V D 0704 Cold Rolling.PPT

- Количество слайдов: 22

Institut für Metallurg Werkstoffumformung 4. Cold Rolling Content 4. Layout CR Production up to Tinplate Processing 4. 1 Pickling Lines 4. 2 CR Process 4. 3 Surface Preparation D Cold Rolling TFV Rolling of flat material 1

Institut für Metallurg Werkstoffumformung 4. Cold Rolling Content 4. Layout CR Production up to Tinplate Processing 4. 1 Pickling Lines 4. 2 CR Process 4. 3 Surface Preparation D Cold Rolling TFV Rolling of flat material 1

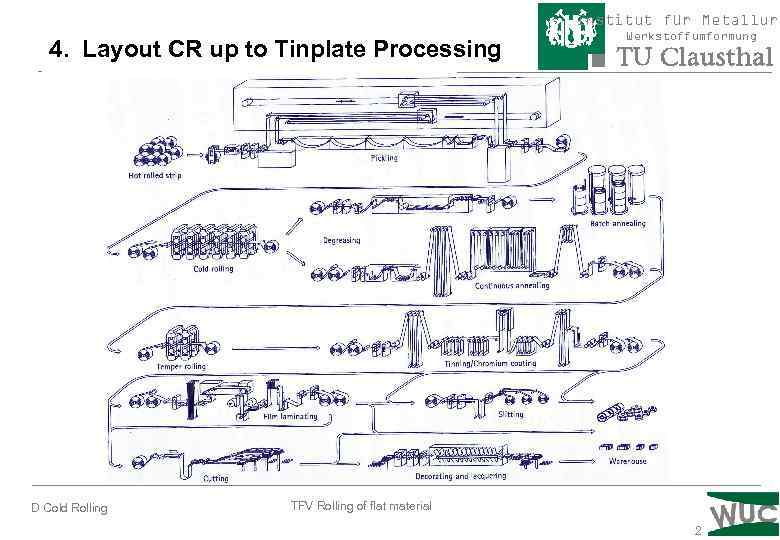

Institut für Metallurg 4. Layout CR up to Tinplate Processing D Cold Rolling Werkstoffumformung TFV Rolling of flat material 2

Institut für Metallurg 4. Layout CR up to Tinplate Processing D Cold Rolling Werkstoffumformung TFV Rolling of flat material 2

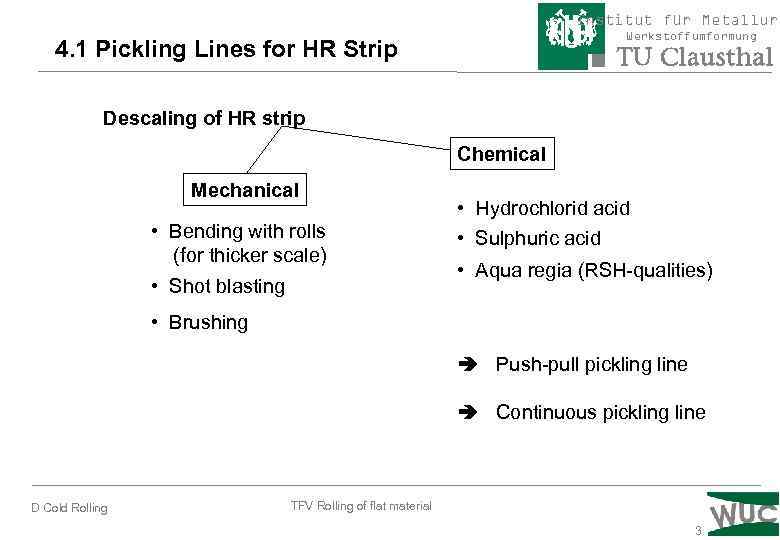

Institut für Metallurg Werkstoffumformung 4. 1 Pickling Lines for HR Strip Descaling of HR strip Chemical Mechanical • Bending with rolls (for thicker scale) • Shot blasting • Hydrochlorid acid • Sulphuric acid • Aqua regia (RSH-qualities) • Brushing Push-pull pickling line Continuous pickling line D Cold Rolling TFV Rolling of flat material 3

Institut für Metallurg Werkstoffumformung 4. 1 Pickling Lines for HR Strip Descaling of HR strip Chemical Mechanical • Bending with rolls (for thicker scale) • Shot blasting • Hydrochlorid acid • Sulphuric acid • Aqua regia (RSH-qualities) • Brushing Push-pull pickling line Continuous pickling line D Cold Rolling TFV Rolling of flat material 3

Institut für Metallurg Werkstoffumformung 4. 2 Cold Rolling Process. . precision forming process • Tolerances • Defined surface topography (e. g. PRETEX) • Material properties adjustable by - rolling - annealing - skin-passing Flatness Tolerances (Profile) Mechanical properties Texture Surface properties - High energy consumption (drives, heat treatment) - Expensive plant engineering (multi-roll stands, bending, shifting of rolls) D Cold Rolling TFV Rolling of flat material 4

