b2db1957a8f2ce2904f8e43fa1fd5a6a.ppt

- Количество слайдов: 43

Integrating Management Systems across Life-Cycle and Functional Areas: DOE Savannah River Site Salt Waste Processing Facility Presenter: Dr. Tom Helms, Parsons Sponsors James Mc. Cullough, DOE-SR Federal Project Director David Amerine, Parsons Senior VP and Project Manager Jack Kasper, Parsons VP and Design/Build Manager

Integrating Management Systems across Life-Cycle and Functional Areas: DOE Savannah River Site Salt Waste Processing Facility Presenter: Dr. Tom Helms, Parsons Sponsors James Mc. Cullough, DOE-SR Federal Project Director David Amerine, Parsons Senior VP and Project Manager Jack Kasper, Parsons VP and Design/Build Manager

Introduction n Salt Waste Processing Facility (SWPF) is a DOE Capital Acquisition Project Presently in Final Design/Limited Construction Life Cycle Phase Approved Documented ISMS (Phase I) for Design and Construction

Introduction n Salt Waste Processing Facility (SWPF) is a DOE Capital Acquisition Project Presently in Final Design/Limited Construction Life Cycle Phase Approved Documented ISMS (Phase I) for Design and Construction

Purpose n n n Describe the importance and central elements of ISMS in the Design Phase for a DOE nonreactor nuclear facility Describe the interactions between Scope refinement, hazard analysis, hazard control selection and feedback mechanisms Discuss Lessons Learned and Recommendations for Improvement

Purpose n n n Describe the importance and central elements of ISMS in the Design Phase for a DOE nonreactor nuclear facility Describe the interactions between Scope refinement, hazard analysis, hazard control selection and feedback mechanisms Discuss Lessons Learned and Recommendations for Improvement

Background: SWPF Mission n n Decontaminate ~38 million gallons of Salt Waste stored in SRS H and F Tank Farms Salt Waste composed largely of fission products mixed with concentrated caustic (Na. OH) + nitrate

Background: SWPF Mission n n Decontaminate ~38 million gallons of Salt Waste stored in SRS H and F Tank Farms Salt Waste composed largely of fission products mixed with concentrated caustic (Na. OH) + nitrate

Background: Regulatory Drivers n n Federal Facility Agreement Negotiated Pursuant to CERCLA Site Treatment Plan Developed Pursuant to the Federal Facility Compliance Act

Background: Regulatory Drivers n n Federal Facility Agreement Negotiated Pursuant to CERCLA Site Treatment Plan Developed Pursuant to the Federal Facility Compliance Act

Background: Salt Waste Disposition n Concentrate will be immobilized in glass/stainless steel • Interim Storage: Glass Waste Storage Facility • Final disposition: Geologic Repository n Decontaminated salt waste will be immobilized in grout • Final disposition: SRS Saltstone Disposal Facility

Background: Salt Waste Disposition n Concentrate will be immobilized in glass/stainless steel • Interim Storage: Glass Waste Storage Facility • Final disposition: Geologic Repository n Decontaminated salt waste will be immobilized in grout • Final disposition: SRS Saltstone Disposal Facility

Background: Technological Challenge n n n Reduce volume of caustic waste requiring vitrification Technological Challenge – separate 137 Cs+1 ions from a solution dominated by Na+1 ions The 2 monovalent species “want” to go to the same places chemically speaking: what removes Cs+1 will tend also to remove Na+1

Background: Technological Challenge n n n Reduce volume of caustic waste requiring vitrification Technological Challenge – separate 137 Cs+1 ions from a solution dominated by Na+1 ions The 2 monovalent species “want” to go to the same places chemically speaking: what removes Cs+1 will tend also to remove Na+1

Background: Basic Processes n 137 Cs removal with Caustic Side Solvent Extraction (CSSX) n n n Solvent contains BOBCalix. C 6: High affinity for Cs over both Na and K BOBCalix. C 6 is a crown ether developed at ORNL Dissolved an Isopar® solution (~ refined kerosene) n 90 Sr + actinides removed with an adsorbent – filtration process n n Adsorbent – Monosodium Titanate (MST) 0. 1 micron crossflow filter

Background: Basic Processes n 137 Cs removal with Caustic Side Solvent Extraction (CSSX) n n n Solvent contains BOBCalix. C 6: High affinity for Cs over both Na and K BOBCalix. C 6 is a crown ether developed at ORNL Dissolved an Isopar® solution (~ refined kerosene) n 90 Sr + actinides removed with an adsorbent – filtration process n n Adsorbent – Monosodium Titanate (MST) 0. 1 micron crossflow filter

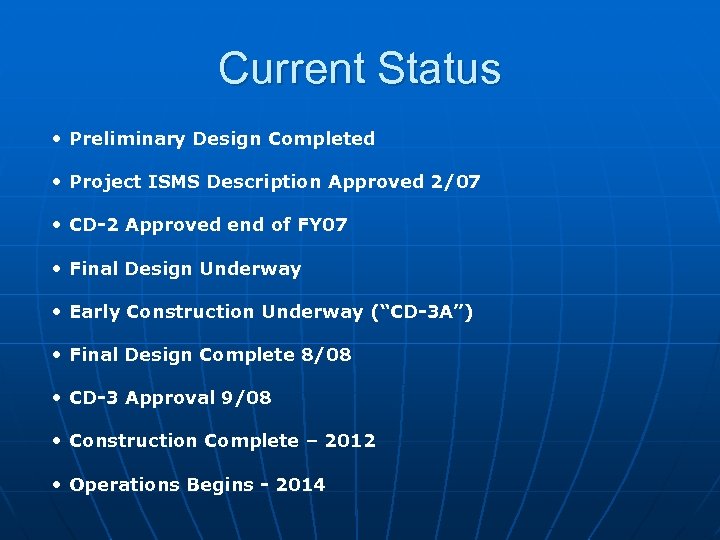

Current Status • Preliminary Design Completed • Project ISMS Description Approved 2/07 • CD-2 Approved end of FY 07 • Final Design Underway • Early Construction Underway (“CD-3 A”) • Final Design Complete 8/08 • CD-3 Approval 9/08 • Construction Complete – 2012 • Operations Begins - 2014

Current Status • Preliminary Design Completed • Project ISMS Description Approved 2/07 • CD-2 Approved end of FY 07 • Final Design Underway • Early Construction Underway (“CD-3 A”) • Final Design Complete 8/08 • CD-3 Approval 9/08 • Construction Complete – 2012 • Operations Begins - 2014

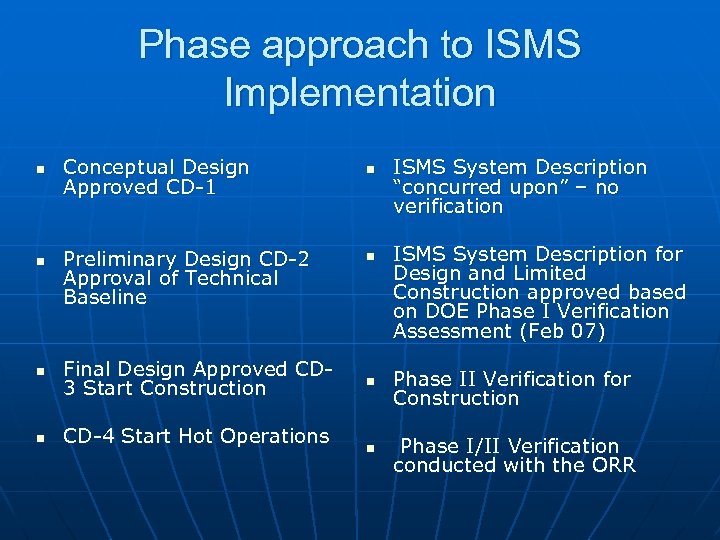

Phase approach to ISMS Implementation n n Conceptual Design Approved CD-1 Preliminary Design CD-2 Approval of Technical Baseline n Final Design Approved CD 3 Start Construction n CD-4 Start Hot Operations n n ISMS System Description “concurred upon” – no verification ISMS System Description for Design and Limited Construction approved based on DOE Phase I Verification Assessment (Feb 07) n Phase II Verification for Construction n Phase I/II Verification conducted with the ORR

