7d85bc766dff12df424fae9470149a4f.ppt

- Количество слайдов: 20

Information Technology & Information Sharing in Supply Chains Zhi-Long Chen Michael O. Ball Robert H. Smith School of Business University of Maryland College Park, MD 20742 1

Information Technology & Information Sharing in Supply Chains Zhi-Long Chen Michael O. Ball Robert H. Smith School of Business University of Maryland College Park, MD 20742 1

Supply Chain Management as a Competitive Weapon It is becoming more difficult for companies to compete on cost or even product quality to seek new competitive advantages, companies are looking to innovative supply chains that can provide: – New levels of customer service especially in terms of order promising response and reliability – Greater product variety – extreme case customizable products – Fast introduction of new technologies – Fast introduction of new products may need to quickly reconfigure supply chain including supply chain partners Great burden on IT infrastructure. 2

Supply Chain Management as a Competitive Weapon It is becoming more difficult for companies to compete on cost or even product quality to seek new competitive advantages, companies are looking to innovative supply chains that can provide: – New levels of customer service especially in terms of order promising response and reliability – Greater product variety – extreme case customizable products – Fast introduction of new technologies – Fast introduction of new products may need to quickly reconfigure supply chain including supply chain partners Great burden on IT infrastructure. 2

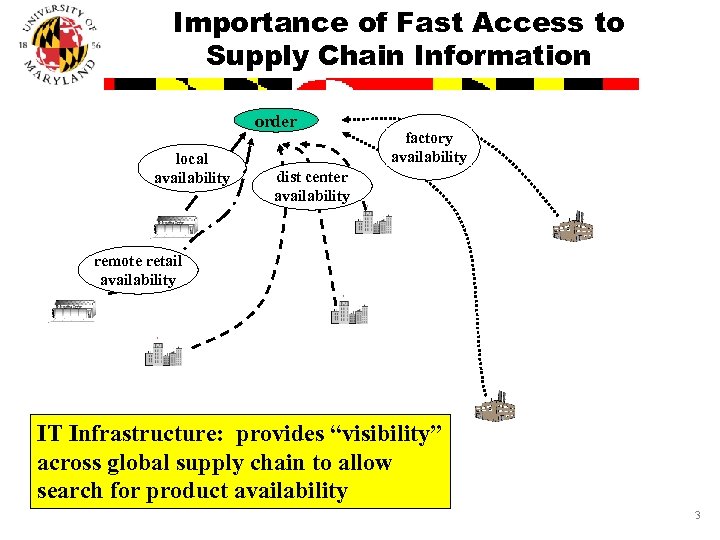

Importance of Fast Access to Supply Chain Information order local availability factory availability dist center availability remote retail availability IT Infrastructure: provides “visibility” across global supply chain to allow search for product availability 3

Importance of Fast Access to Supply Chain Information order local availability factory availability dist center availability remote retail availability IT Infrastructure: provides “visibility” across global supply chain to allow search for product availability 3

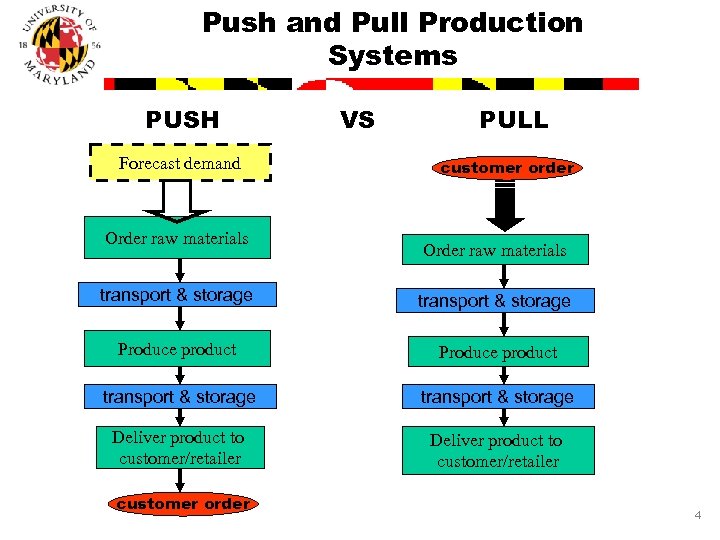

Push and Pull Production Systems PUSH Forecast demand Order raw materials VS PULL customer order Order raw materials transport & storage Produce product transport & storage Deliver product to customer/retailer customer order 4

