b9962bf9127d12b9af0b46f93f2d6502.ppt

- Количество слайдов: 21

Introducing… HVS 4000 & HVS 400 Toxic Gas Detectors from Halogen Valve Systems

Introducing… HVS 4000 & HVS 400 Toxic Gas Detectors from Halogen Valve Systems

Agenda • Introduction to General Monitors – HVS 4000 – HVS 400 • Features & Benefits • Specifications • Calibration • Accessories • Applications • Competition • Closed Loop Marketing • Feedback/Questions PRODUCT LAUNCH

Agenda • Introduction to General Monitors – HVS 4000 – HVS 400 • Features & Benefits • Specifications • Calibration • Accessories • Applications • Competition • Closed Loop Marketing • Feedback/Questions PRODUCT LAUNCH

General Monitors • Established in 1961 by Dr. Frank Linville • Two Manufacturing facilities and R&D Sites - Lake Forest, CA and Ireland • The Best Service & Customer Support • World Class Automated Manufacturing • Total Quality Management • JIT Purchasing

General Monitors • Established in 1961 by Dr. Frank Linville • Two Manufacturing facilities and R&D Sites - Lake Forest, CA and Ireland • The Best Service & Customer Support • World Class Automated Manufacturing • Total Quality Management • JIT Purchasing

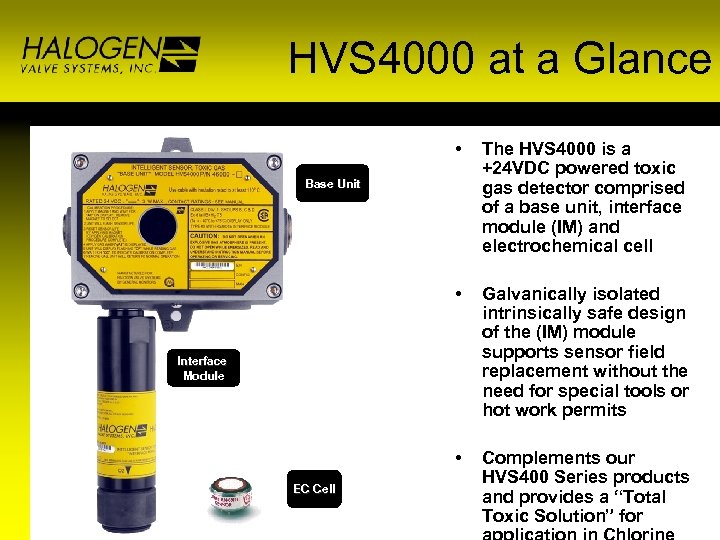

HVS 4000 at a Glance • The HVS 4000 is a +24 VDC powered toxic gas detector comprised of a base unit, interface module (IM) and electrochemical cell • Galvanically isolated intrinsically safe design of the (IM) module supports sensor field replacement without the need for special tools or hot work permits • Complements our HVS 400 Series products and provides a “Total Toxic Solution” for Base Unit Interface Module EC Cell

HVS 4000 at a Glance • The HVS 4000 is a +24 VDC powered toxic gas detector comprised of a base unit, interface module (IM) and electrochemical cell • Galvanically isolated intrinsically safe design of the (IM) module supports sensor field replacement without the need for special tools or hot work permits • Complements our HVS 400 Series products and provides a “Total Toxic Solution” for Base Unit Interface Module EC Cell