Phase approach to ISMS Implementation n n Conceptual Design Approved CD-1 Preliminary Design CD-2 Approval of Technical Baseline n Final Design Approved CD 3 Start Construction n CD-4 Start Hot Operations n n ISMS System Description “concurred upon” – no verification ISMS System Description for Design and Limited Construction approved based on DOE Phase I Verification Assessment (Feb 07) n Phase II Verification for Construction n Phase I/II Verification conducted with the ORR

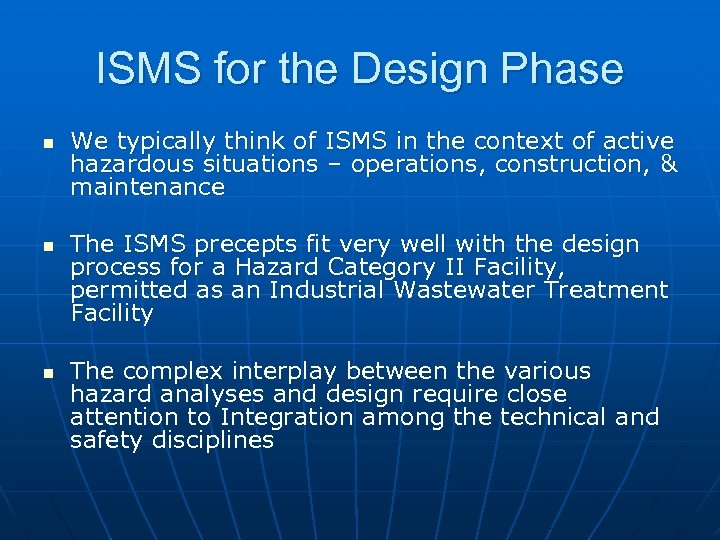

ISMS for the Design Phase n n n We typically think of ISMS in the context of active hazardous situations – operations, construction, & maintenance The ISMS precepts fit very well with the design process for a Hazard Category II Facility, permitted as an Industrial Wastewater Treatment Facility The complex interplay between the various hazard analyses and design require close attention to Integration among the technical and safety disciplines

ISMS for the Design Phase n n n We typically think of ISMS in the context of active hazardous situations – operations, construction, & maintenance The ISMS precepts fit very well with the design process for a Hazard Category II Facility, permitted as an Industrial Wastewater Treatment Facility The complex interplay between the various hazard analyses and design require close attention to Integration among the technical and safety disciplines

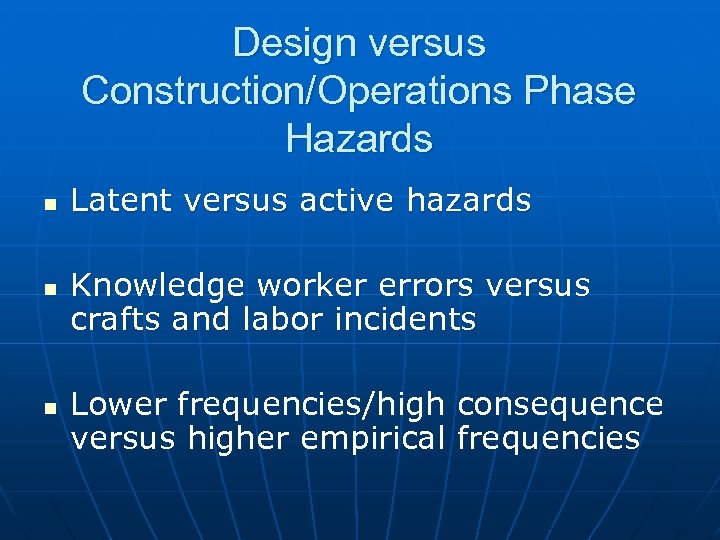

Design versus Construction/Operations Phase Hazards n n n Latent versus active hazards Knowledge worker errors versus crafts and labor incidents Lower frequencies/high consequence versus higher empirical frequencies

Design versus Construction/Operations Phase Hazards n n n Latent versus active hazards Knowledge worker errors versus crafts and labor incidents Lower frequencies/high consequence versus higher empirical frequencies

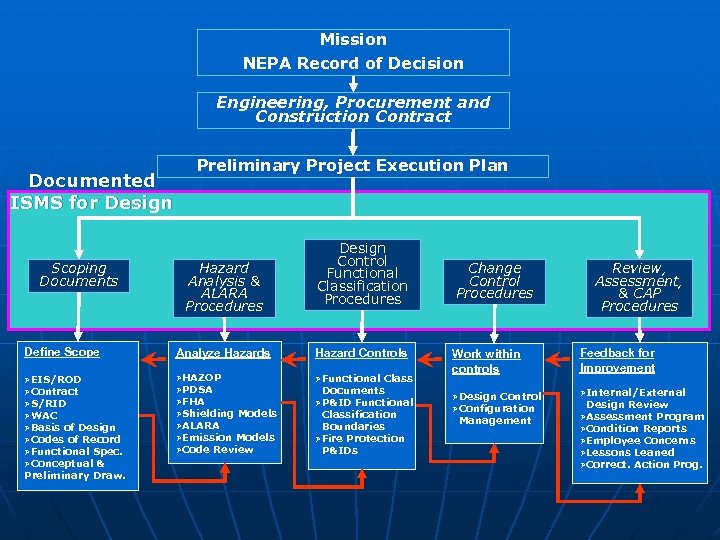

Mission NEPA Record of Decision Engineering, Procurement and Construction Contract Documented ISMS for Design Scoping Documents Preliminary Project Execution Plan Hazard Analysis & ALARA Procedures Design Control Functional Classification Procedures Define Scope Analyze Hazards Hazard Controls ØEIS/ROD ØContract ØS/RID ØWAC ØBasis of Design ØCodes of Record ØFunctional Spec. ØConceptual & ØHAZOP ØPDSA ØFHA ØShielding Models ØALARA ØEmission Models ØCode Review ØFunctional Preliminary Draw. Class Documents ØP&ID Functional Classification Boundaries ØFire Protection P&IDs Change Control Procedures Review, Assessment, & CAP Procedures Work within controls Feedback for Improvement ØDesign Control ØConfiguration ØInternal/External Management Design Review ØAssessment Program ØCondition Reports ØEmployee Concerns ØLessons Leaned ØCorrect. Action Prog.

