740b17f2facc65494330e43311d56c42.ppt

- Количество слайдов: 41

International Conference on: ‘New Role for the World Sugar Economy in a changed Political and Economic Environment’ Pyramisa Isis Island Hotel Aswan, Egypt. 10 th-13 th November, 2012

International Conference on: ‘New Role for the World Sugar Economy in a changed Political and Economic Environment’ Pyramisa Isis Island Hotel Aswan, Egypt. 10 th-13 th November, 2012

Increase production rate and solve bottle necks in Phosphatation and Carbonatation – Clarification types of Sugar Refineries with the use of high performance adsorbents

Increase production rate and solve bottle necks in Phosphatation and Carbonatation – Clarification types of Sugar Refineries with the use of high performance adsorbents

INTRODUCTION Ø This paper reviews the Value added to the production stream of Sugar Refineries and Mills with the application of the Carbo. UA high quality adsorbents. Ø We are presenting four case study with reference to some Refineries where these Carbo. UA adsorbents are used. We also have application in the Raw mills Ø Value added are: Increased productivity, Improved quality of final products, Chemical reduction, energy saving, water saving, increase in return on Investment etc. .

INTRODUCTION Ø This paper reviews the Value added to the production stream of Sugar Refineries and Mills with the application of the Carbo. UA high quality adsorbents. Ø We are presenting four case study with reference to some Refineries where these Carbo. UA adsorbents are used. We also have application in the Raw mills Ø Value added are: Increased productivity, Improved quality of final products, Chemical reduction, energy saving, water saving, increase in return on Investment etc. .

CASE STUDY No 1 Sugar Refinery in Colombia ü Phosphatation Type Refinery ü Attached Refinery to Mill ü Production: 900 Ton/day ü Raw sugar feed: 400 – 500 IU

CASE STUDY No 1 Sugar Refinery in Colombia ü Phosphatation Type Refinery ü Attached Refinery to Mill ü Production: 900 Ton/day ü Raw sugar feed: 400 – 500 IU

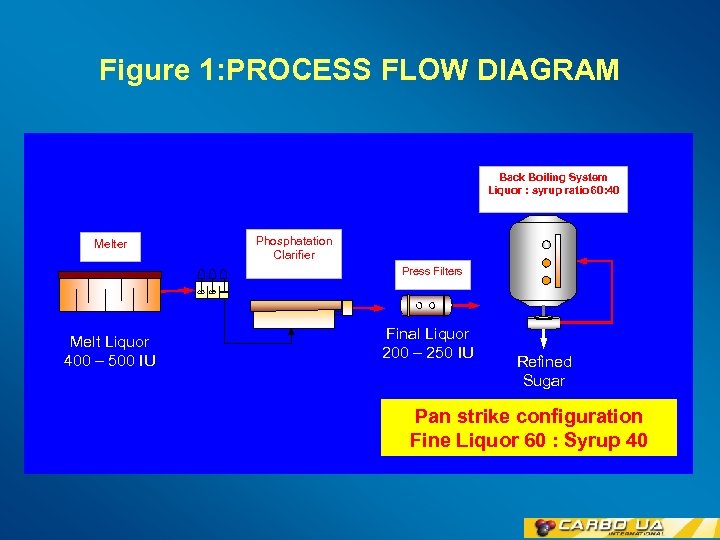

Figure 1: PROCESS FLOW DIAGRAM Back Boiling System Liquor : syrup ratio 60: 40 Melter Phosphatation Clarifier Press Filters Melt Liquor 400 – 500 IU Final Liquor 200 – 250 IU Refined Sugar Pan strike configuration Fine Liquor 60 : Syrup 40

Figure 1: PROCESS FLOW DIAGRAM Back Boiling System Liquor : syrup ratio 60: 40 Melter Phosphatation Clarifier Press Filters Melt Liquor 400 – 500 IU Final Liquor 200 – 250 IU Refined Sugar Pan strike configuration Fine Liquor 60 : Syrup 40

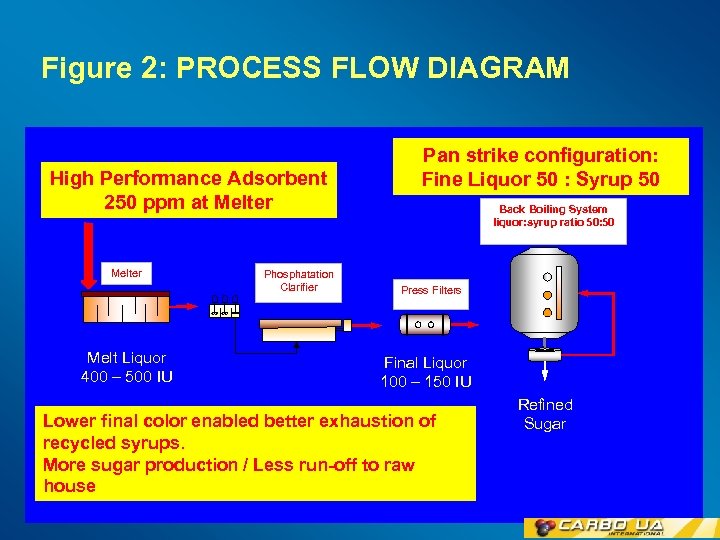

Figure 2: PROCESS FLOW DIAGRAM High Performance Adsorbent 250 ppm at Melter Melt Liquor 400 – 500 IU Phosphatation Clarifier Pan strike configuration: Fine Liquor 50 : Syrup 50 Back Boiling System liquor: syrup ratio 50: 50 Press Filters Final Liquor 100 – 150 IU Lower final color enabled better exhaustion of recycled syrups. More sugar production / Less run-off to raw house Refined Sugar

Figure 2: PROCESS FLOW DIAGRAM High Performance Adsorbent 250 ppm at Melter Melt Liquor 400 – 500 IU Phosphatation Clarifier Pan strike configuration: Fine Liquor 50 : Syrup 50 Back Boiling System liquor: syrup ratio 50: 50 Press Filters Final Liquor 100 – 150 IU Lower final color enabled better exhaustion of recycled syrups. More sugar production / Less run-off to raw house Refined Sugar

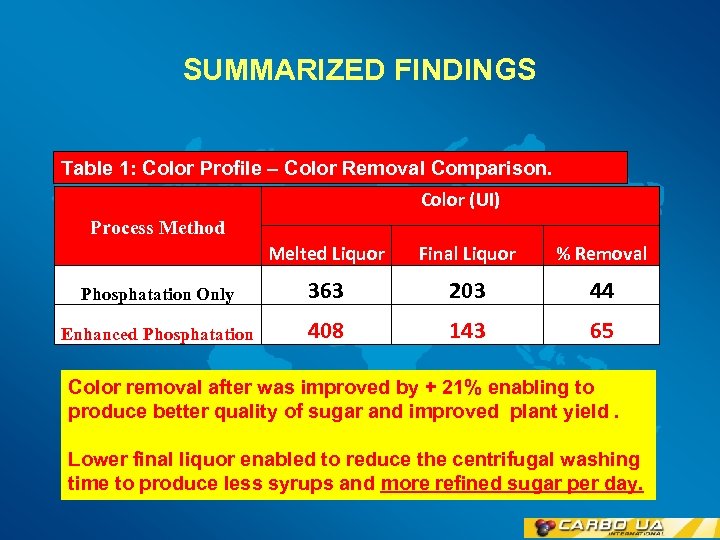

SUMMARIZED FINDINGS Table 1: Color Profile – Color Removal Comparison. Color (UI) Process Method Melted Liquor Final Liquor % Removal Phosphatation Only 363 203 44 Enhanced Phosphatation 408 143 65 Color removal after was improved by + 21% enabling to produce better quality of sugar and improved plant yield. Lower final liquor enabled to reduce the centrifugal washing time to produce less syrups and more refined sugar per day.