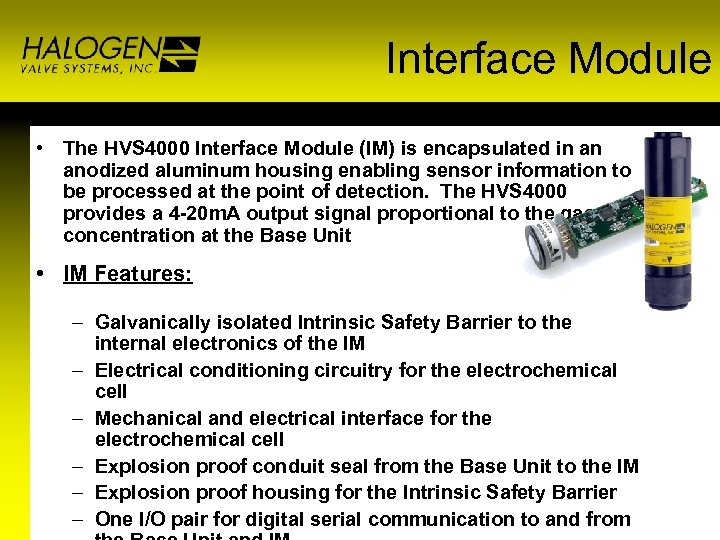

Interface Module • The HVS 4000 Interface Module (IM) is encapsulated in an anodized aluminum housing enabling sensor information to be processed at the point of detection. The HVS 4000 provides a 4 -20 m. A output signal proportional to the gas concentration at the Base Unit • IM Features: – Galvanically isolated Intrinsic Safety Barrier to the internal electronics of the IM – Electrical conditioning circuitry for the electrochemical cell – Mechanical and electrical interface for the electrochemical cell – Explosion proof conduit seal from the Base Unit to the IM – Explosion proof housing for the Intrinsic Safety Barrier – One I/O pair for digital serial communication to and from

Interface Module • The HVS 4000 Interface Module (IM) is encapsulated in an anodized aluminum housing enabling sensor information to be processed at the point of detection. The HVS 4000 provides a 4 -20 m. A output signal proportional to the gas concentration at the Base Unit • IM Features: – Galvanically isolated Intrinsic Safety Barrier to the internal electronics of the IM – Electrical conditioning circuitry for the electrochemical cell – Mechanical and electrical interface for the electrochemical cell – Explosion proof conduit seal from the Base Unit to the IM – Explosion proof housing for the Intrinsic Safety Barrier – One I/O pair for digital serial communication to and from

Base Unit • The HVS 4000 Base Unit provides the display / control device for the entire HVS 4000. The Base Unit is based on the proven Intelligent Sensor platform • Base Unit Features: – – – – Bright LED Digital Display (outdoor readable) MODBUS Communications High Rating Relays One Activation Point for Settings/Calibration Simplified Wiring and Field Connections Standard Platform Calibration Prompts Remote Sensor Placement Capability Remaining Sensor Life Indicator

Base Unit • The HVS 4000 Base Unit provides the display / control device for the entire HVS 4000. The Base Unit is based on the proven Intelligent Sensor platform • Base Unit Features: – – – – Bright LED Digital Display (outdoor readable) MODBUS Communications High Rating Relays One Activation Point for Settings/Calibration Simplified Wiring and Field Connections Standard Platform Calibration Prompts Remote Sensor Placement Capability Remaining Sensor Life Indicator

