b4b143bcaf936fb4aa8e8042cfd3861e.ppt

- Количество слайдов: 51

Industrial IT System 800 x. A Arto Lind © ABB Group - 1 19 -Mar-18 13 mars 2007 ISA-95/S 88 Standards Batch Information Management MES functionality

Industrial IT System 800 x. A Arto Lind © ABB Group - 1 19 -Mar-18 13 mars 2007 ISA-95/S 88 Standards Batch Information Management MES functionality

ISA-95 Perspective on Manufacturing Facility Business Process transactions ISA-95. 01/02 Definition Production Management Transactions Business Planning & Supply Chain Mgmt Production Definition Production Capability Production Plan Production Information Manufacturing Operations Management Level 4 Timeframe: Months, weeks, days, shifts ISA-95. 05 Functionality Level 3 Timeframe: Day, Shift, Hour, Minutes, Seconds ISA-95. 03/04 Functionality Real-Time Control & Events Continuous Batch Discrete Sensors, Actuators and Logical Devices © ABB Group - 2 19 -Mar-18 Level 0, 1, 2 ABB Coverage

ISA-95 Perspective on Manufacturing Facility Business Process transactions ISA-95. 01/02 Definition Production Management Transactions Business Planning & Supply Chain Mgmt Production Definition Production Capability Production Plan Production Information Manufacturing Operations Management Level 4 Timeframe: Months, weeks, days, shifts ISA-95. 05 Functionality Level 3 Timeframe: Day, Shift, Hour, Minutes, Seconds ISA-95. 03/04 Functionality Real-Time Control & Events Continuous Batch Discrete Sensors, Actuators and Logical Devices © ABB Group - 2 19 -Mar-18 Level 0, 1, 2 ABB Coverage

ISA S 95 Standard Scope ENTERPRISE ISA S 88 Standard 95. 01 &. 02 95. 03 © ABB Group - 3 19 -Mar-18 AREA CONTINUOUS PRODUCTION UNIT ISA 95 Standard SITE AREA BATCH PROCESS CELL AREA DISCRETE PRODUCTION LINE

ISA S 95 Standard Scope ENTERPRISE ISA S 88 Standard 95. 01 &. 02 95. 03 © ABB Group - 3 19 -Mar-18 AREA CONTINUOUS PRODUCTION UNIT ISA 95 Standard SITE AREA BATCH PROCESS CELL AREA DISCRETE PRODUCTION LINE

Enterprise and Control Layers are Merging © ABB Group - 4 19 -Mar-18 Plant Instrumentation and Controls Control Layer Extended Manufacturing Production analysis DCS / PLC Product tracking (if existing) Maintenance management CPM Layer* Product Analysis Manufacturing Operations Execution and Control MES SCADA Extended ERP Enterprise Layer Production Data collection Business Planning & Logistics Production Planning ERP 2005 Production Resource Management 1995 Product Data Management Detailed Production Scheduling 1985

Enterprise and Control Layers are Merging © ABB Group - 4 19 -Mar-18 Plant Instrumentation and Controls Control Layer Extended Manufacturing Production analysis DCS / PLC Product tracking (if existing) Maintenance management CPM Layer* Product Analysis Manufacturing Operations Execution and Control MES SCADA Extended ERP Enterprise Layer Production Data collection Business Planning & Logistics Production Planning ERP 2005 Production Resource Management 1995 Product Data Management Detailed Production Scheduling 1985

Platform for Control and CPM/MES n One common platform for all manufacturing functions n Utilize modular 800 x. A software functions as required ERP ISA-95 LIMS/DMS/etc Specific Adaptors Web Services Traditional Interface Enterprise Connectivity Solutions (ECS) Real-Time Asset Batch Manufacturing Information Production Management Optimization Management Intelligence © ABB Group - 5 19 -Mar-18 Common Operations, Engineering, & Data Management - - - - Real-time Data Sources- - - Blending Granulation Tablet Coating Other OPC Enterprise Connectivity Solutions (ECS)

Platform for Control and CPM/MES n One common platform for all manufacturing functions n Utilize modular 800 x. A software functions as required ERP ISA-95 LIMS/DMS/etc Specific Adaptors Web Services Traditional Interface Enterprise Connectivity Solutions (ECS) Real-Time Asset Batch Manufacturing Information Production Management Optimization Management Intelligence © ABB Group - 5 19 -Mar-18 Common Operations, Engineering, & Data Management - - - - Real-time Data Sources- - - Blending Granulation Tablet Coating Other OPC Enterprise Connectivity Solutions (ECS)

Scope of ISA 95 Part 3 To Define: Activities of manufacturing Operations Management n Terminology and a consistent set of concepts and models for defining manufacturing operation management activities n Interactions between activities n © ABB Group - 6 19 -Mar-18 n Data that flows among these activities

