4de1f42401a75a8c5cf6455a419a368f.ppt

- Количество слайдов: 23

In the name of Allah, The most Merciful & Beneficent.

In the name of Allah, The most Merciful & Beneficent.

FAUJI FERTIZER BIN QASIM LTD. COMPARISON OF AZF DPR AND JACOBS SLURRY TECHNOLOGY FOR DAP MANUFACTURING BY: MUHAMMAD WASEEM APP. ENGINEER DAP OPERATIONS

FAUJI FERTIZER BIN QASIM LTD. COMPARISON OF AZF DPR AND JACOBS SLURRY TECHNOLOGY FOR DAP MANUFACTURING BY: MUHAMMAD WASEEM APP. ENGINEER DAP OPERATIONS

OUT LINES Ä Ä Ä DAP formation & plant description. Various methods for DAP manufacturing. Description of AZF double pipe reactor process. Description of Jacobs slurry process. Difference between AZF & Jacobs technology. Advantages of AZF DPR & Jacobs slurry technology.

OUT LINES Ä Ä Ä DAP formation & plant description. Various methods for DAP manufacturing. Description of AZF double pipe reactor process. Description of Jacobs slurry process. Difference between AZF & Jacobs technology. Advantages of AZF DPR & Jacobs slurry technology.

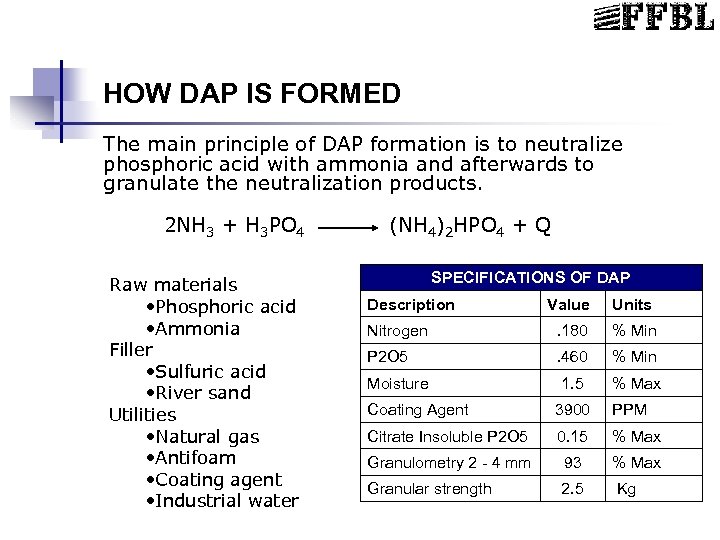

HOW DAP IS FORMED The main principle of DAP formation is to neutralize phosphoric acid with ammonia and afterwards to granulate the neutralization products. 2 NH 3 + H 3 PO 4 Raw materials • Phosphoric acid • Ammonia Filler • Sulfuric acid • River sand Utilities • Natural gas • Antifoam • Coating agent • Industrial water (NH 4)2 HPO 4 + Q SPECIFICATIONS OF DAP Description Value Units Nitrogen . 180 % Min P 2 O 5 . 460 % Min Moisture 1. 5 % Max Coating Agent 3900 PPM Citrate Insoluble P 2 O 5 0. 15 % Max Granulometry 2 - 4 mm 93 % Max Granular strength 2. 5 Kg

HOW DAP IS FORMED The main principle of DAP formation is to neutralize phosphoric acid with ammonia and afterwards to granulate the neutralization products. 2 NH 3 + H 3 PO 4 Raw materials • Phosphoric acid • Ammonia Filler • Sulfuric acid • River sand Utilities • Natural gas • Antifoam • Coating agent • Industrial water (NH 4)2 HPO 4 + Q SPECIFICATIONS OF DAP Description Value Units Nitrogen . 180 % Min P 2 O 5 . 460 % Min Moisture 1. 5 % Max Coating Agent 3900 PPM Citrate Insoluble P 2 O 5 0. 15 % Max Granulometry 2 - 4 mm 93 % Max Granular strength 2. 5 Kg

DESCRIPTION OF DAP PLANT DAP plant consists of Ä Reactors Ä Granulation loop 1. Granulator 2. Dryer 3. Screening & crushing equipment 4. Handling & recycling equipment Ä Product treatment (conditioning) section 1. Cooling 2. Coating Ä Scrubbing section Ä De dusting network

