0591ed73c7c673a14facfe3593133bb3.ppt

- Количество слайдов: 69

Improving Interoperability through the use of ISO 10303 Presented by : Ron Wood Date: 3/15/2018 August 25, 2005 1

Authors § § T. Briggs B. Gischner T. Rando J. Mays § R. Wood Intergraph Corp. Electric Boat Corp. Naval Surface Warfare Center Carderock Division Northrop Grumman Ship Systems 2

Agenda § Background and History • Interoperability • Use of STEP and XML • Development of STEP for Shipbuilding § Integrate Shipbuilding Environment (ISE) Implementation Projects § Summary 3

Background and History 3/15/2018 4

Need for Interoperability 3/15/2018 5

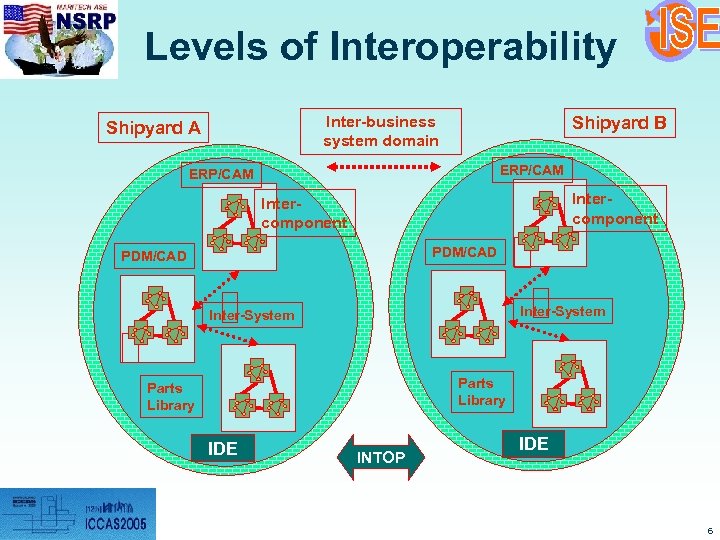

Levels of Interoperability Inter-business system domain Shipyard A Shipyard B ERP/CAM Intercomponent PDM/CAD Inter-System Parts Library IDE INTOP IDE 6

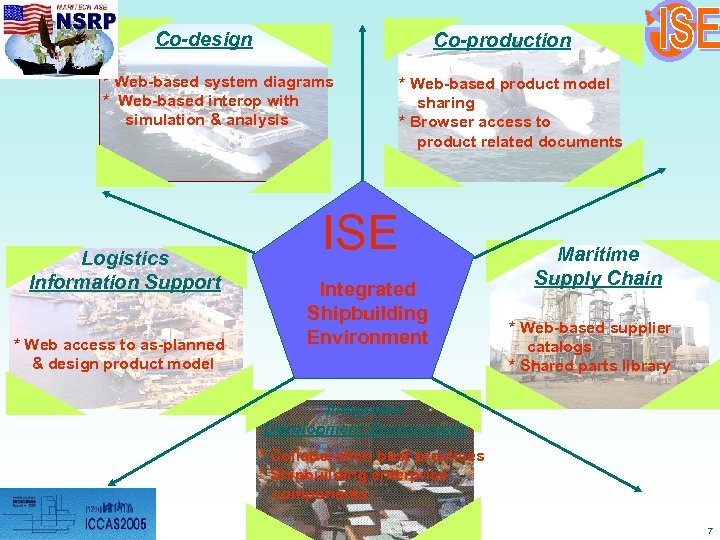

Co-design Co-production * Web-based system diagrams * Web-based interop with simulation & analysis Logistics Information Support * Web access to as-planned & design product model * Web-based product model sharing * Browser access to product related documents ISE Integrated Shipbuilding Environment Maritime Supply Chain * Web-based supplier catalogs * Shared parts library Integrated Development Environment * Collaboration best practices * Shipbuilding enterprise components 7

Collaboration among Shipyards is Required in Today’s Environment § Almost every major recent U. S. Navy ship design and/or construction contract has involved collaboration among multiple shipyards • For example: – – CVNX (NGNN & EB) DDX (NGSS - Ingalls & Bath) Initial LPD Award (NGSS - Avondale & Bath) VIRGINIA (EB & NGNN) § This trend will continue § Navy views system interoperability as enabling multiple yards to be viewed as “One Shipyard” 8

Goals of Integration § Better analysis through simulation § Re-use of data instead of redundant data • increased accuracy • eliminates unnecessary checking • speed of data entry (already entered) § Facilitates partnering with other firms § Reduce overhead costs 9

