8c5740bdd20f0c6bcb99fd8fe0f29b46.ppt

- Количество слайдов: 23

Integration of Design & Control CHEN 4470 – Process Design Practice Dr. Mario Richard Eden Department of Chemical Engineering Auburn University Lecture No. 16 – Integration of Design and Control II March 7, 2013 Contains Material Developed by Dr. Daniel R. Lewin, Technion, Israel

Integration of Design & Control CHEN 4470 – Process Design Practice Dr. Mario Richard Eden Department of Chemical Engineering Auburn University Lecture No. 16 – Integration of Design and Control II March 7, 2013 Contains Material Developed by Dr. Daniel R. Lewin, Technion, Israel

Plantwide Control Design Luyben et al. (1999) suggest a method for the conceptual design of plant-wide control systems, which consists of the following steps: Step 1: Establish the control objectives. Step 2: Determine the control degrees of freedom. Simply stated – the number of control valves – with additions if necessary. Step 3: Establish the energy management system. Regulation of exothermic or endothermic reactors, and placement of controllers to attenuate temperature disturbances. Step 4: Set the production rate. Step 5: Control the product quality and handle safety, environmental, and operational constraints.

Plantwide Control Design Luyben et al. (1999) suggest a method for the conceptual design of plant-wide control systems, which consists of the following steps: Step 1: Establish the control objectives. Step 2: Determine the control degrees of freedom. Simply stated – the number of control valves – with additions if necessary. Step 3: Establish the energy management system. Regulation of exothermic or endothermic reactors, and placement of controllers to attenuate temperature disturbances. Step 4: Set the production rate. Step 5: Control the product quality and handle safety, environmental, and operational constraints.

Plantwide Control Design Step 6: Fix a flow rate in every recycle loop and control vapor and liquid inventories (vessel pressures and levels). Step 7: Check component balances. Establish control to prevent the accumulation of individual chemical species in the process. Step 8: Control the individual process units. Use remaining DOFs to improve local control, but only after resolving more important plant-wide issues. Step 9: Optimize economics and improve dynamic controllability. Add nice-to-have options with any remaining DOFs.

Plantwide Control Design Step 6: Fix a flow rate in every recycle loop and control vapor and liquid inventories (vessel pressures and levels). Step 7: Check component balances. Establish control to prevent the accumulation of individual chemical species in the process. Step 8: Control the individual process units. Use remaining DOFs to improve local control, but only after resolving more important plant-wide issues. Step 9: Optimize economics and improve dynamic controllability. Add nice-to-have options with any remaining DOFs.

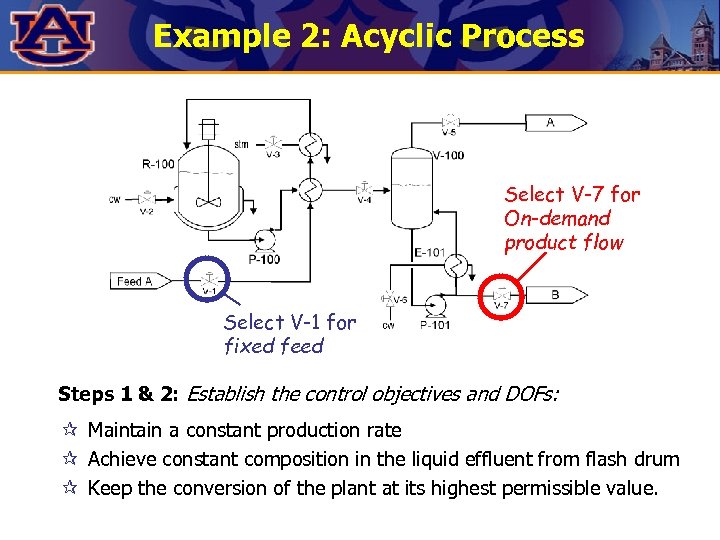

Example 2: Acyclic Process Select V-7 for On-demand product flow Select V-1 for fixed feed Steps 1 & 2: Establish the control objectives and DOFs: ¶ Maintain a constant production rate ¶ Achieve constant composition in the liquid effluent from flash drum ¶ Keep the conversion of the plant at its highest permissible value.

