914dbfcca32555fed55835a9b106dadb.ppt

- Количество слайдов: 57

International Federation of Airworthiness Future MRO in Civil Aviation Maintenance Error Management Workshop 31 st January 2007 1

International Federation of Airworthiness Future MRO in Civil Aviation Maintenance Error Management Workshop 31 st January 2007 1

IFA is indebted to BOEING for permission to use its charts, to the UK CAA for help and advice and to the UK AAIB for access to reports and statistics and to Transport Canada for permission to use its FRMS work. We also thank some large MRO organisations for permission to use data. Copies of Boeing’s work in World Air Safety Analysis are available as part of this workshop 2

IFA is indebted to BOEING for permission to use its charts, to the UK CAA for help and advice and to the UK AAIB for access to reports and statistics and to Transport Canada for permission to use its FRMS work. We also thank some large MRO organisations for permission to use data. Copies of Boeing’s work in World Air Safety Analysis are available as part of this workshop 2

Just how safe is air travel? Let us examine this question before deciding what is wrong. 3

Just how safe is air travel? Let us examine this question before deciding what is wrong. 3

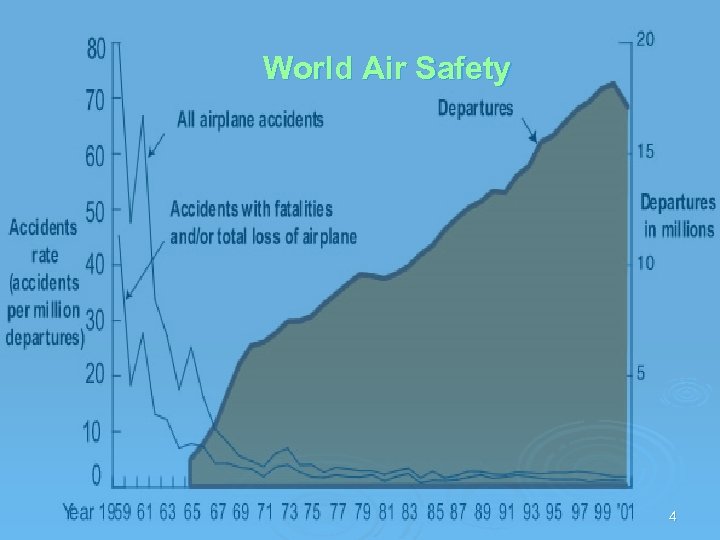

World Air Safety 4

World Air Safety 4

The year is 2000 and the country-the USA 5

The year is 2000 and the country-the USA 5

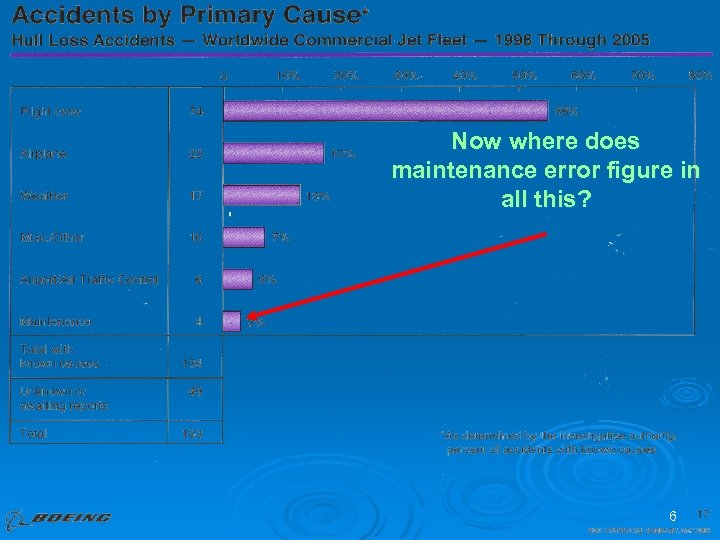

Now where does maintenance error figure in all this? 6

Now where does maintenance error figure in all this? 6

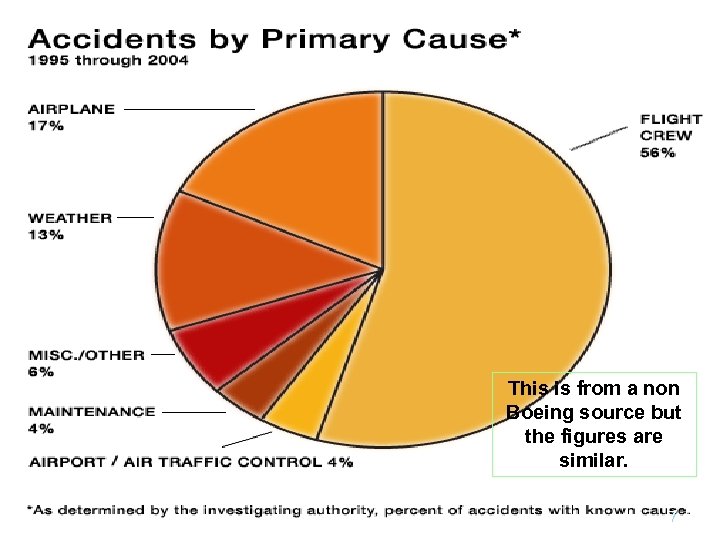

This is from a non Boeing source but the figures are similar. 7

This is from a non Boeing source but the figures are similar. 7

Here is another fact worth looking at! From 1993 to 2002 the causal factor from “flight crew” was 67% The “maintenance” cause in the same period was 3% just like the latest figure 8

Here is another fact worth looking at! From 1993 to 2002 the causal factor from “flight crew” was 67% The “maintenance” cause in the same period was 3% just like the latest figure 8

In the period 1996 to 2005 the “flight crew” figure had fallen to just 55% The “maintenance” figure had not improved at all – it was still 3% 9

In the period 1996 to 2005 the “flight crew” figure had fallen to just 55% The “maintenance” figure had not improved at all – it was still 3% 9

In other words, proportionally, “maintenance error” caused accidents are actually growing in relation to the main cause of “flight crew” related! IFA is of the opinion that this fact understates the influence maintenance error has on other accidents whose cause is allocated to flight crew or airplane. 10

