e119597d8360eea7c1e2c83810e24574.ppt

- Количество слайдов: 22

Innovations in Microarc Discharge Oxidizing technologies Prof. Boris L. Krit K. E. Tsyolkovsky «MATI» - Russian State Technological University Technologies of Materials Treatment by High Energy Flows Department www. tompve. ru tel: +7 -495 -3538334, fax: +7 -495 -3538372, e-mail: tompve-2005@yandex. ru

Microarc Discharge Oxidizing (MDO) Modification by nano-ceramic synthesis on metal surface

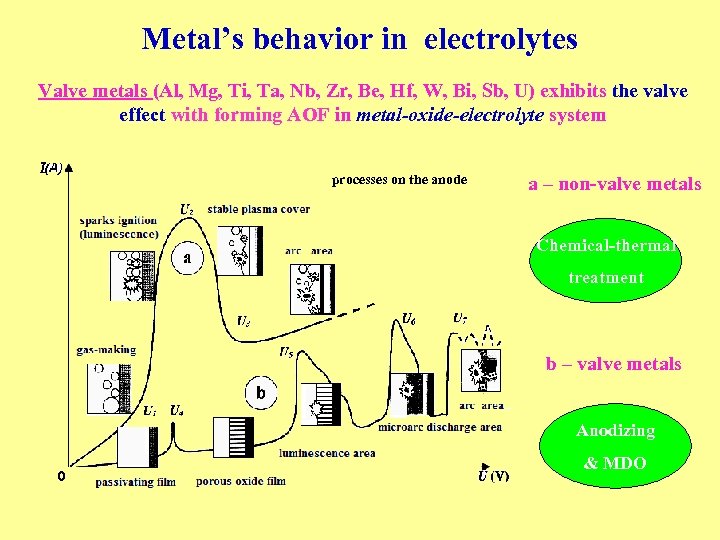

Metal’s behavior in electrolytes Valve metals (Al, Mg, Ti, Ta, Nb, Zr, Be, Hf, W, Bi, Sb, U) exhibits the valve effect with forming AOF in metal-oxide-electrolyte system processes on the anode a – non-valve metals Chemical-thermal treatment b – valve metals Anodizing & MDO

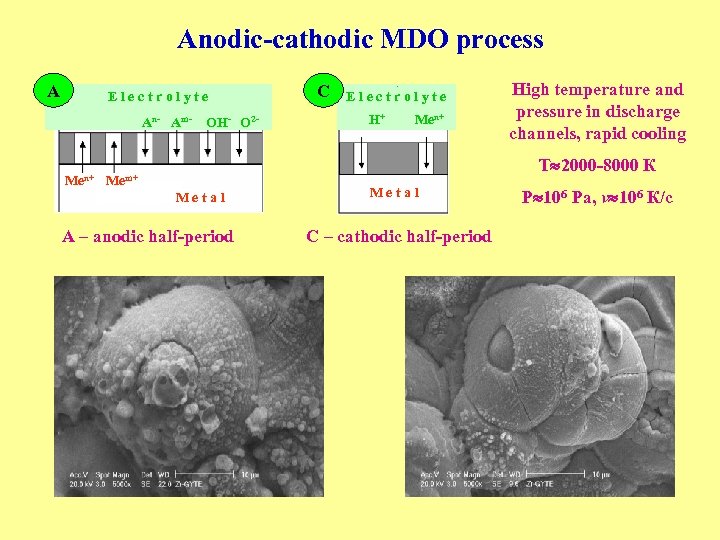

Anodic-cathodic MDO process A Electrolyte An- Am- Men+ OH- O 2 - C . Electrolyte H+ Men+ High temperature and pressure in discharge channels, rapid cooling T 2000 -8000 К Mem+ Metal A – anodic half-period Metal C – cathodic half-period P 106 Pa, v 106 К/с