SUMMARIZED FINDINGS Table 1: Color Profile – Color Removal Comparison. Color (UI) Process Method Melted Liquor Final Liquor % Removal Phosphatation Only 363 203 44 Enhanced Phosphatation 408 143 65 Color removal after was improved by + 21% enabling to produce better quality of sugar and improved plant yield. Lower final liquor enabled to reduce the centrifugal washing time to produce less syrups and more refined sugar per day.

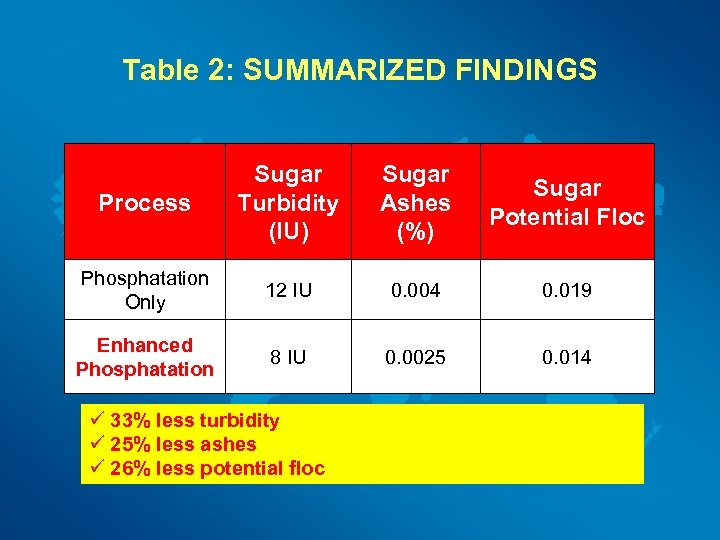

Table 2: SUMMARIZED FINDINGS Process Sugar Turbidity (IU) Sugar Ashes (%) Sugar Potential Floc Phosphatation Only 12 IU 0. 004 0. 019 Enhanced Phosphatation 8 IU 0. 0025 0. 014 ü 33% less turbidity ü 25% less ashes ü 26% less potential floc

Table 2: SUMMARIZED FINDINGS Process Sugar Turbidity (IU) Sugar Ashes (%) Sugar Potential Floc Phosphatation Only 12 IU 0. 004 0. 019 Enhanced Phosphatation 8 IU 0. 0025 0. 014 ü 33% less turbidity ü 25% less ashes ü 26% less potential floc

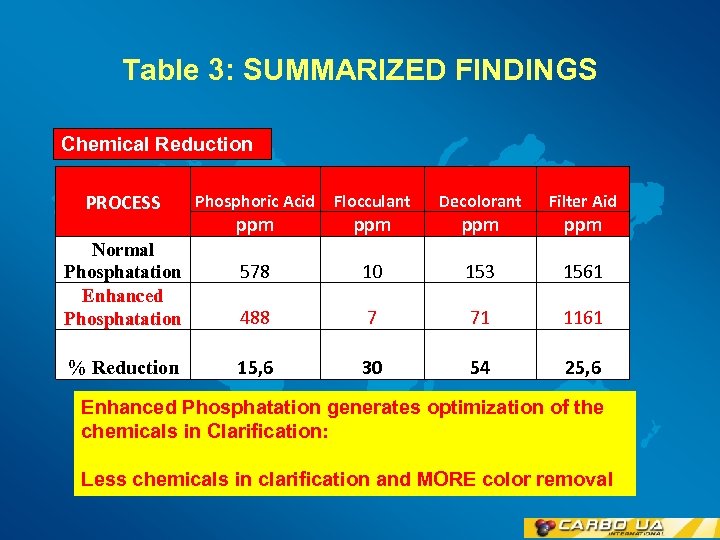

Table 3: SUMMARIZED FINDINGS Chemical Reduction PROCESS Normal Phosphatation Enhanced Phosphatation % Reduction Phosphoric Acid Flocculant Decolorant Filter Aid ppm ppm 578 10 153 1561 488 7 71 1161 15, 6 30 54 25, 6 Enhanced Phosphatation generates optimization of the chemicals in Clarification: Less chemicals in clarification and MORE color removal

Table 3: SUMMARIZED FINDINGS Chemical Reduction PROCESS Normal Phosphatation Enhanced Phosphatation % Reduction Phosphoric Acid Flocculant Decolorant Filter Aid ppm ppm 578 10 153 1561 488 7 71 1161 15, 6 30 54 25, 6 Enhanced Phosphatation generates optimization of the chemicals in Clarification: Less chemicals in clarification and MORE color removal

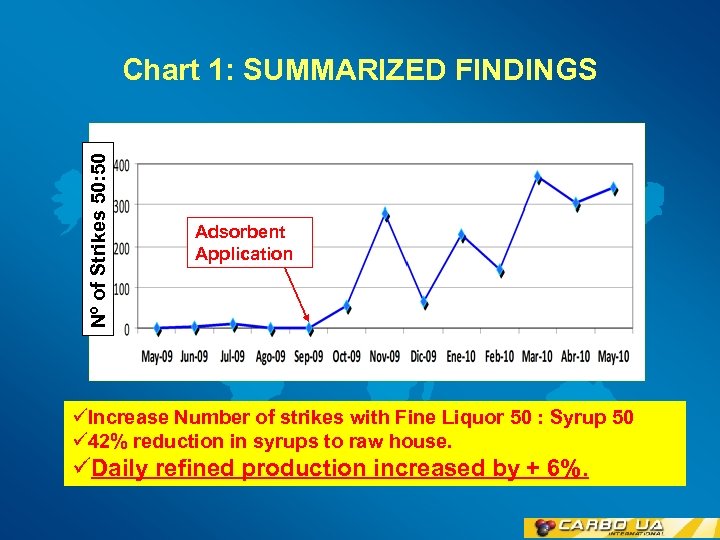

Nº of Strikes 50: 50 Chart 1: SUMMARIZED FINDINGS Adsorbent Application üIncrease Number of strikes with Fine Liquor 50 : Syrup 50 ü 42% reduction in syrups to raw house. üDaily refined production increased by + 6%.

Nº of Strikes 50: 50 Chart 1: SUMMARIZED FINDINGS Adsorbent Application üIncrease Number of strikes with Fine Liquor 50 : Syrup 50 ü 42% reduction in syrups to raw house. üDaily refined production increased by + 6%.