Overview of STEP (ISO 10303 - Industrial automation systems and integration - Product data representation and exchange) § International Standard for the computer-interpretable representation and exchange of product data § The objective is to provide a mechanism that is capable of describing product data throughout the life cycle of a product, independent of any particular system § The nature of this description makes it suitable not only for neutral file exchange, but also as a basis for implementing and sharing product databases and archiving 10

XML- Extensible Markup Language § Traditional STEP transfers have been via STEP Physical File exchange as defined by Part 21 § To take advantage of Web technology, Part 28 is under development to standardize STEP transfers using XML § ISE Project is implementing its transfers using XML as well as permitting Part 21 file exchanges 11

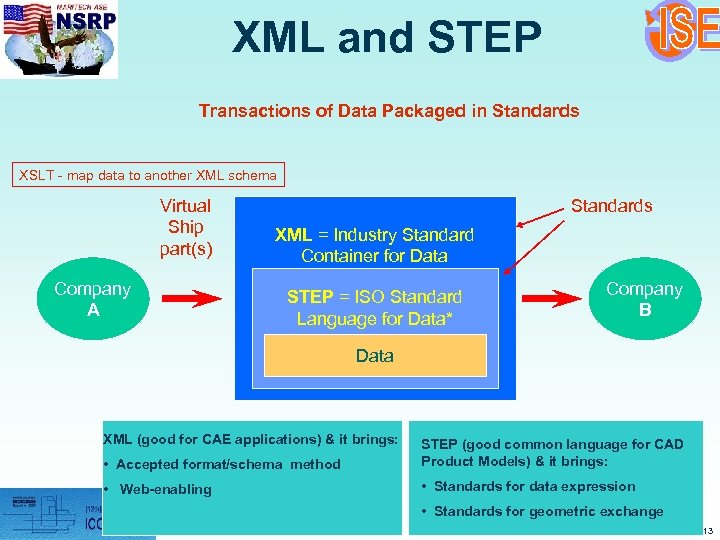

XML Goal and Mission § Goal • Use XML Schema to represent as much of EXPRESS semantics as possible so that XML Schema can be used to: – Document the information model – Provide delegated validation services – Support the XML instance formats standardized in Part 28 § Part 28 Mission • Use XML to publish STEP EXPRESS Schemas • Use XML as a STEP implementation method 12

XML and STEP Transactions of Data Packaged in Standards XSLT - map data to another XML schema Virtual Ship part(s) Company A Standards XML = Industry Standard Container for Data STEP = ISO Standard Language for Data* Company B Data XML (good for CAE applications) & it brings: • Accepted format/schema method STEP (good common language for CAD Product Models) & it brings: • Web-enabling • Standards for data expression • Standards for geometric exchange 13

