86e9306a7a2c8d59452b42ca15a7e7b4.ppt

- Количество слайдов: 36

International Workshop on Ceramic Breeder Blanket Interactions (CBBI-16) Sept. 8 -10, 2011, Portland, OR, USA European Test Blanket Modules Project: Organization, Objectives, Time Schedule and Development Strategy M. Zmitko TBM & MD Project Team, Fusion for Energy (F 4 E), Barcelona, Spain

Presentation Outline – The European Breeder Blanket concepts – European TBM Project Organization – TBM testing at ITER • Time schedule – Ceramic breeder material for BB • Requirements • Some R&D results • Current status – Functional Materials Development Strategy • Key Milestones • Development, qualification and procurement plan • Key Technical Issues 2 2

The European Breeder Blanket concepts

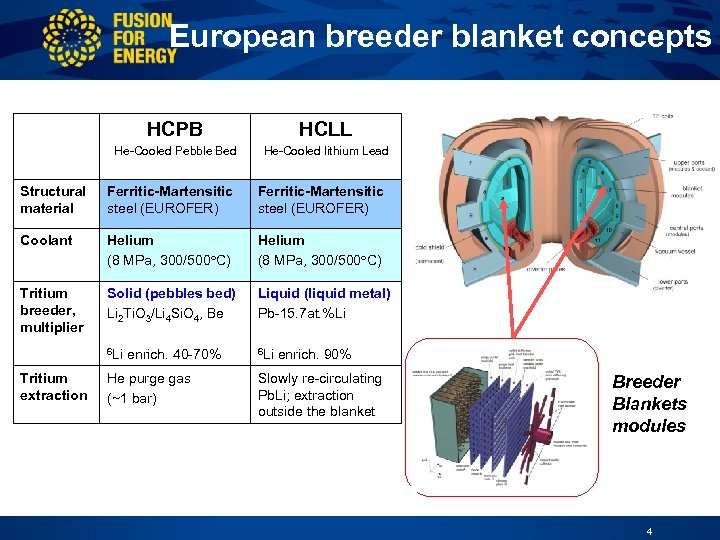

European breeder blanket concepts HCPB HCLL He-Cooled Pebble Bed He-Cooled lithium Lead Structural material Ferritic-Martensitic steel (EUROFER) Coolant Helium (8 MPa, 300/500 C) Tritium breeder, multiplier Solid (pebbles bed) Li 2 Ti. O 3/Li 4 Si. O 4, Be Liquid (liquid metal) Pb-15. 7 at. %Li 6 Li Tritium extraction enrich. 40 -70% He purge gas (~1 bar) enrich. 90% Slowly re-circulating Pb. Li; extraction outside the blanket Breeder Blankets modules 4

The European TBM Project organization

Fusion for Energy • Fusion for Energy is the EU Domestic Agency for ITER • The objectives of Fusion for Energy are threefold: – Provide Europe’s contribution to the ITER international fusion energy project; • EU TBM Project Management & interface with ITER IO – Implement the Broader Approach agreement between Euratom and Japan; – Prepare for the construction of demonstration fusion reactors (DEMO). 6 6

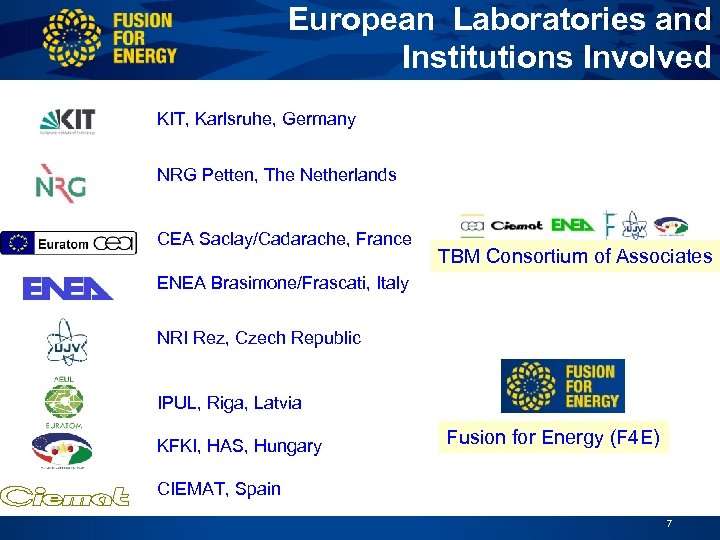

European Laboratories and Institutions Involved KIT, Karlsruhe, Germany NRG Petten, The Netherlands CEA Saclay/Cadarache, France TBM Consortium of Associates ENEA Brasimone/Frascati, Italy NRI Rez, Czech Republic IPUL, Riga, Latvia KFKI, HAS, Hungary Fusion for Energy (F 4 E) CIEMAT, Spain 7

