5592fadb6878b883bc787d49f538332f.ppt

- Количество слайдов: 44

INDEECO ELECTRIC HEATERS FOR INDUSTRIAL APPLICATIONS

INDEECO ELECTRIC HEATERS FOR INDUSTRIAL APPLICATIONS

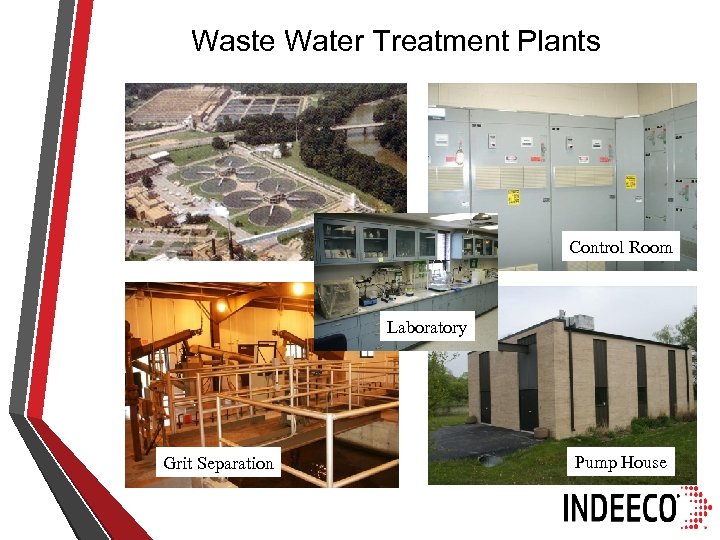

Waste Water Treatment Plants Pump Control Room Laboratory Grit Separation Pump House

Waste Water Treatment Plants Pump Control Room Laboratory Grit Separation Pump House

OIL AND GAS

OIL AND GAS

Chemical Storage

Chemical Storage

Air Make-up

Air Make-up

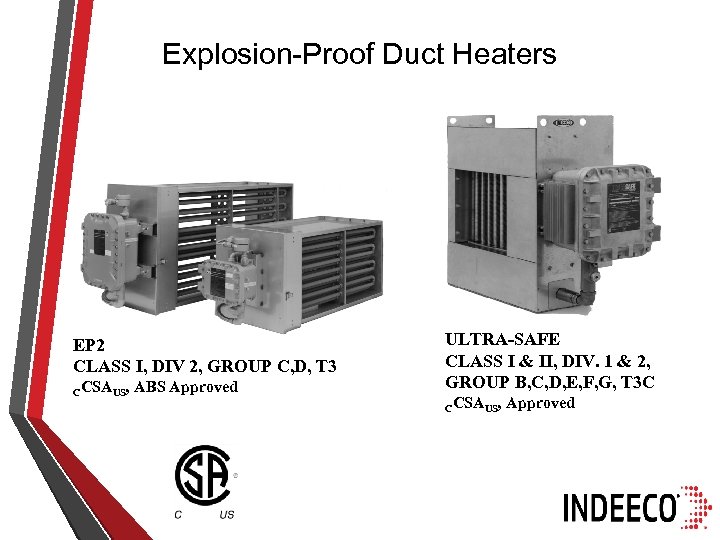

Explosion-Proof Duct Heaters EP 2 CLASS I, DIV 2, GROUP C, D, T 3 CCSAUS, ABS Approved ULTRA-SAFE CLASS I & II, DIV. 1 & 2, GROUP B, C, D, E, F, G, T 3 C CCSAUS, Approved

Explosion-Proof Duct Heaters EP 2 CLASS I, DIV 2, GROUP C, D, T 3 CCSAUS, ABS Approved ULTRA-SAFE CLASS I & II, DIV. 1 & 2, GROUP B, C, D, E, F, G, T 3 C CCSAUS, Approved

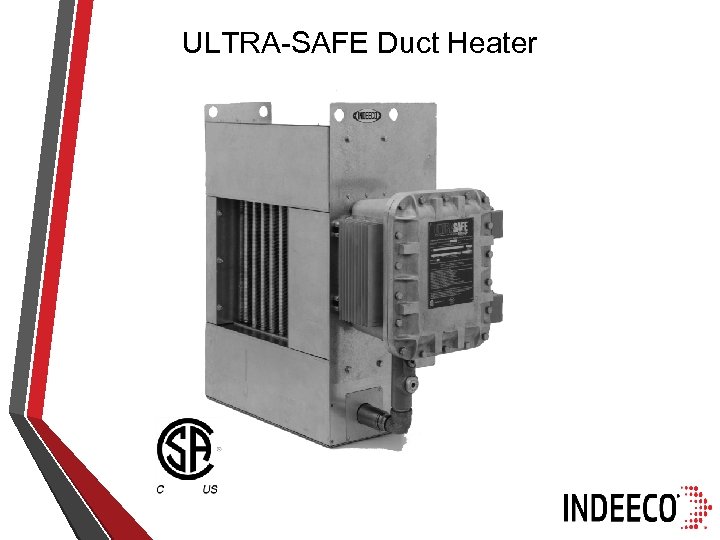

ULTRA-SAFE Duct Heater

ULTRA-SAFE Duct Heater

Ultra-Safe Duct Heaters • CSA Approved, Division 1 and 2 Locations • T 3 C Code, Gas and Dusty Locations • Up To 240 k. W, Single and SCR Staging • Horizontal Airflow • Heat Exchanger Design • Corrosion Resistant Construction Available

Ultra-Safe Duct Heaters • CSA Approved, Division 1 and 2 Locations • T 3 C Code, Gas and Dusty Locations • Up To 240 k. W, Single and SCR Staging • Horizontal Airflow • Heat Exchanger Design • Corrosion Resistant Construction Available

