temperature 5 / 7 degress C below Unit Temp • Note DO 1 is De-energized, Hit BACK • Select REM FROM FAVORITES to remove from Favorites list 68

LAB 4 PID Wizard

LAB 4 PID Wizard

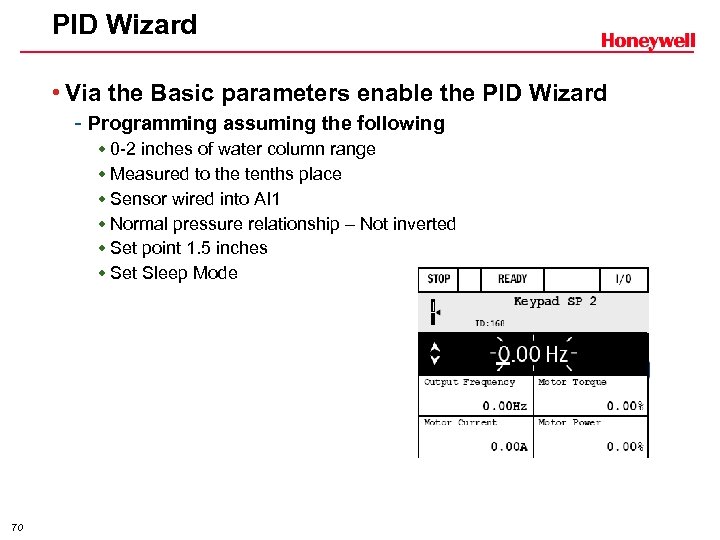

PID Wizard • Via the Basic parameters enable the PID Wizard - Programming assuming the following w 0 -2 inches of water column range w Measured to the tenths place w Sensor wired into AI 1 w Normal pressure relationship – Not inverted w Set point 1. 5 inches w Set Sleep Mode 70

PID Wizard • Via the Basic parameters enable the PID Wizard - Programming assuming the following w 0 -2 inches of water column range w Measured to the tenths place w Sensor wired into AI 1 w Normal pressure relationship – Not inverted w Set point 1. 5 inches w Set Sleep Mode 70

Lab 12 • Complete this lab individually • PID setup • Go to QUICK SETUP, change MIN FREQ to 0 and activate PID MINI WIZARD • Enter following selections: • In wg for engineering units • 0 for process unit minimum • 5 for process unit maximum • 2 for process unit decimals • AI 1 for FB (feedback) 1 source • 0 -10 V for AI 1 signal range • NORMAL for error inversion • KEYPAD SP 1 for SP (setpoint) 1 source • 2 for Keypad SP 1 • NO for Sleep Function • Press OK to exit • Turn DIN 1 on, twist pot and observe • Go to MONITOR, PID CONTROLLER 1, twist pot, observe • Go to 3. 12. 1. 2 and set your INTEGRATION TIME 71

Lab 12 • Complete this lab individually • PID setup • Go to QUICK SETUP, change MIN FREQ to 0 and activate PID MINI WIZARD • Enter following selections: • In wg for engineering units • 0 for process unit minimum • 5 for process unit maximum • 2 for process unit decimals • AI 1 for FB (feedback) 1 source • 0 -10 V for AI 1 signal range • NORMAL for error inversion • KEYPAD SP 1 for SP (setpoint) 1 source • 2 for Keypad SP 1 • NO for Sleep Function • Press OK to exit • Turn DIN 1 on, twist pot and observe • Go to MONITOR, PID CONTROLLER 1, twist pot, observe • Go to 3. 12. 1. 2 and set your INTEGRATION TIME 71

LAB 5 Keypad Control

LAB 5 Keypad Control

Lab 14 • Complete this lab individually • Keypad Control • Will override DIN’s but not active fault • Press LOC/REM button, Select LOCAL • Press LOC/REM button again, select CONTROL PLACE • Note multimonitor screen below, insert tod in top right • Hit OK on speed reference bar (blinks). Ramp the motor up and down using the up and down arrow keys • Hit the STOP button, follow instructions • Return to CONTROL PLACE, ramp up and down • Return to IO control by pressing LOC/REM again and selecting REMOTE • Process simplified next rev 73