Scope of ISA 95 Part 3 To Define: Activities of manufacturing Operations Management n Terminology and a consistent set of concepts and models for defining manufacturing operation management activities n Interactions between activities n © ABB Group - 6 19 -Mar-18 n Data that flows among these activities

Production Operations Product definition Production capability Production schedule Production performance Detailed production scheduling Production resource management Production tracking Production Performance analysis Production dispatching Production data collection Product definition management © ABB Group - 7 19 -Mar-18 Production execution Equipment and process specific production rules Operational commands Operational responses Production level 1 -2 functions Equipment and process specific data

Production Operations Product definition Production capability Production schedule Production performance Detailed production scheduling Production resource management Production tracking Production Performance analysis Production dispatching Production data collection Product definition management © ABB Group - 7 19 -Mar-18 Production execution Equipment and process specific production rules Operational commands Operational responses Production level 1 -2 functions Equipment and process specific data

ISA S 95. 03 d Production Control Functions Product Definitions Production Capability Production Schedule Production Performance Detailed Production Scheduling (QA) Product Analysis Production Dispatching Historical Data Management Product Definition Management © ABB Group - 8 19 -Mar-18 -Batch 800 x. A Information Management Production Tracking Resource Management 800 x. A Production Management Supply Chain Integration ECS – Enterprise Connectivity Solution Production Execution Process Monitoring Manual Operations Process Analysis Production Analysis Automated Control 800 x. A Operations

ISA S 95. 03 d Production Control Functions Product Definitions Production Capability Production Schedule Production Performance Detailed Production Scheduling (QA) Product Analysis Production Dispatching Historical Data Management Product Definition Management © ABB Group - 8 19 -Mar-18 -Batch 800 x. A Information Management Production Tracking Resource Management 800 x. A Production Management Supply Chain Integration ECS – Enterprise Connectivity Solution Production Execution Process Monitoring Manual Operations Process Analysis Production Analysis Automated Control 800 x. A Operations

System 800 x. A Production Management What is 800 x. A Batch Management? Batch Management is a comprehensive batch automation solution for: Configuring recipes and procedures n Configuring batch equipment n Scheduling, monitoring and controlling batches and campaigns n Automatic arbitration of resources between batches at runtime n © ABB Group - 9 19 -Mar-18 n Collecting and storing batch historical information

System 800 x. A Production Management What is 800 x. A Batch Management? Batch Management is a comprehensive batch automation solution for: Configuring recipes and procedures n Configuring batch equipment n Scheduling, monitoring and controlling batches and campaigns n Automatic arbitration of resources between batches at runtime n © ABB Group - 9 19 -Mar-18 n Collecting and storing batch historical information

ISA S 88. 01 Batch Standard Equipment Hierarchy Area t a h Procedure Hierarchy Procedure Process Cell © ABB Group - 10 19 -Mar-18 W Unit Operation Equipment Module Phase w o Unit Procedure H

ISA S 88. 01 Batch Standard Equipment Hierarchy Area t a h Procedure Hierarchy Procedure Process Cell © ABB Group - 10 19 -Mar-18 W Unit Operation Equipment Module Phase w o Unit Procedure H

ISA S 88 Procedure Hierarchy Unit Procedure Operation n Production strategy organized by levels n Procedure Procedural elements can be used in multiple procedures n An element within a Procedure Function Chart (PFC) may represent another nested Procedure Initialize Phase © ABB Group - 11 19 -Mar-18 n An element within a PFC may launch and supervise sequential logic in process controller Unit ready Inert Pressure Press > target Vent

ISA S 88 Procedure Hierarchy Unit Procedure Operation n Production strategy organized by levels n Procedure Procedural elements can be used in multiple procedures n An element within a Procedure Function Chart (PFC) may represent another nested Procedure Initialize Phase © ABB Group - 11 19 -Mar-18 n An element within a PFC may launch and supervise sequential logic in process controller Unit ready Inert Pressure Press > target Vent

System 800 x. A Production Management © ABB Group - 12 19 -Mar-18 n Product Definition Management Procedure Function Chart (PFC) Editor provides a graphical workflow of operations and procedures Single master recipe for automated and manual production workflows

System 800 x. A Production Management © ABB Group - 12 19 -Mar-18 n Product Definition Management Procedure Function Chart (PFC) Editor provides a graphical workflow of operations and procedures Single master recipe for automated and manual production workflows

System 800 x. A Batch Management Integrated Equipment Configuration Supports network, multi-path and single path equipment configurations n Integrates with the common object model of 800 x. A System n Reserves and allocates equipment and other resources at run-time based on priority of each batch n © ABB Group - 13 19 -Mar-18 n Provides views and control of equipment status (Available, Busy, Reserved, etc. ), Batch ID, equipment attributes, and reservation queue Single, unified plant object model reduces engineering costs.