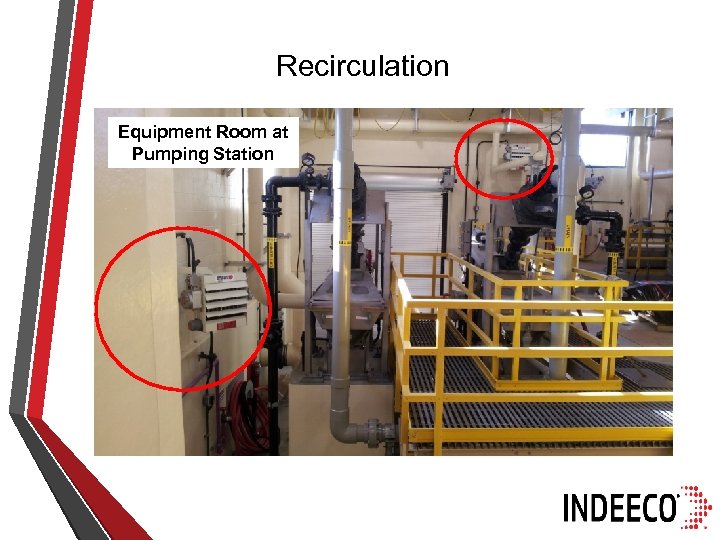

Recirculation Equipment Room at Pumping Station

Recirculation Equipment Room at Pumping Station

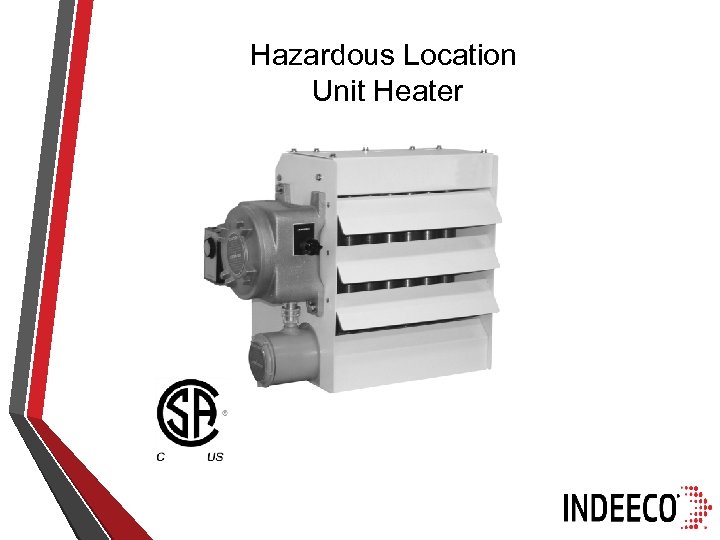

Hazardous Location Unit Heater

Hazardous Location Unit Heater

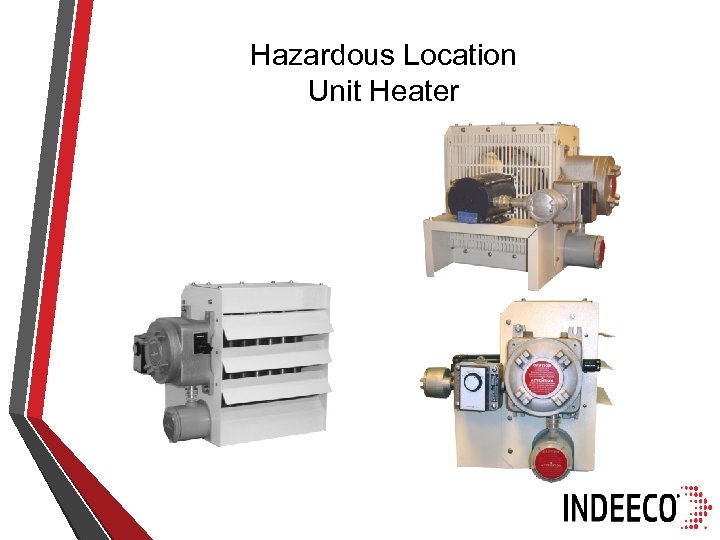

Hazardous Location Unit Heater

Hazardous Location Unit Heater

Classifications Ratings CLASS I, DIVISIONS 1 & 2, GROUPS C & D CLASS II, DIVISIONS 1 & 2, GROUPS E, F &G TEMPERATURE CODE T 3 C, 320ºF (160ºC)

Classifications Ratings CLASS I, DIVISIONS 1 & 2, GROUPS C & D CLASS II, DIVISIONS 1 & 2, GROUPS E, F &G TEMPERATURE CODE T 3 C, 320ºF (160ºC)

Standard Safety Features • T 3 C 320ºF (160ºC) Temperature Code • Dual Over-temperature Protection, Automatic and Manual Reset • Nontoxic Propylene Glycol Heat Transfer Fluid • Low 70 PSIG Pressure Relief Valve Settings • CSA Approval

Standard Safety Features • T 3 C 320ºF (160ºC) Temperature Code • Dual Over-temperature Protection, Automatic and Manual Reset • Nontoxic Propylene Glycol Heat Transfer Fluid • Low 70 PSIG Pressure Relief Valve Settings • CSA Approval