Institut für Metallurg Werkstoffumformung 4. 2 Cold Rolling Process. . precision forming process • Tolerances • Defined surface topography (e. g. PRETEX) • Material properties adjustable by - rolling - annealing - skin-passing Flatness Tolerances (Profile) Mechanical properties Texture Surface properties - High energy consumption (drives, heat treatment) - Expensive plant engineering (multi-roll stands, bending, shifting of rolls) D Cold Rolling TFV Rolling of flat material 4

Institut für Metallurg Werkstoffumformung 4. 2 CR Technology Area of strip thickness covered by modern CRMs: 15 – 0. 10 mm or 3 – 0. 02 mm Roll stands: or D Cold Rolling (2 -high, 4 -, 6 -, . . . , 20 -high) combinations 2 -/4 -high, different WR diameters, tandem mills TFV Rolling of flat material 5

Institut für Metallurg Werkstoffumformung 4. 2 CR Technology Area of strip thickness covered by modern CRMs: 15 – 0. 10 mm or 3 – 0. 02 mm Roll stands: or D Cold Rolling (2 -high, 4 -, 6 -, . . . , 20 -high) combinations 2 -/4 -high, different WR diameters, tandem mills TFV Rolling of flat material 5

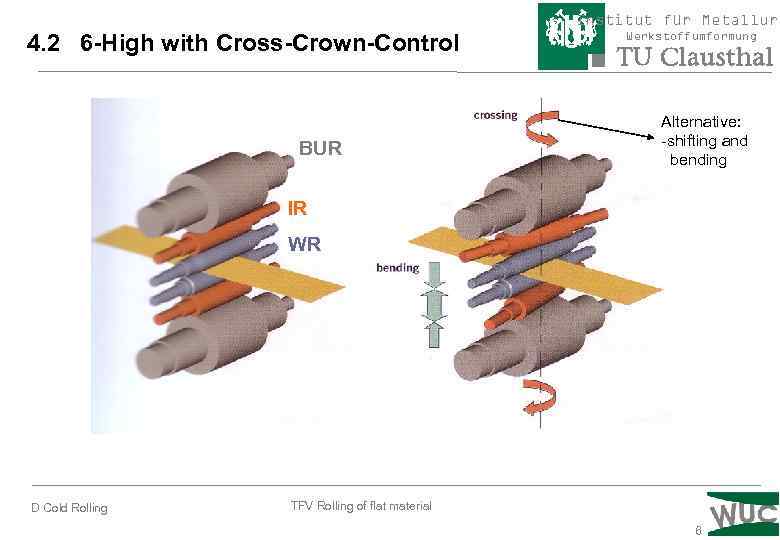

Institut für Metallurg 4. 2 6 -High with Cross-Crown-Control BUR Werkstoffumformung Alternative: -shifting and bending IR WR D Cold Rolling TFV Rolling of flat material 6

Institut für Metallurg 4. 2 6 -High with Cross-Crown-Control BUR Werkstoffumformung Alternative: -shifting and bending IR WR D Cold Rolling TFV Rolling of flat material 6

Institut für Metallurg 4. 2 Advantages of 6 -High Stands Werkstoffumformung Regular control mechanism: WRB Tilting Zone cooling (CVC) • Improved flatness of the strip Axial shifting of IR Simultaneous bending of IR Crossing of IR Improved productivity (less wavy material, reduced starting phase) • Schedule free rolling SFR • Reduced edge drop Covering wide range of width without great restrictions; positioning edges of IR exactly over/below strip edges: active width Improved tool life, extension of rolling program length • Cylindric rolls No special grinding Reducing no. of circulating rolls rapidly D Cold Rolling TFV Rolling of flat material 7

Institut für Metallurg 4. 2 Advantages of 6 -High Stands Werkstoffumformung Regular control mechanism: WRB Tilting Zone cooling (CVC) • Improved flatness of the strip Axial shifting of IR Simultaneous bending of IR Crossing of IR Improved productivity (less wavy material, reduced starting phase) • Schedule free rolling SFR • Reduced edge drop Covering wide range of width without great restrictions; positioning edges of IR exactly over/below strip edges: active width Improved tool life, extension of rolling program length • Cylindric rolls No special grinding Reducing no. of circulating rolls rapidly D Cold Rolling TFV Rolling of flat material 7