Push and Pull Production Systems PUSH Forecast demand Order raw materials VS PULL customer order Order raw materials transport & storage Produce product transport & storage Deliver product to customer/retailer customer order 4

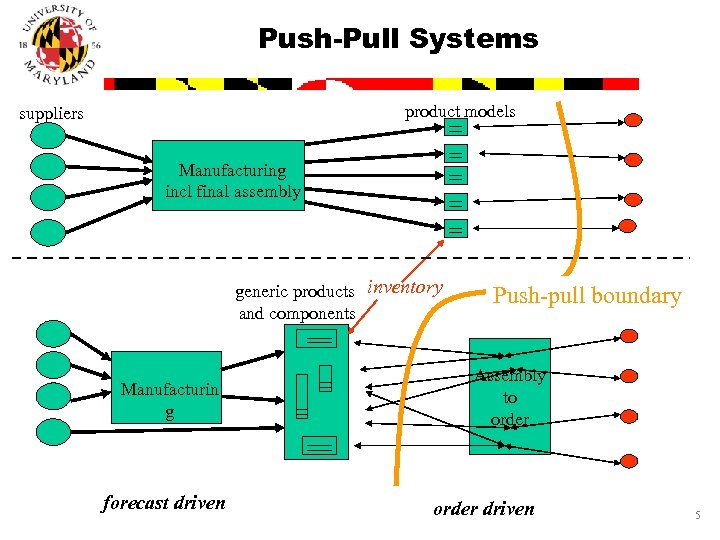

Push-Pull Systems product models suppliers Manufacturing incl final assembly generic products inventory and components Manufacturin g forecast driven Push-pull boundary Assembly to order driven 5

Push-Pull Systems product models suppliers Manufacturing incl final assembly generic products inventory and components Manufacturin g forecast driven Push-pull boundary Assembly to order driven 5

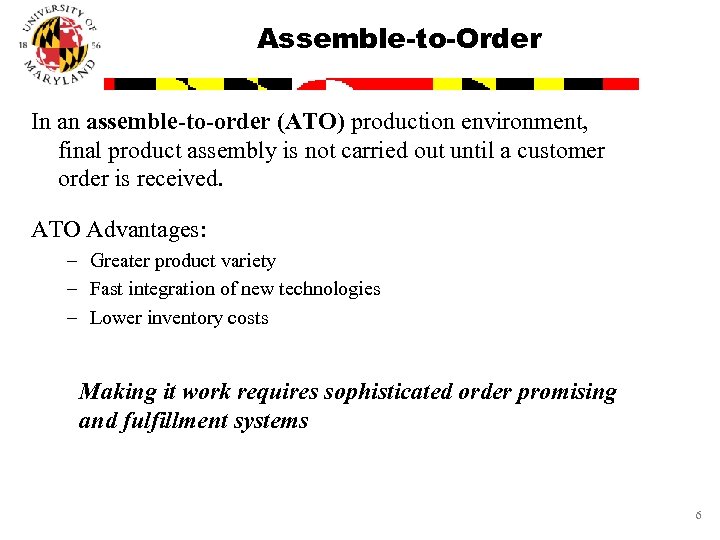

Assemble-to-Order In an assemble-to-order (ATO) production environment, final product assembly is not carried out until a customer order is received. ATO Advantages: – Greater product variety – Fast integration of new technologies – Lower inventory costs Making it work requires sophisticated order promising and fulfillment systems 6

Assemble-to-Order In an assemble-to-order (ATO) production environment, final product assembly is not carried out until a customer order is received. ATO Advantages: – Greater product variety – Fast integration of new technologies – Lower inventory costs Making it work requires sophisticated order promising and fulfillment systems 6