DESCRIPTION OF DAP PLANT DAP plant consists of Ä Reactors Ä Granulation loop 1. Granulator 2. Dryer 3. Screening & crushing equipment 4. Handling & recycling equipment Ä Product treatment (conditioning) section 1. Cooling 2. Coating Ä Scrubbing section Ä De dusting network

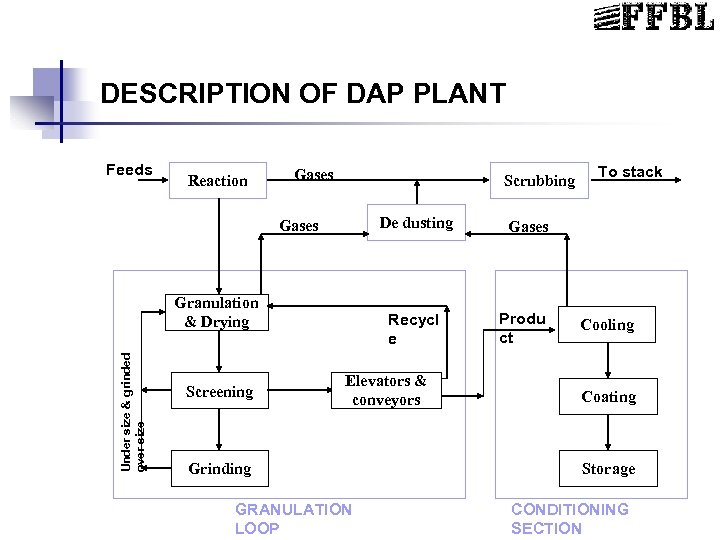

DESCRIPTION OF DAP PLANT Feeds Reaction Gases Scrubbing De dusting Gases Under size & grinded over size Granulation & Drying Screening Recycl e Elevators & conveyors Grinding GRANULATION LOOP To stack Gases Produ ct Cooling Coating Storage CONDITIONING SECTION

DESCRIPTION OF DAP PLANT Feeds Reaction Gases Scrubbing De dusting Gases Under size & grinded over size Granulation & Drying Screening Recycl e Elevators & conveyors Grinding GRANULATION LOOP To stack Gases Produ ct Cooling Coating Storage CONDITIONING SECTION

PROCESSES FOR DAP MANUFACTURING Ä Conventional pre neutralizer process. Ä Single pipe reactor process. Ä Double pipe reactor process. Ä Pre neutralizer with pipe reactor process.

PROCESSES FOR DAP MANUFACTURING Ä Conventional pre neutralizer process. Ä Single pipe reactor process. Ä Double pipe reactor process. Ä Pre neutralizer with pipe reactor process.

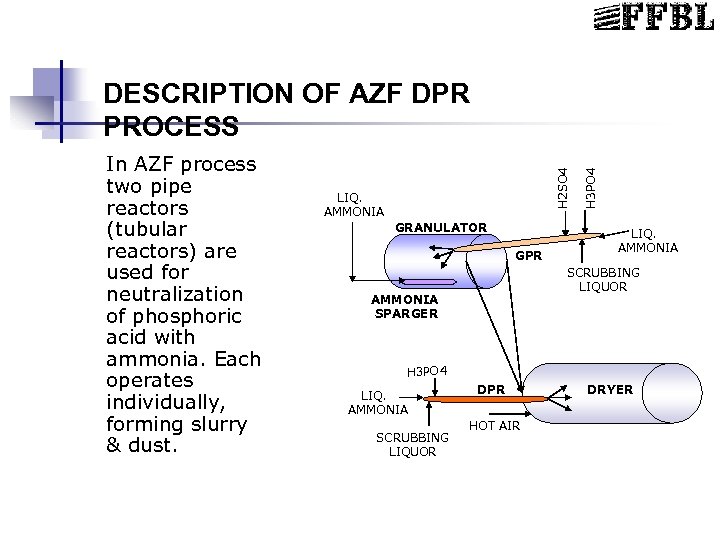

LIQ. AMMONIA GRANULATOR GPR H 3 PO 4 In AZF process two pipe reactors (tubular reactors) are used for neutralization of phosphoric acid with ammonia. Each operates individually, forming slurry & dust. H 2 SO 4 DESCRIPTION OF AZF DPR PROCESS LIQ. AMMONIA SCRUBBING LIQUOR AMMONIA SPARGER H 3 PO 4 LIQ. AMMONIA SCRUBBING LIQUOR DPR HOT AIR DRYER