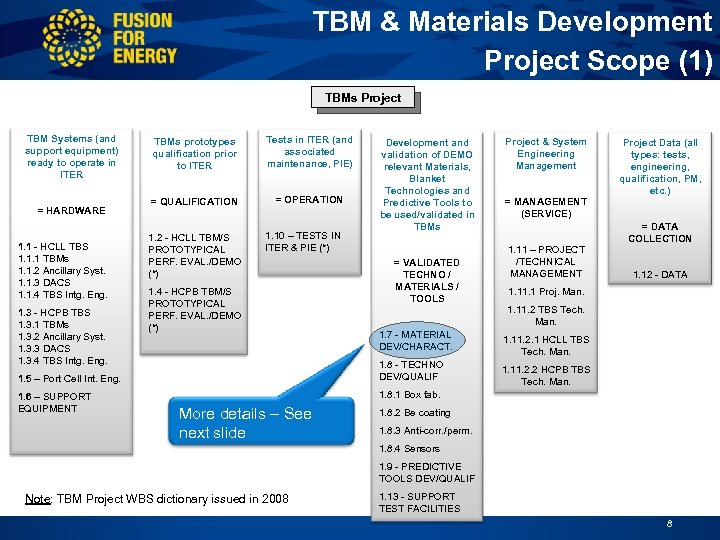

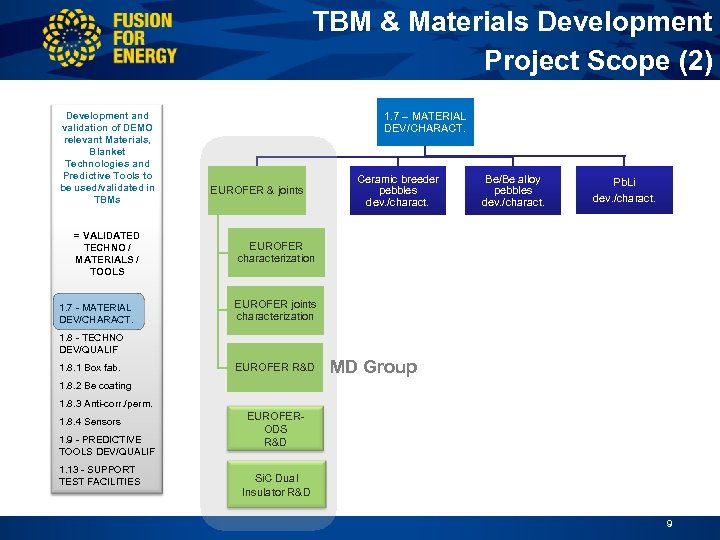

TBM & Materials Development Project Scope (1) TBMs Project TBM Systems (and support equipment) ready to operate in ITER = HARDWARE 1. 1 - HCLL TBS 1. 1. 1 TBMs 1. 1. 2 Ancillary Syst. 1. 1. 3 DACS 1. 1. 4 TBS Intg. Eng. 1. 3 - HCPB TBS 1. 3. 1 TBMs 1. 3. 2 Ancillary Syst. 1. 3. 3 DACS 1. 3. 4 TBS Intg. Eng. TBMs prototypes qualification prior to ITER Tests in ITER (and associated maintenance, PIE) = QUALIFICATION = OPERATION 1. 2 - HCLL TBM/S PROTOTYPICAL PERF. EVAL. /DEMO (*) 1. 10 – TESTS IN ITER & PIE (*) 1. 4 - HCPB TBM/S PROTOTYPICAL PERF. EVAL. /DEMO (*) = VALIDATED TECHNO / MATERIALS / TOOLS Project & System Engineering Management = MANAGEMENT (SERVICE) 1. 11 – PROJECT /TECHNICAL MANAGEMENT Project Data (all types: tests, engineering, qualification, PM, etc. ) = DATA COLLECTION 1. 12 - DATA 1. 1 Proj. Man. 1. 11. 2 TBS Tech. Man. 1. 7 - MATERIAL DEV/CHARACT. 1. 11. 2. 1 HCLL TBS Tech. Man. 1. 8 - TECHNO DEV/QUALIF 1. 5 – Port Cell Int. Eng. 1. 6 – SUPPORT EQUIPMENT Development and validation of DEMO relevant Materials, Blanket Technologies and Predictive Tools to be used/validated in TBMs 1. 11. 2. 2 HCPB TBS Tech. Man. 1. 8. 1 Box fab. More details – See next slide 1. 8. 2 Be coating 1. 8. 3 Anti-corr. /perm. 1. 8. 4 Sensors 1. 9 - PREDICTIVE TOOLS DEV/QUALIF Note: TBM Project WBS dictionary issued in 2008 1. 13 - SUPPORT TEST FACILITIES 8

TBM & Materials Development Project Scope (2) Development and validation of DEMO relevant Materials, Blanket Technologies and Predictive Tools to be used/validated in TBMs = VALIDATED TECHNO / MATERIALS / TOOLS 1. 7 - MATERIAL DEV/CHARACT. 1. 7 – MATERIAL DEV/CHARACT. EUROFER & joints Ceramic breeder pebbles dev. /charact. Be/Be alloy pebbles dev. /charact. Pb. Li dev. /charact. EUROFER characterization EUROFER joints characterization 1. 8 - TECHNO DEV/QUALIF 1. 8. 1 Box fab. EUROFER R&D MD Group 1. 8. 2 Be coating 1. 8. 3 Anti-corr. /perm. 1. 8. 4 Sensors 1. 9 - PREDICTIVE TOOLS DEV/QUALIF 1. 13 - SUPPORT TEST FACILITIES EUROFERODS R&D Si. C Dual Insulator R&D 9

ITER, a unique opportunity to test Breeder Blanket mock-ups: ‘Test Blanket Modules’ (TBMs)

TBMs mission in ITER • To develop and build the European Test Blanket Module (TBM) Systems for ITER • To develop numerical tools for analysis of TBM tests and design of DEMO breeder blankets ITER should test Tritium Breeding Module concepts that would lead in a future reactor to tritium self-sufficiency and to the extraction of high grade heat and electricity production 11

