Insert Manufacturing 1

Insert Manufacturing 1

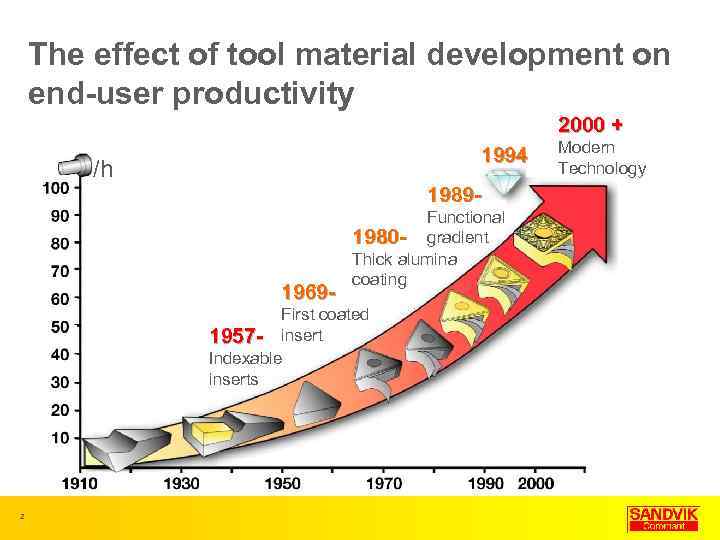

The effect of tool material development on end-user productivity 2000 + 1994 /h 1989 - 1969 - Functional 1980 - gradient Thick alumina coating First coated 1957 - insert Indexable inserts 2 Modern Technology

The effect of tool material development on end-user productivity 2000 + 1994 /h 1989 - 1969 - Functional 1980 - gradient Thick alumina coating First coated 1957 - insert Indexable inserts 2 Modern Technology

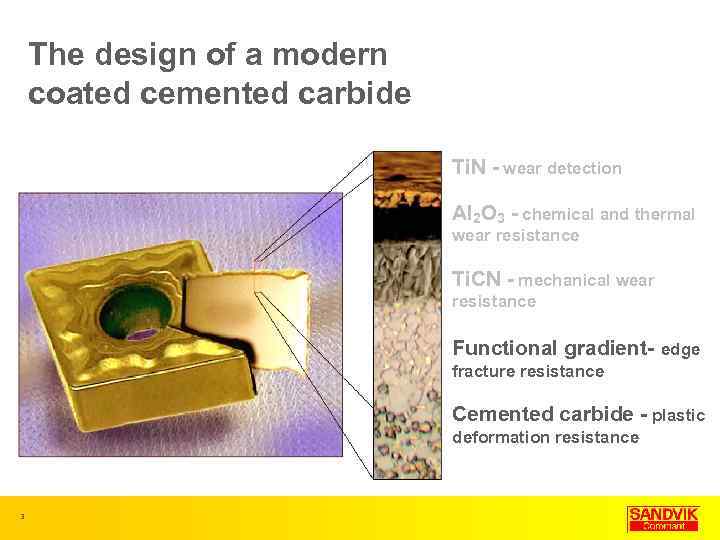

The design of a modern coated cemented carbide Ti. N - wear detection Al 2 O 3 - chemical and thermal wear resistance Ti. CN - mechanical wear resistance Functional gradient- edge fracture resistance Cemented carbide - plastic deformation resistance 3

The design of a modern coated cemented carbide Ti. N - wear detection Al 2 O 3 - chemical and thermal wear resistance Ti. CN - mechanical wear resistance Functional gradient- edge fracture resistance Cemented carbide - plastic deformation resistance 3

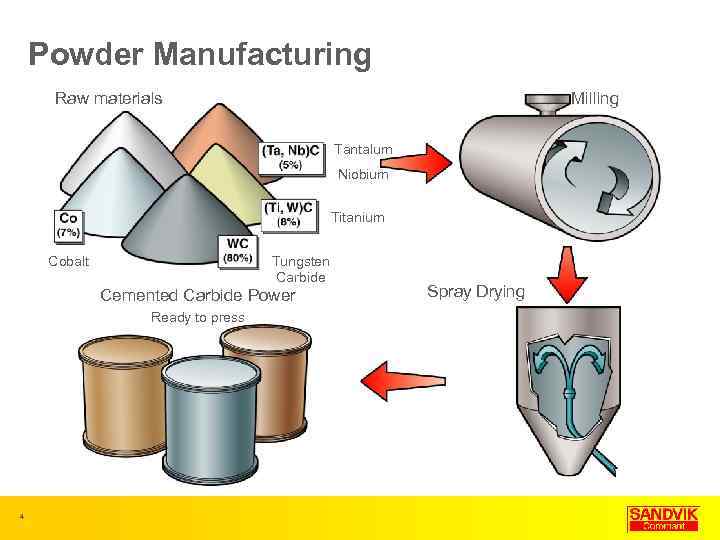

Powder Manufacturing Raw materials Milling Tantalum Niobium Titanium Cobalt Tungsten Carbide Cemented Carbide Power Ready to press 4 Spray Drying

