def3504b4ee820a7bf06efbcb1fe9fc7.ppt

- Количество слайдов: 27

INBOUND SUPPLY CHAIN SOLUTION Spread Logistics Service Package

Information of Spread Logistics Company Found: 2005 Jan. Capital: US$ 30, 000. 00 Worldwide Offices : Own offices- Hong Kong, Shenzhen, Taiwan, Shanghai With agents all over world Existing Customers: Foxconn, Intel, TPK, Epson, Apple, Boardtex, Compeq, Giat Int’l and others

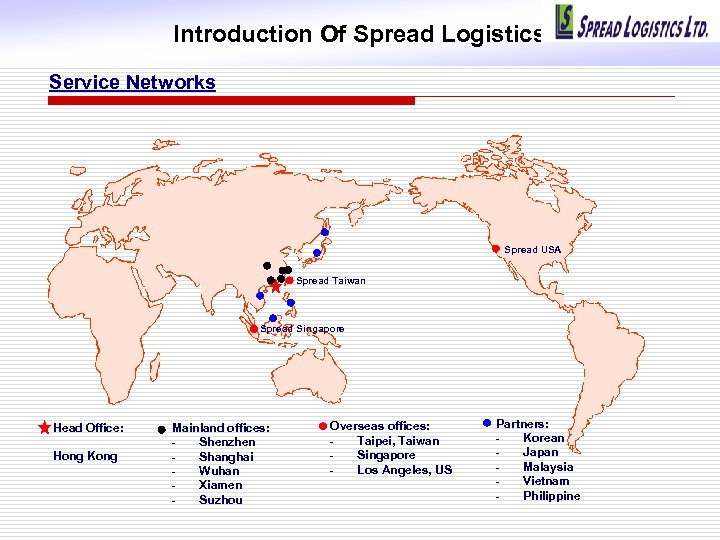

Introduction Of Spread Logistics Service Networks Spread USA Spread Taiwan Spread Singapore Head Office: Hong Kong Mainland offices: Shenzhen Shanghai Wuhan Xiamen Suzhou Overseas offices: Taipei, Taiwan Singapore Los Angeles, US Partners: Korean Japan Malaysia Vietnam Philippine

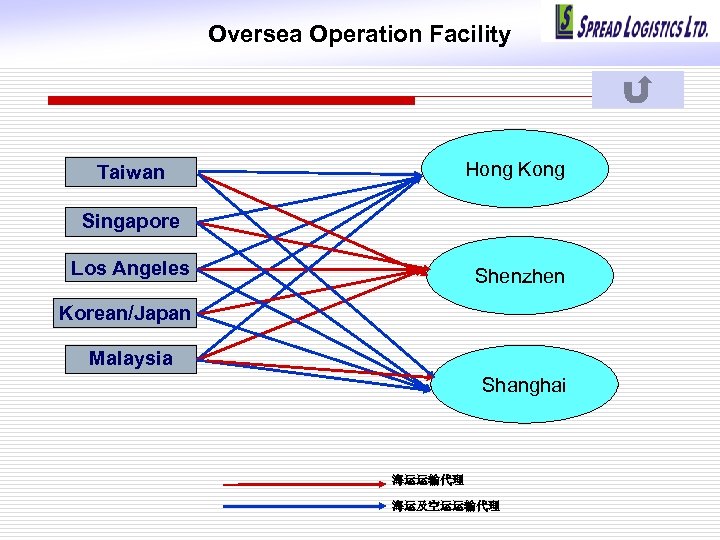

Oversea Operation Facility Hong Kong Taiwan Singapore Los Angeles Shenzhen Korean/Japan Malaysia Shanghai 海运运输代理 海运及空运运输代理

Spread Hong Kong • Warehouse Space: Approx 9, 800 sqmt • Warehouse Loading Bay: 18 Unit 4008 -4013 E, 4 th Fl. , ATL Logistics Centre, Centre B, Berth 3 , Kwai Chung Container Terminal , Kwai Chung , N. T. HK • Distance from HK airport: 50 minutes • Distance to Shenzhen border: 60 minutes