LIQ. AMMONIA GRANULATOR GPR H 3 PO 4 In AZF process two pipe reactors (tubular reactors) are used for neutralization of phosphoric acid with ammonia. Each operates individually, forming slurry & dust. H 2 SO 4 DESCRIPTION OF AZF DPR PROCESS LIQ. AMMONIA SCRUBBING LIQUOR AMMONIA SPARGER H 3 PO 4 LIQ. AMMONIA SCRUBBING LIQUOR DPR HOT AIR DRYER

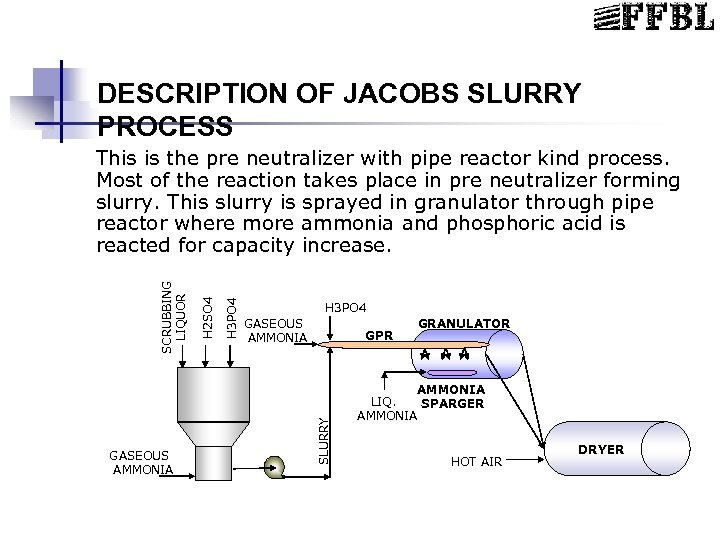

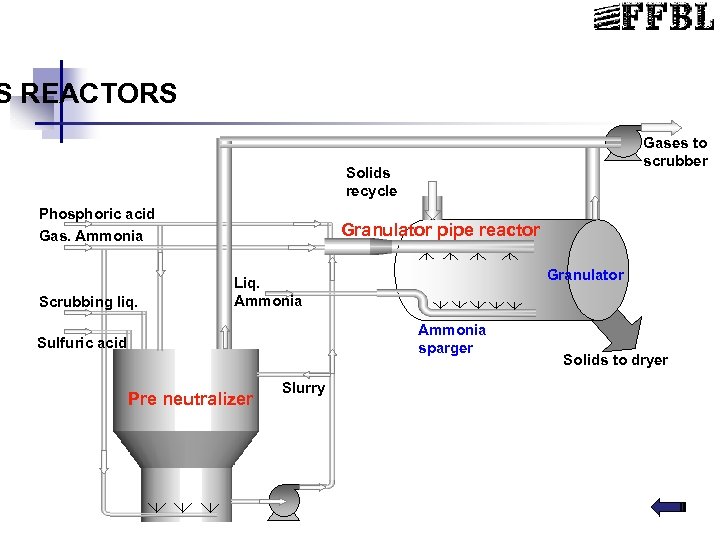

DESCRIPTION OF JACOBS SLURRY PROCESS H 3 PO 4 H 2 SO 4 SCRUBBING LIQUOR This is the pre neutralizer with pipe reactor kind process. Most of the reaction takes place in pre neutralizer forming slurry. This slurry is sprayed in granulator through pipe reactor where more ammonia and phosphoric acid is reacted for capacity increase. H 3 PO 4 GASEOUS AMMONIA GPR GASEOUS AMMONIA SLURRY PN GRANULATOR AMMONIA LIQ. SPARGER AMMONIA HOT AIR DRYER

DESCRIPTION OF JACOBS SLURRY PROCESS H 3 PO 4 H 2 SO 4 SCRUBBING LIQUOR This is the pre neutralizer with pipe reactor kind process. Most of the reaction takes place in pre neutralizer forming slurry. This slurry is sprayed in granulator through pipe reactor where more ammonia and phosphoric acid is reacted for capacity increase. H 3 PO 4 GASEOUS AMMONIA GPR GASEOUS AMMONIA SLURRY PN GRANULATOR AMMONIA LIQ. SPARGER AMMONIA HOT AIR DRYER

