e396ca6bbf5a453a4e29e5ba3c051c4a.ppt

- Количество слайдов: 67

Indoor Air & Moisture Issues

Indoor Air & Moisture Issues

Indoor Pollutants • • • Carbon monoxide (CO) Tobacco smoke Nitrogen oxides, hydrocarbon dust Volatile organic compounds (VOC) Radon Biological Particles (bacteria, , viruses, dust mites, cockroaches, fungi, mold, raw sewage, rotting wood) • Asbestos and Fiberglass • Lead-based paints • Water vapor

Indoor Pollutants • • • Carbon monoxide (CO) Tobacco smoke Nitrogen oxides, hydrocarbon dust Volatile organic compounds (VOC) Radon Biological Particles (bacteria, , viruses, dust mites, cockroaches, fungi, mold, raw sewage, rotting wood) • Asbestos and Fiberglass • Lead-based paints • Water vapor

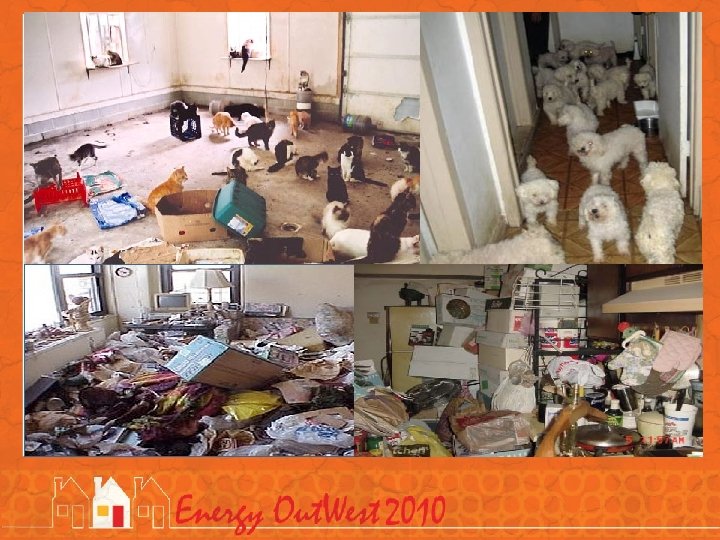

Indoor Pollutants How will you deal with these? • Lifestyle (pets outside, door mats, no shoes indoors, regular • • • cleaning) Careful product purchase decisions (low VOC) Hard floor surfaces in lieu of carpeting Sealed combustion appliances (furnace, fireplace) House pressure balancing (jump ducts, transfer grills) Moisture management (humidity control) Ventilation – Whole house – Spot (bathrooms, kitchen, crawl spaces for radon) • Air filtration

Indoor Pollutants How will you deal with these? • Lifestyle (pets outside, door mats, no shoes indoors, regular • • • cleaning) Careful product purchase decisions (low VOC) Hard floor surfaces in lieu of carpeting Sealed combustion appliances (furnace, fireplace) House pressure balancing (jump ducts, transfer grills) Moisture management (humidity control) Ventilation – Whole house – Spot (bathrooms, kitchen, crawl spaces for radon) • Air filtration

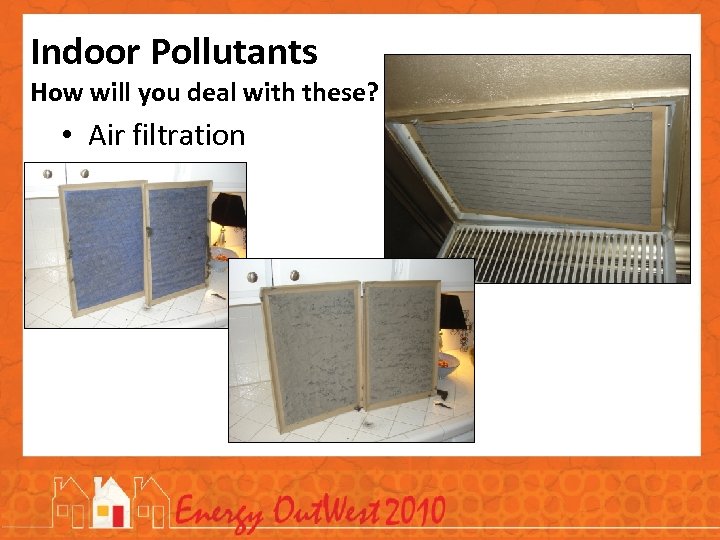

Indoor Pollutants How will you deal with these? • Air filtration

Indoor Pollutants How will you deal with these? • Air filtration

Indoor Pollutants How will you deal with these? • Air filtration

Indoor Pollutants How will you deal with these? • Air filtration

Indoor Pollutants How will you deal with these? • Air filtration 4” Return grille media filter Media air cleaner Electronic air cleaner

Indoor Pollutants How will you deal with these? • Air filtration 4” Return grille media filter Media air cleaner Electronic air cleaner

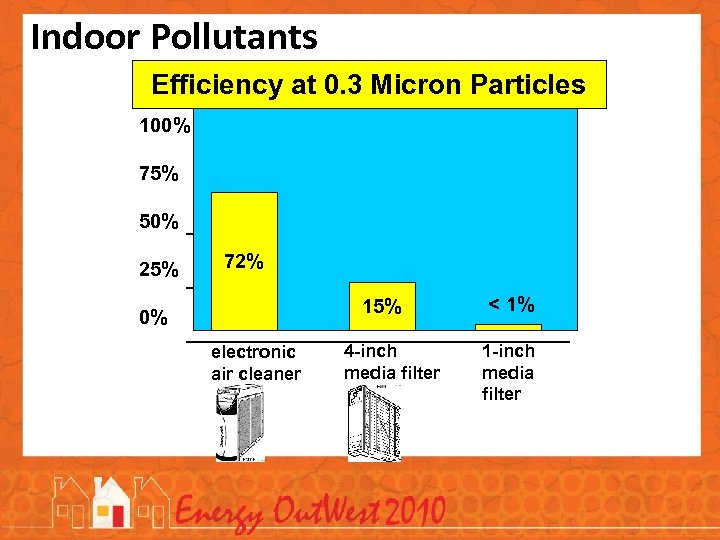

Indoor Pollutants Efficiency at 0. 3 Micron Particles 100% 75% 50% 25% 72% 15% 0% electronic air cleaner 4 -inch media filter < 1% 1 -inch media filter

Indoor Pollutants Efficiency at 0. 3 Micron Particles 100% 75% 50% 25% 72% 15% 0% electronic air cleaner 4 -inch media filter < 1% 1 -inch media filter

Moisture • Moisture is the number one pollutant in homes – Need to be aware of its sources – Basic knowledge of determining moisture levels – Solving moisture problems

Moisture • Moisture is the number one pollutant in homes – Need to be aware of its sources – Basic knowledge of determining moisture levels – Solving moisture problems

Dealing With Moisture • Keep water out – Roof, plumbing, grading of ground…fix problems • Understand that moisture will get in – Ventilation is needed • Make sure moisture can get out – Material selection (vinyl wallpaper is a bad choice) BPI Analyst Certification – Basic Principles of Energy

Dealing With Moisture • Keep water out – Roof, plumbing, grading of ground…fix problems • Understand that moisture will get in – Ventilation is needed • Make sure moisture can get out – Material selection (vinyl wallpaper is a bad choice) BPI Analyst Certification – Basic Principles of Energy

Moisture Movement Through Buildings • Moisture in buildings can be tracked to one or more of the following (in order of importance) – Liquid flow: Roof leaks, plumbing leaks, ground water… – Capillary seepage: Liquid water being pulled into a material or assembly – Air movement: Carrying water vapor into or out of a building and its cavities – Vapor diffusion: Vapor will move through solid objects depending on the object’s permeance and the vapor pressure

Moisture Movement Through Buildings • Moisture in buildings can be tracked to one or more of the following (in order of importance) – Liquid flow: Roof leaks, plumbing leaks, ground water… – Capillary seepage: Liquid water being pulled into a material or assembly – Air movement: Carrying water vapor into or out of a building and its cavities – Vapor diffusion: Vapor will move through solid objects depending on the object’s permeance and the vapor pressure

Controlling Moisture … • • 1 inch of rain on 1, 000 sq. ft. roof = 623 gallons High water table Foundation plants Leaking water spigot

Controlling Moisture … • • 1 inch of rain on 1, 000 sq. ft. roof = 623 gallons High water table Foundation plants Leaking water spigot

Moisture Movement • Vapor pressure: Vapor pressure is created by different amounts of water vapor in two different air masses. Moves from high to low. • Relative humidity: The percentage of the maximum moisture that air can hold at a given temperature – The higher the temperature of the air, the more moisture it can hold BPI Analyst Certification – Basic Principles of Energy

Moisture Movement • Vapor pressure: Vapor pressure is created by different amounts of water vapor in two different air masses. Moves from high to low. • Relative humidity: The percentage of the maximum moisture that air can hold at a given temperature – The higher the temperature of the air, the more moisture it can hold BPI Analyst Certification – Basic Principles of Energy

Relative Humidity • Key point: relative humidity (RH) changes as temperature changes • When cooled enough, air at 50% RH, for example, will hit 100% RH and the moisture in the air will condense on cool surfaces – In the winter, warm indoor air is forced out of a building – In the summer, hot humid air is pulled into an air conditioned space……. under this condition, there is a potential for MOLD.