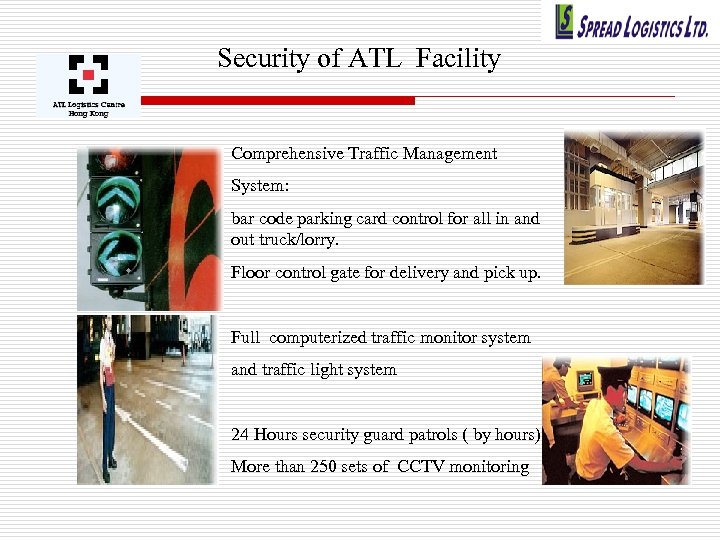

Security of ATL Facility Comprehensive Traffic Management System: bar code parking card control for all in and out truck/lorry. Floor control gate for delivery and pick up. Full computerized traffic monitor system and traffic light system 24 Hours security guard patrols ( by hours) More than 250 sets of CCTV monitoring

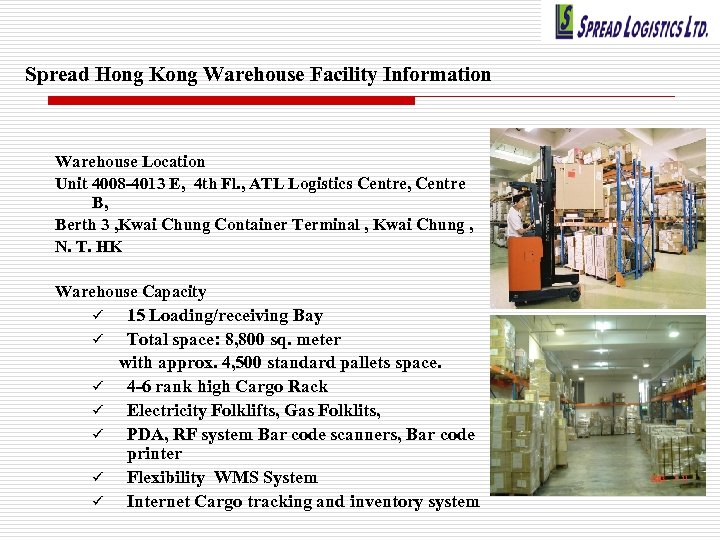

Spread Hong Kong Warehouse Facility Information Warehouse Location Unit 4008 -4013 E, 4 th Fl. , ATL Logistics Centre, Centre B, Berth 3 , Kwai Chung Container Terminal , Kwai Chung , N. T. HK Warehouse Capacity ü ü ü ü 15 Loading/receiving Bay Total space: 8, 800 sq. meter with approx. 4, 500 standard pallets space. 4 -6 rank high Cargo Rack Electricity Folklifts, Gas Folklits, PDA, RF system Bar code scanners, Bar code printer Flexibility WMS System Internet Cargo tracking and inventory system

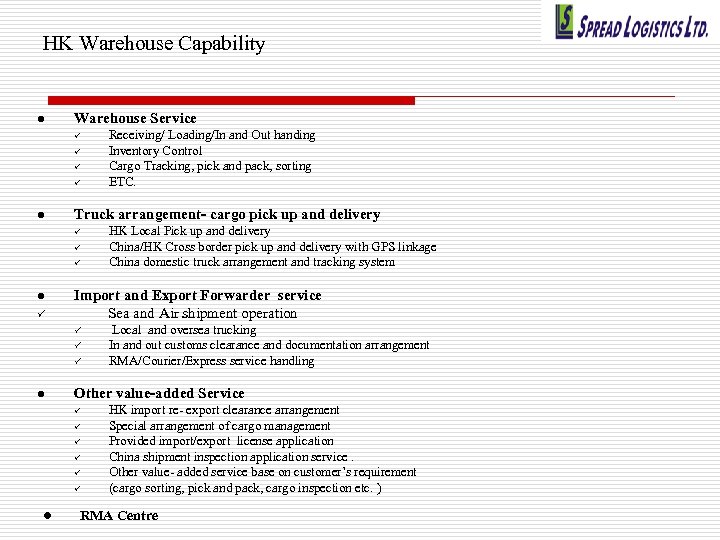

HK Warehouse Capability l Warehouse Service ü ü l Truck arrangement- cargo pick up and delivery ü ü ü l ü ü ü Local and oversea trucking In and out customs clearance and documentation arrangement RMA/Courier/Express service handling Other value-added Service ü ü ü l HK Local Pick up and delivery China/HK Cross border pick up and delivery with GPS linkage China domestic truck arrangement and tracking system Import and Export Forwarder service Sea and Air shipment operation ü l Receiving/ Loading/In and Out handing Inventory Control Cargo Tracking, pick and pack, sorting ETC. HK import re- export clearance arrangement Special arrangement of cargo management Provided import/export license application China shipment inspection application service. Other value- added service base on customer’s requirement (cargo sorting, pick and pack, cargo inspection etc. ) RMA Centre