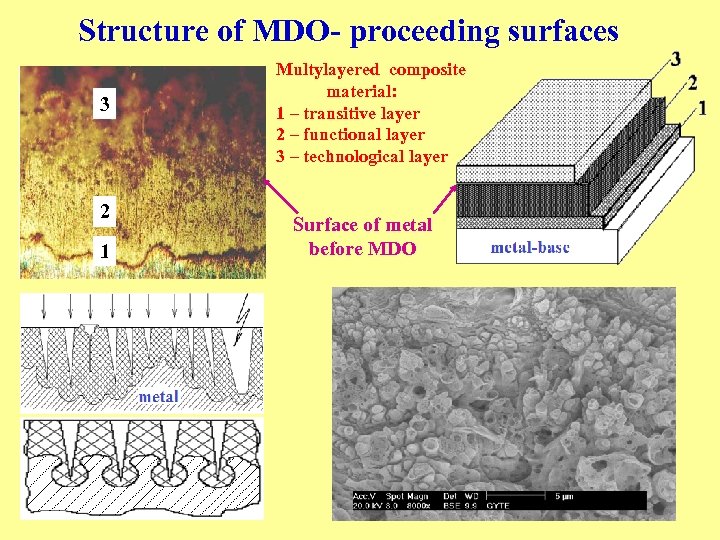

Structure of MDO- proceeding surfaces 3 2 1 Multylayered composite material: 1 – transitive layer 2 – functional layer 3 – technological layer Surface of metal before MDO

Comparative indicators of MDO Technology: Parameter MDO Anodizing Thermal Spraying ● max thickness, μm up to 400 up to 150 up to 5000 ● roughness Ra, μm 0. 1 – 10 0. 1 – 15 more 20 ●adhesion, kg/mm 2 up to 50 up to 12 up to 30 ● micro hardness HV, kg/mm 2 up to 2200 up to 750 up to 1800 ● breakdown voltage, V up to 5000 up to 600 up to 4000 ● corrosion resistance, mark * 9 6 6 -7 ● volume wear indicator, mm 3∙ 10 -3 1. 5 more 10 2. 0 ● thermal shock resistance, 0 С up to 2500 up to 800 up to 2000 ● total porosity, % 2 – 50% (controllable) 2 – 45% (limited controllable) more 30 ● ecological compatibility + – ± * ГОСТ 27597 -88 (Russian state standard)

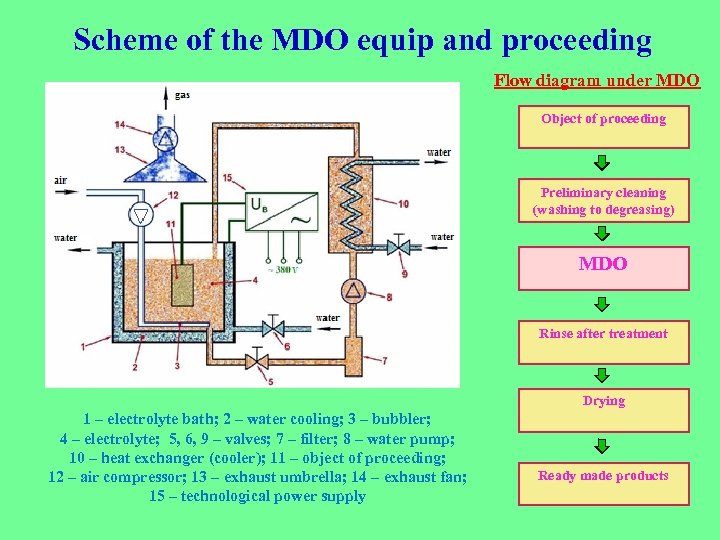

Scheme of the MDO equip and proceeding Flow diagram under MDO Object of proceeding Preliminary cleaning (washing to degreasing) MDO Rinse after treatment Drying 1 – electrolyte bath; 2 – water cooling; 3 – bubbler; 4 – electrolyte; 5, 6, 9 – valves; 7 – filter; 8 – water pump; 10 – heat exchanger (cooler); 11 – object of proceeding; 12 – air compressor; 13 – exhaust umbrella; 14 – exhaust fan; 15 – technological power supply Ready made products