Mission NEPA Record of Decision Engineering, Procurement and Construction Contract Documented ISMS for Design Scoping Documents Preliminary Project Execution Plan Hazard Analysis & ALARA Procedures Design Control Functional Classification Procedures Define Scope Analyze Hazards Hazard Controls ØEIS/ROD ØContract ØS/RID ØWAC ØBasis of Design ØCodes of Record ØFunctional Spec. ØConceptual & ØHAZOP ØPDSA ØFHA ØShielding Models ØALARA ØEmission Models ØCode Review ØFunctional Preliminary Draw. Class Documents ØP&ID Functional Classification Boundaries ØFire Protection P&IDs Change Control Procedures Review, Assessment, & CAP Procedures Work within controls Feedback for Improvement ØDesign Control ØConfiguration ØInternal/External Management Design Review ØAssessment Program ØCondition Reports ØEmployee Concerns ØLessons Leaned ØCorrect. Action Prog.

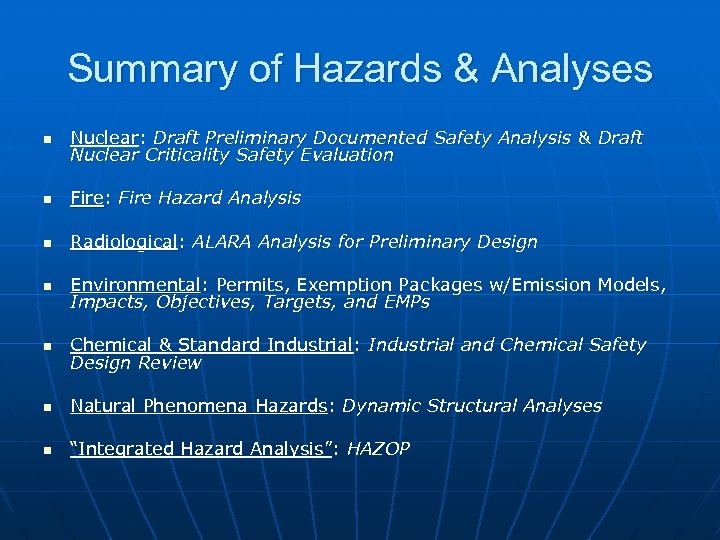

Summary of Hazards & Analyses n Nuclear: Draft Preliminary Documented Safety Analysis & Draft Nuclear Criticality Safety Evaluation n Fire: Fire Hazard Analysis n Radiological: ALARA Analysis for Preliminary Design n Environmental: Permits, Exemption Packages w/Emission Models, Impacts, Objectives, Targets, and EMPs n Chemical & Standard Industrial: Industrial and Chemical Safety Design Review n Natural Phenomena Hazards: Dynamic Structural Analyses n “Integrated Hazard Analysis”: HAZOP

Summary of Hazards & Analyses n Nuclear: Draft Preliminary Documented Safety Analysis & Draft Nuclear Criticality Safety Evaluation n Fire: Fire Hazard Analysis n Radiological: ALARA Analysis for Preliminary Design n Environmental: Permits, Exemption Packages w/Emission Models, Impacts, Objectives, Targets, and EMPs n Chemical & Standard Industrial: Industrial and Chemical Safety Design Review n Natural Phenomena Hazards: Dynamic Structural Analyses n “Integrated Hazard Analysis”: HAZOP

Nuclear Hazards n Per DOE-STD-1027: Hazard Category 2 Nuclear Facility n Evaluation Guide of 25 rem per DOE-STD-3009: Max. Off-Site TEDE is < 1 rem n No Safety Class hazard controls credited in Draft PDSA n n Safety-related controls credited in Draft PDSA for facility worker: Safety Significant Systems, Structures and Components (SSCs) Criticality: Nuclear Criticality Safety Evaluation (NSCE) in development

Nuclear Hazards n Per DOE-STD-1027: Hazard Category 2 Nuclear Facility n Evaluation Guide of 25 rem per DOE-STD-3009: Max. Off-Site TEDE is < 1 rem n No Safety Class hazard controls credited in Draft PDSA n n Safety-related controls credited in Draft PDSA for facility worker: Safety Significant Systems, Structures and Components (SSCs) Criticality: Nuclear Criticality Safety Evaluation (NSCE) in development

Radiological Hazards n n n Confinement ventilation – radiological zoning Salt waste contains 137 Cs and its daughter, 137 Ba → g Shielding analysis is an integral component of the design process for safe operation and maintenance

Radiological Hazards n n n Confinement ventilation – radiological zoning Salt waste contains 137 Cs and its daughter, 137 Ba → g Shielding analysis is an integral component of the design process for safe operation and maintenance

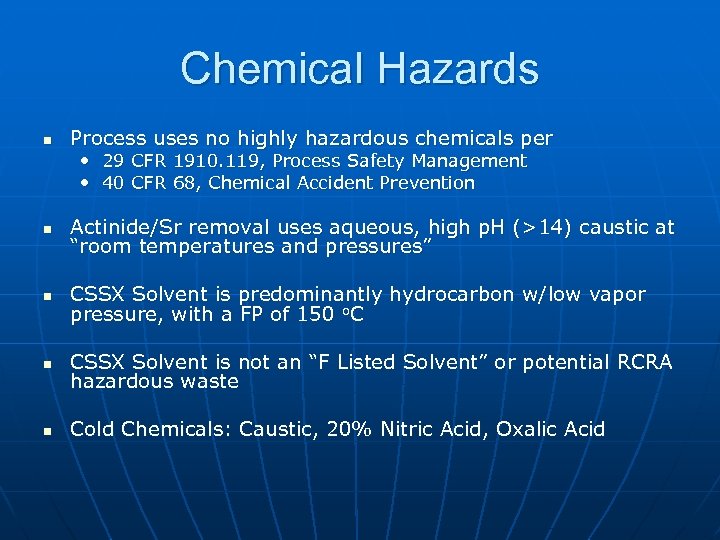

Chemical Hazards n Process uses no highly hazardous chemicals per • 29 CFR 1910. 119, Process Safety Management • 40 CFR 68, Chemical Accident Prevention n Actinide/Sr removal uses aqueous, high p. H (>14) caustic at “room temperatures and pressures” n CSSX Solvent is predominantly hydrocarbon w/low vapor pressure, with a FP of 150 o. C n CSSX Solvent is not an “F Listed Solvent” or potential RCRA hazardous waste n Cold Chemicals: Caustic, 20% Nitric Acid, Oxalic Acid

Chemical Hazards n Process uses no highly hazardous chemicals per • 29 CFR 1910. 119, Process Safety Management • 40 CFR 68, Chemical Accident Prevention n Actinide/Sr removal uses aqueous, high p. H (>14) caustic at “room temperatures and pressures” n CSSX Solvent is predominantly hydrocarbon w/low vapor pressure, with a FP of 150 o. C n CSSX Solvent is not an “F Listed Solvent” or potential RCRA hazardous waste n Cold Chemicals: Caustic, 20% Nitric Acid, Oxalic Acid

