3e5c043f64050b21db768a1d91735592.ppt

- Количество слайдов: 38

Interactive Modeling, Simulation, Animation, and Real-Time Control (Mo. SART) Flexible Inverted Pendulum Environment Jose I. Hernandez Richard P. Metzger Jr. Chen-I Lim Armando A. Rodriguez ASEE Pacific Southwest Meeting `99 Saturday, March 20 th 1999 Harrah’s Hotel Las Vegas, Nevada Ack : White House , NSF, WAESO/CIMD, Boeing, Intel, Microsoft, CADSI, Knowledge Revolution, Math. Works, Lego, Xilinx, Honeywell, National Instruments, Integrated Systems, ASU CIEE. http: //www. eas. asu. edu/~aar/research/mosart

Interactive Modeling, Simulation, Animation, and Real-Time Control (Mo. SART) Flexible Inverted Pendulum Environment Jose I. Hernandez Richard P. Metzger Jr. Chen-I Lim Armando A. Rodriguez ASEE Pacific Southwest Meeting `99 Saturday, March 20 th 1999 Harrah’s Hotel Las Vegas, Nevada Ack : White House , NSF, WAESO/CIMD, Boeing, Intel, Microsoft, CADSI, Knowledge Revolution, Math. Works, Lego, Xilinx, Honeywell, National Instruments, Integrated Systems, ASU CIEE. http: //www. eas. asu. edu/~aar/research/mosart

Outline Motivation Flexible Inverted Pendulum (FIP) System Dynamics: Model & Control Laws Description of Interactive Mo. SART FIP Environment Utility of Environment Summary and Future Directions

Outline Motivation Flexible Inverted Pendulum (FIP) System Dynamics: Model & Control Laws Description of Interactive Mo. SART FIP Environment Utility of Environment Summary and Future Directions

Motivation Advanced visualization tools are needed for system analysis and design. Research/education can be enhanced with interactive multimedia environments. PC platforms now offer substantial computing power for engineering design.

Motivation Advanced visualization tools are needed for system analysis and design. Research/education can be enhanced with interactive multimedia environments. PC platforms now offer substantial computing power for engineering design.

New Technologies • Affordable High Performance Computing • Hi-fidelity Simulation Capability – Simulink / MATLAB, etc… – Visual C++ • PC Animation Creation / Manipulation Technologies – 3 D Modeling Software (e. g. 3 D Studio, RPM D 3 D toolbox, etc. ) – Microsoft Direct. X (provides: 3 D-animation, sound, video, user-input, etc. ) • Object Oriented Programming (OOP) Framework – Active. X / OLE

New Technologies • Affordable High Performance Computing • Hi-fidelity Simulation Capability – Simulink / MATLAB, etc… – Visual C++ • PC Animation Creation / Manipulation Technologies – 3 D Modeling Software (e. g. 3 D Studio, RPM D 3 D toolbox, etc. ) – Microsoft Direct. X (provides: 3 D-animation, sound, video, user-input, etc. ) • Object Oriented Programming (OOP) Framework – Active. X / OLE

Key Environment Features • Accelerated-time simulation • Alter model/controller: – structure – parameters (on-the-fly) • Advanced visualization: – real-time graphics – visual indicators/aids – 3 D animation models • Direct user input via joystick, mouse, etc. • Integration with MATLAB and Simulink

Key Environment Features • Accelerated-time simulation • Alter model/controller: – structure – parameters (on-the-fly) • Advanced visualization: – real-time graphics – visual indicators/aids – 3 D animation models • Direct user input via joystick, mouse, etc. • Integration with MATLAB and Simulink

Contributions of Work System-specific interactive Mo. SART environments High performance: Windows/ C++ Advanced visualization tools: Direct-3 D Extensible: integration with MATLAB User friendly

Contributions of Work System-specific interactive Mo. SART environments High performance: Windows/ C++ Advanced visualization tools: Direct-3 D Extensible: integration with MATLAB User friendly

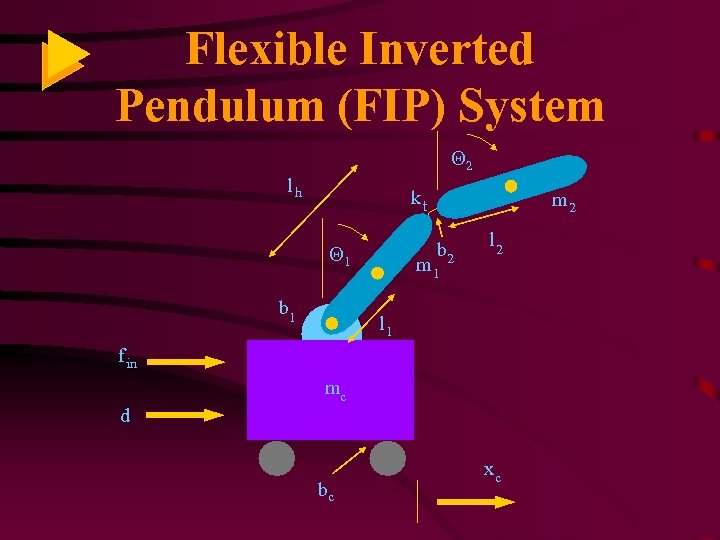

Flexible Inverted Pendulum (FIP) System 2 lh kt b 2 1 b 1 m 2 m 1 l 2 l 1 f in d mc bc xc

Flexible Inverted Pendulum (FIP) System 2 lh kt b 2 1 b 1 m 2 m 1 l 2 l 1 f in d mc bc xc

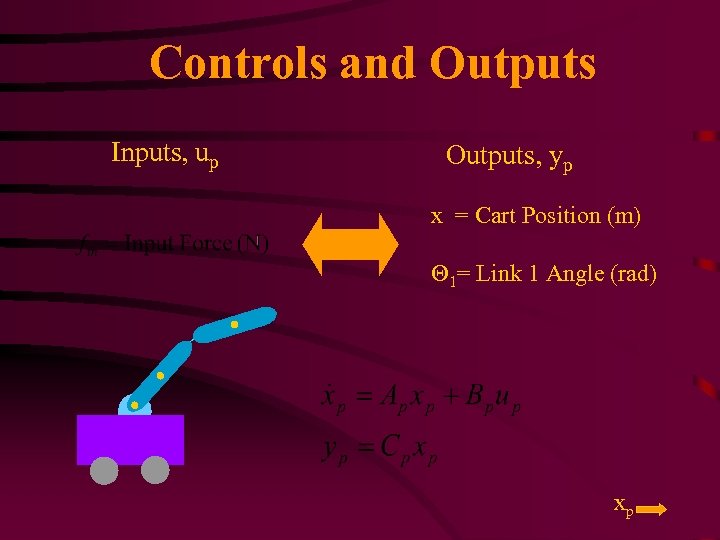

Controls and Outputs Inputs, up Outputs, yp x = Cart Position (m) 1= Link 1 Angle (rad) xp