Experience of the equipment implementation • Moscow State Industrial University, Russia (60 k. W) • Joint-stock company «ENA» , Russia (100 k. W) • R&D company «Orion» , Russia (200 k. W) • Penza polytechnic institute, Russia (60 k. W) • Beijing central R&D institute of Mining and Metallurgy «BCRIMM» , China (100 k. W) • Beijing XIN OU Science & Technology Development Co. , Ltd. , China (100 k. W) • Hauzer Techno Coating, Netherlands (100 k. W) • HPB, International Water Technology, Austria (100 k. W) Technological power supply (TPS) Electrolyte bath (reactor) • Belgorod State University, Russia (60 k. W) • Joint-stock company Cryogenmash» , Russia (100 k. W) • National Research Centre «Kurchatov Institute» , Russia (60 k. W) • Gebze Institute of Technology (GYTE), Turkey (100 k. W) • MOFRA group, France (60 k. W) • Saratov electro instrument-making factory name by Sergo Ordzhonikidze, Russia (100 k. W) • FSUE «Ufa Device Production Association» , Russia (100 k. W) Automated TPS Automated technological line

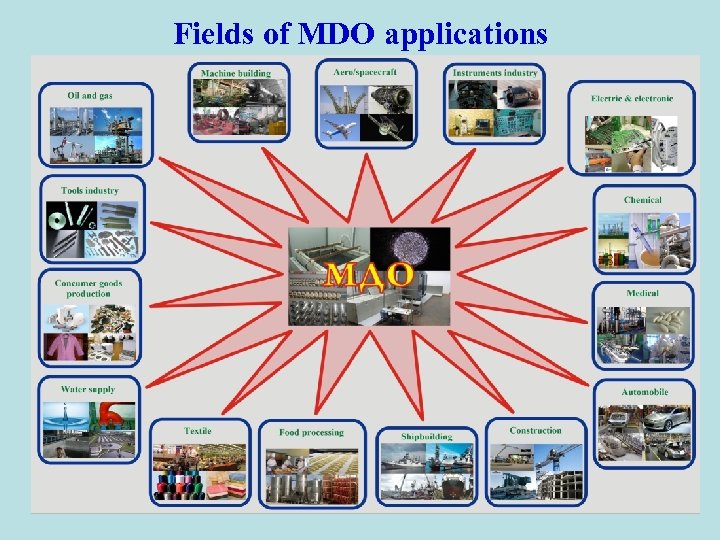

Fields of MDO applications

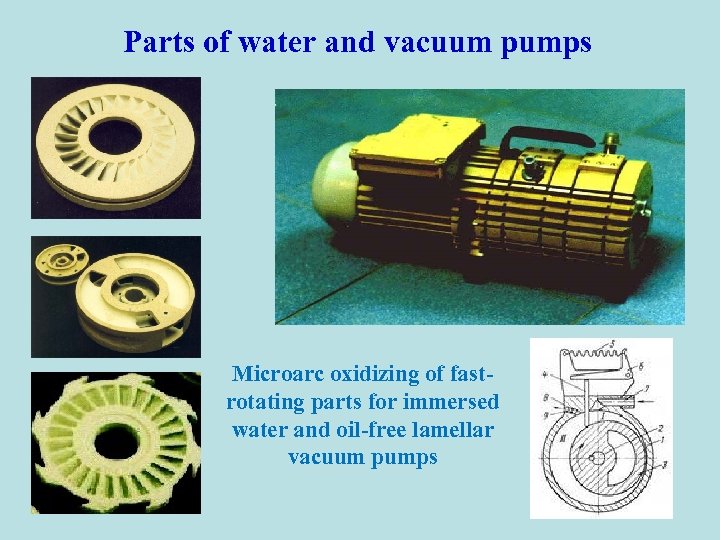

Parts of water and vacuum pumps Microarc oxidizing of fastrotating parts for immersed water and oil-free lamellar vacuum pumps

Lapped end - face consolidation for compressors Parts of disintegrators (mills)