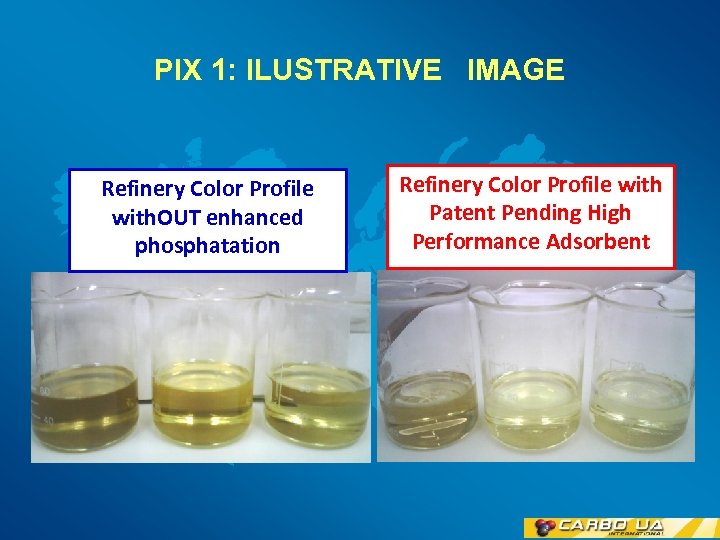

PIX 1: ILUSTRATIVE IMAGE Refinery Color Profile with. OUT enhanced phosphatation Refinery Color Profile with Patent Pending High Performance Adsorbent

PIX 1: ILUSTRATIVE IMAGE Refinery Color Profile with. OUT enhanced phosphatation Refinery Color Profile with Patent Pending High Performance Adsorbent

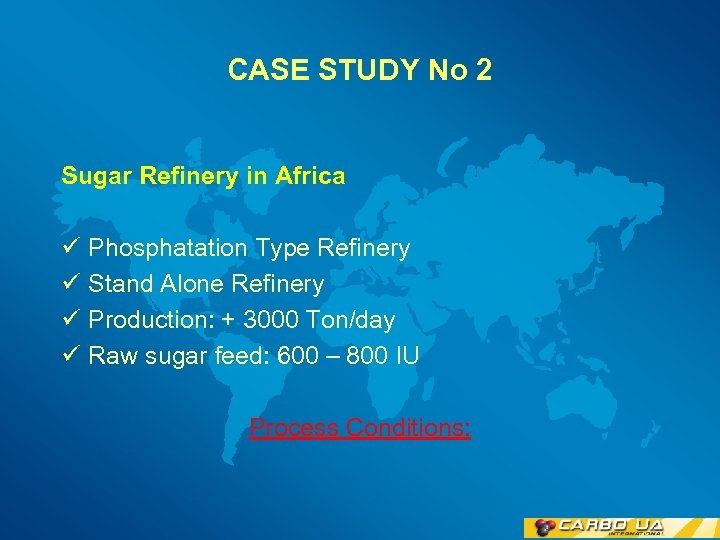

CASE STUDY No 2 Sugar Refinery in Africa ü Phosphatation Type Refinery ü Stand Alone Refinery ü Production: + 3000 Ton/day ü Raw sugar feed: 600 – 800 IU Process Conditions:

CASE STUDY No 2 Sugar Refinery in Africa ü Phosphatation Type Refinery ü Stand Alone Refinery ü Production: + 3000 Ton/day ü Raw sugar feed: 600 – 800 IU Process Conditions:

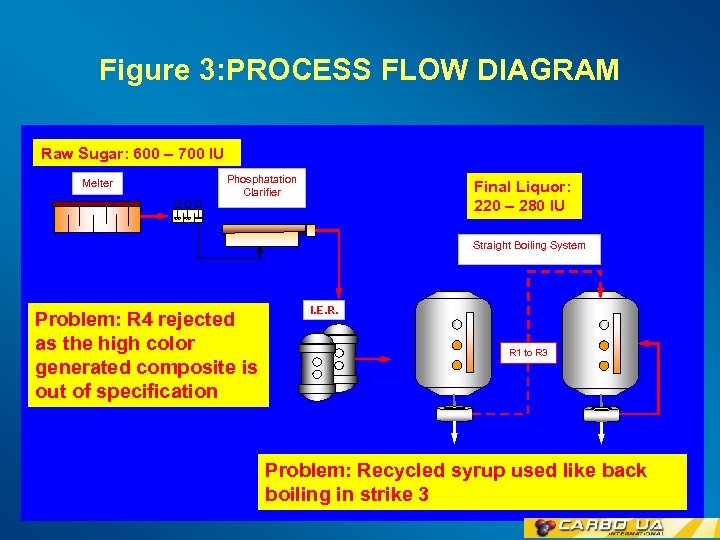

Figure 3: PROCESS FLOW DIAGRAM Raw Sugar: 600 – 700 IU Melter Phosphatation Clarifier Final Liquor: 220 – 280 IU Straight Boiling System Problem: R 4 rejected as the high color generated composite is out of specification I. E. R. R 1 to R 3 Problem: Recycled syrup used like back boiling in strike 3

Figure 3: PROCESS FLOW DIAGRAM Raw Sugar: 600 – 700 IU Melter Phosphatation Clarifier Final Liquor: 220 – 280 IU Straight Boiling System Problem: R 4 rejected as the high color generated composite is out of specification I. E. R. R 1 to R 3 Problem: Recycled syrup used like back boiling in strike 3

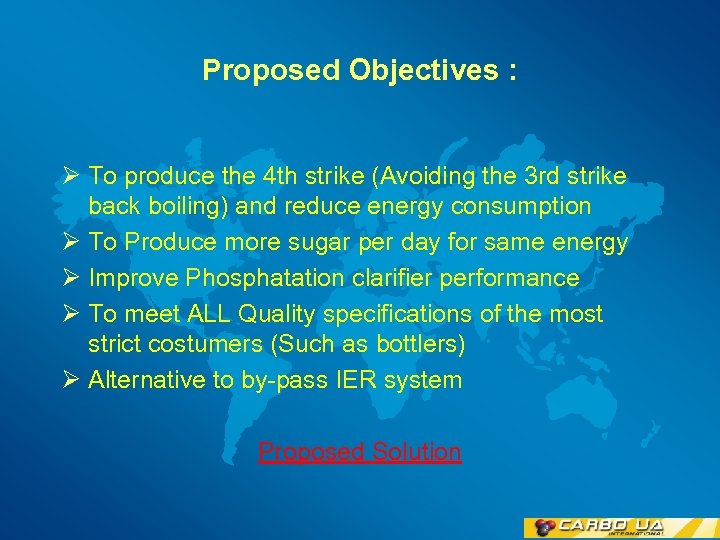

Proposed Objectives : Ø To produce the 4 th strike (Avoiding the 3 rd strike back boiling) and reduce energy consumption Ø To Produce more sugar per day for same energy Ø Improve Phosphatation clarifier performance Ø To meet ALL Quality specifications of the most strict costumers (Such as bottlers) Ø Alternative to by-pass IER system Proposed Solution

Proposed Objectives : Ø To produce the 4 th strike (Avoiding the 3 rd strike back boiling) and reduce energy consumption Ø To Produce more sugar per day for same energy Ø Improve Phosphatation clarifier performance Ø To meet ALL Quality specifications of the most strict costumers (Such as bottlers) Ø Alternative to by-pass IER system Proposed Solution