Controls and Outputs Inputs, up Outputs, yp x = Cart Position (m) 1= Link 1 Angle (rad) xp

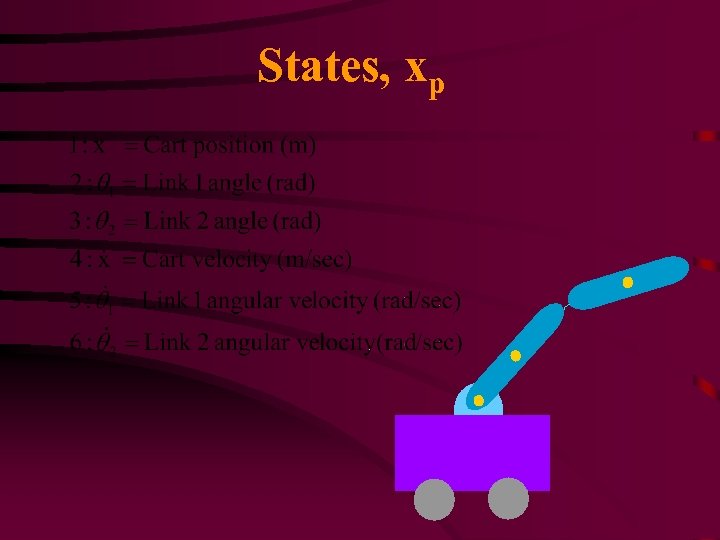

States, xp

States, xp

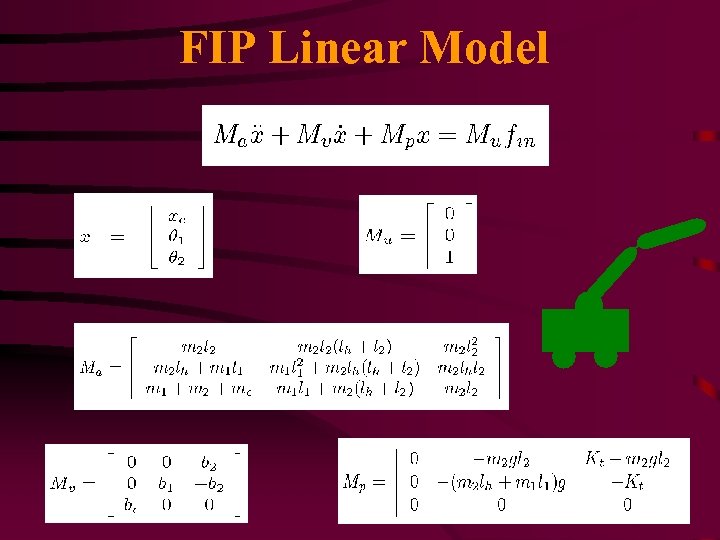

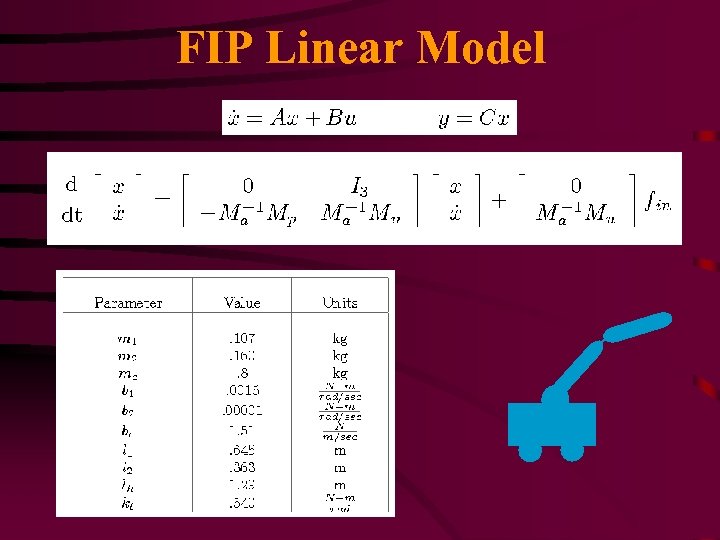

FIP Linear Model

FIP Linear Model

FIP Linear Model

FIP Linear Model

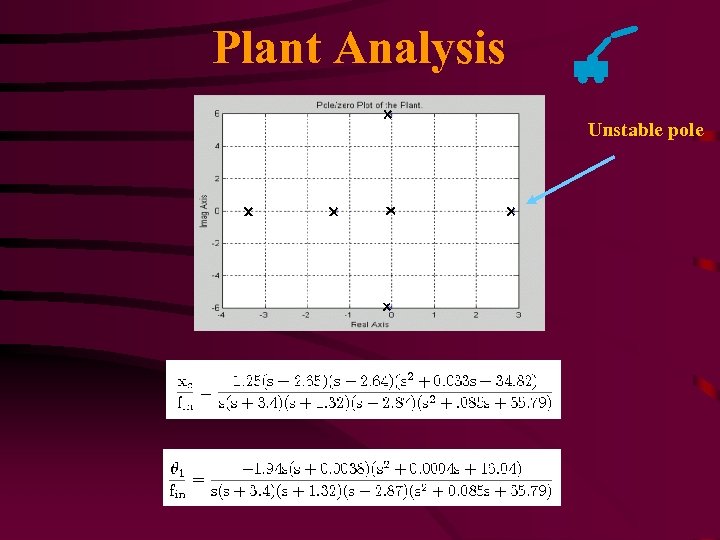

Plant Analysis Unstable pole

Plant Analysis Unstable pole

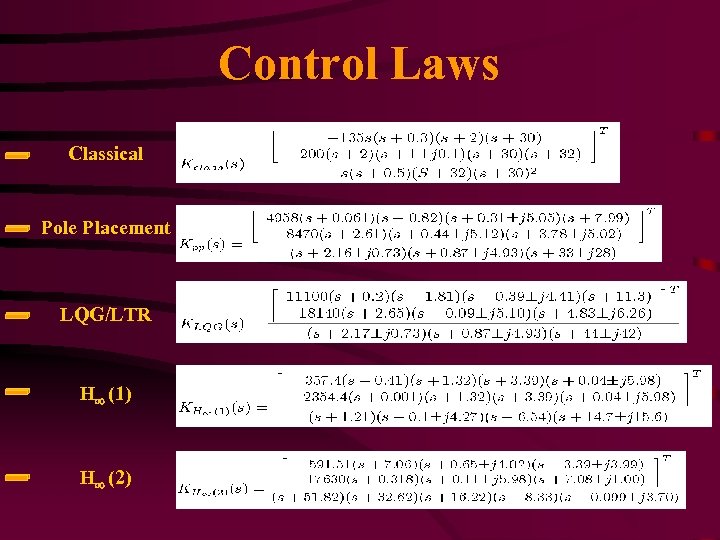

Control Laws Classical Pole Placement LQG/LTR H (1) H (2)