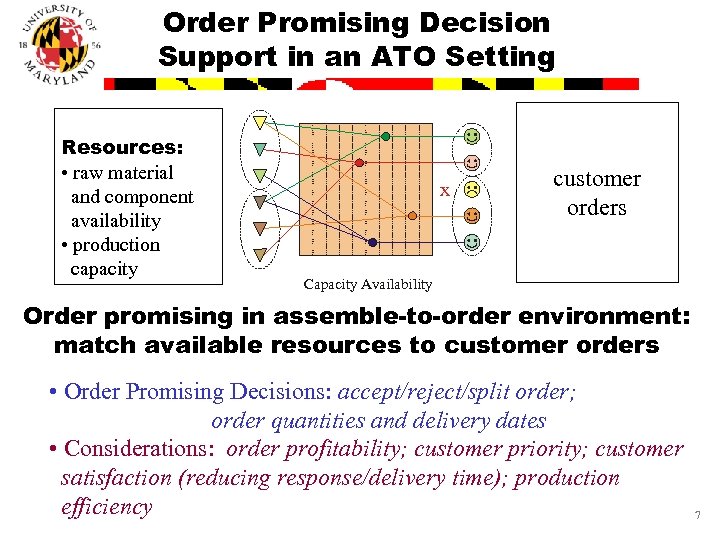

Order Promising Decision Support in an ATO Setting Capacity Planning Resources: Aggregate Planning • raw material Master Production and component Scheduling (MPS) availability Material Requirements • production Planning (MRP) capacity Picking Production x customer Assembly orders Packaging Shipping Capacity Availability Order promising in assemble-to-order environment: match available resources to customer orders • Order Promising Decisions: accept/reject/split order; order quantities and delivery dates • Considerations: order profitability; customer priority; customer satisfaction (reducing response/delivery time); production efficiency 7

Order Promising Decision Support in an ATO Setting Capacity Planning Resources: Aggregate Planning • raw material Master Production and component Scheduling (MPS) availability Material Requirements • production Planning (MRP) capacity Picking Production x customer Assembly orders Packaging Shipping Capacity Availability Order promising in assemble-to-order environment: match available resources to customer orders • Order Promising Decisions: accept/reject/split order; order quantities and delivery dates • Considerations: order profitability; customer priority; customer satisfaction (reducing response/delivery time); production efficiency 7

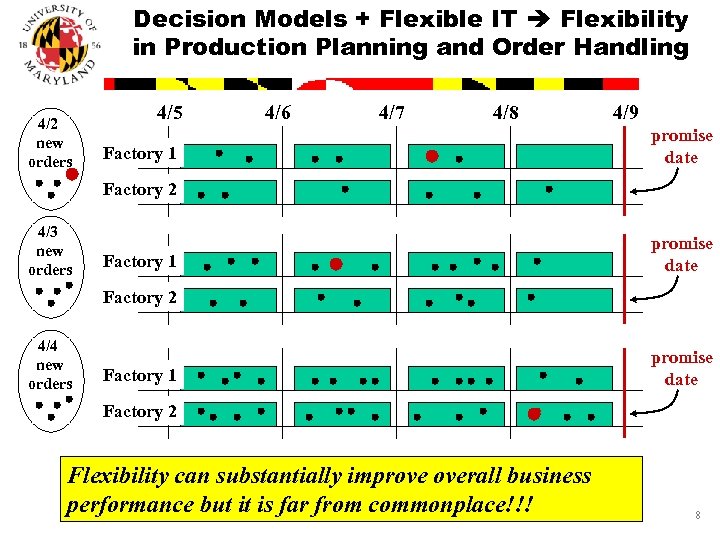

Decision Models + Flexible IT Flexibility in Production Planning and Order Handling 4/2 new orders 4/5 4/6 4/7 4/8 Factory 1 4/9 promise date Factory 2 4/3 new orders Factory 1 promise date Factory 2 4/4 new orders Factory 1 promise date Factory 2 Flexibility can substantially improve overall business performance but it is far from commonplace!!! 8

Decision Models + Flexible IT Flexibility in Production Planning and Order Handling 4/2 new orders 4/5 4/6 4/7 4/8 Factory 1 4/9 promise date Factory 2 4/3 new orders Factory 1 promise date Factory 2 4/4 new orders Factory 1 promise date Factory 2 Flexibility can substantially improve overall business performance but it is far from commonplace!!! 8