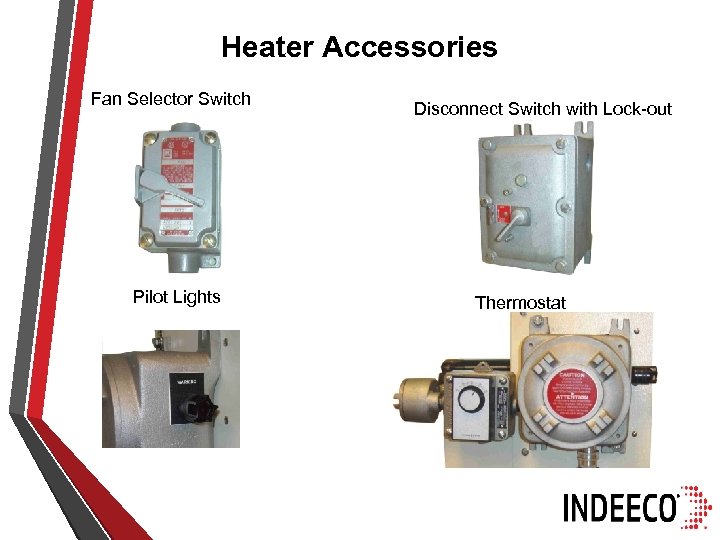

Heater Accessories Fan Selector Switch Pilot Lights Disconnect Switch with Lock-out Thermostat

Heater Accessories Fan Selector Switch Pilot Lights Disconnect Switch with Lock-out Thermostat

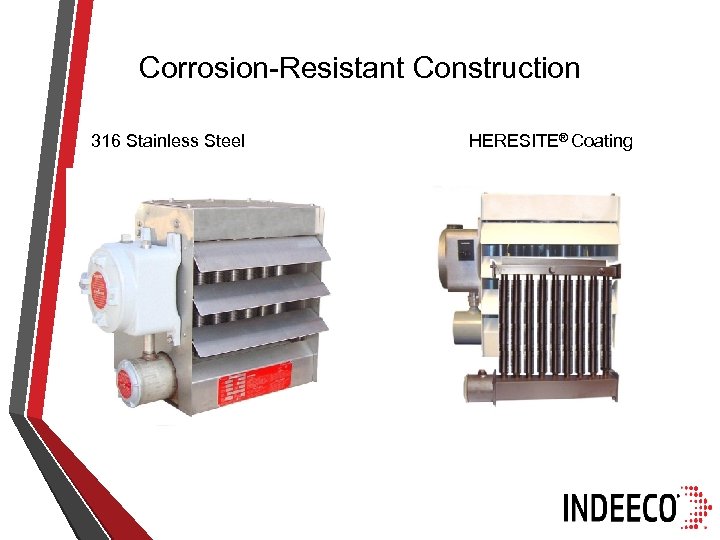

Corrosion-Resistant Construction 316 Stainless Steel HERESITE® Coating

Corrosion-Resistant Construction 316 Stainless Steel HERESITE® Coating

316 Stainless Steel Corrosion-Resistant Construction • Recommended for Waste Water Treatment Plants • Recommended for Hydrogen Sulfide (H 2 S)GAS Environments • Extended Life Expectancy in Corrosive Areas over Carbon Steel

316 Stainless Steel Corrosion-Resistant Construction • Recommended for Waste Water Treatment Plants • Recommended for Hydrogen Sulfide (H 2 S)GAS Environments • Extended Life Expectancy in Corrosive Areas over Carbon Steel

HERESITE® Coating Corrosion-Resistant Construction • Recommended for use in Chemical Plants • HERESITE baked phenolic coatings will withstand exposure to practically all corrosive atmospheres with the exception of strong alkalies such as potassium and sodium hydroxide, strong oxidizers such as aqua regia and wet bromine, chlorine and fluorine in concentrations greater than 100 ppm.

HERESITE® Coating Corrosion-Resistant Construction • Recommended for use in Chemical Plants • HERESITE baked phenolic coatings will withstand exposure to practically all corrosive atmospheres with the exception of strong alkalies such as potassium and sodium hydroxide, strong oxidizers such as aqua regia and wet bromine, chlorine and fluorine in concentrations greater than 100 ppm.

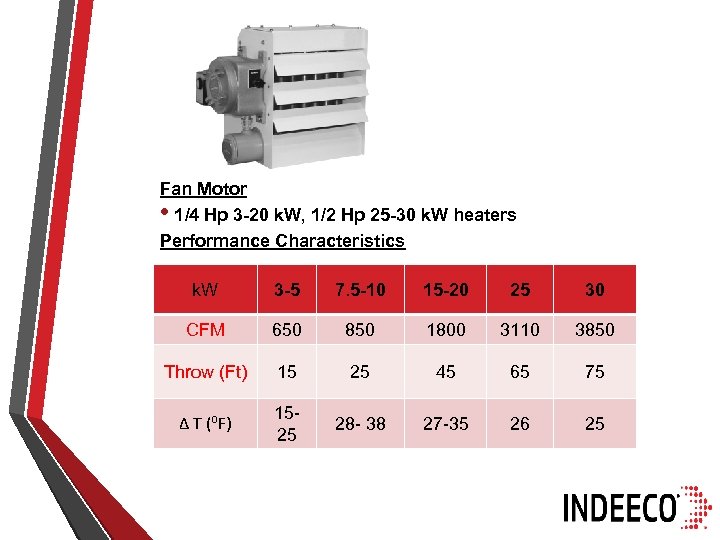

Fan Motor • 1/4 Hp 3 -20 k. W, 1/2 Hp 25 -30 k. W heaters Performance Characteristics k. W 3 -5 7. 5 -10 15 -20 25 30 CFM 650 850 1800 3110 3850 Throw (Ft) 15 25 45 65 75 ∆ T (⁰F) 1525 28 - 38 27 -35 26 25