Control Laws Classical Pole Placement LQG/LTR H (1) H (2)

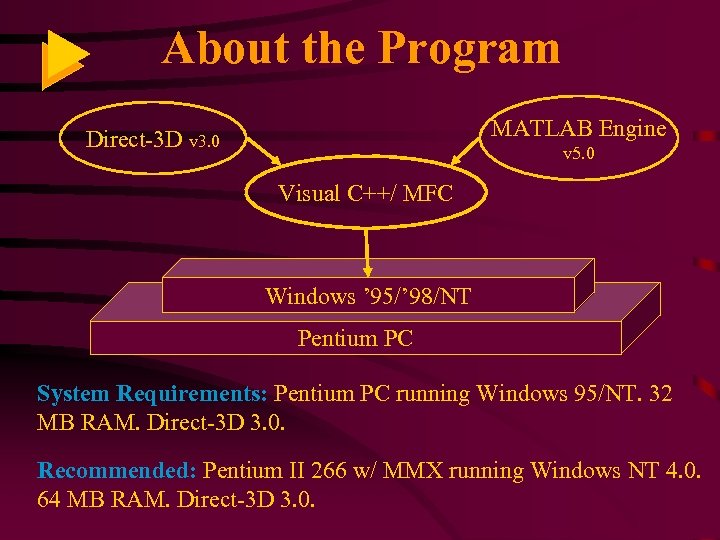

About the Program MATLAB Engine Direct-3 D v 3. 0 v 5. 0 Visual C++/ MFC Windows ’ 95/’ 98/NT Pentium PC System Requirements: Pentium PC running Windows 95/NT. 32 MB RAM. Direct-3 D 3. 0. Recommended: Pentium II 266 w/ MMX running Windows NT 4. 0. 64 MB RAM. Direct-3 D 3. 0.

About the Program MATLAB Engine Direct-3 D v 3. 0 v 5. 0 Visual C++/ MFC Windows ’ 95/’ 98/NT Pentium PC System Requirements: Pentium PC running Windows 95/NT. 32 MB RAM. Direct-3 D 3. 0. Recommended: Pentium II 266 w/ MMX running Windows NT 4. 0. 64 MB RAM. Direct-3 D 3. 0.

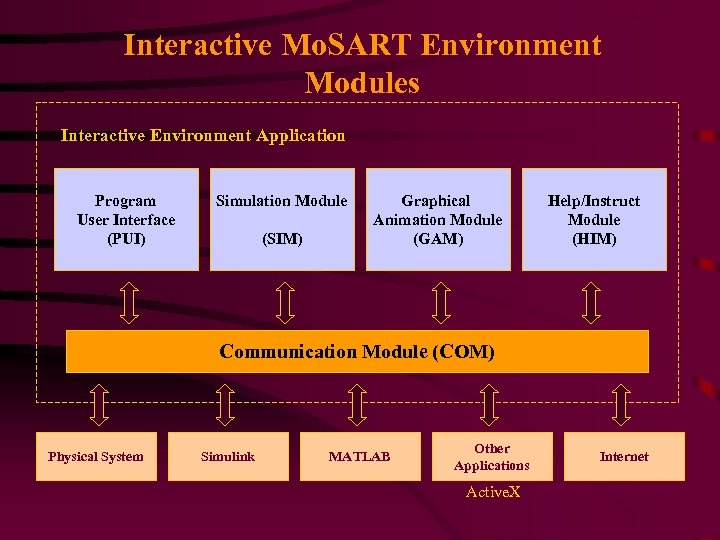

Interactive Mo. SART Environment Modules Interactive Environment Application Program User Interface (PUI) Simulation Module (SIM) Graphical Animation Module (GAM) Help/Instruct Module (HIM) Communication Module (COM) Physical System Simulink MATLAB Other Applications Active. X Internet

Interactive Mo. SART Environment Modules Interactive Environment Application Program User Interface (PUI) Simulation Module (SIM) Graphical Animation Module (GAM) Help/Instruct Module (HIM) Communication Module (COM) Physical System Simulink MATLAB Other Applications Active. X Internet

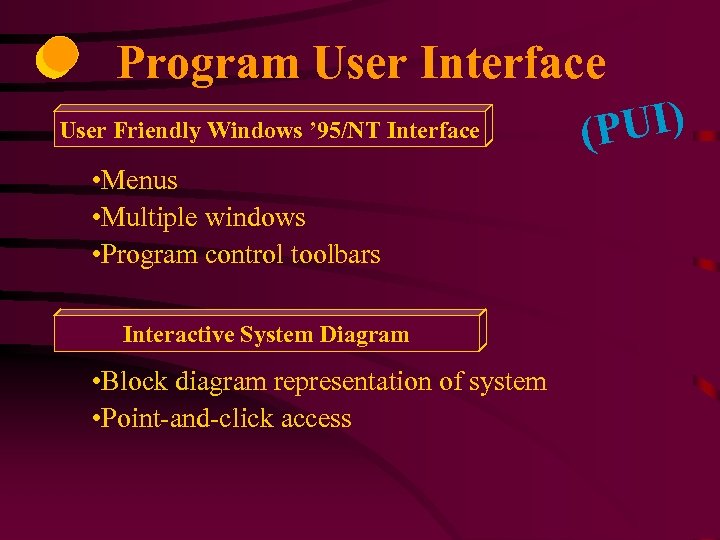

Program User Interface User Friendly Windows ’ 95/NT Interface • Menus • Multiple windows • Program control toolbars Interactive System Diagram • Block diagram representation of system • Point-and-click access UI) (P

Program User Interface User Friendly Windows ’ 95/NT Interface • Menus • Multiple windows • Program control toolbars Interactive System Diagram • Block diagram representation of system • Point-and-click access UI) (P