Development of STEP and XML for Shipbuilding 3/15/2018 14

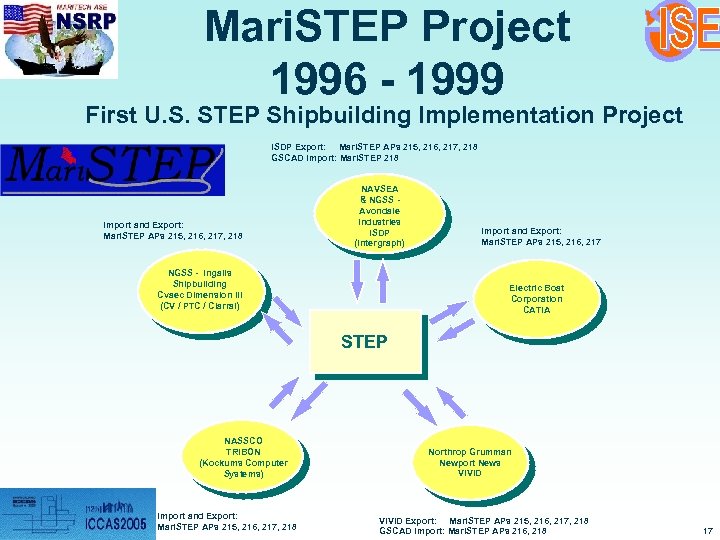

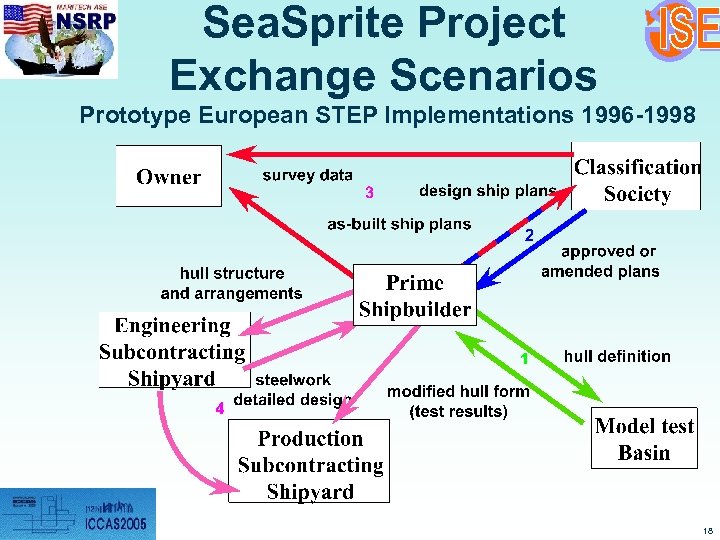

ISO Shipbuilding – Background § Effort of Shipbuilders, Regulatory Bodies, CAD Software Companies, MOD, DOD from Various countries § 1996 to 1999 US Effort under Mari. STEP Project • Funded under DARPA/MARITECH – DARPA (Defense Advanced Research Projects) • Prototyped early versions of AP 215, 216, 217 and 218 • Exchanged AP 218 data with European Sea. Sprite Project § Current U. S. effort under NSRP ASE 15

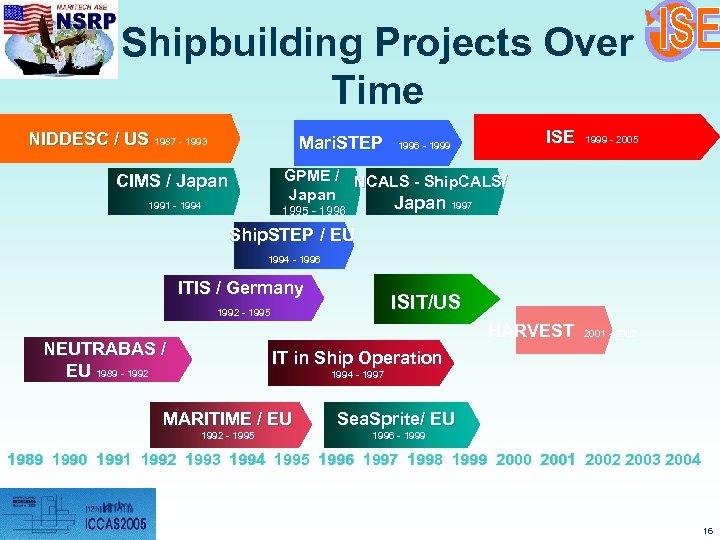

Shipbuilding Projects Over Time Mari. STEP ISE 1999 - 2005 HARVEST NIDDESC / US 1987 - 1993 2001 - 2002 1996 - 1999 GPME / NCALS - Ship. CALS/ Japan CIMS / Japan 1991 - 1994 Japan 1997 1995 - 1996 Ship. STEP / EU 1994 - 1996 ITIS / Germany ISIT/US 1992 - 1995 NEUTRABAS / EU 1989 - 1992 IT in Ship Operation 1994 - 1997 MARITIME / EU Sea. Sprite/ EU 1992 - 1995 1996 - 1999 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 16

Mari. STEP Project 1996 - 1999 First U. S. STEP Shipbuilding Implementation Project ISDP Export: Mari. STEP APs 215, 216, 217, 218 GSCAD Import: Mari. STEP 218 Import and Export: Mari. STEP APs 215, 216, 217, 218 NAVSEA & NGSS Avondale Industries ISDP (Intergraph) NGSS - Ingalls Shipbuilding Cvaec Dimension III (CV / PTC / Ciarrai) Import and Export: Mari. STEP APs 215, 216, 217 Electric Boat Corporation CATIA STEP NASSCO TRIBON (Kockums Computer Systems) Import and Export: Mari. STEP APs 215, 216, 217, 218 Northrop Grumman Newport News VIVID Export: Mari. STEP APs 215, 216, 217, 218 GSCAD Import: Mari. STEP APs 216, 218 17

Sea. Sprite Project Exchange Scenarios Prototype European STEP Implementations 1996 -1998 18