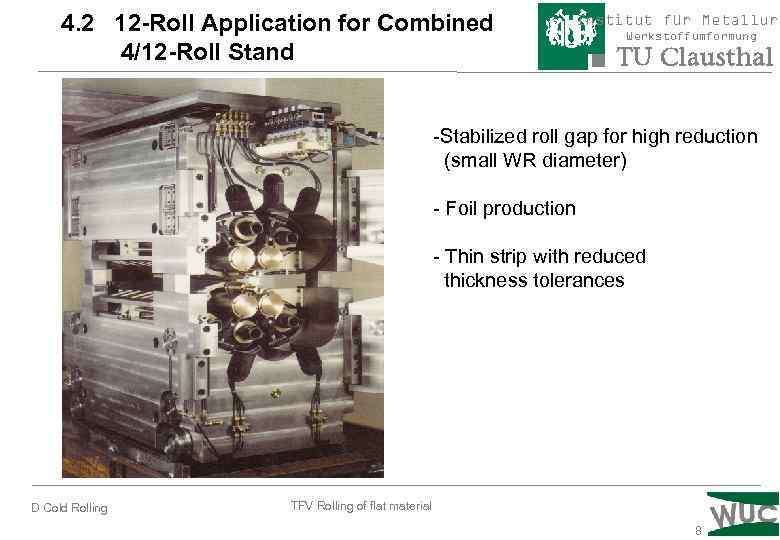

4. 2 12 -Roll Application for Combined 4/12 -Roll Stand Institut für Metallurg Werkstoffumformung -Stabilized roll gap for high reduction (small WR diameter) - Foil production - Thin strip with reduced thickness tolerances D Cold Rolling TFV Rolling of flat material 8

4. 2 12 -Roll Application for Combined 4/12 -Roll Stand Institut für Metallurg Werkstoffumformung -Stabilized roll gap for high reduction (small WR diameter) - Foil production - Thin strip with reduced thickness tolerances D Cold Rolling TFV Rolling of flat material 8

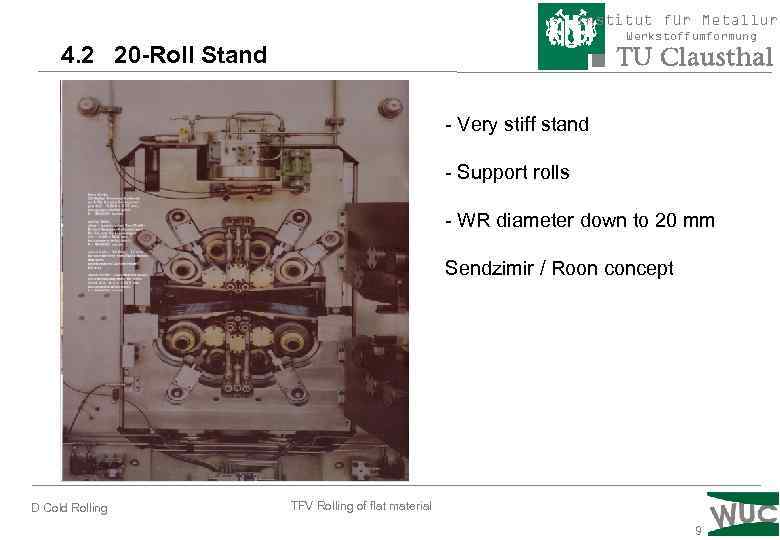

Institut für Metallurg Werkstoffumformung 4. 2 20 -Roll Stand - Very stiff stand - Support rolls - WR diameter down to 20 mm Sendzimir / Roon concept D Cold Rolling TFV Rolling of flat material 9

Institut für Metallurg Werkstoffumformung 4. 2 20 -Roll Stand - Very stiff stand - Support rolls - WR diameter down to 20 mm Sendzimir / Roon concept D Cold Rolling TFV Rolling of flat material 9

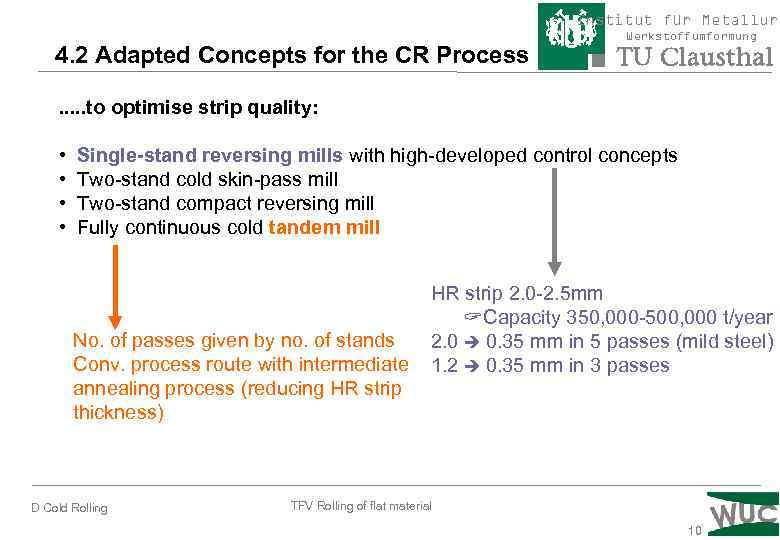

Institut für Metallurg 4. 2 Adapted Concepts for the CR Process Werkstoffumformung . . . to optimise strip quality: • • Single-stand reversing mills with high-developed control concepts Two-stand cold skin-pass mill Two-stand compact reversing mill Fully continuous cold tandem mill No. of passes given by no. of stands Conv. process route with intermediate annealing process (reducing HR strip thickness) D Cold Rolling HR strip 2. 0 -2. 5 mm Capacity 350, 000 -500, 000 t/year 2. 0 0. 35 mm in 5 passes (mild steel) 1. 2 0. 35 mm in 3 passes TFV Rolling of flat material 10