Relative Humidity • Key point: relative humidity (RH) changes as temperature changes • When cooled enough, air at 50% RH, for example, will hit 100% RH and the moisture in the air will condense on cool surfaces – In the winter, warm indoor air is forced out of a building – In the summer, hot humid air is pulled into an air conditioned space……. under this condition, there is a potential for MOLD.

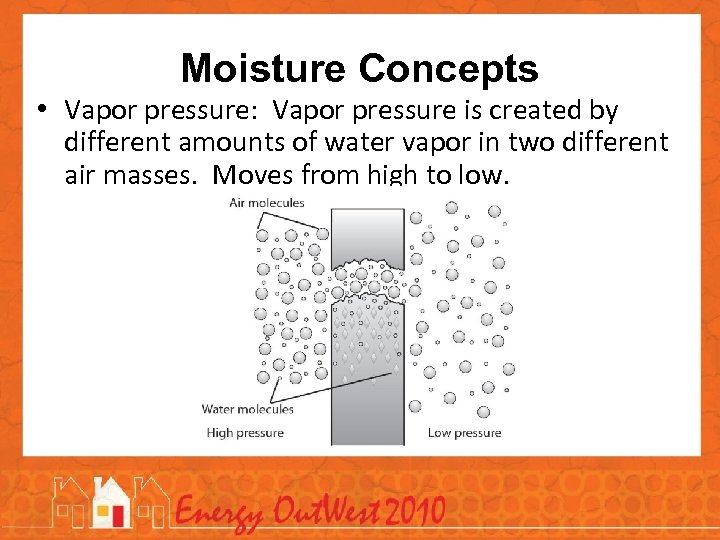

Moisture Concepts • Vapor pressure: Vapor pressure is created by different amounts of water vapor in two different air masses. Moves from high to low.

Moisture Concepts • Vapor pressure: Vapor pressure is created by different amounts of water vapor in two different air masses. Moves from high to low.

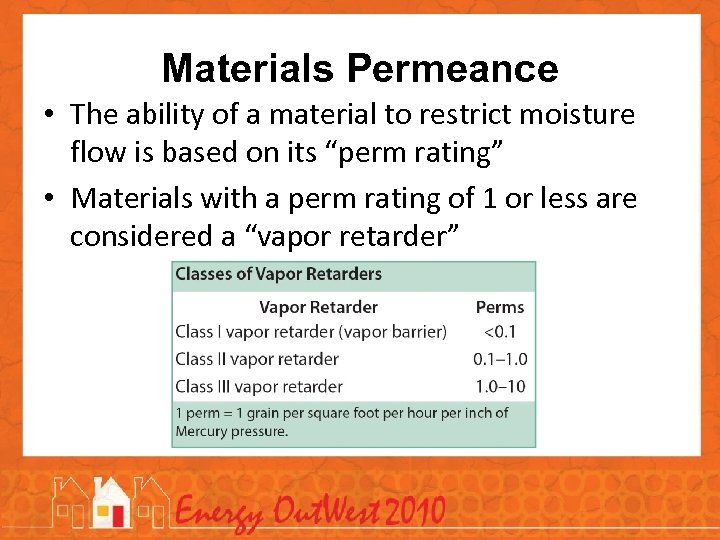

Materials Permeance • The ability of a material to restrict moisture flow is based on its “perm rating” • Materials with a perm rating of 1 or less are considered a “vapor retarder”

Materials Permeance • The ability of a material to restrict moisture flow is based on its “perm rating” • Materials with a perm rating of 1 or less are considered a “vapor retarder”

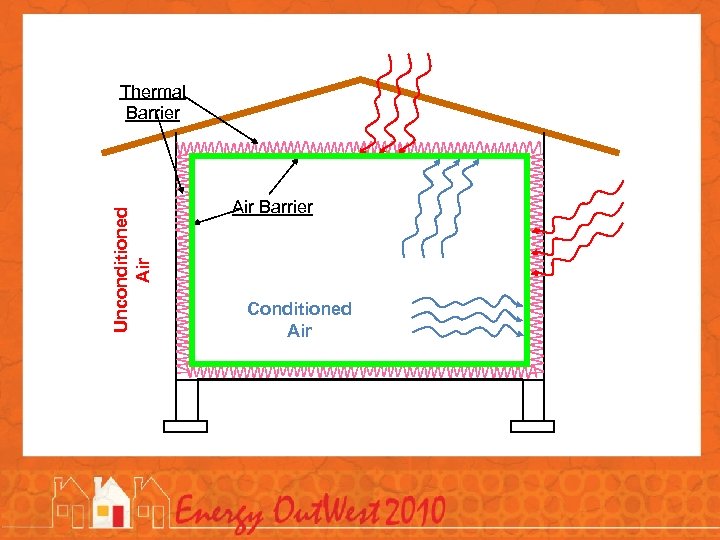

Unconditioned Air Thermal Barrier Air Barrier Conditioned Air

Unconditioned Air Thermal Barrier Air Barrier Conditioned Air

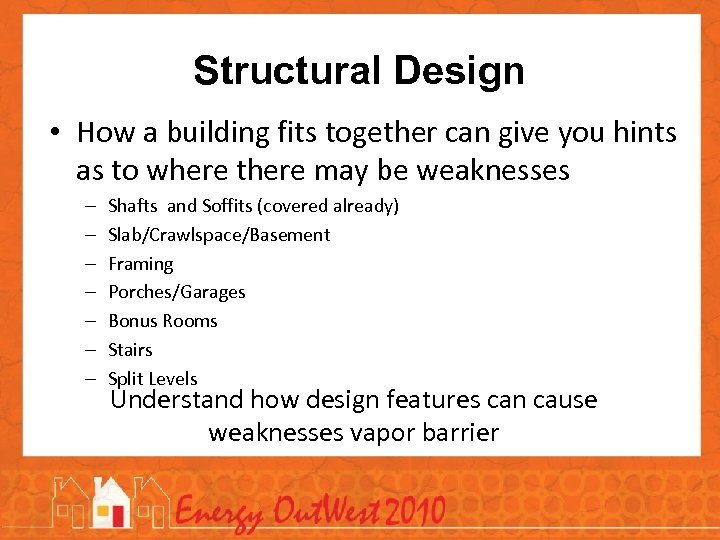

Structural Design • How a building fits together can give you hints as to where there may be weaknesses – – – – Shafts and Soffits (covered already) Slab/Crawlspace/Basement Framing Porches/Garages Bonus Rooms Stairs Split Levels Understand how design features can cause weaknesses vapor barrier

Structural Design • How a building fits together can give you hints as to where there may be weaknesses – – – – Shafts and Soffits (covered already) Slab/Crawlspace/Basement Framing Porches/Garages Bonus Rooms Stairs Split Levels Understand how design features can cause weaknesses vapor barrier

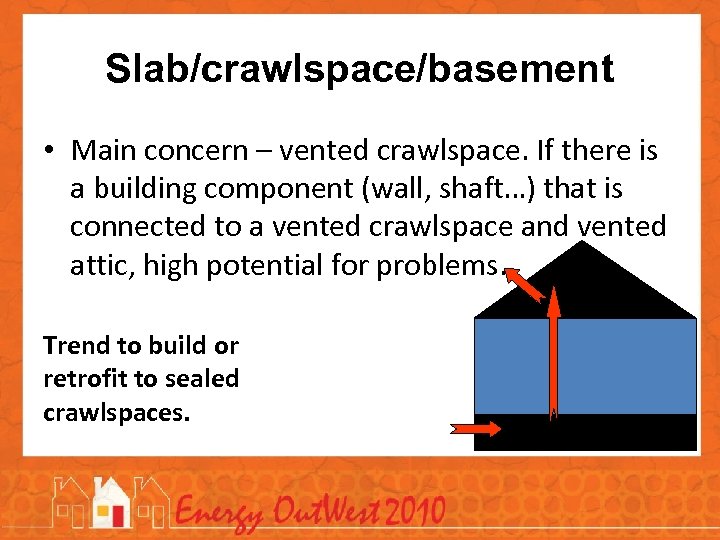

Slab/crawlspace/basement • Main concern – vented crawlspace. If there is a building component (wall, shaft…) that is connected to a vented crawlspace and vented attic, high potential for problems. Trend to build or retrofit to sealed crawlspaces.

Slab/crawlspace/basement • Main concern – vented crawlspace. If there is a building component (wall, shaft…) that is connected to a vented crawlspace and vented attic, high potential for problems. Trend to build or retrofit to sealed crawlspaces.