Fan Motor • 1/4 Hp 3 -20 k. W, 1/2 Hp 25 -30 k. W heaters Performance Characteristics k. W 3 -5 7. 5 -10 15 -20 25 30 CFM 650 850 1800 3110 3850 Throw (Ft) 15 25 45 65 75 ∆ T (⁰F) 1525 28 - 38 27 -35 26 25

Water Treatment Plants

Water Treatment Plants

Food Processing

Food Processing

Car Wash

Car Wash

Coal Processing Plants and Mines Coal Processing Facility Potash Mining Coal Crusher Large Drilling Carriage

Coal Processing Plants and Mines Coal Processing Facility Potash Mining Coal Crusher Large Drilling Carriage

Hose Down Unit Heater

Hose Down Unit Heater

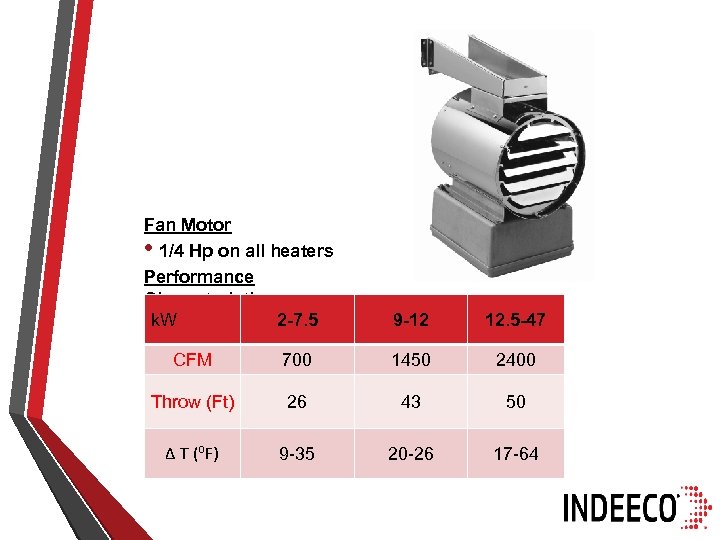

Fan Motor • 1/4 Hp on all heaters Performance Characteristics k. W 2 -7. 5 9 -12 12. 5 -47 CFM 700 1450 2400 Throw (Ft) 26 43 50 ∆ T (⁰F) 9 -35 20 -26 17 -64

Fan Motor • 1/4 Hp on all heaters Performance Characteristics k. W 2 -7. 5 9 -12 12. 5 -47 CFM 700 1450 2400 Throw (Ft) 26 43 50 ∆ T (⁰F) 9 -35 20 -26 17 -64

HAZARDOUS (CLASSIFIED) LOCATIONS

HAZARDOUS (CLASSIFIED) LOCATIONS

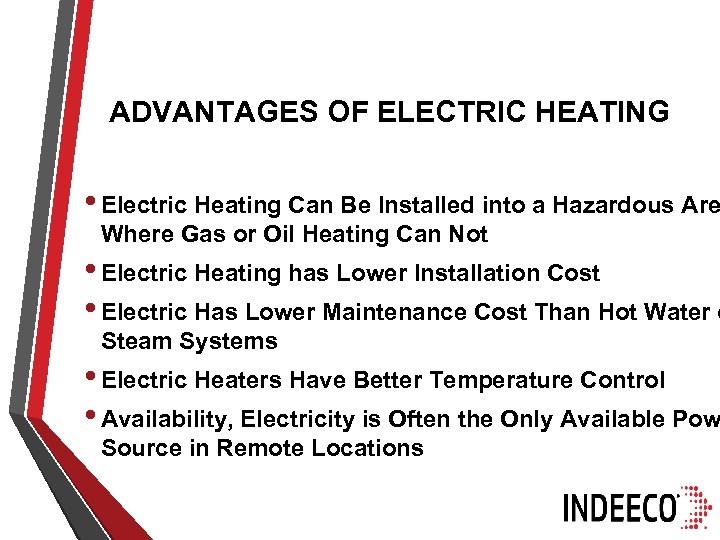

ADVANTAGES OF ELECTRIC HEATING • Electric Heating Can Be Installed into a Hazardous Are Where Gas or Oil Heating Can Not • Electric Heating has Lower Installation Cost • Electric Has Lower Maintenance Cost Than Hot Water o Steam Systems • Electric Heaters Have Better Temperature Control • Availability, Electricity is Often the Only Available Pow Source in Remote Locations

ADVANTAGES OF ELECTRIC HEATING • Electric Heating Can Be Installed into a Hazardous Are Where Gas or Oil Heating Can Not • Electric Heating has Lower Installation Cost • Electric Has Lower Maintenance Cost Than Hot Water o Steam Systems • Electric Heaters Have Better Temperature Control • Availability, Electricity is Often the Only Available Pow Source in Remote Locations

APPLICATIONS FOR HAZARDOUS LOCATIONS CLASS 1 Oil And Gas Drilling Rigs, Petroleum Or Pumping Facilities, Petrochemical Plants, Wastewater Treatment Plants, Solvent Extraction Plants.

APPLICATIONS FOR HAZARDOUS LOCATIONS CLASS 1 Oil And Gas Drilling Rigs, Petroleum Or Pumping Facilities, Petrochemical Plants, Wastewater Treatment Plants, Solvent Extraction Plants.