Institut für Metallurg 4. 2 Adapted Concepts for the CR Process Werkstoffumformung . . . to optimise strip quality: • • Single-stand reversing mills with high-developed control concepts Two-stand cold skin-pass mill Two-stand compact reversing mill Fully continuous cold tandem mill No. of passes given by no. of stands Conv. process route with intermediate annealing process (reducing HR strip thickness) D Cold Rolling HR strip 2. 0 -2. 5 mm Capacity 350, 000 -500, 000 t/year 2. 0 0. 35 mm in 5 passes (mild steel) 1. 2 0. 35 mm in 3 passes TFV Rolling of flat material 10

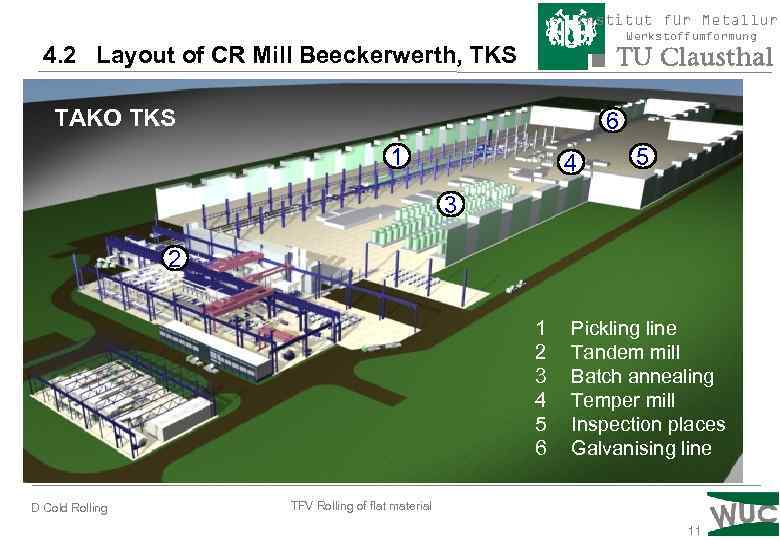

Institut für Metallurg Werkstoffumformung 4. 2 Layout of CR Mill Beeckerwerth, TKS TAKO TKS 6 1 4 5 3 2 1 2 3 4 5 6 D Cold Rolling Pickling line Tandem mill Batch annealing Temper mill Inspection places Galvanising line TFV Rolling of flat material 11

Institut für Metallurg Werkstoffumformung 4. 2 Layout of CR Mill Beeckerwerth, TKS TAKO TKS 6 1 4 5 3 2 1 2 3 4 5 6 D Cold Rolling Pickling line Tandem mill Batch annealing Temper mill Inspection places Galvanising line TFV Rolling of flat material 11

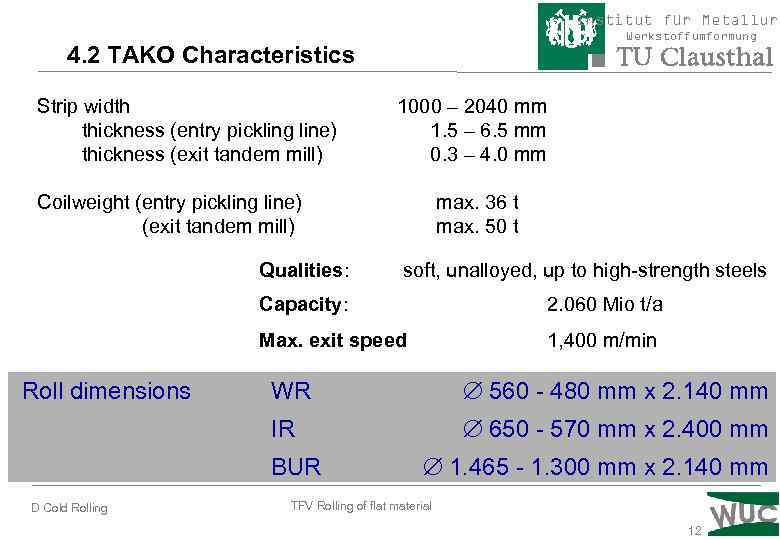

Institut für Metallurg Werkstoffumformung 4. 2 TAKO Characteristics Strip width thickness (entry pickling line) thickness (exit tandem mill) 1000 – 2040 mm 1. 5 – 6. 5 mm 0. 3 – 4. 0 mm Coilweight (entry pickling line) (exit tandem mill) Qualities: max. 36 t max. 50 t soft, unalloyed, up to high-strength steels Capacity: 2. 060 Mio t/a Max. exit speed 1, 400 m/min WR 560 - 480 mm x 2. 140 mm IR Roll dimensions 650 - 570 mm x 2. 400 mm BUR D Cold Rolling 1. 465 - 1. 300 mm x 2. 140 mm TFV Rolling of flat material 12

