bb0259193baf8e2119f21d8b63de7a4e.ppt

- Количество слайдов: 25

International Workshop on a Very Large Volume Neutrino Telescope for the Mediterranean Sea A comparison of AC and DC power feeding systems based on the NEMO experiences Rosanna Cocimano for the NEMO Collaboration 22 -24 April 2008, Toulon Palais Neptune Conference Centre Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

International Workshop on a Very Large Volume Neutrino Telescope for the Mediterranean Sea A comparison of AC and DC power feeding systems based on the NEMO experiences Rosanna Cocimano for the NEMO Collaboration 22 -24 April 2008, Toulon Palais Neptune Conference Centre Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

AGENDA Ø NEMO PHASE 1 ELECTRICAL POWER SYSTEM - AC THREE- PHASE ØNEMO PHASE 1 POWER CONTROL SYSTEM ØNEMO PHASE 2 ELECTRICAL POWER SYSTEM – DC ØPRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

AGENDA Ø NEMO PHASE 1 ELECTRICAL POWER SYSTEM - AC THREE- PHASE ØNEMO PHASE 1 POWER CONTROL SYSTEM ØNEMO PHASE 2 ELECTRICAL POWER SYSTEM – DC ØPRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

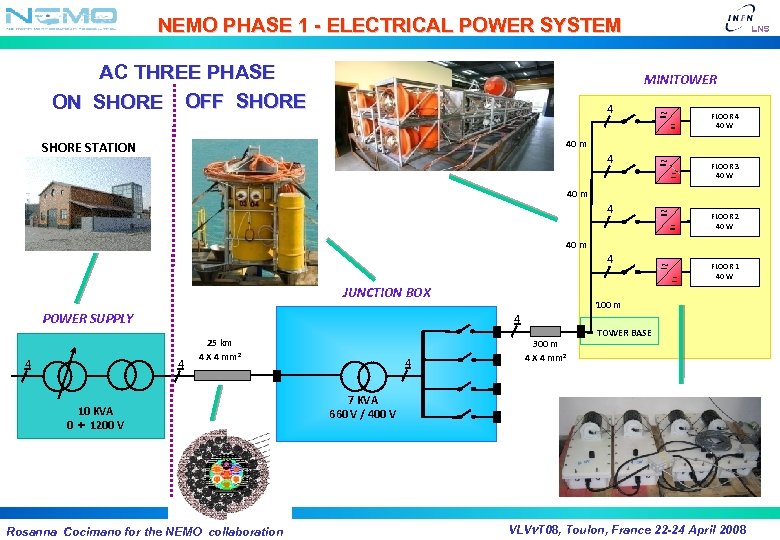

NEMO PHASE 1 - ELECTRICAL POWER SYSTEM AC THREE PHASE ON SHORE OFF SHORE MINITOWER 4 ~ - FLOOR 4 40 W 40 m SHORE STATION 4 ~ - FLOOR 3 40 W 40 m - FLOOR 2 40 W ~ ~ - FLOOR 1 40 W 40 m 4 JUNCTION BOX POWER SUPPLY 4 100 m 4 4 25 km 4 X 4 mm 2 10 KVA 0 1200 V Rosanna Cocimano for the NEMO collaboration 4 300 m 4 X 4 mm 2 TOWER BASE 7 KVA 660 V / 400 V VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 1 - ELECTRICAL POWER SYSTEM AC THREE PHASE ON SHORE OFF SHORE MINITOWER 4 ~ - FLOOR 4 40 W 40 m SHORE STATION 4 ~ - FLOOR 3 40 W 40 m - FLOOR 2 40 W ~ ~ - FLOOR 1 40 W 40 m 4 JUNCTION BOX POWER SUPPLY 4 100 m 4 4 25 km 4 X 4 mm 2 10 KVA 0 1200 V Rosanna Cocimano for the NEMO collaboration 4 300 m 4 X 4 mm 2 TOWER BASE 7 KVA 660 V / 400 V VLVn. T 08, Toulon, France 22 -24 April 2008

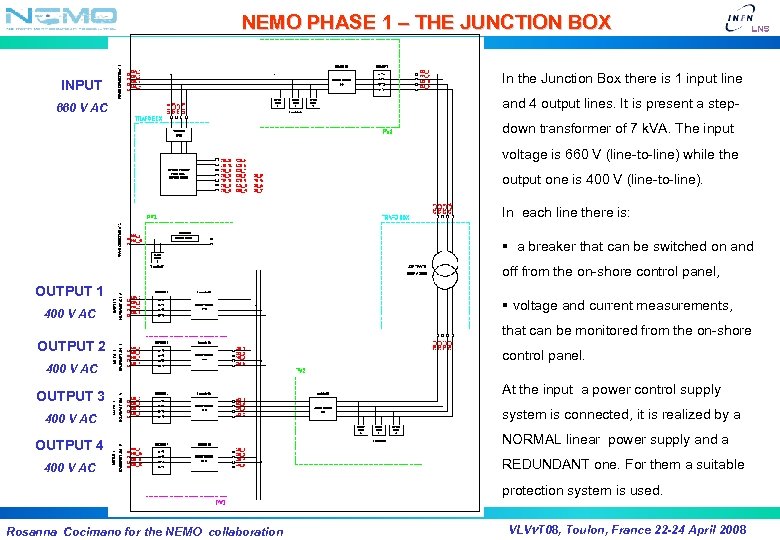

NEMO PHASE 1 – THE JUNCTION BOX INPUT 660 V AC In the Junction Box there is 1 input line and 4 output lines. It is present a stepdown transformer of 7 k. VA. The input voltage is 660 V (line-to-line) while the output one is 400 V (line-to-line). In each line there is: § a breaker that can be switched on and off from the on-shore control panel, OUTPUT 1 400 V AC § voltage and current measurements, that can be monitored from the on-shore OUTPUT 2 400 V AC OUTPUT 3 400 V AC OUTPUT 4 400 V AC control panel. At the input a power control supply system is connected, it is realized by a NORMAL linear power supply and a REDUNDANT one. For them a suitable protection system is used. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 1 – THE JUNCTION BOX INPUT 660 V AC In the Junction Box there is 1 input line and 4 output lines. It is present a stepdown transformer of 7 k. VA. The input voltage is 660 V (line-to-line) while the output one is 400 V (line-to-line). In each line there is: § a breaker that can be switched on and off from the on-shore control panel, OUTPUT 1 400 V AC § voltage and current measurements, that can be monitored from the on-shore OUTPUT 2 400 V AC OUTPUT 3 400 V AC OUTPUT 4 400 V AC control panel. At the input a power control supply system is connected, it is realized by a NORMAL linear power supply and a REDUNDANT one. For them a suitable protection system is used. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