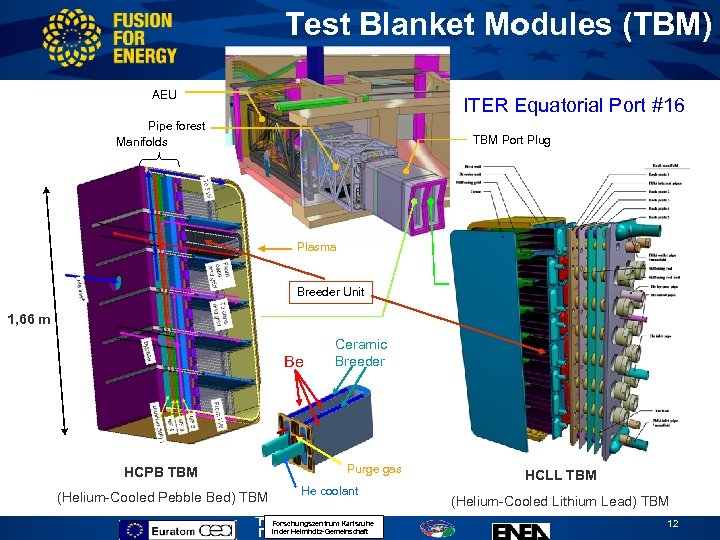

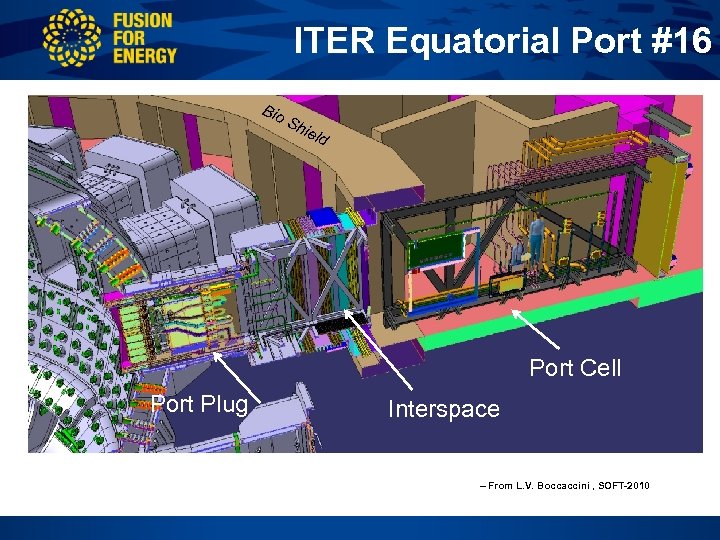

Test Blanket Modules (TBM) AEU ITER Equatorial Port #16 Pipe forest Manifolds TBM Port Plug Plasma Breeder Unit 1, 66 m Be HCPB TBM (Helium-Cooled Pebble Bed) TBM Ceramic Breeder Purge gas He coolant Forschungszentrum Karlsruhe in der Helmholtz-Gemeinschaft HCLL TBM (Helium-Cooled Lithium Lead) TBM 12

ITER Equatorial Port #16 Bio Sh ield Port Cell Port Plug Interspace – From L. V. Boccaccini , SOFT-2010

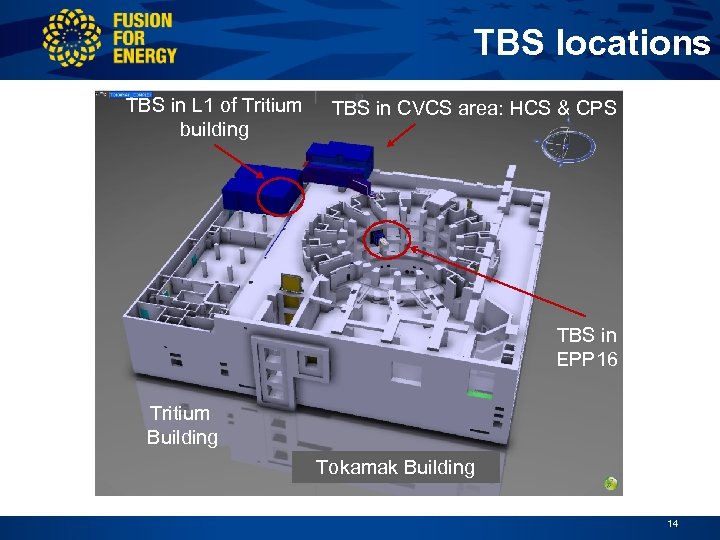

TBS locations TBS in L 1 of Tritium building TBS in CVCS area: HCS & CPS TBS in EPP 16 Tritium Building Tokamak Building 14