Lab 14 • Complete this lab individually • Keypad Control • Will override DIN’s but not active fault • Press LOC/REM button, Select LOCAL • Press LOC/REM button again, select CONTROL PLACE • Note multimonitor screen below, insert tod in top right • Hit OK on speed reference bar (blinks). Ramp the motor up and down using the up and down arrow keys • Hit the STOP button, follow instructions • Return to CONTROL PLACE, ramp up and down • Return to IO control by pressing LOC/REM again and selecting REMOTE • Process simplified next rev 73

http//. customer. honeywell. com/VFD Beyondinnovation. honeywell. com Technical Support – 888 516 9347 74

http//. customer. honeywell. com/VFD Beyondinnovation. honeywell. com Technical Support – 888 516 9347 74

Lab 1 • Relax • Complete this lab as a team • Keypad Review • Menu Review • Restore Factory Defaults - M 6 User Settings; M 6. 5 Parameter Backup; M 6. 5. 1 Restore factory defaults - Unit restarts - Select ENGLISH, US, Set TIME, DATE (day. month), YEAR - Startup wizard = Yes - Select FAN, 1720 RPM, 3. 55 A • Puts you back in Basic Monitor Mode 75

Lab 1 • Relax • Complete this lab as a team • Keypad Review • Menu Review • Restore Factory Defaults - M 6 User Settings; M 6. 5 Parameter Backup; M 6. 5. 1 Restore factory defaults - Unit restarts - Select ENGLISH, US, Set TIME, DATE (day. month), YEAR - Startup wizard = Yes - Select FAN, 1720 RPM, 3. 55 A • Puts you back in Basic Monitor Mode 75

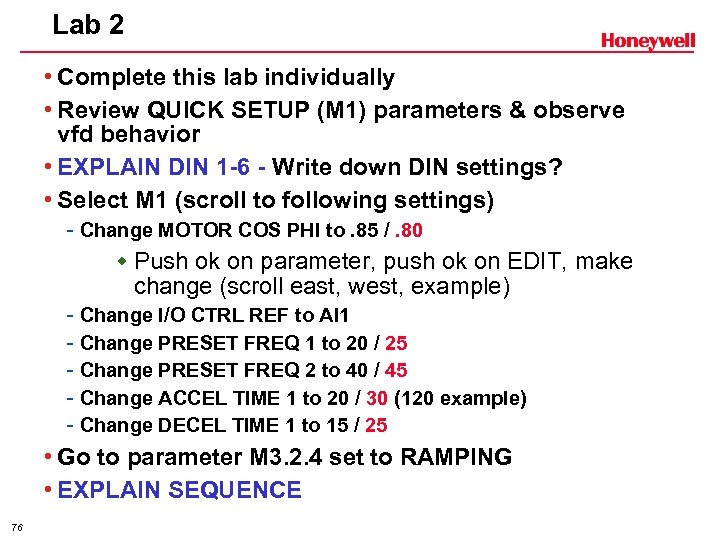

Lab 2 • Complete this lab individually • Review QUICK SETUP (M 1) parameters & observe vfd behavior • EXPLAIN DIN 1 -6 - Write down DIN settings? • Select M 1 (scroll to following settings) - Change MOTOR COS PHI to. 85 /. 80 w Push ok on parameter, push ok on EDIT, make change (scroll east, west, example) - Change I/O CTRL REF to AI 1 - Change PRESET FREQ 1 to 20 / 25 - Change PRESET FREQ 2 to 40 / 45 - Change ACCEL TIME 1 to 20 / 30 (120 example) - Change DECEL TIME 1 to 15 / 25 • Go to parameter M 3. 2. 4 set to RAMPING • EXPLAIN SEQUENCE 76

Lab 2 • Complete this lab individually • Review QUICK SETUP (M 1) parameters & observe vfd behavior • EXPLAIN DIN 1 -6 - Write down DIN settings? • Select M 1 (scroll to following settings) - Change MOTOR COS PHI to. 85 /. 80 w Push ok on parameter, push ok on EDIT, make change (scroll east, west, example) - Change I/O CTRL REF to AI 1 - Change PRESET FREQ 1 to 20 / 25 - Change PRESET FREQ 2 to 40 / 45 - Change ACCEL TIME 1 to 20 / 30 (120 example) - Change DECEL TIME 1 to 15 / 25 • Go to parameter M 3. 2. 4 set to RAMPING • EXPLAIN SEQUENCE 76