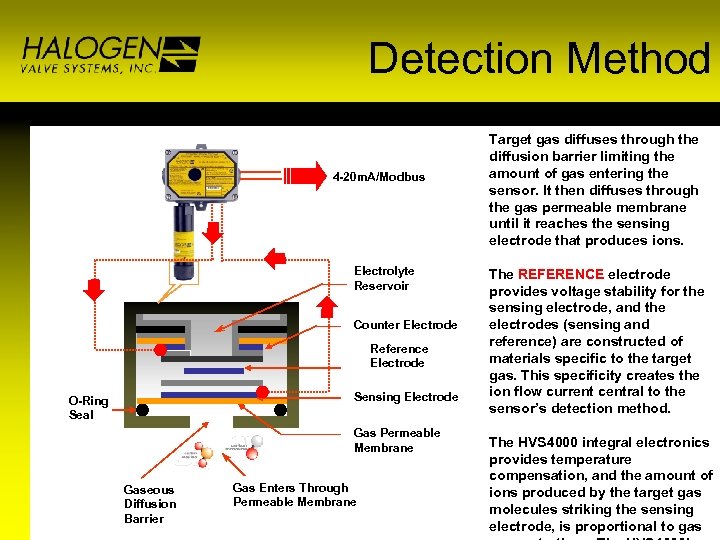

Detection Method TS 4000 Electronics 4 -20 m. A/Modbus Electrolyte Reservoir Counter Electrode Reference Electrode Sensing Electrode O-Ring Seal Gas Permeable Membrane Gaseous Diffusion Barrier Gas Enters Through Permeable Membrane Target gas diffuses through the diffusion barrier limiting the amount of gas entering the sensor. It then diffuses through the gas permeable membrane until it reaches the sensing electrode that produces ions. The REFERENCE electrode provides voltage stability for the sensing electrode, and the electrodes (sensing and reference) are constructed of materials specific to the target gas. This specificity creates the ion flow current central to the sensor’s detection method. The HVS 4000 integral electronics provides temperature compensation, and the amount of ions produced by the target gas molecules striking the sensing electrode, is proportional to gas

Detection Method TS 4000 Electronics 4 -20 m. A/Modbus Electrolyte Reservoir Counter Electrode Reference Electrode Sensing Electrode O-Ring Seal Gas Permeable Membrane Gaseous Diffusion Barrier Gas Enters Through Permeable Membrane Target gas diffuses through the diffusion barrier limiting the amount of gas entering the sensor. It then diffuses through the gas permeable membrane until it reaches the sensing electrode that produces ions. The REFERENCE electrode provides voltage stability for the sensing electrode, and the electrodes (sensing and reference) are constructed of materials specific to the target gas. This specificity creates the ion flow current central to the sensor’s detection method. The HVS 4000 integral electronics provides temperature compensation, and the amount of ions produced by the target gas molecules striking the sensing electrode, is proportional to gas

Available Gases • • Ammonia Carbon Monoxide Chlorine Dioxide Ozone Oxygen Sulfur Dioxide 0 -50, 0 -100 ppm 0 -100, 0 -500 ppm 0 -10 ppm, 0 -20 ppm 0 -3 ppm 0 -1 ppm 0 -25% by Volume 0 -20 ppm

Available Gases • • Ammonia Carbon Monoxide Chlorine Dioxide Ozone Oxygen Sulfur Dioxide 0 -50, 0 -100 ppm 0 -100, 0 -500 ppm 0 -10 ppm, 0 -20 ppm 0 -3 ppm 0 -1 ppm 0 -25% by Volume 0 -20 ppm

Key Features & Benefits • Microprocessor-Based Electronics: Monitors fault conditions, processes input signals from the electrochemical cell, and provides outputs in the form of display codes and analog / digital signals • One Person Adjustment-Free Calibration: Using a magnet to initiate the calibration sequence, apply the gas, and wait for the display to indicate that the unit has completed the calibration. No user adjustments are required. • Three Digit, Seven Segment LED: Indicates gas presence, operational modes, fault codes and calibration cues • Two Discrete LED Indicators: Indicates alarm and warning conditions • Three 8 A rated Relays: Warning, Alarm and Fault • Remote Mounting of Interface Module: Provides application flexibility • 4 -20 m. A Analog Output: Transmits fault, calibration, and gas

Key Features & Benefits • Microprocessor-Based Electronics: Monitors fault conditions, processes input signals from the electrochemical cell, and provides outputs in the form of display codes and analog / digital signals • One Person Adjustment-Free Calibration: Using a magnet to initiate the calibration sequence, apply the gas, and wait for the display to indicate that the unit has completed the calibration. No user adjustments are required. • Three Digit, Seven Segment LED: Indicates gas presence, operational modes, fault codes and calibration cues • Two Discrete LED Indicators: Indicates alarm and warning conditions • Three 8 A rated Relays: Warning, Alarm and Fault • Remote Mounting of Interface Module: Provides application flexibility • 4 -20 m. A Analog Output: Transmits fault, calibration, and gas