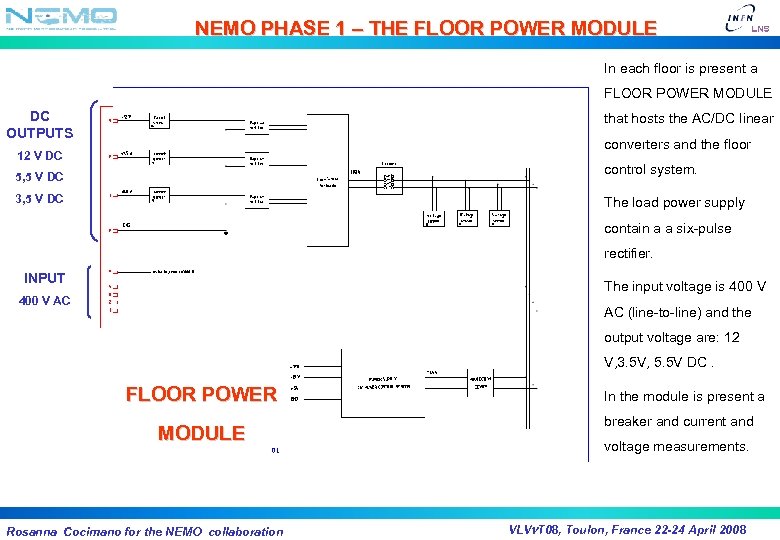

NEMO PHASE 1 – THE FLOOR POWER MODULE In each floor is present a FLOOR POWER MODULE DC OUTPUTS that hosts the AC/DC linear converters and the floor 12 V DC control system. 5, 5 V DC 3, 5 V DC The load power supply contain a a six-pulse rectifier. INPUT The input voltage is 400 V AC AC (line-to-line) and the output voltage are: 12 V, 3. 5 V, 5. 5 V DC. FLOOR POWER MODULE Rosanna Cocimano for the NEMO collaboration In the module is present a breaker and current and voltage measurements. VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 1 – THE FLOOR POWER MODULE In each floor is present a FLOOR POWER MODULE DC OUTPUTS that hosts the AC/DC linear converters and the floor 12 V DC control system. 5, 5 V DC 3, 5 V DC The load power supply contain a a six-pulse rectifier. INPUT The input voltage is 400 V AC AC (line-to-line) and the output voltage are: 12 V, 3. 5 V, 5. 5 V DC. FLOOR POWER MODULE Rosanna Cocimano for the NEMO collaboration In the module is present a breaker and current and voltage measurements. VLVn. T 08, Toulon, France 22 -24 April 2008

AGENDA Ø NEMO PHASE 1 ELECTRICAL POWER SYSTEM - AC THREE- PHASE ØNEMO PHASE 1 POWER CONTROL SYSTEM ØNEMO PHASE 2 ELECTRICAL POWER SYSTEM – DC ØPRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

AGENDA Ø NEMO PHASE 1 ELECTRICAL POWER SYSTEM - AC THREE- PHASE ØNEMO PHASE 1 POWER CONTROL SYSTEM ØNEMO PHASE 2 ELECTRICAL POWER SYSTEM – DC ØPRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 1 - POWER CONTROL SYSTEM THE POWER CONTROL SYSTEM IS ABLE TO: § acquire physics parameters such us temperature, humidity and pressure inside the boxes and acquire the values of current and voltage in each line § switch the power on and off to each feeding line under ordinary conditions and reveal the electric fault and remotely control the breakers in order to isolate the portion interested by the fault, set the breaker threshold from remote. DURING DESIGN WAS IMPORTANT: § foresee the storage of as much as possible devices in an oil and high pressure environment, to reduce the pressure vessel dimensions § use, where it is possible, commercial devices already tested and used, § minimize the failure points to maximize reliability, § foresee the right redundancies. Both the power supply and all boards and sensors of the power control system are redundant, so there is a NORMAL power control system and a REDUNDANT one. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 1 - POWER CONTROL SYSTEM THE POWER CONTROL SYSTEM IS ABLE TO: § acquire physics parameters such us temperature, humidity and pressure inside the boxes and acquire the values of current and voltage in each line § switch the power on and off to each feeding line under ordinary conditions and reveal the electric fault and remotely control the breakers in order to isolate the portion interested by the fault, set the breaker threshold from remote. DURING DESIGN WAS IMPORTANT: § foresee the storage of as much as possible devices in an oil and high pressure environment, to reduce the pressure vessel dimensions § use, where it is possible, commercial devices already tested and used, § minimize the failure points to maximize reliability, § foresee the right redundancies. Both the power supply and all boards and sensors of the power control system are redundant, so there is a NORMAL power control system and a REDUNDANT one. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

