f64e01261247e7fb1b06095847352ff1.ppt

- Количество слайдов: 4

“Industrial Product Development Best Practices for Vaccines” Rémi PAULE Deputy Director, Methods & Indicators, Global Manufacturing Technology Sanofi pasteur Storyboard Presentation – Unique Customization February 20 -21, 2007 / St. Pete’s Beach, FL

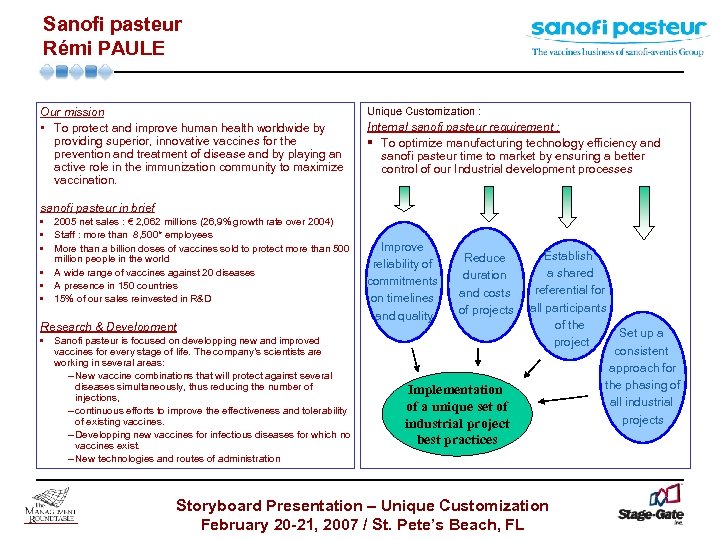

Sanofi pasteur Rémi PAULE Our mission • To protect and improve human health worldwide by providing superior, innovative vaccines for the prevention and treatment of disease and by playing an active role in the immunization community to maximize vaccination. Unique Customization : Internal sanofi pasteur requirement : § To optimize manufacturing technology efficiency and sanofi pasteur time to market by ensuring a better control of our Industrial development processes sanofi pasteur in brief • 2005 net sales : € 2, 062 millions (26, 9% growth rate over 2004) • Staff : more than 8, 500* employees • More than a billion doses of vaccines sold to protect more than 500 million people in the world • A wide range of vaccines against 20 diseases • A presence in 150 countries • 15% of our sales reinvested in R&D Research & Development • Sanofi pasteur is focused on developping new and improved vaccines for every stage of life. The company’s scientists are working in several areas: – New vaccine combinations that will protect against several diseases simultaneously, thus reducing the number of injections, – continuous efforts to improve the effectiveness and tolerability of existing vaccines. – Developping new vaccines for infectious diseases for which no vaccines exist. – New technologies and routes of administration Improve reliability of commitments on timelines and quality Reduce duration and costs of projects Implementation of a unique set of industrial project best practices Establish a shared referential for all participants of the Set up a project consistent approach for the phasing of all industrial projects Storyboard Presentation – Unique Customization February 20 -21, 2007 / St. Pete’s Beach, FL

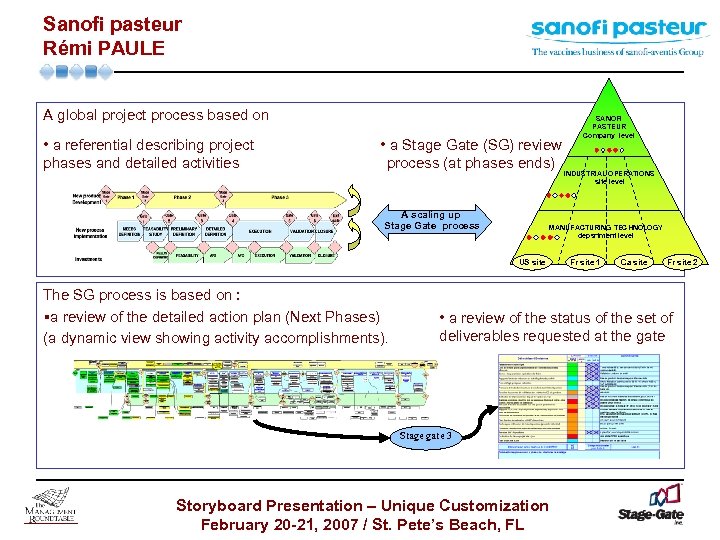

Sanofi pasteur Rémi PAULE Company Logo A global project process based on • a referential describing project phases and detailed activities • a Stage Gate (SG) review process (at phases ends) SANOFI PASTEUR Company level INDUSTRIAL OPERATIONS site level A scaling up Stage Gate process MANUFACTURING TECHNOLOGY depsrtment level US site The SG process is based on : §a review of the detailed action plan (Next Phases) (a dynamic view showing activity accomplishments). Fr site 1 Ca site Fr site 2 • a review of the status of the set of deliverables requested at the gate Stage gate 3 Storyboard Presentation – Unique Customization February 20 -21, 2007 / St. Pete’s Beach, FL

Sanofi pasteur Rémi PAULE Team: Company Logo Results: § Sponsor : René LABATUT (VP Global MTECH) § A common referential to manage our industrial projects worldwide, and a shared process between § Project Leader : Jean Michel VIOLAY / Rémi PAULE functions involved. (Director / Project leader – Global MTECH) § A process providing a clear and harmonized picture § Project team : Peter THOMPSON (MTECH US) of our projects. The SG follow up is used as a basis for Larry TAN (MTECH Ca) our Key Project Milestone indicator. François LEGUELLEC (MTECH Fr) § A better mid & long term visibility about project + all directors from functions portfolio that improve our prioritization process. involved in projects (R&D, § A dynamic road map used as a basis for cycle time QUALITY, manufacturing, …) reduction for projects Lessons Learned: § § § Involvement : This SG process based on a simple and practical « road map » is easily implemented, with good buy in by the users and the management Visibility : The delivery of a dynamic view of each project increases reactivity and promotes flexibility and decision making process regarding the project strategy. Efficacy - Shared vision across functions : The implementation of this referential & stage gate process increases commitments and expectations between all the functions involved in the projects Change management process : Continuous improvement is managed with close relationship with all functions involved in projects, to promote partnership and buy in of these Best Practices and Stage Gate process Next steps : To improve the road map with standard schedules in order to manage project cycle time reduction. Storyboard Presentation – Unique Customization February 20 -21, 2007 / St. Pete’s Beach, FL

f64e01261247e7fb1b06095847352ff1.ppt