In other words, proportionally, “maintenance error” caused accidents are actually growing in relation to the main cause of “flight crew” related! IFA is of the opinion that this fact understates the influence maintenance error has on other accidents whose cause is allocated to flight crew or airplane. 10

Let’s not leave here today thinking that “only” 3% is insignificant! 11

Let’s not leave here today thinking that “only” 3% is insignificant! 11

Operations and MRO Interface ØThe Operator’s contract with its MRO should always provide for good communication at working level! ØIt should spell out where the customer’s reps responsibility ends. ØEnsure in the contract that reasonableness reigns where delivery times are quoted. Nothing causes more friction than delays to promised or guaranteed times. ØAllow for routine and regular meetings between the MRO staff and technical staff (including flight crew) of the operator. 12

Operations and MRO Interface ØThe Operator’s contract with its MRO should always provide for good communication at working level! ØIt should spell out where the customer’s reps responsibility ends. ØEnsure in the contract that reasonableness reigns where delivery times are quoted. Nothing causes more friction than delays to promised or guaranteed times. ØAllow for routine and regular meetings between the MRO staff and technical staff (including flight crew) of the operator. 12

Examples of incidents from maintenance. You will recall some of them. ØA 320 released after overnight with one flight spoiler locked out- subsequent control difficulties. ØBAe 146 released after maintenance with no O rings fitted to engine chip detectors – subsequent single engine landing. ØB 737 released after overnight with gearbox hand turning covers not fitted – subsequent CAA prosecution. ØEmbraer Brasilia-LH stabiliser LE not secured after overnight. Fatal ØBAe 1 -11 – Loss of a flight deck window after overnight. Crew injury 13

Examples of incidents from maintenance. You will recall some of them. ØA 320 released after overnight with one flight spoiler locked out- subsequent control difficulties. ØBAe 146 released after maintenance with no O rings fitted to engine chip detectors – subsequent single engine landing. ØB 737 released after overnight with gearbox hand turning covers not fitted – subsequent CAA prosecution. ØEmbraer Brasilia-LH stabiliser LE not secured after overnight. Fatal ØBAe 1 -11 – Loss of a flight deck window after overnight. Crew injury 13

ØB 757 released after washing with tape over static vents – Fatal. ØB 777 - recently installed software caused a flight upset when a crew temporarily were unable to avoid sharp climbs and dives of some 3000 ft. (This is added merely to show that not only the traditional mechanics make mistakes. ) ØA 320 - Loss of complete engine cowls after overnight. Serious damage. 14