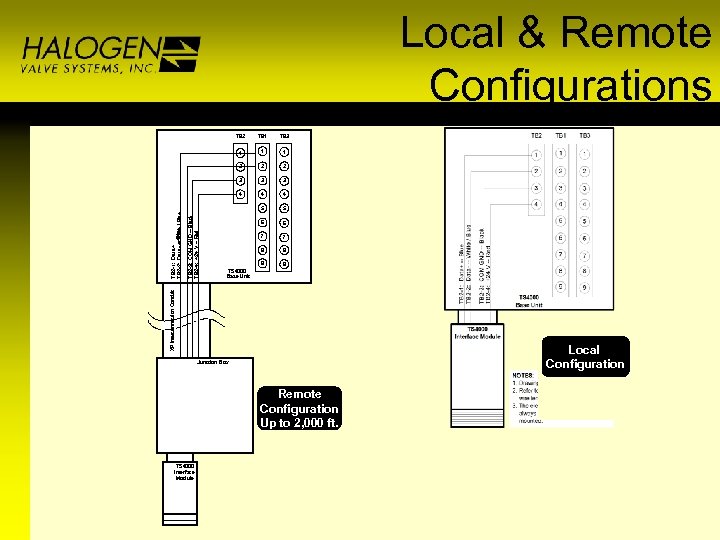

Local & Remote Configurations TB 3 1 1 2 2 2 3 3 3 4 4 4 5 5 6 6 7 7 8 8 9 9 TS 4000 Base Unit XP Interconnection Conduit TB 2 -3: COM GND -- Black TB 2 -4: + 24 V -- Red TB 1 1 TB 2 -1: Data+ -- Blue TB 2 -2: Data- -- White / Blue TB 2 Local Configuration Junction Box Remote Configuration Up to 2, 000 ft. TS 4000 Interface Module NOTES : 1. Drawing not to scale. 2. Refer to Section 9. 4 for maximum wire lengths (BU to IM). 3. The electrochemical cell should always point downward when mounted.

Local & Remote Configurations TB 3 1 1 2 2 2 3 3 3 4 4 4 5 5 6 6 7 7 8 8 9 9 TS 4000 Base Unit XP Interconnection Conduit TB 2 -3: COM GND -- Black TB 2 -4: + 24 V -- Red TB 1 1 TB 2 -1: Data+ -- Blue TB 2 -2: Data- -- White / Blue TB 2 Local Configuration Junction Box Remote Configuration Up to 2, 000 ft. TS 4000 Interface Module NOTES : 1. Drawing not to scale. 2. Refer to Section 9. 4 for maximum wire lengths (BU to IM). 3. The electrochemical cell should always point downward when mounted.