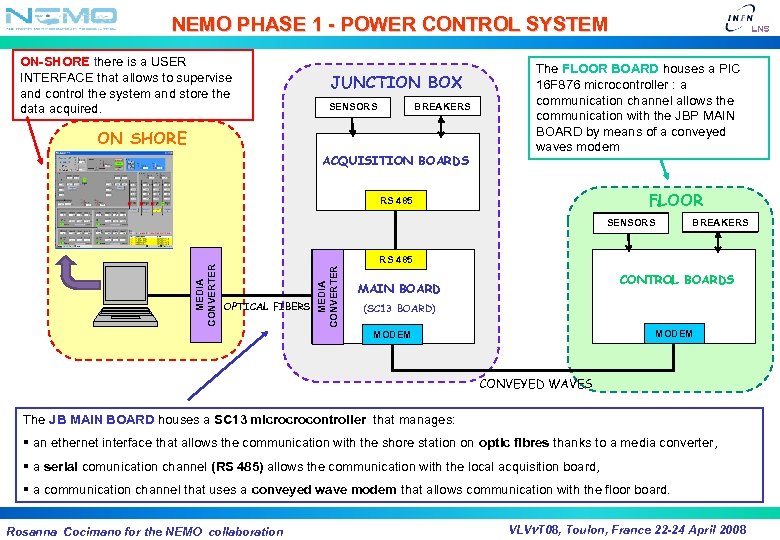

NEMO PHASE 1 - POWER CONTROL SYSTEM ON-SHORE there is a USER INTERFACE that allows to supervise and control the system and store the data acquired. JUNCTION BOX BREAKERS SENSORS ON SHORE ACQUISITION BOARDS The FLOOR BOARD houses a PIC 16 F 876 microcontroller : a communication channel allows the communication with the JBP MAIN BOARD by means of a conveyed waves modem FLOOR RS 485 BREAKERS RS 485 OPTICAL FIBERS MEDIA CONVERTER SENSORS CONTROL BOARDS MAIN BOARD (SC 13 BOARD) MODEM CONVEYED WAVES The JB MAIN BOARD houses a SC 13 microcrocontroller that manages: § an ethernet interface that allows the communication with the shore station on optic fibres thanks to a media converter, § a serial comunication channel (RS 485) allows the communication with the local acquisition board, § a communication channel that uses a conveyed wave modem that allows communication with the floor board. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 1 - POWER CONTROL SYSTEM ON-SHORE there is a USER INTERFACE that allows to supervise and control the system and store the data acquired. JUNCTION BOX BREAKERS SENSORS ON SHORE ACQUISITION BOARDS The FLOOR BOARD houses a PIC 16 F 876 microcontroller : a communication channel allows the communication with the JBP MAIN BOARD by means of a conveyed waves modem FLOOR RS 485 BREAKERS RS 485 OPTICAL FIBERS MEDIA CONVERTER SENSORS CONTROL BOARDS MAIN BOARD (SC 13 BOARD) MODEM CONVEYED WAVES The JB MAIN BOARD houses a SC 13 microcrocontroller that manages: § an ethernet interface that allows the communication with the shore station on optic fibres thanks to a media converter, § a serial comunication channel (RS 485) allows the communication with the local acquisition board, § a communication channel that uses a conveyed wave modem that allows communication with the floor board. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

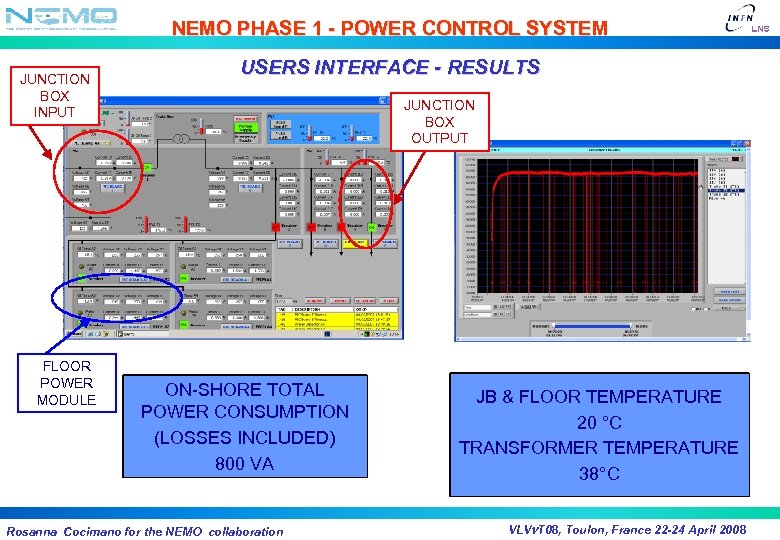

NEMO PHASE 1 - POWER CONTROL SYSTEM JUNCTION BOX INPUT FLOOR POWER MODULE USERS INTERFACE - RESULTS JUNCTION BOX OUTPUT ON-SHORE TOTAL POWER CONSUMPTION (LOSSES INCLUDED) 800 VA Rosanna Cocimano for the NEMO collaboration JB & FLOOR TEMPERATURE 20 °C TRANSFORMER TEMPERATURE 38°C VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 1 - POWER CONTROL SYSTEM JUNCTION BOX INPUT FLOOR POWER MODULE USERS INTERFACE - RESULTS JUNCTION BOX OUTPUT ON-SHORE TOTAL POWER CONSUMPTION (LOSSES INCLUDED) 800 VA Rosanna Cocimano for the NEMO collaboration JB & FLOOR TEMPERATURE 20 °C TRANSFORMER TEMPERATURE 38°C VLVn. T 08, Toulon, France 22 -24 April 2008

