3-Jens Munk Ebbesen.pptx

- Количество слайдов: 26

INTERNATIONAL SCIENTIFIC WORKSHOP «Implementation of HACCP system in processing enterprises. HACCP system internal audit» 3 rd – 4 th June 2016 St Petersburg “HACCP implementation in Denmark & Company and governmental control” Jens Munk Ebbesen, DVM, Director Food- & Veterinary Issues Danish Agriculture & Food Council

INTERNATIONAL SCIENTIFIC WORKSHOP «Implementation of HACCP system in processing enterprises. HACCP system internal audit» 3 rd – 4 th June 2016 St Petersburg “HACCP implementation in Denmark & Company and governmental control” Jens Munk Ebbesen, DVM, Director Food- & Veterinary Issues Danish Agriculture & Food Council

Agenda • Cooperation between stakeholders • Food Safety HACCP, incl financing

Agenda • Cooperation between stakeholders • Food Safety HACCP, incl financing

Danish Agriculture & Food Council • Brings together the largest industry grouping in Denmark • Represents the Danish food and farming industry : • • • Farmers (all sectors) Food processors and the agricultural supply industry (slaughterhouses, dairies, feed mills etc. ) Agribusiness (genetics, equipment etc. ) • Key activities include : • • Providing political representation Securing market access and export promotion Delivery of advisory services Supporting knowledge and innovation

Danish Agriculture & Food Council • Brings together the largest industry grouping in Denmark • Represents the Danish food and farming industry : • • • Farmers (all sectors) Food processors and the agricultural supply industry (slaughterhouses, dairies, feed mills etc. ) Agribusiness (genetics, equipment etc. ) • Key activities include : • • Providing political representation Securing market access and export promotion Delivery of advisory services Supporting knowledge and innovation

Cooperation between stakeholders “The Danish Model” • Good and trustful cooperation between industry and authorities for decades: • Regular meetings • Working groups • R&D • Network and personal contacts

Cooperation between stakeholders “The Danish Model” • Good and trustful cooperation between industry and authorities for decades: • Regular meetings • Working groups • R&D • Network and personal contacts

11. februar 2018 Cooperation: ”The Danish ”Model

11. februar 2018 Cooperation: ”The Danish ”Model

Food safety = responsibility of the producer/ manufacturer

Food safety = responsibility of the producer/ manufacturer

Food Safety – stable to table

Food Safety – stable to table

Danish Quality System The Concept Special Contract Production Voluntary Industry agreements National Legislation EU Legislation QA programme ”The Farm”

Danish Quality System The Concept Special Contract Production Voluntary Industry agreements National Legislation EU Legislation QA programme ”The Farm”

Focus - from plough to plate Grain Soil Feeding stuffs Farm Transport Pig Slaughterhouse Meat Distribution Sale Table

Focus - from plough to plate Grain Soil Feeding stuffs Farm Transport Pig Slaughterhouse Meat Distribution Sale Table

HACCP (Hazard analysis and critical control points)

HACCP (Hazard analysis and critical control points)

Why HACCP ? Prevention is better than cure!

Why HACCP ? Prevention is better than cure!