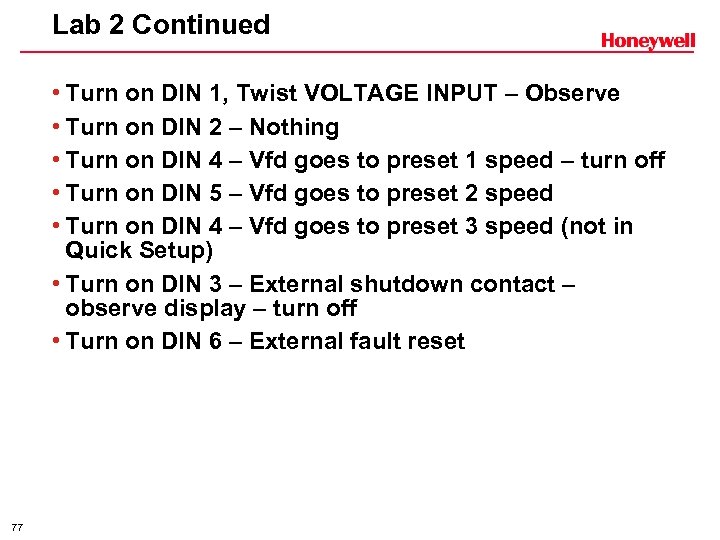

Lab 2 Continued • Turn on DIN 1, Twist VOLTAGE INPUT – Observe • Turn on DIN 2 – Nothing • Turn on DIN 4 – Vfd goes to preset 1 speed – turn off • Turn on DIN 5 – Vfd goes to preset 2 speed • Turn on DIN 4 – Vfd goes to preset 3 speed (not in Quick Setup) • Turn on DIN 3 – External shutdown contact – observe display – turn off • Turn on DIN 6 – External fault reset 77

Lab 2 Continued • Turn on DIN 1, Twist VOLTAGE INPUT – Observe • Turn on DIN 2 – Nothing • Turn on DIN 4 – Vfd goes to preset 1 speed – turn off • Turn on DIN 5 – Vfd goes to preset 2 speed • Turn on DIN 4 – Vfd goes to preset 3 speed (not in Quick Setup) • Turn on DIN 3 – External shutdown contact – observe display – turn off • Turn on DIN 6 – External fault reset 77

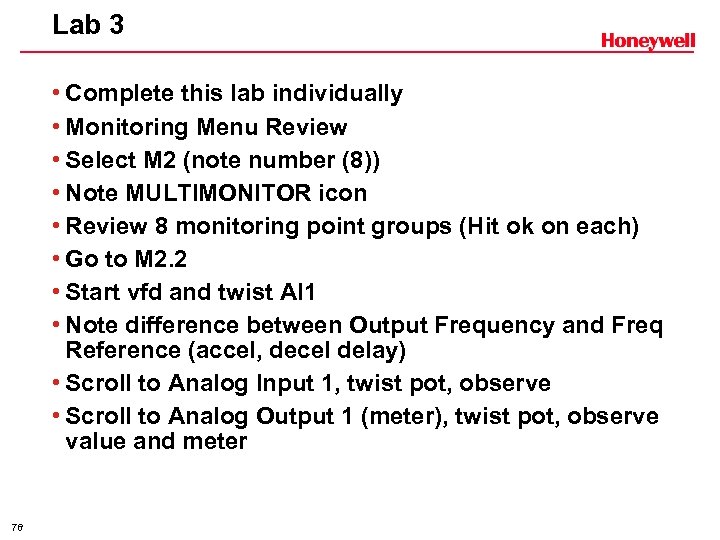

Lab 3 • Complete this lab individually • Monitoring Menu Review • Select M 2 (note number (8)) • Note MULTIMONITOR icon • Review 8 monitoring point groups (Hit ok on each) • Go to M 2. 2 • Start vfd and twist AI 1 • Note difference between Output Frequency and Freq Reference (accel, decel delay) • Scroll to Analog Input 1, twist pot, observe • Scroll to Analog Output 1 (meter), twist pot, observe value and meter 78

Lab 3 • Complete this lab individually • Monitoring Menu Review • Select M 2 (note number (8)) • Note MULTIMONITOR icon • Review 8 monitoring point groups (Hit ok on each) • Go to M 2. 2 • Start vfd and twist AI 1 • Note difference between Output Frequency and Freq Reference (accel, decel delay) • Scroll to Analog Input 1, twist pot, observe • Scroll to Analog Output 1 (meter), twist pot, observe value and meter 78