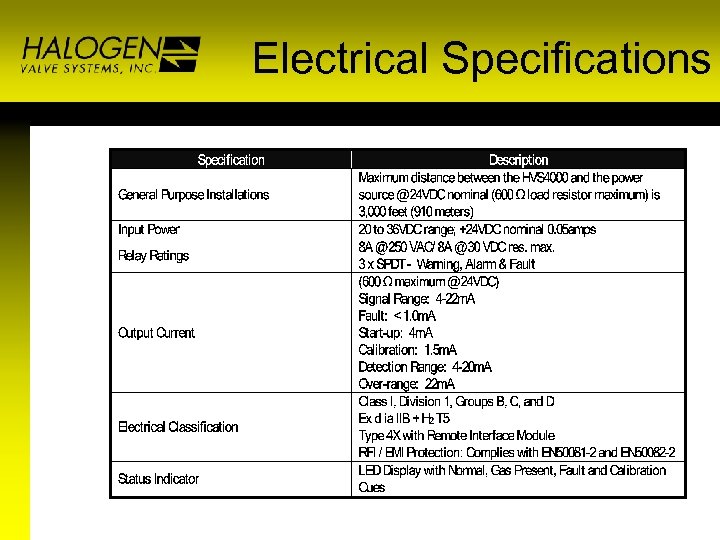

Electrical Specifications

Electrical Specifications

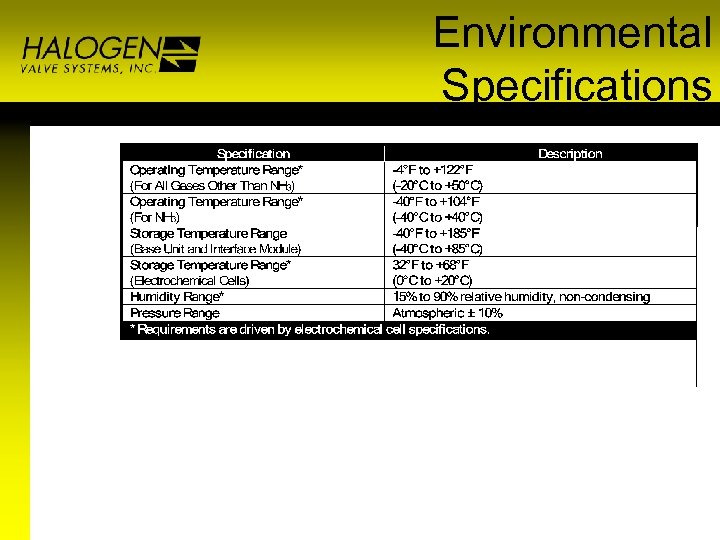

Environmental Specifications

Environmental Specifications

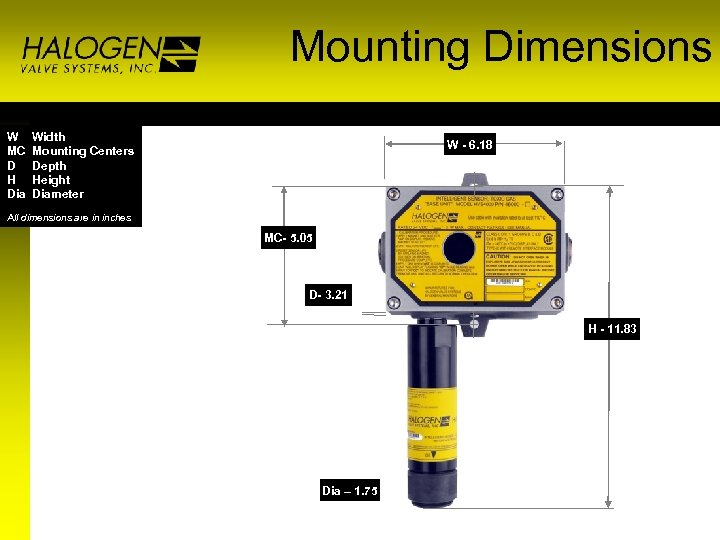

Mounting Dimensions W MC D H Dia Width Mounting Centers Depth Height Diameter W - 6. 18 All dimensions are in inches MC- 5. 05 D- 3. 21 H - 11. 83 Dia – 1. 75

Mounting Dimensions W MC D H Dia Width Mounting Centers Depth Height Diameter W - 6. 18 All dimensions are in inches MC- 5. 05 D- 3. 21 H - 11. 83 Dia – 1. 75

Simple Calibration • Apply and hold the magnet over the HVS logo on the cover of the Base Unit. Wait until AC appears in the display window. Remove the magnet to select AC. The unit is now in Calibration Mode. • The display flashes the Remaining Sensor Life. The user can choose to reset or not to reset the sensor life at this point. • The Remaining Sensor Life flashes while the unit is being set to zero. Once the unit has been set to zero g. AS appears in the display window • Apply the calibration gas concentration to the sensor (50% FS of the required range of detected gas). The display changes from g. AS (apply gas) to CP (Calibration in Progress) indicating that the sensor is responding to the calibration gas. While the unit is reading the gas concentration, the menu is disabled • After three to five minutes, the display changes from CP to CC indicating that the calibration is complete • Remove the gas and wait for the unit to return to normal operation. The display may indicate a few percent FS and will eventually drop to 0. If a unit time out occurs the The HVS 4000 is now calibrated and the new sensor SPAN values (or calibration constants) user receives a calibration fault are stored in the non-volatile memory (EEPROM)