System 800 x. A Batch Management Integrated Equipment Configuration Supports network, multi-path and single path equipment configurations n Integrates with the common object model of 800 x. A System n Reserves and allocates equipment and other resources at run-time based on priority of each batch n © ABB Group - 13 19 -Mar-18 n Provides views and control of equipment status (Available, Busy, Reserved, etc. ), Batch ID, equipment attributes, and reservation queue Single, unified plant object model reduces engineering costs.

System 800 x. A Production Management Production Resource Management View equipment status (Available, Busy, Reserved, etc. ) n View Batch ID n View and change equipment attributes n © ABB Group - 14 19 -Mar-18 n View and manipulate reservation queue

System 800 x. A Production Management Production Resource Management View equipment status (Available, Busy, Reserved, etc. ) n View Batch ID n View and change equipment attributes n © ABB Group - 14 19 -Mar-18 n View and manipulate reservation queue

System 800 x. A Production Management Production Scheduling / Dispatching Schedule control recipes based on master recipes and batch-specific formulation data n Supports multiple execution of batches within a campaign n Select equipment at schedule time or dynamically at runtime n View batch status, parameters, history options and messages n © ABB Group - 15 19 -Mar-18 n Easily navigate procedure hierarchy of all active batches n One-button duplicate feature Simple utilities for Recipe, Resource, and Production Management provide full functionality.

System 800 x. A Production Management Production Scheduling / Dispatching Schedule control recipes based on master recipes and batch-specific formulation data n Supports multiple execution of batches within a campaign n Select equipment at schedule time or dynamically at runtime n View batch status, parameters, history options and messages n © ABB Group - 15 19 -Mar-18 n Easily navigate procedure hierarchy of all active batches n One-button duplicate feature Simple utilities for Recipe, Resource, and Production Management provide full functionality.

System 800 x. A Production Management n n Production Schedule Interface Enables interfaces from 800 x. A to external applications Examples of actions supported n Scheduling a batch n Changing batch state and parameters © ABB Group - 16 19 -Mar-18 n Retrieving batch history variables Upload Process Order Execute Process Order Business System 800 x. A Batch Management Production Request(s) Production Response(s) Retrieving status information n Create Process Order Schedule Batches Production Records * * Message broker / Transaction Mgr * Manufacturing Management Provides complete access to information required for business system integration.

System 800 x. A Production Management n n Production Schedule Interface Enables interfaces from 800 x. A to external applications Examples of actions supported n Scheduling a batch n Changing batch state and parameters © ABB Group - 16 19 -Mar-18 n Retrieving batch history variables Upload Process Order Execute Process Order Business System 800 x. A Batch Management Production Request(s) Production Response(s) Retrieving status information n Create Process Order Schedule Batches Production Records * * Message broker / Transaction Mgr * Manufacturing Management Provides complete access to information required for business system integration.

System 800 x. A Production Management Functional Structure and Components Recipes ERP/MES Applications Scheduler Operations Production Orders Production Reports Control Recipes Phases Batch Management Server üControl Procedures üBatch Events üOperator Comments Plant Explorer © ABB Group - 17 19 -Mar-18 Operations Control & I/O DDRIVE (123) RCM (62) (68) AO (29) Engineering Information Management PDL Production üNumeric Trend Data üControl & System Events üOperator Actions

System 800 x. A Production Management Functional Structure and Components Recipes ERP/MES Applications Scheduler Operations Production Orders Production Reports Control Recipes Phases Batch Management Server üControl Procedures üBatch Events üOperator Comments Plant Explorer © ABB Group - 17 19 -Mar-18 Operations Control & I/O DDRIVE (123) RCM (62) (68) AO (29) Engineering Information Management PDL Production üNumeric Trend Data üControl & System Events üOperator Actions

Common Equipment Model of System 800 x. A Object Type Structure Functional Structure Equipment Structure Procedure Structure © ABB Group - 18 19 -Mar-18 Master Recipes Unit Types Instances of Physical Equipment Groups

Common Equipment Model of System 800 x. A Object Type Structure Functional Structure Equipment Structure Procedure Structure © ABB Group - 18 19 -Mar-18 Master Recipes Unit Types Instances of Physical Equipment Groups

AC 800 M Controller Integration Equipment Procedure Template (EPT) Phase Logic Interface to Produce IT Batch n © ABB Group - 19 19 -Mar-18 n Separate code blocks for S 88 states (e. g. running, holding, aborting, etc. )

AC 800 M Controller Integration Equipment Procedure Template (EPT) Phase Logic Interface to Produce IT Batch n © ABB Group - 19 19 -Mar-18 n Separate code blocks for S 88 states (e. g. running, holding, aborting, etc. )

System 800 x. A Production Management Operator Workplace with Batch Overview Procedure Function Chart Process Graphic © ABB Group - 20 19 -Mar-18 Equipment Overview

System 800 x. A Production Management Operator Workplace with Batch Overview Procedure Function Chart Process Graphic © ABB Group - 20 19 -Mar-18 Equipment Overview