Information Technology Challenges • Integration of business information systems: ERP, supply chain mgmt, etc. • Inter-company communication (vital in today’s multi-company supply chains) • Making sophisticated business systems available to small and medium-sized firms • Non-technical challenges: – international regulatory and standards issues – balancing need to share with privacy needs 9

Information Technology Challenges • Integration of business information systems: ERP, supply chain mgmt, etc. • Inter-company communication (vital in today’s multi-company supply chains) • Making sophisticated business systems available to small and medium-sized firms • Non-technical challenges: – international regulatory and standards issues – balancing need to share with privacy needs 9

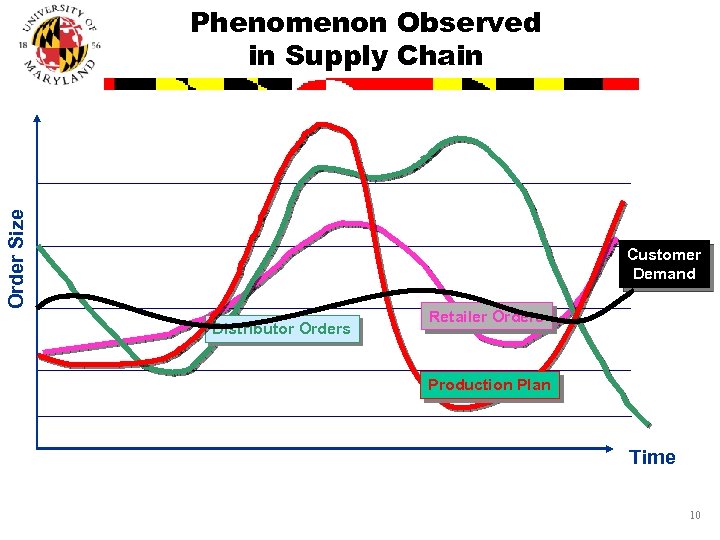

Order Size Phenomenon Observed in Supply Chain Customer Demand Distributor Orders Retailer Orders Production Plan Time 10

Order Size Phenomenon Observed in Supply Chain Customer Demand Distributor Orders Retailer Orders Production Plan Time 10

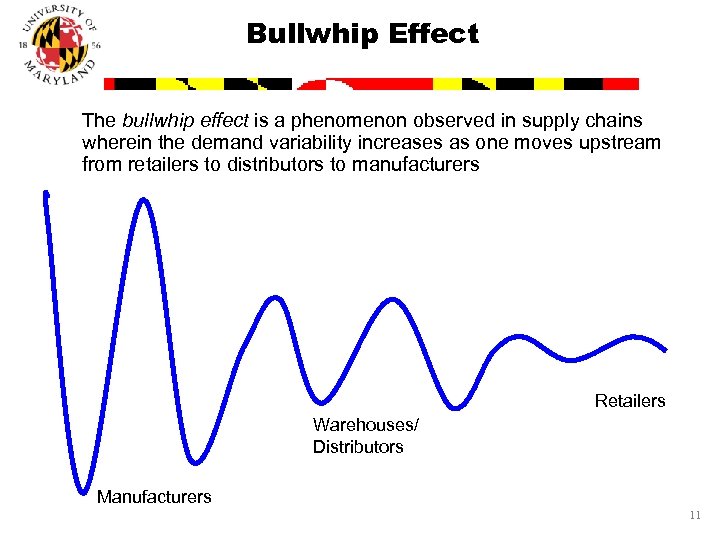

Bullwhip Effect The bullwhip effect is a phenomenon observed in supply chains wherein the demand variability increases as one moves upstream from retailers to distributors to manufacturers Retailers Warehouses/ Distributors Manufacturers 11

Bullwhip Effect The bullwhip effect is a phenomenon observed in supply chains wherein the demand variability increases as one moves upstream from retailers to distributors to manufacturers Retailers Warehouses/ Distributors Manufacturers 11