Simple Calibration • Apply and hold the magnet over the HVS logo on the cover of the Base Unit. Wait until AC appears in the display window. Remove the magnet to select AC. The unit is now in Calibration Mode. • The display flashes the Remaining Sensor Life. The user can choose to reset or not to reset the sensor life at this point. • The Remaining Sensor Life flashes while the unit is being set to zero. Once the unit has been set to zero g. AS appears in the display window • Apply the calibration gas concentration to the sensor (50% FS of the required range of detected gas). The display changes from g. AS (apply gas) to CP (Calibration in Progress) indicating that the sensor is responding to the calibration gas. While the unit is reading the gas concentration, the menu is disabled • After three to five minutes, the display changes from CP to CC indicating that the calibration is complete • Remove the gas and wait for the unit to return to normal operation. The display may indicate a few percent FS and will eventually drop to 0. If a unit time out occurs the The HVS 4000 is now calibrated and the new sensor SPAN values (or calibration constants) user receives a calibration fault are stored in the non-volatile memory (EEPROM)

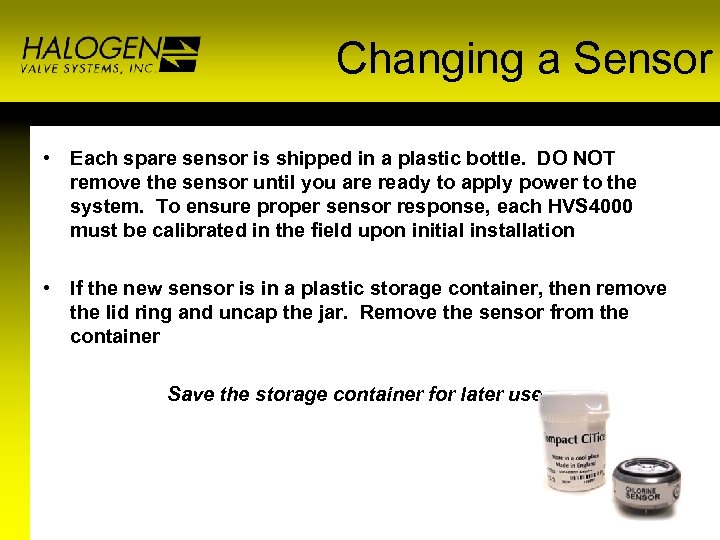

Changing a Sensor • Each spare sensor is shipped in a plastic bottle. DO NOT remove the sensor until you are ready to apply power to the system. To ensure proper sensor response, each HVS 4000 must be calibrated in the field upon initial installation • If the new sensor is in a plastic storage container, then remove the lid ring and uncap the jar. Remove the sensor from the container Save the storage container for later use.

Changing a Sensor • Each spare sensor is shipped in a plastic bottle. DO NOT remove the sensor until you are ready to apply power to the system. To ensure proper sensor response, each HVS 4000 must be calibrated in the field upon initial installation • If the new sensor is in a plastic storage container, then remove the lid ring and uncap the jar. Remove the sensor from the container Save the storage container for later use.

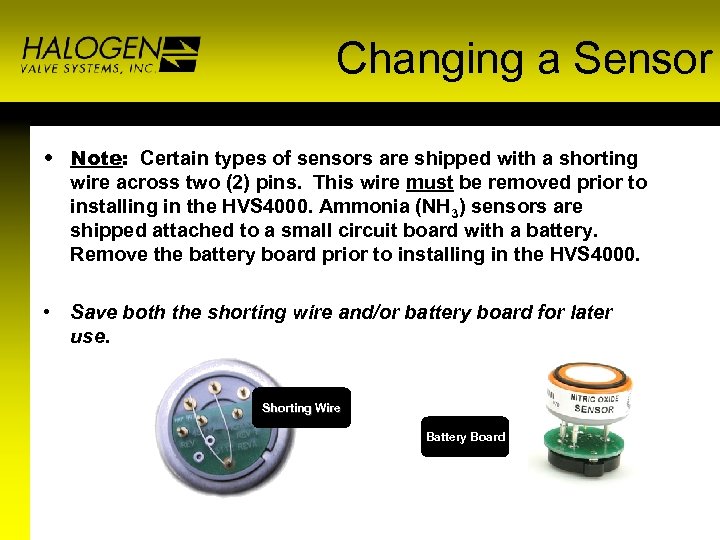

Changing a Sensor • Note: Certain types of sensors are shipped with a shorting wire across two (2) pins. This wire must be removed prior to installing in the HVS 4000. Ammonia (NH 3) sensors are shipped attached to a small circuit board with a battery. Remove the battery board prior to installing in the HVS 4000. • Save both the shorting wire and/or battery board for later use. Shorting Wire Battery Board