System 800 x. A Production Management Flexible Recipe Management Improves production yields, minimizes scrap, and improves overall production profitability. Reusable recipe building blocks follow S 88 batch control standard n Exception procedures provide recipe-driven error handling capability, breakpoints and block skip points n View current status of recipe procedures and associated standard operating procedure n © ABB Group - 21 19 -Mar-18 n Supports on-line changes to control recipe without suspending the batch Procedure Function Chart Standard Operating Procedure

System 800 x. A Production Management Flexible Recipe Management Improves production yields, minimizes scrap, and improves overall production profitability. Reusable recipe building blocks follow S 88 batch control standard n Exception procedures provide recipe-driven error handling capability, breakpoints and block skip points n View current status of recipe procedures and associated standard operating procedure n © ABB Group - 21 19 -Mar-18 n Supports on-line changes to control recipe without suspending the batch Procedure Function Chart Standard Operating Procedure

Full Support for FDA 21 CFR Part 11 n System 800 x. A provides features across the entire system that facilitate validation n Security – authorization & access control n Configuration change management n Versioning n Synchronization between engineering & production systems n Batch will provide on-line versions for procedures n Audit trail – logging by audit event type n E-signatures & signature/record linking n Record archiving & retrieval © ABB Group - 22 19 -Mar-18 n Reporting - printed copy of records for inspection n System checks - device checks and permitted sequences n Native language support n SOPs for Part 11 and c. GMP

Full Support for FDA 21 CFR Part 11 n System 800 x. A provides features across the entire system that facilitate validation n Security – authorization & access control n Configuration change management n Versioning n Synchronization between engineering & production systems n Batch will provide on-line versions for procedures n Audit trail – logging by audit event type n E-signatures & signature/record linking n Record archiving & retrieval © ABB Group - 22 19 -Mar-18 n Reporting - printed copy of records for inspection n System checks - device checks and permitted sequences n Native language support n SOPs for Part 11 and c. GMP

Batch Production Data Management Logs batches according to procedure hierarchy n Displays and analyzes trends of same or different batches n Supports LAB data entry n Prints reports using third party report builder n Archives data and reports n © ABB Group - 23 19 -Mar-18 n Provides access to other applications through SQL and programmed APIs The hierarchical data storage greatly facilitates batch to batch analysis quickly providing useful information for making intelligent business decisions.

Batch Production Data Management Logs batches according to procedure hierarchy n Displays and analyzes trends of same or different batches n Supports LAB data entry n Prints reports using third party report builder n Archives data and reports n © ABB Group - 23 19 -Mar-18 n Provides access to other applications through SQL and programmed APIs The hierarchical data storage greatly facilitates batch to batch analysis quickly providing useful information for making intelligent business decisions.

ISA S 95. 03 d Production Control Functions Product Definitions Production Capability Production Schedule Production Performance Detailed Production Scheduling (QA) Product Analysis Production Dispatching Historical Data Management Product Definition Management © ABB Group - 24 19 -Mar-18 -Batch 800 x. A Information Management Production Tracking Resource Management 800 x. A Production Management Supply Chain Integration ECS – Enterprise Connectivity Solution Production Execution Process Monitoring Manual Operations Process Analysis Production Analysis Automated Control 800 x. A Operations

ISA S 95. 03 d Production Control Functions Product Definitions Production Capability Production Schedule Production Performance Detailed Production Scheduling (QA) Product Analysis Production Dispatching Historical Data Management Product Definition Management © ABB Group - 24 19 -Mar-18 -Batch 800 x. A Information Management Production Tracking Resource Management 800 x. A Production Management Supply Chain Integration ECS – Enterprise Connectivity Solution Production Execution Process Monitoring Manual Operations Process Analysis Production Analysis Automated Control 800 x. A Operations

Information Management Production Performance Analyses - Information Management Desktop, Reporting & Analysis Information availability Archiving Engine © ABB Group - 25 19 -Mar-18 Control Room Process Data External Production Data Application (ERP, MES etc. . ) Integration Data Alarm & Event Data Production Data

Information Management Production Performance Analyses - Information Management Desktop, Reporting & Analysis Information availability Archiving Engine © ABB Group - 25 19 -Mar-18 Control Room Process Data External Production Data Application (ERP, MES etc. . ) Integration Data Alarm & Event Data Production Data