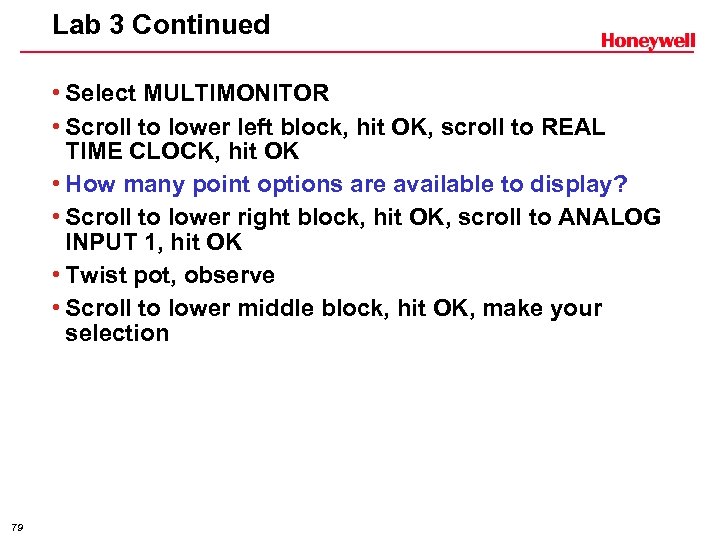

Lab 3 Continued • Select MULTIMONITOR • Scroll to lower left block, hit OK, scroll to REAL TIME CLOCK, hit OK • How many point options are available to display? • Scroll to lower right block, hit OK, scroll to ANALOG INPUT 1, hit OK • Twist pot, observe • Scroll to lower middle block, hit OK, make your selection 79

Lab 3 Continued • Select MULTIMONITOR • Scroll to lower left block, hit OK, scroll to REAL TIME CLOCK, hit OK • How many point options are available to display? • Scroll to lower right block, hit OK, scroll to ANALOG INPUT 1, hit OK • Twist pot, observe • Scroll to lower middle block, hit OK, make your selection 79

Lab 4 • Complete this lab individually • Fan won’t run until damper interlock is made • Explain DIG IN SLOT A. 2 • Turn DIN 1 off • Go to parameter M 3. 5. 1. 11 RUN INTERLOCK 1 • Hit OK and EDIT (scroll through options on both sides of. ) • Set to Dig. INSlot. A. 2 / 4 • Turn DIN 1 on; Result? • Turn DIN 2 / 4 on; Result? • Return to parameter M 3. 5. 1. 11, set to Dig. INSlot 0. 2 / 4 • Turn on DIN 1; fan should run 80

Lab 4 • Complete this lab individually • Fan won’t run until damper interlock is made • Explain DIG IN SLOT A. 2 • Turn DIN 1 off • Go to parameter M 3. 5. 1. 11 RUN INTERLOCK 1 • Hit OK and EDIT (scroll through options on both sides of. ) • Set to Dig. INSlot. A. 2 / 4 • Turn DIN 1 on; Result? • Turn DIN 2 / 4 on; Result? • Return to parameter M 3. 5. 1. 11, set to Dig. INSlot 0. 2 / 4 • Turn on DIN 1; fan should run 80

Lab 7 • Complete this lab individually • Fault Review (M 4 Diagnostics Menu) • Max 10 Active Faults simultaneously • Max 40 Faults in history • FAULT, ALARM, INFO • Blinking fault displayed on keypad • Fault codes listed in chapter 3. 7. 2 in Application Manual 81

Lab 7 • Complete this lab individually • Fault Review (M 4 Diagnostics Menu) • Max 10 Active Faults simultaneously • Max 40 Faults in history • FAULT, ALARM, INFO • Blinking fault displayed on keypad • Fault codes listed in chapter 3. 7. 2 in Application Manual 81

Lab 7 Continued • Turn on DIN 1, twist pot • Turn on DIN 3, external shutdown switch • Display blinking fault, Hit OK, Read info, Notice Fault Code, Hit OK • Fault name displayed, Hit OK, Select DETAILS • Review fault details, Hit BACK • Turn off DIN 3, Hit BACK • Select RESET FAULTS, Select RESET FAULTS (Active Faults = 0) • Motor starts • Turn on DIN 3, Turn off DIN 3 • Hit BACK, Select RESET FAULTS, Motor runs 82

