a023000deb746731e9eb6c4cfe92d574.ppt

- Количество слайдов: 40

Introducing the DSQII Terry Jeffers

Introducing the DSQII Terry Jeffers

Agenda • Update on Thermo’s Environmental Initiatives • Discussion on new approaches to the challenges of 8270 • Introducing Thermo Electrons Productivity Kits • Enviro. Lab Forms 2. 0 – High Throughput Quatification • New application note: Rapid Analysis of 8270 2

Agenda • Update on Thermo’s Environmental Initiatives • Discussion on new approaches to the challenges of 8270 • Introducing Thermo Electrons Productivity Kits • Enviro. Lab Forms 2. 0 – High Throughput Quatification • New application note: Rapid Analysis of 8270 2

Thermo Electron: Environmental Initiative • Focus on Environmental Laboratory needs: – Requirement for Productivity – Need for good work flow in Generating, Reviewing and Reporting data – Benefit from guides for operation, maintenance and troubleshooting specific Methodologies 3

Thermo Electron: Environmental Initiative • Focus on Environmental Laboratory needs: – Requirement for Productivity – Need for good work flow in Generating, Reviewing and Reporting data – Benefit from guides for operation, maintenance and troubleshooting specific Methodologies 3

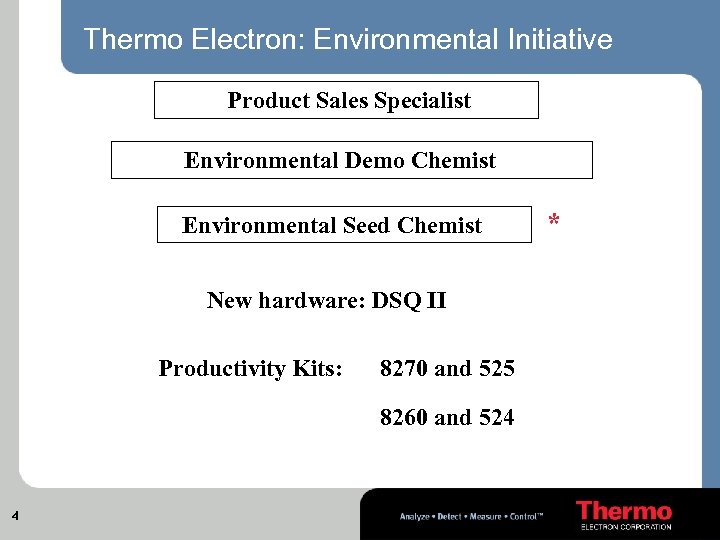

Thermo Electron: Environmental Initiative Product Sales Specialist Environmental Demo Chemist Environmental Seed Chemist New hardware: DSQ II Productivity Kits: 8270 and 525 8260 and 524 4 *

Thermo Electron: Environmental Initiative Product Sales Specialist Environmental Demo Chemist Environmental Seed Chemist New hardware: DSQ II Productivity Kits: 8270 and 525 8260 and 524 4 *

Pitt Falls for Method 8270 Those little things that stop everything

Pitt Falls for Method 8270 Those little things that stop everything

Activity in the GC/MS system • Activity – These sites can be everywhere • Injector, column, source • SPCC compounds are used to show good system – Nitrophenols are some of the best compounds to find active sites • Minimizing Effects of Activity – Deactivated liners – Good column that shows no active sites – High flow rates to reduce the residence time of any active compound. – Balance temperature zones to reduce activity and thermal break down. 6

Activity in the GC/MS system • Activity – These sites can be everywhere • Injector, column, source • SPCC compounds are used to show good system – Nitrophenols are some of the best compounds to find active sites • Minimizing Effects of Activity – Deactivated liners – Good column that shows no active sites – High flow rates to reduce the residence time of any active compound. – Balance temperature zones to reduce activity and thermal break down. 6

Chromatography How important is it really?

Chromatography How important is it really?

