9dc05a986bf0ad63ce8ffa139ac03ef9.ppt

- Количество слайдов: 35

Industrial. IT for Power EMS ABB bv - 1 6 -11 -2001 Power Management for Industrial Plants. ABB

Industrial. IT for Power EMS Electrical Process System configuration Functionality Power EMS References Benefits

Why Power EMS? } } Critical Loads Limited In-plant Generation Insufficient reliability of Public Grid Load Shedding Several Generators Contracted Power Importation Power Control Different Electrical Operational Configurations possible ABB bv - 3 Complex Distribution Networks “Local only” Control facilities Mode Control SCADA ABB

Why ABB Power EMS? Deep knowledge of the electrical process n 15 years experience in Power EMS in many projects (green-field and running plants) n Standard software, well documented, tested, proven technology n Fast Response Time for Load Shedding, Mode Control, Power Control, Re-acceleration n High Resolution and Accuracy of Sequence of Event recording n Comply to class 3 EMC immunity n ABB bv - 4 n Single responsibility: One supplier for Power EMS integrated with protection, governor, excitation, tapchanger, Motor Control Centre, Variable Speed Drive, etc. ABB

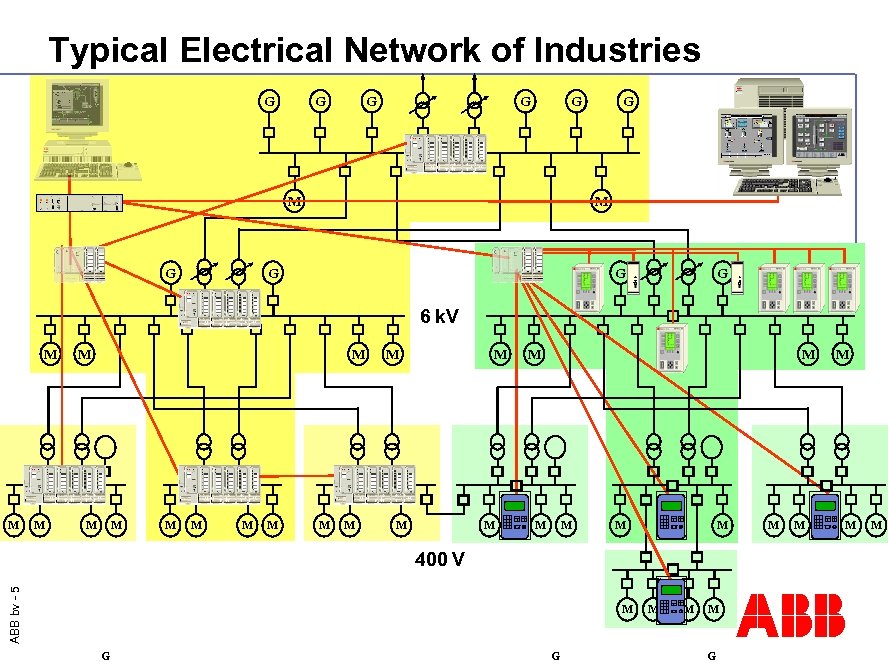

Typical Electrical Network of Industries G G G M G G G 6 k. V M M M M M M M ABB bv - 5 400 V M G G M M M G ABB M

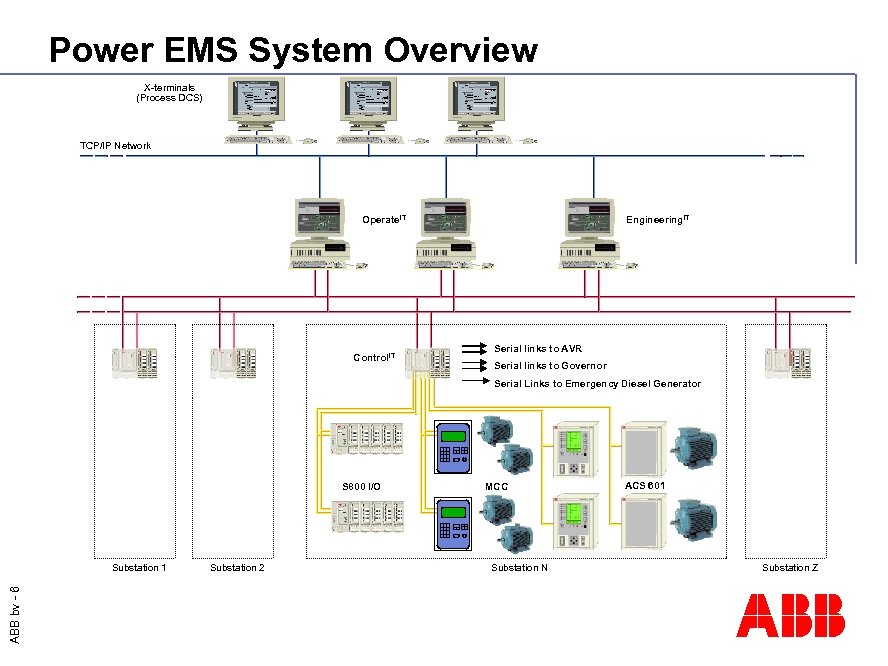

Power EMS System Overview X-terminals (Process DCS) Fast Functions are performed by Controllers: TCP/IP Network n Load Shedding / Re-Acceleration / Re-Starting n Power Control n Mode Control Operate. IT Control. IT Engineering. IT Serial links to AVR Serial links to Governor Serial Links to Emergency Diesel Generator S 800 I/O ABB bv - 6 Substation 1 Substation 2 MCC Substation N ACS 601 Substation Z ABB

Functionality Power EMS Load Shedding n Active and Reactive Power Control n Supervision, Control and Data Acquisition (SCADA) n Mode Control n Re-Acceleration / Re-Starting n ABB bv - 7 n Synchronisation ABB

Functionality Power EMS n Load Shedding ? ABB bv - 8 With Load Shedding Without Load Shedding ABB