ØB 757 released after washing with tape over static vents – Fatal. ØB 777 - recently installed software caused a flight upset when a crew temporarily were unable to avoid sharp climbs and dives of some 3000 ft. (This is added merely to show that not only the traditional mechanics make mistakes. ) ØA 320 - Loss of complete engine cowls after overnight. Serious damage. 14

15

15

Need we go on? 16

Need we go on? 16

Reporting Systems ØWhy report? ØWhat to report? ØDoes it achieve anything? ØThe regulations. 17

Reporting Systems ØWhy report? ØWhat to report? ØDoes it achieve anything? ØThe regulations. 17

Reporting Systems Reporting safety incidents is part of aviation culture – no real change here. The USA and UK have led the field. Some EU countries have also been leaders but now it is mandatory under EASA. For the record Part 145. A. 60 and Part M. A. 302 ØLet’s consider the value before the rule book is quoted! 18

Reporting Systems Reporting safety incidents is part of aviation culture – no real change here. The USA and UK have led the field. Some EU countries have also been leaders but now it is mandatory under EASA. For the record Part 145. A. 60 and Part M. A. 302 ØLet’s consider the value before the rule book is quoted! 18

A view from a Regulator ØThe MOR system was more detailed and fruitful than less onerous systems. (It was 30 years old in 2006) ØECCAIRS is taking over in EU countries ØThe SDR system is used in the United States. 19

A view from a Regulator ØThe MOR system was more detailed and fruitful than less onerous systems. (It was 30 years old in 2006) ØECCAIRS is taking over in EU countries ØThe SDR system is used in the United States. 19

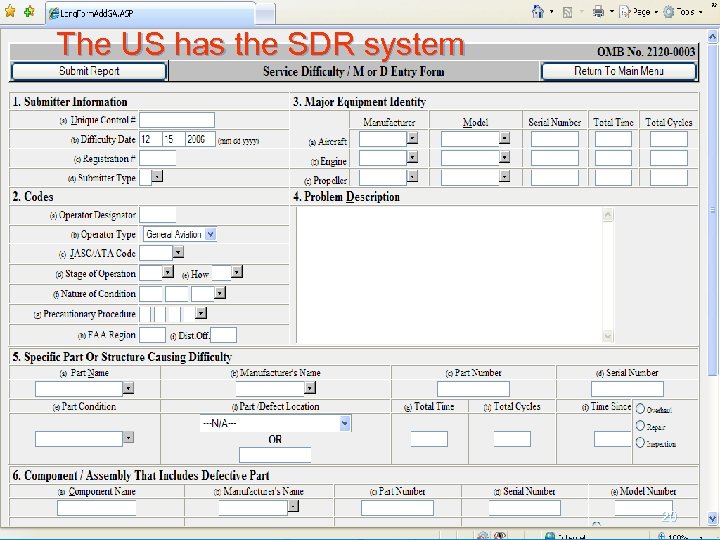

The US has the SDR system 20

The US has the SDR system 20

Let’s briefly mention CHIRP ØCHIRP, based at Farnborough in England, is a charitable trust set up to receive, analyse and publish confidential human factor reports. ØIt receives many reports from flight deck and cabin staff, quite a number from ATC personnel but, sadly, rather few from maintenance engineers* ØCHIRP is very sensitive in publishing reports to preserve confidentiality. Ø * We will open this point up shortly! 21

Let’s briefly mention CHIRP ØCHIRP, based at Farnborough in England, is a charitable trust set up to receive, analyse and publish confidential human factor reports. ØIt receives many reports from flight deck and cabin staff, quite a number from ATC personnel but, sadly, rather few from maintenance engineers* ØCHIRP is very sensitive in publishing reports to preserve confidentiality. Ø * We will open this point up shortly! 21