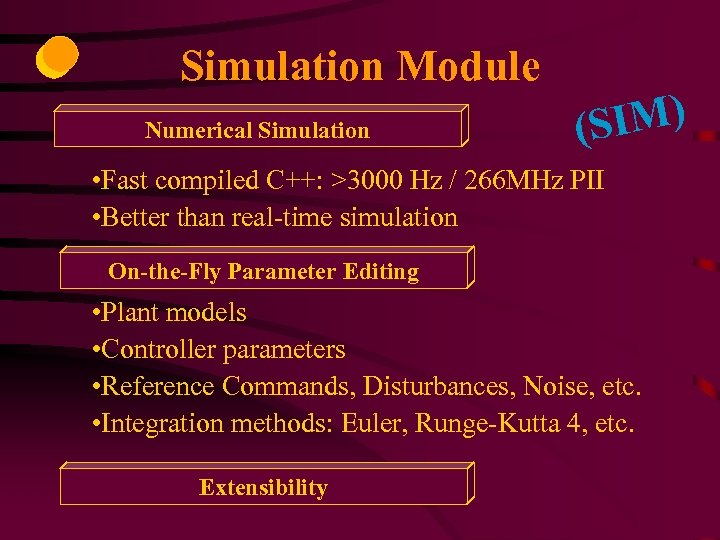

Simulation Module Numerical Simulation IM) (S • Fast compiled C++: >3000 Hz / 266 MHz PII • Better than real-time simulation On-the-Fly Parameter Editing • Plant models • Controller parameters • Reference Commands, Disturbances, Noise, etc. • Integration methods: Euler, Runge-Kutta 4, etc. Extensibility

Simulation Module Numerical Simulation IM) (S • Fast compiled C++: >3000 Hz / 266 MHz PII • Better than real-time simulation On-the-Fly Parameter Editing • Plant models • Controller parameters • Reference Commands, Disturbances, Noise, etc. • Integration methods: Euler, Runge-Kutta 4, etc. Extensibility

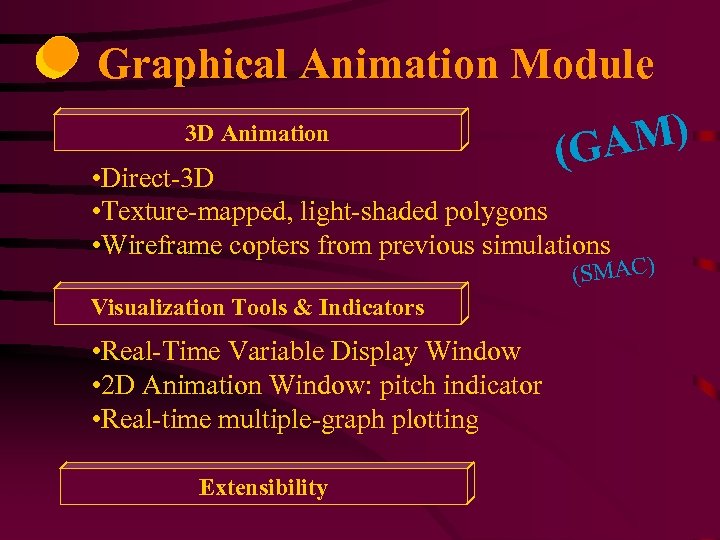

Graphical Animation Module 3 D Animation M) (GA • Direct-3 D • Texture-mapped, light-shaded polygons • Wireframe copters from previous simulations (SMAC) Visualization Tools & Indicators • Real-Time Variable Display Window • 2 D Animation Window: pitch indicator • Real-time multiple-graph plotting Extensibility

Graphical Animation Module 3 D Animation M) (GA • Direct-3 D • Texture-mapped, light-shaded polygons • Wireframe copters from previous simulations (SMAC) Visualization Tools & Indicators • Real-Time Variable Display Window • 2 D Animation Window: pitch indicator • Real-time multiple-graph plotting Extensibility

Help-Instruct Module On-line Help • Instructions on using the environment • Program reference HTML / PDF Documents • Model documentation/ references • Interactive tutorials IM) (H

Help-Instruct Module On-line Help • Instructions on using the environment • Program reference HTML / PDF Documents • Model documentation/ references • Interactive tutorials IM) (H

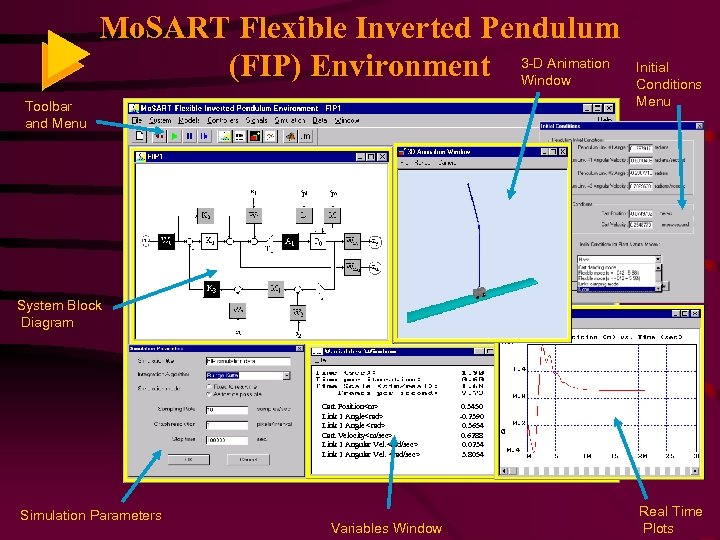

Mo. SART Flexible Inverted Pendulum (FIP) Environment 3 -D Animation Window Toolbar and Menu Initial Conditions Menu System Block Diagram Cart Position

Mo. SART Flexible Inverted Pendulum (FIP) Environment 3 -D Animation Window Toolbar and Menu Initial Conditions Menu System Block Diagram Cart Position

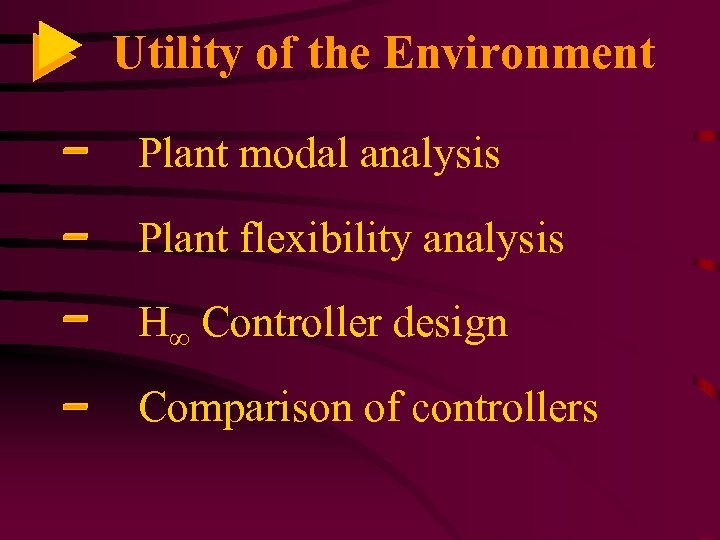

Utility of the Environment Plant modal analysis Plant flexibility analysis H Controller design Comparison of controllers