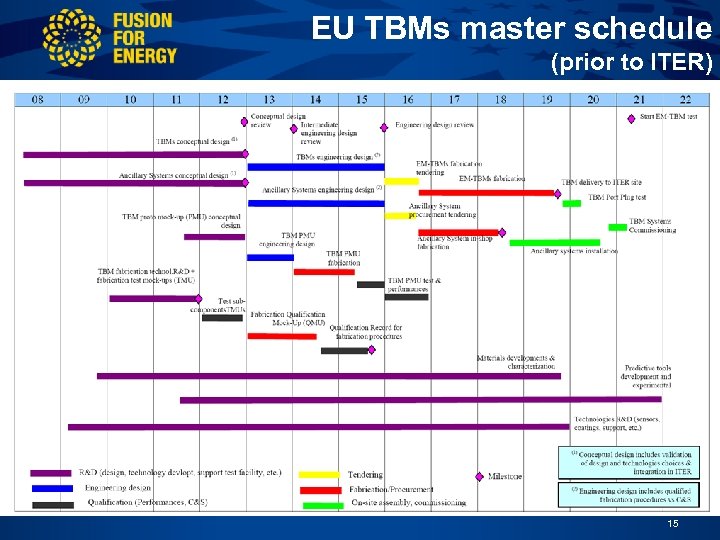

EU TBMs master schedule (prior to ITER) 15

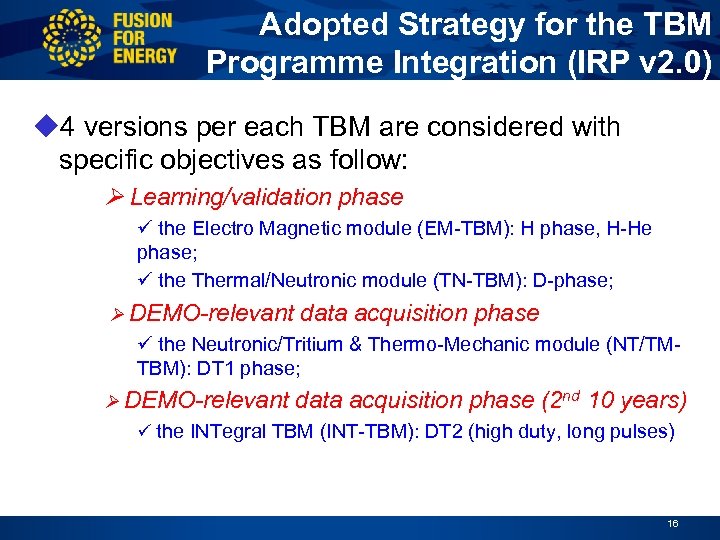

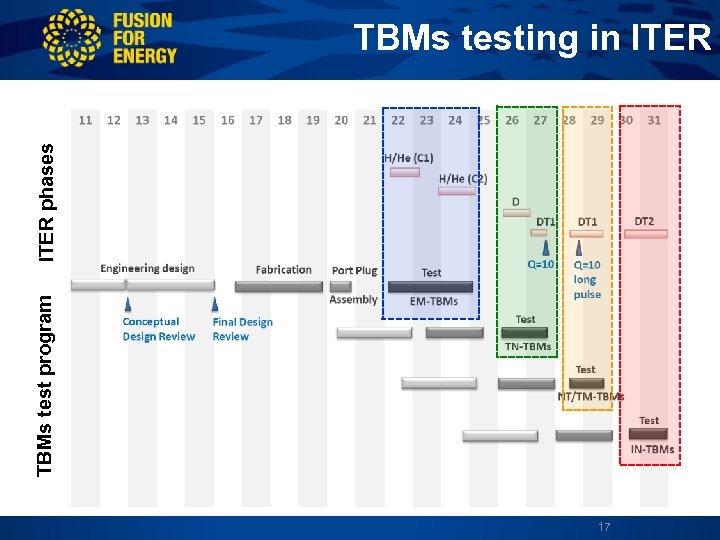

Adopted Strategy for the TBM Programme Integration (IRP v 2. 0) u 4 versions per each TBM are considered with specific objectives as follow: Learning/validation phase the Electro Magnetic module (EM-TBM): H phase, H-He phase; the Thermal/Neutronic module (TN-TBM): D-phase; DEMO-relevant data acquisition phase the Neutronic/Tritium & Thermo-Mechanic module (NT/TMTBM): DT 1 phase; DEMO-relevant data acquisition phase (2 nd 10 years) the INTegral TBM (INT-TBM): DT 2 (high duty, long pulses) 16

TBMs test program ITER phases TBMs testing in ITER 17

Ceramic Breeder Materials

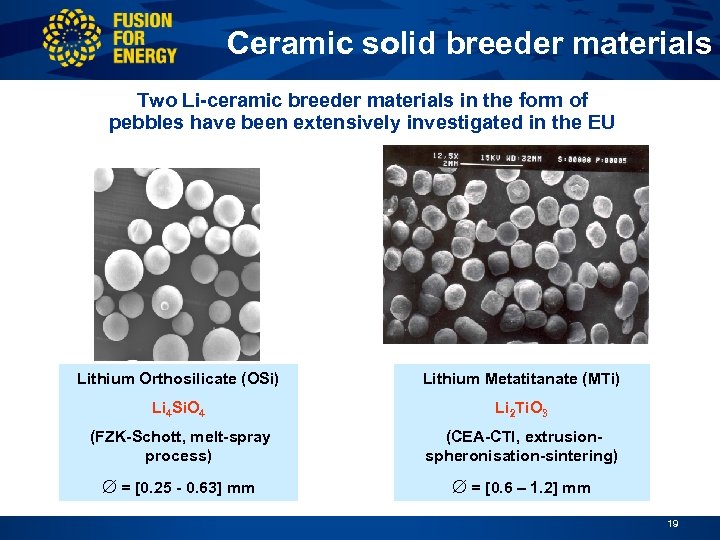

Ceramic solid breeder materials Two Li-ceramic breeder materials in the form of pebbles have been extensively investigated in the EU Lithium Orthosilicate (OSi) Lithium Metatitanate (MTi) Li 4 Si. O 4 Li 2 Ti. O 3 (FZK-Schott, melt-spray process) (CEA-CTI, extrusionspheronisation-sintering) = [0. 25 - 0. 63] mm = [0. 6 – 1. 2] mm 19

Ceramic breeder materials: Functional requirements • Withstand stresses without excessive fragmentation • Heat transfer parameters of the pebble beds (temperature control Tmax = 920°C) • Compatibility between the ceramic and EUROFER (max. T~ 550°C) • Neutron irradiation resistance • Low tritium residence time in the Li ceramics to minimize tritium inventory (safety) • As low as possible activation under neutron irradiation (impurities) • Easy reprocessing capability 20

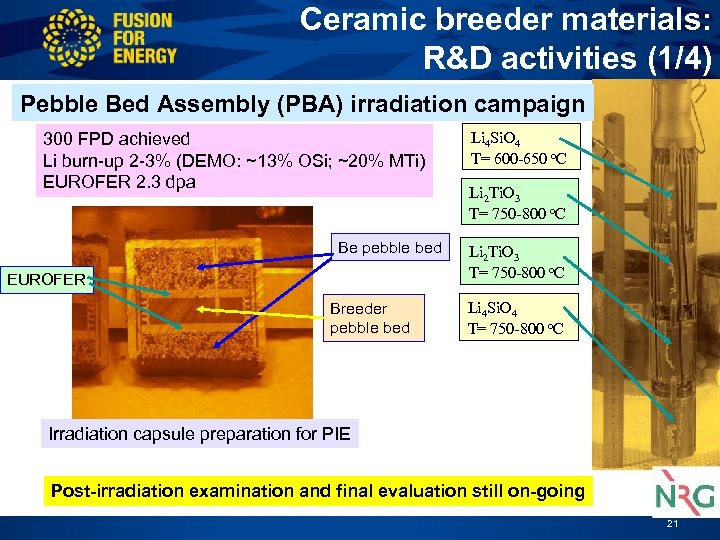

Ceramic breeder materials: R&D activities (1/4) Pebble Bed Assembly (PBA) irradiation campaign 300 FPD achieved Li burn-up 2 -3% (DEMO: ~13% OSi; ~20% MTi) EUROFER 2. 3 dpa Be pebble bed EUROFER Breeder pebble bed Li 4 Si. O 4 T= 600 -650 o. C Li 2 Ti. O 3 T= 750 -800 o. C Li 4 Si. O 4 T= 750 -800 o. C Irradiation capsule preparation for PIE Post-irradiation examination and final evaluation still on-going 21