Example 2: Acyclic Process Select V-7 for On-demand product flow Select V-1 for fixed feed Steps 1 & 2: Establish the control objectives and DOFs: ¶ Maintain a constant production rate ¶ Achieve constant composition in the liquid effluent from flash drum ¶ Keep the conversion of the plant at its highest permissible value.

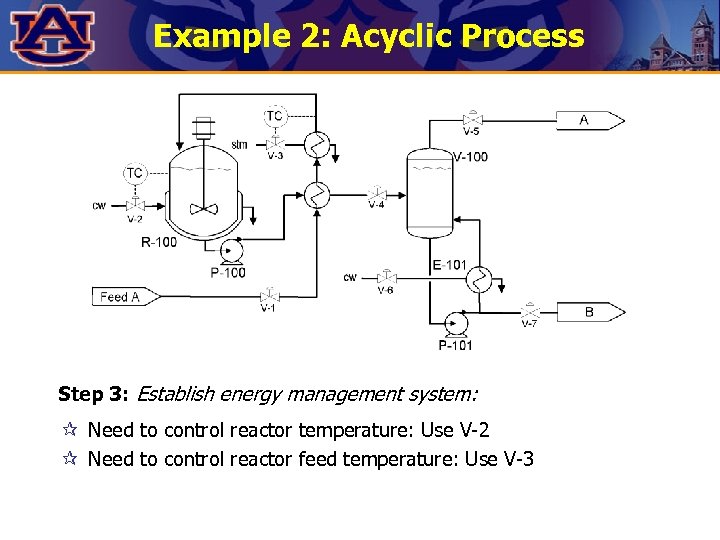

Example 2: Acyclic Process Step 3: Establish energy management system: ¶ Need to control reactor temperature: Use V-2 ¶ Need to control reactor feed temperature: Use V-3

Example 2: Acyclic Process Step 3: Establish energy management system: ¶ Need to control reactor temperature: Use V-2 ¶ Need to control reactor feed temperature: Use V-3

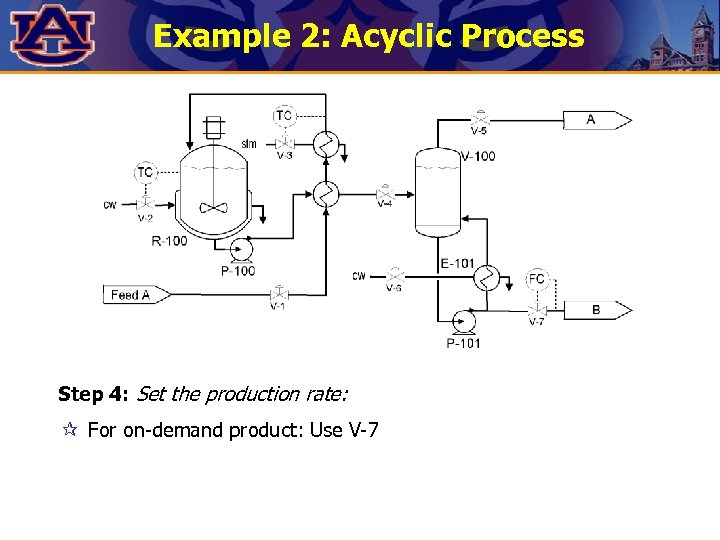

Example 2: Acyclic Process Step 4: Set the production rate: ¶ For on-demand product: Use V-7

Example 2: Acyclic Process Step 4: Set the production rate: ¶ For on-demand product: Use V-7