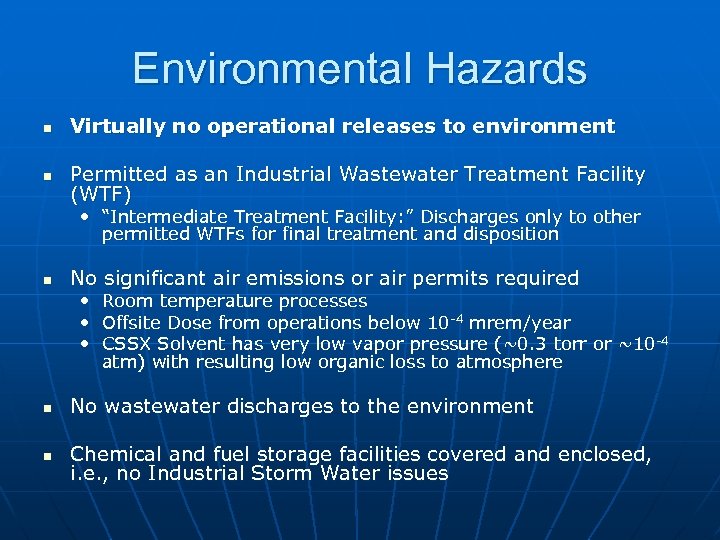

Environmental Hazards n Virtually no operational releases to environment n Permitted as an Industrial Wastewater Treatment Facility (WTF) • “Intermediate Treatment Facility: ” Discharges only to other permitted WTFs for final treatment and disposition n No significant air emissions or air permits required • Room temperature processes • Offsite Dose from operations below 10 -4 mrem/year • CSSX Solvent has very low vapor pressure (~0. 3 torr or ~10 -4 atm) with resulting low organic loss to atmosphere n No wastewater discharges to the environment n Chemical and fuel storage facilities covered and enclosed, i. e. , no Industrial Storm Water issues

Environmental Hazards n Virtually no operational releases to environment n Permitted as an Industrial Wastewater Treatment Facility (WTF) • “Intermediate Treatment Facility: ” Discharges only to other permitted WTFs for final treatment and disposition n No significant air emissions or air permits required • Room temperature processes • Offsite Dose from operations below 10 -4 mrem/year • CSSX Solvent has very low vapor pressure (~0. 3 torr or ~10 -4 atm) with resulting low organic loss to atmosphere n No wastewater discharges to the environment n Chemical and fuel storage facilities covered and enclosed, i. e. , no Industrial Storm Water issues

Std Industrial Hazards n n n n Overhead Cranes Electrical Compressed Gases Walking & Working Surfaces Lighting Sanitation Combustible liquids Corrosive process chemicals

Std Industrial Hazards n n n n Overhead Cranes Electrical Compressed Gases Walking & Working Surfaces Lighting Sanitation Combustible liquids Corrosive process chemicals

Integrating Safety Into Design The “I” in ISMS is critically import at all phase but is of penultimate importance during design • ES&H Disciplines must effectively Integrate with Design • ES&H Disciplines must effectively Integrate with each other • New Facilities must effectively integrate with the site infrastructure

Integrating Safety Into Design The “I” in ISMS is critically import at all phase but is of penultimate importance during design • ES&H Disciplines must effectively Integrate with Design • ES&H Disciplines must effectively Integrate with each other • New Facilities must effectively integrate with the site infrastructure

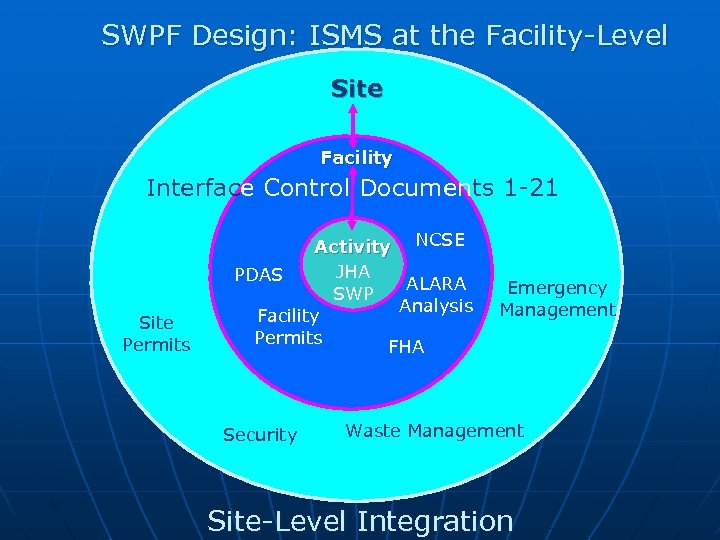

SWPF Design: ISMS at the Facility-Level Site Facility Interface Control Documents 1 -21 Site Permits Activity NCSE JHA D PDAS D ALARA SWP Analysis Facility Permits FHA Security Emergency Management Waste Management Site-Level Integration

SWPF Design: ISMS at the Facility-Level Site Facility Interface Control Documents 1 -21 Site Permits Activity NCSE JHA D PDAS D ALARA SWP Analysis Facility Permits FHA Security Emergency Management Waste Management Site-Level Integration

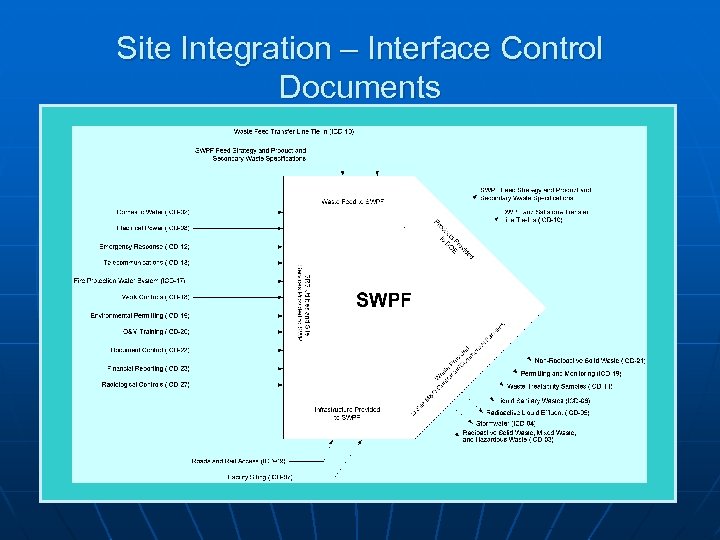

Site Integration – Interface Control Documents

Site Integration – Interface Control Documents

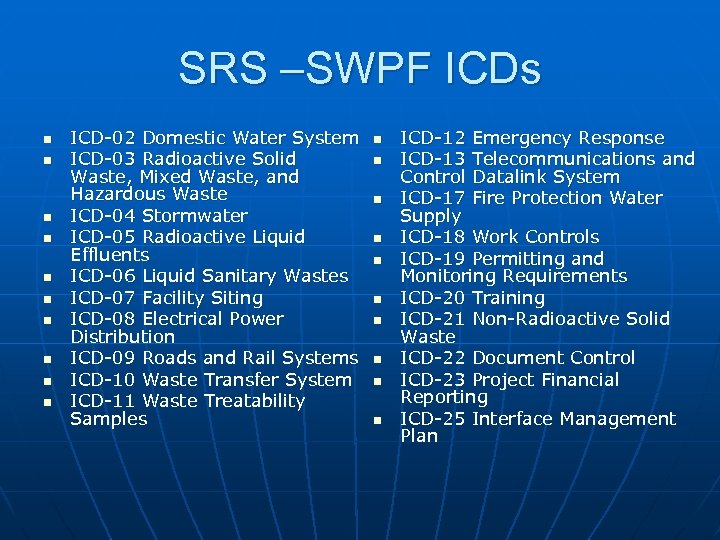

SRS –SWPF ICDs n n n n n ICD-02 Domestic Water System ICD-03 Radioactive Solid Waste, Mixed Waste, and Hazardous Waste ICD-04 Stormwater ICD-05 Radioactive Liquid Effluents ICD-06 Liquid Sanitary Wastes ICD-07 Facility Siting ICD-08 Electrical Power Distribution ICD-09 Roads and Rail Systems ICD-10 Waste Transfer System ICD-11 Waste Treatability Samples n n n n n ICD-12 Emergency Response ICD-13 Telecommunications and Control Datalink System ICD-17 Fire Protection Water Supply ICD-18 Work Controls ICD-19 Permitting and Monitoring Requirements ICD-20 Training ICD-21 Non-Radioactive Solid Waste ICD-22 Document Control ICD-23 Project Financial Reporting ICD-25 Interface Management Plan