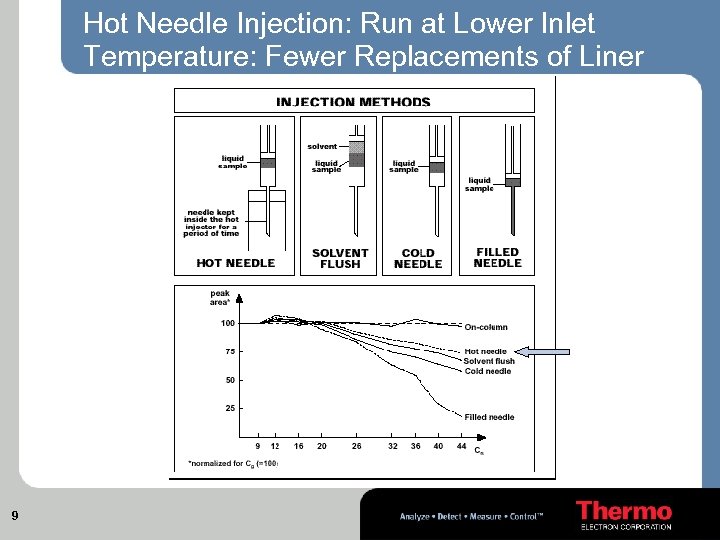

GC and Autosampler • Separations accomplished with slow chromatography – Common GC methods for 8270 • • • Fast injection 250 - 300 0 C injector temperature 1 m. L/min flow rate 30 m x 0. 25 mm ID column Oven ramps between 5 0 and 10 0 C/min from 35 0 to 300 0 C • Separations accomplished with fast chromatography – Alternate GC method for 8270 • • • 8 Hot needle injection 250 0 C injector temperature 3 m. L/min flow rate 30 m x 0. 25 mm ID x 0. 5 µm column Oven stepped ramps to provide the critical pair separations.

GC and Autosampler • Separations accomplished with slow chromatography – Common GC methods for 8270 • • • Fast injection 250 - 300 0 C injector temperature 1 m. L/min flow rate 30 m x 0. 25 mm ID column Oven ramps between 5 0 and 10 0 C/min from 35 0 to 300 0 C • Separations accomplished with fast chromatography – Alternate GC method for 8270 • • • 8 Hot needle injection 250 0 C injector temperature 3 m. L/min flow rate 30 m x 0. 25 mm ID x 0. 5 µm column Oven stepped ramps to provide the critical pair separations.

Hot Needle Injection: Run at Lower Inlet Temperature: Fewer Replacements of Liner 9

Hot Needle Injection: Run at Lower Inlet Temperature: Fewer Replacements of Liner 9