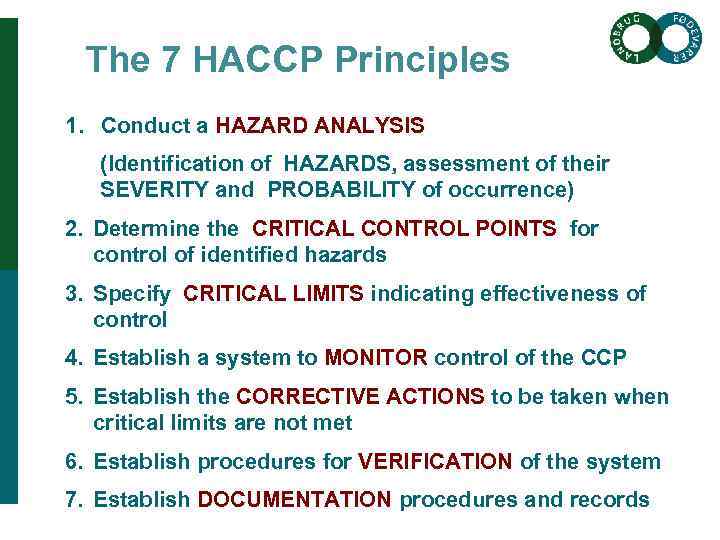

The 7 HACCP Principles 1. Conduct a HAZARD ANALYSIS (Identification of HAZARDS, assessment of their SEVERITY and PROBABILITY of occurrence) 2. Determine the CRITICAL CONTROL POINTS for control of identified hazards 3. Specify CRITICAL LIMITS indicating effectiveness of control 4. Establish a system to MONITOR control of the CCP 5. Establish the CORRECTIVE ACTIONS to be taken when critical limits are not met 6. Establish procedures for VERIFICATION of the system 7. Establish DOCUMENTATION procedures and records

The 7 HACCP Principles 1. Conduct a HAZARD ANALYSIS (Identification of HAZARDS, assessment of their SEVERITY and PROBABILITY of occurrence) 2. Determine the CRITICAL CONTROL POINTS for control of identified hazards 3. Specify CRITICAL LIMITS indicating effectiveness of control 4. Establish a system to MONITOR control of the CCP 5. Establish the CORRECTIVE ACTIONS to be taken when critical limits are not met 6. Establish procedures for VERIFICATION of the system 7. Establish DOCUMENTATION procedures and records

The framework for national guides • Developed & maintained by a sector • Codex regulations taken into account • Consultation of authorities and other relevant stakeholders • ”Approval” by national authories • Voluntary to apply

The framework for national guides • Developed & maintained by a sector • Codex regulations taken into account • Consultation of authorities and other relevant stakeholders • ”Approval” by national authories • Voluntary to apply

Primary roles of a National Guide 1. Transforms (and interprets) EUregulations to facilitate practical implementation § ”Blue stamping” of interpretations § Legalizes options/scenarios 2. Harmonises certain procedures og practices 3. New: Generic hazard analysis • Adapted to ISO 22000 certification • Assists in focusing auto-control efforts • Provides argumentation for communication with auditors and customers

Primary roles of a National Guide 1. Transforms (and interprets) EUregulations to facilitate practical implementation § ”Blue stamping” of interpretations § Legalizes options/scenarios 2. Harmonises certain procedures og practices 3. New: Generic hazard analysis • Adapted to ISO 22000 certification • Assists in focusing auto-control efforts • Provides argumentation for communication with auditors and customers

NATIONAL DAIRY GUIDES SINCE 1993 Dairy processing guide Dairy farming guide • First version in 1993 • 4 revisions • 5 th revision in 2015 • First version in 2006 • 2 revisions Key role of the dairy processing guide • Assists in implementation of the regulatory framework and any specific requirements • Transforms regulatory principles into operational guidance • Provides explanatory material on HACCP and food safety management (training purpose) • Assists in implementation of ISO 22000

NATIONAL DAIRY GUIDES SINCE 1993 Dairy processing guide Dairy farming guide • First version in 1993 • 4 revisions • 5 th revision in 2015 • First version in 2006 • 2 revisions Key role of the dairy processing guide • Assists in implementation of the regulatory framework and any specific requirements • Transforms regulatory principles into operational guidance • Provides explanatory material on HACCP and food safety management (training purpose) • Assists in implementation of ISO 22000

The approach to dairy farming • Communication and collaboration with and around the farmer • Veterinary practitioners & milk quality advisors • Private laboratories & dairy companies • Competent authorities & sector organizations • Education & training of the farmer • Good Practices program “The Farm” • • Farmers own-check procedures Verification of bulk milk quality Surveillance of test results Quality Advisory System • Economic incitements QA programme ”The Farm”

The approach to dairy farming • Communication and collaboration with and around the farmer • Veterinary practitioners & milk quality advisors • Private laboratories & dairy companies • Competent authorities & sector organizations • Education & training of the farmer • Good Practices program “The Farm” • • Farmers own-check procedures Verification of bulk milk quality Surveillance of test results Quality Advisory System • Economic incitements QA programme ”The Farm”