Load Shedding: The types Fast Load Shedding on Loss of Power Resources n Load Shedding on Frequency Drop n Slow Load Shedding on Overload n Slow Load Shedding for Peak Shaving n ABB bv - 9 n Manual Load Shedding ABB

Power EMS Load Shedding: Keywords Fast n Exact n Flexible n Co-ordinated n Deterministic n Security and Reliability n Accurate Event Logging n Operator Guidance n ABB bv - 10 n Independent Back-up System ABB

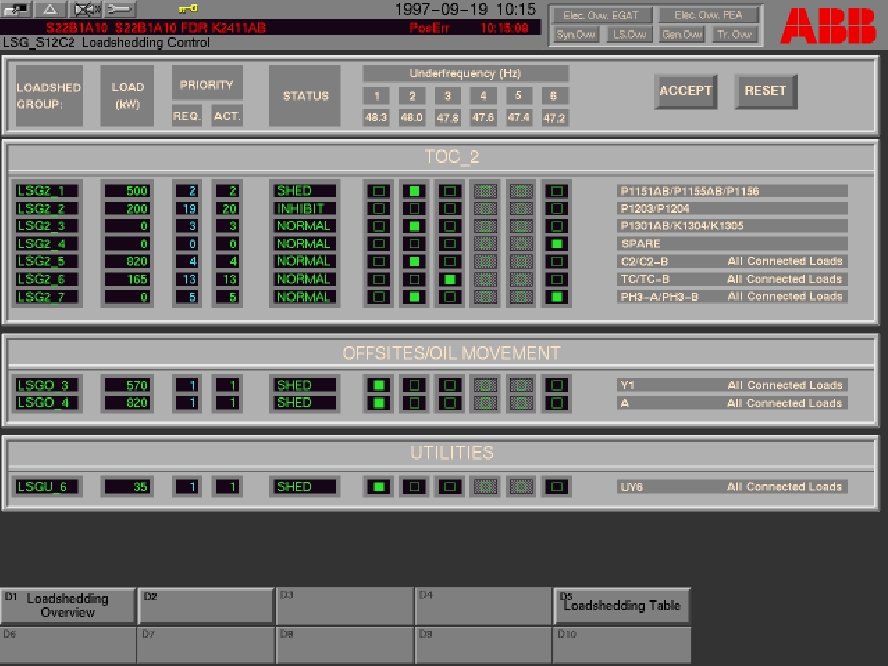

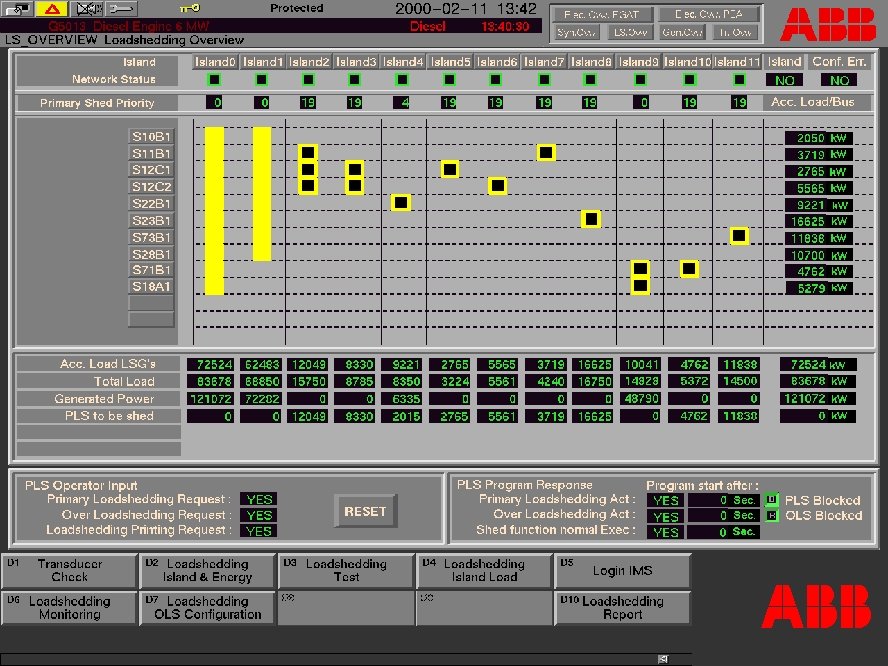

Display Load Shedding Control