Utility of the Environment Plant modal analysis Plant flexibility analysis H Controller design Comparison of controllers

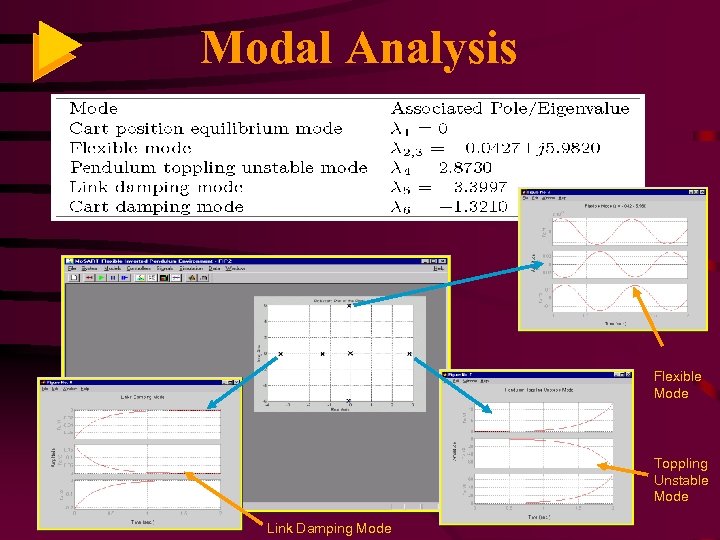

Modal Analysis Flexible Mode Toppling Unstable Mode Link Damping Mode

Modal Analysis Flexible Mode Toppling Unstable Mode Link Damping Mode

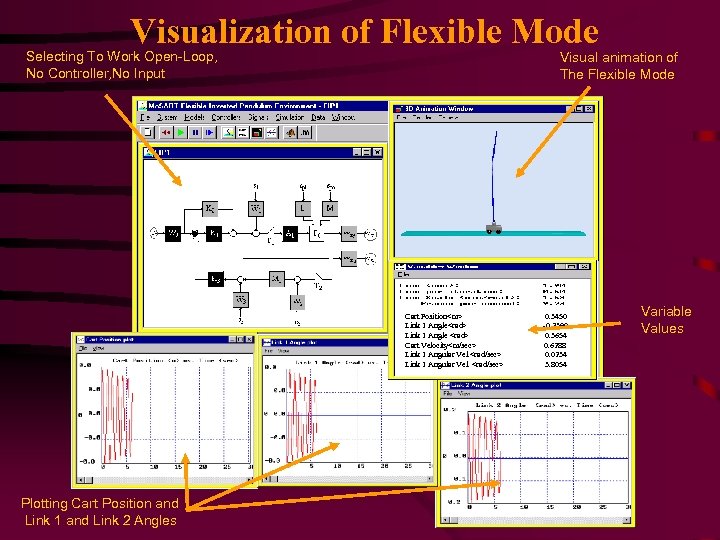

Visualization of Flexible Mode Selecting To Work Open-Loop, No Controller, No Input Visual animation of The Flexible Mode Cart Position

Visualization of Flexible Mode Selecting To Work Open-Loop, No Controller, No Input Visual animation of The Flexible Mode Cart Position

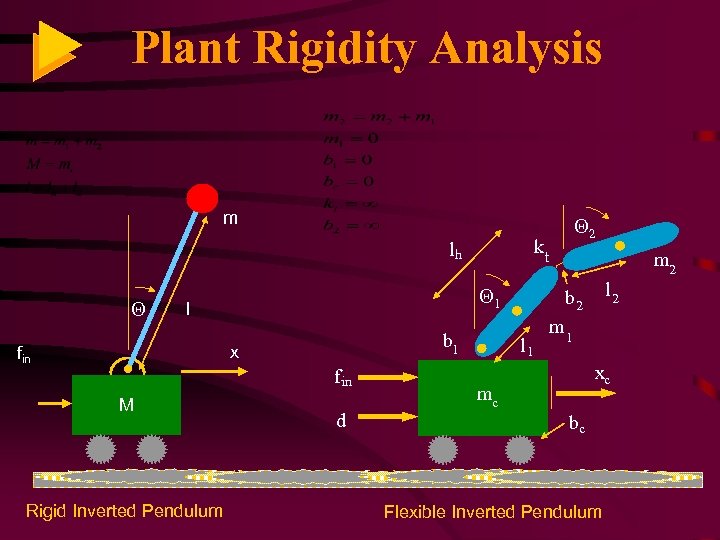

Plant Rigidity Analysis m kt lh 1 l b 1 x fin M Rigid Inverted Pendulum d 2 m 2 l 2 b 2 l 1 m 1 xc mc bc Flexible Inverted Pendulum

Plant Rigidity Analysis m kt lh 1 l b 1 x fin M Rigid Inverted Pendulum d 2 m 2 l 2 b 2 l 1 m 1 xc mc bc Flexible Inverted Pendulum

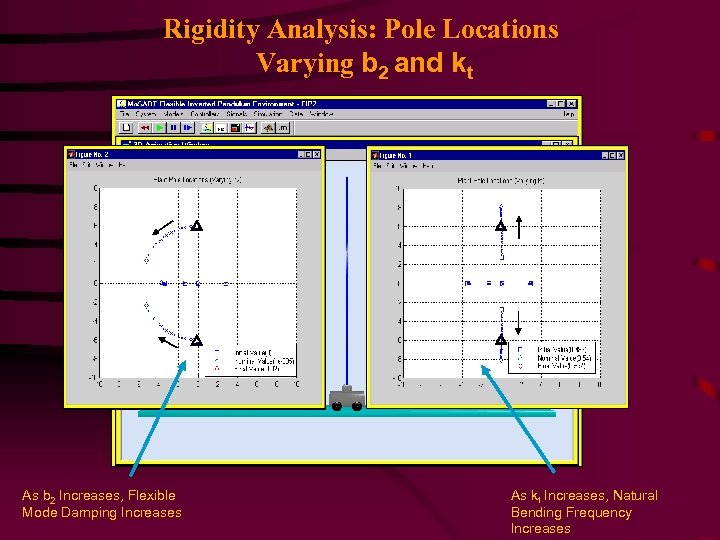

Rigidity Analysis: Pole Locations Varying b 2 and kt As b 2 Increases, Flexible Mode Damping Increases As kt Increases, Natural Bending Frequency Increases