Institut für Metallurg Werkstoffumformung 4. 2 TAKO Characteristics Strip width thickness (entry pickling line) thickness (exit tandem mill) 1000 – 2040 mm 1. 5 – 6. 5 mm 0. 3 – 4. 0 mm Coilweight (entry pickling line) (exit tandem mill) Qualities: max. 36 t max. 50 t soft, unalloyed, up to high-strength steels Capacity: 2. 060 Mio t/a Max. exit speed 1, 400 m/min WR 560 - 480 mm x 2. 140 mm IR Roll dimensions 650 - 570 mm x 2. 400 mm BUR D Cold Rolling 1. 465 - 1. 300 mm x 2. 140 mm TFV Rolling of flat material 12

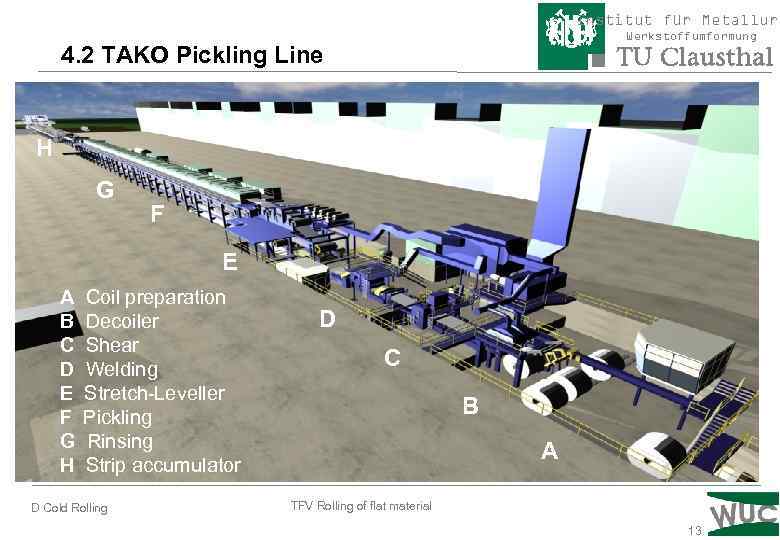

Institut für Metallurg Werkstoffumformung 4. 2 TAKO Pickling Line H G F E A B C D E F G H Coil preparation Decoiler Shear Welding Stretch-Leveller Pickling Rinsing Strip accumulator D Cold Rolling D C B A TFV Rolling of flat material 13

Institut für Metallurg Werkstoffumformung 4. 2 TAKO Pickling Line H G F E A B C D E F G H Coil preparation Decoiler Shear Welding Stretch-Leveller Pickling Rinsing Strip accumulator D Cold Rolling D C B A TFV Rolling of flat material 13

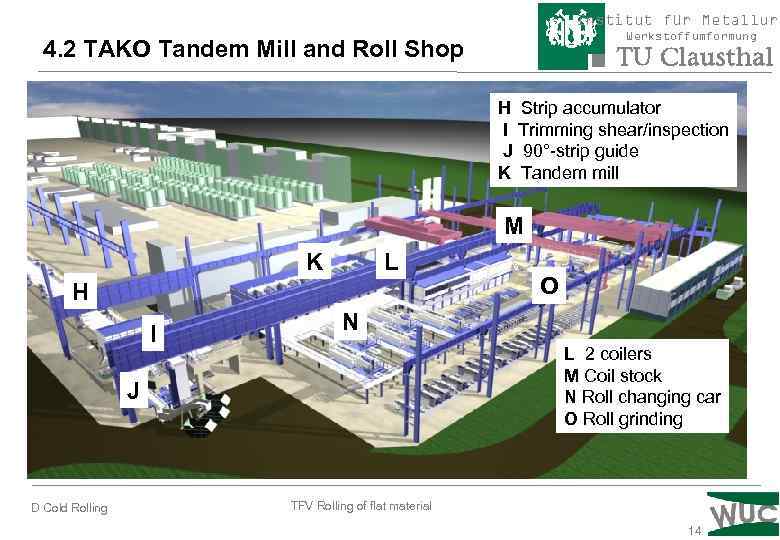

Institut für Metallurg Werkstoffumformung 4. 2 TAKO Tandem Mill and Roll Shop H Strip accumulator I Trimming shear/inspection J 90°-strip guide K Tandem mill M K L H I N L 2 coilers M Coil stock N Roll changing car O Roll grinding J D Cold Rolling O TFV Rolling of flat material 14

Institut für Metallurg Werkstoffumformung 4. 2 TAKO Tandem Mill and Roll Shop H Strip accumulator I Trimming shear/inspection J 90°-strip guide K Tandem mill M K L H I N L 2 coilers M Coil stock N Roll changing car O Roll grinding J D Cold Rolling O TFV Rolling of flat material 14