22

22

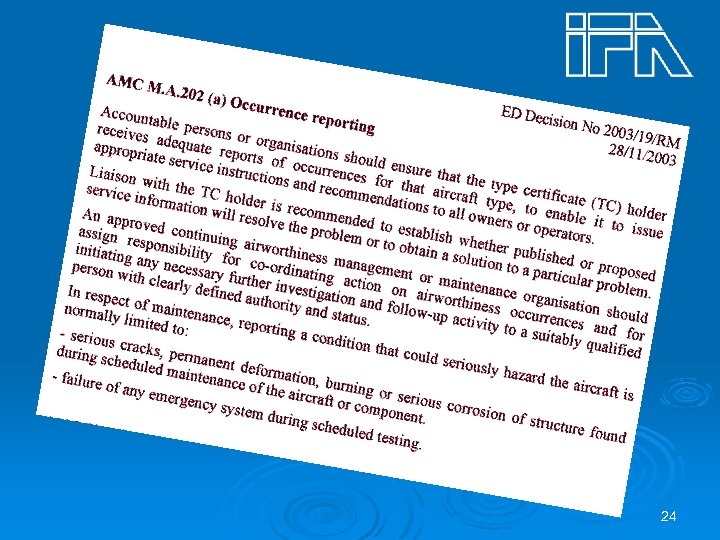

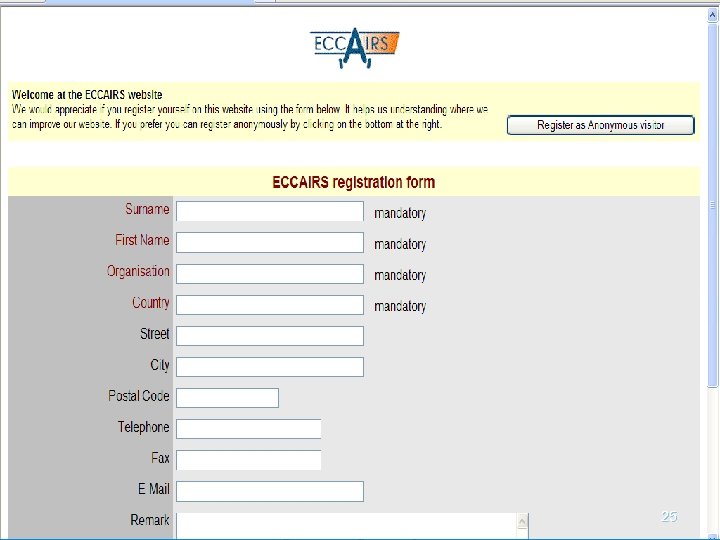

ECCAIRS ØThis is the EASA system mandatory since 2003 and becoming effective in 2005. ØIt requires national regulators to set up and operate their own reporting systems. ØA software system is being developed that will eventually contain all EASA incident reports. 23

ECCAIRS ØThis is the EASA system mandatory since 2003 and becoming effective in 2005. ØIt requires national regulators to set up and operate their own reporting systems. ØA software system is being developed that will eventually contain all EASA incident reports. 23

24

24

25

25

MEDA ØThe Boeing MEDA system (Maintenance Error Decision Aid) has been around for some 20 years. ØIncidentally – if you look up MEDA on the internet it comes up with Middle Eastern Dance Association! ØMany organisations use MEDA in some form to investigate human error in maintenance. ØWhat views are there amongst us today? 26

MEDA ØThe Boeing MEDA system (Maintenance Error Decision Aid) has been around for some 20 years. ØIncidentally – if you look up MEDA on the internet it comes up with Middle Eastern Dance Association! ØMany organisations use MEDA in some form to investigate human error in maintenance. ØWhat views are there amongst us today? 26

MEMS ØLets not forget Maintenance Error Management Systems ØThese are also widely used to investigate incidents and to preclude similar events. ØHow many of you use, understand or support MEMS? ØMany UK operators have signed up to it as have larger MRO’s. It is now mandatory in UK via AWN 71. 27

MEMS ØLets not forget Maintenance Error Management Systems ØThese are also widely used to investigate incidents and to preclude similar events. ØHow many of you use, understand or support MEMS? ØMany UK operators have signed up to it as have larger MRO’s. It is now mandatory in UK via AWN 71. 27