Rigidity Analysis: Pole Locations Varying b 2 and kt As b 2 Increases, Flexible Mode Damping Increases As kt Increases, Natural Bending Frequency Increases

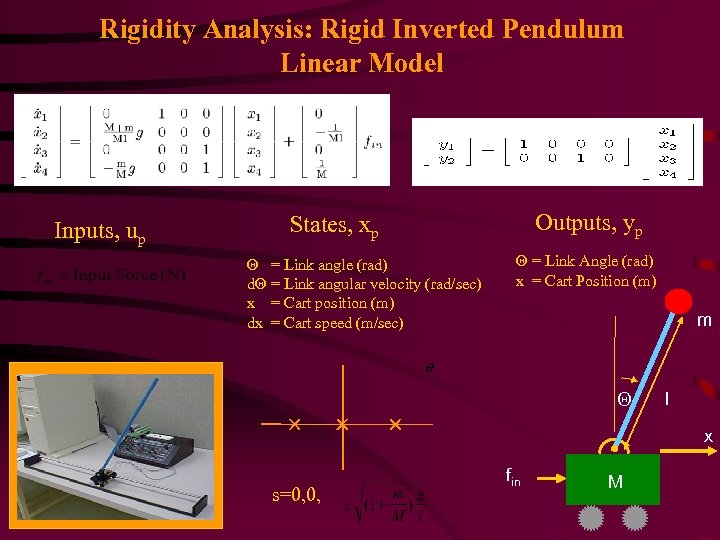

Rigidity Analysis: Rigid Inverted Pendulum Linear Model Inputs, up Outputs, yp States, xp = Link angle (rad) d = Link angular velocity (rad/sec) x = Cart position (m) dx = Cart speed (m/sec) = Link Angle (rad) x = Cart Position (m) m l x s=0, 0, fin M

Rigidity Analysis: Rigid Inverted Pendulum Linear Model Inputs, up Outputs, yp States, xp = Link angle (rad) d = Link angular velocity (rad/sec) x = Cart position (m) dx = Cart speed (m/sec) = Link Angle (rad) x = Cart Position (m) m l x s=0, 0, fin M

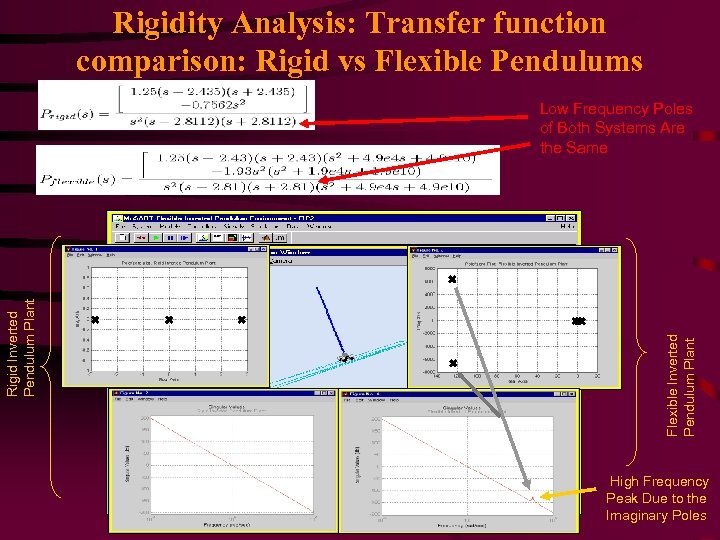

Rigidity Analysis: Transfer function comparison: Rigid vs Flexible Pendulums Flexible Inverted Pendulum Plant Rigid Inverted Pendulum Plant Low Frequency Poles of Both Systems Are the Same High Frequency Peak Due to the Imaginary Poles

Rigidity Analysis: Transfer function comparison: Rigid vs Flexible Pendulums Flexible Inverted Pendulum Plant Rigid Inverted Pendulum Plant Low Frequency Poles of Both Systems Are the Same High Frequency Peak Due to the Imaginary Poles

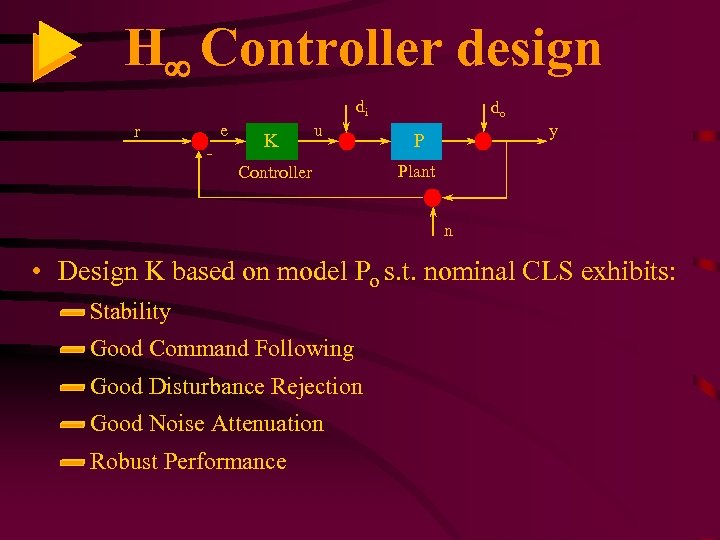

H Controller design di r e K u Controller do y P Plant n • Design K based on model Po s. t. nominal CLS exhibits: – Stability – Good Command Following – Good Disturbance Rejection – Good Noise Attenuation – Robust Performance

H Controller design di r e K u Controller do y P Plant n • Design K based on model Po s. t. nominal CLS exhibits: – Stability – Good Command Following – Good Disturbance Rejection – Good Noise Attenuation – Robust Performance