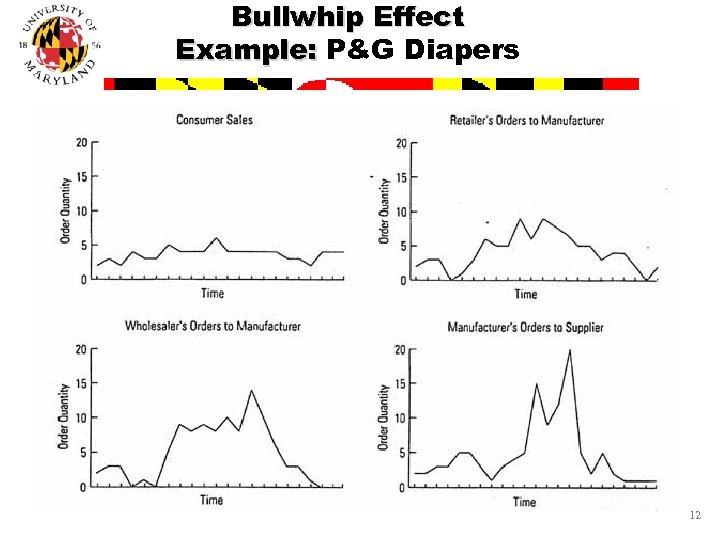

Bullwhip Effect Example: P&G Diapers 12

Bullwhip Effect Example: P&G Diapers 12

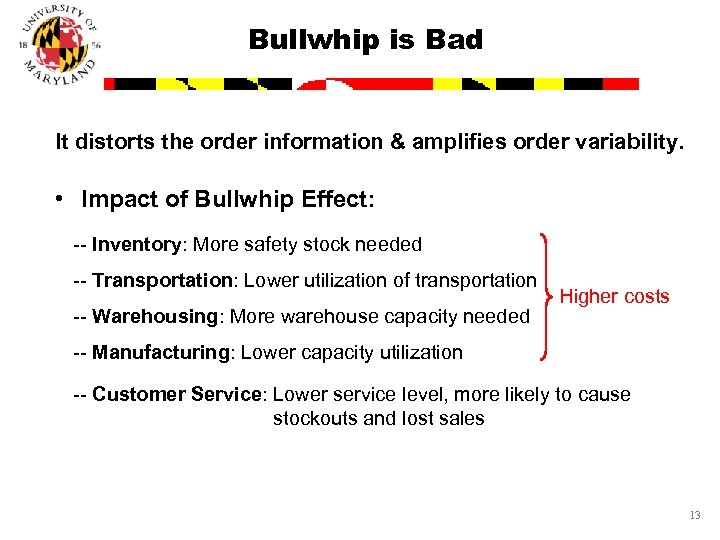

Bullwhip is Bad It distorts the order information & amplifies order variability. • Impact of Bullwhip Effect: -- Inventory: More safety stock needed -- Transportation: Lower utilization of transportation -- Warehousing: More warehouse capacity needed Higher costs -- Manufacturing: Lower capacity utilization -- Customer Service: Lower service level, more likely to cause stockouts and lost sales 13

Bullwhip is Bad It distorts the order information & amplifies order variability. • Impact of Bullwhip Effect: -- Inventory: More safety stock needed -- Transportation: Lower utilization of transportation -- Warehousing: More warehouse capacity needed Higher costs -- Manufacturing: Lower capacity utilization -- Customer Service: Lower service level, more likely to cause stockouts and lost sales 13

Causes of Bullwhip Effect • Root Causes: Lack of Information 1. Demand forecast updating 2. Rationing and shortage gaming 14

Causes of Bullwhip Effect • Root Causes: Lack of Information 1. Demand forecast updating 2. Rationing and shortage gaming 14