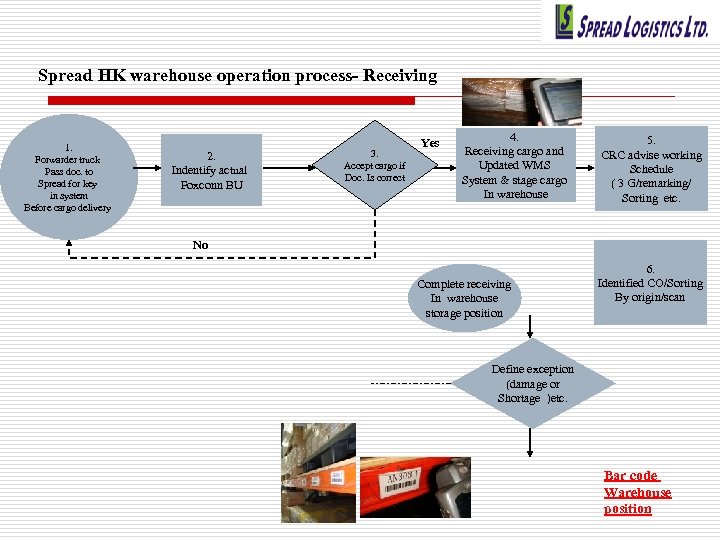

Spread HK warehouse operation process- Receiving 1. Forwarder truck Pass doc. to Spread for key in system Before cargo delivery 2. Indentify actual Foxconn BU 3. Accept cargo if Doc. Is correct Yes 4. Receiving cargo and Updated WMS System & stage cargo In warehouse 5. CRC advise working Schedule ( 3 G/remarking/ Sorting etc. No Complete receiving In warehouse storage position 6. Identified CO/Sorting By origin/scan Define exception (damage or Shortage )etc. Bar code Warehouse position

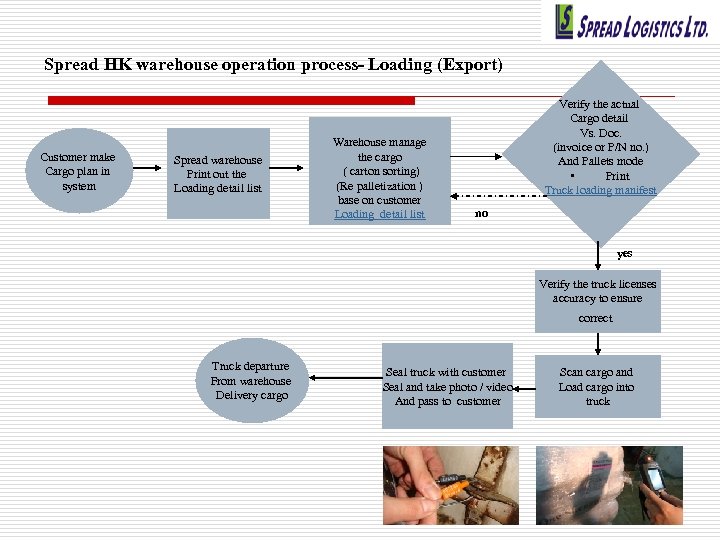

Spread HK warehouse operation process- Loading (Export) Customer make Cargo plan in system Spread warehouse Print out the Loading detail list Warehouse manage the cargo ( carton sorting) (Re palletization ) base on customer Loading detail list Verify the actual Cargo detail Vs. Doc. (invoice or P/N no. ) And Pallets mode • Print Truck loading manifest no yes Verify the truck licenses accuracy to ensure correct Truck departure From warehouse Delivery cargo Seal truck with customer Seal and take photo / video And pass to customer Scan cargo and Load cargo into truck