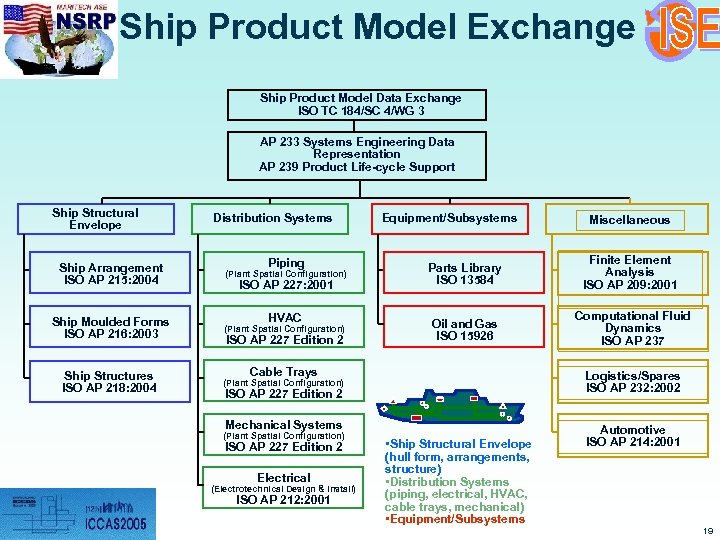

Ship Product Model Exchange Ship Product Model Data Exchange ISO TC 184/SC 4/WG 3 AP 233 Systems Engineering Data Representation AP 239 Product Life-cycle Support Ship Structural Envelope Distribution Systems Piping Ship Arrangement ISO AP 215: 2004 (Plant Spatial Configuration) Ship Moulded Forms ISO AP 216: 2003 (Plant Spatial Configuration) Ship Structures ISO AP 218: 2004 Equipment/Subsystems Parts Library ISO 13584 Finite Element Analysis ISO AP 209: 2001 Oil and Gas ISO 15926 Computational Fluid Dynamics ISO AP 237 (Plant Spatial Configuration) ISO AP 227: 2001 HVAC ISO AP 227 Edition 2 Cable Trays Logistics/Spares ISO AP 232: 2002 ISO AP 227 Edition 2 Mechanical Systems (Plant Spatial Configuration) ISO AP 227 Edition 2 Electrical (Electrotechnical Design & Install) ISO AP 212: 2001 Miscellaneous • Ship Structural Envelope (hull form, arrangements, structure) • Distribution Systems (piping, electrical, HVAC, cable trays, mechanical) • Equipment/Subsystems Automotive ISO AP 214: 2001 19

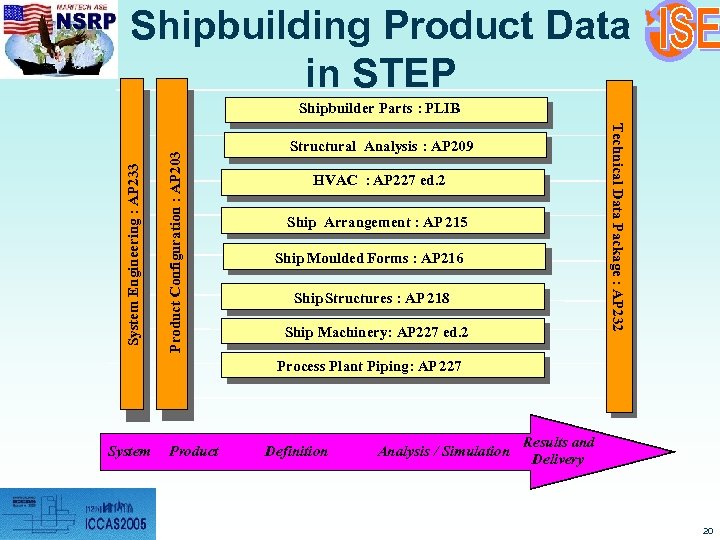

Shipbuilding Product Data in STEP Product Configuration : AP 203 Technical Data Package : AP 232 System Engineering : AP 233 Shipbuilder Parts : PLIB Structural Analysis : AP 209 HVAC : AP 227 ed. 2 Cable harness design : AP 212 Ship Arrangement : : AP 215 Ship Arrangement AP Ship Moulded Forms : AP 216 Ship Moulded Forms : AP Ship Structures : AP 218 Ship Structures : AP Ship Machinery: AP 227 ed. 2 Ship Machinery: AP Process Plant Piping: AP 227 Process Plant Piping: AP System Product Definition Analysis / Simulation Results and Delivery 20

Ship APs Now ISO Standards § AP 215, ISO TC 184/SC 4 10303 -215 IS "Application protocol: Ship Arrangement". • available from Geneva or National Standards bodies as ISO 10303215: 2004. § AP 216, TC 184/SC 4 10303 -215 IS "Application protocol: Ship Moulded Forms”. • available from Geneva or National Standards bodies as ISO 10303216: 2003. § AP 218 ISO TC 184/SC 4 10303 -218 IS "Application protocol: Ship structures". • available from Geneva or National Standards bodies as ISO 10303218: 2004. § AP 227 ISO TC 184/SC 4/WG 3 “Plant Spatial Configuration”. AP 227 • has now passed its final ballot for Edition 2 has been sent to Geneva for publication. • Includes all the information needed for the marine industries to exchange information about piping, HVAC and machinery. 21