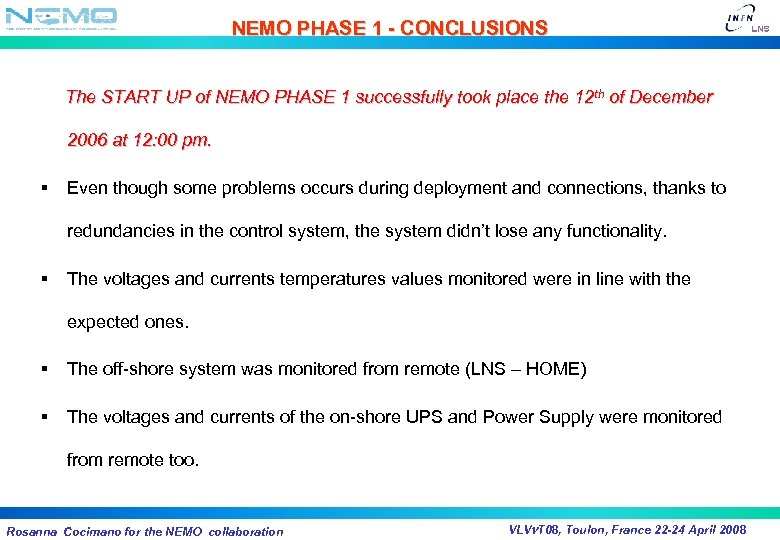

NEMO PHASE 1 - CONCLUSIONS The START UP of NEMO PHASE 1 successfully took place the 12 th of December 2006 at 12: 00 pm. § Even though some problems occurs during deployment and connections, thanks to redundancies in the control system, the system didn’t lose any functionality. § The voltages and currents temperatures values monitored were in line with the expected ones. § The off-shore system was monitored from remote (LNS – HOME) § The voltages and currents of the on-shore UPS and Power Supply were monitored from remote too. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 1 - CONCLUSIONS The START UP of NEMO PHASE 1 successfully took place the 12 th of December 2006 at 12: 00 pm. § Even though some problems occurs during deployment and connections, thanks to redundancies in the control system, the system didn’t lose any functionality. § The voltages and currents temperatures values monitored were in line with the expected ones. § The off-shore system was monitored from remote (LNS – HOME) § The voltages and currents of the on-shore UPS and Power Supply were monitored from remote too. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

AGENDA Ø NEMO PHASE 1 ELECTRICAL POWER SYSTEM - AC THREE- PHASE ØNEMO PHASE 1 POWER CONTROL SYSTEM ØNEMO PHASE 2 ELECTRICAL POWER SYSTEM – DC ØPRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

AGENDA Ø NEMO PHASE 1 ELECTRICAL POWER SYSTEM - AC THREE- PHASE ØNEMO PHASE 1 POWER CONTROL SYSTEM ØNEMO PHASE 2 ELECTRICAL POWER SYSTEM – DC ØPRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

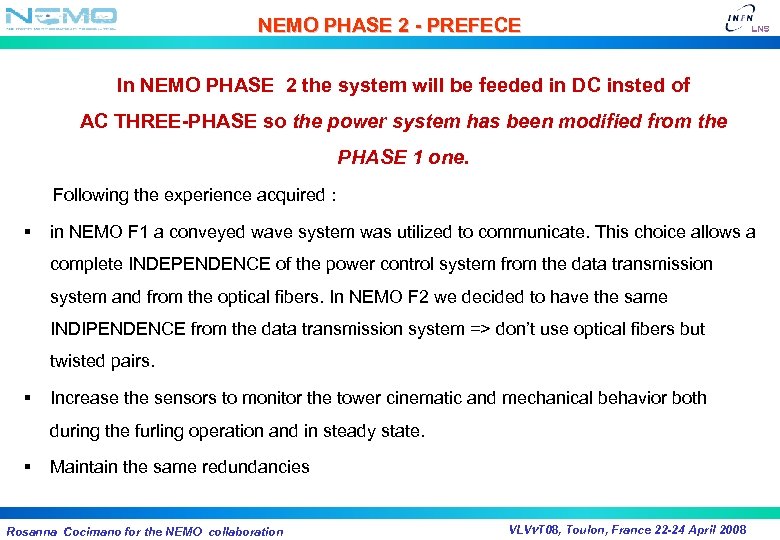

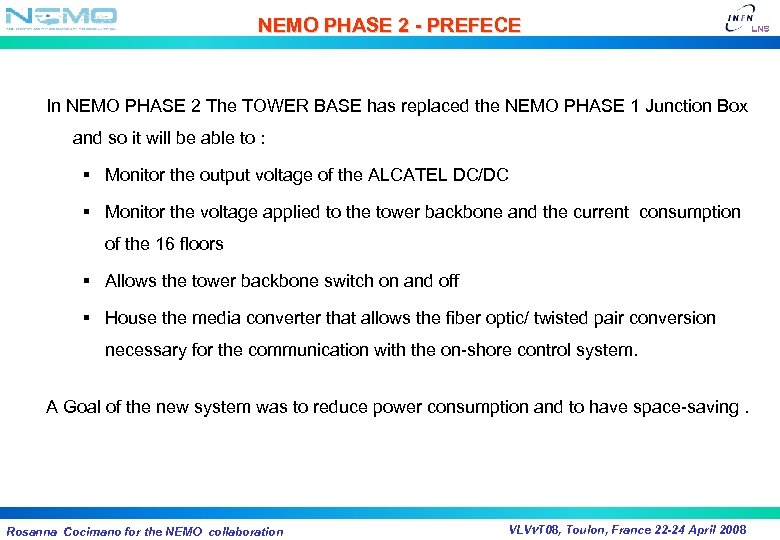

NEMO PHASE 2 - PREFECE In NEMO PHASE 2 the system will be feeded in DC insted of AC THREE-PHASE so the power system has been modified from the PHASE 1 one. Following the experience acquired : § in NEMO F 1 a conveyed wave system was utilized to communicate. This choice allows a complete INDEPENDENCE of the power control system from the data transmission system and from the optical fibers. In NEMO F 2 we decided to have the same INDIPENDENCE from the data transmission system => don’t use optical fibers but twisted pairs. § Increase the sensors to monitor the tower cinematic and mechanical behavior both during the furling operation and in steady state. § Maintain the same redundancies Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 - PREFECE In NEMO PHASE 2 the system will be feeded in DC insted of AC THREE-PHASE so the power system has been modified from the PHASE 1 one. Following the experience acquired : § in NEMO F 1 a conveyed wave system was utilized to communicate. This choice allows a complete INDEPENDENCE of the power control system from the data transmission system and from the optical fibers. In NEMO F 2 we decided to have the same INDIPENDENCE from the data transmission system => don’t use optical fibers but twisted pairs. § Increase the sensors to monitor the tower cinematic and mechanical behavior both during the furling operation and in steady state. § Maintain the same redundancies Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 - PREFECE In NEMO PHASE 2 The TOWER BASE has replaced the NEMO PHASE 1 Junction Box and so it will be able to : § Monitor the output voltage of the ALCATEL DC/DC § Monitor the voltage applied to the tower backbone and the current consumption of the 16 floors § Allows the tower backbone switch on and off § House the media converter that allows the fiber optic/ twisted pair conversion necessary for the communication with the on-shore control system. A Goal of the new system was to reduce power consumption and to have space-saving. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 - PREFECE In NEMO PHASE 2 The TOWER BASE has replaced the NEMO PHASE 1 Junction Box and so it will be able to : § Monitor the output voltage of the ALCATEL DC/DC § Monitor the voltage applied to the tower backbone and the current consumption of the 16 floors § Allows the tower backbone switch on and off § House the media converter that allows the fiber optic/ twisted pair conversion necessary for the communication with the on-shore control system. A Goal of the new system was to reduce power consumption and to have space-saving. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

