5a5c08bca88727f60bb2fd751d6fc5c4.ppt

- Количество слайдов: 12

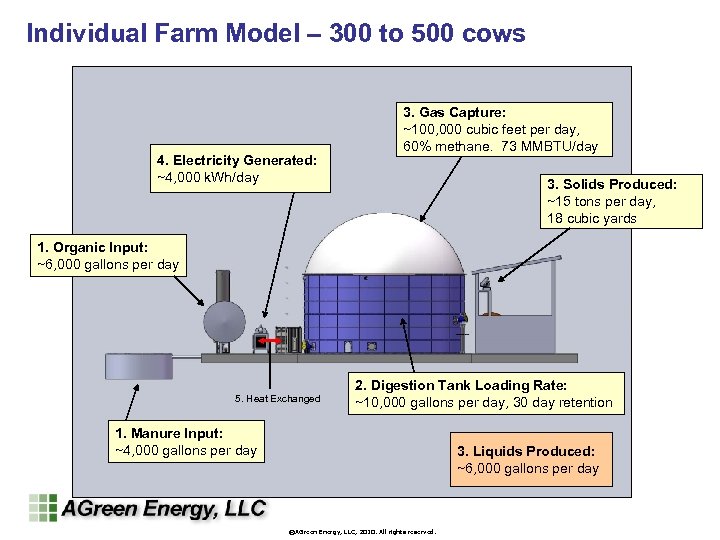

Individual Farm Model – 300 to 500 cows 4. Electricity Generated: ~4, 000 k. Wh/day 3. Gas Capture: ~100, 000 cubic feet per day, 60% methane. 73 MMBTU/day 3. Solids Produced: ~15 tons per day, 18 cubic yards 1. Organic Input: ~6, 000 gallons per day 5. Heat Exchanged 2. Digestion Tank Loading Rate: ~10, 000 gallons per day, 30 day retention 1. Manure Input: ~4, 000 gallons per day 3. Liquids Produced: ~6, 000 gallons per day ©AGreen Energy, LLC, 2010. All rights reserved.

Individual Farm Model – 300 to 500 cows 4. Electricity Generated: ~4, 000 k. Wh/day 3. Gas Capture: ~100, 000 cubic feet per day, 60% methane. 73 MMBTU/day 3. Solids Produced: ~15 tons per day, 18 cubic yards 1. Organic Input: ~6, 000 gallons per day 5. Heat Exchanged 2. Digestion Tank Loading Rate: ~10, 000 gallons per day, 30 day retention 1. Manure Input: ~4, 000 gallons per day 3. Liquids Produced: ~6, 000 gallons per day ©AGreen Energy, LLC, 2010. All rights reserved.

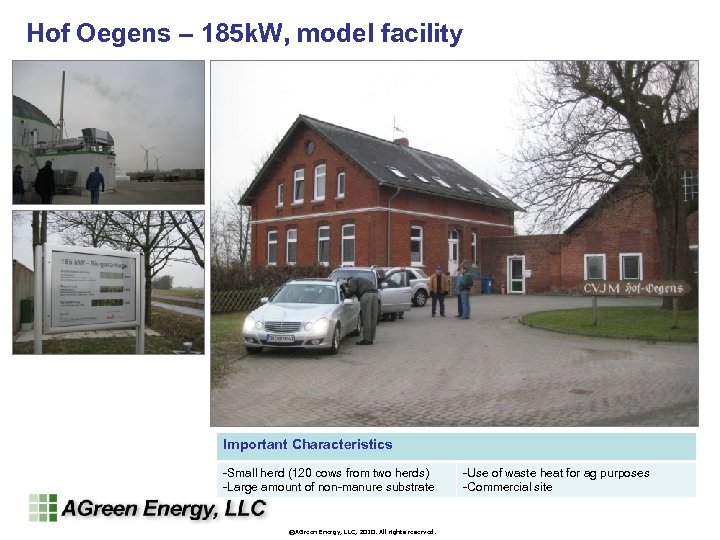

Hof Oegens – 185 k. W, model facility Important Characteristics -Small herd (120 cows from two herds) -Large amount of non-manure substrate ©AGreen Energy, LLC, 2010. All rights reserved. -Use of waste heat for ag purposes -Commercial site