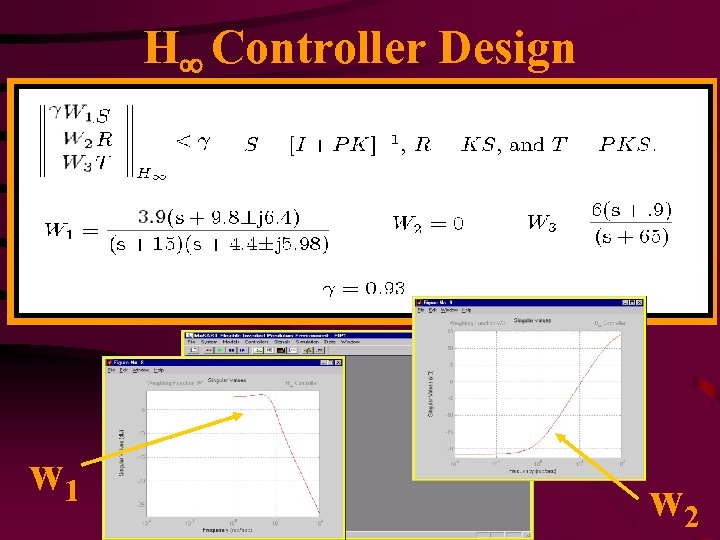

H Controller Design w 1 w 2

H Controller Design w 1 w 2

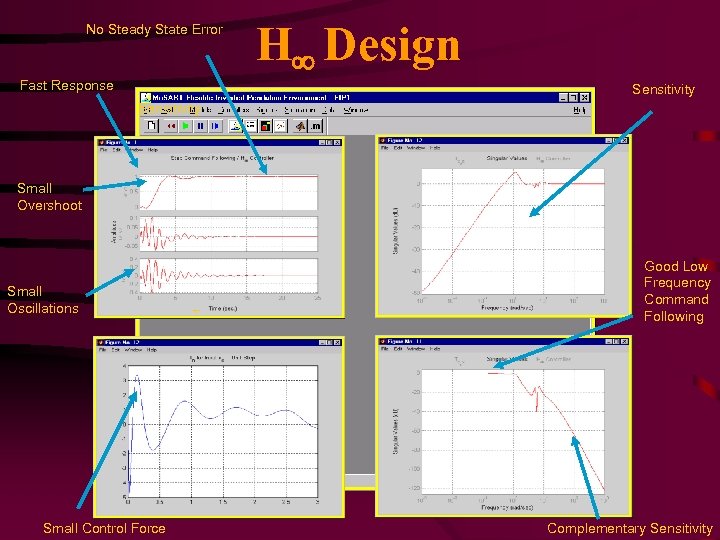

No Steady State Error Fast Response H Design Sensitivity Good Low Frequency Command Following 2 Small Oscillations 1 Small Overshoot Small Control Force Complementary Sensitivity

No Steady State Error Fast Response H Design Sensitivity Good Low Frequency Command Following 2 Small Oscillations 1 Small Overshoot Small Control Force Complementary Sensitivity

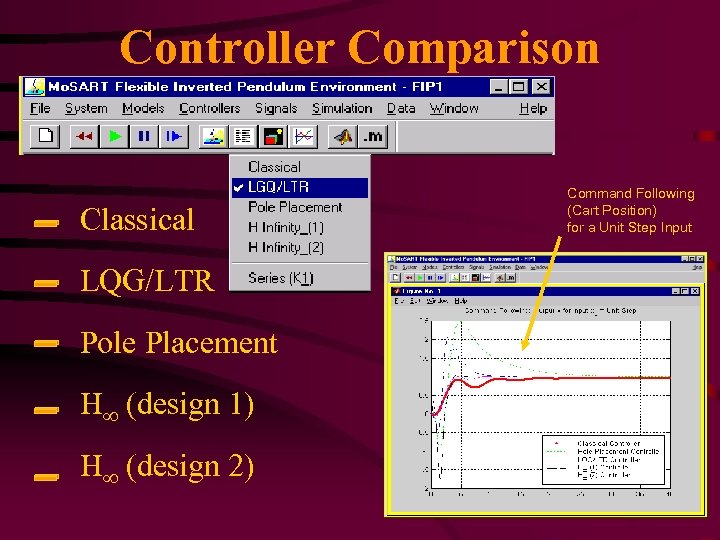

Controller Comparison Classical LQG/LTR Pole Placement H (design 1) H (design 2) Command Following (Cart Position) for a Unit Step Input

Controller Comparison Classical LQG/LTR Pole Placement H (design 1) H (design 2) Command Following (Cart Position) for a Unit Step Input

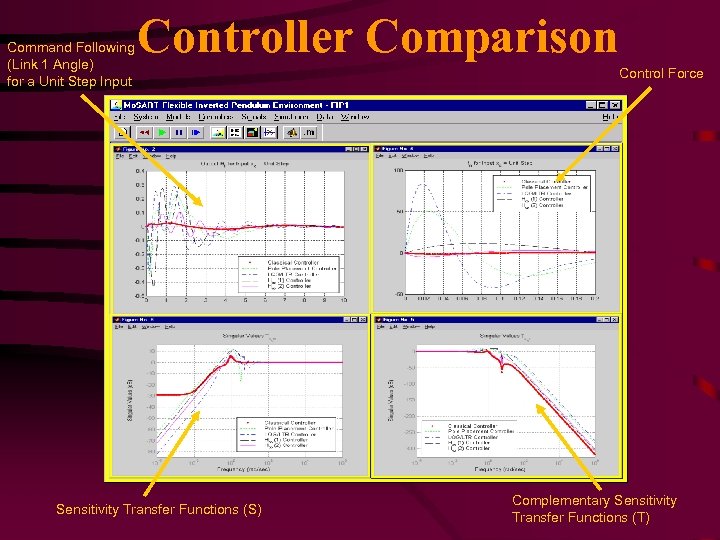

Command Following (Link 1 Angle) for a Unit Step Input Controller Comparison Sensitivity Transfer Functions (S) Control Force Complementary Sensitivity Transfer Functions (T)

Command Following (Link 1 Angle) for a Unit Step Input Controller Comparison Sensitivity Transfer Functions (S) Control Force Complementary Sensitivity Transfer Functions (T)

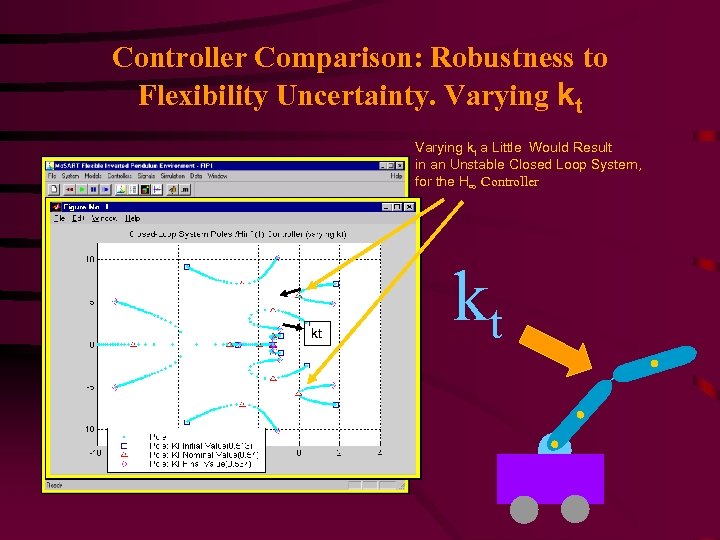

Controller Comparison: Robustness to Flexibility Uncertainty. Varying kt a Little Would Result in an Unstable Closed Loop System, for the H Controller kt kt