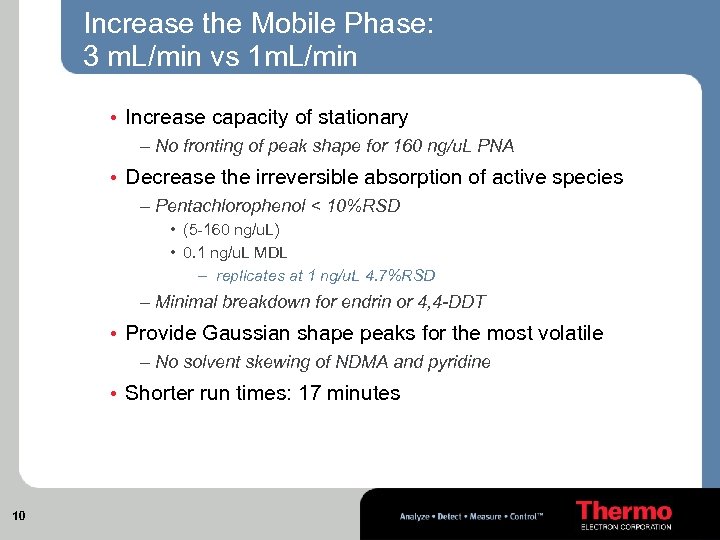

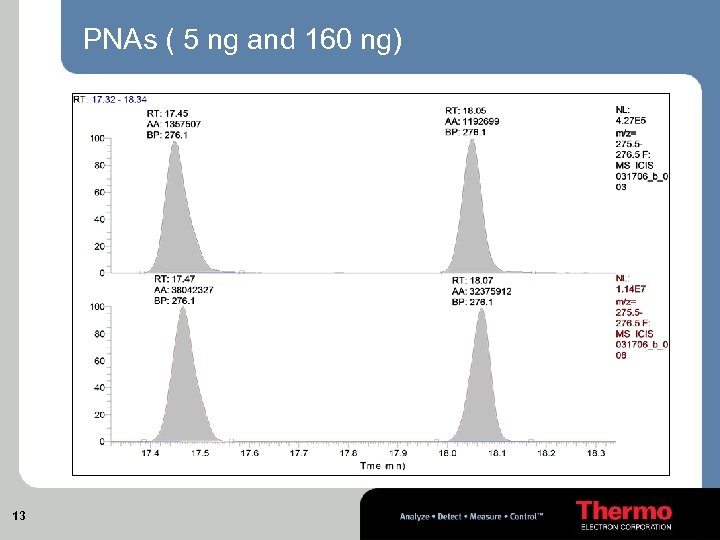

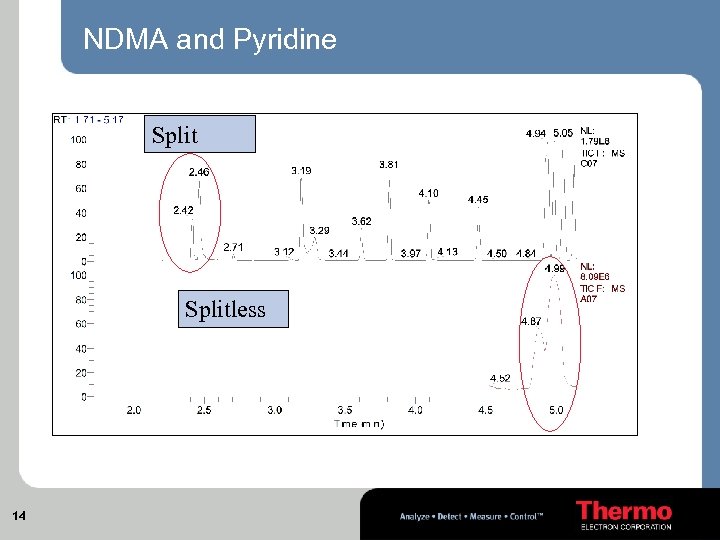

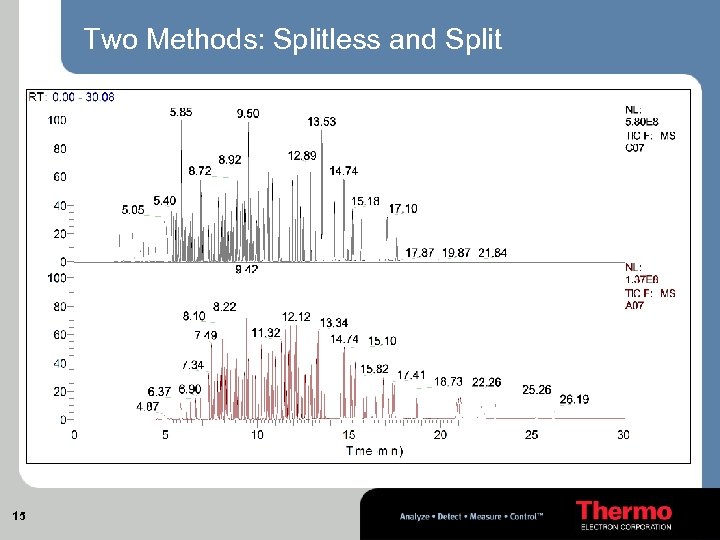

Increase the Mobile Phase: 3 m. L/min vs 1 m. L/min • Increase capacity of stationary – No fronting of peak shape for 160 ng/u. L PNA • Decrease the irreversible absorption of active species – Pentachlorophenol < 10%RSD • (5 -160 ng/u. L) • 0. 1 ng/u. L MDL – replicates at 1 ng/u. L 4. 7%RSD – Minimal breakdown for endrin or 4, 4 -DDT • Provide Gaussian shape peaks for the most volatile – No solvent skewing of NDMA and pyridine • Shorter run times: 17 minutes 10

Increase the Mobile Phase: 3 m. L/min vs 1 m. L/min • Increase capacity of stationary – No fronting of peak shape for 160 ng/u. L PNA • Decrease the irreversible absorption of active species – Pentachlorophenol < 10%RSD • (5 -160 ng/u. L) • 0. 1 ng/u. L MDL – replicates at 1 ng/u. L 4. 7%RSD – Minimal breakdown for endrin or 4, 4 -DDT • Provide Gaussian shape peaks for the most volatile – No solvent skewing of NDMA and pyridine • Shorter run times: 17 minutes 10

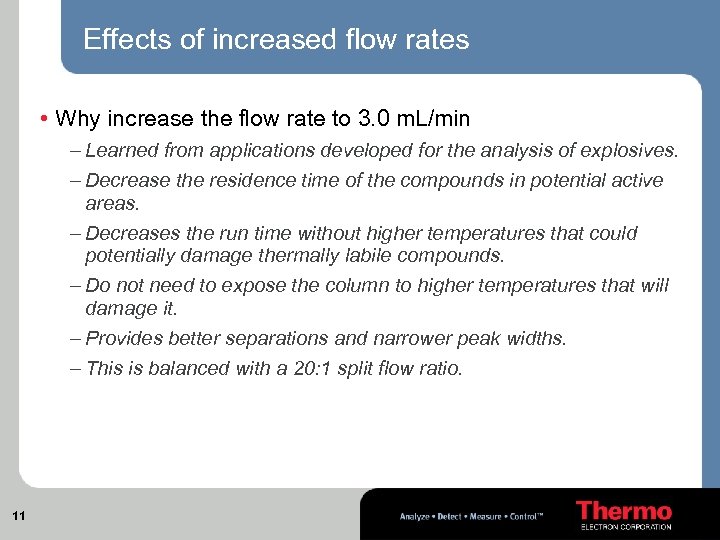

Effects of increased flow rates • Why increase the flow rate to 3. 0 m. L/min – Learned from applications developed for the analysis of explosives. – Decrease the residence time of the compounds in potential active areas. – Decreases the run time without higher temperatures that could potentially damage thermally labile compounds. – Do not need to expose the column to higher temperatures that will damage it. – Provides better separations and narrower peak widths. – This is balanced with a 20: 1 split flow ratio. 11

Effects of increased flow rates • Why increase the flow rate to 3. 0 m. L/min – Learned from applications developed for the analysis of explosives. – Decrease the residence time of the compounds in potential active areas. – Decreases the run time without higher temperatures that could potentially damage thermally labile compounds. – Do not need to expose the column to higher temperatures that will damage it. – Provides better separations and narrower peak widths. – This is balanced with a 20: 1 split flow ratio. 11