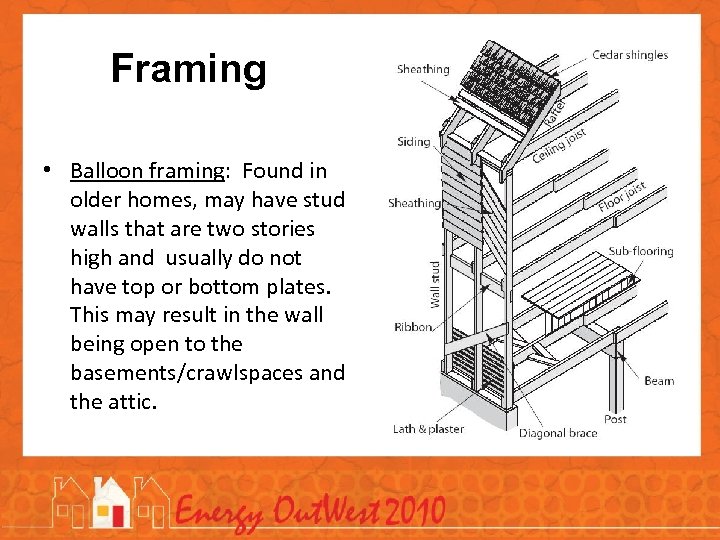

Framing • Balloon framing: Found in older homes, may have stud walls that are two stories high and usually do not have top or bottom plates. This may result in the wall being open to the basements/crawlspaces and the attic.

Framing • Balloon framing: Found in older homes, may have stud walls that are two stories high and usually do not have top or bottom plates. This may result in the wall being open to the basements/crawlspaces and the attic.

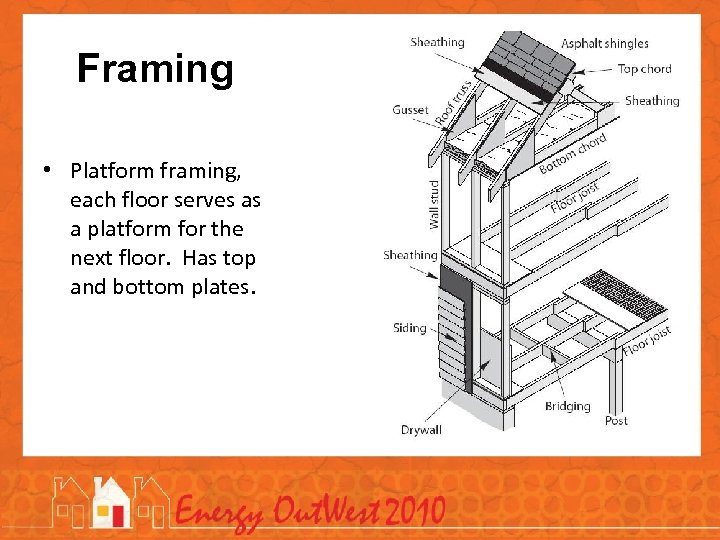

Framing • Platform framing, each floor serves as a platform for the next floor. Has top and bottom plates.

Framing • Platform framing, each floor serves as a platform for the next floor. Has top and bottom plates.

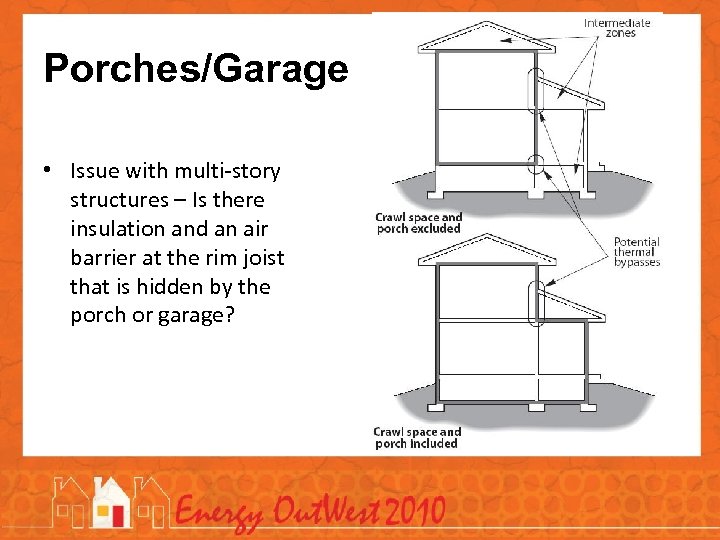

Porches/Garage • Issue with multi-story structures – Is there insulation and an air barrier at the rim joist that is hidden by the porch or garage?

Porches/Garage • Issue with multi-story structures – Is there insulation and an air barrier at the rim joist that is hidden by the porch or garage?

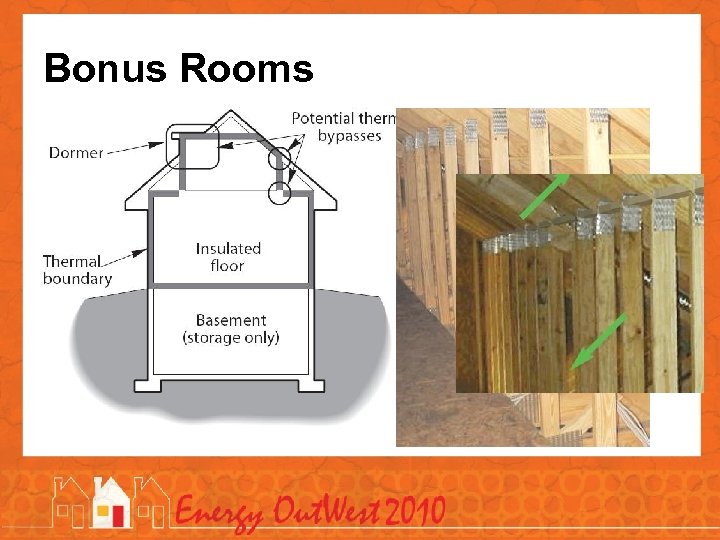

Bonus Rooms

Bonus Rooms

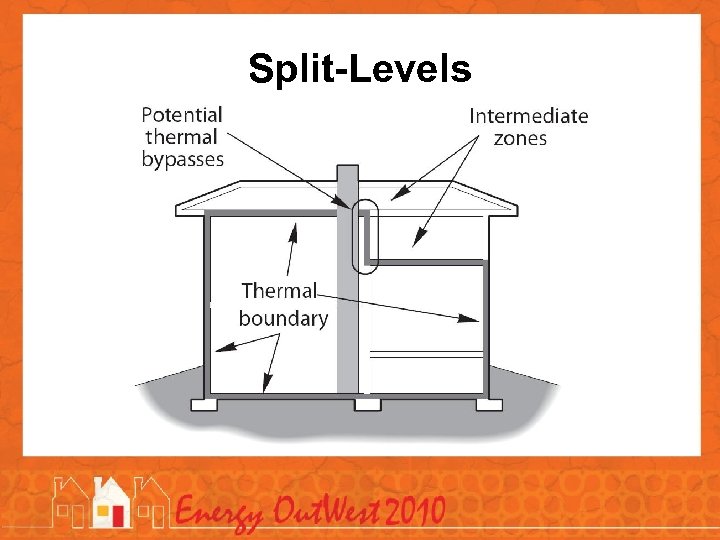

Split-Levels

Split-Levels

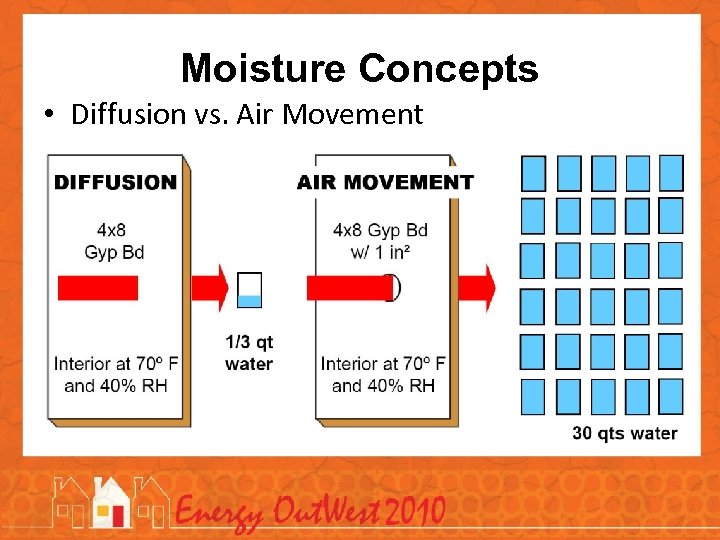

Moisture Concepts • Diffusion vs. Air Movement

Moisture Concepts • Diffusion vs. Air Movement

A Primer on Air Flow • For air to flow you need a hole and a pressure. – No hole, no flow – No pressure, no flow

A Primer on Air Flow • For air to flow you need a hole and a pressure. – No hole, no flow – No pressure, no flow

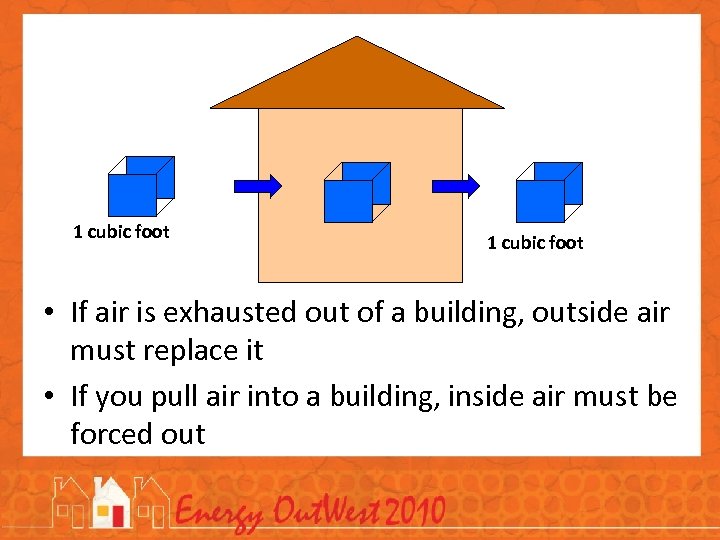

1 cubic foot • If air is exhausted out of a building, outside air must replace it • If you pull air into a building, inside air must be forced out

1 cubic foot • If air is exhausted out of a building, outside air must replace it • If you pull air into a building, inside air must be forced out

CFM 50 Leakage Tests • Provides information on how leaky the house is. – Remember, how leaky, not how much leakage. Amount of air movement depends on pressure! • Post air sealing test can give valuable feedback on the success of your work. • Find where the holes are. • Predictions on the impact of work.