DIFFERENCES B/W JACOBS & AZF TECHNOLOGY Process Reactors Raw material feeding system Recycle ratio Scrubbing system Bag house Ammonia vaporization Environmental impact

DIFFERENCES B/W JACOBS & AZF TECHNOLOGY Process Reactors Raw material feeding system Recycle ratio Scrubbing system Bag house Ammonia vaporization Environmental impact

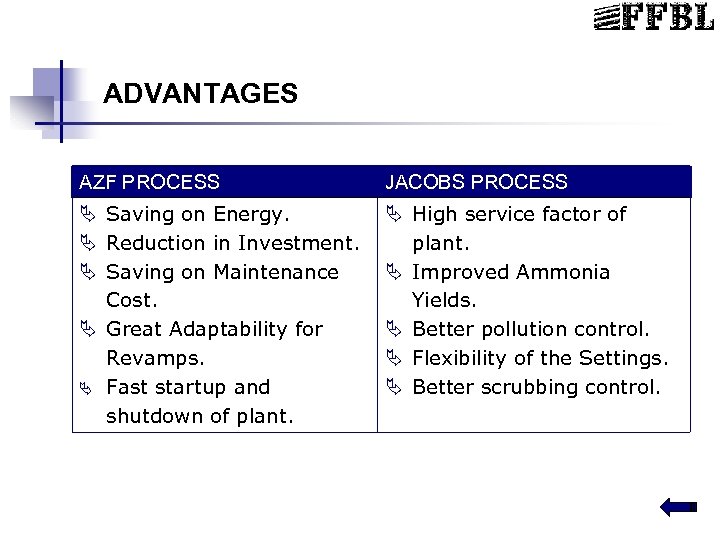

ADVANTAGES AZF PROCESS JACOBS PROCESS Ä Saving on Energy. Ä Reduction in Investment. Ä Saving on Maintenance Cost. Ä Great Adaptability for Revamps. Ä Fast startup and shutdown of plant. Ä High service factor of plant. Ä Improved Ammonia Yields. Ä Better pollution control. Ä Flexibility of the Settings. Ä Better scrubbing control.

ADVANTAGES AZF PROCESS JACOBS PROCESS Ä Saving on Energy. Ä Reduction in Investment. Ä Saving on Maintenance Cost. Ä Great Adaptability for Revamps. Ä Fast startup and shutdown of plant. Ä High service factor of plant. Ä Improved Ammonia Yields. Ä Better pollution control. Ä Flexibility of the Settings. Ä Better scrubbing control.