Changing a Sensor • Note: Certain types of sensors are shipped with a shorting wire across two (2) pins. This wire must be removed prior to installing in the HVS 4000. Ammonia (NH 3) sensors are shipped attached to a small circuit board with a battery. Remove the battery board prior to installing in the HVS 4000. • Save both the shorting wire and/or battery board for later use. Shorting Wire Battery Board

Accessories - Calibration Kit • 500 sccm flow rate regulator for: – NH 3 – SO 2 – CO • 1000 sccm flow rate regulator for: – Cl 2 – Cl. O 2 – O 3 Purge Gas Cylinders

Accessories - Calibration Kit • 500 sccm flow rate regulator for: – NH 3 – SO 2 – CO • 1000 sccm flow rate regulator for: – Cl 2 – Cl. O 2 – O 3 Purge Gas Cylinders

Accessories - Splash Guards 45167 -1 Splash Guard for Cl 2, Cl. O 2 and O 3 gases. More holes are needed for gas to reach the sensor 70631 -2 Splash Guard used for all other gases

Accessories - Splash Guards 45167 -1 Splash Guard for Cl 2, Cl. O 2 and O 3 gases. More holes are needed for gas to reach the sensor 70631 -2 Splash Guard used for all other gases

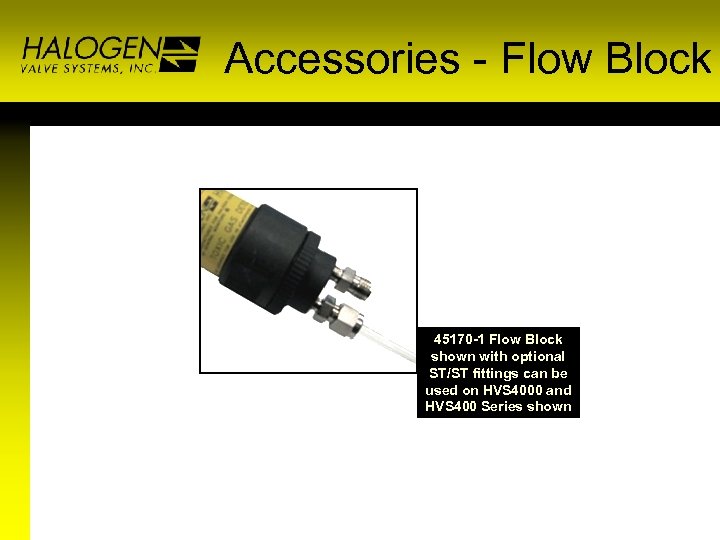

Accessories - Flow Block 45170 -1 Flow Block shown with optional ST/ST fittings can be used on HVS 4000 and HVS 400 Series shown

Accessories - Flow Block 45170 -1 Flow Block shown with optional ST/ST fittings can be used on HVS 4000 and HVS 400 Series shown

Accessories - Cal Plug & Cup 45172 -1 Calibration Plug (used when no splash guard attached) P/N 1400152 -1 Calibration Cup (used with units equipped with splash guard)

Accessories - Cal Plug & Cup 45172 -1 Calibration Plug (used when no splash guard attached) P/N 1400152 -1 Calibration Cup (used with units equipped with splash guard)

Configurations HVS 4000 Local w/ No Relays & Communications HVS 4000 Local w/ Relays & Communications HVS 4000 Remote w/Customer Provided J-Box HVS 4000 Remote w/ P/N 10252 J-Box HVS 4000 Remote w/ P/N 31305 -2 J-Box

Configurations HVS 4000 Local w/ No Relays & Communications HVS 4000 Local w/ Relays & Communications HVS 4000 Remote w/Customer Provided J-Box HVS 4000 Remote w/ P/N 10252 J-Box HVS 4000 Remote w/ P/N 31305 -2 J-Box