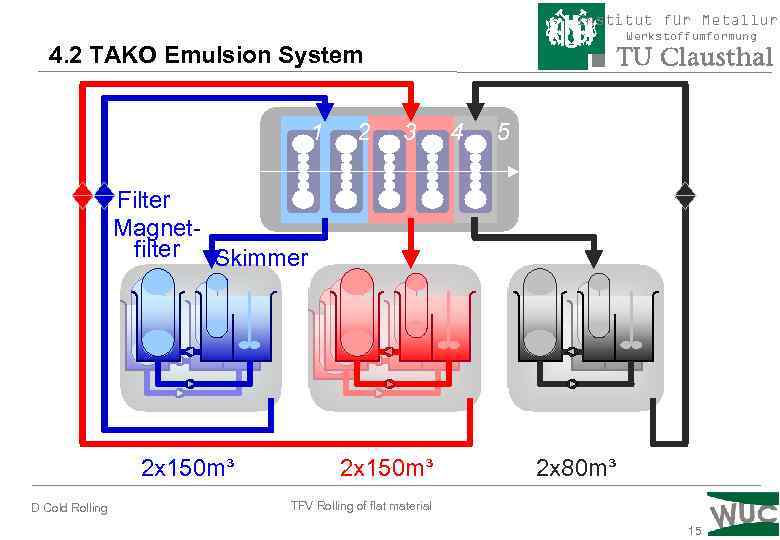

Institut für Metallurg Werkstoffumformung 4. 2 TAKO Emulsion System 1 2 3 4 5 Filter Magnetfilter Skimmer 2 x 150 m³ D Cold Rolling 2 x 150 m³ 2 x 80 m³ TFV Rolling of flat material 15

Institut für Metallurg Werkstoffumformung 4. 2 TAKO Emulsion System 1 2 3 4 5 Filter Magnetfilter Skimmer 2 x 150 m³ D Cold Rolling 2 x 150 m³ 2 x 80 m³ TFV Rolling of flat material 15

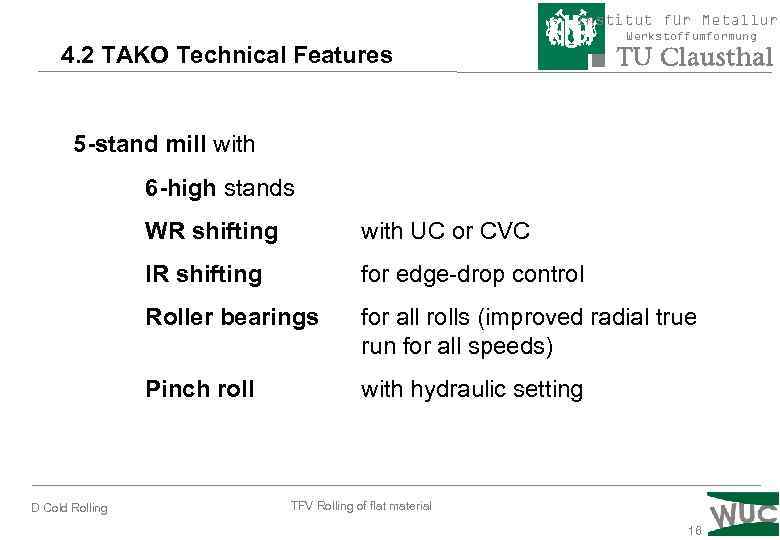

Institut für Metallurg 4. 2 TAKO Technical Features Werkstoffumformung 5 -stand mill with 6 -high stands WR shifting IR shifting for edge-drop control Roller bearings for all rolls (improved radial true run for all speeds) Pinch roll D Cold Rolling with UC or CVC with hydraulic setting TFV Rolling of flat material 16

Institut für Metallurg 4. 2 TAKO Technical Features Werkstoffumformung 5 -stand mill with 6 -high stands WR shifting IR shifting for edge-drop control Roller bearings for all rolls (improved radial true run for all speeds) Pinch roll D Cold Rolling with UC or CVC with hydraulic setting TFV Rolling of flat material 16

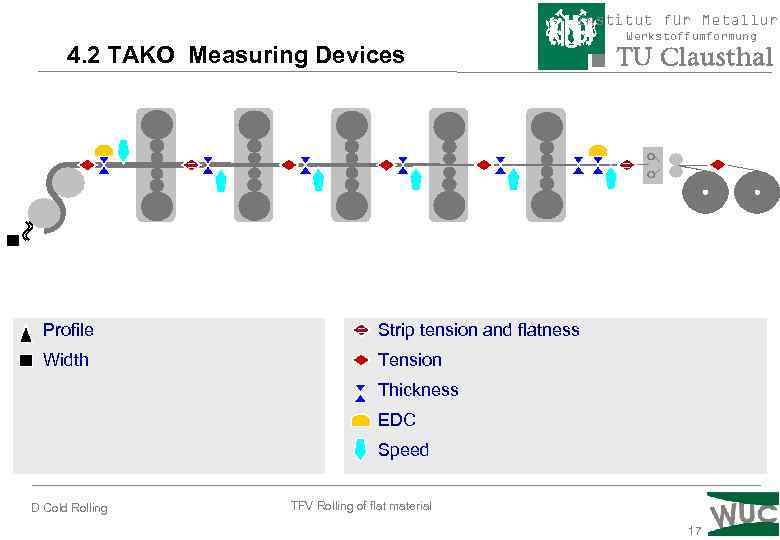

Institut für Metallurg 4. 2 TAKO Measuring Devices = Profile Width Werkstoffumformung = = Strip tension and flatness Tension Thickness EDC Speed D Cold Rolling TFV Rolling of flat material 17