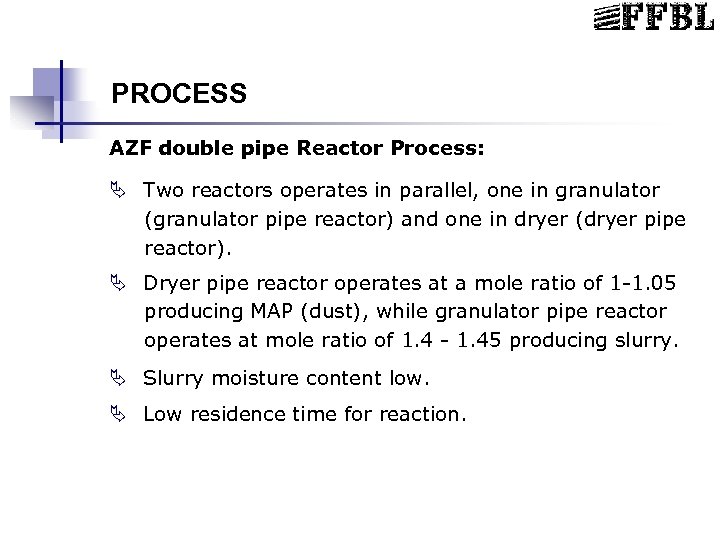

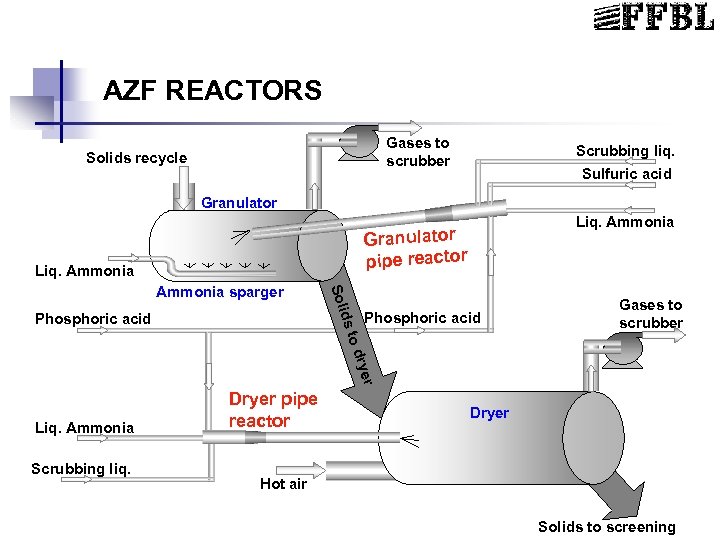

PROCESS AZF double pipe Reactor Process: Ä Two reactors operates in parallel, one in granulator (granulator pipe reactor) and one in dryer (dryer pipe reactor). Ä Dryer pipe reactor operates at a mole ratio of 1 -1. 05 producing MAP (dust), while granulator pipe reactor operates at mole ratio of 1. 4 - 1. 45 producing slurry. Ä Slurry moisture content low. Ä Low residence time for reaction.

PROCESS AZF double pipe Reactor Process: Ä Two reactors operates in parallel, one in granulator (granulator pipe reactor) and one in dryer (dryer pipe reactor). Ä Dryer pipe reactor operates at a mole ratio of 1 -1. 05 producing MAP (dust), while granulator pipe reactor operates at mole ratio of 1. 4 - 1. 45 producing slurry. Ä Slurry moisture content low. Ä Low residence time for reaction.

PROCESS Jacobs slurry Process : Ä Two reactors operates in series, one is a pre neutralizer (CSTR) and other a pipe reactor which operates in granulator. Ä Pre neutralizer operates at a mole ratio of 1. 45 producing slurry. This slurry is sprayed in granulator through granulator pipe reactor where more ammonia increase. Ä Slurry moisture content high. Ä High residence time for reaction.

PROCESS Jacobs slurry Process : Ä Two reactors operates in series, one is a pre neutralizer (CSTR) and other a pipe reactor which operates in granulator. Ä Pre neutralizer operates at a mole ratio of 1. 45 producing slurry. This slurry is sprayed in granulator through granulator pipe reactor where more ammonia increase. Ä Slurry moisture content high. Ä High residence time for reaction.

AZF REACTORS Gases to scrubber Solids recycle Scrubbing liq. Sulfuric acid Granulator Liq. Ammonia Granulator pipe reactor Liq. Ammonia Sol Ammonia sparger t ids Phosphoric acid Gases to scrubber yer o dr Liq. Ammonia Scrubbing liq. Dryer pipe reactor Dryer Hot air Solids to screening

AZF REACTORS Gases to scrubber Solids recycle Scrubbing liq. Sulfuric acid Granulator Liq. Ammonia Granulator pipe reactor Liq. Ammonia Sol Ammonia sparger t ids Phosphoric acid Gases to scrubber yer o dr Liq. Ammonia Scrubbing liq. Dryer pipe reactor Dryer Hot air Solids to screening

S REACTORS Gases to scrubber Solids recycle Phosphoric acid Gas. Ammonia Scrubbing liq. Granulator pipe reactor Granulator Liq. Ammonia sparger Sulfuric acid Pre neutralizer Slurry Solids to dryer

S REACTORS Gases to scrubber Solids recycle Phosphoric acid Gas. Ammonia Scrubbing liq. Granulator pipe reactor Granulator Liq. Ammonia sparger Sulfuric acid Pre neutralizer Slurry Solids to dryer