SRS –SWPF ICDs n n n n n ICD-02 Domestic Water System ICD-03 Radioactive Solid Waste, Mixed Waste, and Hazardous Waste ICD-04 Stormwater ICD-05 Radioactive Liquid Effluents ICD-06 Liquid Sanitary Wastes ICD-07 Facility Siting ICD-08 Electrical Power Distribution ICD-09 Roads and Rail Systems ICD-10 Waste Transfer System ICD-11 Waste Treatability Samples n n n n n ICD-12 Emergency Response ICD-13 Telecommunications and Control Datalink System ICD-17 Fire Protection Water Supply ICD-18 Work Controls ICD-19 Permitting and Monitoring Requirements ICD-20 Training ICD-21 Non-Radioactive Solid Waste ICD-22 Document Control ICD-23 Project Financial Reporting ICD-25 Interface Management Plan

Hazard & Scope are a functions of One Another n n Initial scope derives from CERCLA Hazardous Ranking Score (40 CFR 300): National Priorities List (NPL) Federal Facility Agreement (FFA) and Tank Farm Milestones Scope is further refined through Alternatives Selection and the NEPA Environmental Impact Statement (EIS): a quantitative evaluation of the risk and hazards of each Alternative DOE Contract contains further scoping through qualitative judgments about the hazards that lead to the stipulated ES&H design criteria and standards to protect the worker, public and environment Final refinements to the scope occurs as the various hazard analyses are initiated, refined and completed to support the conceptual, preliminary and final design

Hazard & Scope are a functions of One Another n n Initial scope derives from CERCLA Hazardous Ranking Score (40 CFR 300): National Priorities List (NPL) Federal Facility Agreement (FFA) and Tank Farm Milestones Scope is further refined through Alternatives Selection and the NEPA Environmental Impact Statement (EIS): a quantitative evaluation of the risk and hazards of each Alternative DOE Contract contains further scoping through qualitative judgments about the hazards that lead to the stipulated ES&H design criteria and standards to protect the worker, public and environment Final refinements to the scope occurs as the various hazard analyses are initiated, refined and completed to support the conceptual, preliminary and final design

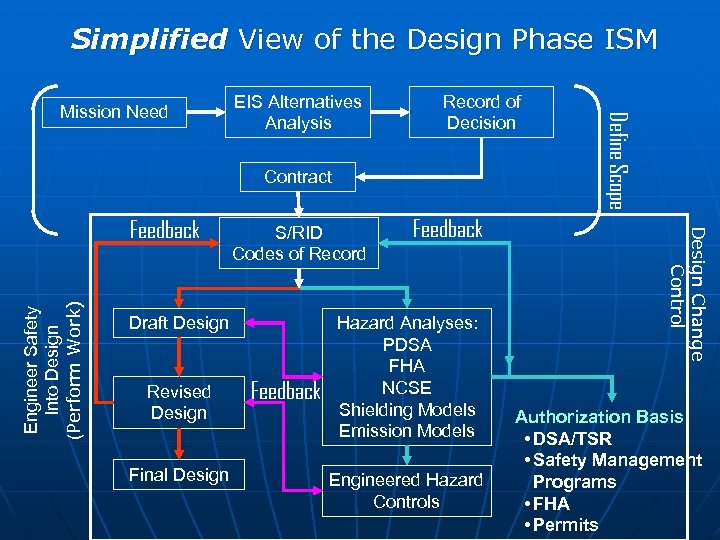

Simplified View of the Design Phase ISM EIS Alternatives Analysis Record of Decision Contract Engineer Safety Into Design (Perform Work) S/RID Codes of Record Draft Design Revised Design Final Design Feedback Hazard Analyses: PDSA FHA NCSE Shielding Models Emission Models Engineered Hazard Controls Design Change Control Feedback Define Scope Mission Need Authorization Basis • DSA/TSR • Safety Management Programs • FHA • Permits

Simplified View of the Design Phase ISM EIS Alternatives Analysis Record of Decision Contract Engineer Safety Into Design (Perform Work) S/RID Codes of Record Draft Design Revised Design Final Design Feedback Hazard Analyses: PDSA FHA NCSE Shielding Models Emission Models Engineered Hazard Controls Design Change Control Feedback Define Scope Mission Need Authorization Basis • DSA/TSR • Safety Management Programs • FHA • Permits

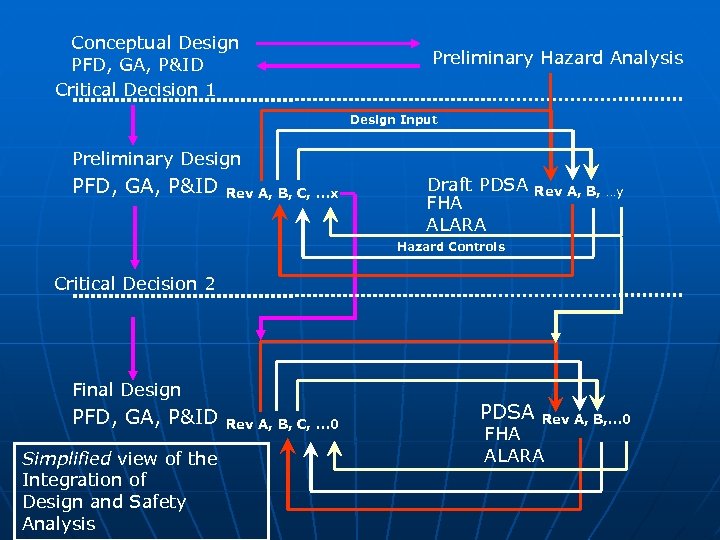

Conceptual Design PFD, GA, P&ID Critical Decision 1 Preliminary Hazard Analysis Design Input Preliminary Design PFD, GA, P&ID Rev A, B, C, …x Draft PDSA FHA ALARA Rev A, B, …y Hazard Controls Critical Decision 2 Final Design PFD, GA, P&ID Simplified view of the Integration of Design and Safety Analysis Rev A, B, C, … 0 PDSA Rev A, B, … 0 FHA ALARA

Conceptual Design PFD, GA, P&ID Critical Decision 1 Preliminary Hazard Analysis Design Input Preliminary Design PFD, GA, P&ID Rev A, B, C, …x Draft PDSA FHA ALARA Rev A, B, …y Hazard Controls Critical Decision 2 Final Design PFD, GA, P&ID Simplified view of the Integration of Design and Safety Analysis Rev A, B, C, … 0 PDSA Rev A, B, … 0 FHA ALARA