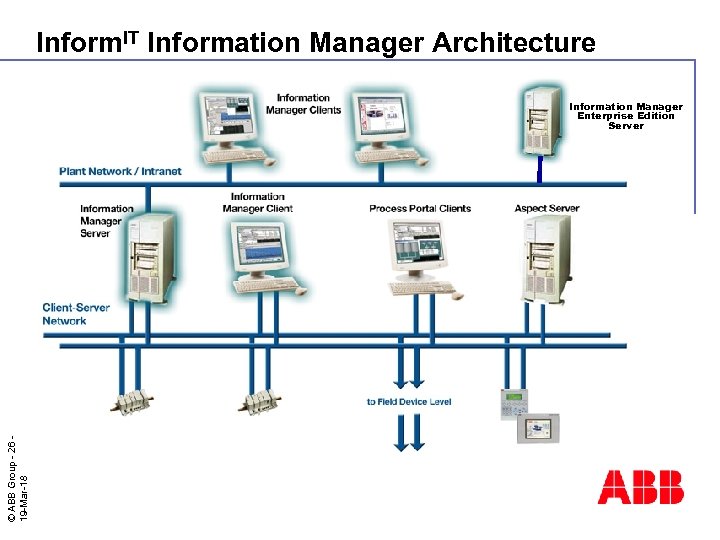

Inform. IT Information Manager Architecture © ABB Group - 26 19 -Mar-18 Information Manager Enterprise Edition Server

Inform. IT Information Manager Architecture © ABB Group - 26 19 -Mar-18 Information Manager Enterprise Edition Server

Information Management Seamless handling of historical data Operator Workplace/Desktop Display Messages in the 800 x. A System alarms/events Audit Trail alarms/events 50 k messages Real-time and History data in History Server Seamless view of all data 50 k messages – 12 million messages 1 sec /1 week - 1 sec / 10 years Process alarms/events Historical storage © ABB Group - 27 19 -Mar-18 Trend logs in Connectivity Server OPC Data Access items: 40. 000 items OPC update rate: > 0. 1 s (1 s default) Primary logs/Con. Server: 5. 000 logs Primary logs/IM Hist. Server: 30. 000 logs Updated min log values: 30. 000/min Req. max buffer size: Con. Server: 3 months Max buffer size: IM Hist. Server: 10 years 1 sec /1 week Control Network Archive

Information Management Seamless handling of historical data Operator Workplace/Desktop Display Messages in the 800 x. A System alarms/events Audit Trail alarms/events 50 k messages Real-time and History data in History Server Seamless view of all data 50 k messages – 12 million messages 1 sec /1 week - 1 sec / 10 years Process alarms/events Historical storage © ABB Group - 27 19 -Mar-18 Trend logs in Connectivity Server OPC Data Access items: 40. 000 items OPC update rate: > 0. 1 s (1 s default) Primary logs/Con. Server: 5. 000 logs Primary logs/IM Hist. Server: 30. 000 logs Updated min log values: 30. 000/min Req. max buffer size: Con. Server: 3 months Max buffer size: IM Hist. Server: 10 years 1 sec /1 week Control Network Archive

Information Management Production Data Log Robust data structures n Correlation of batch history with continuous history (highly configurable -- doesn’t require custom code) n Batch to Batch comparisons n Pre-canned reports that can be used “right out of the box” n B Campaign Job Name: Recipe Name: Batch Name: Start T ime: End T ime: B a tc h 1 Unit Proceedure 1 © ABB Group - 28 19 -Mar-18 Operation B a tc h 2 Production Polystyrene grade 4 Polystyrene_A 4 Batch 1 9/29/95 14: 05: 00 9/29/95 22: 07: 25 Unit Procedure: Unitname: Start time: End time: Phasename: start: initial temp: target temp: end: final temp: Reaction Reactor R-105 9/29/95 14: 30: 20 9/29/95 18: 23: 03 Heat 9/29/95 14: 32: 40 23. 5 Deg. C 55. 0 Deg. C 9/29/95 16: 35: 12 55. 1 Deg. C

Information Management Production Data Log Robust data structures n Correlation of batch history with continuous history (highly configurable -- doesn’t require custom code) n Batch to Batch comparisons n Pre-canned reports that can be used “right out of the box” n B Campaign Job Name: Recipe Name: Batch Name: Start T ime: End T ime: B a tc h 1 Unit Proceedure 1 © ABB Group - 28 19 -Mar-18 Operation B a tc h 2 Production Polystyrene grade 4 Polystyrene_A 4 Batch 1 9/29/95 14: 05: 00 9/29/95 22: 07: 25 Unit Procedure: Unitname: Start time: End time: Phasename: start: initial temp: target temp: end: final temp: Reaction Reactor R-105 9/29/95 14: 30: 20 9/29/95 18: 23: 03 Heat 9/29/95 14: 32: 40 23. 5 Deg. C 55. 0 Deg. C 9/29/95 16: 35: 12 55. 1 Deg. C

Information Management n Presentation and Navigation Seamless process and history data retrieval Straightforward trend presentation n Process Portal Trend Display and Information Manager Display Clients present common (short and long term) set of data n © ABB Group - 29 19 -Mar-18 n Plant Explorer navigation for Information Manager data

Information Management n Presentation and Navigation Seamless process and history data retrieval Straightforward trend presentation n Process Portal Trend Display and Information Manager Display Clients present common (short and long term) set of data n © ABB Group - 29 19 -Mar-18 n Plant Explorer navigation for Information Manager data