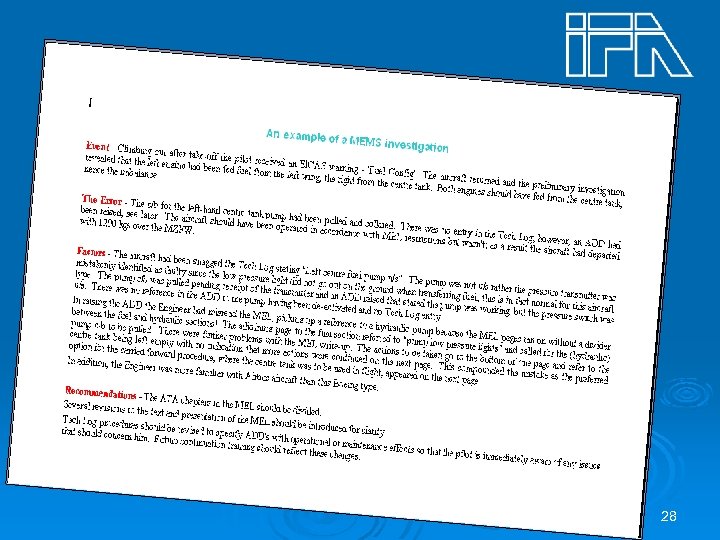

28

28

The part played by NGO’s like IFA and the RAe. S 29

The part played by NGO’s like IFA and the RAe. S 29

Back at 10: 45 please 30

Back at 10: 45 please 30

International Federation of Airworthiness Future MRO in Civil Aviation 2 nd Session 31

International Federation of Airworthiness Future MRO in Civil Aviation 2 nd Session 31

Human Factors and Fatigue Management ØThousands of words, tons of trees and no doubt garages of gigabytes have been expended by very clever people on this subject. ØWe don’t pretend to be more knowledgeable than they. ØVery many sources are available with detailed analysis, case studies and recommendations on the subject. ØIFA published a white paper just over a year ago and we offer copies to you here today. 32

Human Factors and Fatigue Management ØThousands of words, tons of trees and no doubt garages of gigabytes have been expended by very clever people on this subject. ØWe don’t pretend to be more knowledgeable than they. ØVery many sources are available with detailed analysis, case studies and recommendations on the subject. ØIFA published a white paper just over a year ago and we offer copies to you here today. 32

One fatigue management System! Ø Transport Canada has published an interesting programme called FRMS “fatigue risk management system” Ø A copy is on the IFA CD Ø Australia has done a huge amount of research on the subject 33

One fatigue management System! Ø Transport Canada has published an interesting programme called FRMS “fatigue risk management system” Ø A copy is on the IFA CD Ø Australia has done a huge amount of research on the subject 33

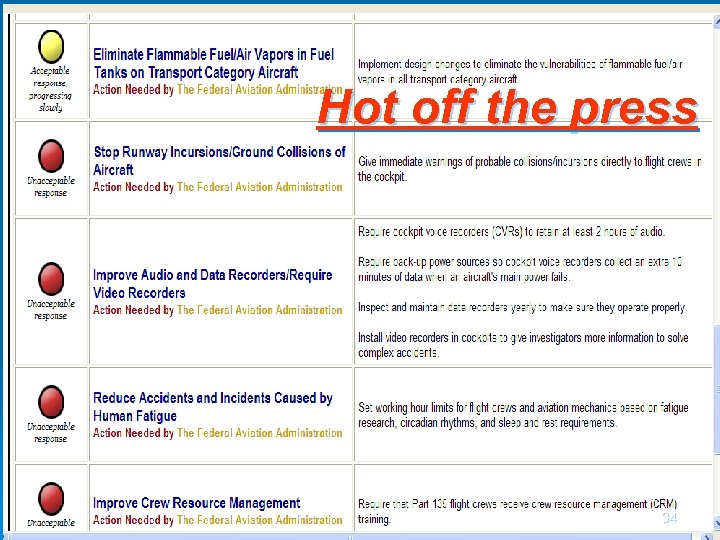

Hot off the press 34

Hot off the press 34

Concentrate. Ø A word on concentration! Ø Several accident and incident reports have quoted distraction of people at crucial times. Ø If you as managers, are able to, divert distractions away from personnel especially during finalisation. 35

Concentrate. Ø A word on concentration! Ø Several accident and incident reports have quoted distraction of people at crucial times. Ø If you as managers, are able to, divert distractions away from personnel especially during finalisation. 35

Human Factors and Fatigue Management - why the gap? ØBefore the break we remarked on the excellent progress made in reducing flight crew caused accidents. What are the reasons? ØWhy then are maintenance errors not reducing at the same rate? ØAre we despondent? Never. ØWe should be concerned though. 36

Human Factors and Fatigue Management - why the gap? ØBefore the break we remarked on the excellent progress made in reducing flight crew caused accidents. What are the reasons? ØWhy then are maintenance errors not reducing at the same rate? ØAre we despondent? Never. ØWe should be concerned though. 36

Human Factors and Fatigue Management - the gap ØCast your mind back to the CHIRP comment. Few reports come from maintenance people. ØWhy is this? ØCould it be complacency. You remember – one of the seven deadly sins! ØIs that famous 3% giving us a false sense of security? 37