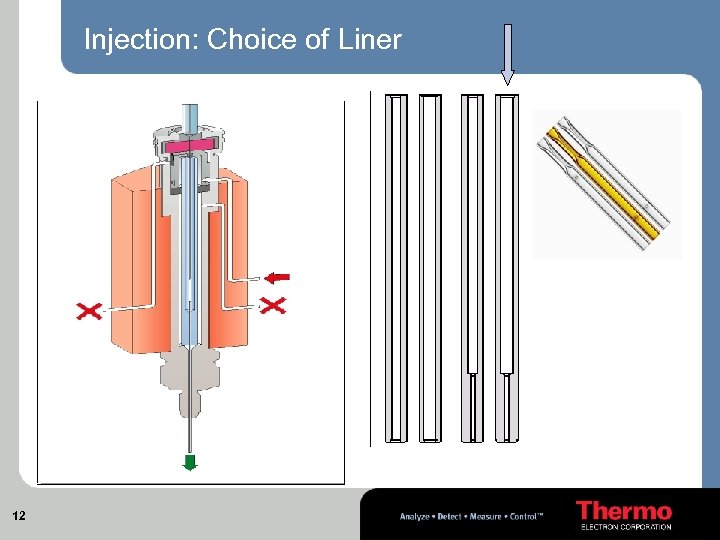

Injection: Choice of Liner 12

Injection: Choice of Liner 12

PNAs ( 5 ng and 160 ng) 13

PNAs ( 5 ng and 160 ng) 13

NDMA and Pyridine Splitless 14

NDMA and Pyridine Splitless 14

Two Methods: Splitless and Split 15

Two Methods: Splitless and Split 15

TRACE Ultra DSQ II GC/MS 16

TRACE Ultra DSQ II GC/MS 16

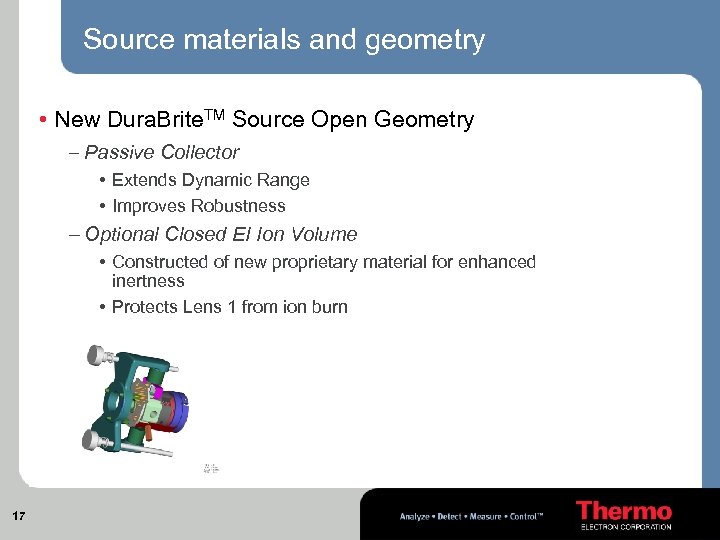

Source materials and geometry • New Dura. Brite. TM Source Open Geometry – Passive Collector • Extends Dynamic Range • Improves Robustness – Optional Closed EI Ion Volume • Constructed of new proprietary material for enhanced inertness • Protects Lens 1 from ion burn 17

Source materials and geometry • New Dura. Brite. TM Source Open Geometry – Passive Collector • Extends Dynamic Range • Improves Robustness – Optional Closed EI Ion Volume • Constructed of new proprietary material for enhanced inertness • Protects Lens 1 from ion burn 17

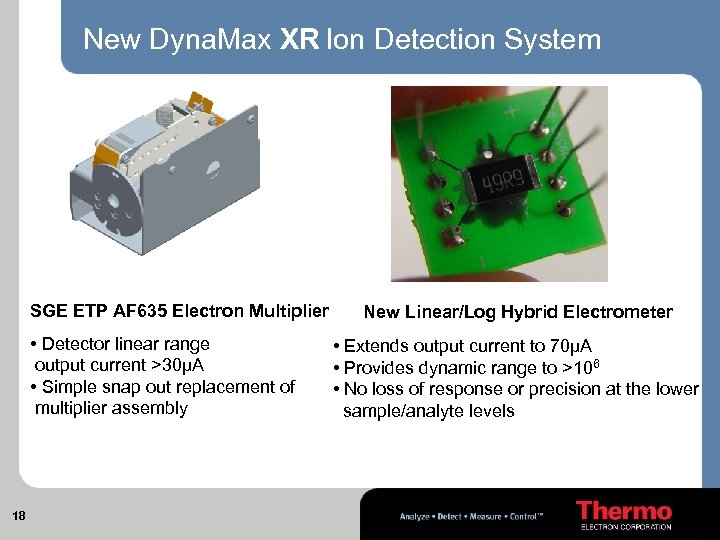

New Dyna. Max XR Ion Detection System SGE ETP AF 635 Electron Multiplier • Detector linear range output current >30µA • Simple snap out replacement of multiplier assembly 18 New Linear/Log Hybrid Electrometer • Extends output current to 70µA • Provides dynamic range to >106 • No loss of response or precision at the lower sample/analyte levels

New Dyna. Max XR Ion Detection System SGE ETP AF 635 Electron Multiplier • Detector linear range output current >30µA • Simple snap out replacement of multiplier assembly 18 New Linear/Log Hybrid Electrometer • Extends output current to 70µA • Provides dynamic range to >106 • No loss of response or precision at the lower sample/analyte levels

Expected Results I can get, you can get them too.