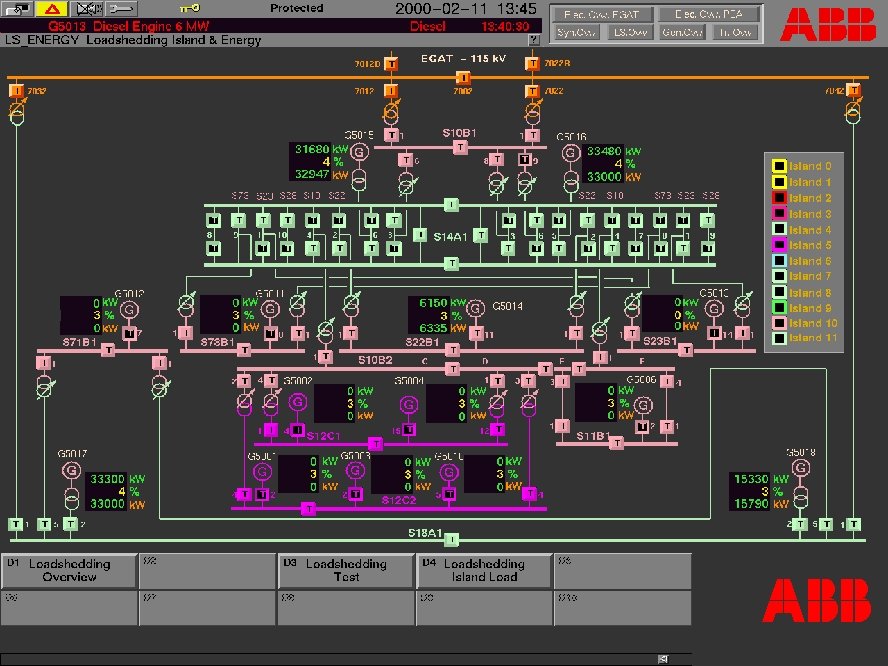

ABB bv - 12 Display Load Shedding Islands ABB

Display Load Shedding Overview ABB

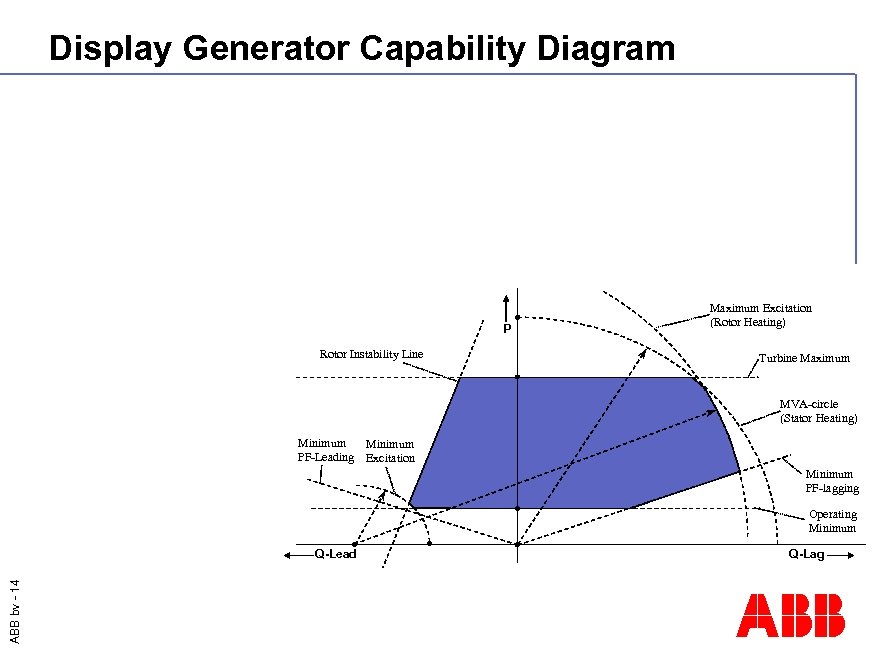

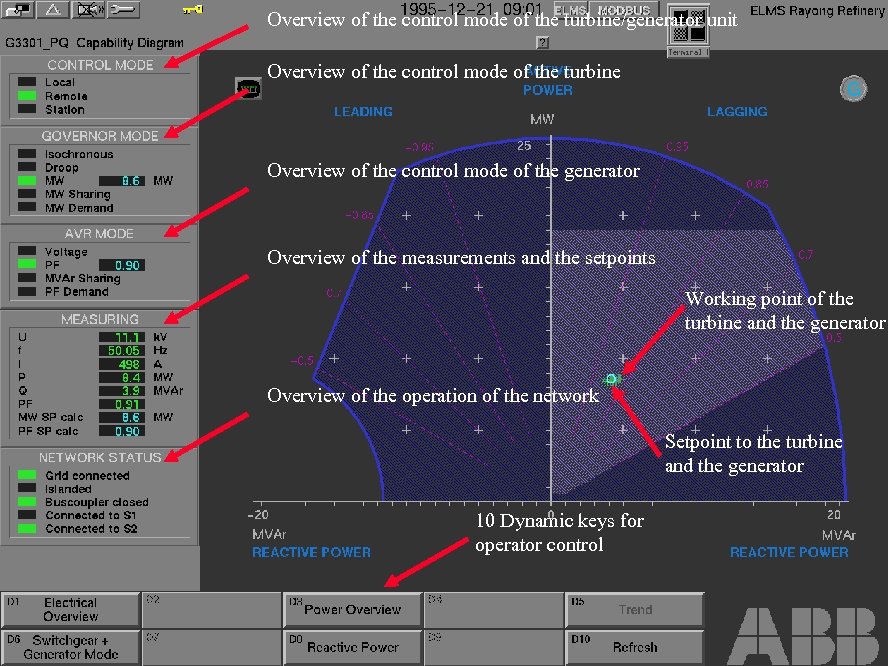

Display Generator Capability Diagram Functionality Power EMS n Load Shedding n Active and Reactive Power Control P Rotor Instability Line Maximum Excitation (Rotor Heating) Turbine Maximum MVA-circle (Stator Heating) Minimum PF-Leading Excitation Minimum PF-lagging Operating Minimum ABB bv - 14 Q-Lead Q-Lag ABB