CFM 50 Leakage Tests • Provides information on how leaky the house is. – Remember, how leaky, not how much leakage. Amount of air movement depends on pressure! • Post air sealing test can give valuable feedback on the success of your work. • Find where the holes are. • Predictions on the impact of work.

What does a CFM 50 value tell you about the house? • CFM 50 is like a 20 mile per hour wind blowing on all sides of the house. – From this value you can estimate the natural leakage of a home (see appendix E in the BD manual). • The CFM 50 value can give you a good indication of the total size of all the holes in a home. – A tenth (remove the last digit) of the CFM 50 number is about equal to the square inches of holes in the house. 1500 CFM 50 = about 150 sq. inches of holes.

What does a CFM 50 value tell you about the house? • CFM 50 is like a 20 mile per hour wind blowing on all sides of the house. – From this value you can estimate the natural leakage of a home (see appendix E in the BD manual). • The CFM 50 value can give you a good indication of the total size of all the holes in a home. – A tenth (remove the last digit) of the CFM 50 number is about equal to the square inches of holes in the house. 1500 CFM 50 = about 150 sq. inches of holes.

Door Closure • The average pressure that natural forces will put on a house are between 1. 5 Pa (low desert) to 3 Pa (high country). • Pressure created by door closure can be many times higher than natural pressure. • The higher the pressures, the higher the infiltration rate. • Room pressure tests will show if there is a problem and help determine the solution. BPI Analyst Certification – Pressure Diagnostics

Door Closure • The average pressure that natural forces will put on a house are between 1. 5 Pa (low desert) to 3 Pa (high country). • Pressure created by door closure can be many times higher than natural pressure. • The higher the pressures, the higher the infiltration rate. • Room pressure tests will show if there is a problem and help determine the solution. BPI Analyst Certification – Pressure Diagnostics

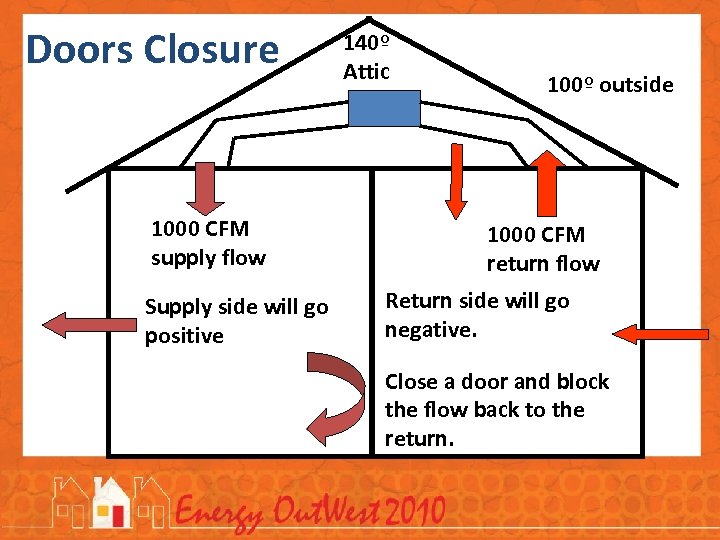

Doors Closure 1000 CFM supply flow Supply side will go positive 140º Attic 100º outside 1000 CFM return flow Return side will go negative. Close a door and block the flow back to the return.

Doors Closure 1000 CFM supply flow Supply side will go positive 140º Attic 100º outside 1000 CFM return flow Return side will go negative. Close a door and block the flow back to the return.

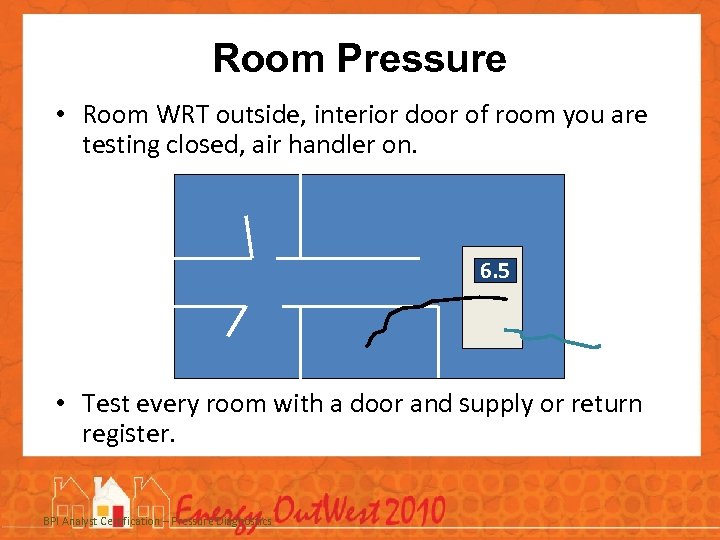

Room Pressure • Room WRT outside, interior door of room you are testing closed, air handler on. 6. 5 • Test every room with a door and supply or return register. BPI Analyst Certification – Pressure Diagnostics

Room Pressure • Room WRT outside, interior door of room you are testing closed, air handler on. 6. 5 • Test every room with a door and supply or return register. BPI Analyst Certification – Pressure Diagnostics

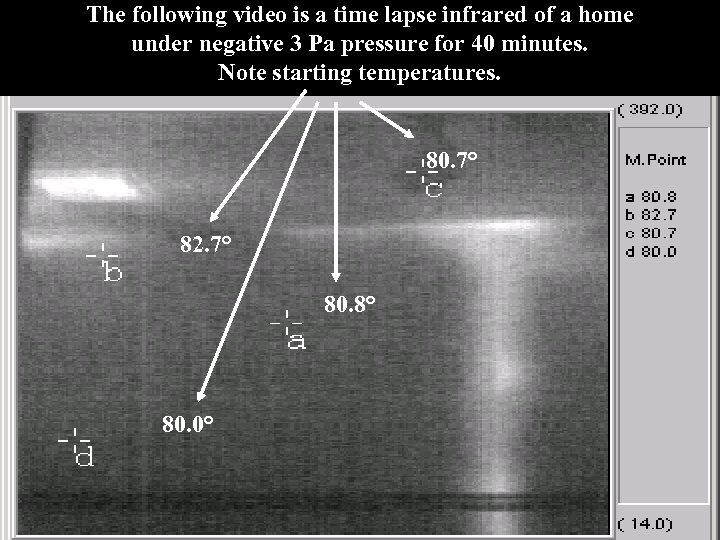

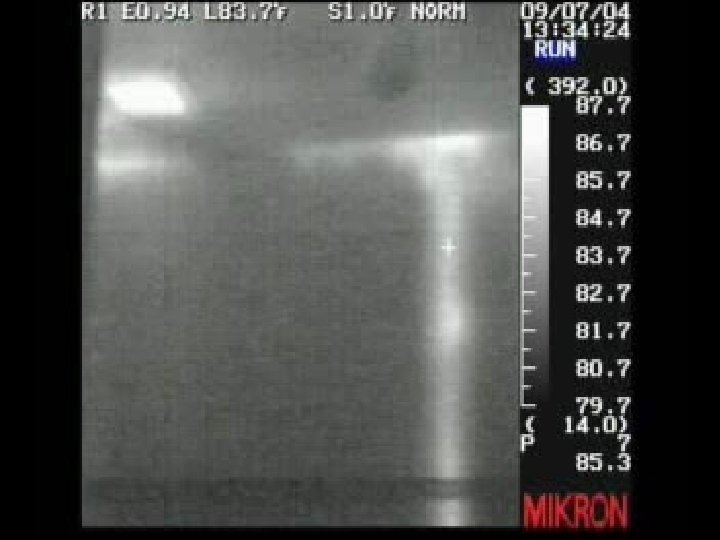

The following video is a time lapse infrared of a home under negative 3 Pa pressure for 40 minutes. Note starting temperatures. 80. 7° 82. 7° 80. 8° 80. 0°

The following video is a time lapse infrared of a home under negative 3 Pa pressure for 40 minutes. Note starting temperatures. 80. 7° 82. 7° 80. 8° 80. 0°