Institut für Metallurg 4. 2 TAKO Measuring Devices = Profile Width Werkstoffumformung = = Strip tension and flatness Tension Thickness EDC Speed D Cold Rolling TFV Rolling of flat material 17

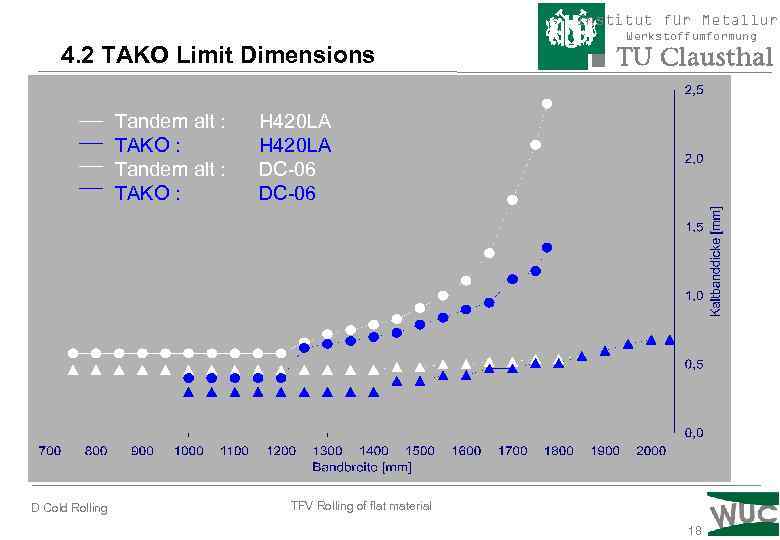

Institut für Metallurg 4. 2 TAKO Limit Dimensions Tandem alt : TAKO : D Cold Rolling Werkstoffumformung H 420 LA DC-06 TFV Rolling of flat material 18

Institut für Metallurg 4. 2 TAKO Limit Dimensions Tandem alt : TAKO : D Cold Rolling Werkstoffumformung H 420 LA DC-06 TFV Rolling of flat material 18

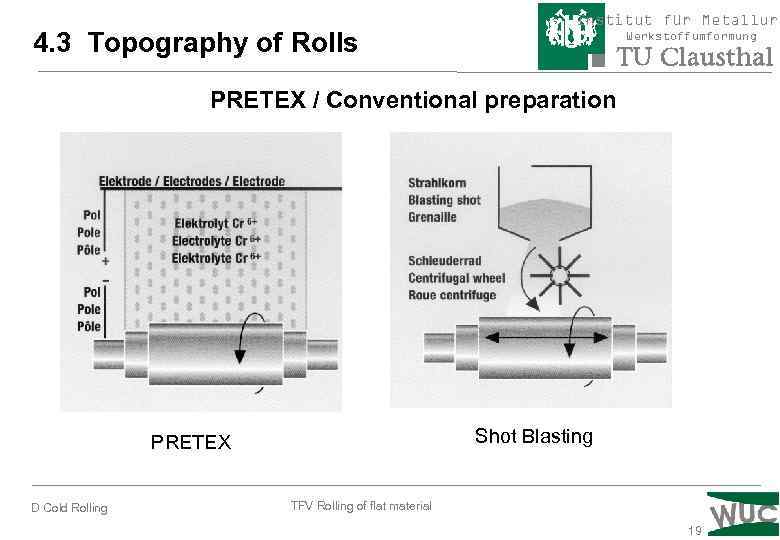

4. 3 Topography of Rolls Institut für Metallurg Werkstoffumformung PRETEX / Conventional preparation Shot Blasting PRETEX D Cold Rolling TFV Rolling of flat material 19

4. 3 Topography of Rolls Institut für Metallurg Werkstoffumformung PRETEX / Conventional preparation Shot Blasting PRETEX D Cold Rolling TFV Rolling of flat material 19

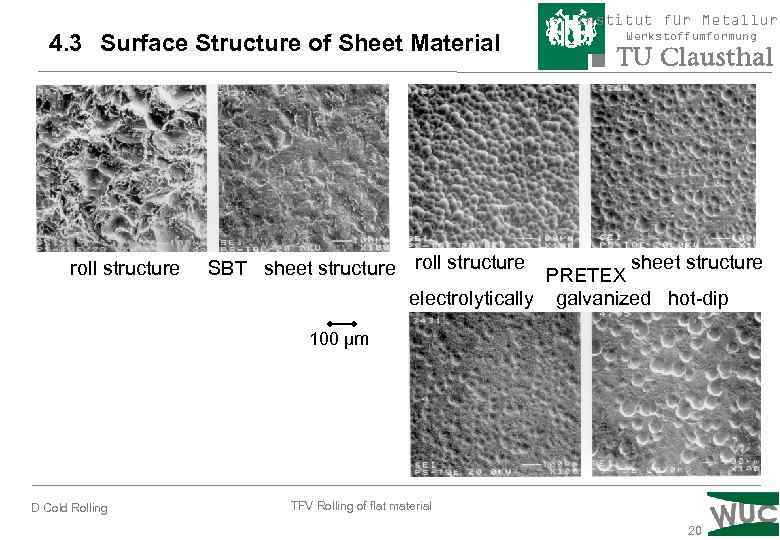

Institut für Metallurg 4. 3 Surface Structure of Sheet Material roll structure Werkstoffumformung sheet structure PRETEX electrolytically galvanized hot-dip SBT sheet structure roll structure 100 µm D Cold Rolling TFV Rolling of flat material 20