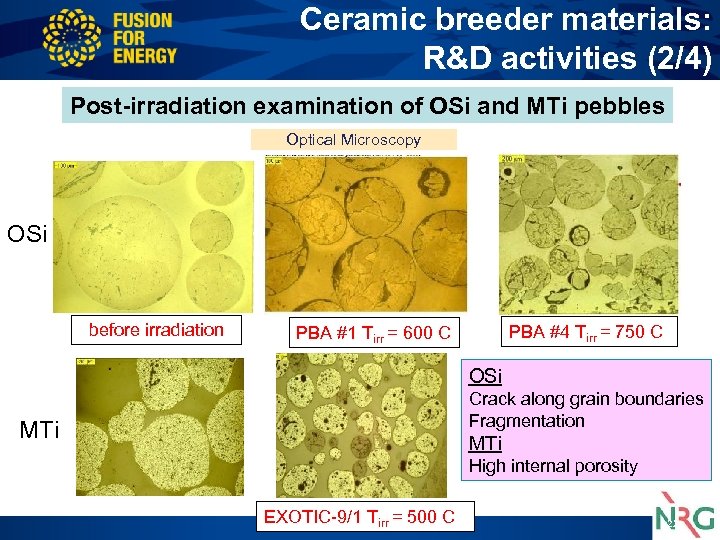

Ceramic breeder materials: R&D activities (2/4) Post-irradiation examination of OSi and MTi pebbles Optical Microscopy OSi before irradiation PBA #4 Tirr = 750 C PBA #1 Tirr = 600 C OSi Crack along grain boundaries Fragmentation MTi High internal porosity EXOTIC-9/1 Tirr = 500 C 22

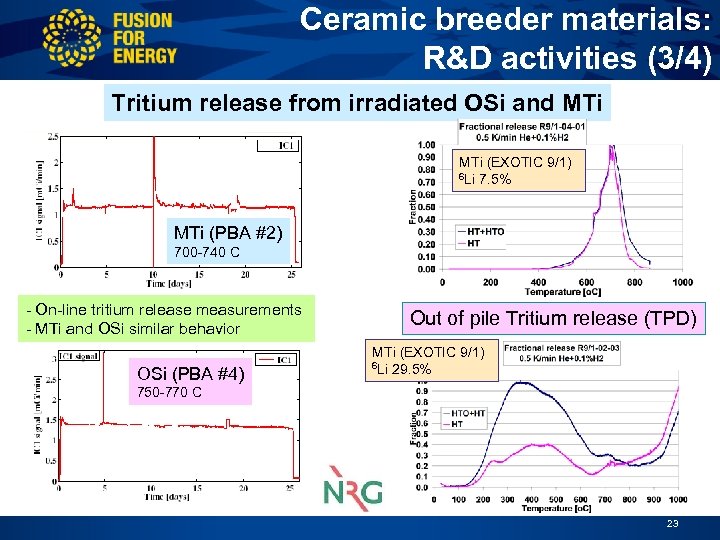

Ceramic breeder materials: R&D activities (3/4) Tritium release from irradiated OSi and MTi (EXOTIC 9/1) 6 Li 7. 5% MTi (PBA #2) 700 -740 C - On-line tritium release measurements - MTi and OSi similar behavior OSi (PBA #4) Out of pile Tritium release (TPD) MTi (EXOTIC 9/1) 6 Li 29. 5% 750 -770 C 23

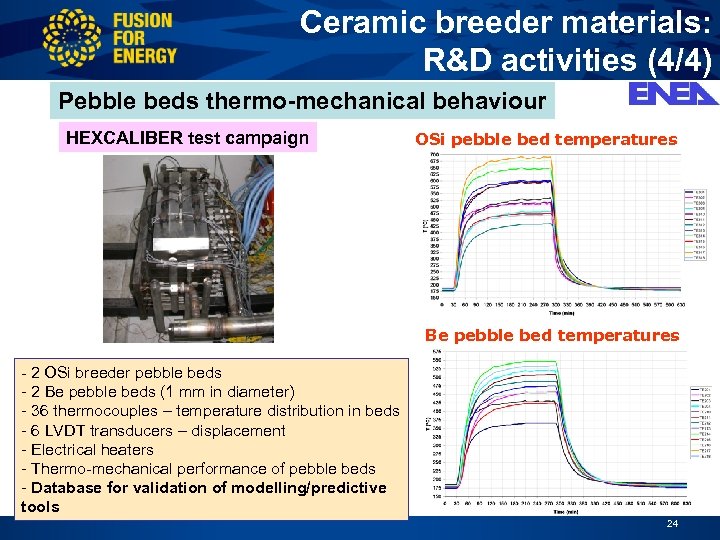

Ceramic breeder materials: R&D activities (4/4) Pebble beds thermo-mechanical behaviour HEXCALIBER test campaign OSi pebble bed temperatures Be pebble bed temperatures - 2 OSi breeder pebble beds - 2 Be pebble beds (1 mm in diameter) - 36 thermocouples – temperature distribution in beds - 6 LVDT transducers – displacement - Electrical heaters - Thermo-mechanical performance of pebble beds - Database for validation of modelling/predictive tools 24