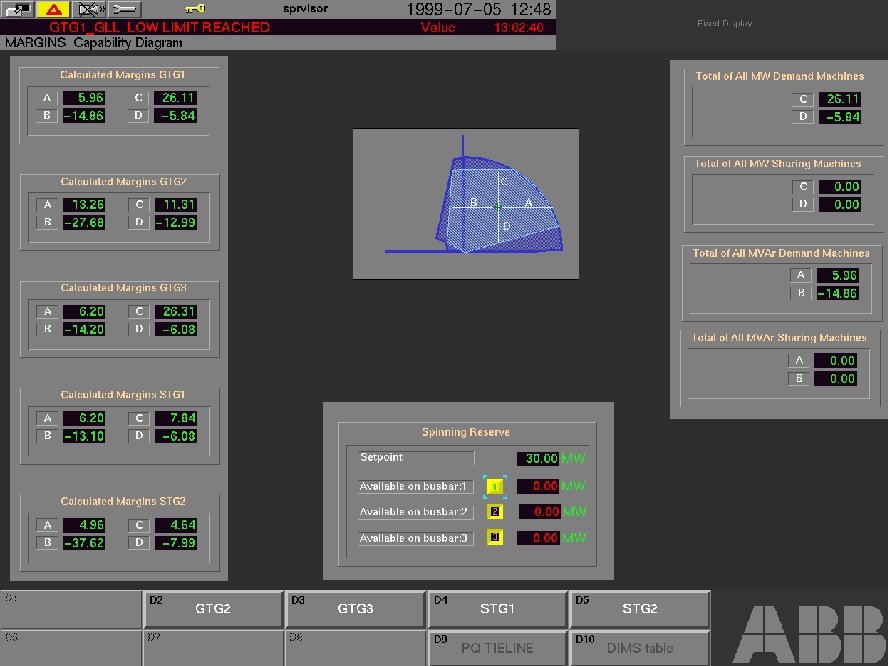

ABB bv - 15 Display Calculated Control Margins ABB

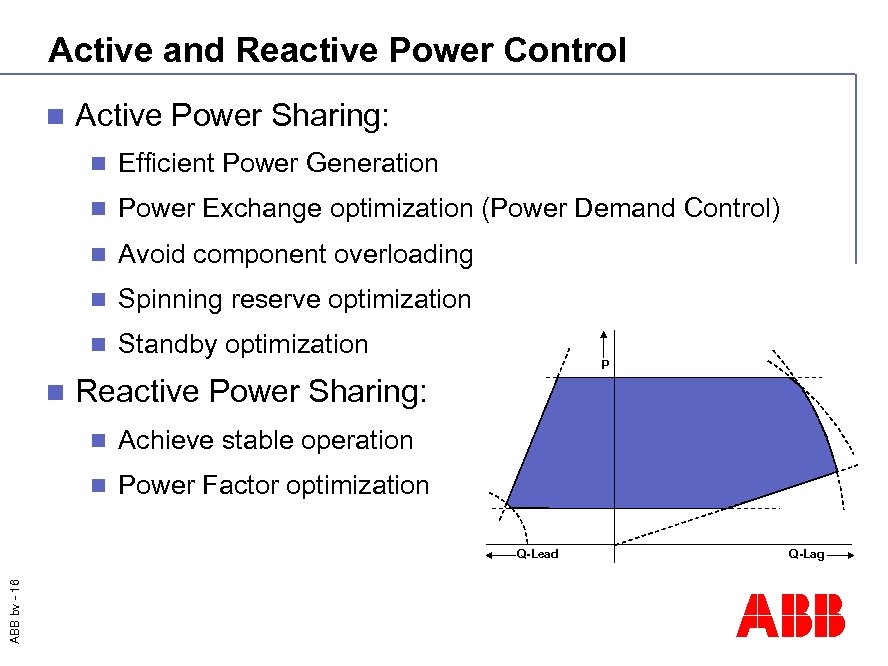

Active and Reactive Power Control n Active Power Sharing: n n Power Exchange optimization (Power Demand Control) n Avoid component overloading n Spinning reserve optimization n n Efficient Power Generation Standby optimization P Reactive Power Sharing: n Achieve stable operation n Power Factor optimization ABB bv - 16 Q-Lead Q-Lag ABB

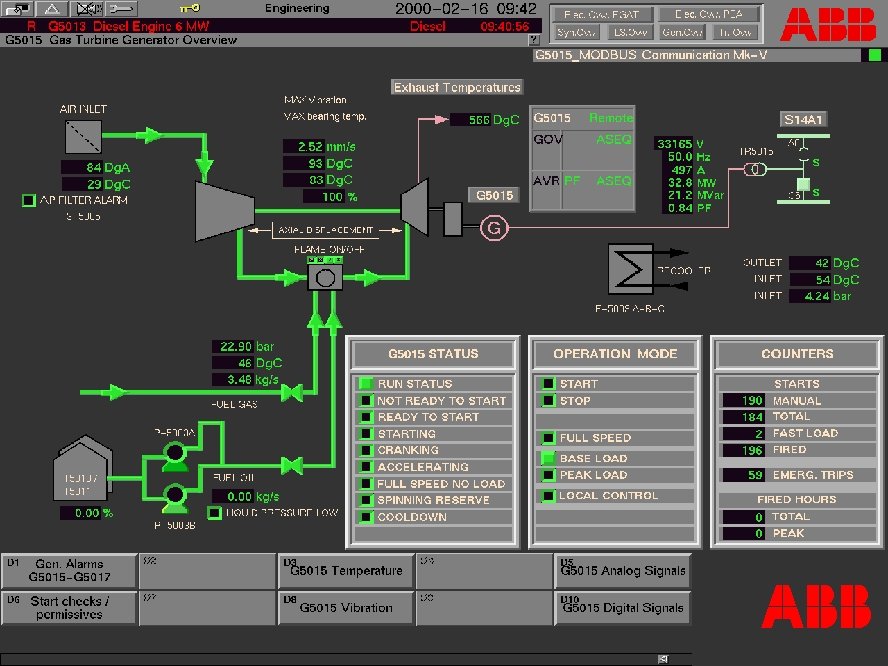

Overview of the control mode of the turbine/generator unit Display Generator of the control mode of the turbine Capability Diagram Overview of the control mode of the generator Overview of the measurements and the setpoints Working point of the turbine and the generator Overview of the operation of the network Setpoint to the turbine and the generator 10 Dynamic keys for operator control