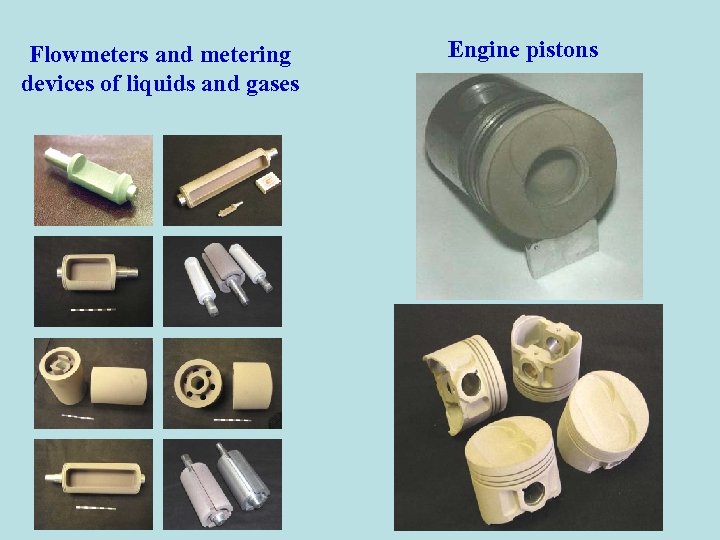

Flowmeters and metering devices of liquids and gases Engine pistons

Details of aerospace devices

Pneumatic/hydraulic systems for aerospace craft

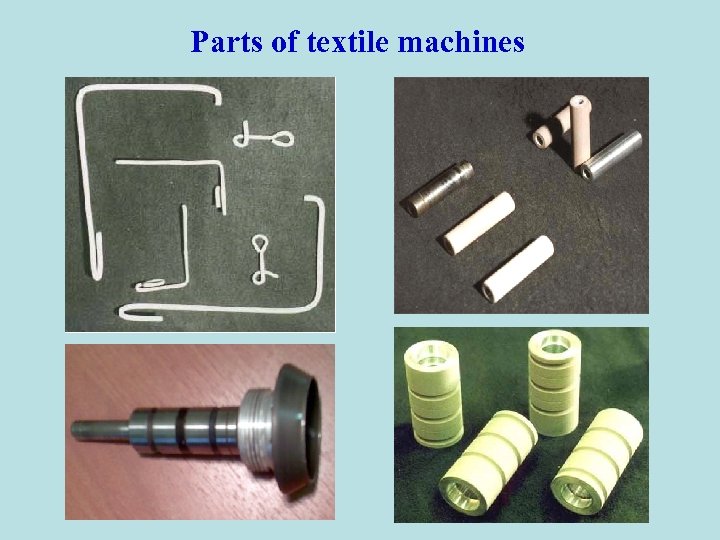

Parts of textile machines

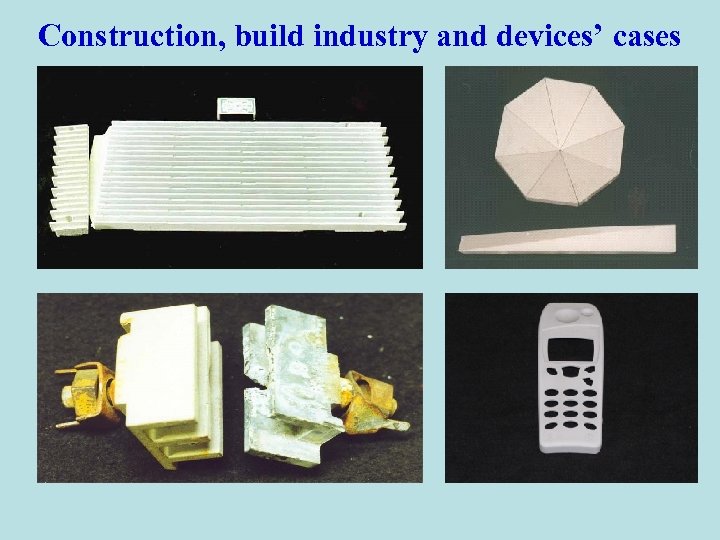

Construction, build industry and devices’ cases

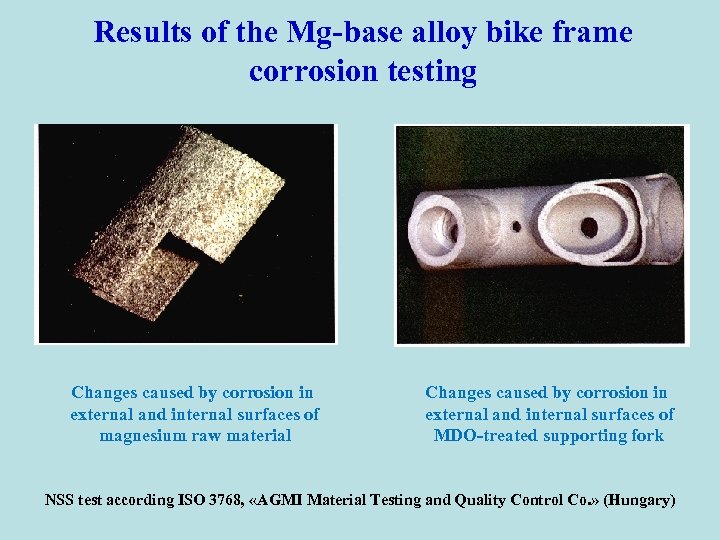

Results of the Mg-base alloy bike frame corrosion testing Changes caused by corrosion in external and internal surfaces of magnesium raw material Changes caused by corrosion in external and internal surfaces of MDO-treated supporting fork NSS test according ISO 3768, «AGMI Material Testing and Quality Control Co. » (Hungary)

Medical applications Coxofemoral joint implants Orthopaedic implants Handle of medical tools Nippers, tweezers