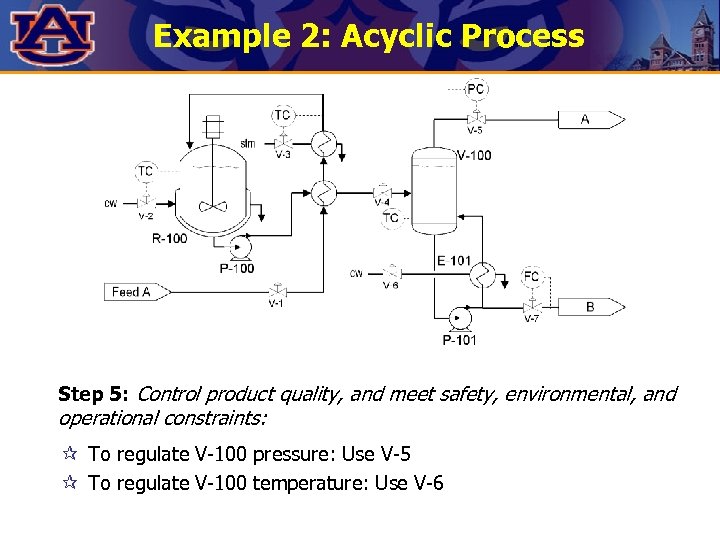

Example 2: Acyclic Process Step 5: Control product quality, and meet safety, environmental, and operational constraints: ¶ To regulate V-100 pressure: Use V-5 ¶ To regulate V-100 temperature: Use V-6

Example 2: Acyclic Process Step 5: Control product quality, and meet safety, environmental, and operational constraints: ¶ To regulate V-100 pressure: Use V-5 ¶ To regulate V-100 temperature: Use V-6

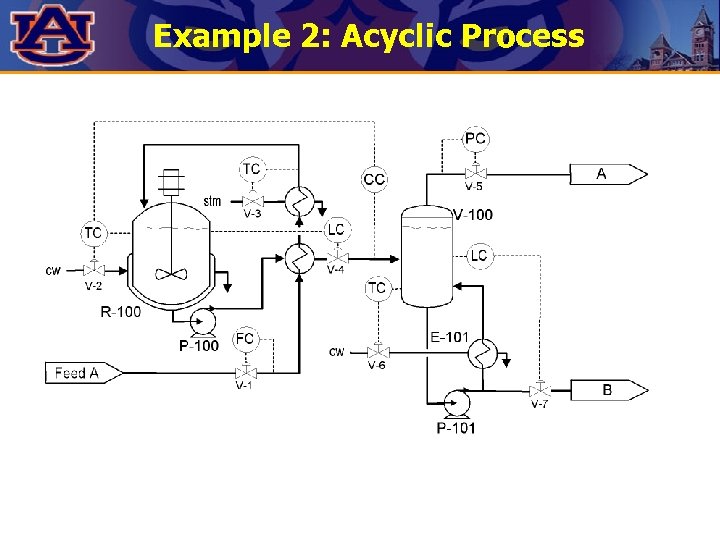

Example 2: Acyclic Process Step 6: Fix recycle flow rates and vapor and liquid inventories : ¶ Need to control vapor inventory in V-100: Use V-5 (already installed) ¶ Need to control liquid inventory in V-100: Use V-4 ¶ Need to control liquid inventory in R-100: Use V-1

Example 2: Acyclic Process Step 6: Fix recycle flow rates and vapor and liquid inventories : ¶ Need to control vapor inventory in V-100: Use V-5 (already installed) ¶ Need to control liquid inventory in V-100: Use V-4 ¶ Need to control liquid inventory in R-100: Use V-1