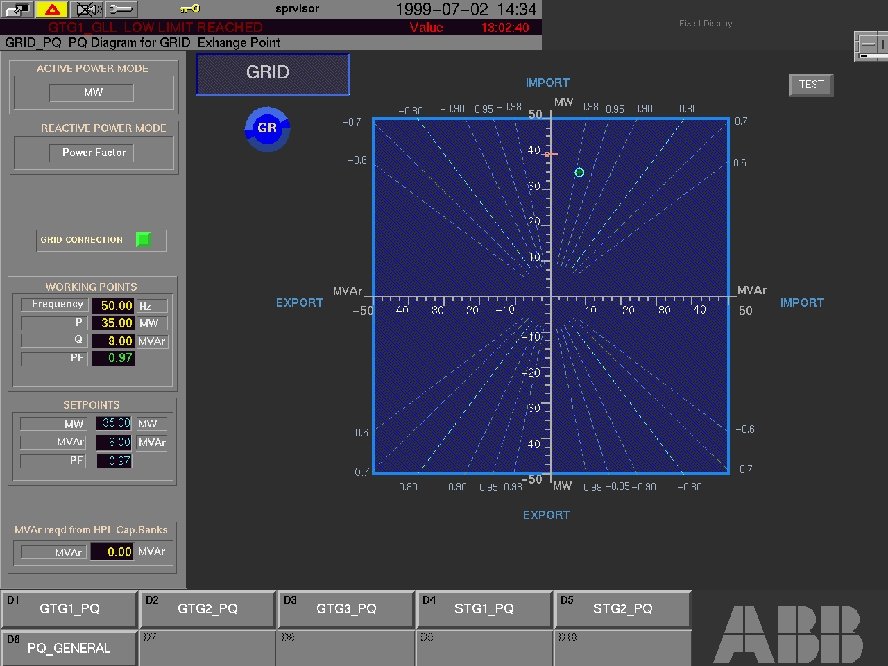

ABB bv - 18 Display Grid Capability Diagram ABB

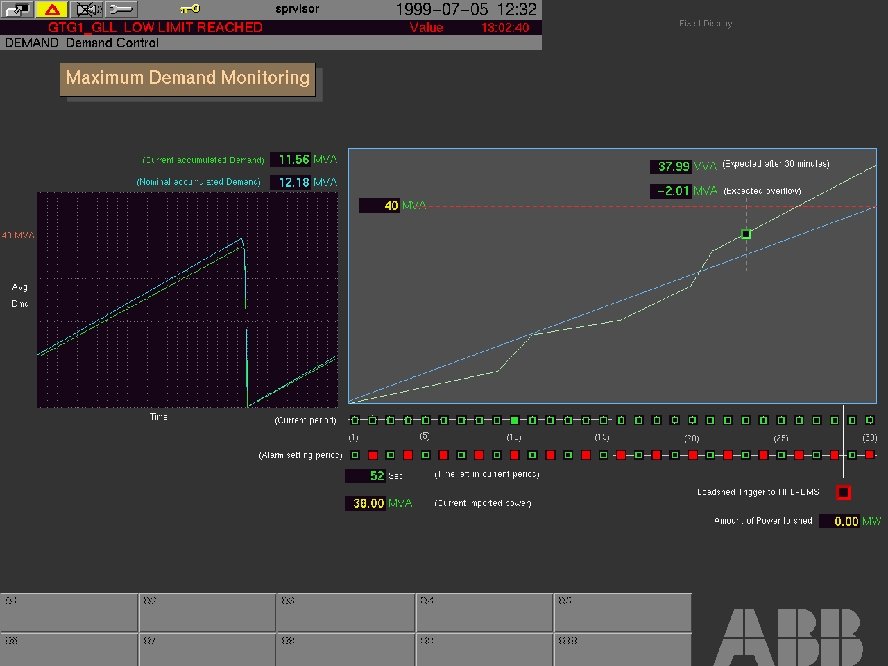

ABB bv - 19 Display Maximum Demand Monitoring ABB

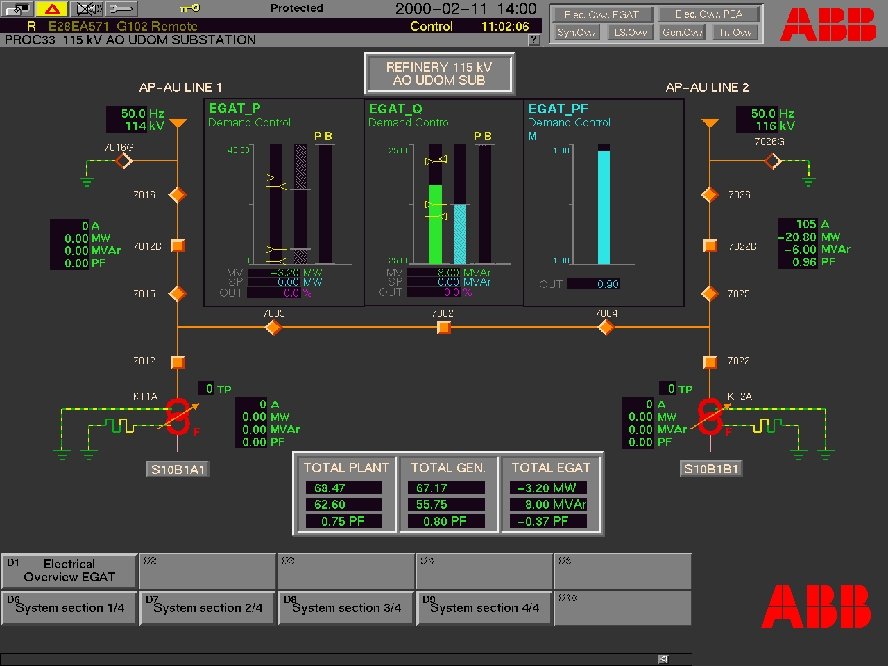

ABB bv - 20 Display Monitoring Tie-line ABB

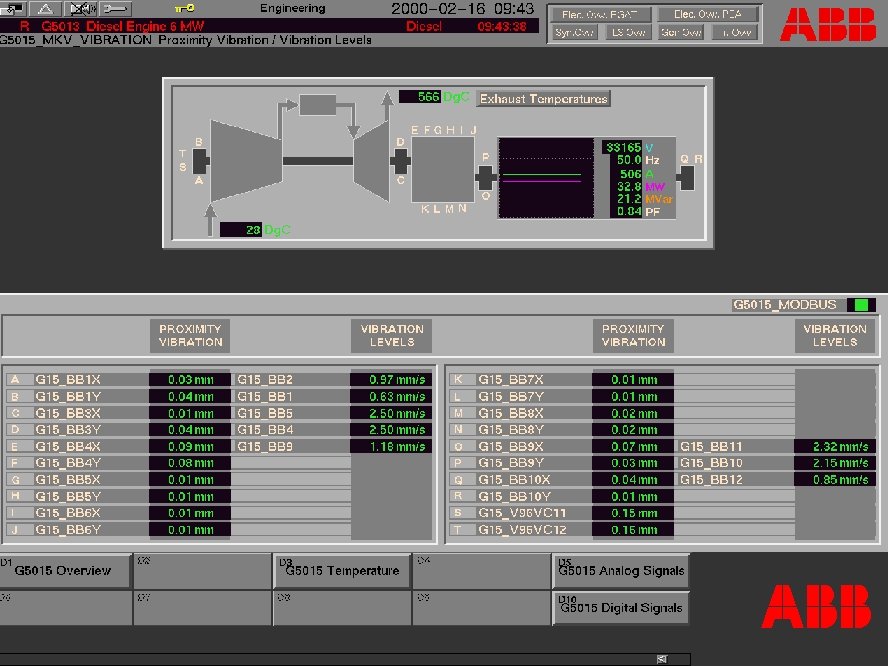

ABB bv - 21 Display Mark V Vibration ABB

ABB bv - 22 Display Mark V Gas Turbine Generator Overview ABB

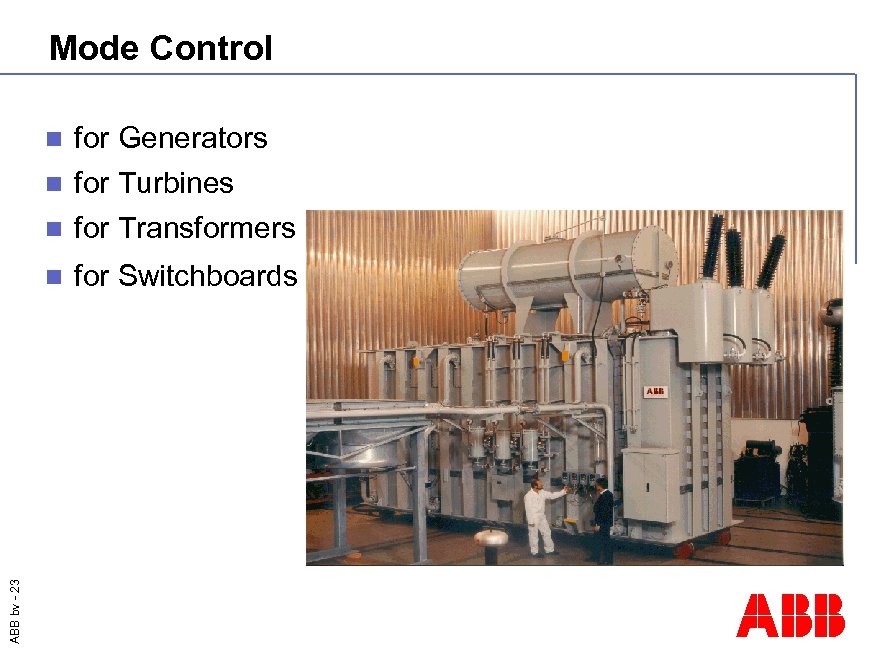

Functionality Power EMS Mode Control n for Generators Load Shedding for Turbines Active and Reactive Power Control n for Transformers Mode Control n ABB bv - 23 n for Switchboards ABB

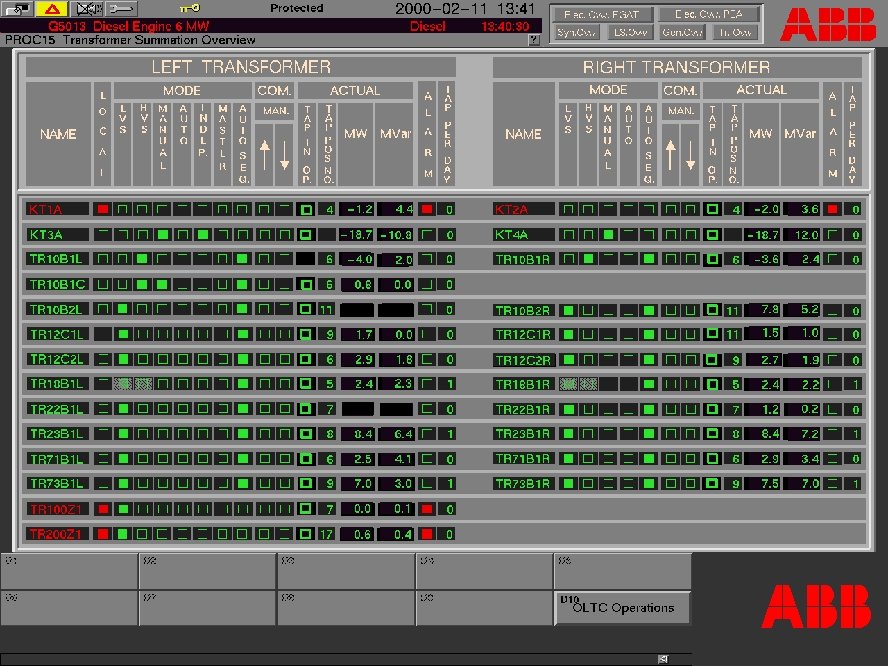

ABB bv - 24 ABB

Functionality Power EMS Acquisition Supervision, Control and Data Clearly Structured Presentation Load Shedding Controls - Select Before Execute Active and Reactive Power Control Status Indications Mode Control Consistency Analysis Supervision, Control and Data Acquisition Time Tagged Events (1 ms resolution) n Alarmhandling, Reports, Trends n Supervision and Self Diagnostics n ABB bv - 25 n n n n n Single Window concept ABB

Integration with supervisory systems Plant Information Systems - MIS n Regional Dispatch Centres n Power Generation Co-ordination Centres n Energy Trading n Utility Management Systems n ABB bv - 26 n Process DCS ABB