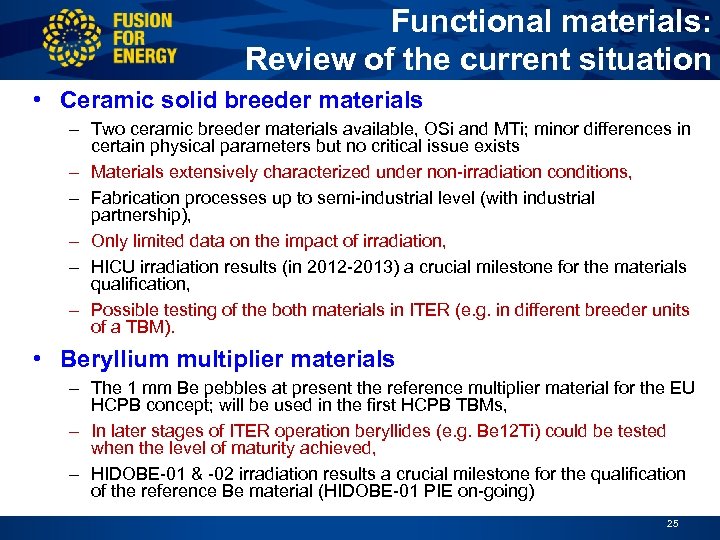

Functional materials: Review of the current situation • Ceramic solid breeder materials – Two ceramic breeder materials available, OSi and MTi; minor differences in certain physical parameters but no critical issue exists – Materials extensively characterized under non-irradiation conditions, – Fabrication processes up to semi-industrial level (with industrial partnership), – Only limited data on the impact of irradiation, – HICU irradiation results (in 2012 -2013) a crucial milestone for the materials qualification, – Possible testing of the both materials in ITER (e. g. in different breeder units of a TBM). • Beryllium multiplier materials – The 1 mm Be pebbles at present the reference multiplier material for the EU HCPB concept; will be used in the first HCPB TBMs, – In later stages of ITER operation beryllides (e. g. Be 12 Ti) could be tested when the level of maturity achieved, – HIDOBE-01 & -02 irradiation results a crucial milestone for the qualification of the reference Be material (HIDOBE-01 PIE on-going) 25

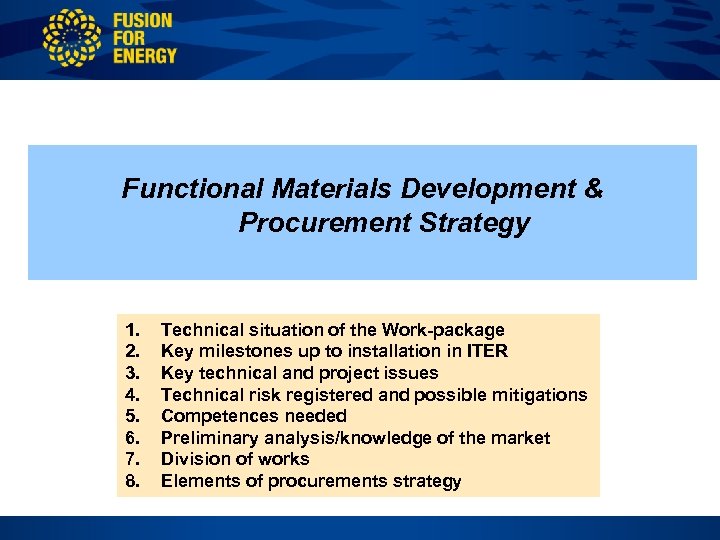

Functional Materials Development & Procurement Strategy 1. 2. 3. 4. 5. 6. 7. 8. Technical situation of the Work-package Key milestones up to installation in ITER Key technical and project issues Technical risk registered and possible mitigations Competences needed Preliminary analysis/knowledge of the market Division of works Elements of procurements strategy

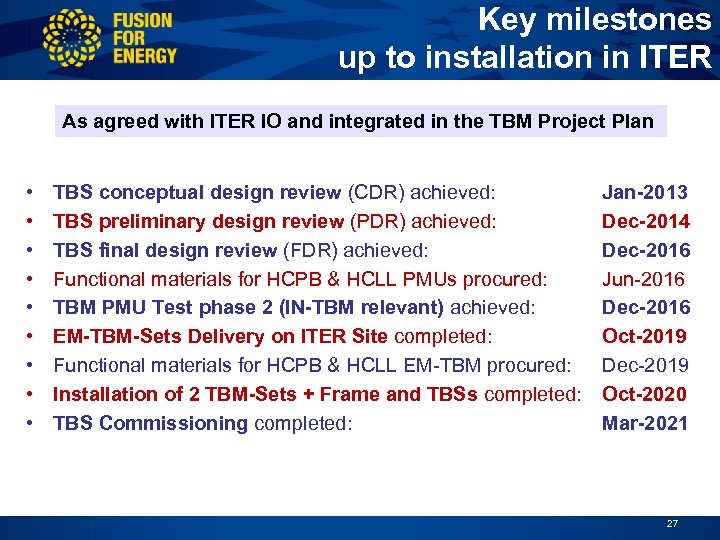

Key milestones up to installation in ITER As agreed with ITER IO and integrated in the TBM Project Plan • • • TBS conceptual design review (CDR) achieved: TBS preliminary design review (PDR) achieved: TBS final design review (FDR) achieved: Functional materials for HCPB & HCLL PMUs procured: TBM PMU Test phase 2 (IN-TBM relevant) achieved: EM-TBM-Sets Delivery on ITER Site completed: Functional materials for HCPB & HCLL EM-TBM procured: Installation of 2 TBM-Sets + Frame and TBSs completed: TBS Commissioning completed: Jan-2013 Dec-2014 Dec-2016 Jun-2016 Dec-2016 Oct-2019 Dec-2019 Oct-2020 Mar-2021 27