Lab 7 Continued • Turn on DIN 1, twist pot • Turn on DIN 3, external shutdown switch • Display blinking fault, Hit OK, Read info, Notice Fault Code, Hit OK • Fault name displayed, Hit OK, Select DETAILS • Review fault details, Hit BACK • Turn off DIN 3, Hit BACK • Select RESET FAULTS, Select RESET FAULTS (Active Faults = 0) • Motor starts • Turn on DIN 3, Turn off DIN 3 • Hit BACK, Select RESET FAULTS, Motor runs 82

Lab 7 Continued • Complete this as a team • Go to PROTECTIONS (M 3. 9) • Select M 3. 9. 2 EXTERNAL FAULT • Select EDIT, Review options • Select ALARM • Turn on DIN 3, Note alarm, Motor continues to run • Reset (clear) ACTIVE FAULT • Go back to M 3. 9. 2 and make EXTERNAL FAULT a FAULT • Review options in M 3. 9. 1 AI LOW FAULT 83

Lab 7 Continued • Complete this as a team • Go to PROTECTIONS (M 3. 9) • Select M 3. 9. 2 EXTERNAL FAULT • Select EDIT, Review options • Select ALARM • Turn on DIN 3, Note alarm, Motor continues to run • Reset (clear) ACTIVE FAULT • Go back to M 3. 9. 2 and make EXTERNAL FAULT a FAULT • Review options in M 3. 9. 1 AI LOW FAULT 83

Lab 8 • Complete this lab individually • Motor Preheat Function • Turn DIN 1 OFF • Go to M 3. 1. 2. 3 PREHEAT FUNCTION • Select TEMP LIMIT, enter 40 / 38 degrees C, Hit BACK • Select ADD TO FAVORITES, Hit OK • Note DO 1 is energized and display reads HEATING • Go to 2. 2. 11 (BASIC MONITORING) • Note UNIT TEMPERATURE • Go to M 7 Favorites, Select PREHEAT TEMP LIMIT • Enter a temperature 5 / 7 degress C below Unit Temp • Note DO 1 is De-energized, Hit BACK • Select REM FROM FAVORITES to remove from Favorites list 84

Lab 8 • Complete this lab individually • Motor Preheat Function • Turn DIN 1 OFF • Go to M 3. 1. 2. 3 PREHEAT FUNCTION • Select TEMP LIMIT, enter 40 / 38 degrees C, Hit BACK • Select ADD TO FAVORITES, Hit OK • Note DO 1 is energized and display reads HEATING • Go to 2. 2. 11 (BASIC MONITORING) • Note UNIT TEMPERATURE • Go to M 7 Favorites, Select PREHEAT TEMP LIMIT • Enter a temperature 5 / 7 degress C below Unit Temp • Note DO 1 is De-energized, Hit BACK • Select REM FROM FAVORITES to remove from Favorites list 84

Lab 9 • One person program 9 other person 10 • Use internal timeclock to start stop vfd • Turn all DIN’s off • Insert time of day in multimonitor – note time • Go to parameter 3. 11. 1. 1 – 00: 00 (Interval 1) • . 2 – 23: 00 • . 3 – Sunday • . 4 – Saturday • . 5 – Time. Channel. 1 • Go to parameter 3. 5. 1. 1 – Time. Channel. 1 • Vfd should start • Press STOP button on keypad, follow instructions to restart 85

Lab 9 • One person program 9 other person 10 • Use internal timeclock to start stop vfd • Turn all DIN’s off • Insert time of day in multimonitor – note time • Go to parameter 3. 11. 1. 1 – 00: 00 (Interval 1) • . 2 – 23: 00 • . 3 – Sunday • . 4 – Saturday • . 5 – Time. Channel. 1 • Go to parameter 3. 5. 1. 1 – Time. Channel. 1 • Vfd should start • Press STOP button on keypad, follow instructions to restart 85

Lab 10 • One program 9 other 10 • Use internal timeclock to invoke preset speed • Turn all DIN’s off • Insert time of day in multimonitor – note time • Note preset speed 1 setting and put in Favorites • Go to parameter 3. 11. 2. 1 – 00: 00 (Interval 2) • . 2 – 23: 00 • . 3 – Sunday • . 4 – Saturday • . 5 – Time. Channel. 2 • Go to parameter 3. 5. 1. 16 – Time. Channel. 2 • Vfd should run at preset speed 1 • Press STOP button on keypad, follow instructions to restart 86