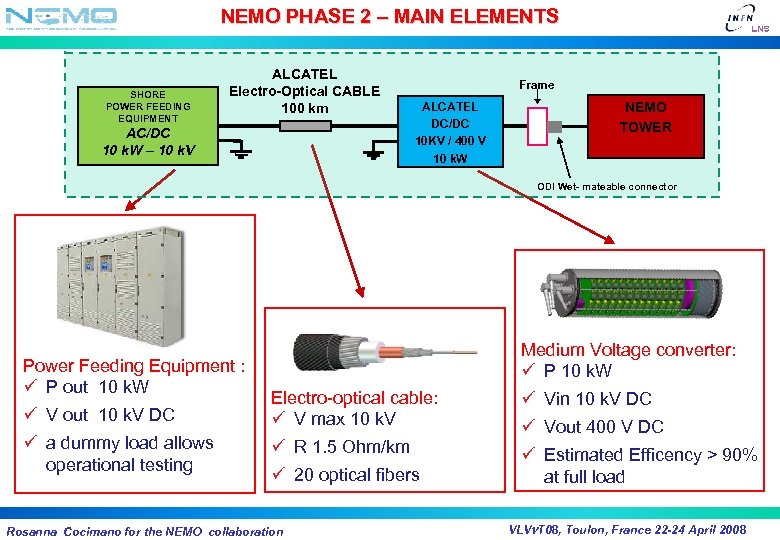

NEMO PHASE 2 – MAIN ELEMENTS SHORE POWER FEEDING EQUIPMENT ALCATEL Electro-Optical CABLE 100 km AC/DC 10 k. W – 10 k. V Frame ALCATEL DC/DC 10 KV / 400 V 10 k. W NEMO TOWER ODI Wet- mateable connector Power Feeding Equipment : ü P out 10 k. W Medium Voltage converter: ü P 10 k. W ü V out 10 k. V DC Electro-optical cable: ü V max 10 k. V ü Vin 10 k. V DC ü a dummy load allows operational testing ü R 1. 5 Ohm/km ü Estimated Efficency > 90% at full load ü 20 optical fibers Rosanna Cocimano for the NEMO collaboration ü Vout 400 V DC VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 – MAIN ELEMENTS SHORE POWER FEEDING EQUIPMENT ALCATEL Electro-Optical CABLE 100 km AC/DC 10 k. W – 10 k. V Frame ALCATEL DC/DC 10 KV / 400 V 10 k. W NEMO TOWER ODI Wet- mateable connector Power Feeding Equipment : ü P out 10 k. W Medium Voltage converter: ü P 10 k. W ü V out 10 k. V DC Electro-optical cable: ü V max 10 k. V ü Vin 10 k. V DC ü a dummy load allows operational testing ü R 1. 5 Ohm/km ü Estimated Efficency > 90% at full load ü 20 optical fibers Rosanna Cocimano for the NEMO collaboration ü Vout 400 V DC VLVn. T 08, Toulon, France 22 -24 April 2008

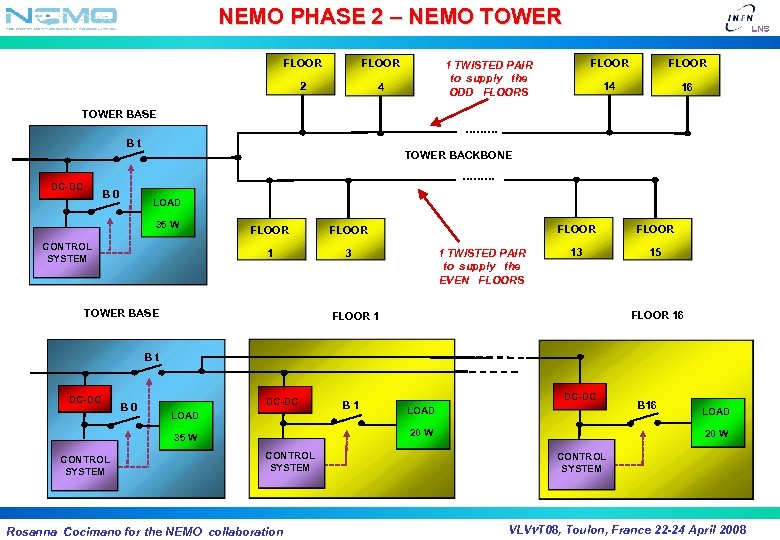

NEMO PHASE 2 – NEMO TOWER FLOOR 2 4 FLOOR 14 1 TWISTED PAIR to supply the ODD FLOORS 16 TOWER BASE ……… Bt TOWER BACKBONE ……… DC-DC B 0 LOAD 35 W FLOOR 1 CONTROL SYSTEM FLOOR 3 TOWER BASE 1 TWISTED PAIR to supply the EVEN FLOORS FLOOR 13 15 FLOOR 16 FLOOR 1 Bt DC-DC B 0 DC-DC LOAD 20 W 35 W CONTROL SYSTEM B 1 CONTROL SYSTEM Rosanna Cocimano for the NEMO collaboration B 16 LOAD 20 W CONTROL SYSTEM VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 – NEMO TOWER FLOOR 2 4 FLOOR 14 1 TWISTED PAIR to supply the ODD FLOORS 16 TOWER BASE ……… Bt TOWER BACKBONE ……… DC-DC B 0 LOAD 35 W FLOOR 1 CONTROL SYSTEM FLOOR 3 TOWER BASE 1 TWISTED PAIR to supply the EVEN FLOORS FLOOR 13 15 FLOOR 16 FLOOR 1 Bt DC-DC B 0 DC-DC LOAD 20 W 35 W CONTROL SYSTEM B 1 CONTROL SYSTEM Rosanna Cocimano for the NEMO collaboration B 16 LOAD 20 W CONTROL SYSTEM VLVn. T 08, Toulon, France 22 -24 April 2008