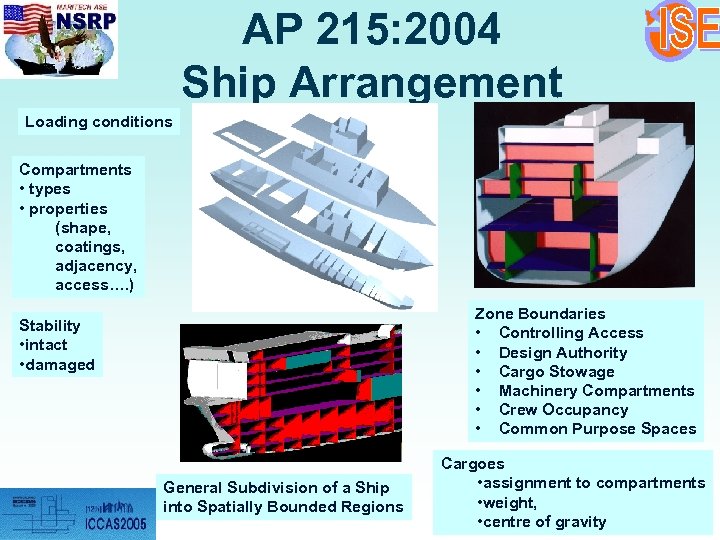

AP 215: 2004 Ship Arrangement Loading conditions Compartments • types • properties (shape, coatings, adjacency, access…. ) Zone Boundaries • Controlling Access • Design Authority • Cargo Stowage • Machinery Compartments • Crew Occupancy • Common Purpose Spaces Stability • intact • damaged General Subdivision of a Ship into Spatially Bounded Regions Cargoes • assignment to compartments • weight, • centre of gravity 22

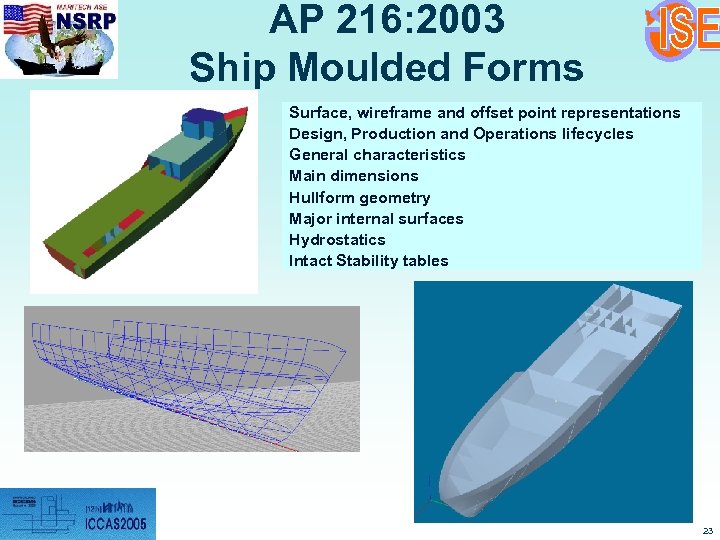

AP 216: 2003 Ship Moulded Forms Surface, wireframe and offset point representations Design, Production and Operations lifecycles General characteristics Main dimensions Hullform geometry Major internal surfaces Hydrostatics Intact Stability tables 23

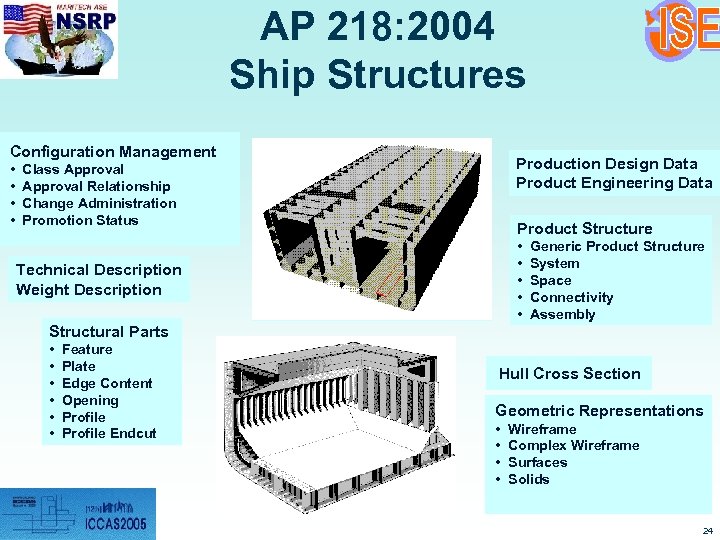

AP 218: 2004 Ship Structures Configuration Management • • Production Design Data Product Engineering Data Class Approval Relationship Change Administration Promotion Status Product Structure • • • Technical Description Weight Description Generic Product Structure System Space Connectivity Assembly Structural Parts • • • Feature Plate Edge Content Opening Profile Endcut Hull Cross Section Geometric Representations • • Wireframe Complex Wireframe Surfaces Solids 24