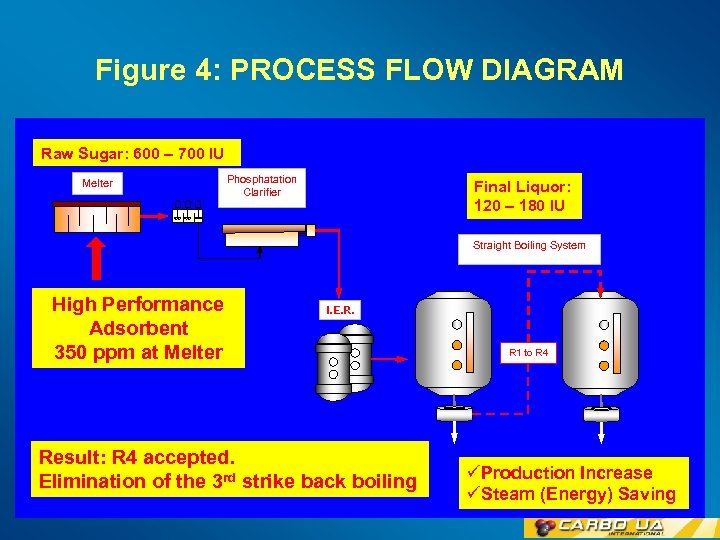

Figure 4: PROCESS FLOW DIAGRAM Raw Sugar: 600 – 700 IU Melter Phosphatation Clarifier Final Liquor: 120 – 180 IU Straight Boiling System High Performance Adsorbent 350 ppm at Melter I. E. R. Result: R 4 accepted. Elimination of the 3 rd strike back boiling R 1 to R 4 üProduction Increase üSteam (Energy) Saving

Figure 4: PROCESS FLOW DIAGRAM Raw Sugar: 600 – 700 IU Melter Phosphatation Clarifier Final Liquor: 120 – 180 IU Straight Boiling System High Performance Adsorbent 350 ppm at Melter I. E. R. Result: R 4 accepted. Elimination of the 3 rd strike back boiling R 1 to R 4 üProduction Increase üSteam (Energy) Saving

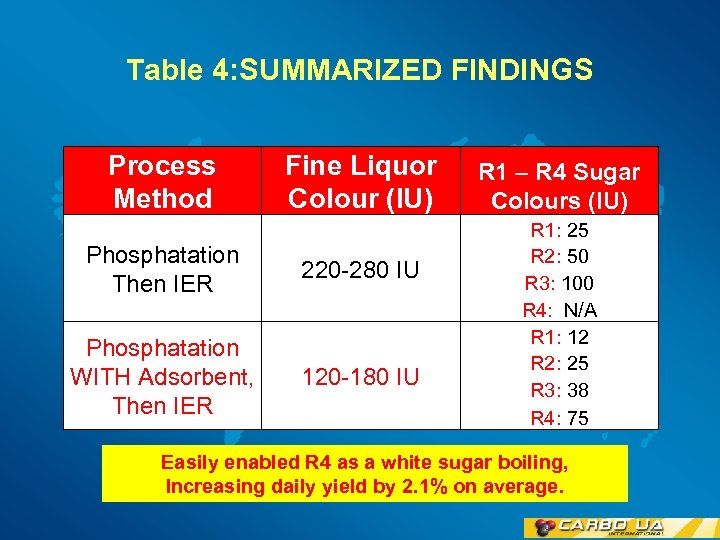

Table 4: SUMMARIZED FINDINGS Process Method Fine Liquor Colour (IU) Phosphatation Then IER 220 -280 IU Phosphatation WITH Adsorbent, Then IER 120 -180 IU R 1 – R 4 Sugar Colours (IU) R 1: 25 R 2: 50 R 3: 100 R 4: N/A R 1: 12 R 2: 25 R 3: 38 R 4: 75 Easily enabled R 4 as a white sugar boiling, Increasing daily yield by 2. 1% on average.

Table 4: SUMMARIZED FINDINGS Process Method Fine Liquor Colour (IU) Phosphatation Then IER 220 -280 IU Phosphatation WITH Adsorbent, Then IER 120 -180 IU R 1 – R 4 Sugar Colours (IU) R 1: 25 R 2: 50 R 3: 100 R 4: N/A R 1: 12 R 2: 25 R 3: 38 R 4: 75 Easily enabled R 4 as a white sugar boiling, Increasing daily yield by 2. 1% on average.

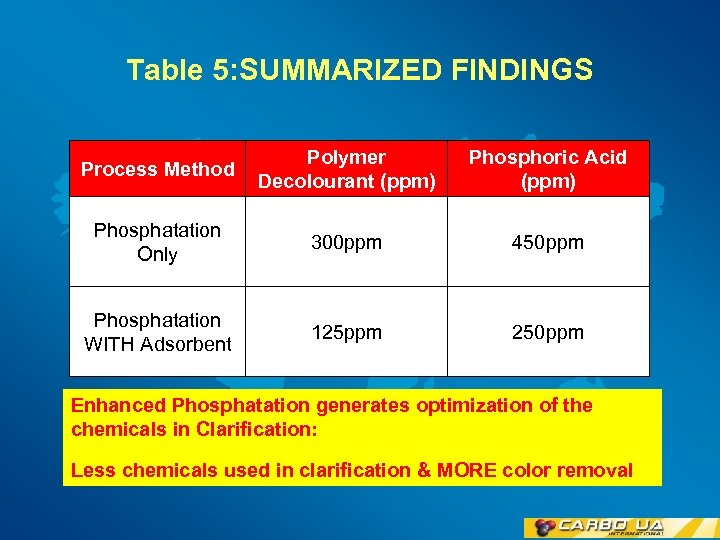

Table 5: SUMMARIZED FINDINGS Process Method Polymer Decolourant (ppm) Phosphoric Acid (ppm) Phosphatation Only 300 ppm 450 ppm Phosphatation WITH Adsorbent 125 ppm 250 ppm Enhanced Phosphatation generates optimization of the chemicals in Clarification: Less chemicals used in clarification & MORE color removal

Table 5: SUMMARIZED FINDINGS Process Method Polymer Decolourant (ppm) Phosphoric Acid (ppm) Phosphatation Only 300 ppm 450 ppm Phosphatation WITH Adsorbent 125 ppm 250 ppm Enhanced Phosphatation generates optimization of the chemicals in Clarification: Less chemicals used in clarification & MORE color removal

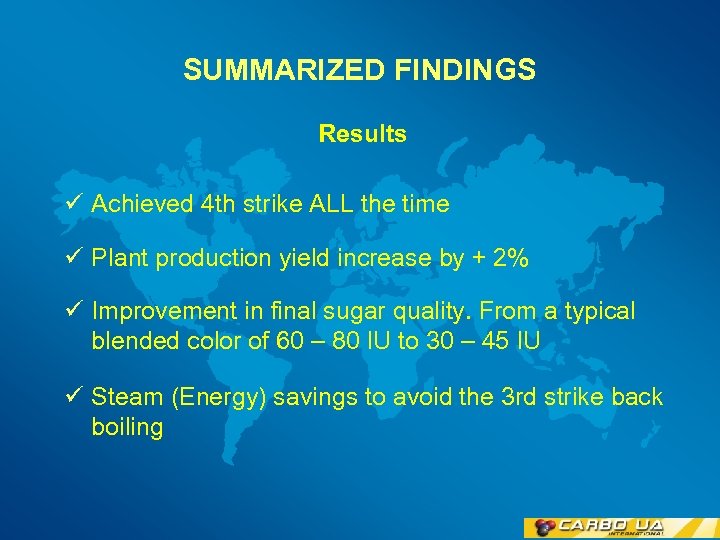

SUMMARIZED FINDINGS Results ü Achieved 4 th strike ALL the time ü Plant production yield increase by + 2% ü Improvement in final sugar quality. From a typical blended color of 60 – 80 IU to 30 – 45 IU ü Steam (Energy) savings to avoid the 3 rd strike back boiling