Hof Oegens – 185 k. W, model facility Important Characteristics -Small herd (120 cows from two herds) -Large amount of non-manure substrate ©AGreen Energy, LLC, 2010. All rights reserved. -Use of waste heat for ag purposes -Commercial site

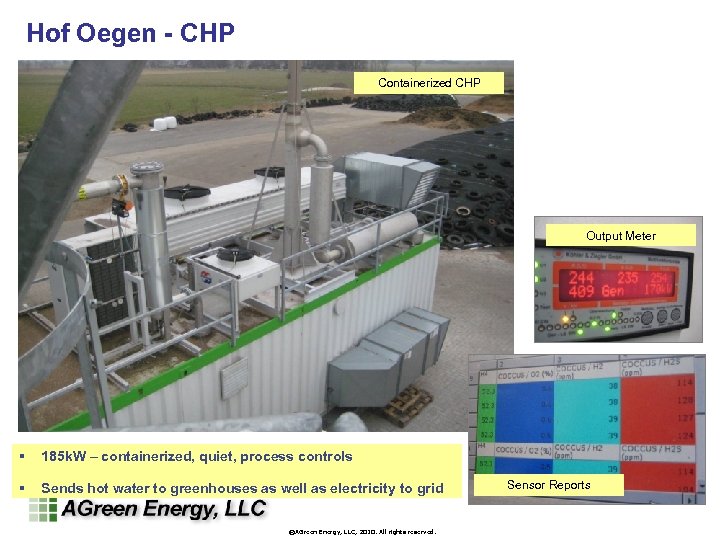

Hof Oegen - CHP Containerized CHP Output Meter § 185 k. W – containerized, quiet, process controls § Sends hot water to greenhouses as well as electricity to grid ©AGreen Energy, LLC, 2010. All rights reserved. Sensor Reports

Hof Oegen - CHP Containerized CHP Output Meter § 185 k. W – containerized, quiet, process controls § Sends hot water to greenhouses as well as electricity to grid ©AGreen Energy, LLC, 2010. All rights reserved. Sensor Reports

Hof Oegen – Waste Heat Utilization Heat Exchanger Soil Sterilizer § 1, 000 m 3 currently, heat production can support up to 4, 000 m 3 Digester Waste Heat Use House/Barns Greenhouses 25% 35% 40% (10% now) ©AGreen Energy, LLC, 2010. All rights reserved. §Looking to upgrade to a more efficient heat exchanger

Hof Oegen – Waste Heat Utilization Heat Exchanger Soil Sterilizer § 1, 000 m 3 currently, heat production can support up to 4, 000 m 3 Digester Waste Heat Use House/Barns Greenhouses 25% 35% 40% (10% now) ©AGreen Energy, LLC, 2010. All rights reserved. §Looking to upgrade to a more efficient heat exchanger