Lab 10 • One program 9 other 10 • Use internal timeclock to invoke preset speed • Turn all DIN’s off • Insert time of day in multimonitor – note time • Note preset speed 1 setting and put in Favorites • Go to parameter 3. 11. 2. 1 – 00: 00 (Interval 2) • . 2 – 23: 00 • . 3 – Sunday • . 4 – Saturday • . 5 – Time. Channel. 2 • Go to parameter 3. 5. 1. 16 – Time. Channel. 2 • Vfd should run at preset speed 1 • Press STOP button on keypad, follow instructions to restart 86

Lab 11 • Restore factory defaults • Setup drive • Setup mini wizard using defaults 87

Lab 11 • Restore factory defaults • Setup drive • Setup mini wizard using defaults 87

Lab 12 • Complete this lab individually • PID setup • Go to QUICK SETUP, change MIN FREQ to 0 and activate PID MINI WIZARD • Enter following selections: • In wg for engineering units • 0 for process unit minimum • 5 for process unit maximum • 2 for process unit decimals • AI 1 for FB (feedback) 1 source • 0 -10 V for AI 1 signal range • NORMAL for error inversion • KEYPAD SP 1 for SP (setpoint) 1 source • 2 for Keypad SP 1 • NO for Sleep Function • Press OK to exit • Turn DIN 1 on, twist pot and observe • Go to MONITOR, PID CONTROLLER 1, twist pot, observe • Go to 3. 12. 1. 2 and set your INTEGRATION TIME 88

Lab 12 • Complete this lab individually • PID setup • Go to QUICK SETUP, change MIN FREQ to 0 and activate PID MINI WIZARD • Enter following selections: • In wg for engineering units • 0 for process unit minimum • 5 for process unit maximum • 2 for process unit decimals • AI 1 for FB (feedback) 1 source • 0 -10 V for AI 1 signal range • NORMAL for error inversion • KEYPAD SP 1 for SP (setpoint) 1 source • 2 for Keypad SP 1 • NO for Sleep Function • Press OK to exit • Turn DIN 1 on, twist pot and observe • Go to MONITOR, PID CONTROLLER 1, twist pot, observe • Go to 3. 12. 1. 2 and set your INTEGRATION TIME 88

Lab 13 • Complete this lab as a team • Prohibit frequency • Set range 1 low at 30 and high at 35 • Set range 2 low at 45 and high at 50 • Start vfd, twist pot slowly to observe • Save your program to the keypad and download your program from the keypad (M 6) 89

Lab 13 • Complete this lab as a team • Prohibit frequency • Set range 1 low at 30 and high at 35 • Set range 2 low at 45 and high at 50 • Start vfd, twist pot slowly to observe • Save your program to the keypad and download your program from the keypad (M 6) 89

Lab 14 • Complete this lab individually • Keypad Control • Will override DIN’s but not active fault • Press LOC/REM button, Select LOCAL • Press LOC/REM button again, select CONTROL PLACE • Note multimonitor screen below, insert tod in top right • Hit OK on speed reference bar (blinks). Ramp the motor up and down using the up and down arrow keys • Hit the STOP button, follow instructions • Return to CONTROL PLACE, ramp up and down • Return to IO control by pressing LOC/REM again and selecting REMOTE • Process simplified next rev 90

Lab 14 • Complete this lab individually • Keypad Control • Will override DIN’s but not active fault • Press LOC/REM button, Select LOCAL • Press LOC/REM button again, select CONTROL PLACE • Note multimonitor screen below, insert tod in top right • Hit OK on speed reference bar (blinks). Ramp the motor up and down using the up and down arrow keys • Hit the STOP button, follow instructions • Return to CONTROL PLACE, ramp up and down • Return to IO control by pressing LOC/REM again and selecting REMOTE • Process simplified next rev 90