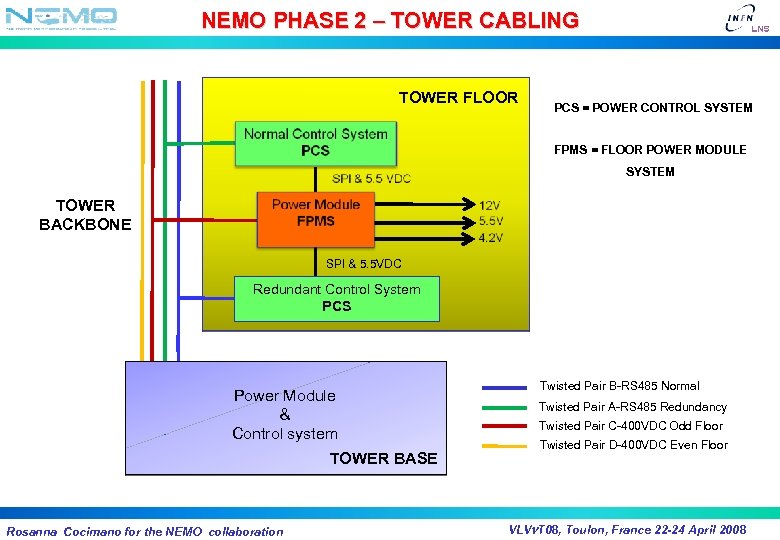

NEMO PHASE 2 – TOWER CABLING TOWER FLOOR PCS = POWER CONTROL SYSTEM FPMS = FLOOR POWER MODULE SYSTEM TOWER BACKBONE SPI & 5. 5 VDC Redundant Control System PCS Power Module & Control system TOWER BASE Rosanna Cocimano for the NEMO collaboration Twisted Pair B-RS 485 Normal Twisted Pair A-RS 485 Redundancy Twisted Pair C-400 VDC Odd Floor Twisted Pair D-400 VDC Even Floor VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 – TOWER CABLING TOWER FLOOR PCS = POWER CONTROL SYSTEM FPMS = FLOOR POWER MODULE SYSTEM TOWER BACKBONE SPI & 5. 5 VDC Redundant Control System PCS Power Module & Control system TOWER BASE Rosanna Cocimano for the NEMO collaboration Twisted Pair B-RS 485 Normal Twisted Pair A-RS 485 Redundancy Twisted Pair C-400 VDC Odd Floor Twisted Pair D-400 VDC Even Floor VLVn. T 08, Toulon, France 22 -24 April 2008

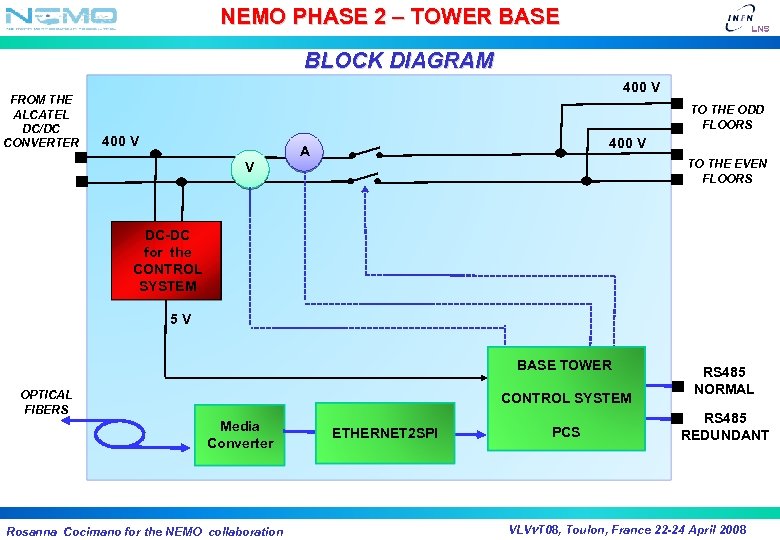

NEMO PHASE 2 – TOWER BASE BLOCK DIAGRAM FROM THE ALCATEL DC/DC CONVERTER 400 V TO THE ODD FLOORS 400 V A TO THE EVEN FLOORS V DC-DC for the CONTROL SYSTEM 5 V BASE TOWER OPTICAL FIBERS CONTROL SYSTEM Media Converter Rosanna Cocimano for the NEMO collaboration ETHERNET 2 SPI PCS RS 485 NORMAL RS 485 REDUNDANT VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 – TOWER BASE BLOCK DIAGRAM FROM THE ALCATEL DC/DC CONVERTER 400 V TO THE ODD FLOORS 400 V A TO THE EVEN FLOORS V DC-DC for the CONTROL SYSTEM 5 V BASE TOWER OPTICAL FIBERS CONTROL SYSTEM Media Converter Rosanna Cocimano for the NEMO collaboration ETHERNET 2 SPI PCS RS 485 NORMAL RS 485 REDUNDANT VLVn. T 08, Toulon, France 22 -24 April 2008