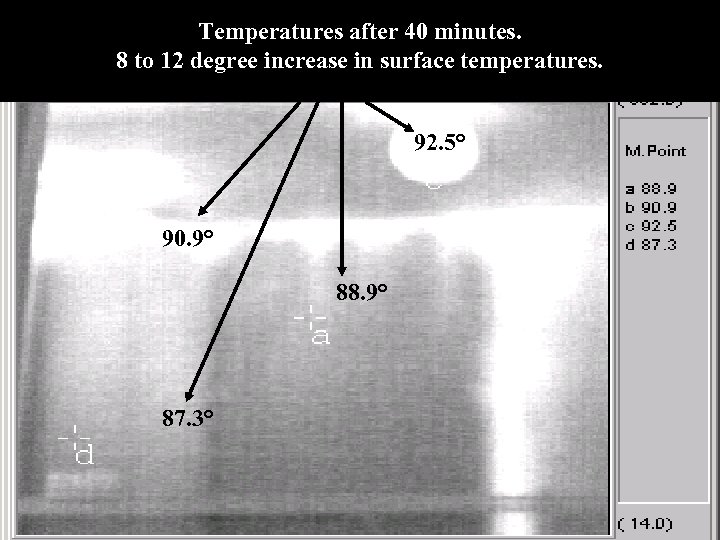

Temperatures after 40 minutes. 8 to 12 degree increase in surface temperatures. 92. 5° 90. 9° 88. 9° 87. 3°

Temperatures after 40 minutes. 8 to 12 degree increase in surface temperatures. 92. 5° 90. 9° 88. 9° 87. 3°

The pressure is getting to me!

The pressure is getting to me!

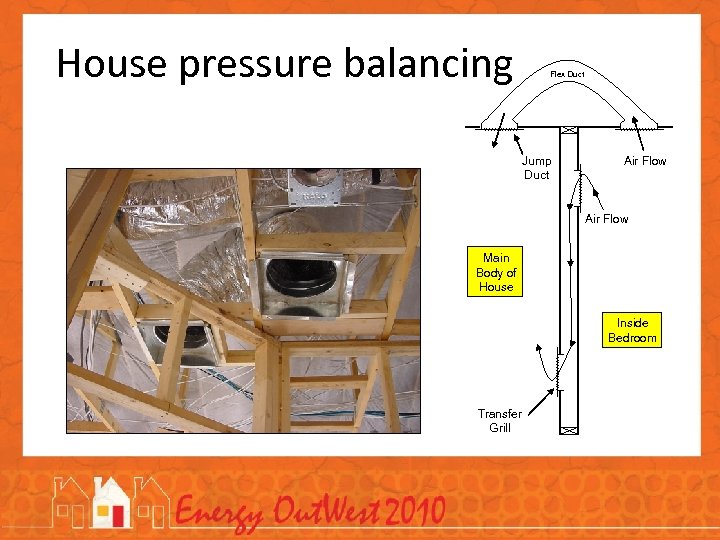

House pressure balancing Flex Duct Jump Duct Air Flow Main Body of House Inside Bedroom Transfer Grill

House pressure balancing Flex Duct Jump Duct Air Flow Main Body of House Inside Bedroom Transfer Grill

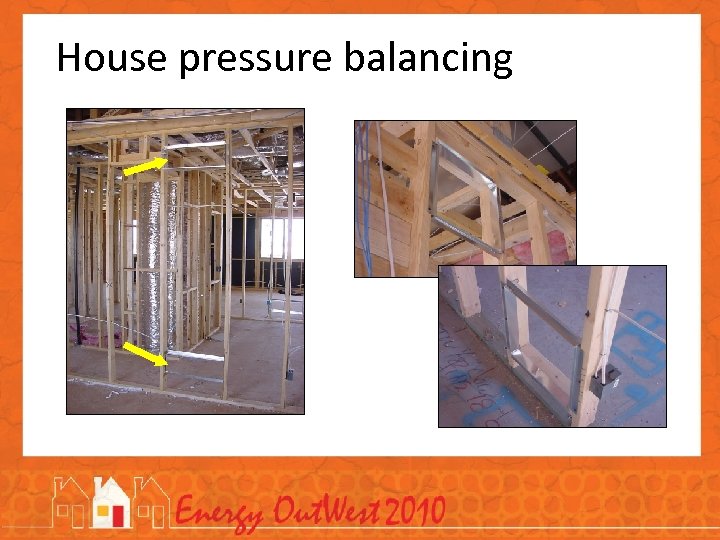

House pressure balancing

House pressure balancing

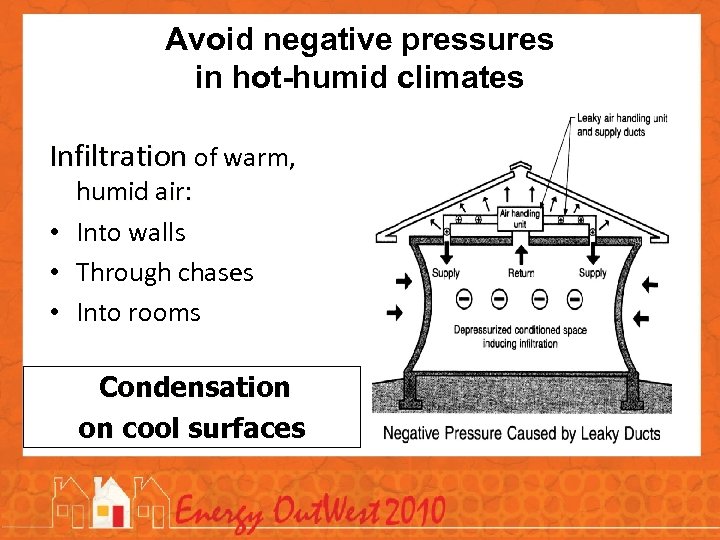

Avoid negative pressures in hot-humid climates Infiltration of warm, humid air: • Into walls • Through chases • Into rooms Condensation on cool surfaces

Avoid negative pressures in hot-humid climates Infiltration of warm, humid air: • Into walls • Through chases • Into rooms Condensation on cool surfaces

The “Perfect House”

The “Perfect House”

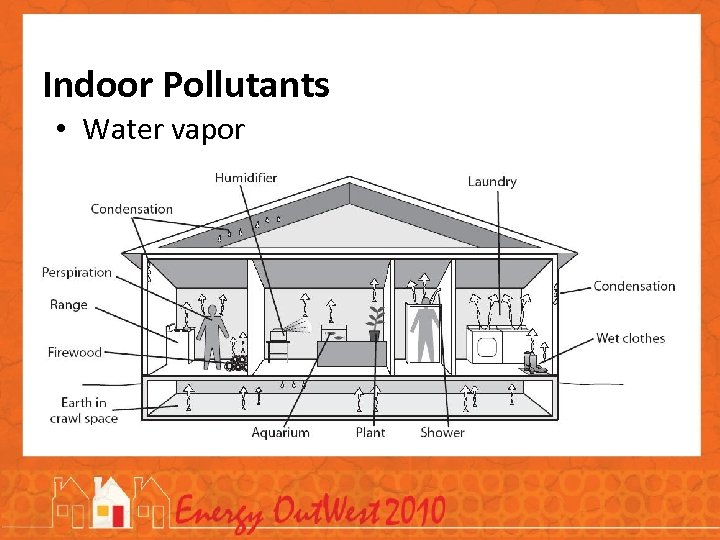

Indoor Pollutants • Water vapor

Indoor Pollutants • Water vapor

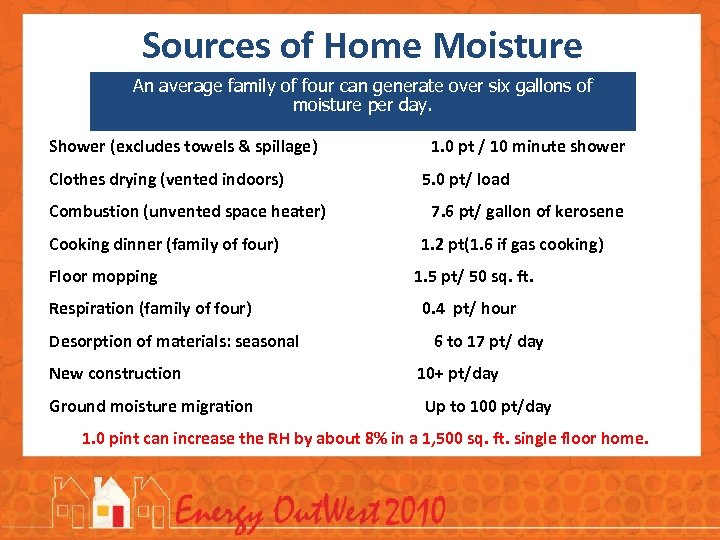

Sources of Home Moisture An average family of four can generate over six gallons of moisture per day. Shower (excludes towels & spillage) 1. 0 pt / 10 minute shower Clothes drying (vented indoors) 5. 0 pt/ load Combustion (unvented space heater) 7. 6 pt/ gallon of kerosene Cooking dinner (family of four) 1. 2 pt(1. 6 if gas cooking) Floor mopping 1. 5 pt/ 50 sq. ft. Respiration (family of four) 0. 4 pt/ hour Desorption of materials: seasonal 6 to 17 pt/ day New construction 10+ pt/day Ground moisture migration Up to 100 pt/day 1. 0 pint can increase the RH by about 8% in a 1, 500 sq. ft. single floor home.