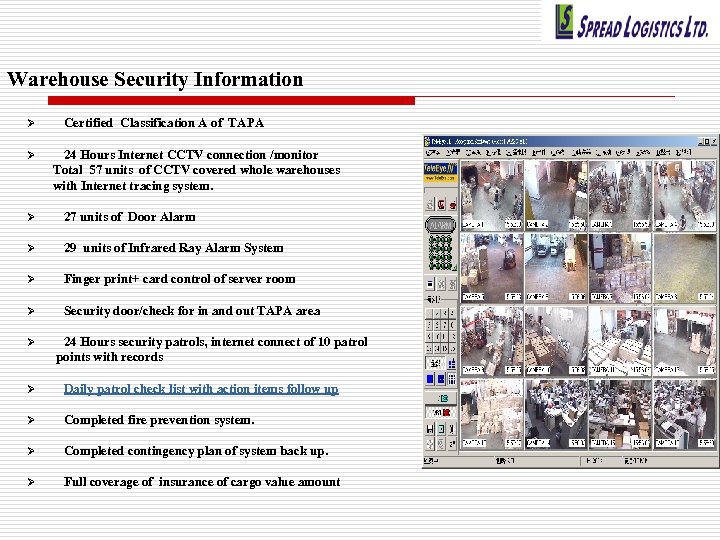

Warehouse Security Information Ø Ø Certified Classification A of TAPA 24 Hours Internet CCTV connection /monitor Total 57 units of CCTV covered whole warehouses with Internet tracing system. Ø 27 units of Door Alarm Ø 29 units of Infrared Ray Alarm System Ø Finger print+ card control of server room Ø Security door/check for in and out TAPA area Ø 24 Hours security patrols, internet connect of 10 patrol points with records Ø Daily patrol check list with action items follow up Ø Completed fire prevention system. Ø Completed contingency plan of system back up. Ø Full coverage of insurance of cargo value amount

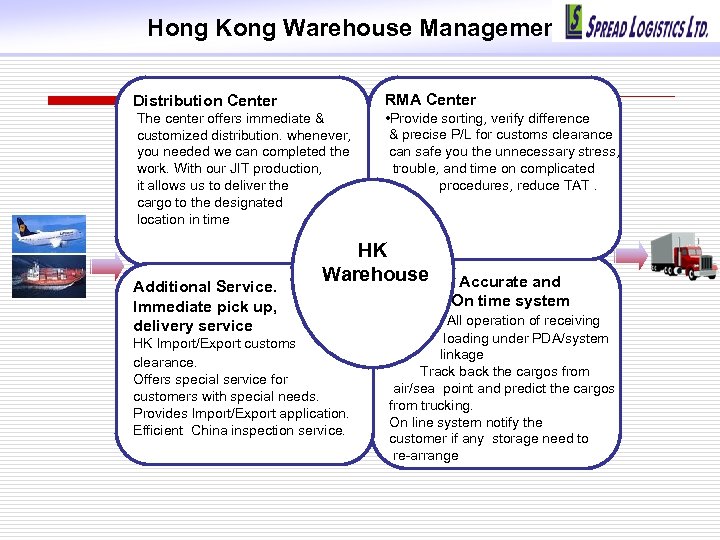

Hong Kong Warehouse Management Distribution Center RMA Center The center offers immediate & customized distribution. whenever, you needed we can completed the work. With our JIT production, it allows us to deliver the cargo to the designated location in time • Provide sorting, verify difference & precise P/L for customs clearance can safe you the unnecessary stress, trouble, and time on complicated procedures, reduce TAT. Additional Service. Immediate pick up, delivery service HK Warehouse HK Import/Export customs clearance. Offers special service for customers with special needs. Provides Import/Export application. Efficient China inspection service. Accurate and On time system All operation of receiving loading under PDA/system linkage Track back the cargos from air/sea point and predict the cargos from trucking. On line system notify the customer if any storage need to re-arrange

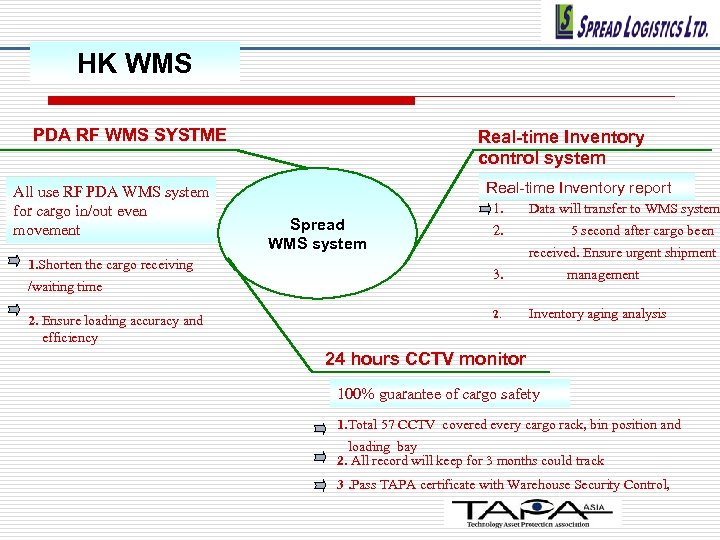

HK WMS PDA RF WMS SYSTME All use RF PDA WMS system for cargo in/out even movement 1. Shorten the cargo receiving /waiting time 2. Ensure loading accuracy and efficiency Real-time Inventory control system Real-time Inventory report Spread WMS system 1. Data will transfer to WMS system 2. 5 second after cargo been received. Ensure urgent shipment 3. management 2. Inventory aging analysis 24 hours CCTV monitor 100% guarantee of cargo safety 1. Total 57 CCTV covered every cargo rack, bin position and loading bay 2. All record will keep for 3 months could track 3. Pass TAPA certificate with Warehouse Security Control,