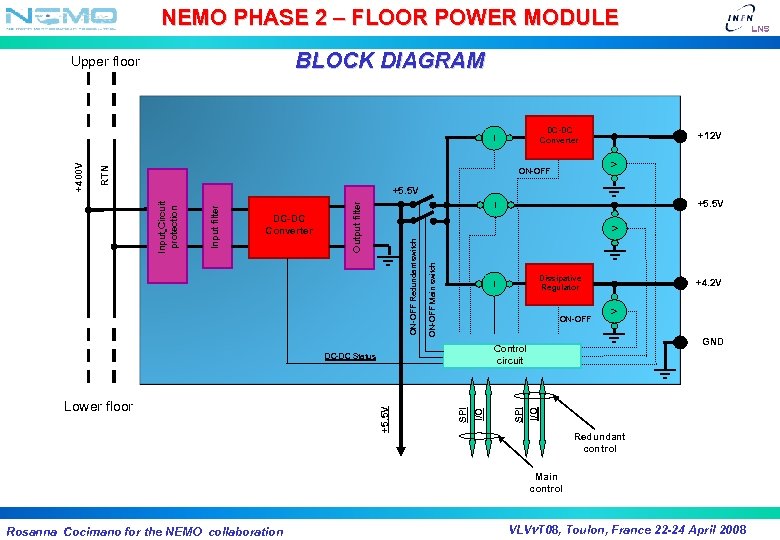

NEMO PHASE 2 – FLOOR POWER MODULE BLOCK DIAGRAM DC-DC Converter RTN ON-OFF +12 V V ON-OFF Main switch +4. 2 V ON-OFF GND I/O SPI +5. 5 V SPI Control circuit DC-DC Status Lower floor Dissipative Regulator I V ON-OFF Redundant switch DC-DC Converter +5. 5 V I Output filter Input filter +5. 5 V Input Circuit protection +400 V I V Upper floor Redundant control Main control Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 – FLOOR POWER MODULE BLOCK DIAGRAM DC-DC Converter RTN ON-OFF +12 V V ON-OFF Main switch +4. 2 V ON-OFF GND I/O SPI +5. 5 V SPI Control circuit DC-DC Status Lower floor Dissipative Regulator I V ON-OFF Redundant switch DC-DC Converter +5. 5 V I Output filter Input filter +5. 5 V Input Circuit protection +400 V I V Upper floor Redundant control Main control Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

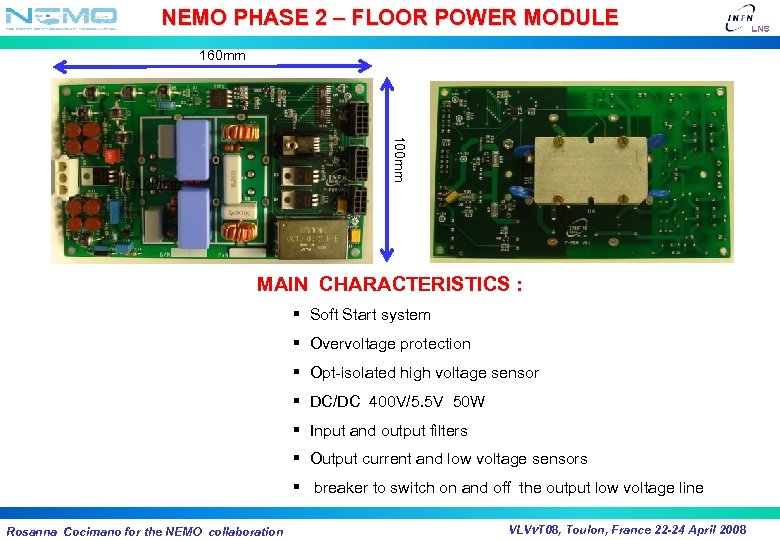

NEMO PHASE 2 – FLOOR POWER MODULE 160 mm 100 mm MAIN CHARACTERISTICS : § Soft Start system § Overvoltage protection § Opt-isolated high voltage sensor § DC/DC 400 V/5. 5 V 50 W § Input and output filters § Output current and low voltage sensors § breaker to switch on and off the output low voltage line Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 – FLOOR POWER MODULE 160 mm 100 mm MAIN CHARACTERISTICS : § Soft Start system § Overvoltage protection § Opt-isolated high voltage sensor § DC/DC 400 V/5. 5 V 50 W § Input and output filters § Output current and low voltage sensors § breaker to switch on and off the output low voltage line Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

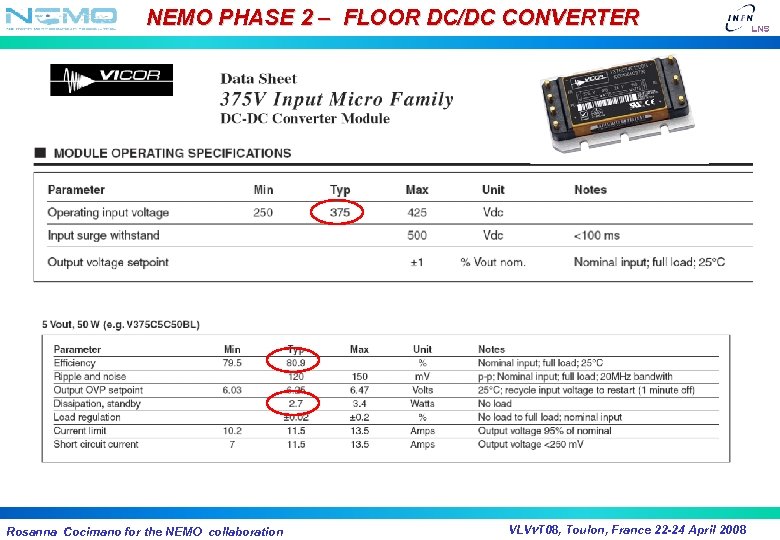

NEMO PHASE 2 – FLOOR DC/DC CONVERTER Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 – FLOOR DC/DC CONVERTER Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