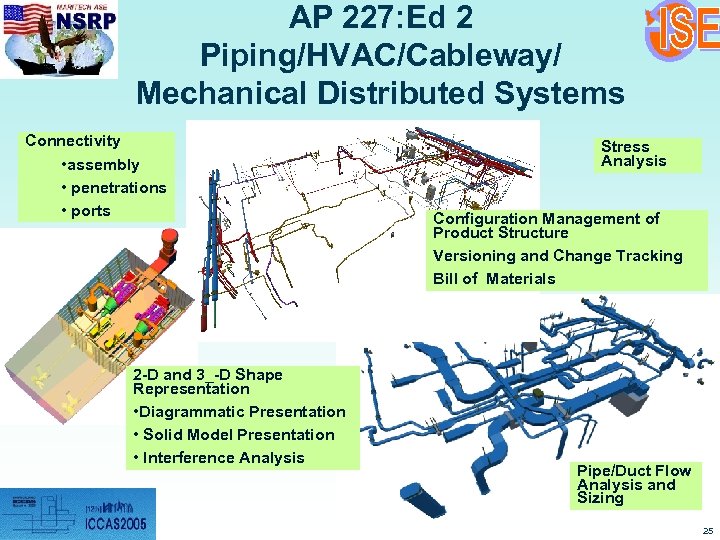

AP 227: Ed 2 Piping/HVAC/Cableway/ Mechanical Distributed Systems Connectivity • assembly • penetrations • ports 2 -D and 3_-D Shape Representation • Diagrammatic Presentation • Solid Model Presentation • Interference Analysis Stress Analysis Configuration Management of Product Structure Versioning and Change Tracking Bill of Materials Pipe/Duct Flow Analysis and Sizing 25

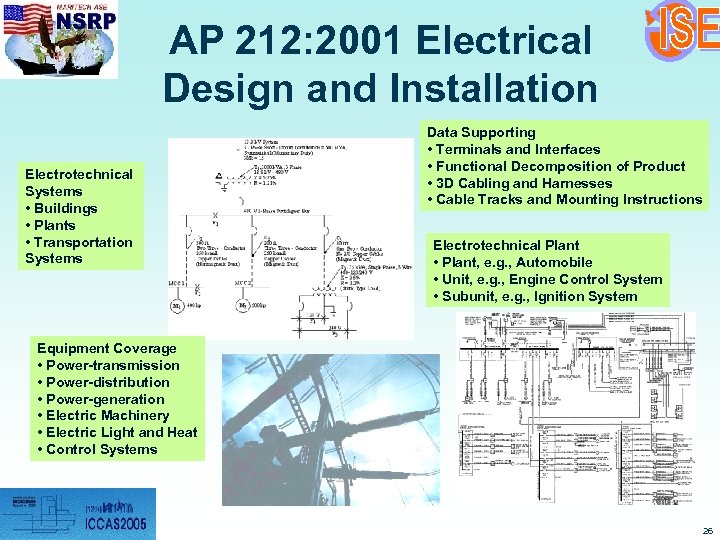

AP 212: 2001 Electrical Design and Installation Electrotechnical Systems • Buildings • Plants • Transportation Systems Data Supporting • Terminals and Interfaces • Functional Decomposition of Product • 3 D Cabling and Harnesses • Cable Tracks and Mounting Instructions Electrotechnical Plant • Plant, e. g. , Automobile • Unit, e. g. , Engine Control System • Subunit, e. g. , Ignition System Equipment Coverage • Power-transmission • Power-distribution • Power-generation • Electric Machinery • Electric Light and Heat • Control Systems 26