Sources of Home Moisture An average family of four can generate over six gallons of moisture per day. Shower (excludes towels & spillage) 1. 0 pt / 10 minute shower Clothes drying (vented indoors) 5. 0 pt/ load Combustion (unvented space heater) 7. 6 pt/ gallon of kerosene Cooking dinner (family of four) 1. 2 pt(1. 6 if gas cooking) Floor mopping 1. 5 pt/ 50 sq. ft. Respiration (family of four) 0. 4 pt/ hour Desorption of materials: seasonal 6 to 17 pt/ day New construction 10+ pt/day Ground moisture migration Up to 100 pt/day 1. 0 pint can increase the RH by about 8% in a 1, 500 sq. ft. single floor home.

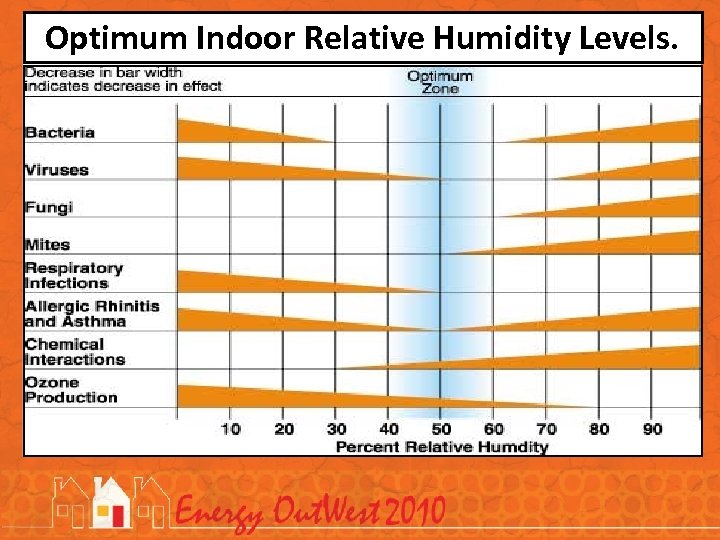

Optimum Indoor Relative Humidity Levels.

Optimum Indoor Relative Humidity Levels.

Sensible and Latent Heat • Sensible heat: The basic relationship between energy and temperature Example: 1 Btu = 1° increase in temperature of 1 lb of water

Sensible and Latent Heat • Sensible heat: The basic relationship between energy and temperature Example: 1 Btu = 1° increase in temperature of 1 lb of water

Sensible and Latent Heat • Latent heat: The heat absorbed or released when a material changes phase between a solid and a liquid or between a liquid and a gas

Sensible and Latent Heat • Latent heat: The heat absorbed or released when a material changes phase between a solid and a liquid or between a liquid and a gas

AIR CONDITIONING • Utilizes the properties of latent heat to move heat through a forced air distribution system – Cooling moves heat out of the house – Removes Latent heat first – Condenses water vapor back into liquid

AIR CONDITIONING • Utilizes the properties of latent heat to move heat through a forced air distribution system – Cooling moves heat out of the house – Removes Latent heat first – Condenses water vapor back into liquid

SIZING • Over-sizing has a negative effect on energy use, comfort, equipment life, and system costs: • Oversized systems run for a short period and do not reach steady state efficiency (think of city vs. highway driving). Impacts both cost and life. • Short run times mean that the air does not get mixed, causing hot spots. • Short run times will not remove humidity, increasing comfort problems. • Over sized equipment costs more to install.

SIZING • Over-sizing has a negative effect on energy use, comfort, equipment life, and system costs: • Oversized systems run for a short period and do not reach steady state efficiency (think of city vs. highway driving). Impacts both cost and life. • Short run times mean that the air does not get mixed, causing hot spots. • Short run times will not remove humidity, increasing comfort problems. • Over sized equipment costs more to install.

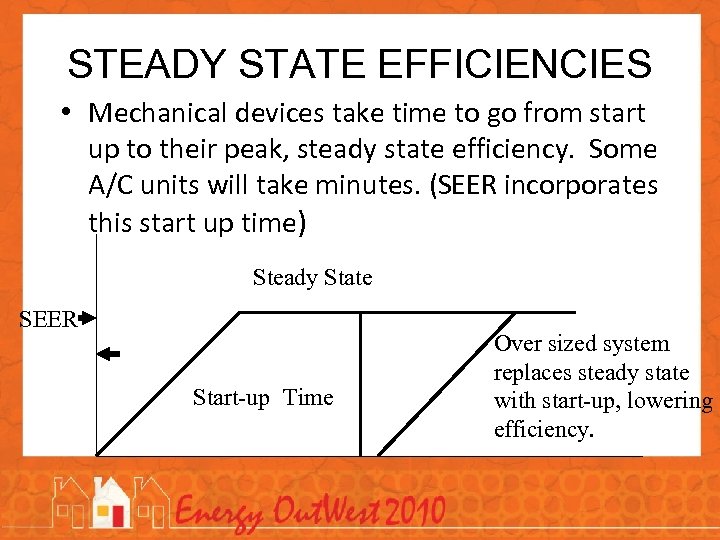

STEADY STATE EFFICIENCIES • Mechanical devices take time to go from start up to their peak, steady state efficiency. Some A/C units will take minutes. (SEER incorporates this start up time) Steady State SEER Start-up Time Over sized system replaces steady state with start-up, lowering efficiency.

STEADY STATE EFFICIENCIES • Mechanical devices take time to go from start up to their peak, steady state efficiency. Some A/C units will take minutes. (SEER incorporates this start up time) Steady State SEER Start-up Time Over sized system replaces steady state with start-up, lowering efficiency.

Kitchen & Bath Moisture Control • Bathrooms, kitchens and utility areas should be vented to the “outside” – never to attic or crawl space. • Exhaust vents rarely discharge rated cfm

Kitchen & Bath Moisture Control • Bathrooms, kitchens and utility areas should be vented to the “outside” – never to attic or crawl space. • Exhaust vents rarely discharge rated cfm

Exhaust Vent Rules 1. • • Size correctly 50 cfm bathroom venting standard (*20 cfm) 100 cfm kitchen venting standard (*25 cfm) 2. Exhaust to outdoor – never into attic 3. Shortest vertical distance to outside or direct vent through wall 4. Control bathroom exhaust with timer or humidistat 5. Use aluminum piping without screws and taped joints * If venting is continuous

Exhaust Vent Rules 1. • • Size correctly 50 cfm bathroom venting standard (*20 cfm) 100 cfm kitchen venting standard (*25 cfm) 2. Exhaust to outdoor – never into attic 3. Shortest vertical distance to outside or direct vent through wall 4. Control bathroom exhaust with timer or humidistat 5. Use aluminum piping without screws and taped joints * If venting is continuous

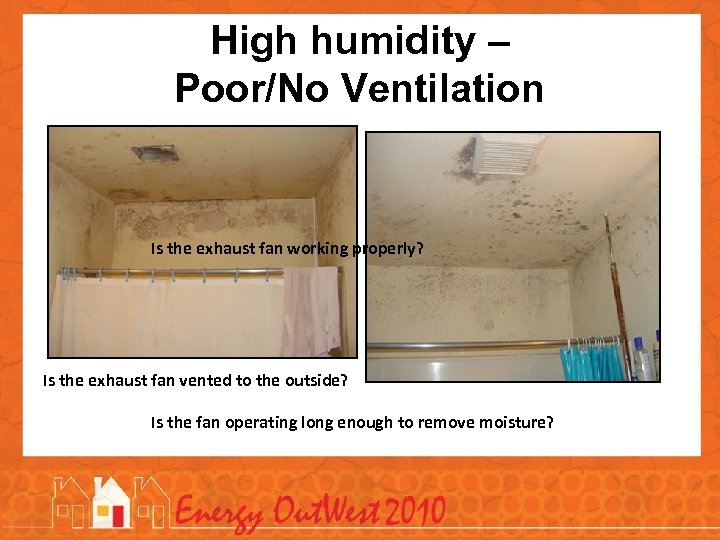

High humidity – Poor/No Ventilation Is the exhaust fan working properly? Is the exhaust fan vented to the outside? Is the fan operating long enough to remove moisture?

High humidity – Poor/No Ventilation Is the exhaust fan working properly? Is the exhaust fan vented to the outside? Is the fan operating long enough to remove moisture?