Powder Manufacturing Raw materials Milling Tantalum Niobium Titanium Cobalt Tungsten Carbide Cemented Carbide Power Ready to press 4 Spray Drying

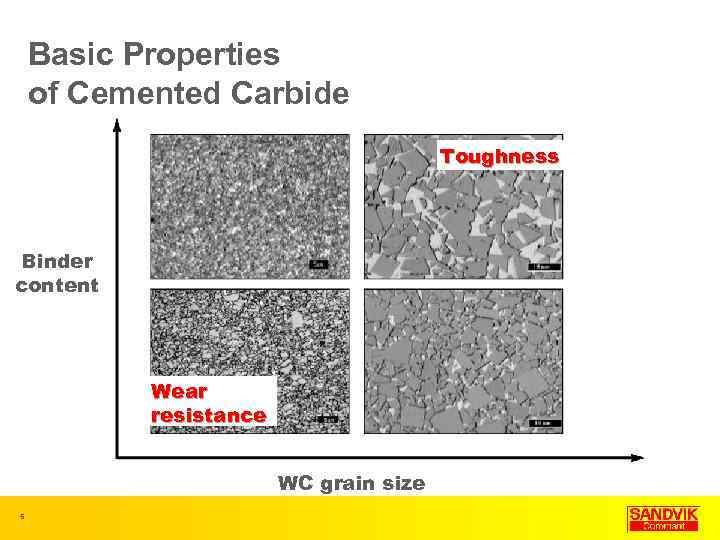

Basic Properties of Cemented Carbide Toughness Binder content Wear resistance WC grain size 5

Basic Properties of Cemented Carbide Toughness Binder content Wear resistance WC grain size 5