Expected Results I can get, you can get them too.

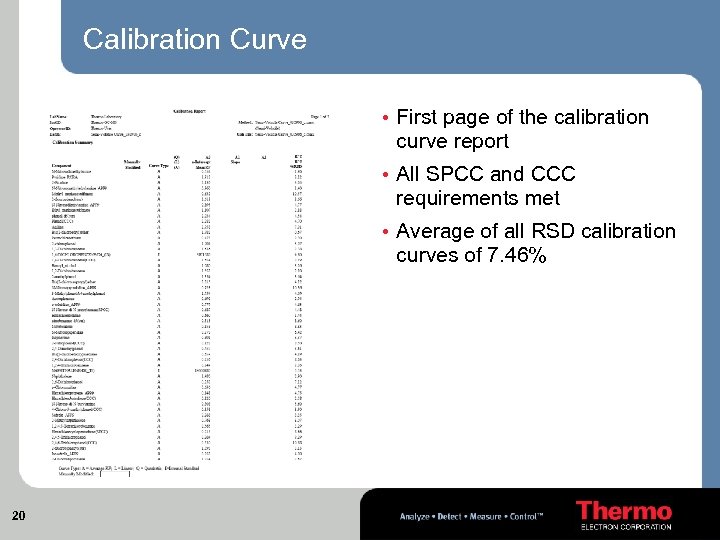

Calibration Curve • First page of the calibration curve report • All SPCC and CCC requirements met • Average of all RSD calibration curves of 7. 46% 20

Calibration Curve • First page of the calibration curve report • All SPCC and CCC requirements met • Average of all RSD calibration curves of 7. 46% 20

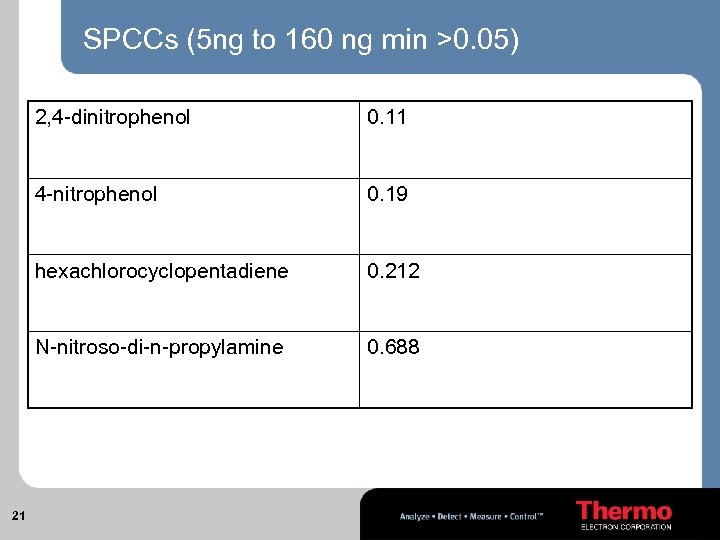

SPCCs (5 ng to 160 ng min >0. 05) 2, 4 -dinitrophenol 4 -nitrophenol 0. 19 hexachlorocyclopentadiene 0. 212 N-nitroso-di-n-propylamine 21 0. 11 0. 688

SPCCs (5 ng to 160 ng min >0. 05) 2, 4 -dinitrophenol 4 -nitrophenol 0. 19 hexachlorocyclopentadiene 0. 212 N-nitroso-di-n-propylamine 21 0. 11 0. 688