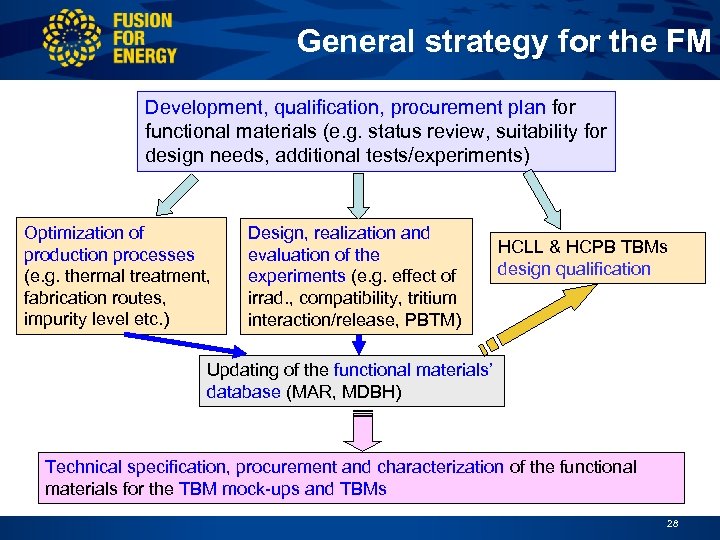

General strategy for the FM Development, qualification, procurement plan for functional materials (e. g. status review, suitability for design needs, additional tests/experiments) Optimization of production processes (e. g. thermal treatment, fabrication routes, impurity level etc. ) Design, realization and evaluation of the experiments (e. g. effect of irrad. , compatibility, tritium interaction/release, PBTM) HCLL & HCPB TBMs design qualification Updating of the functional materials’ database (MAR, MDBH) Technical specification, procurement and characterization of the functional materials for the TBM mock-ups and TBMs 28

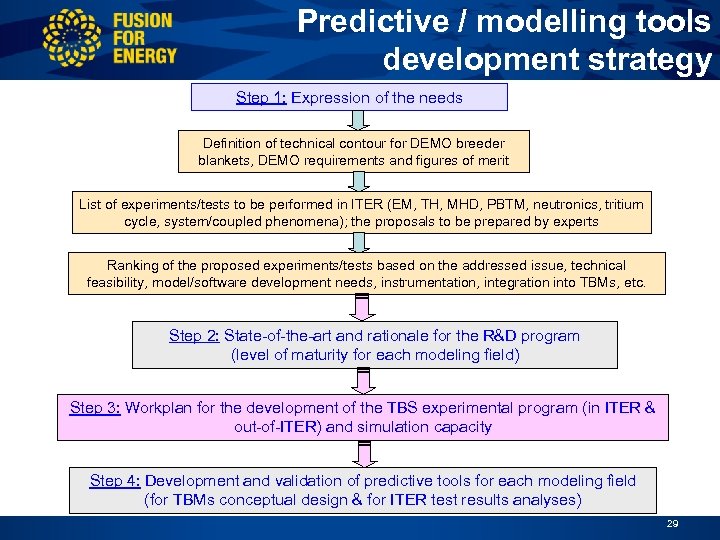

Predictive / modelling tools development strategy Step 1: Expression of the needs Definition of technical contour for DEMO breeder blankets, DEMO requirements and figures of merit List of experiments/tests to be performed in ITER (EM, TH, MHD, PBTM, neutronics, tritium cycle, system/coupled phenomena); the proposals to be prepared by experts Ranking of the proposed experiments/tests based on the addressed issue, technical feasibility, model/software development needs, instrumentation, integration into TBMs, etc. Step 2: State-of-the-art and rationale for the R&D program (level of maturity for each modeling field) Step 3: Workplan for the development of the TBS experimental program (in ITER & out-of-ITER) and simulation capacity Step 4: Development and validation of predictive tools for each modeling field (for TBMs conceptual design & for ITER test results analyses) 29

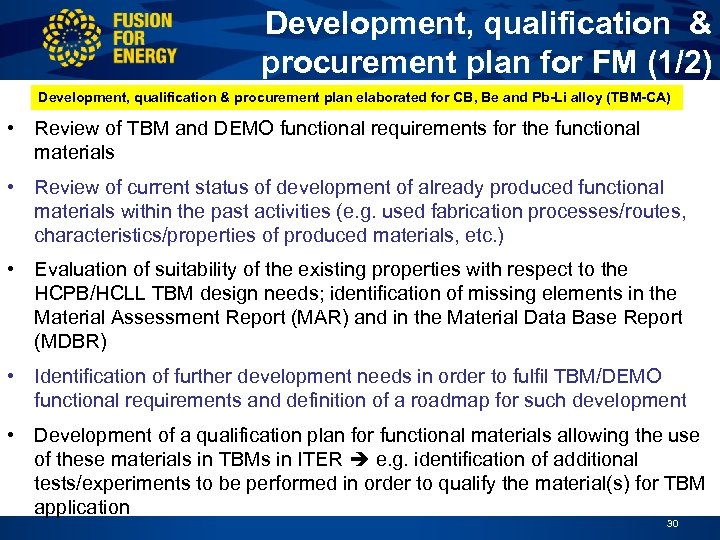

Development, qualification & procurement plan for FM (1/2) Development, qualification & procurement plan elaborated for CB, Be and Pb-Li alloy (TBM-CA) • Review of TBM and DEMO functional requirements for the functional materials • Review of current status of development of already produced functional materials within the past activities (e. g. used fabrication processes/routes, characteristics/properties of produced materials, etc. ) • Evaluation of suitability of the existing properties with respect to the HCPB/HCLL TBM design needs; identification of missing elements in the Material Assessment Report (MAR) and in the Material Data Base Report (MDBR) • Identification of further development needs in order to fulfil TBM/DEMO functional requirements and definition of a roadmap for such development • Development of a qualification plan for functional materials allowing the use of these materials in TBMs in ITER e. g. identification of additional tests/experiments to be performed in order to qualify the material(s) for TBM application 30