SUMMARIZED FINDINGS Results ü Achieved 4 th strike ALL the time ü Plant production yield increase by + 2% ü Improvement in final sugar quality. From a typical blended color of 60 – 80 IU to 30 – 45 IU ü Steam (Energy) savings to avoid the 3 rd strike back boiling

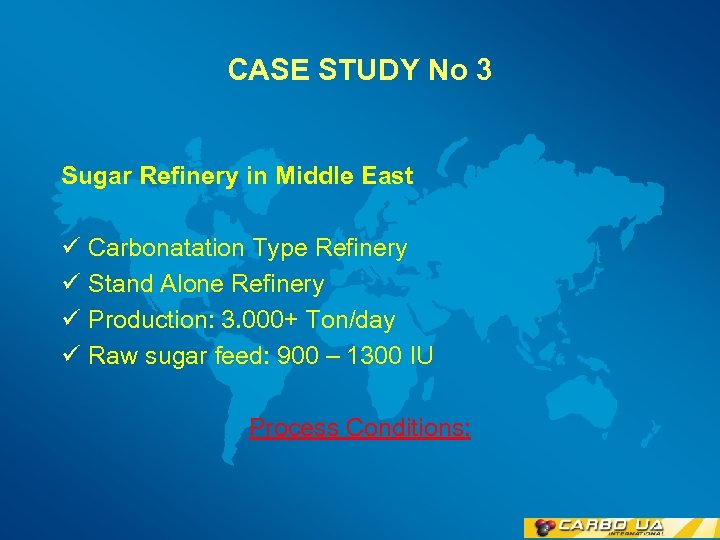

CASE STUDY No 3 Sugar Refinery in Middle East ü Carbonatation Type Refinery ü Stand Alone Refinery ü Production: 3. 000+ Ton/day ü Raw sugar feed: 900 – 1300 IU Process Conditions:

CASE STUDY No 3 Sugar Refinery in Middle East ü Carbonatation Type Refinery ü Stand Alone Refinery ü Production: 3. 000+ Ton/day ü Raw sugar feed: 900 – 1300 IU Process Conditions:

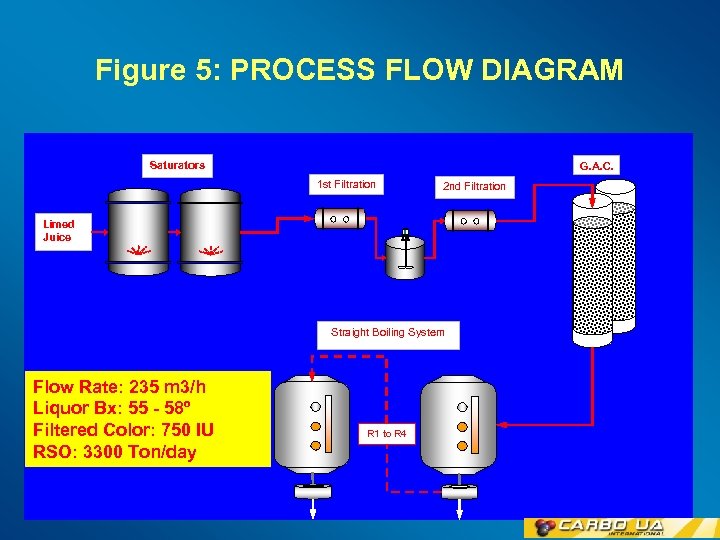

Figure 5: PROCESS FLOW DIAGRAM Saturators G. A. C. 1 st Filtration 2 nd Filtration Limed Juice Straight Boiling System Flow Rate: 235 m 3/h Liquor Bx: 55 - 58º Filtered Color: 750 IU RSO: 3300 Ton/day R 1 to R 4

Figure 5: PROCESS FLOW DIAGRAM Saturators G. A. C. 1 st Filtration 2 nd Filtration Limed Juice Straight Boiling System Flow Rate: 235 m 3/h Liquor Bx: 55 - 58º Filtered Color: 750 IU RSO: 3300 Ton/day R 1 to R 4

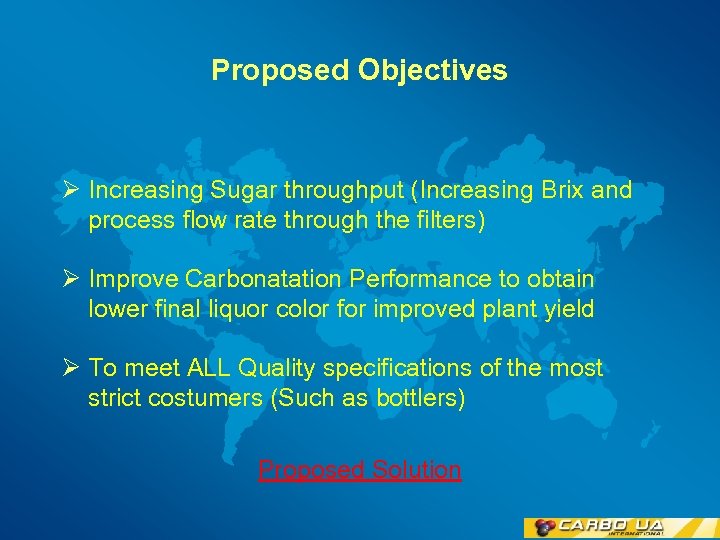

Proposed Objectives Ø Increasing Sugar throughput (Increasing Brix and process flow rate through the filters) Ø Improve Carbonatation Performance to obtain lower final liquor color for improved plant yield Ø To meet ALL Quality specifications of the most strict costumers (Such as bottlers) Proposed Solution

Proposed Objectives Ø Increasing Sugar throughput (Increasing Brix and process flow rate through the filters) Ø Improve Carbonatation Performance to obtain lower final liquor color for improved plant yield Ø To meet ALL Quality specifications of the most strict costumers (Such as bottlers) Proposed Solution

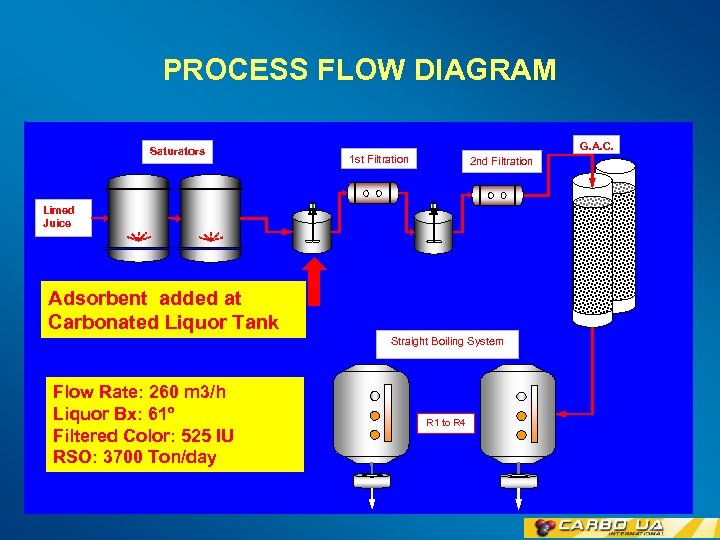

PROCESS FLOW DIAGRAM Saturators G. A. C. 1 st Filtration 2 nd Filtration Limed Juice Adsorbent added at Carbonated Liquor Tank Straight Boiling System Flow Rate: 260 m 3/h Liquor Bx: 61º Filtered Color: 525 IU RSO: 3700 Ton/day R 1 to R 4