APPLICATIONS FOR HAZARDOUS LOCATIONS CLASS 2 Coal Fired Power Plants, Coal Preparation/Coal Handling Facilities, Coal Mines, Grain Elevators, Flour And Feed Mills FLAMMABLE DUST

APPLICATIONS FOR HAZARDOUS LOCATIONS CLASS 2 Coal Fired Power Plants, Coal Preparation/Coal Handling Facilities, Coal Mines, Grain Elevators, Flour And Feed Mills FLAMMABLE DUST

APPLICATIONS FOR HAZARDOUS LOCATIONS CLASS 3 Textile Mills, Woodworking Plants, Cotton Gins And Cotton Seed Mills, Flax Producing Plants CAUTION FLAMMABLE FIBRES OR FLYINGS

APPLICATIONS FOR HAZARDOUS LOCATIONS CLASS 3 Textile Mills, Woodworking Plants, Cotton Gins And Cotton Seed Mills, Flax Producing Plants CAUTION FLAMMABLE FIBRES OR FLYINGS

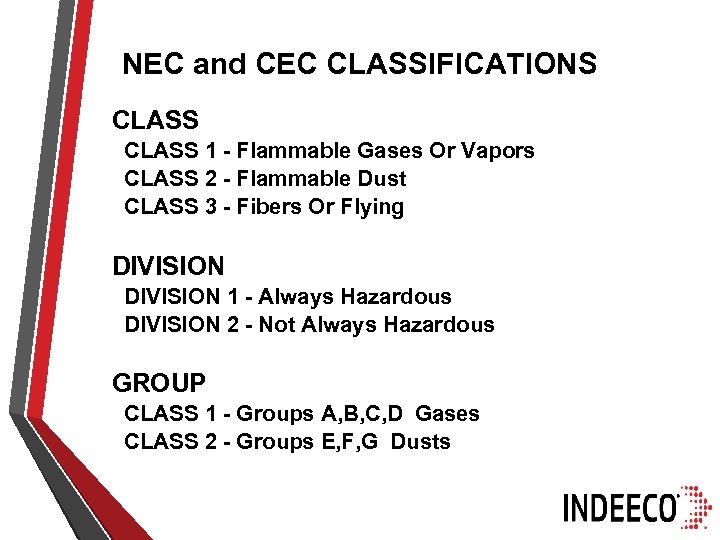

NEC and CEC CLASSIFICATIONS CLASS 1 - Flammable Gases Or Vapors CLASS 2 - Flammable Dust CLASS 3 - Fibers Or Flying DIVISION 1 - Always Hazardous DIVISION 2 - Not Always Hazardous GROUP CLASS 1 - Groups A, B, C, D Gases CLASS 2 - Groups E, F, G Dusts

NEC and CEC CLASSIFICATIONS CLASS 1 - Flammable Gases Or Vapors CLASS 2 - Flammable Dust CLASS 3 - Fibers Or Flying DIVISION 1 - Always Hazardous DIVISION 2 - Not Always Hazardous GROUP CLASS 1 - Groups A, B, C, D Gases CLASS 2 - Groups E, F, G Dusts

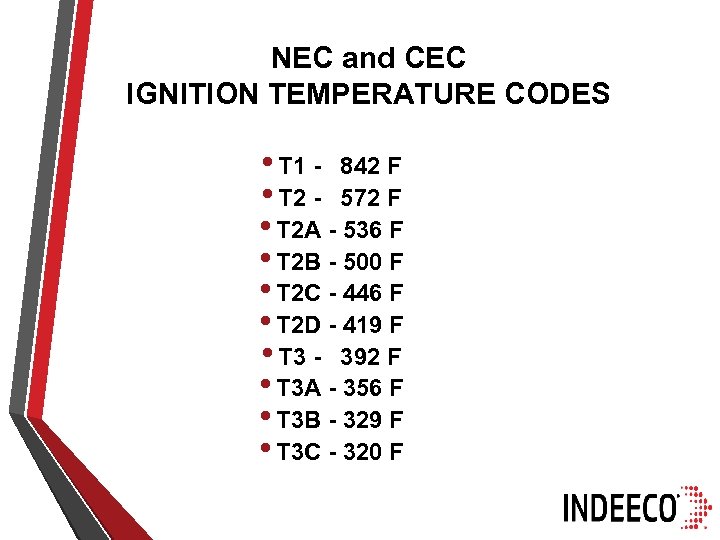

NEC and CEC IGNITION TEMPERATURE CODES • T 1 - 842 F • T 2 - 572 F • T 2 A - 536 F • T 2 B - 500 F • T 2 C - 446 F • T 2 D - 419 F • T 3 - 392 F • T 3 A - 356 F • T 3 B - 329 F • T 3 C - 320 F

NEC and CEC IGNITION TEMPERATURE CODES • T 1 - 842 F • T 2 - 572 F • T 2 A - 536 F • T 2 B - 500 F • T 2 C - 446 F • T 2 D - 419 F • T 3 - 392 F • T 3 A - 356 F • T 3 B - 329 F • T 3 C - 320 F

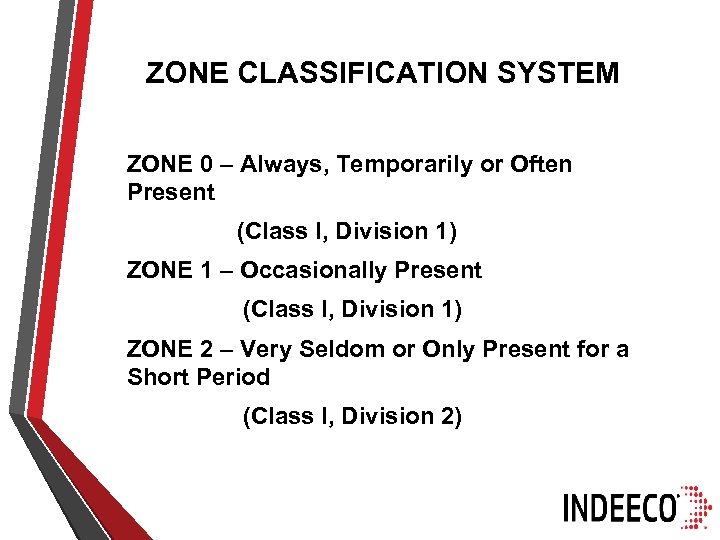

ZONE CLASSIFICATION SYSTEM ZONE 0 – Always, Temporarily or Often Present (Class I, Division 1) ZONE 1 – Occasionally Present (Class I, Division 1) ZONE 2 – Very Seldom or Only Present for a Short Period (Class I, Division 2)