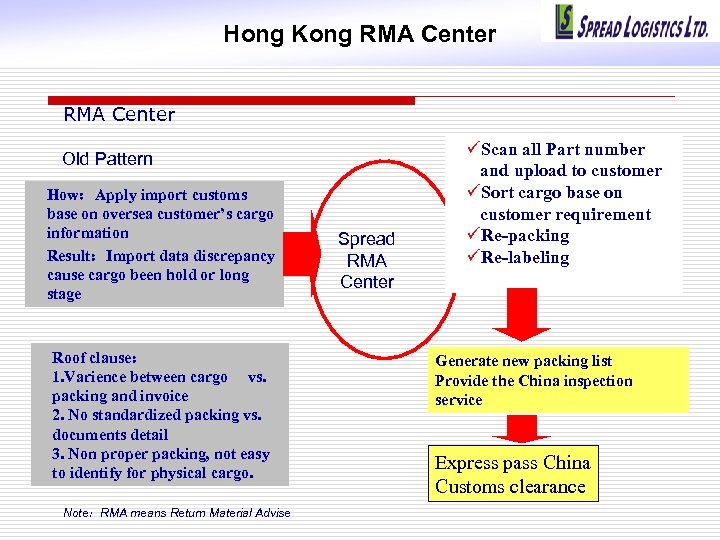

Hong Kong RMA Center Old Pattern How:Apply import customs base on oversea customer’s cargo information Result:Import data discrepancy cause cargo been hold or long stage Roof clause: 1. Varience between cargo vs. packing and invoice 2. No standardized packing vs. documents detail 3. Non proper packing, not easy to identify for physical cargo. Note:RMA means Return Material Advise Spread RMA Center üScan all Part number and upload to customer üSort cargo base on customer requirement üRe-packing üRe-labeling Generate new packing list Provide the China inspection service Express pass China Customs clearance

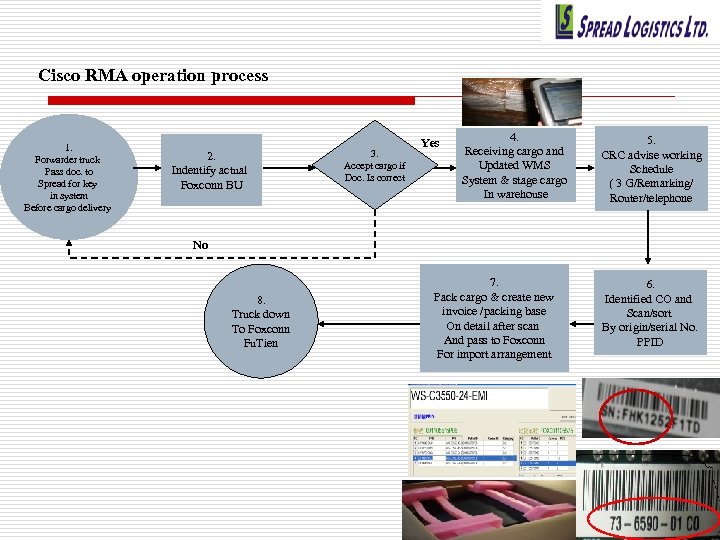

Cisco RMA operation process 1. Forwarder truck Pass doc. to Spread for key in system Before cargo delivery 2. Indentify actual Foxconn BU 3. Accept cargo if Doc. Is correct Yes 4. Receiving cargo and Updated WMS System & stage cargo In warehouse 5. CRC advise working Schedule ( 3 G/Remarking/ Router/telephone No 8. Truck down To Foxconn Fu. Tien 7. Pack cargo & create new invoice /packing base On detail after scan And pass to Foxconn For import arrangement 6. Identified CO and Scan/sort By origin/serial No. PPID