Clothes Dryer Rules: l Always vent to outside l With mobiles vent beyond the skirting l Do not vent into crawl spaces l If possible direct vent to outside using smooth metal piping l If elbows are needed, limit to two

Clothes Dryer Rules: l Always vent to outside l With mobiles vent beyond the skirting l Do not vent into crawl spaces l If possible direct vent to outside using smooth metal piping l If elbows are needed, limit to two

Ventilation • Three basic types of ventilation: – Infiltration – Natural ventilation (opening windows) – Mechanical ventilation • Whole house • Spot

Ventilation • Three basic types of ventilation: – Infiltration – Natural ventilation (opening windows) – Mechanical ventilation • Whole house • Spot

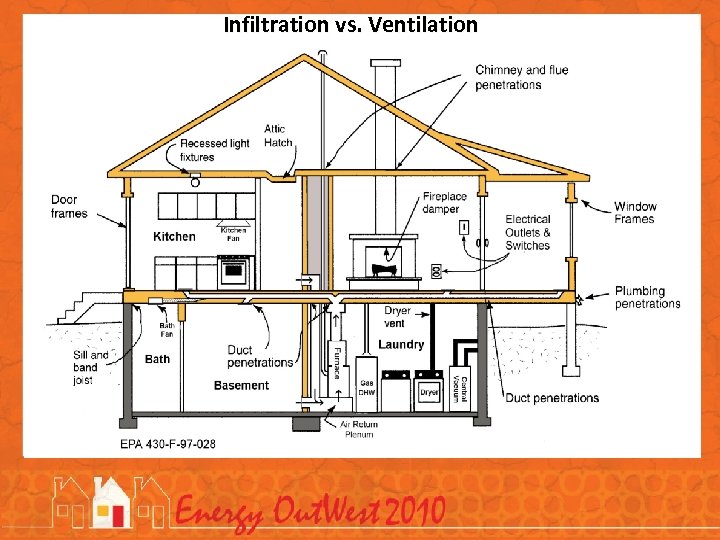

Infiltration vs. Ventilation

Infiltration vs. Ventilation

Mechanical Ventilation • A fan that moves a measured amount of air into a house (supply), out of a house (exhaust) or both (balanced) – Ventilation systems must be selected to reduce the potential for causing problems (mold) in the building • Do not create positive (supply) pressures in extremely cold climates • Do not create negative (exhaust) pressures in hot/humid climates

Mechanical Ventilation • A fan that moves a measured amount of air into a house (supply), out of a house (exhaust) or both (balanced) – Ventilation systems must be selected to reduce the potential for causing problems (mold) in the building • Do not create positive (supply) pressures in extremely cold climates • Do not create negative (exhaust) pressures in hot/humid climates

Do You Need Ventilation in an Existing Home? Depends: • First, does code apply? If so, follow code. • If not (vast majority of weatherization work) – What is in the home that needs to be vented (pollution sources)? – How much ventilation does house already have (fans and leakage)?

Do You Need Ventilation in an Existing Home? Depends: • First, does code apply? If so, follow code. • If not (vast majority of weatherization work) – What is in the home that needs to be vented (pollution sources)? – How much ventilation does house already have (fans and leakage)?

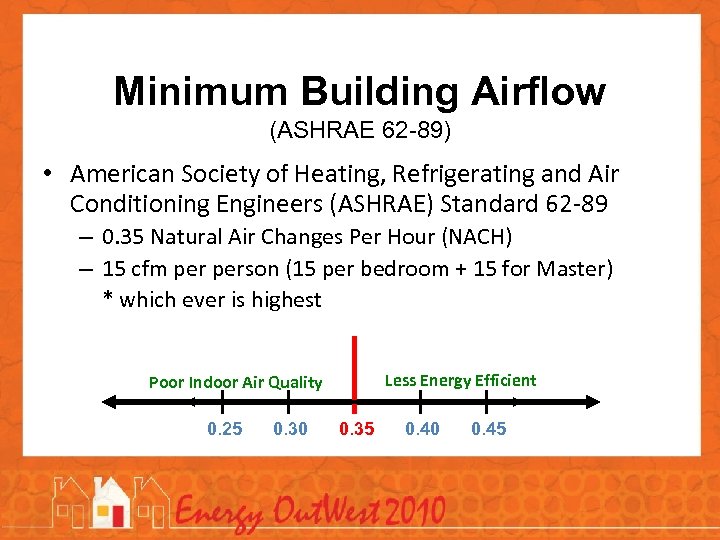

Minimum Building Airflow (ASHRAE 62 -89) • American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE) Standard 62 -89 – 0. 35 Natural Air Changes Per Hour (NACH) – 15 cfm person (15 per bedroom + 15 for Master) * which ever is highest Less Energy Efficient Poor Indoor Air Quality 0. 25 0. 30 0. 35 0. 40 0. 45

Minimum Building Airflow (ASHRAE 62 -89) • American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE) Standard 62 -89 – 0. 35 Natural Air Changes Per Hour (NACH) – 15 cfm person (15 per bedroom + 15 for Master) * which ever is highest Less Energy Efficient Poor Indoor Air Quality 0. 25 0. 30 0. 35 0. 40 0. 45

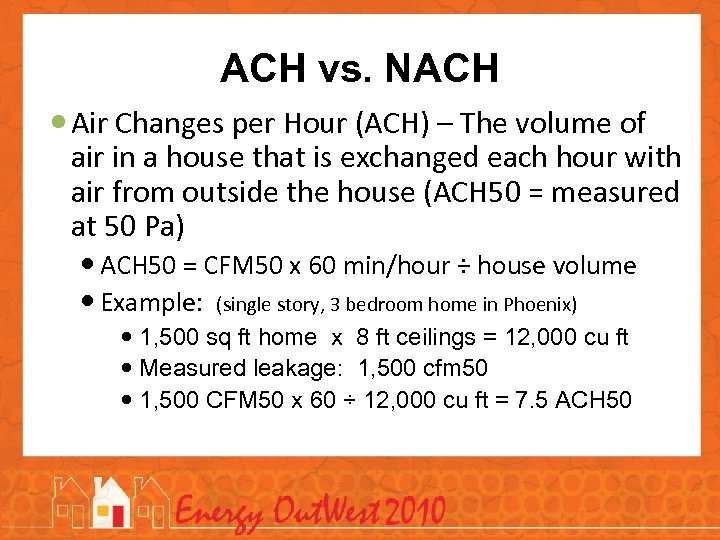

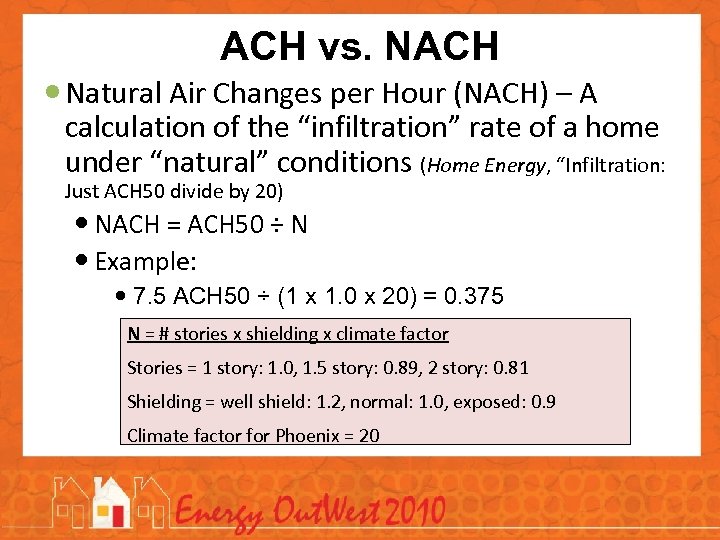

ACH vs. NACH Air Changes per Hour (ACH) – The volume of air in a house that is exchanged each hour with air from outside the house (ACH 50 = measured at 50 Pa) ACH 50 = CFM 50 x 60 min/hour ÷ house volume Example: (single story, 3 bedroom home in Phoenix) 1, 500 sq ft home x 8 ft ceilings = 12, 000 cu ft Measured leakage: 1, 500 cfm 50 1, 500 CFM 50 x 60 ÷ 12, 000 cu ft = 7. 5 ACH 50

ACH vs. NACH Air Changes per Hour (ACH) – The volume of air in a house that is exchanged each hour with air from outside the house (ACH 50 = measured at 50 Pa) ACH 50 = CFM 50 x 60 min/hour ÷ house volume Example: (single story, 3 bedroom home in Phoenix) 1, 500 sq ft home x 8 ft ceilings = 12, 000 cu ft Measured leakage: 1, 500 cfm 50 1, 500 CFM 50 x 60 ÷ 12, 000 cu ft = 7. 5 ACH 50

ACH vs. NACH Natural Air Changes per Hour (NACH) – A calculation of the “infiltration” rate of a home under “natural” conditions (Home Energy, “Infiltration: Just ACH 50 divide by 20) NACH = ACH 50 ÷ N Example: 7. 5 ACH 50 ÷ (1 x 1. 0 x 20) = 0. 375 N = # stories x shielding x climate factor Stories = 1 story: 1. 0, 1. 5 story: 0. 89, 2 story: 0. 81 Shielding = well shield: 1. 2, normal: 1. 0, exposed: 0. 9 Climate factor for Phoenix = 20

ACH vs. NACH Natural Air Changes per Hour (NACH) – A calculation of the “infiltration” rate of a home under “natural” conditions (Home Energy, “Infiltration: Just ACH 50 divide by 20) NACH = ACH 50 ÷ N Example: 7. 5 ACH 50 ÷ (1 x 1. 0 x 20) = 0. 375 N = # stories x shielding x climate factor Stories = 1 story: 1. 0, 1. 5 story: 0. 89, 2 story: 0. 81 Shielding = well shield: 1. 2, normal: 1. 0, exposed: 0. 9 Climate factor for Phoenix = 20