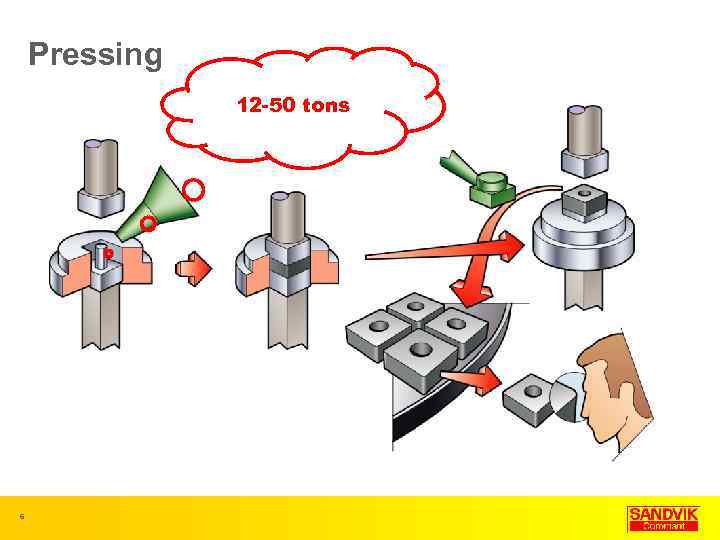

Pressing 12 -50 tons 6

Pressing 12 -50 tons 6

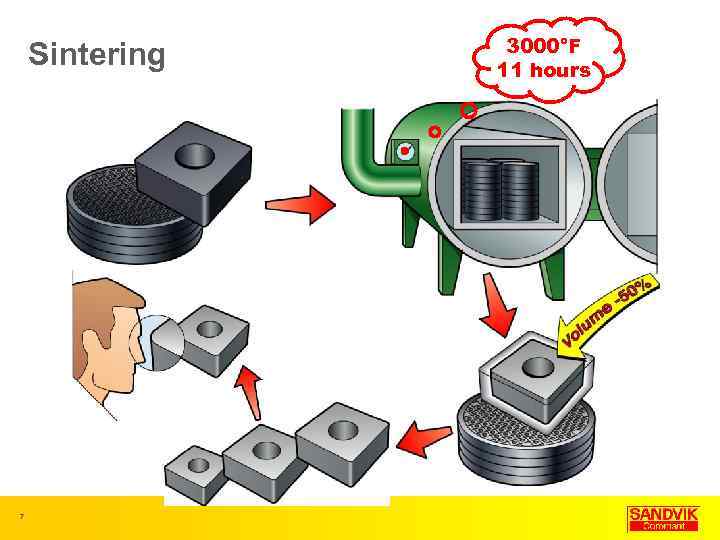

Sintering 7 3000°F 11 hours

Sintering 7 3000°F 11 hours

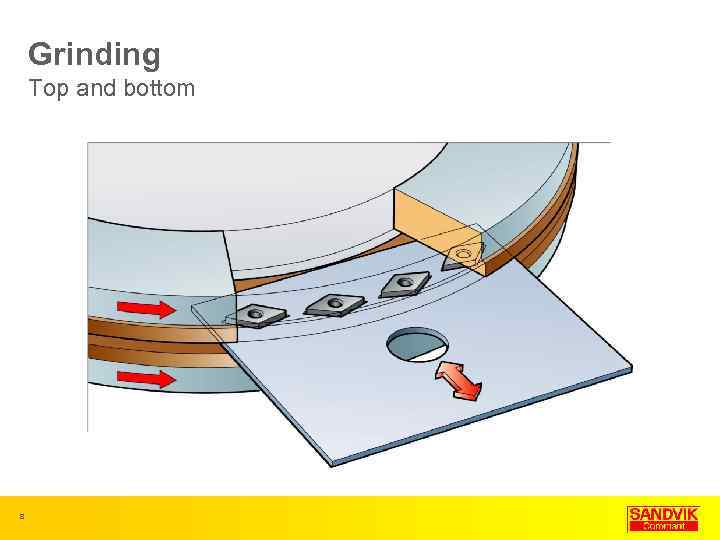

Grinding Top and bottom 8

Grinding Top and bottom 8

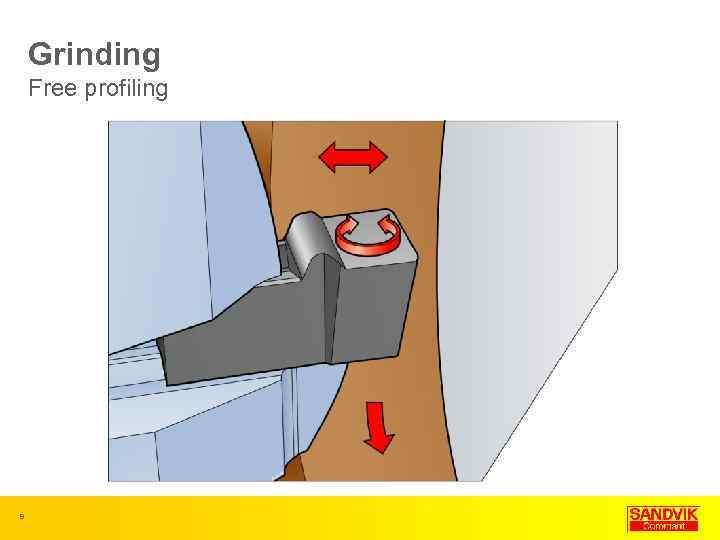

Grinding Free profiling 9

Grinding Free profiling 9

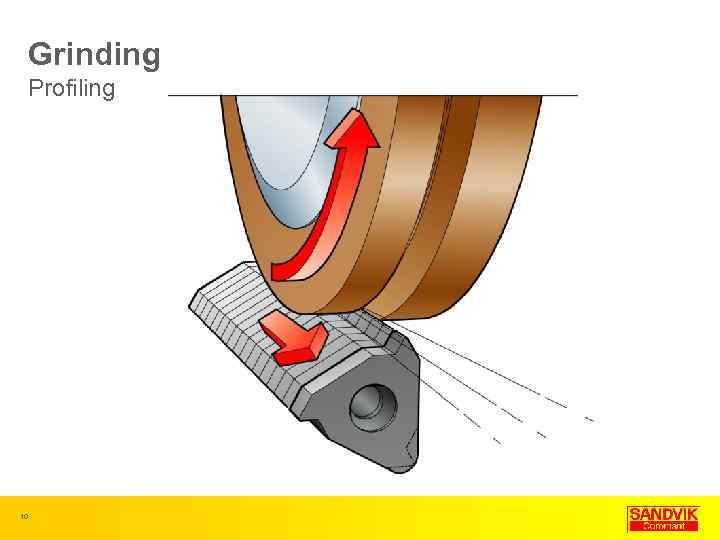

Grinding Profiling 10

Grinding Profiling 10

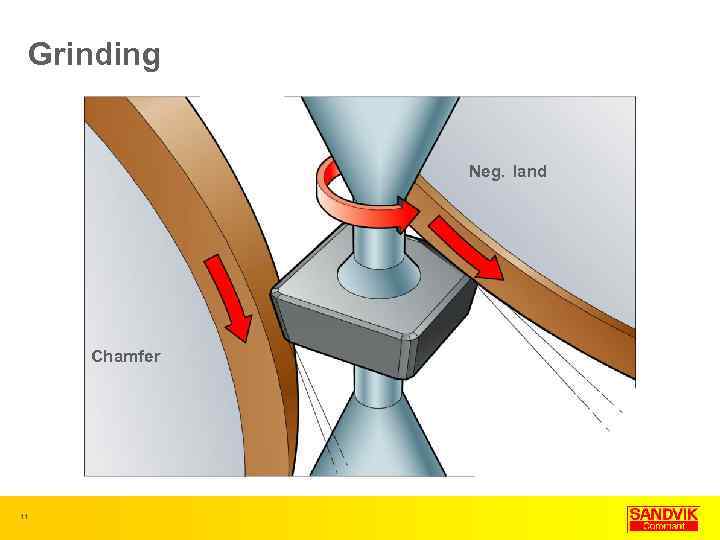