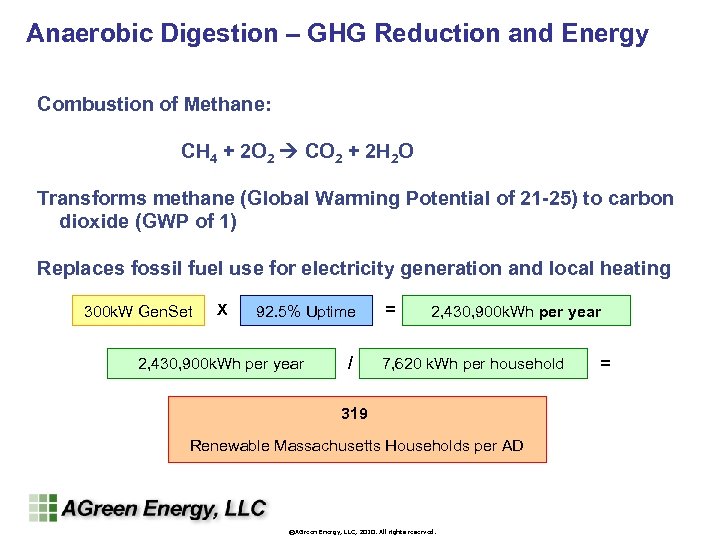

Anaerobic Digestion – GHG Reduction and Energy Combustion of Methane: CH 4 + 2 O 2 CO 2 + 2 H 2 O Transforms methane (Global Warming Potential of 21 -25) to carbon dioxide (GWP of 1) Replaces fossil fuel use for electricity generation and local heating 300 k. W Gen. Set X 92. 5% Uptime 2, 430, 900 k. Wh per year / = 2, 430, 900 k. Wh per year 7, 620 k. Wh per household 319 Renewable Massachusetts Households per AD ©AGreen Energy, LLC, 2010. All rights reserved. =

Anaerobic Digestion – GHG Reduction and Energy Combustion of Methane: CH 4 + 2 O 2 CO 2 + 2 H 2 O Transforms methane (Global Warming Potential of 21 -25) to carbon dioxide (GWP of 1) Replaces fossil fuel use for electricity generation and local heating 300 k. W Gen. Set X 92. 5% Uptime 2, 430, 900 k. Wh per year / = 2, 430, 900 k. Wh per year 7, 620 k. Wh per household 319 Renewable Massachusetts Households per AD ©AGreen Energy, LLC, 2010. All rights reserved. =

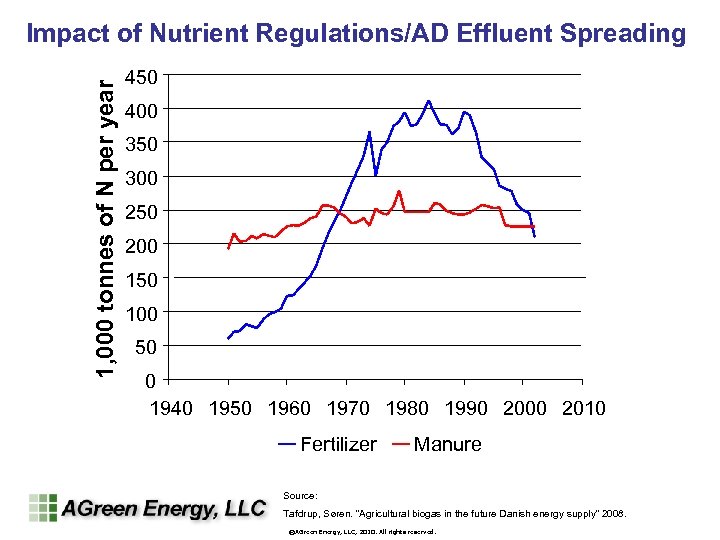

1, 000 tonnes of N per year Impact of Nutrient Regulations/AD Effluent Spreading 450 400 350 300 250 200 150 100 50 0 1940 1950 1960 1970 1980 1990 2000 2010 Fertilizer Manure Source: Tafdrup, Søren. ”Agricultural biogas in the future Danish energy supply” 2008. ©AGreen Energy, LLC, 2010. All rights reserved.

1, 000 tonnes of N per year Impact of Nutrient Regulations/AD Effluent Spreading 450 400 350 300 250 200 150 100 50 0 1940 1950 1960 1970 1980 1990 2000 2010 Fertilizer Manure Source: Tafdrup, Søren. ”Agricultural biogas in the future Danish energy supply” 2008. ©AGreen Energy, LLC, 2010. All rights reserved.