PROCESS FLOW DIAGRAM Saturators G. A. C. 1 st Filtration 2 nd Filtration Limed Juice Adsorbent added at Carbonated Liquor Tank Straight Boiling System Flow Rate: 260 m 3/h Liquor Bx: 61º Filtered Color: 525 IU RSO: 3700 Ton/day R 1 to R 4

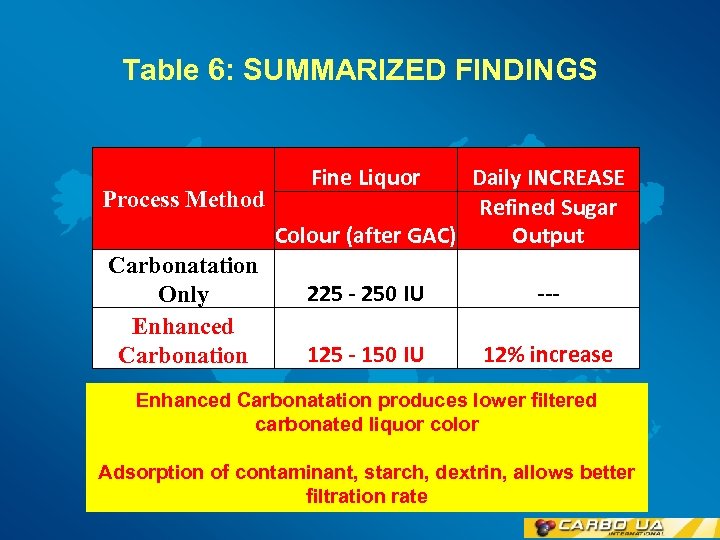

Table 6: SUMMARIZED FINDINGS Fine Liquor Daily INCREASE Process Method Refined Sugar Colour (after GAC) Output Carbonatation 225 - 250 IU --Only Enhanced 125 - 150 IU 12% increase Carbonation Enhanced Carbonatation produces lower filtered carbonated liquor color Adsorption of contaminant, starch, dextrin, allows better filtration rate

Table 6: SUMMARIZED FINDINGS Fine Liquor Daily INCREASE Process Method Refined Sugar Colour (after GAC) Output Carbonatation 225 - 250 IU --Only Enhanced 125 - 150 IU 12% increase Carbonation Enhanced Carbonatation produces lower filtered carbonated liquor color Adsorption of contaminant, starch, dextrin, allows better filtration rate

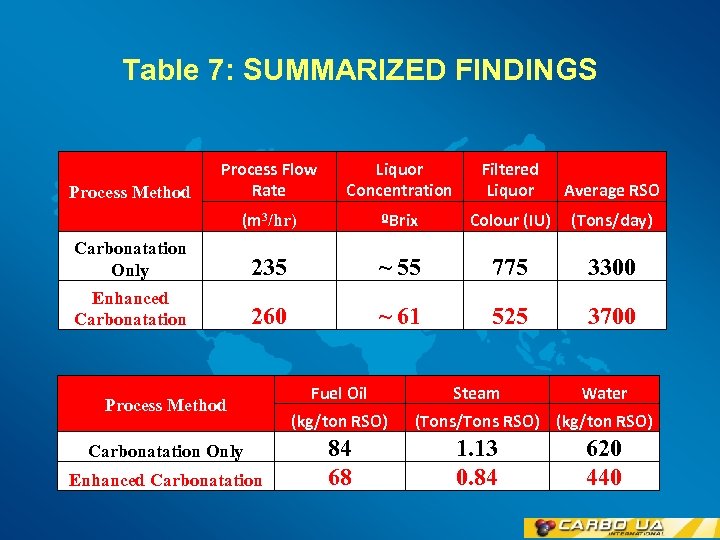

Table 7: SUMMARIZED FINDINGS Process Flow Rate Liquor Concentration Filtered Liquor Average RSO (m 3/hr) ºBrix Colour (IU) (Tons/day) Carbonatation Only 235 ~ 55 775 3300 Enhanced Carbonatation 260 ~ 61 525 3700 Process Method Carbonatation Only Enhanced Carbonatation Fuel Oil (kg/ton RSO) 84 68 Steam Water (Tons/Tons RSO) (kg/ton RSO) 1. 13 0. 84 620 440

Table 7: SUMMARIZED FINDINGS Process Flow Rate Liquor Concentration Filtered Liquor Average RSO (m 3/hr) ºBrix Colour (IU) (Tons/day) Carbonatation Only 235 ~ 55 775 3300 Enhanced Carbonatation 260 ~ 61 525 3700 Process Method Carbonatation Only Enhanced Carbonatation Fuel Oil (kg/ton RSO) 84 68 Steam Water (Tons/Tons RSO) (kg/ton RSO) 1. 13 0. 84 620 440

SUMMARIZED FINDINGS Results Ø Maximizing daily production capacity by 12% within the constraints of the existing vacuum pan and centrifugal capacity Ø Reduced centrifugal wash time to 2/1 seconds on R -1, compared to 3/2 seconds on R-1 with the normal Carbonatation process

SUMMARIZED FINDINGS Results Ø Maximizing daily production capacity by 12% within the constraints of the existing vacuum pan and centrifugal capacity Ø Reduced centrifugal wash time to 2/1 seconds on R -1, compared to 3/2 seconds on R-1 with the normal Carbonatation process

SUMMARIZED FINDINGS Results Ø Substantial improvements in flow rate (9. 6 % more flow rate) and increase melt Brix (~ 3 - 6º) were achieved with Enhanced Carbonatation Process Ø 19% decrease in fuel oil consumption Ø 25% decrease in steam consumption Ø 29% decrease in water consumption achieved

SUMMARIZED FINDINGS Results Ø Substantial improvements in flow rate (9. 6 % more flow rate) and increase melt Brix (~ 3 - 6º) were achieved with Enhanced Carbonatation Process Ø 19% decrease in fuel oil consumption Ø 25% decrease in steam consumption Ø 29% decrease in water consumption achieved

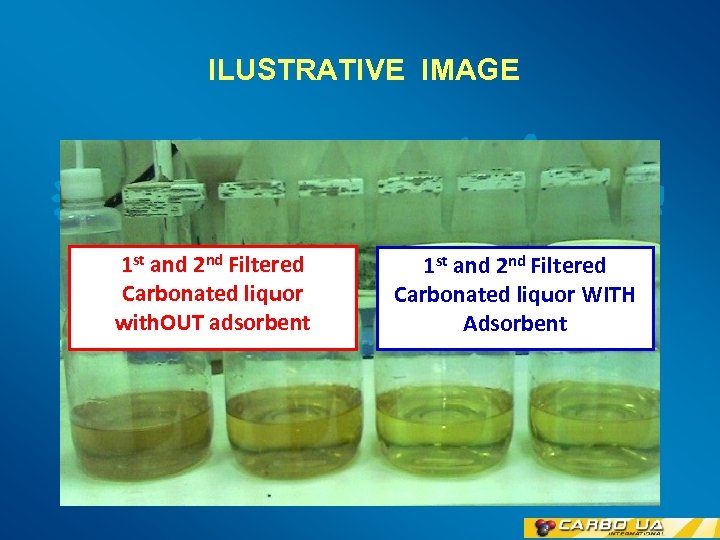

ILUSTRATIVE IMAGE 1 st and 2 nd Filtered Carbonated liquor with. OUT adsorbent 1 st and 2 nd Filtered Carbonated liquor WITH Adsorbent