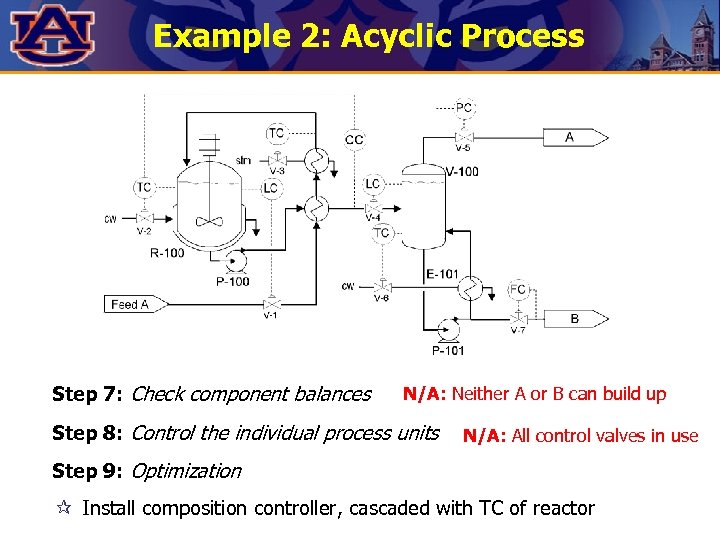

Example 2: Acyclic Process Step 7: Check component balances N/A: Neither A or B can build up Step 8: Control the individual process units N/A: All control valves in use Step 9: Optimization ¶ Install composition controller, cascaded with TC of reactor

Example 2: Acyclic Process Step 7: Check component balances N/A: Neither A or B can build up Step 8: Control the individual process units N/A: All control valves in use Step 9: Optimization ¶ Install composition controller, cascaded with TC of reactor

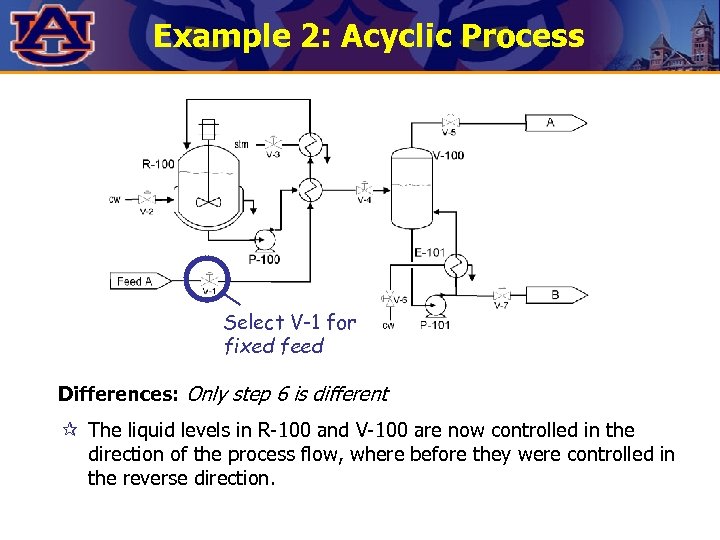

Example 2: Acyclic Process Select V-1 for fixed feed Differences: Only step 6 is different ¶ The liquid levels in R-100 and V-100 are now controlled in the direction of the process flow, where before they were controlled in the reverse direction.

Example 2: Acyclic Process Select V-1 for fixed feed Differences: Only step 6 is different ¶ The liquid levels in R-100 and V-100 are now controlled in the direction of the process flow, where before they were controlled in the reverse direction.

Example 2: Acyclic Process

Example 2: Acyclic Process

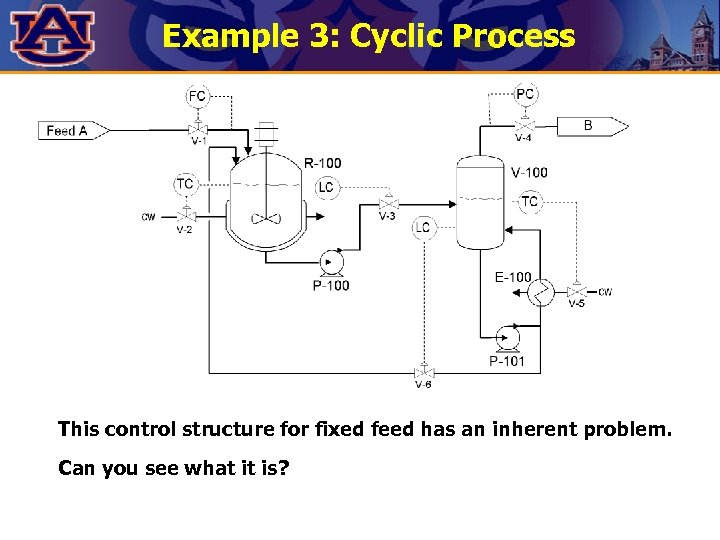

Example 3: Cyclic Process This control structure for fixed feed has an inherent problem. Can you see what it is?