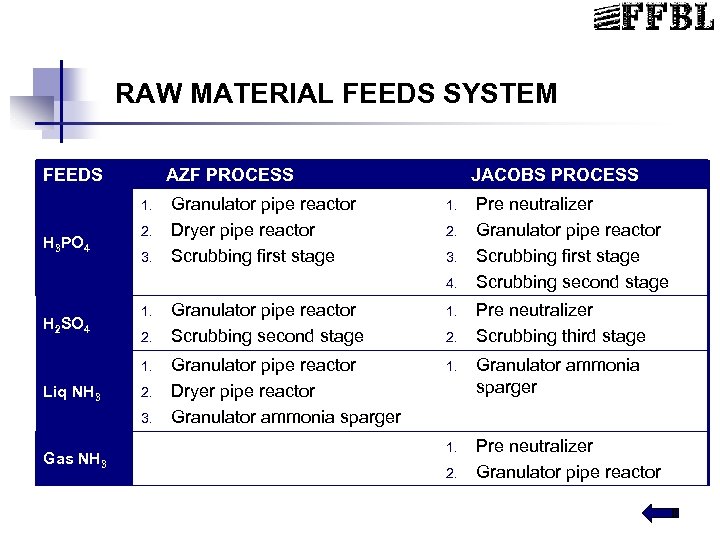

RAW MATERIAL FEEDS SYSTEM FEEDS AZF PROCESS 1. H 3 PO 4 2. 3. Granulator pipe reactor Dryer pipe reactor Scrubbing first stage JACOBS PROCESS 1. 2. 3. 4. H 2 SO 4 1. 2. 1. Liq NH 3 2. 3. Gas NH 3 Pre neutralizer Granulator pipe reactor Scrubbing first stage Scrubbing second stage Granulator pipe reactor Scrubbing second stage 1. Granulator pipe reactor Dryer pipe reactor Granulator ammonia sparger 1. Pre neutralizer Granulator pipe reactor 2. Pre neutralizer Scrubbing third stage

RAW MATERIAL FEEDS SYSTEM FEEDS AZF PROCESS 1. H 3 PO 4 2. 3. Granulator pipe reactor Dryer pipe reactor Scrubbing first stage JACOBS PROCESS 1. 2. 3. 4. H 2 SO 4 1. 2. 1. Liq NH 3 2. 3. Gas NH 3 Pre neutralizer Granulator pipe reactor Scrubbing first stage Scrubbing second stage Granulator pipe reactor Scrubbing second stage 1. Granulator pipe reactor Dryer pipe reactor Granulator ammonia sparger 1. Pre neutralizer Granulator pipe reactor 2. Pre neutralizer Scrubbing third stage

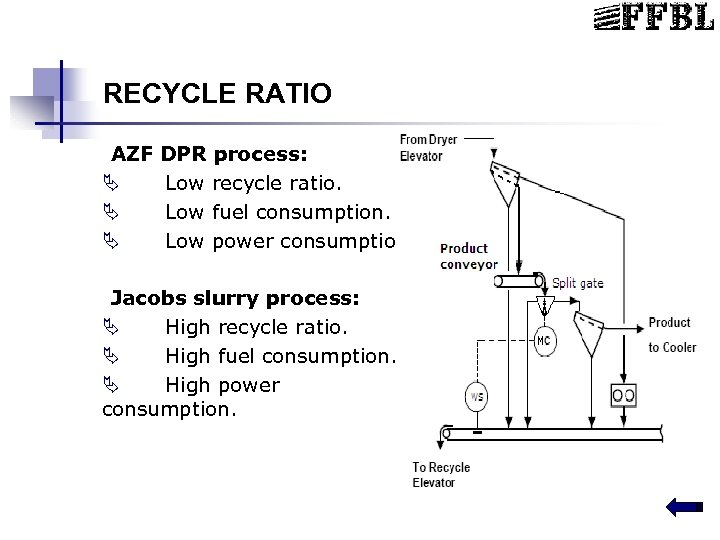

RECYCLE RATIO AZF Ä Ä Ä DPR process: Low recycle ratio. Low fuel consumption. Low power consumption. Jacobs slurry process: Ä High recycle ratio. Ä High fuel consumption. Ä High power consumption.

RECYCLE RATIO AZF Ä Ä Ä DPR process: Low recycle ratio. Low fuel consumption. Low power consumption. Jacobs slurry process: Ä High recycle ratio. Ä High fuel consumption. Ä High power consumption.