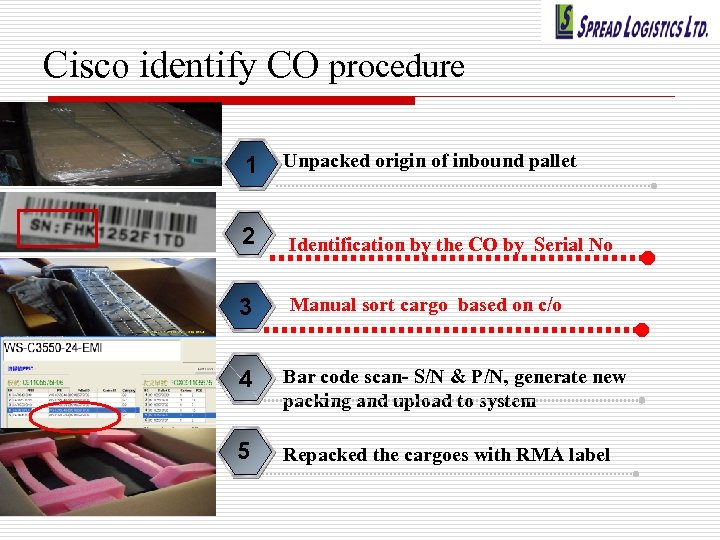

Cisco identify CO procedure 1 Unpacked origin of inbound pallet 2 Identification by the CO by Serial No 3 Manual sort cargo based on c/o 4 Bar code scan- S/N & P/N, generate new packing and upload to system 5 Repacked the cargoes with RMA label

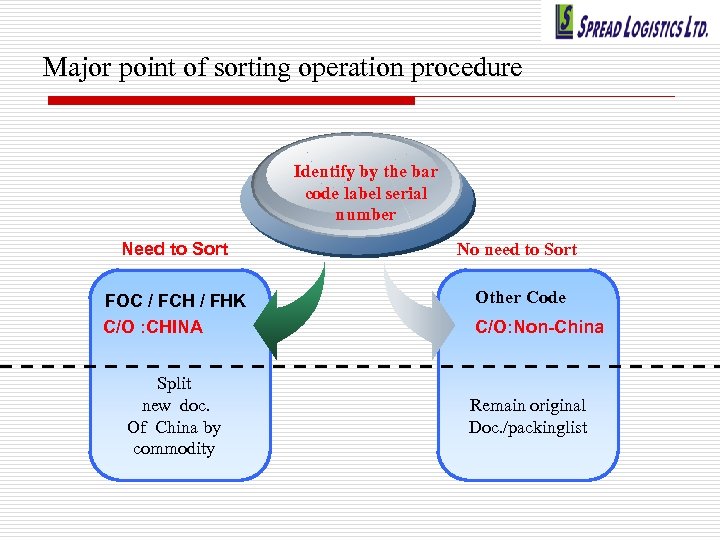

Major point of sorting operation procedure Identify by the bar code label serial number Need to Sort No need to Sort FOC / FCH / FHK C/O : CHINA Other Code Split new doc. Of China by commodity C/O: Non-China Remain original Doc. /packinglist