Integration with subordinated systems Satellite Time Receiver (GPS) n Alarm annunciators n SF-6 Density Monitoring Units n Motor Control Centres n Battery Chargers n Meteorological Stations n Diesel Generators n Generator- and turbine controller n ABB bv - 27 n Protection and Control Units ABB

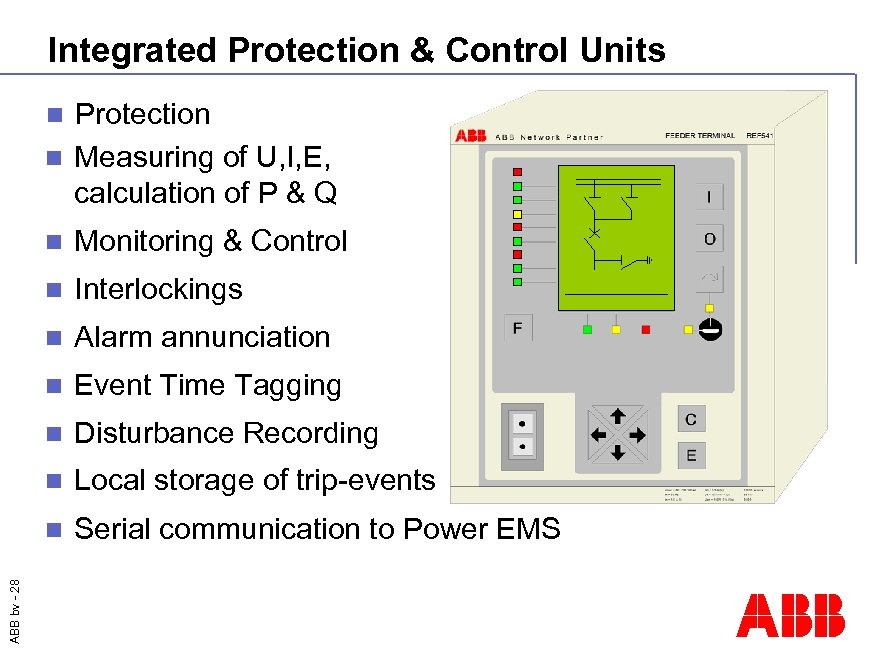

Integrated Protection & Control Units Protection n Measuring of U, I, E, calculation of P & Q n Monitoring & Control n Interlockings n Event Time Tagging n Disturbance Recording n Local storage of trip-events n CB Amps E 3 NOC 3 Low: IL 1 TRUCK OUT 800 IL 2 Amps 99 -07 -06 18: 34: 230 803 TEMPERATURE HIGH IL 3 Amps 801 NOC 3 Low: E 2 Io 0 Iob 99 -07 -06 14: 25: 52: 720 0 U 12 k. V 20 SF 6 GASOpened DENSITY 20 CB-HCU 2: U 23 k. V U 31 k. V 99 -07 -06 14: 02: 48: 430 20 U 1 k. V 11. 5 U 2 k. V 11. 5 U 3 k. V 11. 5 Uo - Volts 0 Alarm annunciation n ABB bv - 28 n CB SPRING READY Measured Values Events Serial communication to Power EMS LOADSHEDDED Use Up and Down to scroll view C-button to clear Events ABB

Functionality Power EMS Re-Starting ABB bv - 29 n n n Triggered by Load Shedding or Undervoltage Load Shedding Individual motors Active and Reactive Power Control Priority per motor Mode Control Max. allowed time delay per motor Supervision, Control and Data Acquisition (SCADA) Network configuration check Re-Acceleration / Re-Starting Network restoration ABB

Functionality Power EMS Synchronisation Automatic Synchronisation after boiler trip Load Shedding Automatic Synchronisation initiated by operator Active and Reactive Power Control Semi Automatic Synchronisation Mode Control Manual Synchronisation Supervision, Control and Data Acquisition (SCADA) n Re-Acceleration / Re-Starting n ABB bv - 30 n n n n Synchronisation ABB