Grinding Neg. land Chamfer 11

Grinding Neg. land Chamfer 11

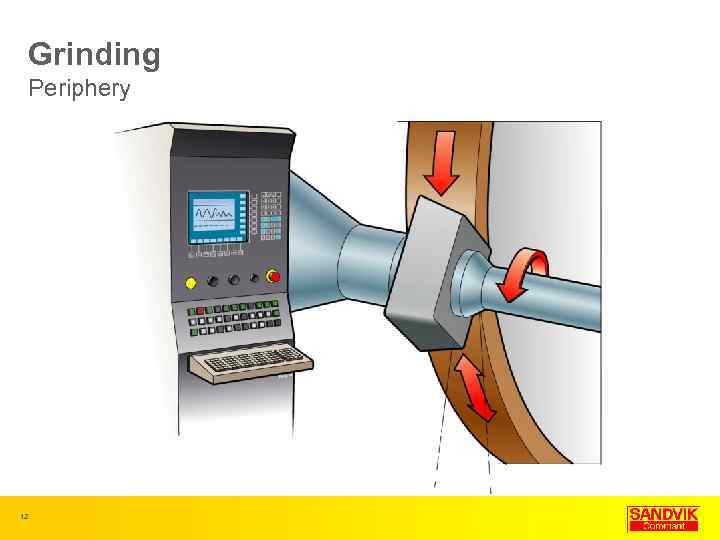

Grinding Periphery 12

Grinding Periphery 12

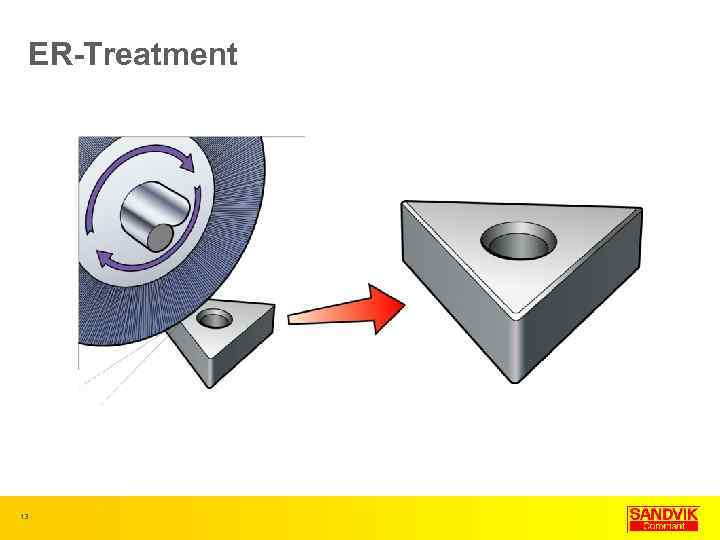

ER-Treatment 13

ER-Treatment 13

Cleaning 14

Cleaning 14

The design of a modern coated cemented carbide Ti. N - wear detection Al 2 O 3 - chemical and thermal wear resistance Ti. CN - mechanical wear resistance Functional gradientedge fracture resistance Cemented carbide plastic deformation resistance 15