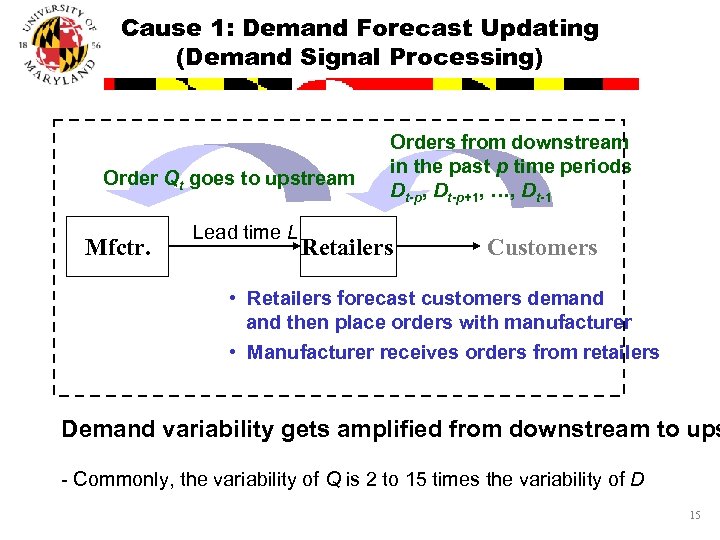

Cause 1: Demand Forecast Updating (Demand Signal Processing) Order Qt goes to upstream Mfctr. Lead time L Orders from downstream in the past p time periods Dt-p, Dt-p+1, …, Dt-1 Retailers Customers • Retailers forecast customers demand then place orders with manufacturer • Manufacturer receives orders from retailers Demand variability gets amplified from downstream to ups - Commonly, the variability of Q is 2 to 15 times the variability of D 15

Cause 1: Demand Forecast Updating (Demand Signal Processing) Order Qt goes to upstream Mfctr. Lead time L Orders from downstream in the past p time periods Dt-p, Dt-p+1, …, Dt-1 Retailers Customers • Retailers forecast customers demand then place orders with manufacturer • Manufacturer receives orders from retailers Demand variability gets amplified from downstream to ups - Commonly, the variability of Q is 2 to 15 times the variability of D 15

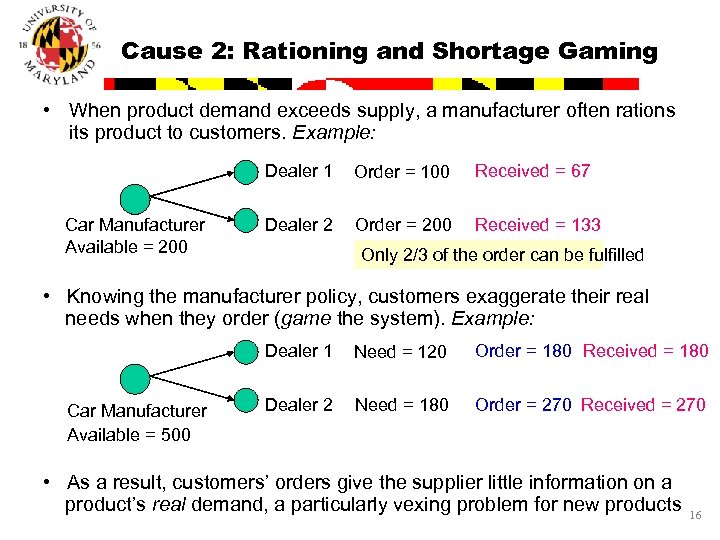

Cause 2: Rationing and Shortage Gaming • When product demand exceeds supply, a manufacturer often rations its product to customers. Example: Dealer 1 Car Manufacturer Available = 200 Order = 100 Received = 67 Dealer 2 Order = 200 Received = 133 Only 2/3 of the order can be fulfilled • Knowing the manufacturer policy, customers exaggerate their real needs when they order (game the system). Example: Dealer 1 Car Manufacturer Available = 500 Need = 120 Order = 180 Received = 180 Dealer 2 Need = 180 Order = 270 Received = 270 • As a result, customers’ orders give the supplier little information on a product’s real demand, a particularly vexing problem for new products 16

Cause 2: Rationing and Shortage Gaming • When product demand exceeds supply, a manufacturer often rations its product to customers. Example: Dealer 1 Car Manufacturer Available = 200 Order = 100 Received = 67 Dealer 2 Order = 200 Received = 133 Only 2/3 of the order can be fulfilled • Knowing the manufacturer policy, customers exaggerate their real needs when they order (game the system). Example: Dealer 1 Car Manufacturer Available = 500 Need = 120 Order = 180 Received = 180 Dealer 2 Need = 180 Order = 270 Received = 270 • As a result, customers’ orders give the supplier little information on a product’s real demand, a particularly vexing problem for new products 16

