2013eb24a045c40d580e2c141e1a1917.ppt

- Количество слайдов: 28

Industrial Laser Cutting Machine Navigator KS based on fiber laser and linear motors JSC VNITEP (Russia)

COMPANY key issues and focus areas • Manufacture and supply of industrial laser cutting systems for sheet metal processing (patented technology) • Job-shops: laser cutting, bending, welding, tooling, lathing etc. • Research and Development

History • 2001 project starts • 2003 made 1 st pilot laser machine Navigator KS-1 equipped with CO 2 laser • 2004 the first time fiber laser was used for sheet metal cutting • 2005 first machine for industrial application; engine layout technology patented • 2007 mass production of industrial metal cutting systems with fiber laser • 2009 new control system, automation, improved appearance, refined key machine units • 2010 entering the European an Asian markets • 2012 at the 22 th International Exhibition of technologies for sheet metal processing Euro. BLECH in Hanover (Germany) double cutting heads machine was presented (world-wide patent)

Navigator KS Multinational VNITEP team: Russia, Germany, France, Estonia

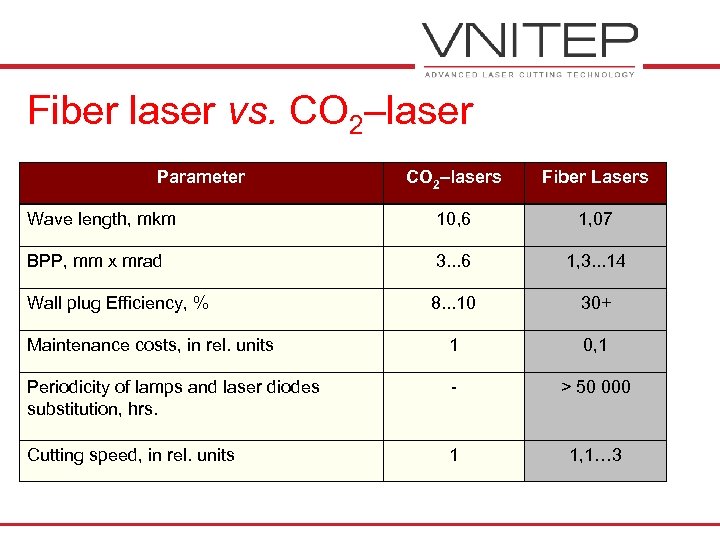

Fiber laser vs. CO 2–laser Parameter CO 2–lasers Fiber Lasers Wave length, mkm 10, 6 1, 07 BPP, mm x mrad 3. . . 6 1, 3. . . 14 Wall plug Efficiency, % 8. . . 10 30+ Maintenance costs, in rel. units 1 0, 1 Periodicity of lamps and laser diodes substitution, hrs. - > 50 000 Cutting speed, in rel. units 1 1, 1… 3

Wave length difference between the absorption coefficients – cutting non-ferrous metals focusing into a spot smaller diameter – minimal heat affected zone, cutting thin and deformable metals

Excellent Beam Parameter Product • creation of the light is 200% more efficient • no expensive optical path • flexible optical fiber up to 300 m long • the focusing lens is sealed in the cutting head

Coefficient of efficiency Wall-plug efficiencies greater than 30% considerably lower running costs

Maintenance costs 50% longer servicing intervals 50% lower servicing costs No moving parts or mirrors - reducing maintenance requirements and operating costs

Laser diodes substitution • fiber laser is modular, built from multiple laser units • allows the laser system to incorporate reserve modules and power margins • could be supplied in bigger case for further gradual upgrade