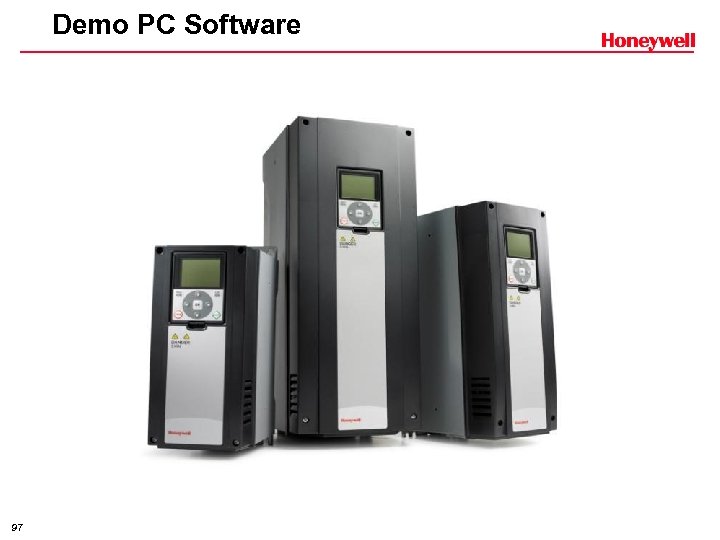

Demo PC Software 97

Demo PC Software 97

http//. customer. honeywell. com/VFD Beyondinnovation. honeywell. com Technical Support – 888 516 9347 98

http//. customer. honeywell. com/VFD Beyondinnovation. honeywell. com Technical Support – 888 516 9347 98

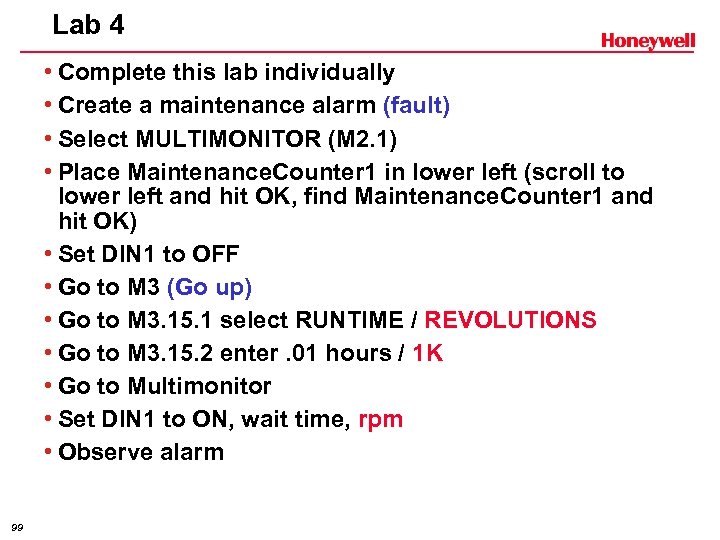

Lab 4 • Complete this lab individually • Create a maintenance alarm (fault) • Select MULTIMONITOR (M 2. 1) • Place Maintenance. Counter 1 in lower left (scroll to lower left and hit OK, find Maintenance. Counter 1 and hit OK) • Set DIN 1 to OFF • Go to M 3 (Go up) • Go to M 3. 15. 1 select RUNTIME / REVOLUTIONS • Go to M 3. 15. 2 enter. 01 hours / 1 K • Go to Multimonitor • Set DIN 1 to ON, wait time, rpm • Observe alarm 99

Lab 4 • Complete this lab individually • Create a maintenance alarm (fault) • Select MULTIMONITOR (M 2. 1) • Place Maintenance. Counter 1 in lower left (scroll to lower left and hit OK, find Maintenance. Counter 1 and hit OK) • Set DIN 1 to OFF • Go to M 3 (Go up) • Go to M 3. 15. 1 select RUNTIME / REVOLUTIONS • Go to M 3. 15. 2 enter. 01 hours / 1 K • Go to Multimonitor • Set DIN 1 to ON, wait time, rpm • Observe alarm 99