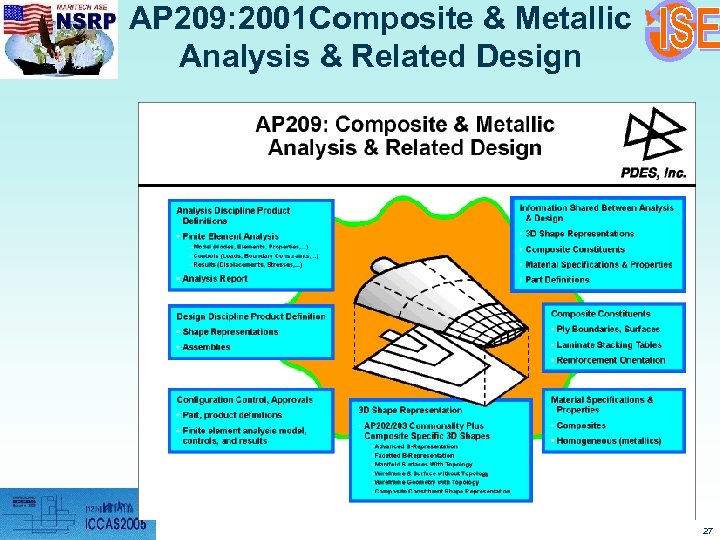

AP 209: 2001 Composite & Metallic Analysis & Related Design 27

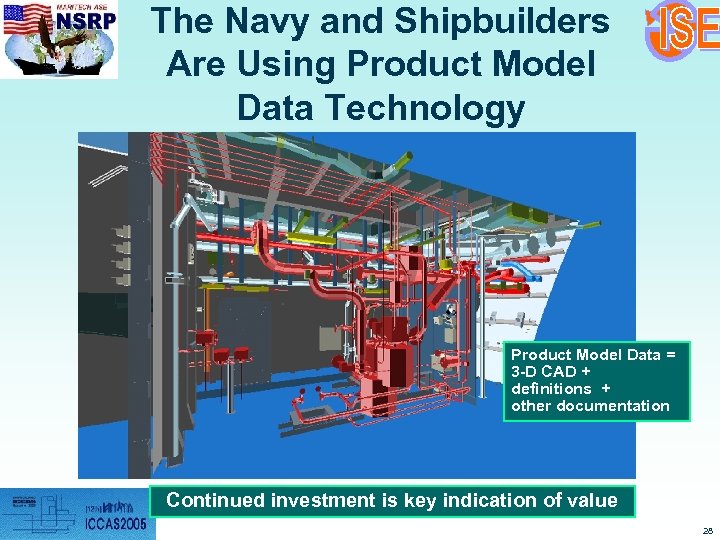

The Navy and Shipbuilders Are Using Product Model Data Technology Product Model Data = 3 -D CAD + definitions + other documentation Continued investment is key indication of value 28

Implementation of the STEP Standards 3/15/2018 29

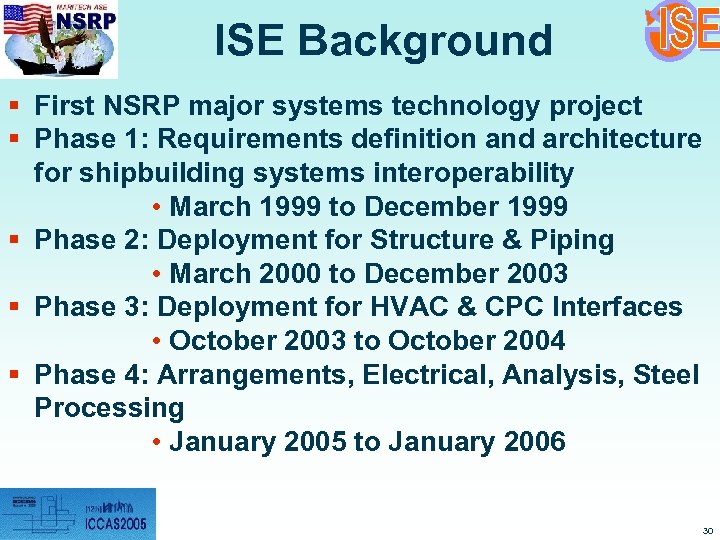

ISE Background § First NSRP major systems technology project § Phase 1: Requirements definition and architecture for shipbuilding systems interoperability • March 1999 to December 1999 § Phase 2: Deployment for Structure & Piping • March 2000 to December 2003 § Phase 3: Deployment for HVAC & CPC Interfaces • October 2003 to October 2004 § Phase 4: Arrangements, Electrical, Analysis, Steel Processing • January 2005 to January 2006 30