ZONE CLASSIFICATION SYSTEM ZONE 0 – Always, Temporarily or Often Present (Class I, Division 1) ZONE 1 – Occasionally Present (Class I, Division 1) ZONE 2 – Very Seldom or Only Present for a Short Period (Class I, Division 2)

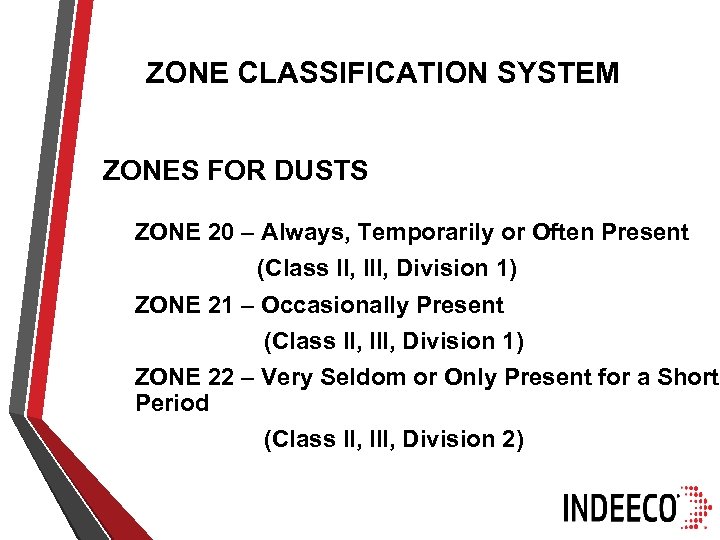

ZONE CLASSIFICATION SYSTEM ZONES FOR DUSTS ZONE 20 – Always, Temporarily or Often Present (Class II, III, Division 1) ZONE 21 – Occasionally Present (Class II, III, Division 1) ZONE 22 – Very Seldom or Only Present for a Short Period (Class II, III, Division 2)

ZONE CLASSIFICATION SYSTEM ZONES FOR DUSTS ZONE 20 – Always, Temporarily or Often Present (Class II, III, Division 1) ZONE 21 – Occasionally Present (Class II, III, Division 1) ZONE 22 – Very Seldom or Only Present for a Short Period (Class II, III, Division 2)

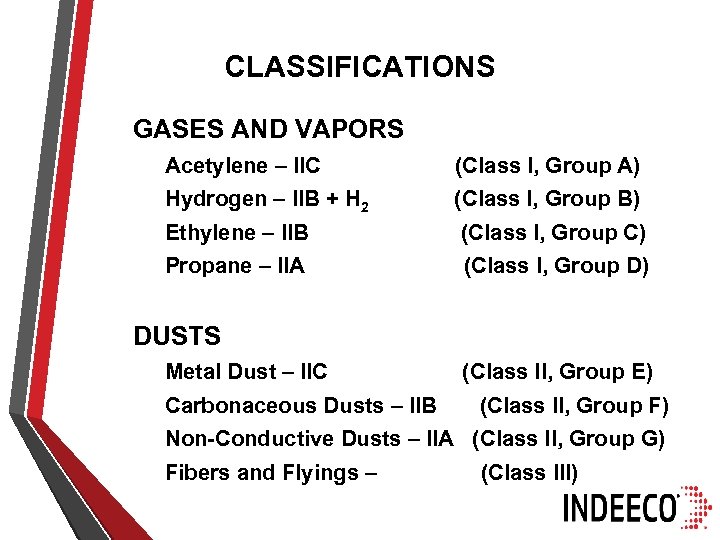

CLASSIFICATIONS GASES AND VAPORS Acetylene – IIC (Class I, Group A) Hydrogen – IIB + H 2 (Class I, Group B) Ethylene – IIB (Class I, Group C) Propane – IIA (Class I, Group D) DUSTS Metal Dust – IIC Carbonaceous Dusts – IIB (Class II, Group E) (Class II, Group F) Non-Conductive Dusts – IIA (Class II, Group G) Fibers and Flyings – (Class III)

CLASSIFICATIONS GASES AND VAPORS Acetylene – IIC (Class I, Group A) Hydrogen – IIB + H 2 (Class I, Group B) Ethylene – IIB (Class I, Group C) Propane – IIA (Class I, Group D) DUSTS Metal Dust – IIC Carbonaceous Dusts – IIB (Class II, Group E) (Class II, Group F) Non-Conductive Dusts – IIA (Class II, Group G) Fibers and Flyings – (Class III)