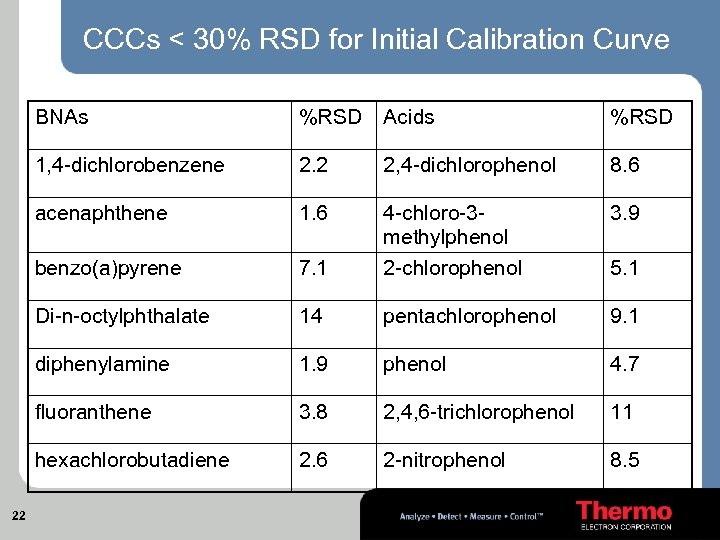

CCCs < 30% RSD for Initial Calibration Curve BNAs Acids %RSD 1, 4 -dichlorobenzene 2. 2 2, 4 -dichlorophenol 8. 6 acenaphthene 1. 6 7. 1 4 -chloro-3 methylphenol 2 -chlorophenol 3. 9 benzo(a)pyrene Di-n-octylphthalate 14 pentachlorophenol 9. 1 diphenylamine 1. 9 phenol 4. 7 fluoranthene 3. 8 2, 4, 6 -trichlorophenol 11 hexachlorobutadiene 22 %RSD 2. 6 2 -nitrophenol 8. 5 5. 1

CCCs < 30% RSD for Initial Calibration Curve BNAs Acids %RSD 1, 4 -dichlorobenzene 2. 2 2, 4 -dichlorophenol 8. 6 acenaphthene 1. 6 7. 1 4 -chloro-3 methylphenol 2 -chlorophenol 3. 9 benzo(a)pyrene Di-n-octylphthalate 14 pentachlorophenol 9. 1 diphenylamine 1. 9 phenol 4. 7 fluoranthene 3. 8 2, 4, 6 -trichlorophenol 11 hexachlorobutadiene 22 %RSD 2. 6 2 -nitrophenol 8. 5 5. 1

Quantitated Data File • First page of the Quantitation Report • This shows the quantitation of the 20 ng/u. L sample for the calibration curve • Meets the requirements of the internal standards and surrogates • Meets all ion ratio requirements • No manual integrations were required 23

Quantitated Data File • First page of the Quantitation Report • This shows the quantitation of the 20 ng/u. L sample for the calibration curve • Meets the requirements of the internal standards and surrogates • Meets all ion ratio requirements • No manual integrations were required 23

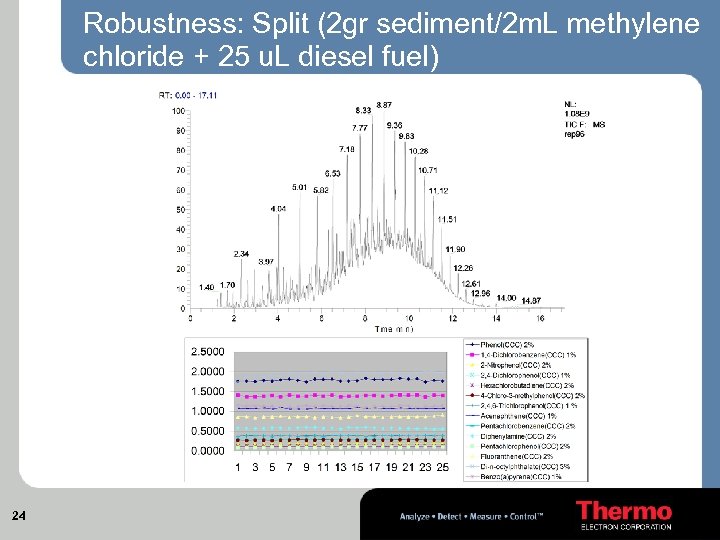

Robustness: Split (2 gr sediment/2 m. L methylene chloride + 25 u. L diesel fuel) 24

Robustness: Split (2 gr sediment/2 m. L methylene chloride + 25 u. L diesel fuel) 24

How can we prove it Productivity Solutions

How can we prove it Productivity Solutions

Productivity Solutions Integrating the DSQ II with Software, Methods, and Consumables to Get Productive, Quickly

Productivity Solutions Integrating the DSQ II with Software, Methods, and Consumables to Get Productive, Quickly

Productivity Solutions • Provide all of the necessary material to run the method – Proven Thermo Column – Deactivated Liners – Standards • Snap and shoot – prediluted for entire method validation – All other consumables for about 2 weeks • Provide all of the software – Enviro. Lab Forms 2. 0 – Interactive Reference CD • All of the methods, sequences, – Validation data used to generate all of what you see here and in the manuals • Two Boxes full of materials, manuals, and CD’s. 27

Productivity Solutions • Provide all of the necessary material to run the method – Proven Thermo Column – Deactivated Liners – Standards • Snap and shoot – prediluted for entire method validation – All other consumables for about 2 weeks • Provide all of the software – Enviro. Lab Forms 2. 0 – Interactive Reference CD • All of the methods, sequences, – Validation data used to generate all of what you see here and in the manuals • Two Boxes full of materials, manuals, and CD’s. 27