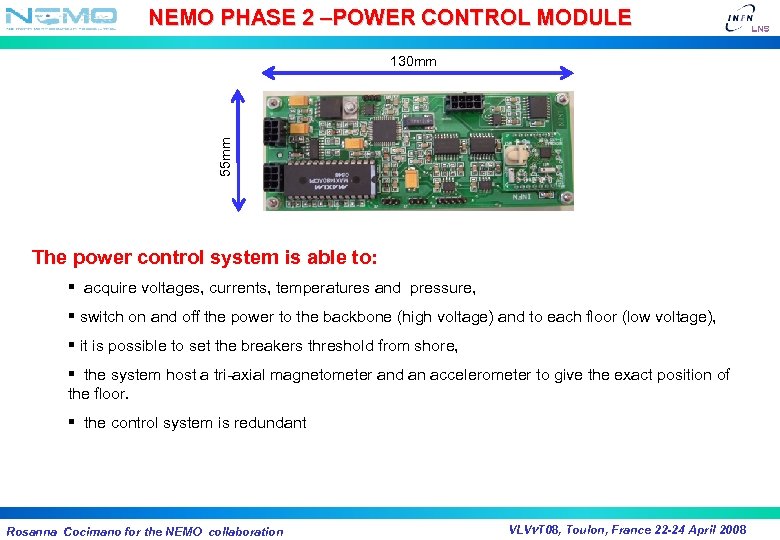

NEMO PHASE 2 –POWER CONTROL MODULE 55 mm 130 mm The power control system is able to: § acquire voltages, currents, temperatures and pressure, § switch on and off the power to the backbone (high voltage) and to each floor (low voltage), § it is possible to set the breakers threshold from shore, § the system host a tri-axial magnetometer and an accelerometer to give the exact position of the floor. § the control system is redundant Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 –POWER CONTROL MODULE 55 mm 130 mm The power control system is able to: § acquire voltages, currents, temperatures and pressure, § switch on and off the power to the backbone (high voltage) and to each floor (low voltage), § it is possible to set the breakers threshold from shore, § the system host a tri-axial magnetometer and an accelerometer to give the exact position of the floor. § the control system is redundant Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 – CONCLUSIONS THE TOWER POWER AND CONTROL SYSTEM HAVE BEEN REALIZED AND TESTED The goals of the power consumption reduction and of the space-saving have been successfully reached NOW WE ARE READY FOR INTEGRATION AND TEST OF THE ENTIRE SYSTEM WITH DUMMY LOADS Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

NEMO PHASE 2 – CONCLUSIONS THE TOWER POWER AND CONTROL SYSTEM HAVE BEEN REALIZED AND TESTED The goals of the power consumption reduction and of the space-saving have been successfully reached NOW WE ARE READY FOR INTEGRATION AND TEST OF THE ENTIRE SYSTEM WITH DUMMY LOADS Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

AGENDA Ø NEMO PHASE 1 ELECTRICAL POWER SYSTEM - AC THREE- PHASE ØNEMO PHASE 1 POWER CONTROL SYSTEM ØNEMO PHASE 2 ELECTRICAL POWER SYSTEM – DC ØPRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

AGENDA Ø NEMO PHASE 1 ELECTRICAL POWER SYSTEM - AC THREE- PHASE ØNEMO PHASE 1 POWER CONTROL SYSTEM ØNEMO PHASE 2 ELECTRICAL POWER SYSTEM – DC ØPRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

PRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS WHY WE DO PRESSURE TESTS: § The storage of as much as possible devices in pressure and oil environment is important for the containers design. In this way the steel pressure vessel houses only the electronic devices that cannot stay under pressure. §This solution will improve on reliability due to the reduced number of sealed connection that represent failure points. §It will improve on costs due to the reduction of its dimensions and to the use of low cost materials rather than expensive alloy such as standard titanium. OUR GOAL HAS BEEN TO TEST AND CHARACTERIZE THE MAXIMUM NUMBER OF ELECTRIC AND ELECTRONIC DEVICES UNDER PRESSURE IN AN OIL ENVIRONMENT Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

PRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS WHY WE DO PRESSURE TESTS: § The storage of as much as possible devices in pressure and oil environment is important for the containers design. In this way the steel pressure vessel houses only the electronic devices that cannot stay under pressure. §This solution will improve on reliability due to the reduced number of sealed connection that represent failure points. §It will improve on costs due to the reduction of its dimensions and to the use of low cost materials rather than expensive alloy such as standard titanium. OUR GOAL HAS BEEN TO TEST AND CHARACTERIZE THE MAXIMUM NUMBER OF ELECTRIC AND ELECTRONIC DEVICES UNDER PRESSURE IN AN OIL ENVIRONMENT Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

PRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS Tests have been curried out on: Transformers, contactors, Solid state relay, Vicor dc/dc converter, current and voltage hall effect trasducers, temperature sensor, quarts crystals, capacitors, microcontrollers, integrated circuits, various electronic components. Tests have been done for over two years in iperbaric chambers at INFN- LNS (Catania), different. ), NURC- Nato Undersea Research Center (La Spezia). No failure have been detected in the majority of the components tested. ALL THE COMPONENTS OF THE NEMO PHASE 1 POWER AND CONTROL SYSTEM WORKED UNDER PRESSURE, NOW WE ARE WORKING TO HAVE THE SAME RESULTS FOR NEMO PHASE 2. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008

PRESSURE TEST ON ELECTRIC AND ELECTRONIC COMPONENTS Tests have been curried out on: Transformers, contactors, Solid state relay, Vicor dc/dc converter, current and voltage hall effect trasducers, temperature sensor, quarts crystals, capacitors, microcontrollers, integrated circuits, various electronic components. Tests have been done for over two years in iperbaric chambers at INFN- LNS (Catania), different. ), NURC- Nato Undersea Research Center (La Spezia). No failure have been detected in the majority of the components tested. ALL THE COMPONENTS OF THE NEMO PHASE 1 POWER AND CONTROL SYSTEM WORKED UNDER PRESSURE, NOW WE ARE WORKING TO HAVE THE SAME RESULTS FOR NEMO PHASE 2. Rosanna Cocimano for the NEMO collaboration VLVn. T 08, Toulon, France 22 -24 April 2008