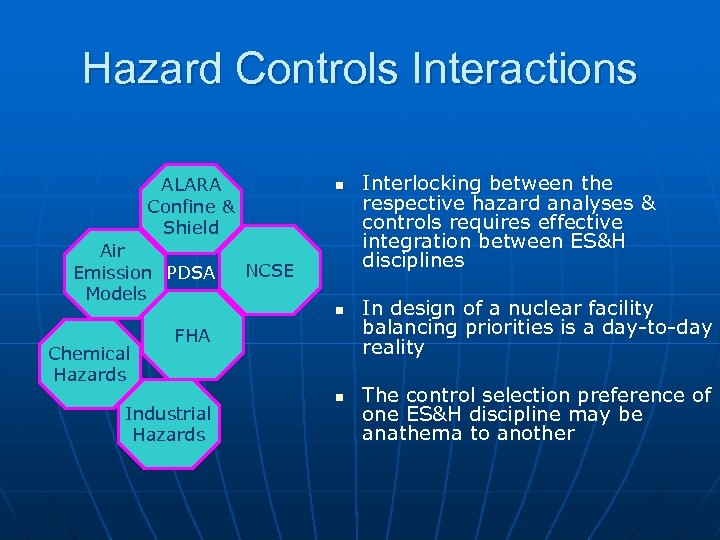

Hazard Controls Interactions ALARA Confine & Shield Air Emission PDSA Models n NCSE n Chemical Hazards FHA Industrial Hazards n Interlocking between the respective hazard analyses & controls requires effective integration between ES&H disciplines In design of a nuclear facility balancing priorities is a day-to-day reality The control selection preference of one ES&H discipline may be anathema to another

Hazard Controls Interactions ALARA Confine & Shield Air Emission PDSA Models n NCSE n Chemical Hazards FHA Industrial Hazards n Interlocking between the respective hazard analyses & controls requires effective integration between ES&H disciplines In design of a nuclear facility balancing priorities is a day-to-day reality The control selection preference of one ES&H discipline may be anathema to another

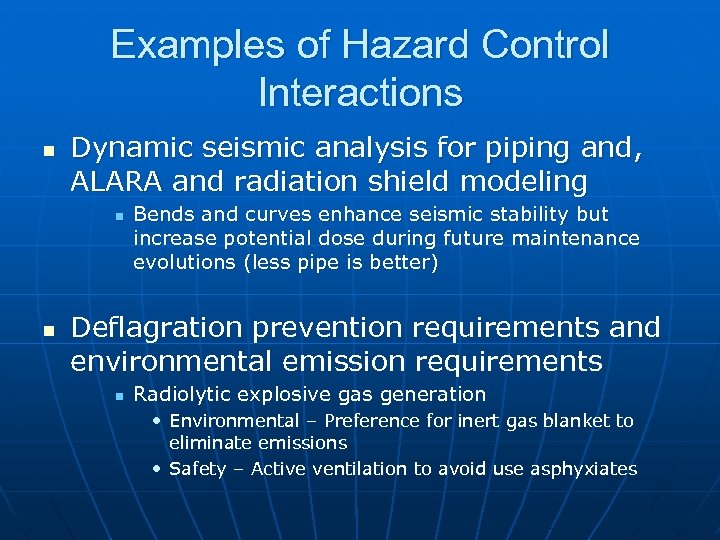

Examples of Hazard Control Interactions n Dynamic seismic analysis for piping and, ALARA and radiation shield modeling n n Bends and curves enhance seismic stability but increase potential dose during future maintenance evolutions (less pipe is better) Deflagration prevention requirements and environmental emission requirements n Radiolytic explosive gas generation • Environmental – Preference for inert gas blanket to eliminate emissions • Safety – Active ventilation to avoid use asphyxiates

Examples of Hazard Control Interactions n Dynamic seismic analysis for piping and, ALARA and radiation shield modeling n n Bends and curves enhance seismic stability but increase potential dose during future maintenance evolutions (less pipe is better) Deflagration prevention requirements and environmental emission requirements n Radiolytic explosive gas generation • Environmental – Preference for inert gas blanket to eliminate emissions • Safety – Active ventilation to avoid use asphyxiates

Integration Tools n Organizational Structure n Mandatory Intra Discipline Reviews n HAZOP Reviews at each life cycle phase

Integration Tools n Organizational Structure n Mandatory Intra Discipline Reviews n HAZOP Reviews at each life cycle phase

Integration Tools: Organization • Organizational Paradigm in Operating Facilities or Construction Projects is to place ES&H Disciplines in a separate ES&H Organization • During design phase, the hazard analyses conducted for nuclear safety, fire protections, radiation protection, environmental protection, etc. have direct input into the line product: Design • SWPF Nuclear Safety and Fire Protection have such a significant role in the design, they are in the Design Build organization • ESH&Q Manager and ES&H Subject Matter Experts have a strong oversight role through the Inter Discipline Review process and the Design Change process

Integration Tools: Organization • Organizational Paradigm in Operating Facilities or Construction Projects is to place ES&H Disciplines in a separate ES&H Organization • During design phase, the hazard analyses conducted for nuclear safety, fire protections, radiation protection, environmental protection, etc. have direct input into the line product: Design • SWPF Nuclear Safety and Fire Protection have such a significant role in the design, they are in the Design Build organization • ESH&Q Manager and ES&H Subject Matter Experts have a strong oversight role through the Inter Discipline Review process and the Design Change process

Integration Tools: Intra Discipline Review (IDR) n n n All design outputs are reviewed (IDR) by the respective environmental, safety and health SMEs to verify that controls are integrated in design Comments from ES&H SMEs and all reviewers must be addressed and the resolution formally concurred upon by the reviewer Design Change Control Process: Multidiscipline Design Change Request review process and Change Control Board

Integration Tools: Intra Discipline Review (IDR) n n n All design outputs are reviewed (IDR) by the respective environmental, safety and health SMEs to verify that controls are integrated in design Comments from ES&H SMEs and all reviewers must be addressed and the resolution formally concurred upon by the reviewer Design Change Control Process: Multidiscipline Design Change Request review process and Change Control Board

Integration Tools: HAZOP n HAZOP - HAZard and OPerability analysis n The Project has conducted in depth HAZOP Reviews with each design phase and life cycle phase n HAZOP conducted over 3 week period with members of all disciplines: • Sponsored by the Design Build Manager • Nuclear Safety, Radiation Protection, Fire Protection, Environmental Protection, Industrial Hygiene and Safety • Operations, Maintenance, Process Engineering, Balance of Plan Engineering: Structural, Piping, HVAC, I&C n Formal multidiscipline, step-by-step review of facility design

Integration Tools: HAZOP n HAZOP - HAZard and OPerability analysis n The Project has conducted in depth HAZOP Reviews with each design phase and life cycle phase n HAZOP conducted over 3 week period with members of all disciplines: • Sponsored by the Design Build Manager • Nuclear Safety, Radiation Protection, Fire Protection, Environmental Protection, Industrial Hygiene and Safety • Operations, Maintenance, Process Engineering, Balance of Plan Engineering: Structural, Piping, HVAC, I&C n Formal multidiscipline, step-by-step review of facility design

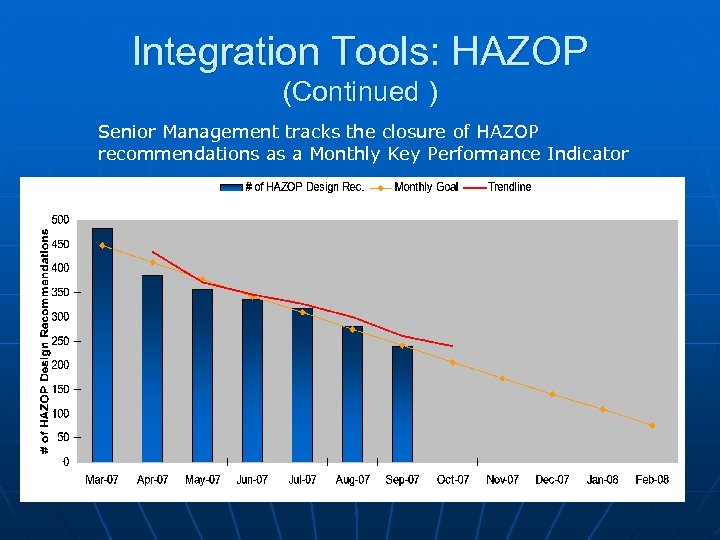

Integration Tools: HAZOP (Continued ) Senior Management tracks the closure of HAZOP recommendations as a Monthly Key Performance Indicator