The approach in the meat production

The approach in the meat production

Benefits of the co-operative system Commercial interest of producers “beyond the farm gate” Trust/stable relationship between producer and abattoir Joint Research Programmes Excellent communication, information flow Easy assimilation of quality initiatives INTEGRATED PRODUCTION SYSTEM 18

Benefits of the co-operative system Commercial interest of producers “beyond the farm gate” Trust/stable relationship between producer and abattoir Joint Research Programmes Excellent communication, information flow Easy assimilation of quality initiatives INTEGRATED PRODUCTION SYSTEM 18

Danish Quality System Documentation and assurance Pig Production “Danish Product Standard” Slaughterhouses “Global Red Meat Standard (GRMS)” Both standards are accredited to EN 45011 used for product certification All Danish farms and co-operative slaughterhouses are audited by an independent third party 19

Danish Quality System Documentation and assurance Pig Production “Danish Product Standard” Slaughterhouses “Global Red Meat Standard (GRMS)” Both standards are accredited to EN 45011 used for product certification All Danish farms and co-operative slaughterhouses are audited by an independent third party 19

DANISH Product Standard Scope • Production of Danish pigs • Since 2007 • Approx. 3. 000 audits per year Aim • Assurance and documentation of that all Danish pig farms comply with Danish legislation and industry agreements Accreditation • The scheme is accredited to EN 45011 • Audit – minimum every third year • Third part • In addition, 5% of producers receive ‘unannounced’ visits from Danish authorities (DVFA) to audit compliance with welfare legislation. Self-audit

DANISH Product Standard Scope • Production of Danish pigs • Since 2007 • Approx. 3. 000 audits per year Aim • Assurance and documentation of that all Danish pig farms comply with Danish legislation and industry agreements Accreditation • The scheme is accredited to EN 45011 • Audit – minimum every third year • Third part • In addition, 5% of producers receive ‘unannounced’ visits from Danish authorities (DVFA) to audit compliance with welfare legislation. Self-audit

Global Red Meat Standard Slaughterhouse Scope • Slaughter, cutting and deboning of red meat • Fresh meat, meat products, meat • preparations and edible by-products Cornerstone is meat product safety, focusing on critical areas affecting maintenance of high meat safety requirements Audits • Independent audit every year Certification • Implemented at all Danish cooperative slaughterhouses and processing plants International recognition • GFSI approval since 2009: GRMS is equal to BRC, IFS and FSSC 22000 21

Global Red Meat Standard Slaughterhouse Scope • Slaughter, cutting and deboning of red meat • Fresh meat, meat products, meat • preparations and edible by-products Cornerstone is meat product safety, focusing on critical areas affecting maintenance of high meat safety requirements Audits • Independent audit every year Certification • Implemented at all Danish cooperative slaughterhouses and processing plants International recognition • GFSI approval since 2009: GRMS is equal to BRC, IFS and FSSC 22000 21

Food Safety Programmes All Sectors Surveillance of residues in animal products / use of antibiotics in livestock production The Salmonella Surveillance Programme Key: Cooperation and control throughout the production chain 22

Food Safety Programmes All Sectors Surveillance of residues in animal products / use of antibiotics in livestock production The Salmonella Surveillance Programme Key: Cooperation and control throughout the production chain 22

Financing – costs

Financing – costs

Official control, financing • Official inspectors • Employed by the Danish Government (Danish Veterinary and Food Administration) • Payed by the Danish Government BUT ! • The establishments pays for all the cost the Danish Government have in relation to the carrying out of the official control, including salary. • • Meat inspection Audit of the HACCP system and own-check programme Audit of special requirements, eg Russian requirements Inspection and issuing of health certificates in relation to export

Official control, financing • Official inspectors • Employed by the Danish Government (Danish Veterinary and Food Administration) • Payed by the Danish Government BUT ! • The establishments pays for all the cost the Danish Government have in relation to the carrying out of the official control, including salary. • • Meat inspection Audit of the HACCP system and own-check programme Audit of special requirements, eg Russian requirements Inspection and issuing of health certificates in relation to export

Very high level of food safety

Very high level of food safety

THANK YOU FOR YOUR ATTENTION ! - Questions?

THANK YOU FOR YOUR ATTENTION ! - Questions?