Example 3: Cyclic Process This control structure for fixed feed has an inherent problem. Can you see what it is?

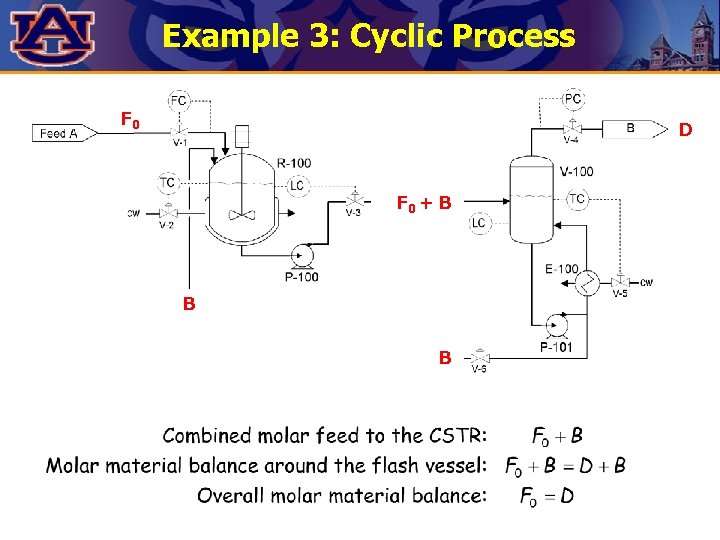

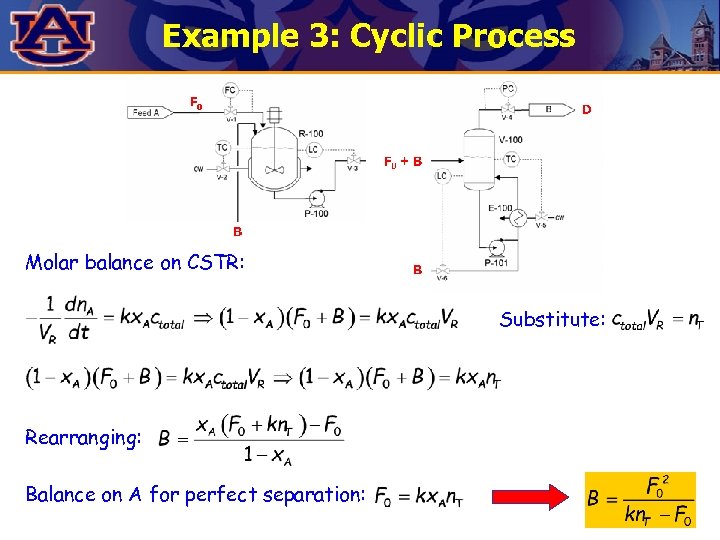

Example 3: Cyclic Process F 0 D F 0 + B B B

Example 3: Cyclic Process F 0 D F 0 + B B B

Example 3: Cyclic Process Molar balance on CSTR: Substitute: Rearranging: Balance on A for perfect separation:

Example 3: Cyclic Process Molar balance on CSTR: Substitute: Rearranging: Balance on A for perfect separation:

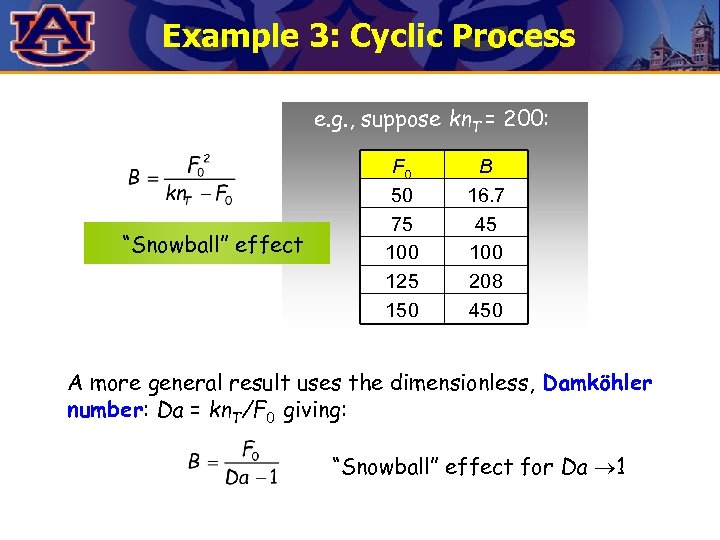

Example 3: Cyclic Process e. g. , suppose kn. T = 200: “Snowball” effect F 0 50 75 100 125 150 B 16. 7 45 100 208 450 A more general result uses the dimensionless, Damköhler number: Da = kn. T/F 0 giving: “Snowball” effect for Da 1

Example 3: Cyclic Process e. g. , suppose kn. T = 200: “Snowball” effect F 0 50 75 100 125 150 B 16. 7 45 100 208 450 A more general result uses the dimensionless, Damköhler number: Da = kn. T/F 0 giving: “Snowball” effect for Da 1

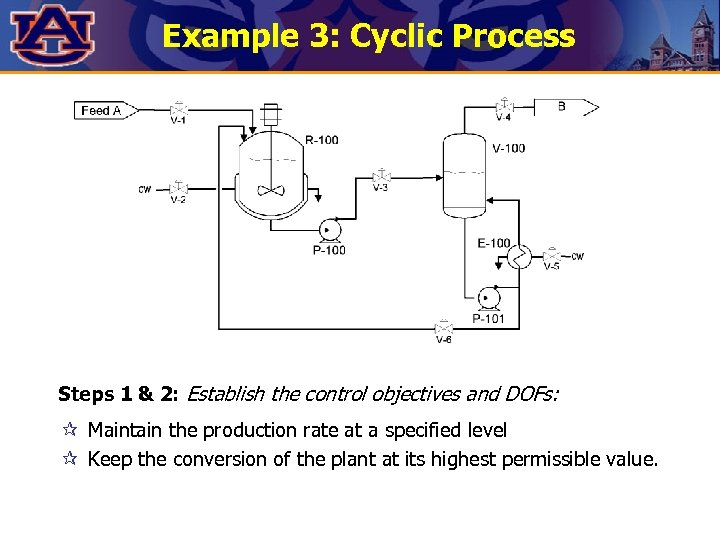

Example 3: Cyclic Process Steps 1 & 2: Establish the control objectives and DOFs: ¶ Maintain the production rate at a specified level ¶ Keep the conversion of the plant at its highest permissible value.

Example 3: Cyclic Process Steps 1 & 2: Establish the control objectives and DOFs: ¶ Maintain the production rate at a specified level ¶ Keep the conversion of the plant at its highest permissible value.

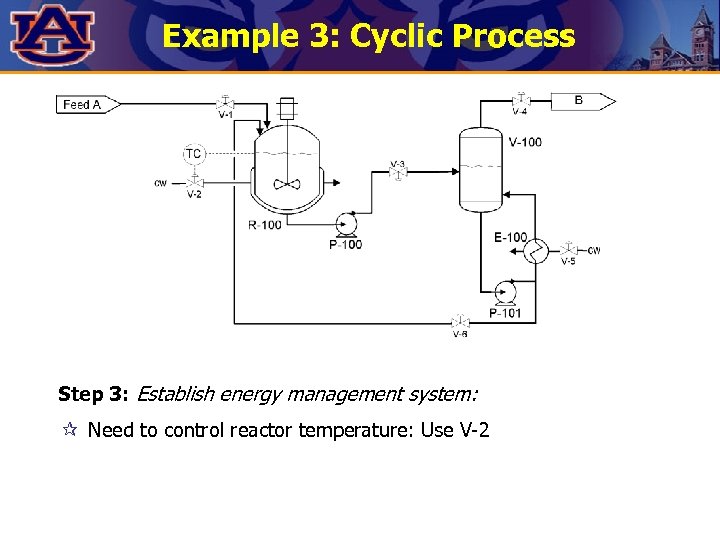

Example 3: Cyclic Process Step 3: Establish energy management system: ¶ Need to control reactor temperature: Use V-2