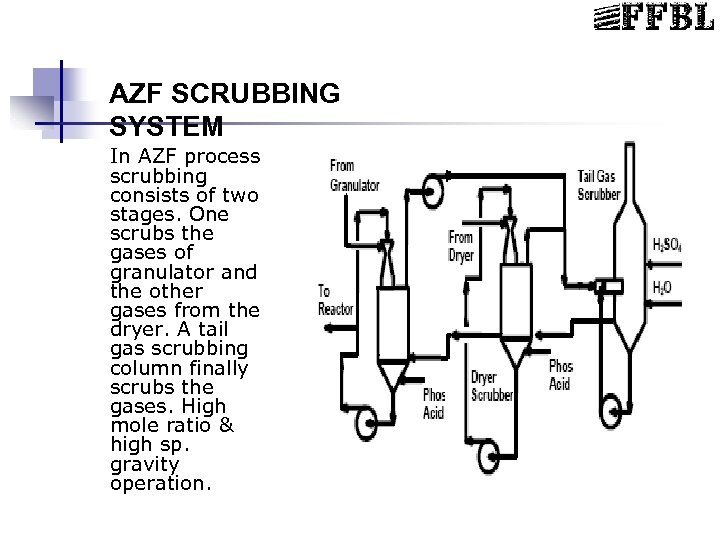

AZF SCRUBBING SYSTEM In AZF process scrubbing consists of two stages. One scrubs the gases of granulator and the other gases from the dryer. A tail gas scrubbing column finally scrubs the gases. High mole ratio & high sp. gravity operation.

AZF SCRUBBING SYSTEM In AZF process scrubbing consists of two stages. One scrubs the gases of granulator and the other gases from the dryer. A tail gas scrubbing column finally scrubs the gases. High mole ratio & high sp. gravity operation.

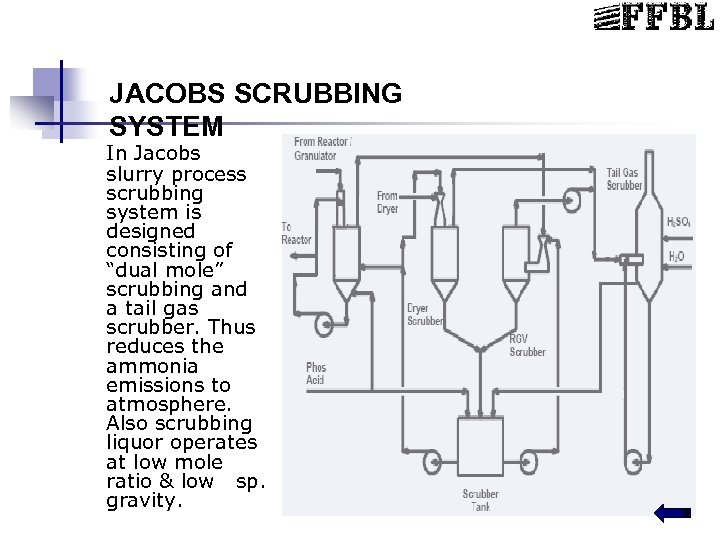

JACOBS SCRUBBING SYSTEM In Jacobs slurry process scrubbing system is designed consisting of “dual mole” scrubbing and a tail gas scrubber. Thus reduces the ammonia emissions to atmosphere. Also scrubbing liquor operates at low mole ratio & low sp. gravity.

JACOBS SCRUBBING SYSTEM In Jacobs slurry process scrubbing system is designed consisting of “dual mole” scrubbing and a tail gas scrubber. Thus reduces the ammonia emissions to atmosphere. Also scrubbing liquor operates at low mole ratio & low sp. gravity.

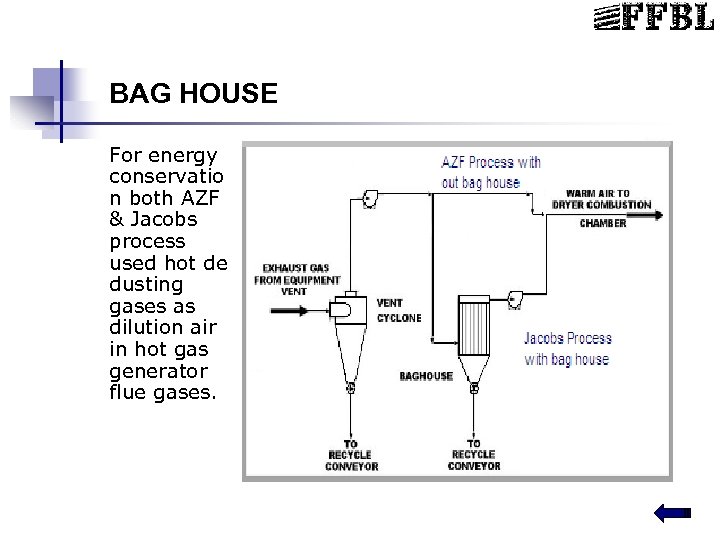

BAG HOUSE For energy conservatio n both AZF & Jacobs process used hot de dusting gases as dilution air in hot gas generator flue gases.