ILUSTRATIVE IMAGE 1 st and 2 nd Filtered Carbonated liquor with. OUT adsorbent 1 st and 2 nd Filtered Carbonated liquor WITH Adsorbent

CASE STUDY No 4 Two Stages Method ü Phosphatation Type Refinery ü Stand Alone Refinery ü Production: + 3000 Ton/day ü Raw sugar feed: 600 – 700 IU Process Conditions:

CASE STUDY No 4 Two Stages Method ü Phosphatation Type Refinery ü Stand Alone Refinery ü Production: + 3000 Ton/day ü Raw sugar feed: 600 – 700 IU Process Conditions:

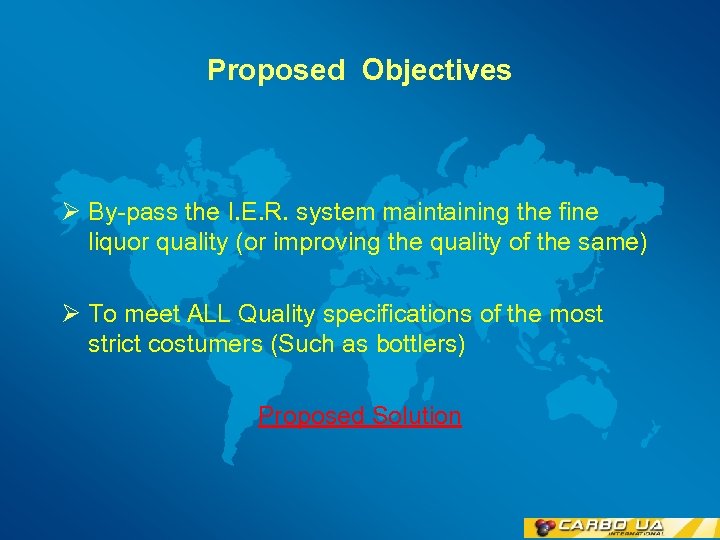

Proposed Objectives Ø By-pass the I. E. R. system maintaining the fine liquor quality (or improving the quality of the same) Ø To meet ALL Quality specifications of the most strict costumers (Such as bottlers) Proposed Solution

Proposed Objectives Ø By-pass the I. E. R. system maintaining the fine liquor quality (or improving the quality of the same) Ø To meet ALL Quality specifications of the most strict costumers (Such as bottlers) Proposed Solution

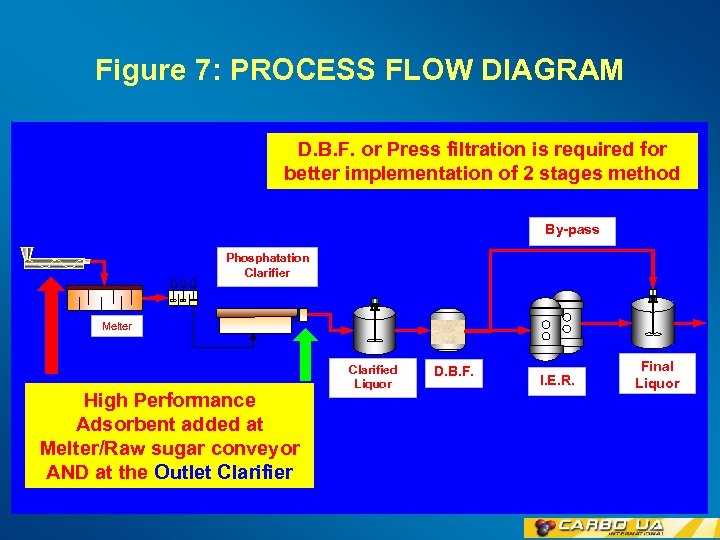

Figure 7: PROCESS FLOW DIAGRAM D. B. F. or Press filtration is required for better implementation of 2 stages method By-pass Phosphatation Clarifier Melter High Performance Adsorbent added at Melter/Raw sugar conveyor AND at the Outlet Clarifier Clarified Liquor D. B. F. I. E. R. Final Liquor

Figure 7: PROCESS FLOW DIAGRAM D. B. F. or Press filtration is required for better implementation of 2 stages method By-pass Phosphatation Clarifier Melter High Performance Adsorbent added at Melter/Raw sugar conveyor AND at the Outlet Clarifier Clarified Liquor D. B. F. I. E. R. Final Liquor

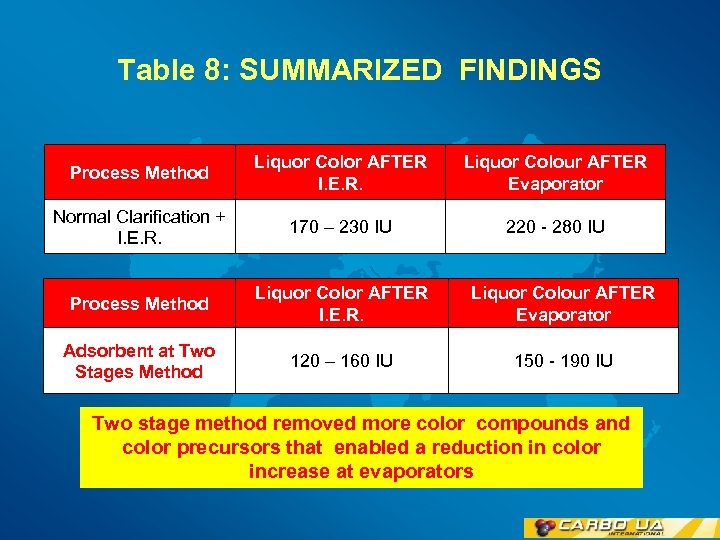

Table 8: SUMMARIZED FINDINGS Process Method Liquor Color AFTER I. E. R. Liquor Colour AFTER Evaporator Normal Clarification + I. E. R. 170 – 230 IU 220 - 280 IU Process Method Liquor Color AFTER I. E. R. Liquor Colour AFTER Evaporator Adsorbent at Two Stages Method 120 – 160 IU 150 - 190 IU Two stage method removed more color compounds and color precursors that enabled a reduction in color increase at evaporators

Table 8: SUMMARIZED FINDINGS Process Method Liquor Color AFTER I. E. R. Liquor Colour AFTER Evaporator Normal Clarification + I. E. R. 170 – 230 IU 220 - 280 IU Process Method Liquor Color AFTER I. E. R. Liquor Colour AFTER Evaporator Adsorbent at Two Stages Method 120 – 160 IU 150 - 190 IU Two stage method removed more color compounds and color precursors that enabled a reduction in color increase at evaporators