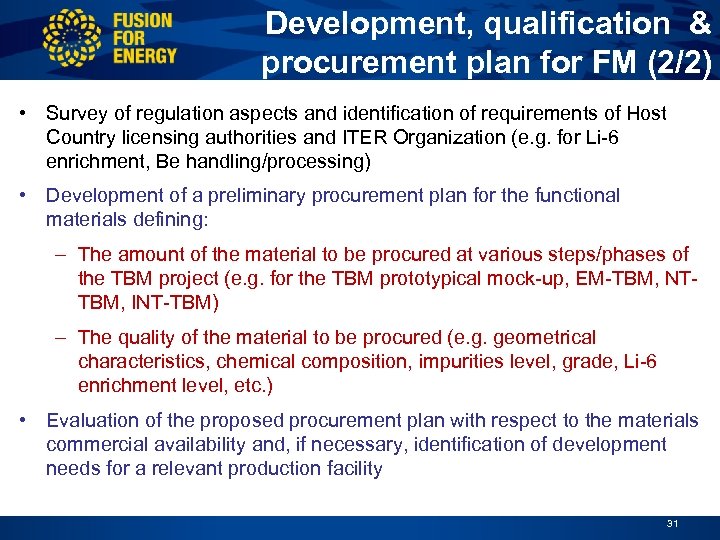

Development, qualification & procurement plan for FM (2/2) • Survey of regulation aspects and identification of requirements of Host Country licensing authorities and ITER Organization (e. g. for Li-6 enrichment, Be handling/processing) • Development of a preliminary procurement plan for the functional materials defining: – The amount of the material to be procured at various steps/phases of the TBM project (e. g. for the TBM prototypical mock-up, EM-TBM, NTTBM, INT-TBM) – The quality of the material to be procured (e. g. geometrical characteristics, chemical composition, impurities level, grade, Li-6 enrichment level, etc. ) • Evaluation of the proposed procurement plan with respect to the materials commercial availability and, if necessary, identification of development needs for a relevant production facility 31

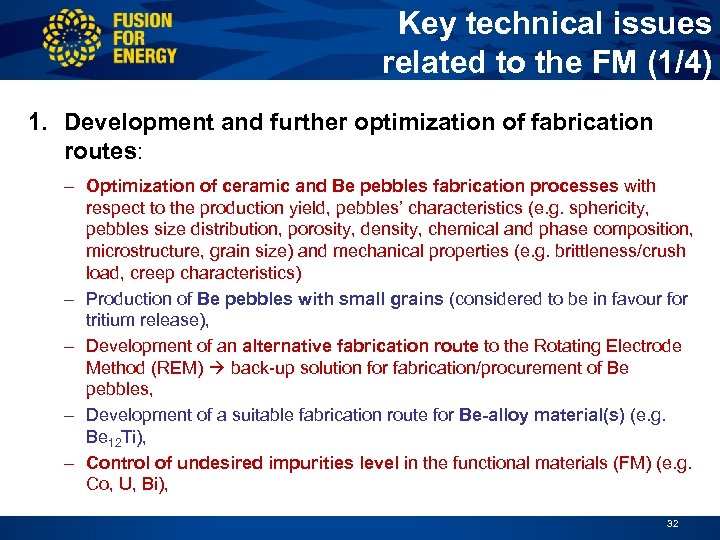

Key technical issues related to the FM (1/4) 1. Development and further optimization of fabrication routes: – Optimization of ceramic and Be pebbles fabrication processes with respect to the production yield, pebbles’ characteristics (e. g. sphericity, pebbles size distribution, porosity, density, chemical and phase composition, microstructure, grain size) and mechanical properties (e. g. brittleness/crush load, creep characteristics) – Production of Be pebbles with small grains (considered to be in favour for tritium release), – Development of an alternative fabrication route to the Rotating Electrode Method (REM) back-up solution for fabrication/procurement of Be pebbles, – Development of a suitable fabrication route for Be-alloy material(s) (e. g. Be 12 Ti), – Control of undesired impurities level in the functional materials (FM) (e. g. Co, U, Bi), 32

Key technical issues related to the FM (2/4) 2. Availability of the materials properties needed for a proper TBMs design: – Effect of neutron irradiation on thermo-mechanical properties as function of irradiation temperature, neutron dose, lithium burn-up (e. g. swelling, thermal conductivity degradation, irradiation induced creep and embrittlement, changes in open/close porosity), – Tritium retention/release characteristics as a function of irradiation temperature, neutron dose, purge gas chemistry, material properties (e. g. porosity, grain size) – Compatibility with structure material under neutron irradiation, – Interaction of air/steam with Be/Be-alloy pebbles and Pb-Li alloy (safety related issue), – Thermal conductivity in pebble beds under compressive loads (e. g. in the bulk of the pebble bed, at the interface between structural material and pebble bed), – Pb-Li alloy properties (e. g. H-isotopes solubility and diffusivity, He transport properties in Pb-Li, corrosion products (Fe, Cr) solubility in Pb-Li, effect of neutron irradiation on He nano bubbles formation, Po/Hg impurities behaviour), 33

Key technical issues related to the FM (3/4) 3. Modelling: – Thermo-mechanical behaviour of pebbles beds: • Further development of the pebble bed thermo-mechanics (PBTM) predictive tool(s) to be used for TBMs design (both DEM & FEM approaches), • Benchmarking and validation of the PBTM predictive tool(s), • Definition and realization of validation experiments necessary for verification of PBTM modelling tools, – Be/Be-alloy materials behaviour: • Be/Be-alloy materials behaviour under neutron irradiation (e. g. involving atomic scale modelling), • Tritium production, inventory and release in irradiated Be/Be-alloy pebbles – Activation analysis: • Definition of allowable limits of impurities in the functional materials (e. g. Bi Po, U Pu, Co 60) 34

Key technical issues related to the FM (4/4) 4. Procurement of functional materials: – Elaboration of a proper Specification for the materials to be procured in various stages of the TBM Project taking into account needed quality (non/nuclear grade, impurities level), quantity and cost; – Decision on selection of a reference ceramic breeder material (OSi or MTi) or/and determination of the amount of OSI & MTi to be procured for dedicated Breeder Units of PMU and EM-TBM to be filled in with OSi & MTi pebbles, – Scaling of the laboratory developed production methods, – Ensure adequate production capability, involving industrial partners, – Limited production capacity batch-like production ensure reproducibility of materials properties at a batch-like fabrication process, – Mass production with proper quality control, – Li-6 enrichment of ceramic breeder (e. g. availability of enriched Li-6 in a proper chemical form, procurement of a sufficient amount of Li-6, dual use material issue), – Standardization (i. e. elaboration of standard procedures) to be used for characterization of the produced materials, 35

Thank you for your attention

86e9306a7a2c8d59452b42ca15a7e7b4.ppt