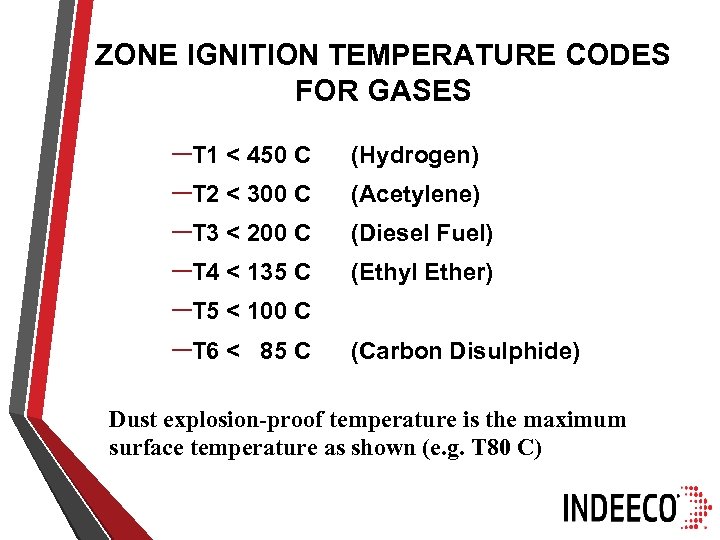

ZONE IGNITION TEMPERATURE CODES FOR GASES –T 1 < 450 C –T 2 < 300 C –T 3 < 200 C –T 4 < 135 C –T 5 < 100 C –T 6 < 85 C (Hydrogen) (Acetylene) (Diesel Fuel) (Ethyl Ether) (Carbon Disulphide) Dust explosion-proof temperature is the maximum surface temperature as shown (e. g. T 80 C)

ZONE IGNITION TEMPERATURE CODES FOR GASES –T 1 < 450 C –T 2 < 300 C –T 3 < 200 C –T 4 < 135 C –T 5 < 100 C –T 6 < 85 C (Hydrogen) (Acetylene) (Diesel Fuel) (Ethyl Ether) (Carbon Disulphide) Dust explosion-proof temperature is the maximum surface temperature as shown (e. g. T 80 C)

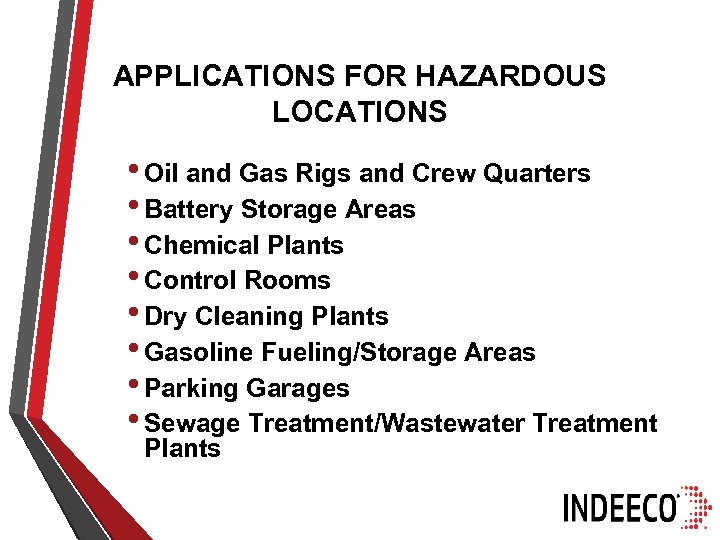

APPLICATIONS FOR HAZARDOUS LOCATIONS • Oil and Gas Rigs and Crew Quarters • Battery Storage Areas • Chemical Plants • Control Rooms • Dry Cleaning Plants • Gasoline Fueling/Storage Areas • Parking Garages • Sewage Treatment/Wastewater Treatment Plants

APPLICATIONS FOR HAZARDOUS LOCATIONS • Oil and Gas Rigs and Crew Quarters • Battery Storage Areas • Chemical Plants • Control Rooms • Dry Cleaning Plants • Gasoline Fueling/Storage Areas • Parking Garages • Sewage Treatment/Wastewater Treatment Plants

SCR PROPORTIONAL Vs ON-OFF CONTROL

SCR PROPORTIONAL Vs ON-OFF CONTROL

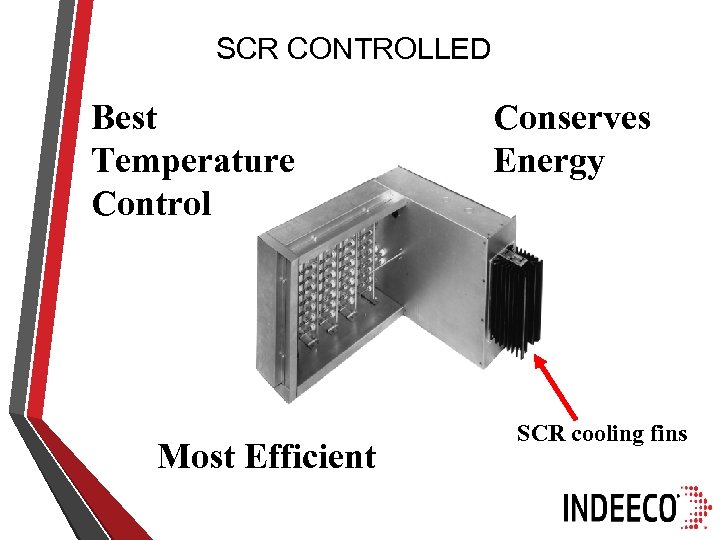

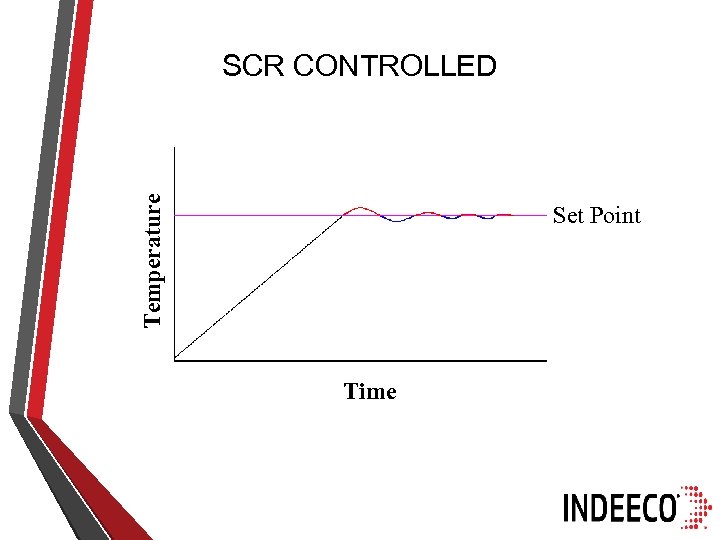

SCR CONTROLLED Best Temperature Control Most Efficient Conserves Energy SCR cooling fins