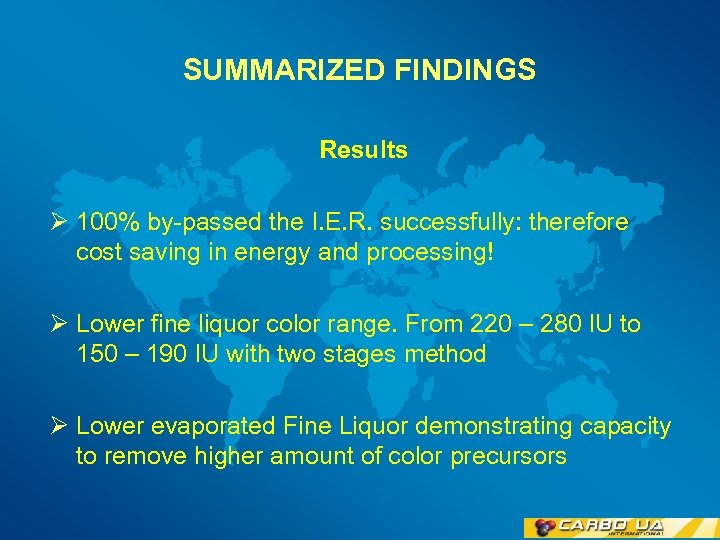

SUMMARIZED FINDINGS Results Ø 100% by-passed the I. E. R. successfully: therefore cost saving in energy and processing! Ø Lower fine liquor color range. From 220 – 280 IU to 150 – 190 IU with two stages method Ø Lower evaporated Fine Liquor demonstrating capacity to remove higher amount of color precursors

SUMMARIZED FINDINGS Results Ø 100% by-passed the I. E. R. successfully: therefore cost saving in energy and processing! Ø Lower fine liquor color range. From 220 – 280 IU to 150 – 190 IU with two stages method Ø Lower evaporated Fine Liquor demonstrating capacity to remove higher amount of color precursors

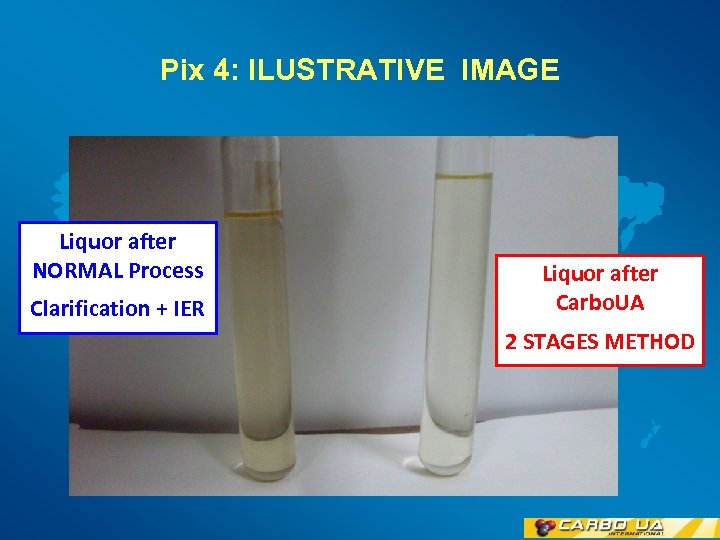

Pix 4: ILUSTRATIVE IMAGE Liquor after NORMAL Process Clarification + IER Liquor after Carbo. UA 2 STAGES METHOD

Pix 4: ILUSTRATIVE IMAGE Liquor after NORMAL Process Clarification + IER Liquor after Carbo. UA 2 STAGES METHOD

OUR APPROACH ü The technical crew of the Sugar Plant explains their technology and bottle necks to the Carbo. UA crew. ü The objectives are set by the technical crew of the Sugar Plant and Carbo. UA technical crew. ü Laboratory test is conducted to select best product and finally a Plant test is done for 2 weeks.

OUR APPROACH ü The technical crew of the Sugar Plant explains their technology and bottle necks to the Carbo. UA crew. ü The objectives are set by the technical crew of the Sugar Plant and Carbo. UA technical crew. ü Laboratory test is conducted to select best product and finally a Plant test is done for 2 weeks.

What is new in Carbo. UA? ü We are happy to introduce to you our latest product line that are all Carbon free and whitish in appearance and gives better in performance. ü We also have a new product line for application in the Pans to remove impurities. ü We also have some latest array of products used in treating the juice in the Mills. ü New products already tried in Zambia and BUA with excellent performance.

What is new in Carbo. UA? ü We are happy to introduce to you our latest product line that are all Carbon free and whitish in appearance and gives better in performance. ü We also have a new product line for application in the Pans to remove impurities. ü We also have some latest array of products used in treating the juice in the Mills. ü New products already tried in Zambia and BUA with excellent performance.

SPECIAL SECTION Energy Saving & Carbon Footprint ü Our Process & Products assist the companies to reduce/optimize its energy consumption. ü In addition to generate economic benefits, it is also contributing to the improvement of the carbon footprint measurements ü Process committed with reduction of carbon footprints!

SPECIAL SECTION Energy Saving & Carbon Footprint ü Our Process & Products assist the companies to reduce/optimize its energy consumption. ü In addition to generate economic benefits, it is also contributing to the improvement of the carbon footprint measurements ü Process committed with reduction of carbon footprints!

SPECIAL SECTION Energy Saving & Carbon Footprint Benefits of using High Performance Adsorbents ü Reduce your organization’s greenhouse gas emissions and help mitigate global warming or destructive climate change ü Implement systems ahead of emerging regulations for your organization and maximize production rate

SPECIAL SECTION Energy Saving & Carbon Footprint Benefits of using High Performance Adsorbents ü Reduce your organization’s greenhouse gas emissions and help mitigate global warming or destructive climate change ü Implement systems ahead of emerging regulations for your organization and maximize production rate

SPECIAL SECTION Energy Saving & Carbon Footprint BENEFITS FOR SUGAR REFINERY ü Demonstrating market leadership ü Delivering cost savings through reduced energy and resource consumed ü Increasing Brand Value and Market Share ü Providing consumer and stakeholder satisfaction

SPECIAL SECTION Energy Saving & Carbon Footprint BENEFITS FOR SUGAR REFINERY ü Demonstrating market leadership ü Delivering cost savings through reduced energy and resource consumed ü Increasing Brand Value and Market Share ü Providing consumer and stakeholder satisfaction

GENERAL CONCLUSIONS ü The use of high performance process aids have shown to significantly enhance Carbonatation and Phosphatation Refinery process in terms of improved colour / impurity removal, reduce operation cost and reduce energy consumption ü In Carbonatation type Refineries is also possible to increase production rate by flow rate and brix increases.

GENERAL CONCLUSIONS ü The use of high performance process aids have shown to significantly enhance Carbonatation and Phosphatation Refinery process in terms of improved colour / impurity removal, reduce operation cost and reduce energy consumption ü In Carbonatation type Refineries is also possible to increase production rate by flow rate and brix increases.

GENERAL CONCLUSIONS ü These benefits (better quality of final liquors) can enable an increase in daily refined sugar output (RSO) even with the constraints of existing process equipment, as well as reduce energy consumption per ton RSO. ü Instead of installing an additional process/stage for color removal, it is now possible to implement the high performance adsorbent technology with little or NO capital investment in new equipment

GENERAL CONCLUSIONS ü These benefits (better quality of final liquors) can enable an increase in daily refined sugar output (RSO) even with the constraints of existing process equipment, as well as reduce energy consumption per ton RSO. ü Instead of installing an additional process/stage for color removal, it is now possible to implement the high performance adsorbent technology with little or NO capital investment in new equipment

Thank you for your attention ! www. carboua. com

Thank you for your attention ! www. carboua. com