Information Management Presentation and Navigation n Single, seamless interface for accessing and viewing all data in the system n Maintain data in original control system format Process alarms, system events, operator actions n © ABB Group - 30 19 -Mar-18 n Production data, process relationships

Information Management Presentation and Navigation n Single, seamless interface for accessing and viewing all data in the system n Maintain data in original control system format Process alarms, system events, operator actions n © ABB Group - 30 19 -Mar-18 n Production data, process relationships

© ABB Group - 31 19 -Mar-18 Information Management Web Clients

© ABB Group - 31 19 -Mar-18 Information Management Web Clients

Information Management n Presentation and Navigation Desk. Top Trend Control n © ABB Group - 32 19 -Mar-18 n Tag Ticker

Information Management n Presentation and Navigation Desk. Top Trend Control n © ABB Group - 32 19 -Mar-18 n Tag Ticker

Softpoints & Calculation exempel User-defined data points Transform data into actionable information Calculation aspect Softpoint object © ABB Group - 33 19 -Mar-18 Softpoint signals Calculation script

Softpoints & Calculation exempel User-defined data points Transform data into actionable information Calculation aspect Softpoint object © ABB Group - 33 19 -Mar-18 Softpoint signals Calculation script

Flexible Reports Flexible Report generation & distribution n Microsoft Excel, Crystal Report n Real time data, historical, lab data, batch- and eventinformation n Report generation Printer n Email n Historical archiving n Lolal- or network-disc © ABB Group - 34 19 -Mar-18 n

Flexible Reports Flexible Report generation & distribution n Microsoft Excel, Crystal Report n Real time data, historical, lab data, batch- and eventinformation n Report generation Printer n Email n Historical archiving n Lolal- or network-disc © ABB Group - 34 19 -Mar-18 n

Security n Secure Data Security in Pharmaceutical Industry Secure historical data storage n Archival/retrieval from external media n CD, DVD, Magneto Optical n Remote disk location n Direct read of archived tag data n Archive based on production event such as batch end n Distributed data storage n Secure report storage n Disk arrays © ABB Group - 35 19 -Mar-18 n User access control

Security n Secure Data Security in Pharmaceutical Industry Secure historical data storage n Archival/retrieval from external media n CD, DVD, Magneto Optical n Remote disk location n Direct read of archived tag data n Archive based on production event such as batch end n Distributed data storage n Secure report storage n Disk arrays © ABB Group - 35 19 -Mar-18 n User access control

System 800 x. A Information Management Production Data Collection / Tracking Camp 1 Campaign Name: Intermediate_S 7_2004 AXH Recipe Name: Int_S 7_Std Batch Name: Start Time: End Time: Batch 1 Batch_1 9/12/04 Unit Procedure: Unitname: Start time: End time: UP 1 14: 05: 00 22: 07: 00 Reaction RE 105 9/12/04 14: 30: 20 9/12/04 18: 23: 03 Operation name: Heat Start time: 9/12/04 14: 32: 10 End time: OPN 1 17: 32: 40 9/12/04 n Single common storage of batch record n Data stored according to batch recipe structure Batch 2 All batch events, operator actions, system events, process alarms and events are stored Complete electronic batch records © ABB Group - 36 19 -Mar-18 n

System 800 x. A Information Management Production Data Collection / Tracking Camp 1 Campaign Name: Intermediate_S 7_2004 AXH Recipe Name: Int_S 7_Std Batch Name: Start Time: End Time: Batch 1 Batch_1 9/12/04 Unit Procedure: Unitname: Start time: End time: UP 1 14: 05: 00 22: 07: 00 Reaction RE 105 9/12/04 14: 30: 20 9/12/04 18: 23: 03 Operation name: Heat Start time: 9/12/04 14: 32: 10 End time: OPN 1 17: 32: 40 9/12/04 n Single common storage of batch record n Data stored according to batch recipe structure Batch 2 All batch events, operator actions, system events, process alarms and events are stored Complete electronic batch records © ABB Group - 36 19 -Mar-18 n

ISA S 95. 03 d Production Control Functions Product Definitions Production Capability Production Schedule Production Performance Detailed Production Scheduling (QA) Product Analysis Production Dispatching Historical Data Management Product Definition Management © ABB Group - 37 19 -Mar-18 -Batch 800 x. A Information Management Production Tracking Resource Management 800 x. A Production Management Supply Chain Integration ECS – Enterprise Connectivity Solution Production Execution Process Monitoring Manual Operations Process Analysis Production Analysis Automated Control 800 x. A Operations

ISA S 95. 03 d Production Control Functions Product Definitions Production Capability Production Schedule Production Performance Detailed Production Scheduling (QA) Product Analysis Production Dispatching Historical Data Management Product Definition Management © ABB Group - 37 19 -Mar-18 -Batch 800 x. A Information Management Production Tracking Resource Management 800 x. A Production Management Supply Chain Integration ECS – Enterprise Connectivity Solution Production Execution Process Monitoring Manual Operations Process Analysis Production Analysis Automated Control 800 x. A Operations