The design of a modern coated cemented carbide Ti. N - wear detection Al 2 O 3 - chemical and thermal wear resistance Ti. CN - mechanical wear resistance Functional gradientedge fracture resistance Cemented carbide plastic deformation resistance 15

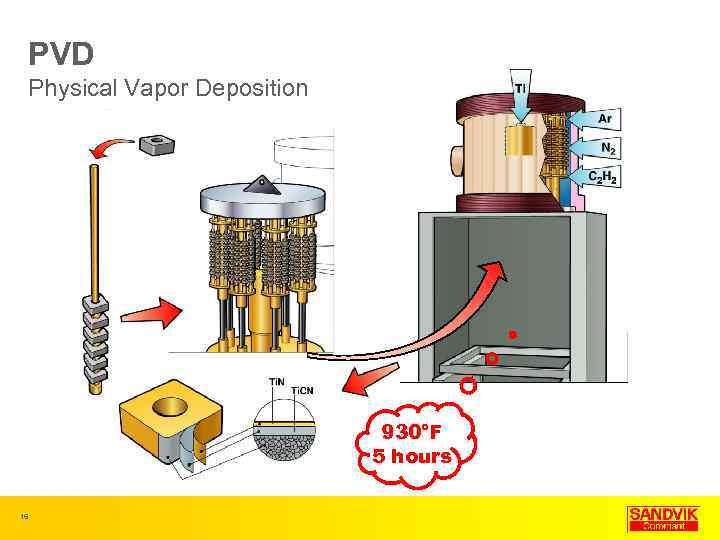

PVD Physical Vapor Deposition 930°F 5 hours 16

PVD Physical Vapor Deposition 930°F 5 hours 16

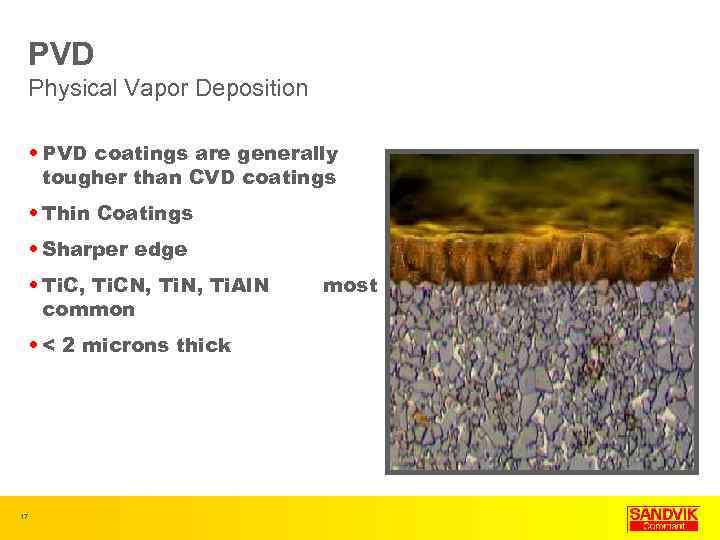

PVD Physical Vapor Deposition • PVD coatings are generally tougher than CVD coatings • Thin Coatings • Sharper edge • Ti. C, Ti. CN, Ti. Al. N common • < 2 microns thick 17 most

PVD Physical Vapor Deposition • PVD coatings are generally tougher than CVD coatings • Thin Coatings • Sharper edge • Ti. C, Ti. CN, Ti. Al. N common • < 2 microns thick 17 most

CVD Chemical Vapor Deposition Ti. Cl 4 N 2 Al 2 O 3 CO 2 Ti. Cl 4 CH 3 CN H 2 1800°F 30 hours 18

CVD Chemical Vapor Deposition Ti. Cl 4 N 2 Al 2 O 3 CO 2 Ti. Cl 4 CH 3 CN H 2 1800°F 30 hours 18