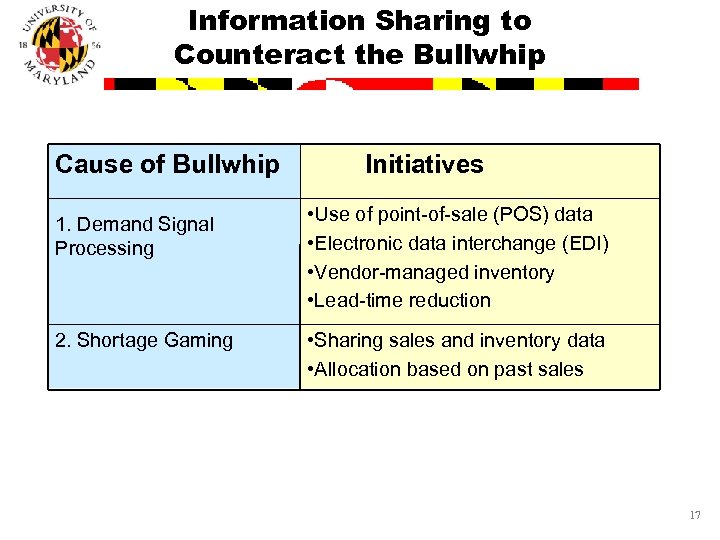

Information Sharing to Counteract the Bullwhip Cause of Bullwhip 1. Demand Signal Processing 2. Shortage Gaming Initiatives • Use of point-of-sale (POS) data • Electronic data interchange (EDI) • Vendor-managed inventory • Lead-time reduction • Sharing sales and inventory data • Allocation based on past sales 17

Information Sharing to Counteract the Bullwhip Cause of Bullwhip 1. Demand Signal Processing 2. Shortage Gaming Initiatives • Use of point-of-sale (POS) data • Electronic data interchange (EDI) • Vendor-managed inventory • Lead-time reduction • Sharing sales and inventory data • Allocation based on past sales 17

Famous Success Story: Benetton • Benetton, the Italian sportswear manufacturer, was founded in 1964. In 1975, Benetton had 200 stores across Italy. • Ten years later, the company expanded to the U. S. , Japan and Eastern Europe. Sales in 1991 reached 2 trillion. • Many attribute Benetton’s success to successful use of communication and information technologies in their supply chain. 18

Famous Success Story: Benetton • Benetton, the Italian sportswear manufacturer, was founded in 1964. In 1975, Benetton had 200 stores across Italy. • Ten years later, the company expanded to the U. S. , Japan and Eastern Europe. Sales in 1991 reached 2 trillion. • Many attribute Benetton’s success to successful use of communication and information technologies in their supply chain. 18

Famous Success Story: Benetton 1. Integrated Information Systems • Global EDI network that links agents with production and inventory information • EDI order transmission to HQ • EDI linkage with air carriers • Data linked to manufacturing 2. Coordinated Planning • Frequent review allows fast reaction • Integrated distribution strategy 19

Famous Success Story: Benetton 1. Integrated Information Systems • Global EDI network that links agents with production and inventory information • EDI order transmission to HQ • EDI linkage with air carriers • Data linked to manufacturing 2. Coordinated Planning • Frequent review allows fast reaction • Integrated distribution strategy 19

Information Sharing Challenges • Build strategic partnerships between manufacturers, distributors, and retailers • Develop effective collaborative demand forecasting methods • Create effective mechanisms for information sharing across supply chain partners: – Technical issues • Integrating incompatible systems • standards – Business issues: • incentives to share • Overcoming privacy/proprietary information concerns 20

Information Sharing Challenges • Build strategic partnerships between manufacturers, distributors, and retailers • Develop effective collaborative demand forecasting methods • Create effective mechanisms for information sharing across supply chain partners: – Technical issues • Integrating incompatible systems • standards – Business issues: • incentives to share • Overcoming privacy/proprietary information concerns 20