Introduction n ECS Framework closes information gap between Business processes and the Manufacturing processes (machines, control systems). © ABB Group - 38 19 -Mar-18 ECS

Introduction n ECS Framework closes information gap between Business processes and the Manufacturing processes (machines, control systems). © ABB Group - 38 19 -Mar-18 ECS

Functionality n BRIDGE BETWEEN PLANT FLOOR CONTROL n ENHANCEMENT n MANUFACTURING VISIBILITY - EFFICIENCY n PRODUCTION REALITY – PLAN, RESPOND AND n QUALITY DATA MANAGEMENT - RECOGNISE ECS = SYSTEMS AND ENTERPRISE BUSINESS SYSTEMS OF RESPONSIVENESS TO BUSINESS DECISIONS ISSUES, PRODUCTIVITY ISSUES, AND QUALITY ISSUES IN CONTEXT CHANGE ON DEMAND; NO MORE GUESSING © ABB Group - 39 19 -Mar-18 AND RESPOND TO QUALITY CHALLENGES n EVOLUTIONARY APPROACH - CONTINUOUS IMPROVEMENT

Functionality n BRIDGE BETWEEN PLANT FLOOR CONTROL n ENHANCEMENT n MANUFACTURING VISIBILITY - EFFICIENCY n PRODUCTION REALITY – PLAN, RESPOND AND n QUALITY DATA MANAGEMENT - RECOGNISE ECS = SYSTEMS AND ENTERPRISE BUSINESS SYSTEMS OF RESPONSIVENESS TO BUSINESS DECISIONS ISSUES, PRODUCTIVITY ISSUES, AND QUALITY ISSUES IN CONTEXT CHANGE ON DEMAND; NO MORE GUESSING © ABB Group - 39 19 -Mar-18 AND RESPOND TO QUALITY CHALLENGES n EVOLUTIONARY APPROACH - CONTINUOUS IMPROVEMENT

© ABB Group - 40 19 -Mar-18 Levels

© ABB Group - 40 19 -Mar-18 Levels

ECS Based Connectivity n ECS Makes Business Systems visible to the rest of the 800 x. A System as just another control equipment Business System © ABB Group - 41 19 -Mar-18 800 x. A Core 800 M Controller

ECS Based Connectivity n ECS Makes Business Systems visible to the rest of the 800 x. A System as just another control equipment Business System © ABB Group - 41 19 -Mar-18 800 x. A Core 800 M Controller

Manufacturing Process Model n Based on S 95 standard n Includes n n n Process data Process workflow definition Representation of the process model is saved as an XML file © ABB Group - 42 19 -Mar-18 S 95 Objects

Manufacturing Process Model n Based on S 95 standard n Includes n n n Process data Process workflow definition Representation of the process model is saved as an XML file © ABB Group - 42 19 -Mar-18 S 95 Objects

Manufacturing Process Execution Manufacturing Process Modeling tool (S 95) Executable Code © ABB Group - 43 19 -Mar-18 Manufacturing Process Database Model-based Integration Business System 1 Systems Devices People (GUI)

Manufacturing Process Execution Manufacturing Process Modeling tool (S 95) Executable Code © ABB Group - 43 19 -Mar-18 Manufacturing Process Database Model-based Integration Business System 1 Systems Devices People (GUI)

MES ECS- Enterprise Connection Solution Configurable connectivity to various business systems (e. g. SAP) or any ERP from SSA Global including BAAN n Tracking & Traceability, Reports, Database connector n Based on n - 95 n Case: SAP PPPI – ABB 800 x. A Batch Management integration n Download of the SAP control recipe to 800 x. A System with all parameters required for batch production n 800 x. A system updates SAP system with production status throughout the batch execution n At the end of batch production 800 x. A system reports to SAP all production relevant data (consumption per ingredient, produced material quantity, Phase confirmation and report of used machine and total production time etc. ) Batch production data (consumption, confirmation, quantity produced) BAPIs, RFCs © ABB Group - 44 19 -Mar-18 SAP Control Recipe 800 x. A IM 800 x. A Batch Control System ECS SAP PP-PI

MES ECS- Enterprise Connection Solution Configurable connectivity to various business systems (e. g. SAP) or any ERP from SSA Global including BAAN n Tracking & Traceability, Reports, Database connector n Based on n - 95 n Case: SAP PPPI – ABB 800 x. A Batch Management integration n Download of the SAP control recipe to 800 x. A System with all parameters required for batch production n 800 x. A system updates SAP system with production status throughout the batch execution n At the end of batch production 800 x. A system reports to SAP all production relevant data (consumption per ingredient, produced material quantity, Phase confirmation and report of used machine and total production time etc. ) Batch production data (consumption, confirmation, quantity produced) BAPIs, RFCs © ABB Group - 44 19 -Mar-18 SAP Control Recipe 800 x. A IM 800 x. A Batch Control System ECS SAP PP-PI