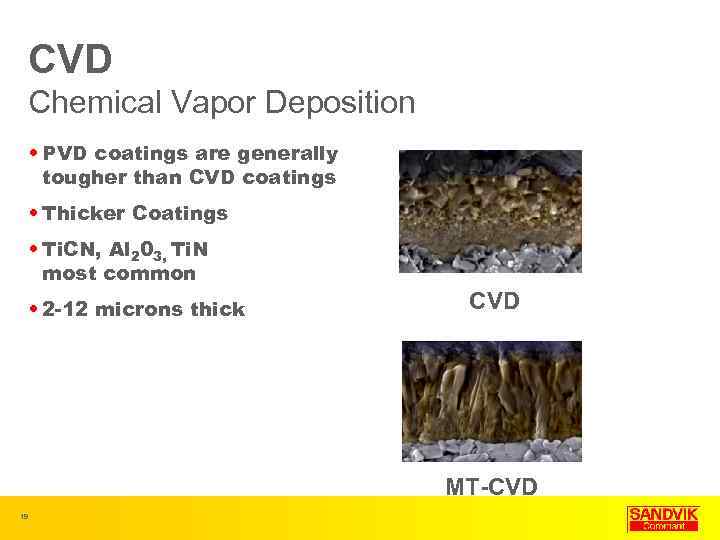

CVD Chemical Vapor Deposition • PVD coatings are generally tougher than CVD coatings • Thicker Coatings • Ti. CN, Al 203, Ti. N most common • 2 -12 microns thick CVD MT-CVD 19

CVD Chemical Vapor Deposition • PVD coatings are generally tougher than CVD coatings • Thicker Coatings • Ti. CN, Al 203, Ti. N most common • 2 -12 microns thick CVD MT-CVD 19

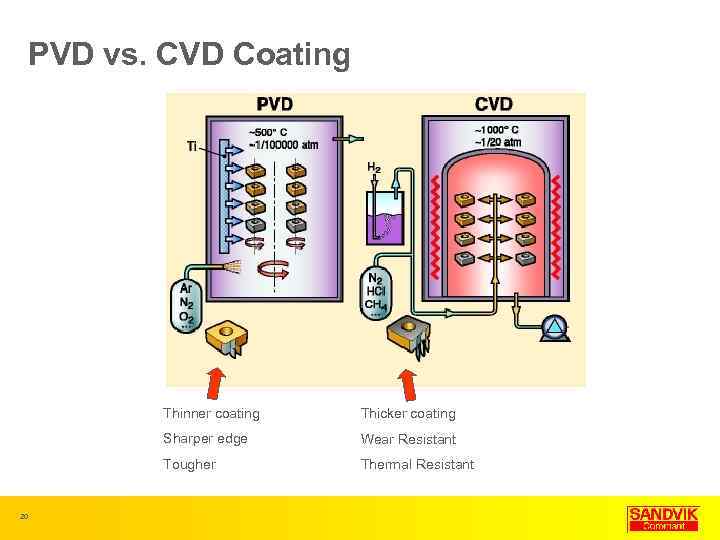

PVD vs. CVD Coating Thinner coating Sharper edge Wear Resistant Tougher 20 Thicker coating Thermal Resistant

PVD vs. CVD Coating Thinner coating Sharper edge Wear Resistant Tougher 20 Thicker coating Thermal Resistant

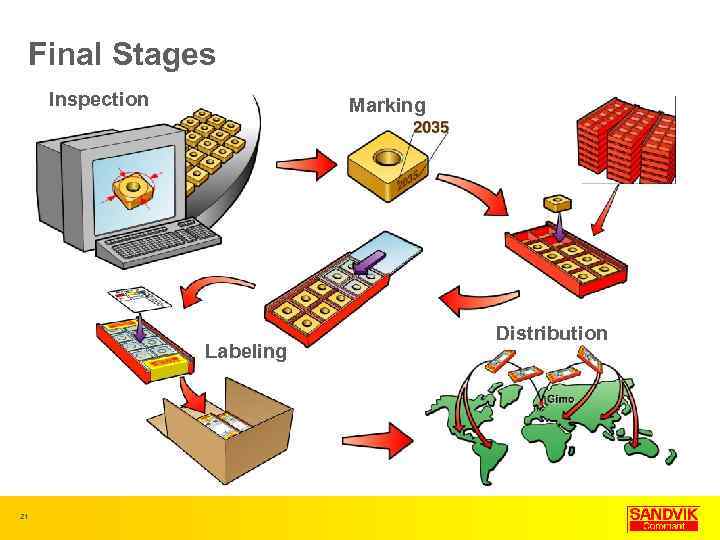

Final Stages Inspection Marking Labeling 21 Distribution

Final Stages Inspection Marking Labeling 21 Distribution

Insert Manufacturing Video 22

Insert Manufacturing Video 22

23

23