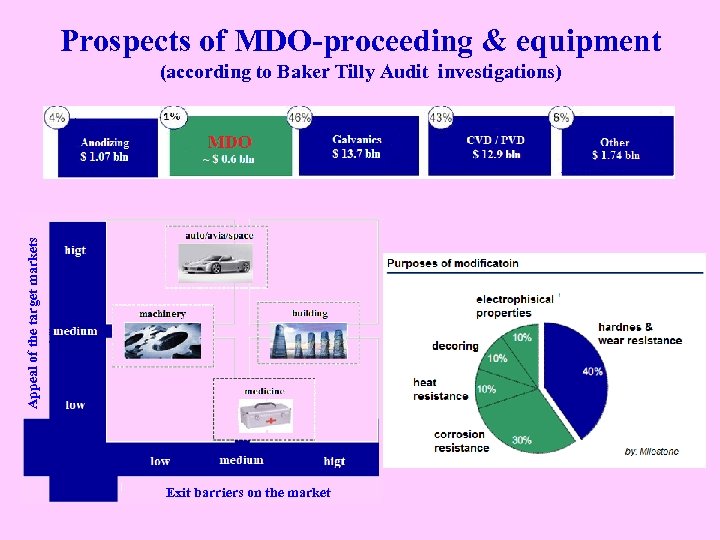

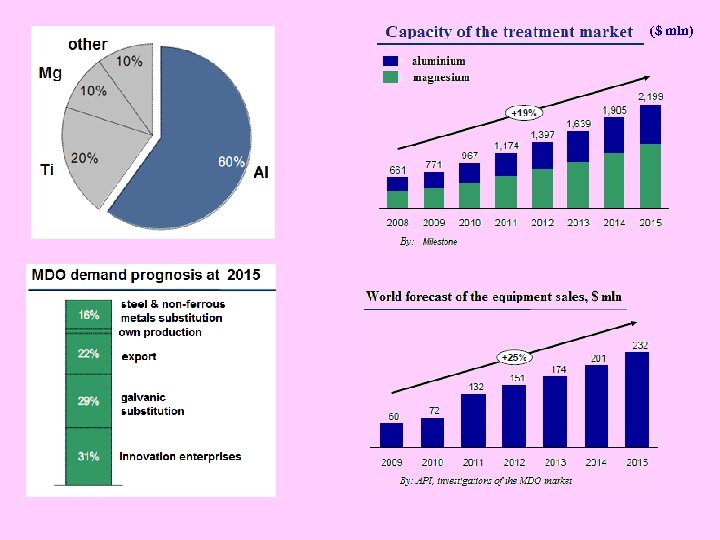

Prospects of MDO-proceeding & equipment Appeal of the target markets (according to Baker Tilly Audit investigations) Exit barriers on the market

($ mln)

Conclusion: Total capacity of surface modifications market ~ $ 30 bln Promising of the MDO market rising ~19% & of the MDO equipment market rising ~25% till 2015 MDO is at an early stage of industrial development and has the perfect future! Many thanks for your attention! K. E. Tsyolkovsky «MATI» - Russian State Technological University Technologies of Materials Treatment by High Energy Flows Department www. tompve. ru tel: +7 -495 -3538334, fax: +7 -495 -3538372, e-mail: tompve-2005@yandex. ru

e119597d8360eea7c1e2c83810e24574.ppt