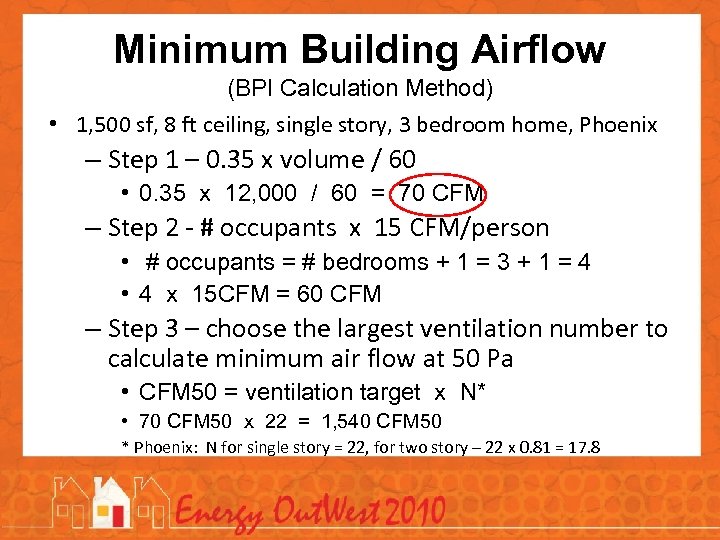

Minimum Building Airflow (BPI Calculation Method) • 1, 500 sf, 8 ft ceiling, single story, 3 bedroom home, Phoenix – Step 1 – 0. 35 x volume / 60 • 0. 35 x 12, 000 / 60 = 70 CFM – Step 2 - # occupants x 15 CFM/person • # occupants = # bedrooms + 1 = 3 + 1 = 4 • 4 x 15 CFM = 60 CFM – Step 3 – choose the largest ventilation number to calculate minimum air flow at 50 Pa • CFM 50 = ventilation target x N* • 70 CFM 50 x 22 = 1, 540 CFM 50 * Phoenix: N for single story = 22, for two story – 22 x 0. 81 = 17. 8

Minimum Building Airflow (BPI Calculation Method) • 1, 500 sf, 8 ft ceiling, single story, 3 bedroom home, Phoenix – Step 1 – 0. 35 x volume / 60 • 0. 35 x 12, 000 / 60 = 70 CFM – Step 2 - # occupants x 15 CFM/person • # occupants = # bedrooms + 1 = 3 + 1 = 4 • 4 x 15 CFM = 60 CFM – Step 3 – choose the largest ventilation number to calculate minimum air flow at 50 Pa • CFM 50 = ventilation target x N* • 70 CFM 50 x 22 = 1, 540 CFM 50 * Phoenix: N for single story = 22, for two story – 22 x 0. 81 = 17. 8

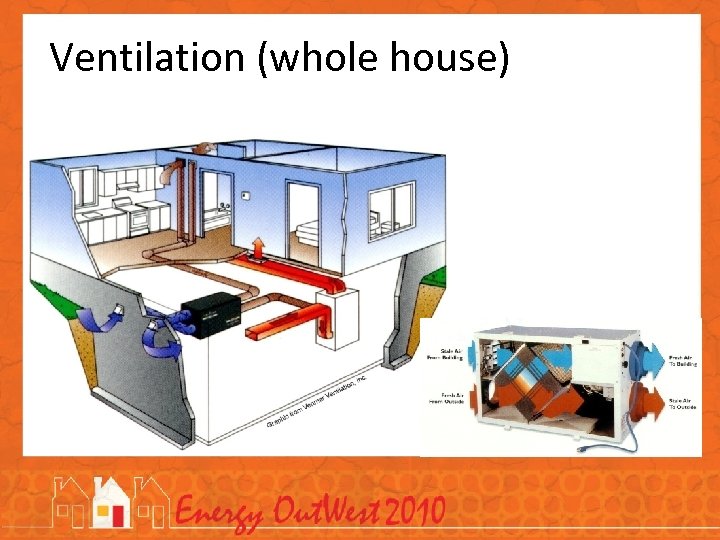

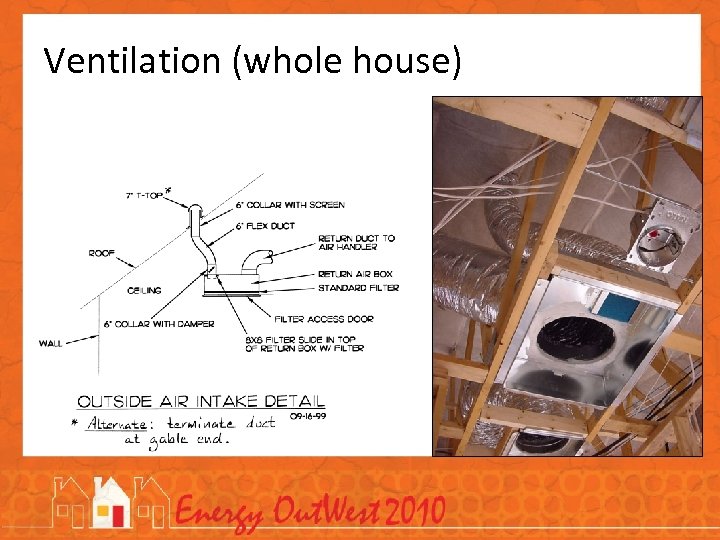

Ventilation (whole house)

Ventilation (whole house)

Ventilation (whole house)

Ventilation (whole house)

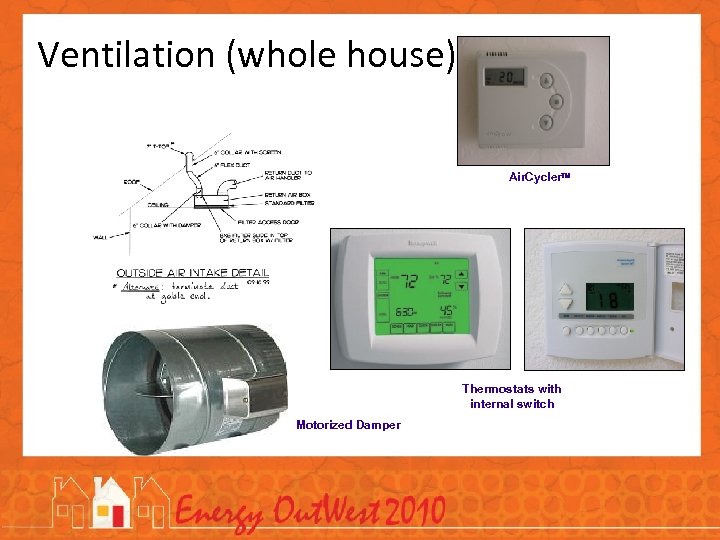

Ventilation (whole house) Air. Cycler Thermostats with internal switch Motorized Damper

Ventilation (whole house) Air. Cycler Thermostats with internal switch Motorized Damper

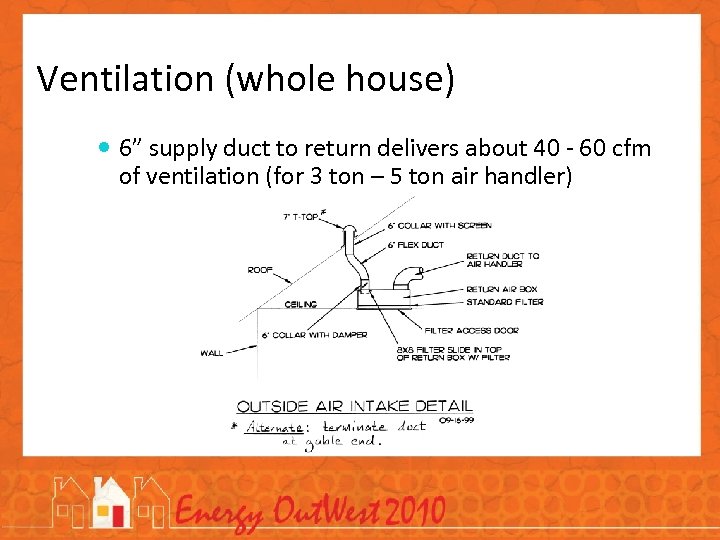

Ventilation (whole house) 6” supply duct to return delivers about 40 - 60 cfm of ventilation (for 3 ton – 5 ton air handler)

Ventilation (whole house) 6” supply duct to return delivers about 40 - 60 cfm of ventilation (for 3 ton – 5 ton air handler)

Health and Safety • Health and safety should be #1 consideration when testing and repairing homes! • Never do anything to save energy that has a negative impact on health and safety. • All (existing and potential) health and safety issues should be remedied prior to, or in conjunction with, doing work. Each individual organization needs to establish its definition of remedied.

Health and Safety • Health and safety should be #1 consideration when testing and repairing homes! • Never do anything to save energy that has a negative impact on health and safety. • All (existing and potential) health and safety issues should be remedied prior to, or in conjunction with, doing work. Each individual organization needs to establish its definition of remedied.

REQUIRE IT!

REQUIRE IT!