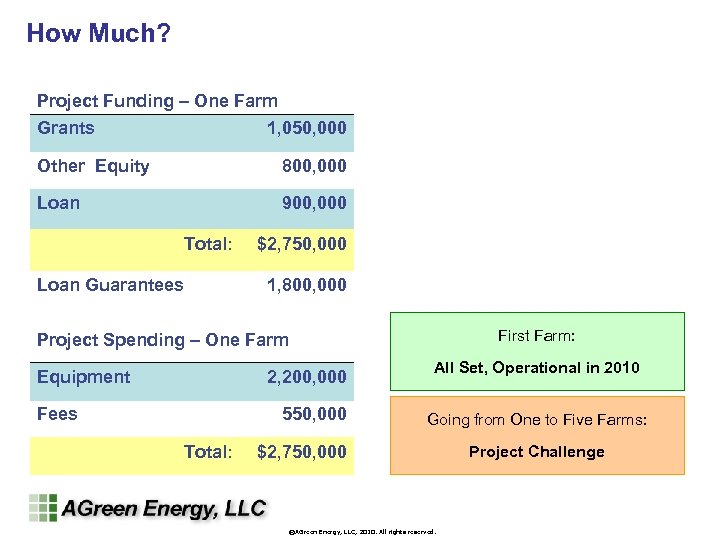

How Much? Project Funding – One Farm Grants 1, 050, 000 Other Equity 800, 000 Loan 900, 000 Total: Loan Guarantees $2, 750, 000 1, 800, 000 First Farm: Project Spending – One Farm Equipment 2, 200, 000 Fees 550, 000 Total: All Set, Operational in 2010 Going from One to Five Farms: $2, 750, 000 ©AGreen Energy, LLC, 2010. All rights reserved. Project Challenge

How Much? Project Funding – One Farm Grants 1, 050, 000 Other Equity 800, 000 Loan 900, 000 Total: Loan Guarantees $2, 750, 000 1, 800, 000 First Farm: Project Spending – One Farm Equipment 2, 200, 000 Fees 550, 000 Total: All Set, Operational in 2010 Going from One to Five Farms: $2, 750, 000 ©AGreen Energy, LLC, 2010. All rights reserved. Project Challenge

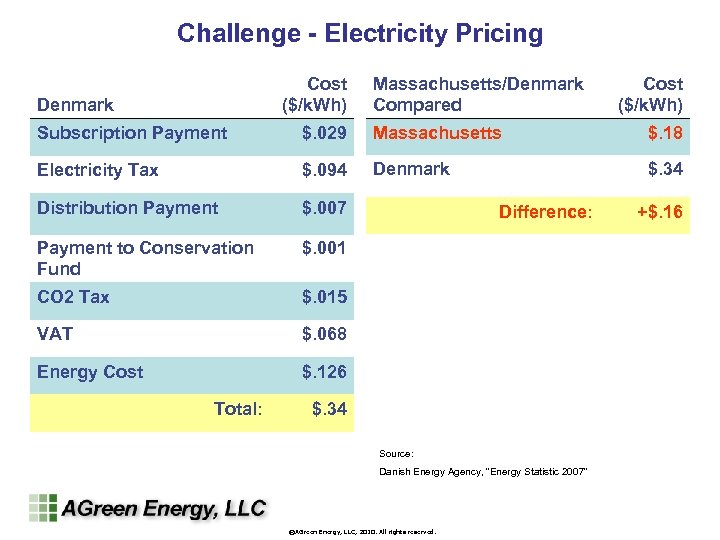

Challenge - Electricity Pricing Cost ($/k. Wh) Denmark Massachusetts/Denmark Compared Cost ($/k. Wh) Subscription Payment $. 029 Massachusetts $. 18 Electricity Tax $. 094 Denmark $. 34 Distribution Payment $. 007 Payment to Conservation Fund $. 001 CO 2 Tax $. 015 VAT $. 068 Energy Cost $. 126 Total: Difference: $. 34 Source: Danish Energy Agency, “Energy Statistic 2007” ©AGreen Energy, LLC, 2010. All rights reserved. +$. 16