Example 3: Cyclic Process Step 3: Establish energy management system: ¶ Need to control reactor temperature: Use V-2

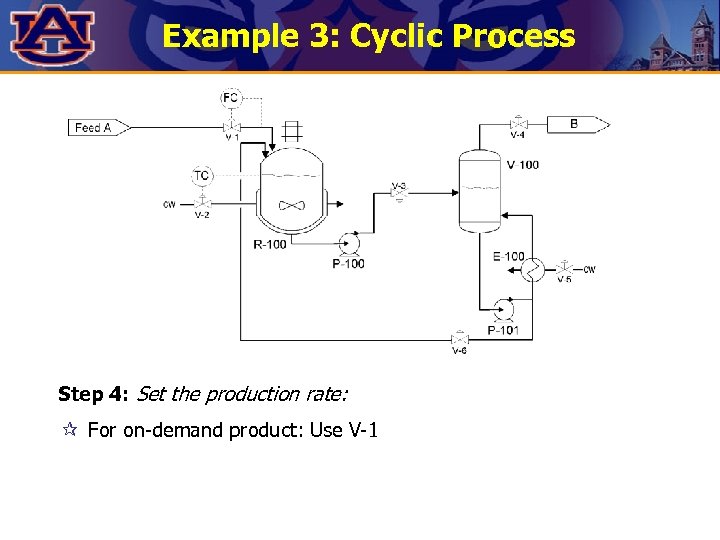

Example 3: Cyclic Process Step 4: Set the production rate: ¶ For on-demand product: Use V-1

Example 3: Cyclic Process Step 4: Set the production rate: ¶ For on-demand product: Use V-1

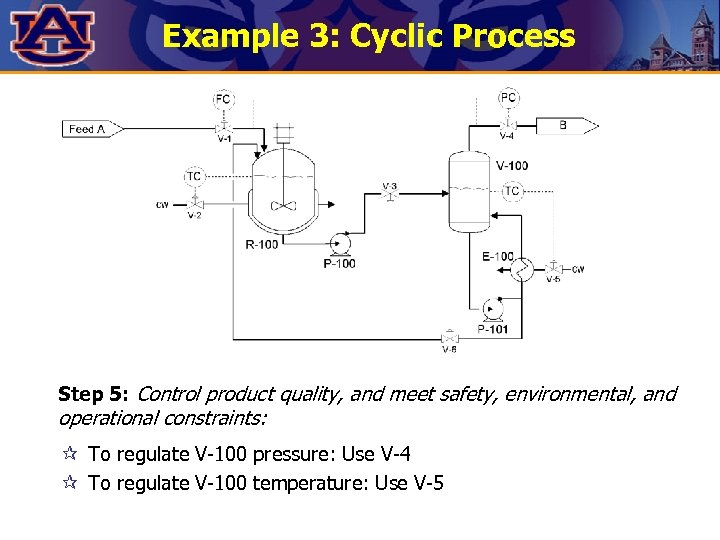

Example 3: Cyclic Process Step 5: Control product quality, and meet safety, environmental, and operational constraints: ¶ To regulate V-100 pressure: Use V-4 ¶ To regulate V-100 temperature: Use V-5

Example 3: Cyclic Process Step 5: Control product quality, and meet safety, environmental, and operational constraints: ¶ To regulate V-100 pressure: Use V-4 ¶ To regulate V-100 temperature: Use V-5