Human Factors and Fatigue Management - the gap ØCast your mind back to the CHIRP comment. Few reports come from maintenance people. ØWhy is this? ØCould it be complacency. You remember – one of the seven deadly sins! ØIs that famous 3% giving us a false sense of security? 37

Let us look at Fatigue for a moment. ØWe trust at this point that no one is nodding! ØIt does continue to be an issue however. ØWhat does the EU Working Time Directive do for aviation maintenance staff? ØHow are staff coping? Are there solutions which cope with flexible working AND just as important, unsupervised working. Those lovely men at the pointy end always work in pairs don’t forget. 38

Let us look at Fatigue for a moment. ØWe trust at this point that no one is nodding! ØIt does continue to be an issue however. ØWhat does the EU Working Time Directive do for aviation maintenance staff? ØHow are staff coping? Are there solutions which cope with flexible working AND just as important, unsupervised working. Those lovely men at the pointy end always work in pairs don’t forget. 38

39

39

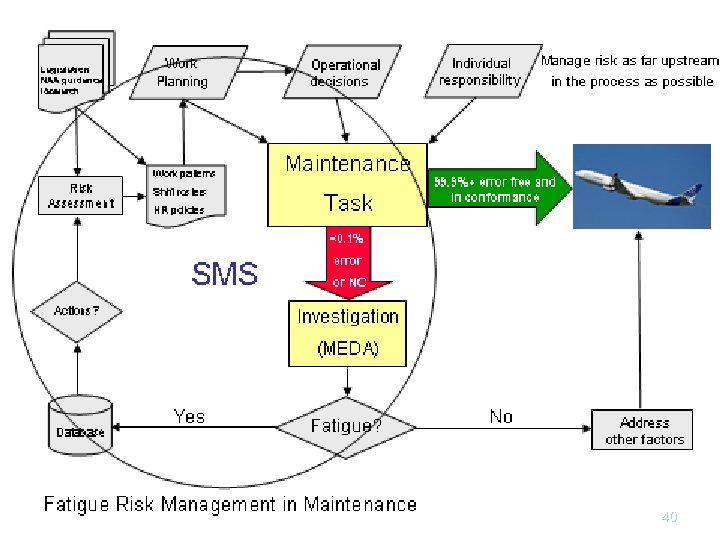

40

40

Let’s examine error avoidance Ø Train! Ø Instil a culture. Ø Foster reporting. Ø Operate fatigue mitigation policies. Ø Train! Ø Modify, placard, revise manuals, kick the backside of manufacturers. Ø Ensure that the “acceptance threshold” remains high. Ø Operate a “dual disturbance” policy. Ø And last of all - Train. 41

Let’s examine error avoidance Ø Train! Ø Instil a culture. Ø Foster reporting. Ø Operate fatigue mitigation policies. Ø Train! Ø Modify, placard, revise manuals, kick the backside of manufacturers. Ø Ensure that the “acceptance threshold” remains high. Ø Operate a “dual disturbance” policy. Ø And last of all - Train. 41

42

42

What is your understanding of this word? Ø A great many incidents have resulted from a failure to properly function previous maintenance. Ø Never tolerate inadequate function testing-don’t leave it to the crew. Ø Insist that the culture is “automatic” Ø Have your documents finish with “Function Carried Out” Ø Give time for the function test – it will save you grief 43

What is your understanding of this word? Ø A great many incidents have resulted from a failure to properly function previous maintenance. Ø Never tolerate inadequate function testing-don’t leave it to the crew. Ø Insist that the culture is “automatic” Ø Have your documents finish with “Function Carried Out” Ø Give time for the function test – it will save you grief 43

Don’t go over the top though! 44

Don’t go over the top though! 44

And finally, don’t think your efforts are only a drop in the ocean! 45

And finally, don’t think your efforts are only a drop in the ocean! 45

46

46

Maintenance reduction. Ø If aircraft could stand it, it would be better not to carry out maintenance at all. Ø Since this is clearly ridiculous, look seriously at what is really necessary. Ø Avoid speculative component changes. Ø Why? First it may not fix the problem, second it may induce a maintenance error and third it costs $. 47

Maintenance reduction. Ø If aircraft could stand it, it would be better not to carry out maintenance at all. Ø Since this is clearly ridiculous, look seriously at what is really necessary. Ø Avoid speculative component changes. Ø Why? First it may not fix the problem, second it may induce a maintenance error and third it costs $. 47