BAG HOUSE For energy conservatio n both AZF & Jacobs process used hot de dusting gases as dilution air in hot gas generator flue gases.

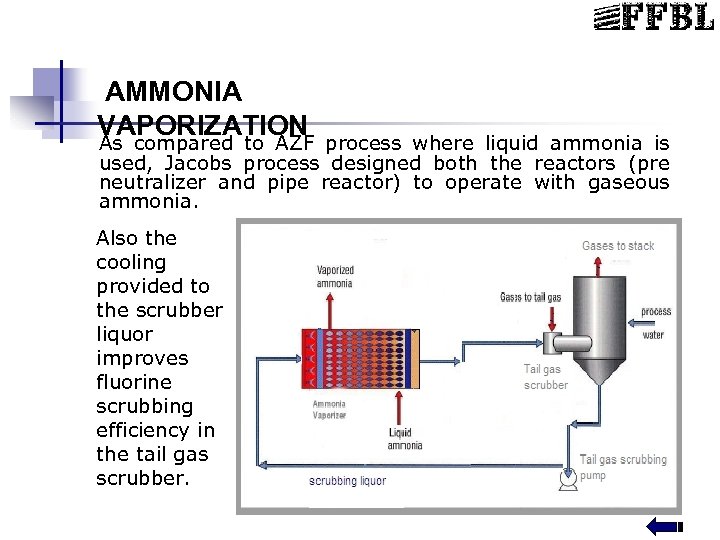

AMMONIA VAPORIZATION As compared to AZF process where liquid ammonia is used, Jacobs process designed both the reactors (pre neutralizer and pipe reactor) to operate with gaseous ammonia. Also the cooling provided to the scrubber liquor improves fluorine scrubbing efficiency in the tail gas scrubber.

AMMONIA VAPORIZATION As compared to AZF process where liquid ammonia is used, Jacobs process designed both the reactors (pre neutralizer and pipe reactor) to operate with gaseous ammonia. Also the cooling provided to the scrubber liquor improves fluorine scrubbing efficiency in the tail gas scrubber.

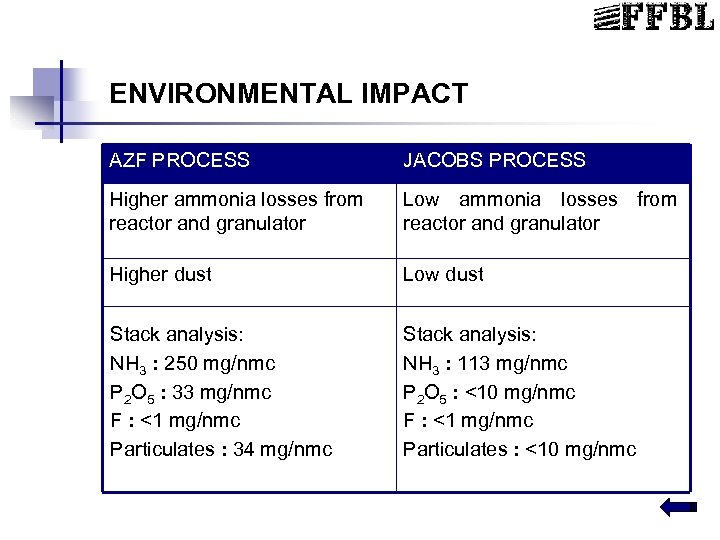

ENVIRONMENTAL IMPACT AZF PROCESS JACOBS PROCESS Higher ammonia losses from reactor and granulator Low ammonia losses from reactor and granulator Higher dust Low dust Stack analysis: NH 3 : 250 mg/nmc P 2 O 5 : 33 mg/nmc F : <1 mg/nmc Particulates : 34 mg/nmc Stack analysis: NH 3 : 113 mg/nmc P 2 O 5 : <10 mg/nmc F : <1 mg/nmc Particulates : <10 mg/nmc

ENVIRONMENTAL IMPACT AZF PROCESS JACOBS PROCESS Higher ammonia losses from reactor and granulator Low ammonia losses from reactor and granulator Higher dust Low dust Stack analysis: NH 3 : 250 mg/nmc P 2 O 5 : 33 mg/nmc F : <1 mg/nmc Particulates : 34 mg/nmc Stack analysis: NH 3 : 113 mg/nmc P 2 O 5 : <10 mg/nmc F : <1 mg/nmc Particulates : <10 mg/nmc

THANK YOU Questions? ?

THANK YOU Questions? ?