Development of the ABB-SAP Joint Solution ABB-SAP Co-operation initiated 2004 -04 ABB-SAP Task force Pulp & Paper 2004 -04 -12 Task force results with recommendations Joint solution development 2004 -12 2005 Joint solution ready to deploy 2006 Sapphire Paris Initial industry: Pulp Detailed analysis of production and businessrecommendations presented to & Paper Concrete development Taskforce results and processes of various P&P Taskforce Charter: industry segments ABB CPM Connector for Pulp & Paper management 17 workshop sessions, 8 months Define appropriate customer segmentation. Agreed to continue to concrete actions: (products, regions, …) ABB ECS framework SAP Connectivity and Netweaver Identify pain points of the different customer groups certification Pilot customers Determine where there are pain points which are significant and refined we can Integrated scenarios where find/have a combined solution © ABB Group - 45 19 -Mar-18 Identify value proposition (quantifiable) for n Customer n ABB n SAP Define possible integration scenarios Describe potential partnership scenarios

Development of the ABB-SAP Joint Solution ABB-SAP Co-operation initiated 2004 -04 ABB-SAP Task force Pulp & Paper 2004 -04 -12 Task force results with recommendations Joint solution development 2004 -12 2005 Joint solution ready to deploy 2006 Sapphire Paris Initial industry: Pulp Detailed analysis of production and businessrecommendations presented to & Paper Concrete development Taskforce results and processes of various P&P Taskforce Charter: industry segments ABB CPM Connector for Pulp & Paper management 17 workshop sessions, 8 months Define appropriate customer segmentation. Agreed to continue to concrete actions: (products, regions, …) ABB ECS framework SAP Connectivity and Netweaver Identify pain points of the different customer groups certification Pilot customers Determine where there are pain points which are significant and refined we can Integrated scenarios where find/have a combined solution © ABB Group - 45 19 -Mar-18 Identify value proposition (quantifiable) for n Customer n ABB n SAP Define possible integration scenarios Describe potential partnership scenarios

Connecting to SAP – View from 800 x. A © ABB Group - 46 19 -Mar-18 In 800 x. A, the structure required to call the selected SAP function is imported as a set of Aspect Objects.

Connecting to SAP – View from 800 x. A © ABB Group - 46 19 -Mar-18 In 800 x. A, the structure required to call the selected SAP function is imported as a set of Aspect Objects.

Connecting to SAP – View from 800 x. A © ABB Group - 47 19 -Mar-18 The complete SAP table is now available in 800 x. A, and we can “subscribe” to SAP data in the same manner as with process Data.

Connecting to SAP – View from 800 x. A © ABB Group - 47 19 -Mar-18 The complete SAP table is now available in 800 x. A, and we can “subscribe” to SAP data in the same manner as with process Data.

© ABB Group - 48 19 -Mar-18 SQL / OLE DB / ODBC

© ABB Group - 48 19 -Mar-18 SQL / OLE DB / ODBC

ECS – Enterprise Connection Solution MES Point to Point Interfaces Services Based Integration n SCM CRM x. MII E Business Legacy © ABB Group - 49 19 -Mar-18 Lower TCO with simpler systems Integration Enterprise Interface Integrated Composite Applications ECS No need to rip and replace n ERP Reduced risk n ERP CRM SCM Open technology n Business Solution Business Systems ECS Benefits Plant Interface Plant Floor Systems ABB and 3 rd party control systems, historians and CPM

ECS – Enterprise Connection Solution MES Point to Point Interfaces Services Based Integration n SCM CRM x. MII E Business Legacy © ABB Group - 49 19 -Mar-18 Lower TCO with simpler systems Integration Enterprise Interface Integrated Composite Applications ECS No need to rip and replace n ERP Reduced risk n ERP CRM SCM Open technology n Business Solution Business Systems ECS Benefits Plant Interface Plant Floor Systems ABB and 3 rd party control systems, historians and CPM

Industrial IT - Summary 800 x. A includes a very comprehensive flexible batch solution n Information Management as info system with excellent reporting and analyses tools n ECS incorporates MES functionality and ERP connections to e. g. SAP n 800 x. A is flexible to delivery of automation solutions that includes the “supply of” or “interface to” third-party COTS software products © ABB Group - 50 19 -Mar-18 n

Industrial IT - Summary 800 x. A includes a very comprehensive flexible batch solution n Information Management as info system with excellent reporting and analyses tools n ECS incorporates MES functionality and ERP connections to e. g. SAP n 800 x. A is flexible to delivery of automation solutions that includes the “supply of” or “interface to” third-party COTS software products © ABB Group - 50 19 -Mar-18 n