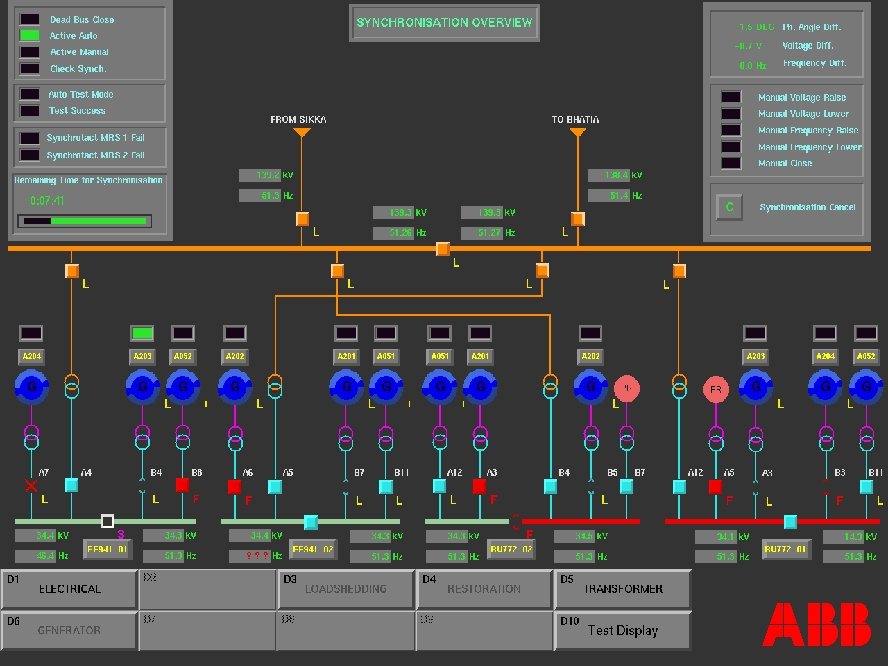

ABB bv - 31 Display Synchronisation ABB

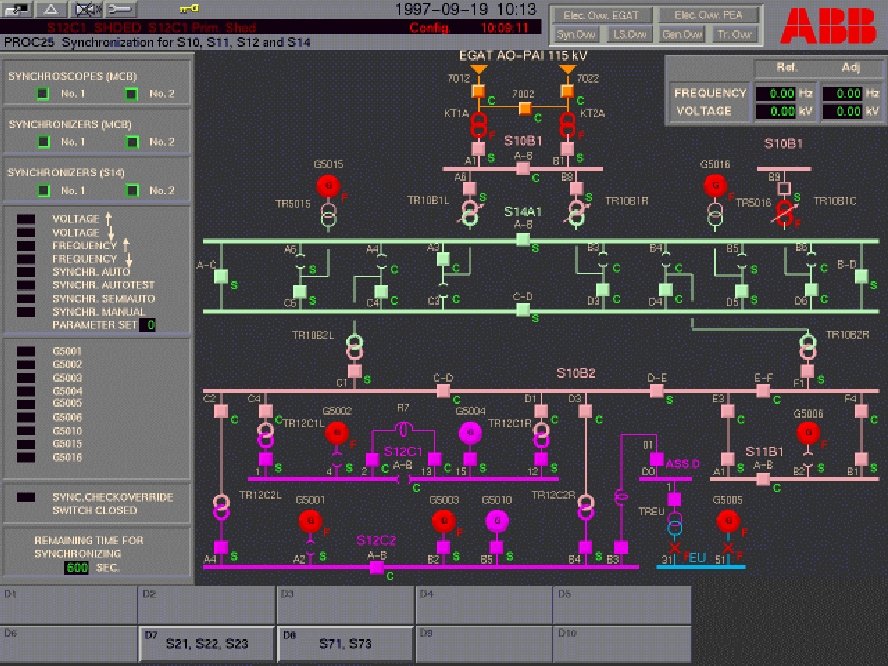

ABB bv - 32 Display Synchronisation ABB

Functionality Power EMS Load Shedding n Active and Reactive Power Control n Mode Control n Supervision, Control and Data Acquisition (SCADA) n Re-Starting n Synchronisation n Circuitbreaker Control n Transformer Control n Motor Control n ABB bv - 33 n Generator Control n Network Configuration Determination ABB

References HAR, refinery in Greece Shell Pernis refinery in the Netherlands Shell BLNG in Brunei Shell PDO in Oman Hoogovens, steel-industry in the Netherlands Thai. Oil, Thai. Lube, RRC refineries in Thailand La Roche, CHP in UK Petrobras: REPAR, REDUC, RLAM refineries in Brazil Reliance: Hazira, Jamnagar & Haldia refineries in India ABB bv - 34 AFPC, Omar refinery in Syria MLNG Satu, Dua & Tiga in Malaysia ABB Stat. Oil Gullfaks & BP Amoco Valhall in Norway

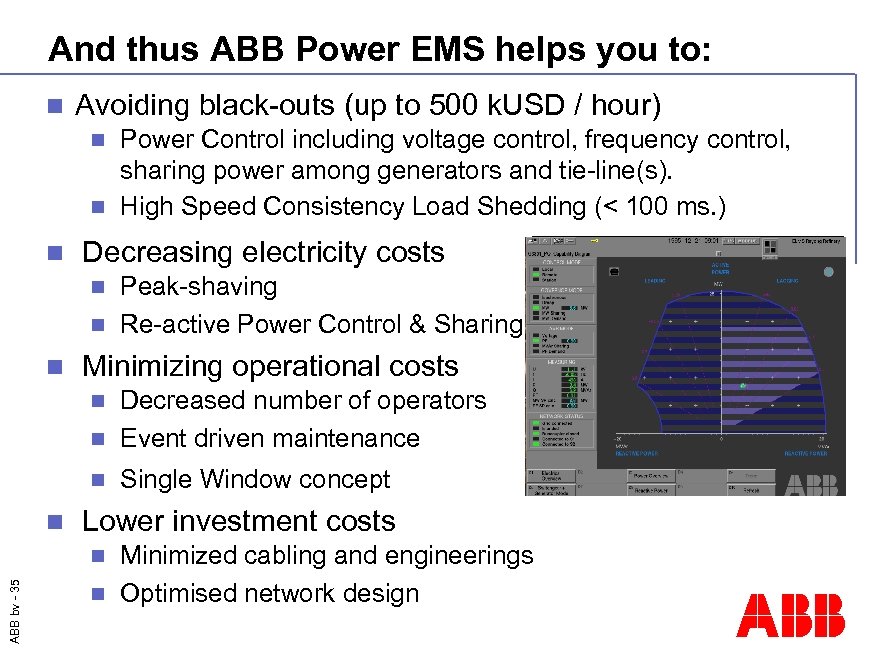

And thus ABB Power EMS helps you to: n Avoiding black-outs (up to 500 k. USD / hour) Power Control including voltage control, frequency control, sharing power among generators and tie-line(s). n High Speed Consistency Load Shedding (< 100 ms. ) n n Decreasing electricity costs Peak-shaving n Re-active Power Control & Sharing n n Minimizing operational costs ? Decreased number of operators n Event driven maintenance n n n Single Window concept Lower investmentacosts In. Powerof accumulated switched-off casetotal shortage of electrical power, The Control, Standby Optimization, Minimized Human SCADA, aetc. are performed of Optimizing the stability of the critical or The cabling Machine circuitbreaker loads n+1 shortcurrents by power to operation by secure the available Interfaces for all the Criteria, and engineerings n Optimisedelectrical off the noneduring peak time network and electricalwith protection bycontrol theswitching designgenerator distribution Limiting sub-systems canimportantthe in by the interfaces ofnot anymore & loads Serial systemgeneration- and integrated the number import be starts No needaccording toadynamicbasecable ducts units for. Energy Management System and decreasingforwiring & charge Maintaining operatorsprimary equipment the bigspaghettianof load Factor avoid triggergood industry are network ofpeak a oversizingmaintenance Power tables ABB bv - 35 n ABB

9dc05a986bf0ad63ce8ffa139ac03ef9.ppt