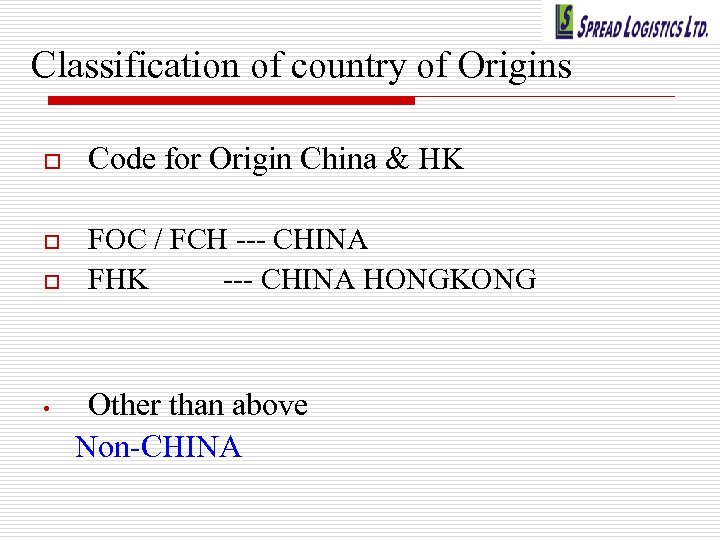

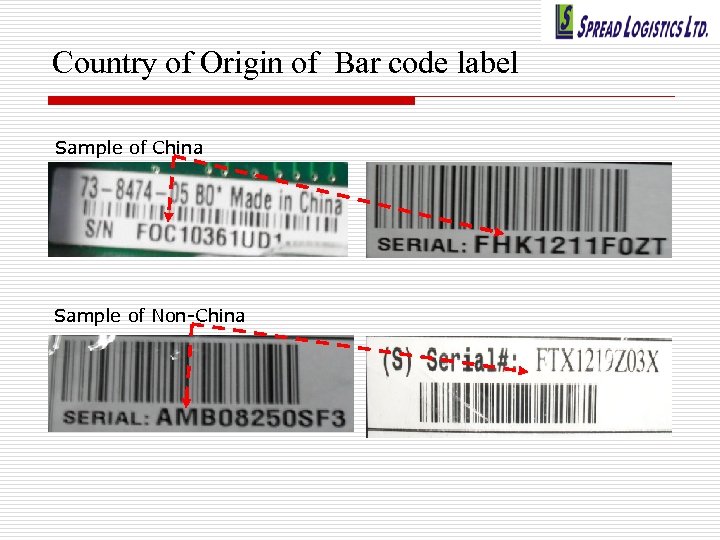

Classification of country of Origins o Code for Origin China & HK o FOC / FCH --- CHINA FHK --- CHINA HONGKONG o Other than above Non-CHINA •

Country of Origin of Bar code label Sample of China Sample of Non-China

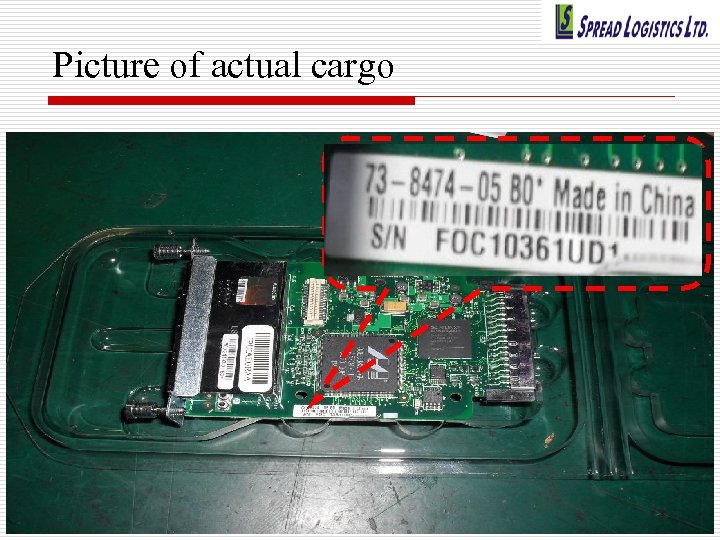

Picture of actual cargo

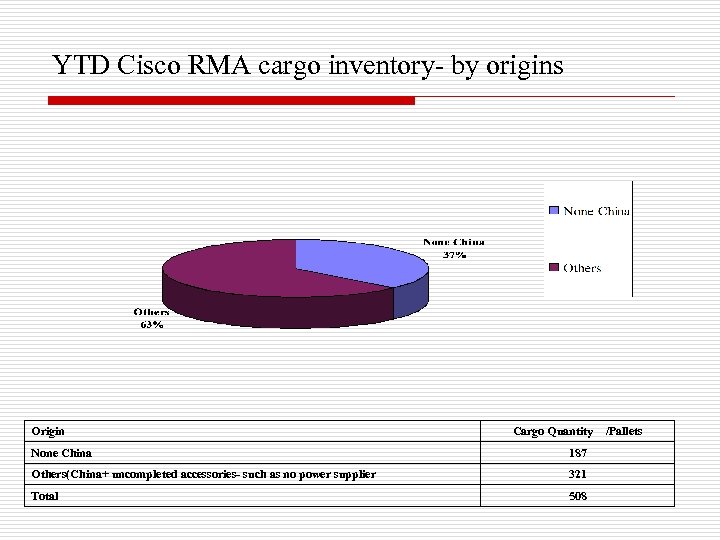

YTD Cisco RMA cargo inventory- by origins Origin Cargo Quantity /Pallets None China 187 Others(China+ uncompleted accessories- such as no power supplier 321 Total 508