Challenge - Electricity Pricing Cost ($/k. Wh) Denmark Massachusetts/Denmark Compared Cost ($/k. Wh) Subscription Payment $. 029 Massachusetts $. 18 Electricity Tax $. 094 Denmark $. 34 Distribution Payment $. 007 Payment to Conservation Fund $. 001 CO 2 Tax $. 015 VAT $. 068 Energy Cost $. 126 Total: Difference: $. 34 Source: Danish Energy Agency, “Energy Statistic 2007” ©AGreen Energy, LLC, 2010. All rights reserved. +$. 16

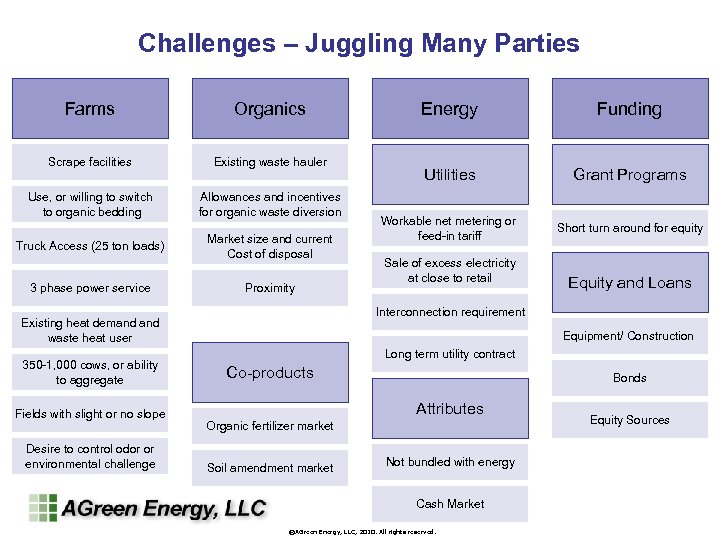

Challenges – Juggling Many Parties Farms Organics Scrape facilities Existing waste hauler Use, or willing to switch to organic bedding Allowances and incentives for organic waste diversion Truck Access (25 ton loads) Market size and current Cost of disposal 3 phase power service Proximity Fields with slight or no slope Desire to control odor or environmental challenge Funding Utilities Grant Programs Workable net metering or feed-in tariff Short turn around for equity Sale of excess electricity at close to retail Equity and Loans Interconnection requirement Existing heat demand waste heat user 350 -1, 000 cows, or ability to aggregate Energy Equipment/ Construction Long term utility contract Co-products Bonds Attributes Organic fertilizer market Soil amendment market Not bundled with energy Cash Market ©AGreen Energy, LLC, 2010. All rights reserved. Equity Sources

Challenges – Juggling Many Parties Farms Organics Scrape facilities Existing waste hauler Use, or willing to switch to organic bedding Allowances and incentives for organic waste diversion Truck Access (25 ton loads) Market size and current Cost of disposal 3 phase power service Proximity Fields with slight or no slope Desire to control odor or environmental challenge Funding Utilities Grant Programs Workable net metering or feed-in tariff Short turn around for equity Sale of excess electricity at close to retail Equity and Loans Interconnection requirement Existing heat demand waste heat user 350 -1, 000 cows, or ability to aggregate Energy Equipment/ Construction Long term utility contract Co-products Bonds Attributes Organic fertilizer market Soil amendment market Not bundled with energy Cash Market ©AGreen Energy, LLC, 2010. All rights reserved. Equity Sources

©AGreen Energy, LLC, 2010. All rights reserved.

©AGreen Energy, LLC, 2010. All rights reserved.

©AGreen Energy, LLC, 2010. All rights reserved.

©AGreen Energy, LLC, 2010. All rights reserved.