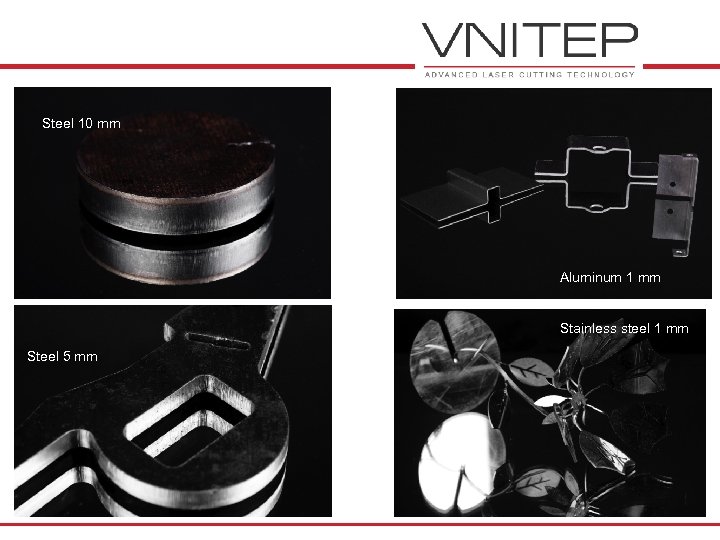

Steel 10 mm Aluminum 1 mm Stainless steel 1 mm Steel 5 mm

Brass 2 mm Stainless steel 1 mm Stainless steel 2 mm Steel 10 mm

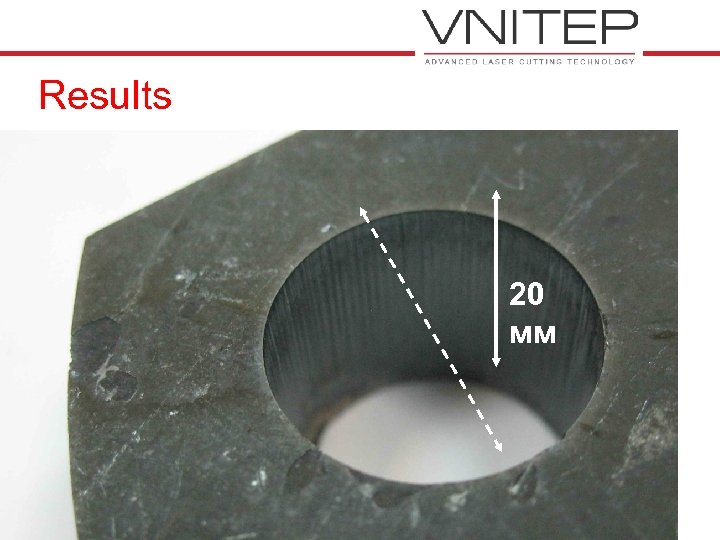

Results 20 мм

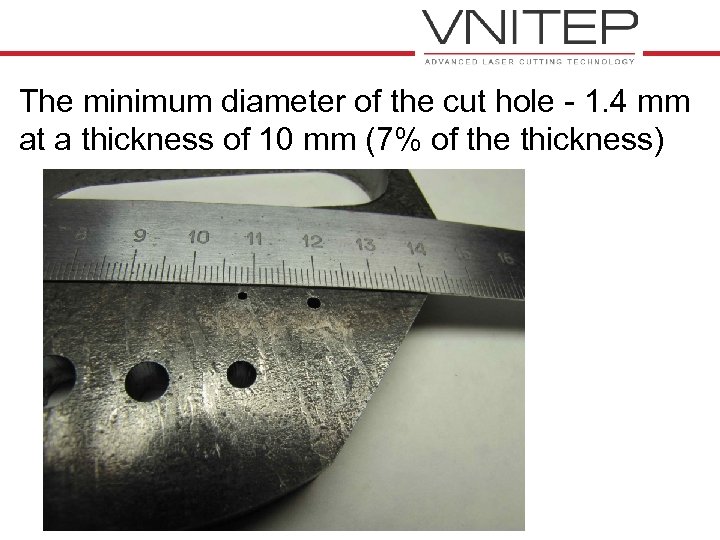

The minimum diameter of the cut hole - 1. 4 mm at a thickness of 10 mm (7% of the thickness)