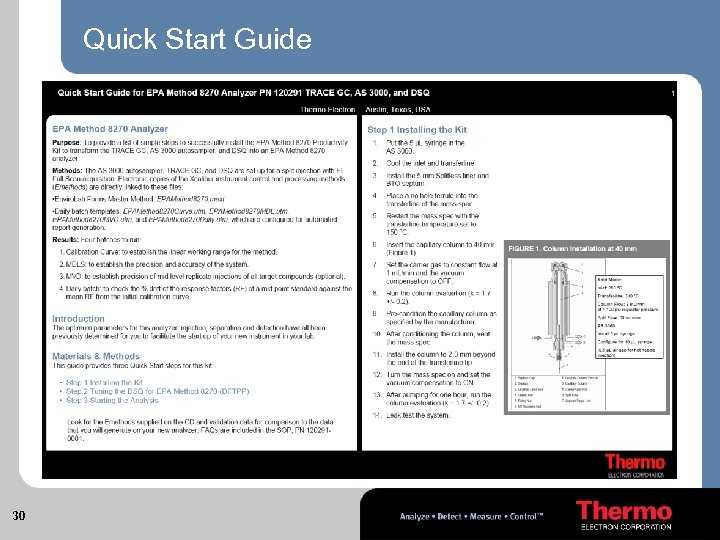

Productivity Kit • SOP manual for method • How to Guide • Quick Start Guide • Provide consumables for running method – Standards, liners, septa, syringes, column, … • Instrument method, processing method, reporting package • CD deliverable – SOP – Data from method validation – Instrument method – Processing method – Reporting software with templates 28

Productivity Kit • SOP manual for method • How to Guide • Quick Start Guide • Provide consumables for running method – Standards, liners, septa, syringes, column, … • Instrument method, processing method, reporting package • CD deliverable – SOP – Data from method validation – Instrument method – Processing method – Reporting software with templates 28

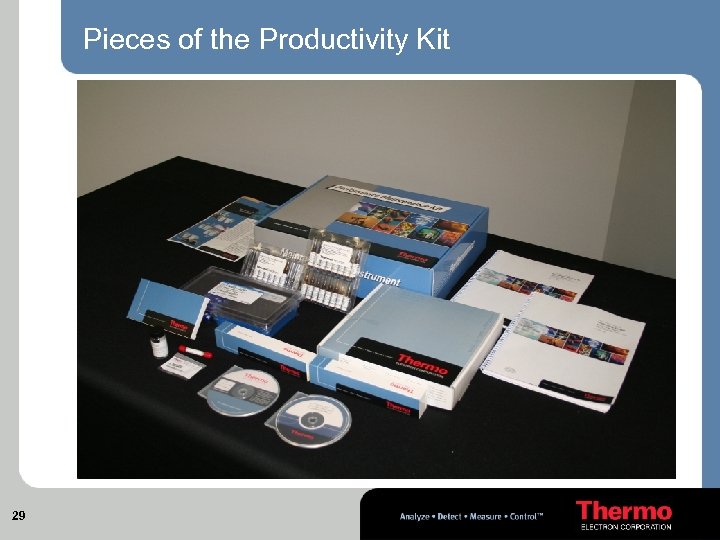

Pieces of the Productivity Kit 29

Pieces of the Productivity Kit 29

Quick Start Guide 30

Quick Start Guide 30

8270 C/D Productivity Solution • Customer’s system can be taken from installation sign off to method IDL’s in as little as 2 days! • 8270 is a value added product which will sell for ~ $3000 US • Add on service provided by Thermo FSE’s • US Field Service Engineers are being trained on the 8270 PS • Kits serve as a great tool for training aides for the lab 31

8270 C/D Productivity Solution • Customer’s system can be taken from installation sign off to method IDL’s in as little as 2 days! • 8270 is a value added product which will sell for ~ $3000 US • Add on service provided by Thermo FSE’s • US Field Service Engineers are being trained on the 8270 PS • Kits serve as a great tool for training aides for the lab 31

Productivity Solutions are a Win-Win • Good for customers – – Improves overall experience – Increases satisfaction – Eases transition to Thermo GC/MS – Gives optimal performance for the DSQ II • Good for Thermo – Easy to support these solutions Helps the customer and support by establishing a known set of criteria to achieve success. Address the new lab environment less highly skilled users with higher throughput requirements 32

Productivity Solutions are a Win-Win • Good for customers – – Improves overall experience – Increases satisfaction – Eases transition to Thermo GC/MS – Gives optimal performance for the DSQ II • Good for Thermo – Easy to support these solutions Helps the customer and support by establishing a known set of criteria to achieve success. Address the new lab environment less highly skilled users with higher throughput requirements 32

tw So f t Ki ar e Redefining the Way We Look at GC/MS Hardware Productivity Solutions target routine GC/MS applications to offer value to the customer 33

tw So f t Ki ar e Redefining the Way We Look at GC/MS Hardware Productivity Solutions target routine GC/MS applications to offer value to the customer 33