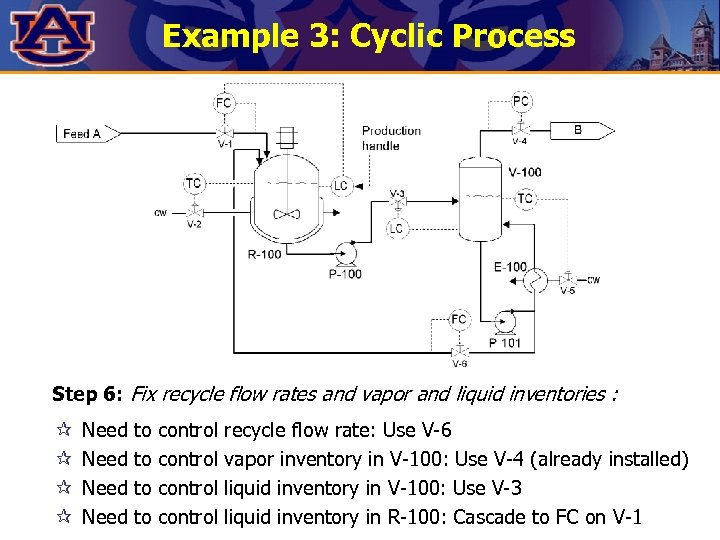

Example 3: Cyclic Process Step 6: Fix recycle flow rates and vapor and liquid inventories : ¶ ¶ Need to to control recycle flow rate: Use V-6 vapor inventory in V-100: Use V-4 (already installed) liquid inventory in V-100: Use V-3 liquid inventory in R-100: Cascade to FC on V-1

Example 3: Cyclic Process Step 6: Fix recycle flow rates and vapor and liquid inventories : ¶ ¶ Need to to control recycle flow rate: Use V-6 vapor inventory in V-100: Use V-4 (already installed) liquid inventory in V-100: Use V-3 liquid inventory in R-100: Cascade to FC on V-1

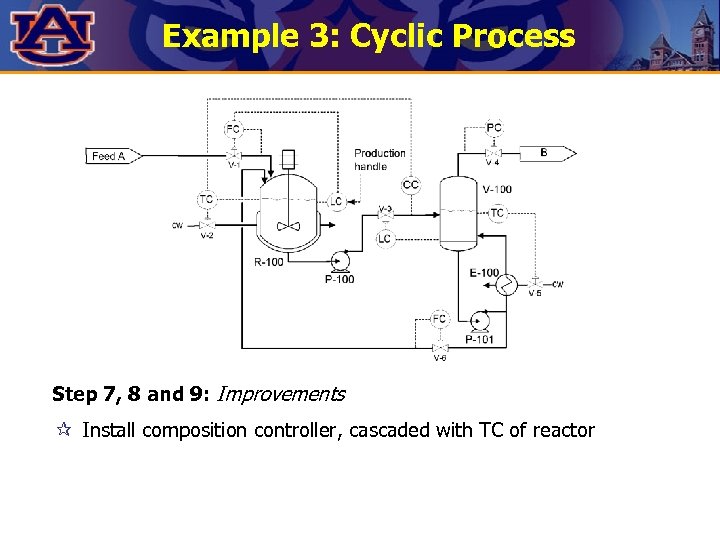

Example 3: Cyclic Process Step 7, 8 and 9: Improvements ¶ Install composition controller, cascaded with TC of reactor

Example 3: Cyclic Process Step 7, 8 and 9: Improvements ¶ Install composition controller, cascaded with TC of reactor

Summary Part I: Previous Lecture Provided motivation for handling flowsheet controllability and resiliency as an integral part of the design process Outlined qualitative approach for unit by unit control structure selection Part II – This Lecture Outlined a qualitative approach for plantwide control structure selection

Summary Part I: Previous Lecture Provided motivation for handling flowsheet controllability and resiliency as an integral part of the design process Outlined qualitative approach for unit by unit control structure selection Part II – This Lecture Outlined a qualitative approach for plantwide control structure selection

Other Business • Next Lecture – March 19 – • Equipment sizing and pinch analysis Q&A Session with Consultant – March 21 – – Bob Kline will participate via videoconference Questions can be sent to Bob and/or me ahead of time

Other Business • Next Lecture – March 19 – • Equipment sizing and pinch analysis Q&A Session with Consultant – March 21 – – Bob Kline will participate via videoconference Questions can be sent to Bob and/or me ahead of time