Integration Tools: HAZOP (Continued ) Senior Management tracks the closure of HAZOP recommendations as a Monthly Key Performance Indicator

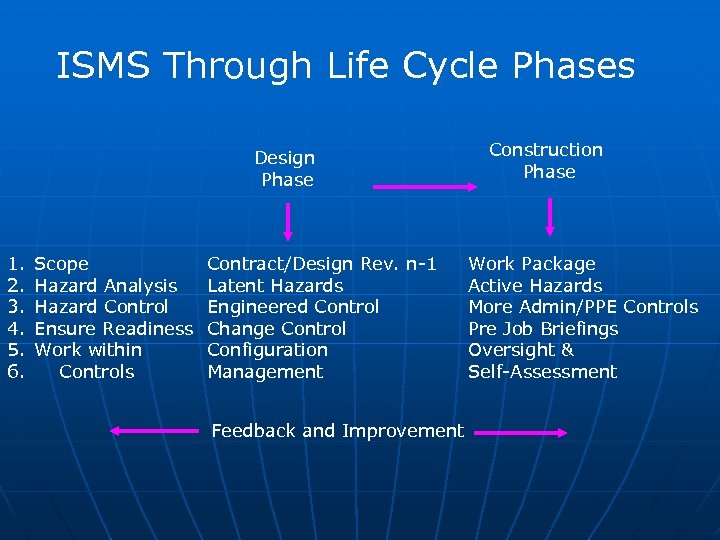

ISMS Through Life Cycle Phases Design Phase 1. 2. 3. 4. 5. 6. Scope Hazard Analysis Hazard Control Ensure Readiness Work within Controls Contract/Design Rev. n-1 Latent Hazards Engineered Control Change Control Configuration Management Feedback and Improvement Construction Phase Work Package Active Hazards More Admin/PPE Controls Pre Job Briefings Oversight & Self-Assessment

ISMS Through Life Cycle Phases Design Phase 1. 2. 3. 4. 5. 6. Scope Hazard Analysis Hazard Control Ensure Readiness Work within Controls Contract/Design Rev. n-1 Latent Hazards Engineered Control Change Control Configuration Management Feedback and Improvement Construction Phase Work Package Active Hazards More Admin/PPE Controls Pre Job Briefings Oversight & Self-Assessment

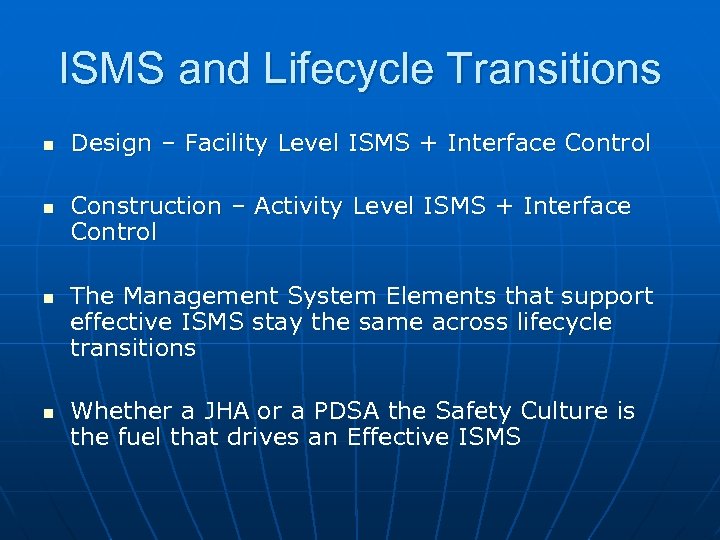

ISMS and Lifecycle Transitions n n Design – Facility Level ISMS + Interface Control Construction – Activity Level ISMS + Interface Control The Management System Elements that support effective ISMS stay the same across lifecycle transitions Whether a JHA or a PDSA the Safety Culture is the fuel that drives an Effective ISMS

ISMS and Lifecycle Transitions n n Design – Facility Level ISMS + Interface Control Construction – Activity Level ISMS + Interface Control The Management System Elements that support effective ISMS stay the same across lifecycle transitions Whether a JHA or a PDSA the Safety Culture is the fuel that drives an Effective ISMS

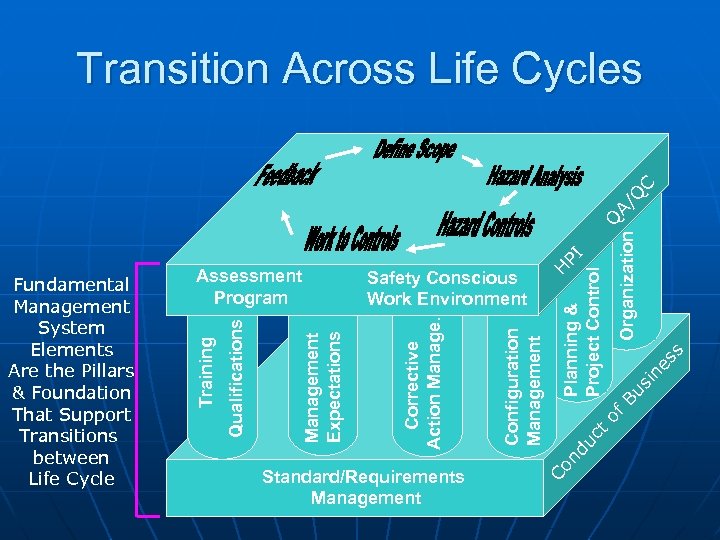

uc t si ne ss Organization Bu of H nd Co Standard/Requirements Management Configuration Management Safety Conscious Work Environment Corrective Action Management Expectations Qualifications Assessment Program Training Fundamental Management System Elements Are the Pillars & Foundation That Support Transitions between Life Cycle PI Planning & Project Control Q A/ Q C Transition Across Life Cycles

uc t si ne ss Organization Bu of H nd Co Standard/Requirements Management Configuration Management Safety Conscious Work Environment Corrective Action Management Expectations Qualifications Assessment Program Training Fundamental Management System Elements Are the Pillars & Foundation That Support Transitions between Life Cycle PI Planning & Project Control Q A/ Q C Transition Across Life Cycles

Lessons Learned n n n DOE Directives provide a solid framework for analyzing latent hazards in the design process The expectations for selecting and developing hazard controls could be refined The least glamorous ISMS Core Function, “DEFINE SCOPE OF WORK” is where we need to focus for design-build projects

Lessons Learned n n n DOE Directives provide a solid framework for analyzing latent hazards in the design process The expectations for selecting and developing hazard controls could be refined The least glamorous ISMS Core Function, “DEFINE SCOPE OF WORK” is where we need to focus for design-build projects

DOE Directives Define Scope That Directly Impacts Facility Design n Laws, regulations, and …even DOE Directives have conflicts and ambiguities that require interpretation by Lawyers, Managers and Subject Matter Experts n Variation in interpretation is inevitable: GREAT MINDS DO NOT ALWAYS THINK ALIKE n In matters other than statutes and regulations, there may be no clear authority for adjudication on points of difference n Licenses, Permits, and Consent Agreements are used to assure mutual understanding between regulators and the regulated n DOE is not quite a regulator (Title 10 aside) n DOE is commonly a contracts manager