Published in Rio 1999 48

Published in Rio 1999 48

Interactive Role in Safety Management Ø It is notable that a quick search on the web shows USA, Canada, Australasia, the UK and now EASA with the most hits on error reports. Ø Is it therefore coincidence that these nations have the lowest accident rates? Ø Help make a reporting culture your contribution. 49

Interactive Role in Safety Management Ø It is notable that a quick search on the web shows USA, Canada, Australasia, the UK and now EASA with the most hits on error reports. Ø Is it therefore coincidence that these nations have the lowest accident rates? Ø Help make a reporting culture your contribution. 49

The part played by design Ø Up till now we have been quite calm. Ø Why is that billions have been spent stopping the lovely chaps up front digging holes in the ground? Ø Yet next to nothing has been expended on reducing maintenance errors. Ø The cry goes out “I know - we’ll teach them Human Factors”. 50

The part played by design Ø Up till now we have been quite calm. Ø Why is that billions have been spent stopping the lovely chaps up front digging holes in the ground? Ø Yet next to nothing has been expended on reducing maintenance errors. Ø The cry goes out “I know - we’ll teach them Human Factors”. 50

Design aims Ø There must be no let up in changing aircraft to help maintenance people!! Ø The next slide will show some improvements IFA would like. How many can we collect from you in advance of us showing it? 51

Design aims Ø There must be no let up in changing aircraft to help maintenance people!! Ø The next slide will show some improvements IFA would like. How many can we collect from you in advance of us showing it? 51

Ø Make even mechanical components self testing. Ø We expect all systems to be built with positive action to avoid mis-assembly. Ø All system areas e. g. gear bays, to be provided with the best lighting available. Ø Don’t fit loose spacers to axles. Ø Make access panels large enough for modern man. Ø Airports to provide facilities for ground running. Ø Use standard parts where ever possible. Ø Use anchor nuts where ever possible. Ø Only use locking devices that are self evident if not secure! Ø Stop the political correctness in manuals. Only print what it takes to fix the job not cover the arses of the manufacturers. Ø Fasteners of large items like engine cowls to be so obvious when not done up that a blind guide dog would spot them 52

Ø Make even mechanical components self testing. Ø We expect all systems to be built with positive action to avoid mis-assembly. Ø All system areas e. g. gear bays, to be provided with the best lighting available. Ø Don’t fit loose spacers to axles. Ø Make access panels large enough for modern man. Ø Airports to provide facilities for ground running. Ø Use standard parts where ever possible. Ø Use anchor nuts where ever possible. Ø Only use locking devices that are self evident if not secure! Ø Stop the political correctness in manuals. Only print what it takes to fix the job not cover the arses of the manufacturers. Ø Fasteners of large items like engine cowls to be so obvious when not done up that a blind guide dog would spot them 52

Don’t hold Your Breath Ø With the best will, design changes take decades to work through. Ø A “Human Centred Design Project” has commenced. Ø Regulators must have their say by changing airworthiness codes now! Ø Keep up the pressure from your airline, MRO, Regulator and trade bodies on this. Ø IFA is with you. 53

Don’t hold Your Breath Ø With the best will, design changes take decades to work through. Ø A “Human Centred Design Project” has commenced. Ø Regulators must have their say by changing airworthiness codes now! Ø Keep up the pressure from your airline, MRO, Regulator and trade bodies on this. Ø IFA is with you. 53

Summary Ø In summary air transport is safe Ø Maintenance Error is a small part of the overall causal factor. Ø Scope for improvement is, however, large! The mountain we have to climb needs us to recognise that a 1% reduction in “maintenance caused” is a 30% reduction in real terms! Ø 54

Summary Ø In summary air transport is safe Ø Maintenance Error is a small part of the overall causal factor. Ø Scope for improvement is, however, large! The mountain we have to climb needs us to recognise that a 1% reduction in “maintenance caused” is a 30% reduction in real terms! Ø 54

Finally, IFA would like to offer a sincere word of corporate advice to any Maintenance or Quality Manager who is unfortunate enough to be involved in an aviation accident! 55

Finally, IFA would like to offer a sincere word of corporate advice to any Maintenance or Quality Manager who is unfortunate enough to be involved in an aviation accident! 55

Run like hell. 56

Run like hell. 56

Thank you for listening and participating with us today 57

Thank you for listening and participating with us today 57