Institut für Metallurg 4. 3 Surface Structure of Sheet Material roll structure Werkstoffumformung sheet structure PRETEX electrolytically galvanized hot-dip SBT sheet structure roll structure 100 µm D Cold Rolling TFV Rolling of flat material 20

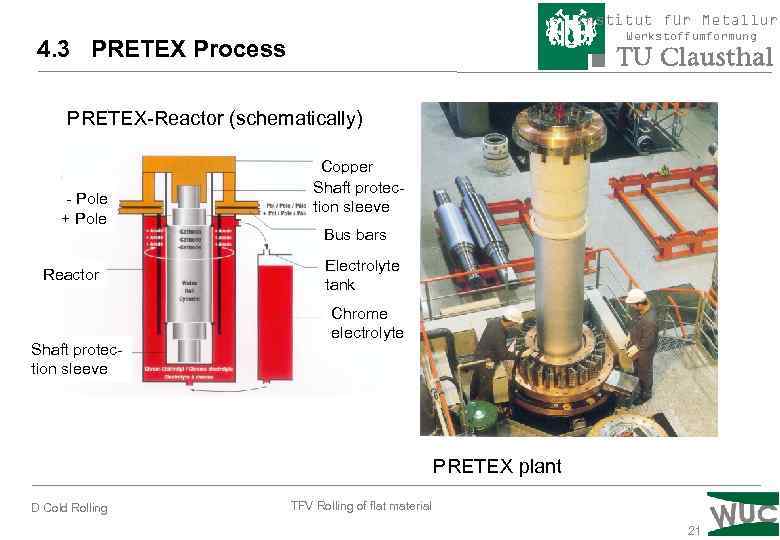

Institut für Metallurg Werkstoffumformung 4. 3 PRETEX Process PRETEX-Reactor (schematically) - Pole + Pole Reactor Shaft protection sleeve Copper head Shaft protection sleeve Bus bars Electrolyte tank Chrome electrolyte PRETEX plant D Cold Rolling TFV Rolling of flat material 21

Institut für Metallurg Werkstoffumformung 4. 3 PRETEX Process PRETEX-Reactor (schematically) - Pole + Pole Reactor Shaft protection sleeve Copper head Shaft protection sleeve Bus bars Electrolyte tank Chrome electrolyte PRETEX plant D Cold Rolling TFV Rolling of flat material 21

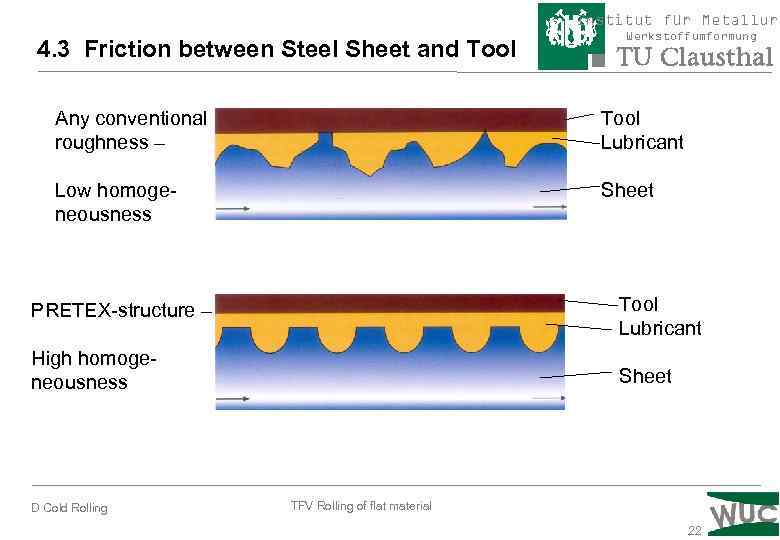

Institut für Metallurg 4. 3 Friction between Steel Sheet and Tool Werkstoffumformung Any conventional roughness – Tool Lubricant Low homogeneousness Sheet PRETEX-structure – Tool Lubricant High homogeneousness Sheet D Cold Rolling TFV Rolling of flat material 22

Institut für Metallurg 4. 3 Friction between Steel Sheet and Tool Werkstoffumformung Any conventional roughness – Tool Lubricant Low homogeneousness Sheet PRETEX-structure – Tool Lubricant High homogeneousness Sheet D Cold Rolling TFV Rolling of flat material 22