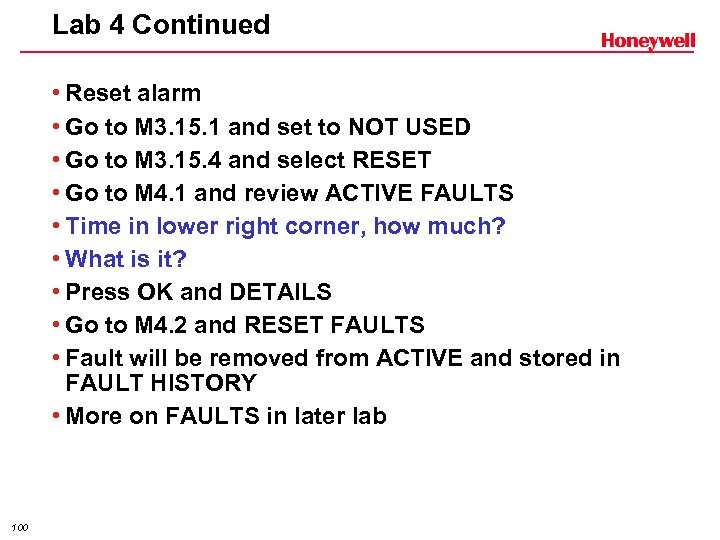

Lab 4 Continued • Reset alarm • Go to M 3. 15. 1 and set to NOT USED • Go to M 3. 15. 4 and select RESET • Go to M 4. 1 and review ACTIVE FAULTS • Time in lower right corner, how much? • What is it? • Press OK and DETAILS • Go to M 4. 2 and RESET FAULTS • Fault will be removed from ACTIVE and stored in FAULT HISTORY • More on FAULTS in later lab 100

Lab 4 Continued • Reset alarm • Go to M 3. 15. 1 and set to NOT USED • Go to M 3. 15. 4 and select RESET • Go to M 4. 1 and review ACTIVE FAULTS • Time in lower right corner, how much? • What is it? • Press OK and DETAILS • Go to M 4. 2 and RESET FAULTS • Fault will be removed from ACTIVE and stored in FAULT HISTORY • More on FAULTS in later lab 100

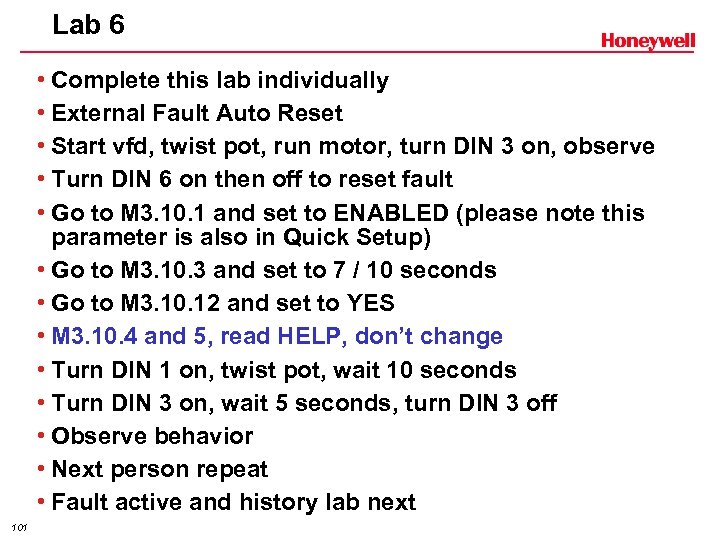

Lab 6 • Complete this lab individually • External Fault Auto Reset • Start vfd, twist pot, run motor, turn DIN 3 on, observe • Turn DIN 6 on then off to reset fault • Go to M 3. 10. 1 and set to ENABLED (please note this parameter is also in Quick Setup) • Go to M 3. 10. 3 and set to 7 / 10 seconds • Go to M 3. 10. 12 and set to YES • M 3. 10. 4 and 5, read HELP, don’t change • Turn DIN 1 on, twist pot, wait 10 seconds • Turn DIN 3 on, wait 5 seconds, turn DIN 3 off • Observe behavior • Next person repeat • Fault active and history lab next 101

Lab 6 • Complete this lab individually • External Fault Auto Reset • Start vfd, twist pot, run motor, turn DIN 3 on, observe • Turn DIN 6 on then off to reset fault • Go to M 3. 10. 1 and set to ENABLED (please note this parameter is also in Quick Setup) • Go to M 3. 10. 3 and set to 7 / 10 seconds • Go to M 3. 10. 12 and set to YES • M 3. 10. 4 and 5, read HELP, don’t change • Turn DIN 1 on, twist pot, wait 10 seconds • Turn DIN 3 on, wait 5 seconds, turn DIN 3 off • Observe behavior • Next person repeat • Fault active and history lab next 101