Al, 8 mm

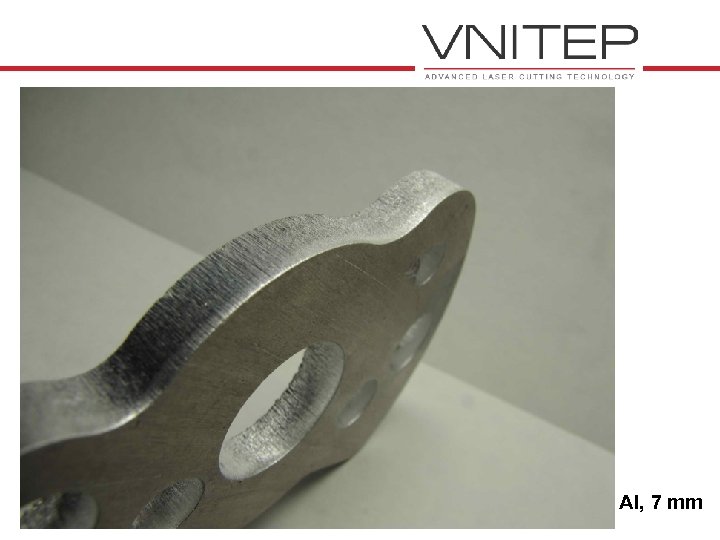

Al, 7 mm

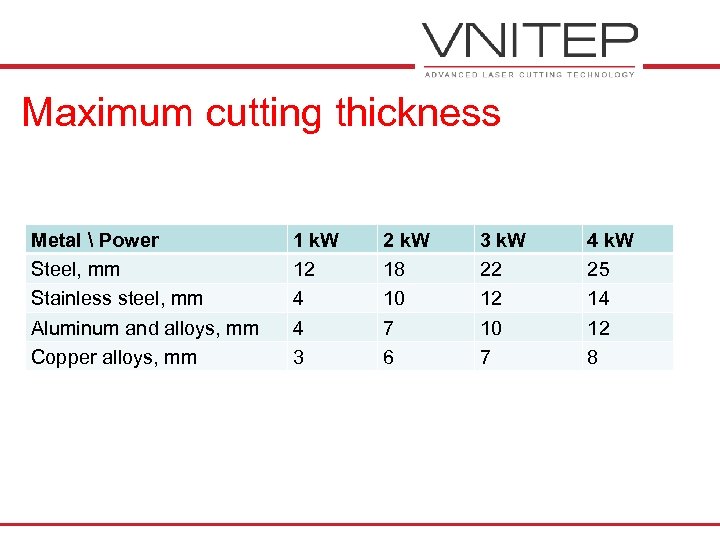

Maximum cutting thickness Metal Power Steel, mm Stainless steel, mm Aluminum and alloys, mm Copper alloys, mm 1 k. W 12 4 4 3 2 k. W 18 10 7 6 3 k. W 22 12 10 7 4 k. W 25 14 12 8

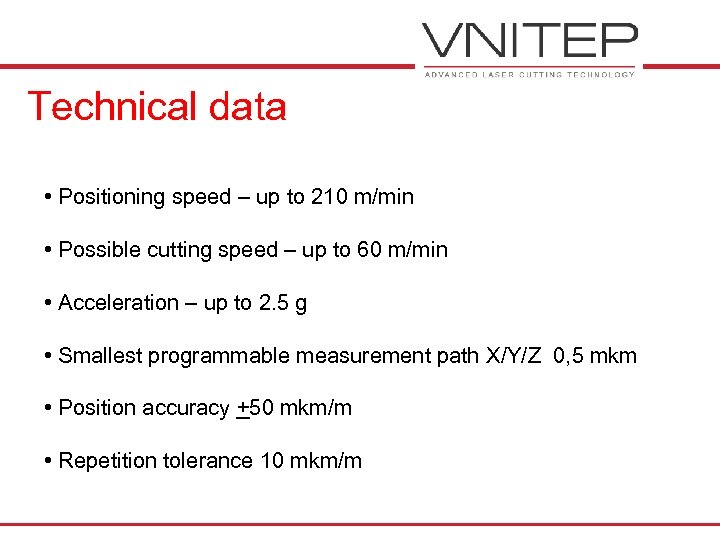

Technical data • Positioning speed – up to 210 m/min • Possible cutting speed – up to 60 m/min • Acceleration – up to 2. 5 g • Smallest programmable measurement path X/Y/Z 0, 5 mkm • Position accuracy +50 mkm/m • Repetition tolerance 10 mkm/m

Competitive advantages • Best price-to-perfomance ratio • Low ownership cost • High reliability • High safety • Automated determination of the sheet metal position on the cutting table

Price-to-perfomance • cutting speed 1. 1 - 3 times higher • part of useful laser time provides a low cost of production

Low cost • power consumption • operating costs • space

Reliability • warranty period - 17 500 hours or 2 years • 24/7 • laser diodes substitution 50 000 hrs. • guides and linear motors resource over 100 000 km

Reliable components from the best suppliers provide the reliability of the machine. • IPG Photonics or Rofin Sinar fiber laser • INA linear guidance systems • IGUS cable carriers • RENISHAW linear encoders • SIEMENS linear motors • DELTA TAU CNC • FESTO and CAMOZZI pneumatic components

Benefits over machines similar in operation • One linear motor on each axis - reliability and control at high speeds • Rigidity and vibration resistance • Best rate between moving and static weight of the machine • Composite Y-beam – Russian aerospace technologies • Editable software – creation of new technologies for specific customer’s tasks and materials • Coordinate table design has the upgrade ability to increase productivity of at least 1. 8 times • A wide range of models, scalable machine design • Pallet shuttle changing system

Latest research • Suppression system resonance oscillations in HSM is designed to accelerate the machine to 5 g • Sealed cutting head with automatic focus adjustment and rapid replacement of the focusing lens • A more productive control system with high fidelity given circuit • Automated nozzle changing system

Geography More than 100 laser cutting mashines are installed in Russia Equipment purchased and installed in • Estonia 2 • Lithuania 2 • Bulgaria 1 • Belarus 2 • Kazakhstan 2

Thank you for your attention! Questions? www. vnitep. ru

2013eb24a045c40d580e2c141e1a1917.ppt