SCR CONTROLLED Best Temperature Control Most Efficient Conserves Energy SCR cooling fins

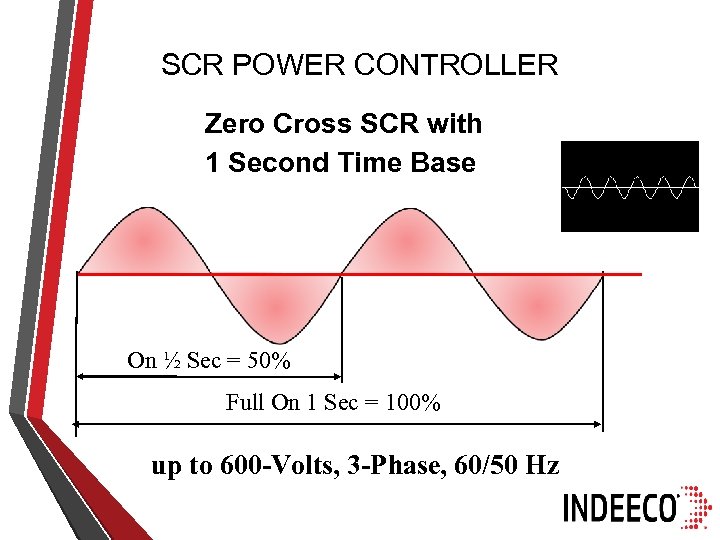

SCR POWER CONTROLLER Zero Cross SCR with 1 Second Time Base On ½ Sec = 50% Full On 1 Sec = 100% up to 600 -Volts, 3 -Phase, 60/50 Hz

SCR POWER CONTROLLER Zero Cross SCR with 1 Second Time Base On ½ Sec = 50% Full On 1 Sec = 100% up to 600 -Volts, 3 -Phase, 60/50 Hz

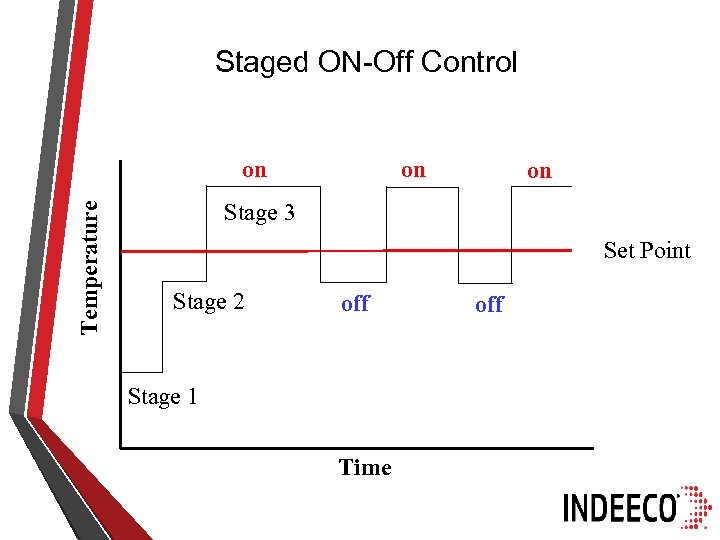

Staged ON-Off Control on Temperature on on Stage 3 Set Point Stage 2 off Stage 1 Time off

Staged ON-Off Control on Temperature on on Stage 3 Set Point Stage 2 off Stage 1 Time off

Temperature SCR CONTROLLED Set Point Time

Temperature SCR CONTROLLED Set Point Time

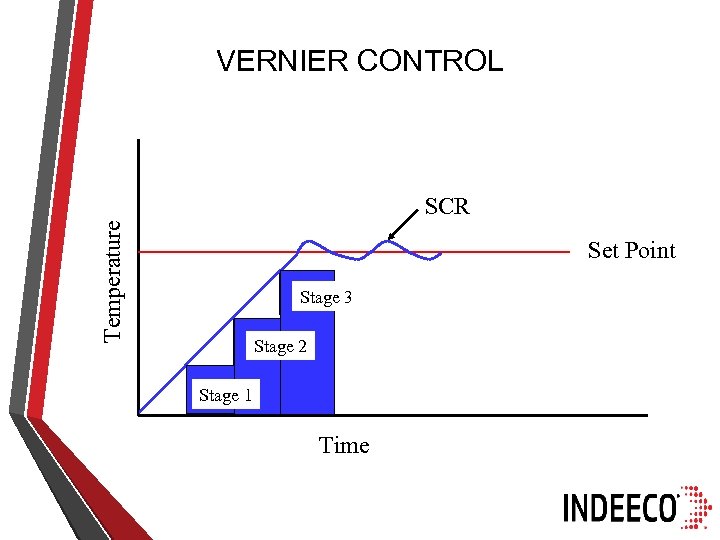

VERNIER CONTROL Temperature SCR Set Point Stage 3 Stage 2 Stage 1 Time

VERNIER CONTROL Temperature SCR Set Point Stage 3 Stage 2 Stage 1 Time

Thank You

Thank You