DOE Directives Define Scope That Directly Impacts Facility Design n Laws, regulations, and …even DOE Directives have conflicts and ambiguities that require interpretation by Lawyers, Managers and Subject Matter Experts n Variation in interpretation is inevitable: GREAT MINDS DO NOT ALWAYS THINK ALIKE n In matters other than statutes and regulations, there may be no clear authority for adjudication on points of difference n Licenses, Permits, and Consent Agreements are used to assure mutual understanding between regulators and the regulated n DOE is not quite a regulator (Title 10 aside) n DOE is commonly a contracts manager

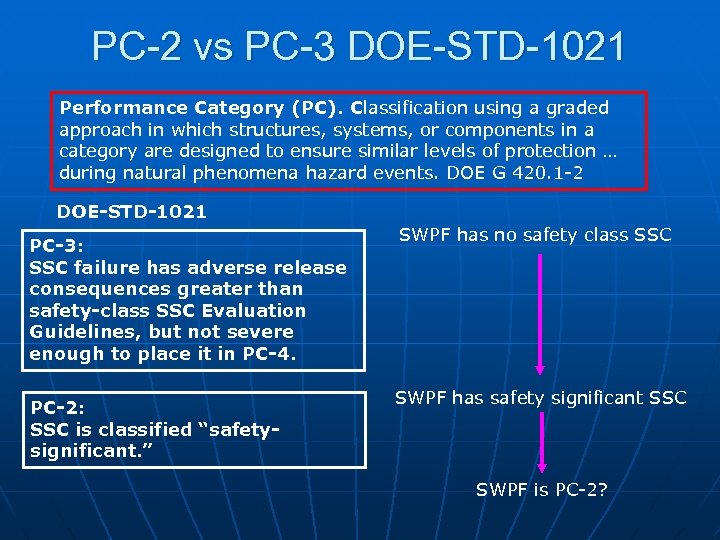

PC-2 vs PC-3 DOE-STD-1021 Performance Category (PC). Classification using a graded approach in which structures, systems, or components in a category are designed to ensure similar levels of protection … during natural phenomena hazard events. DOE G 420. 1 -2 DOE-STD-1021 PC-3: SSC failure has adverse release consequences greater than safety-class SSC Evaluation Guidelines, but not severe enough to place it in PC-4. PC-2: SSC is classified “safetysignificant. ” SWPF has no safety class SSC SWPF has safety significant SSC SWPF is PC-2?

PC-2 vs PC-3 DOE-STD-1021 Performance Category (PC). Classification using a graded approach in which structures, systems, or components in a category are designed to ensure similar levels of protection … during natural phenomena hazard events. DOE G 420. 1 -2 DOE-STD-1021 PC-3: SSC failure has adverse release consequences greater than safety-class SSC Evaluation Guidelines, but not severe enough to place it in PC-4. PC-2: SSC is classified “safetysignificant. ” SWPF has no safety class SSC SWPF has safety significant SSC SWPF is PC-2?

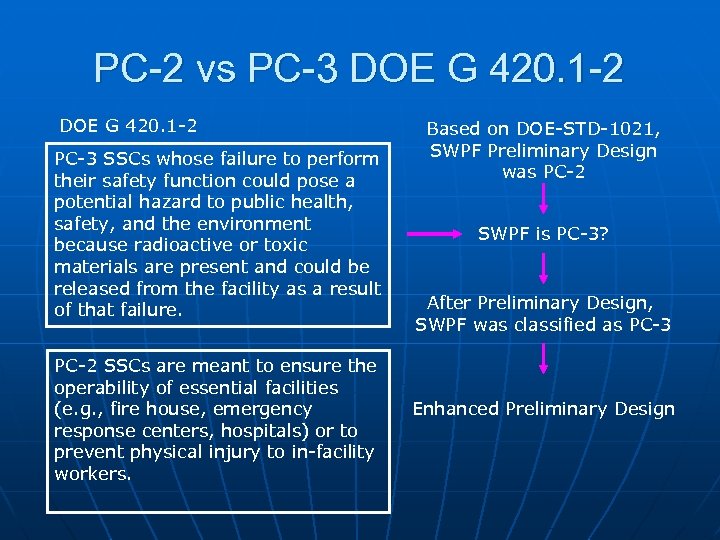

PC-2 vs PC-3 DOE G 420. 1 -2 PC-3 SSCs whose failure to perform their safety function could pose a potential hazard to public health, safety, and the environment because radioactive or toxic materials are present and could be released from the facility as a result of that failure. PC-2 SSCs are meant to ensure the operability of essential facilities (e. g. , fire house, emergency response centers, hospitals) or to prevent physical injury to in-facility workers. Based on DOE-STD-1021, SWPF Preliminary Design was PC-2 SWPF is PC-3? After Preliminary Design, SWPF was classified as PC-3 Enhanced Preliminary Design

PC-2 vs PC-3 DOE G 420. 1 -2 PC-3 SSCs whose failure to perform their safety function could pose a potential hazard to public health, safety, and the environment because radioactive or toxic materials are present and could be released from the facility as a result of that failure. PC-2 SSCs are meant to ensure the operability of essential facilities (e. g. , fire house, emergency response centers, hospitals) or to prevent physical injury to in-facility workers. Based on DOE-STD-1021, SWPF Preliminary Design was PC-2 SWPF is PC-3? After Preliminary Design, SWPF was classified as PC-3 Enhanced Preliminary Design

Recommendation n Operations Authorization Agreement • Established in DOE M 411. 1 -1 C: Defines the terms and conditions by which DOE approves and the contractor conducts the safe operation of a nuclear facility, e. g. , TSRs, USQ Process, etc. n Why not a “Design Authorization Agreement”?

Recommendation n Operations Authorization Agreement • Established in DOE M 411. 1 -1 C: Defines the terms and conditions by which DOE approves and the contractor conducts the safe operation of a nuclear facility, e. g. , TSRs, USQ Process, etc. n Why not a “Design Authorization Agreement”?

Design Authorization Agreement • Establish the criteria to be used in the design of nuclear and any other hazardous facility @ CD-1 or the start of Preliminary Design • Conceptual Design and PHA completed – first order hazards should be well characterized • Reviewed and approved by DOE CTA, Chief Operating Officer and Field Element Manager, and with concurrence from the DNFSB, and state and Federal environmental regulators

Design Authorization Agreement • Establish the criteria to be used in the design of nuclear and any other hazardous facility @ CD-1 or the start of Preliminary Design • Conceptual Design and PHA completed – first order hazards should be well characterized • Reviewed and approved by DOE CTA, Chief Operating Officer and Field Element Manager, and with concurrence from the DNFSB, and state and Federal environmental regulators

Summary n The framework for ISMS is well established for DOE Design Build Projects n Integration among ES&H Functional Areas and the Design Organization is crucial n Multidiscipline HAZOP provides effective tool to enhance integration n n ES&H Disciplines need to be part of or closely aligned with the line organization during design – hazard analyses are a design input Recommend development of a “Design Authorization Agreements” to preclude “in process” scope changes for future Design Build Projects

Summary n The framework for ISMS is well established for DOE Design Build Projects n Integration among ES&H Functional Areas and the Design Organization is crucial n Multidiscipline HAZOP provides effective tool to enhance integration n n ES&H Disciplines need to be part of or closely aligned with the line organization during design – hazard analyses are a design input Recommend development of a “Design Authorization Agreements” to preclude “in process” scope changes for future Design Build Projects