Enviro. Lab Forms v 2. 0 High Throughput Quantification

Enviro. Lab Forms v 2. 0 High Throughput Quantification

Enviro. Lab Forms v 2. 0 • An entirely new data processing and reporting system running as a layer over Xcalibur 1. 4 • While targeted towards environmental laboratories and applications, it has been shown to be valuable for any laboratory performing high-throughput quantification • Adds a significant complement of capabilities that Xcalibur – Ion ratio calculations • Peak integration • Reporting – Integrated data review and reporting • No more batch reprocessing to re-generate reports of edited results – Fully automated while still allowing sophisticated manual review 35

Enviro. Lab Forms v 2. 0 • An entirely new data processing and reporting system running as a layer over Xcalibur 1. 4 • While targeted towards environmental laboratories and applications, it has been shown to be valuable for any laboratory performing high-throughput quantification • Adds a significant complement of capabilities that Xcalibur – Ion ratio calculations • Peak integration • Reporting – Integrated data review and reporting • No more batch reprocessing to re-generate reports of edited results – Fully automated while still allowing sophisticated manual review 35

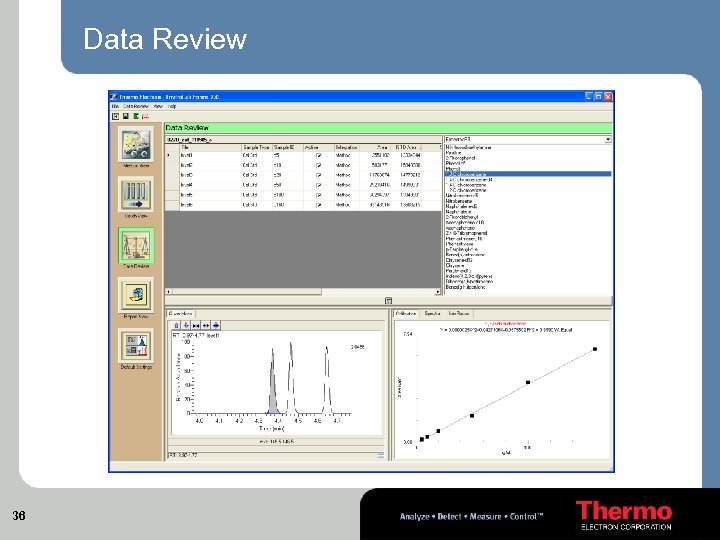

Data Review 36

Data Review 36

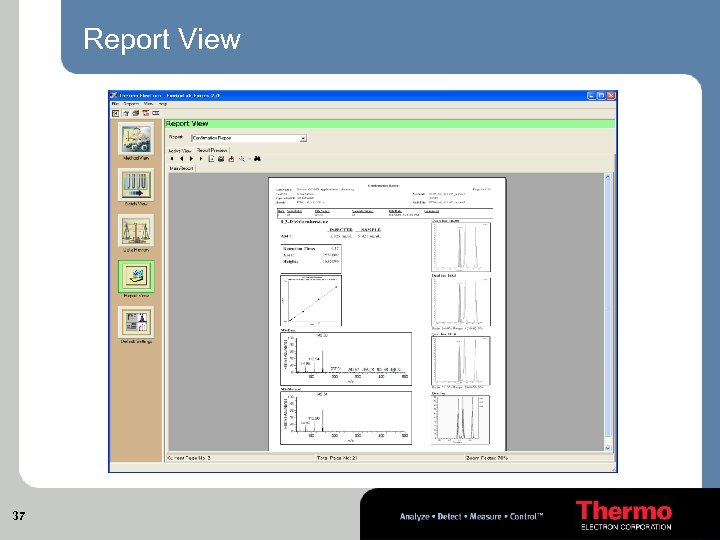

Report View 37

Report View 37

Enviro. Lab Forms v 2. 0 • Brand new workflow oriented user interface • Substantially improved ion ratio review and editing support • Comprehensive set of textual and graphical reports • Fully automated, fully manual or any combination in between • Can be used as a high-throughput quantification engine for any application – Simply turn off or don’t use those options which aren’t relevant for a given user 38

Enviro. Lab Forms v 2. 0 • Brand new workflow oriented user interface • Substantially improved ion ratio review and editing support • Comprehensive set of textual and graphical reports • Fully automated, fully manual or any combination in between • Can be used as a high-throughput quantification engine for any application – Simply turn off or don’t use those options which aren’t relevant for a given user 38

Conclusion • The DSQ II system provides updates to hardware and software that make it easy to use • The Productivity Solution for method 8270 provides a method that has been validated across multiple DSQ II systems. • All of this allows a new operator to be productive immediately • The proven changes to the method allow an increased amount of productivity and throughput for the analyst and the laboratory. 39

Conclusion • The DSQ II system provides updates to hardware and software that make it easy to use • The Productivity Solution for method 8270 provides a method that has been validated across multiple DSQ II systems. • All of this allows a new operator to be productive immediately • The proven changes to the method allow an increased amount of productivity and throughput for the analyst and the laboratory. 39

• Questions? Thank You 40

• Questions? Thank You 40