Controller Comparison: Robustness to Flexibility Uncertainty. Varying kt a Little Would Result in an Unstable Closed Loop System, for the H Controller kt kt

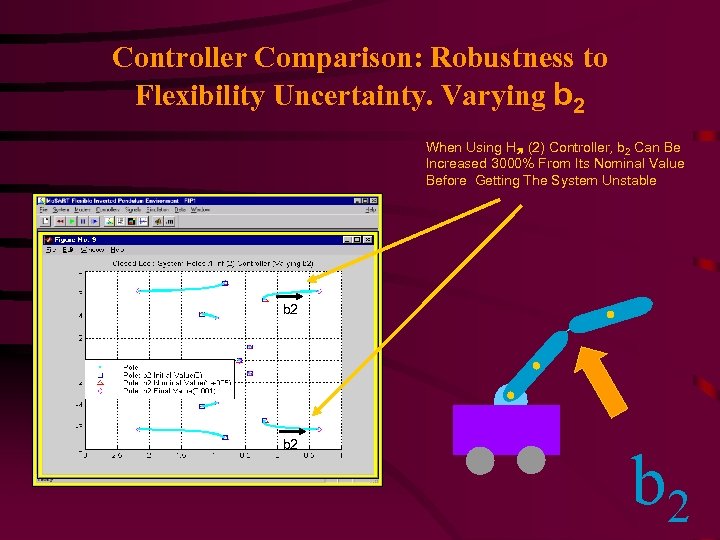

Controller Comparison: Robustness to Flexibility Uncertainty. Varying b 2 When Using H (2) Controller, b 2 Can Be Increased 3000% From Its Nominal Value Before Getting The System Unstable b 2 b 2

Controller Comparison: Robustness to Flexibility Uncertainty. Varying b 2 When Using H (2) Controller, b 2 Can Be Increased 3000% From Its Nominal Value Before Getting The System Unstable b 2 b 2

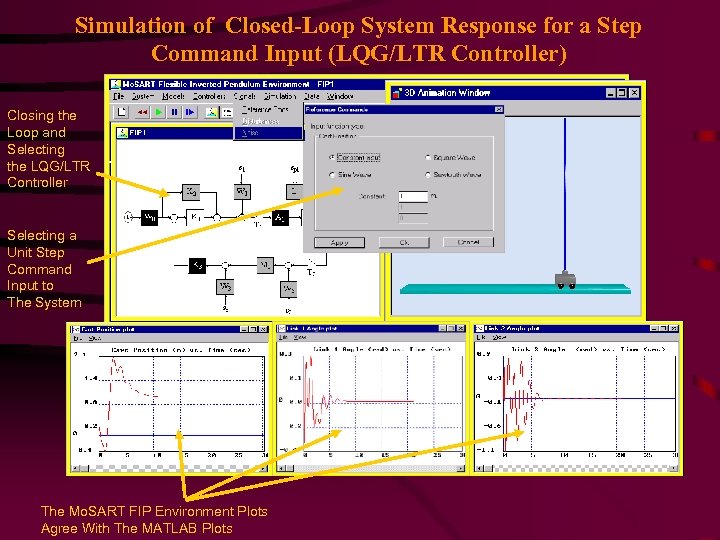

Simulation of Closed-Loop System Response for a Step Command Input (LQG/LTR Controller) Closing the Loop and Selecting the LQG/LTR Controller Selecting a Unit Step Command Input to The System The Mo. SART FIP Environment Plots Agree With The MATLAB Plots

Simulation of Closed-Loop System Response for a Step Command Input (LQG/LTR Controller) Closing the Loop and Selecting the LQG/LTR Controller Selecting a Unit Step Command Input to The System The Mo. SART FIP Environment Plots Agree With The MATLAB Plots

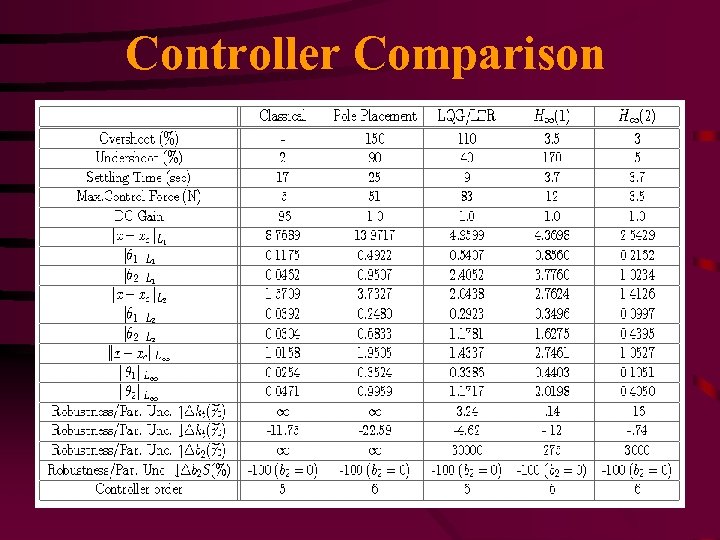

Controller Comparison

Controller Comparison

Summary • Versatile system-specific interactive Mo. SART environments • Windows / C++ / Direct-X / MATLAB • User friendly: accessible & intuitive • User can alter model structures & parameters (on-the-fly) • Highly extensible: ability to incorporate new simulation/animation models

Summary • Versatile system-specific interactive Mo. SART environments • Windows / C++ / Direct-X / MATLAB • User friendly: accessible & intuitive • User can alter model structures & parameters (on-the-fly) • Highly extensible: ability to incorporate new simulation/animation models

Future Directions -More visual indicators -Advanced SIM and GAM (e. g. TLHS) -Expanded HIM: web support, multimedia -Develop Model Documentation Feature -Enhanced integration with MATLAB / SIMULINK LABVIEW / Excel…. all are Active. X Compatible -Integrated design & analysis environment -Develop Additional Environments … development of VISIT: Facility http: //www. eas. asu. edu/~aar/research/mosart/Presentations/

Future Directions -More visual indicators -Advanced SIM and GAM (e. g. TLHS) -Expanded HIM: web support, multimedia -Develop Model Documentation Feature -Enhanced integration with MATLAB / SIMULINK LABVIEW / Excel…. all are Active. X Compatible -Integrated design & analysis environment -Develop Additional Environments … development of VISIT: Facility http: //www. eas. asu. edu/~aar/research/mosart/Presentations/