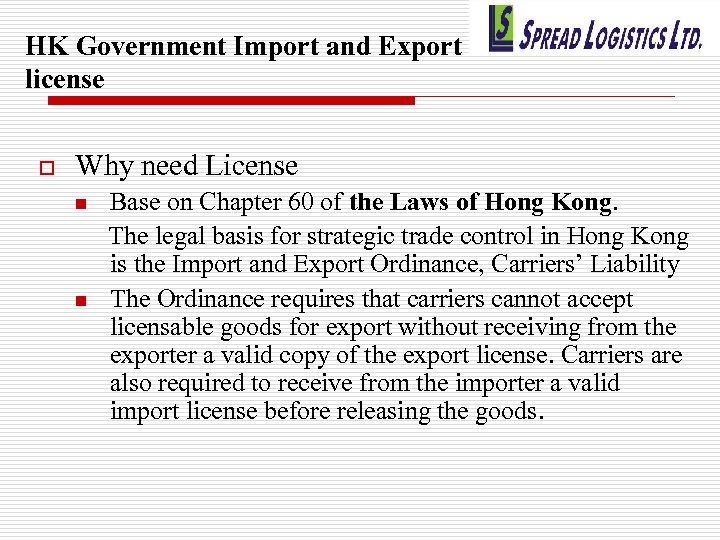

HK Government Import and Export license o Why need License Base on Chapter 60 of the Laws of Hong Kong. The legal basis for strategic trade control in Hong Kong is the Import and Export Ordinance, Carriers’ Liability n The Ordinance requires that carriers cannot accept licensable goods for export without receiving from the exporter a valid copy of the export license. Carriers are also required to receive from the importer a valid import license before releasing the goods. n

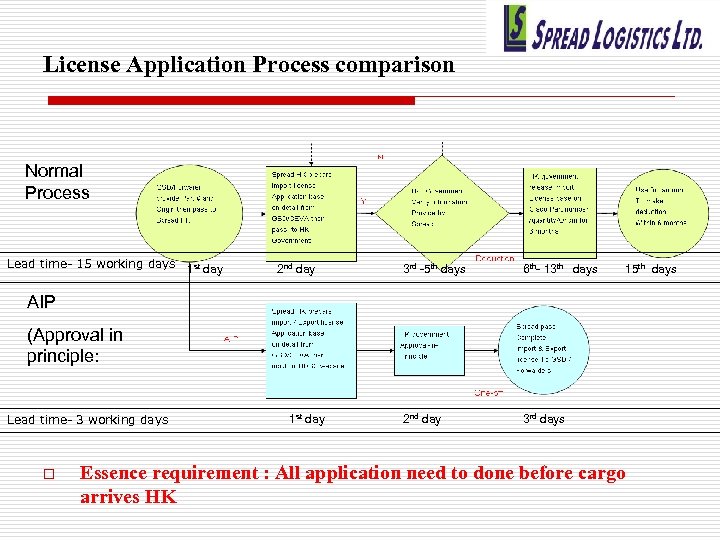

License Application Process comparison Normal Process Lead time- 15 working days 1 st day 2 nd day 3 rd -5 th days 6 th- 13 th days 2 nd day 15 th days 3 rd days AIP (Approval in principle: Lead time- 3 working days o 1 st day Essence requirement : All application need to done before cargo arrives HK

AIP Qualification by TISC o o o Selective customer /carrier Volume customer Creditable customer/HK rep. Good record for import and export application for 2 years at least Commodity no need end- user statement Take 4 - 6 working weeks for first application

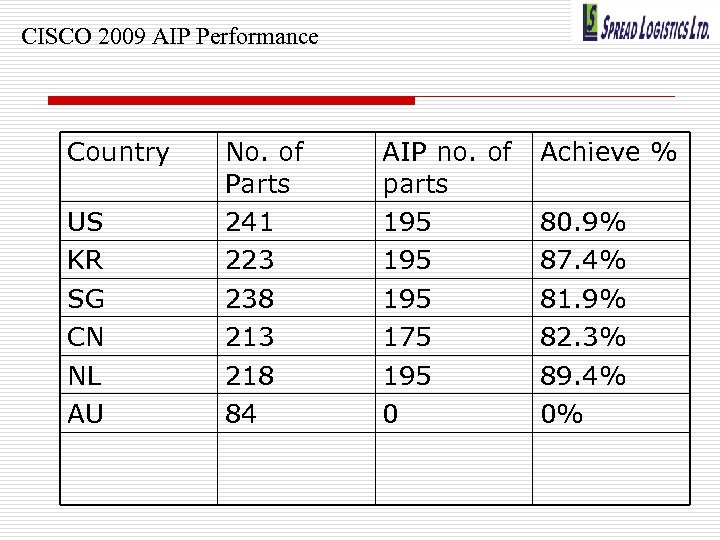

CISCO 2009 AIP Performance Country US KR SG CN NL AU No. of Parts 241 223 238 213 218 84 AIP no. of parts 195 195 175 195 0 Achieve % 80. 9% 87. 4% 81. 9% 82. 3% 89. 4% 0%

Issue of Discussion o No timely application Not been notified for license application before shipment Arrival / Departure HK n Impact A. Need to provide explain letter to TISC and may pre long the application time to 2 -4 weeks) B. Penalty or Warning Letter) n o o Unlimited fine Imprisonment for seven years

def3504b4ee820a7bf06efbcb1fe9fc7.ppt