ISE Team Participants 31

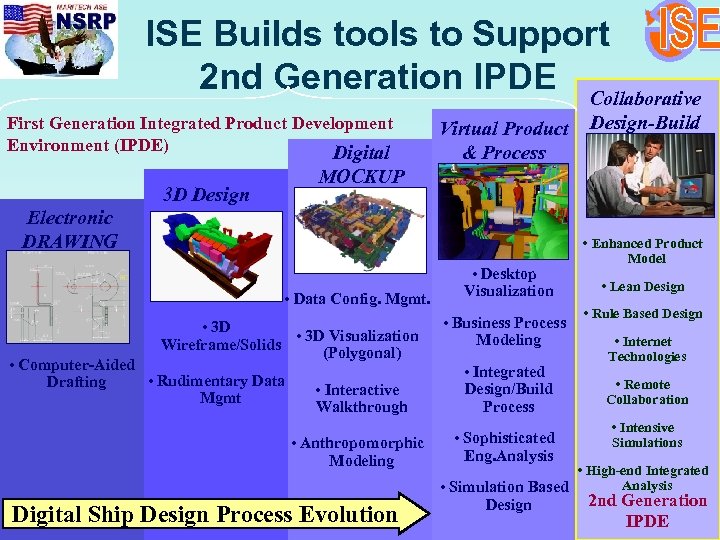

ISE Builds tools to Support 2 nd Generation IPDE Collaborative First Generation Integrated Product Development Environment (IPDE) Digital Virtual Product & Process Design-Build MOCKUP 3 D Design Electronic DRAWING • Data Config. Mgmt. • 3 D Visualization Wireframe/Solids (Polygonal) • Computer-Aided • Rudimentary Data Drafting Mgmt • Desktop Visualization • Business Process Modeling • Interactive Walkthrough • Integrated Design/Build Process • Anthropomorphic Modeling • Sophisticated Eng. Analysis Digital Ship Design Process Evolution • Enhanced Product Model • Lean Design • Rule Based Design • Internet Technologies • Remote Collaboration • Intensive Simulations • High-end Integrated Analysis • Simulation Based Design 2 nd Generation IPDE 32

ISE Project Approach § Develop and demonstrate tools that are low cost • can be selectively used by shipyards to support interoperability • capitalize on XML and related Internet technologies § Flexibility is critical • allow shipyards to transform their data to/from common information model § Drive development of shipbuilding product data standards (e. g. STEP, PLIB) • Construct a single Shipbuilding Information Model • Demonstrate and educate U. S. shipbuilding community 33

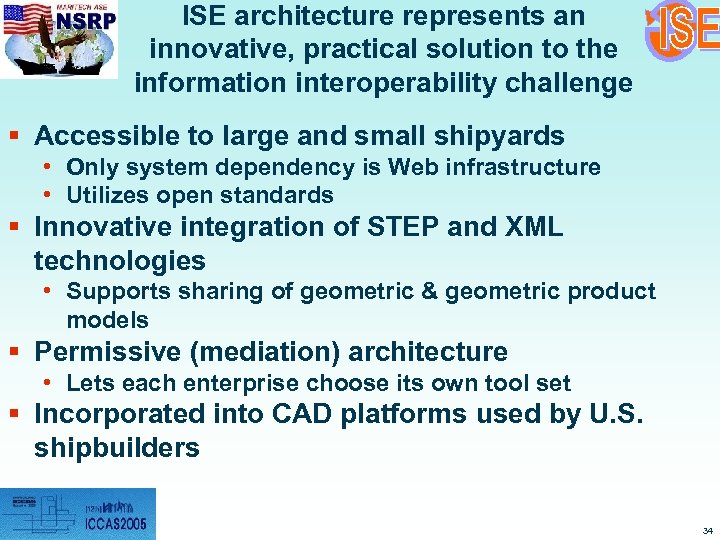

ISE architecture represents an innovative, practical solution to the information interoperability challenge § Accessible to large and small shipyards • Only system dependency is Web infrastructure • Utilizes open standards § Innovative integration of STEP and XML technologies • Supports sharing of geometric & geometric product models § Permissive (mediation) architecture • Lets each enterprise choose its own tool set § Incorporated into CAD platforms used by U. S. shipbuilders 34

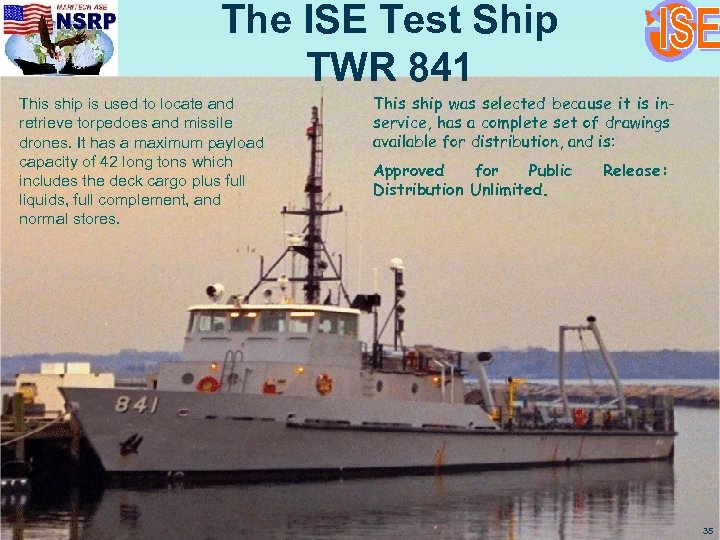

The ISE Test Ship TWR 841 This ship is used to locate and retrieve torpedoes and missile drones. It has a maximum payload capacity of 42 long tons which includes the deck cargo plus full liquids, full complement, and normal stores. This ship was selected because it is inservice, has a complete set of drawings available for distribution, and is: Approved for Public Distribution Unlimited. Release: 35

ISE-2: Moulded Forms, Structure and Pipe 3/15/2018 36

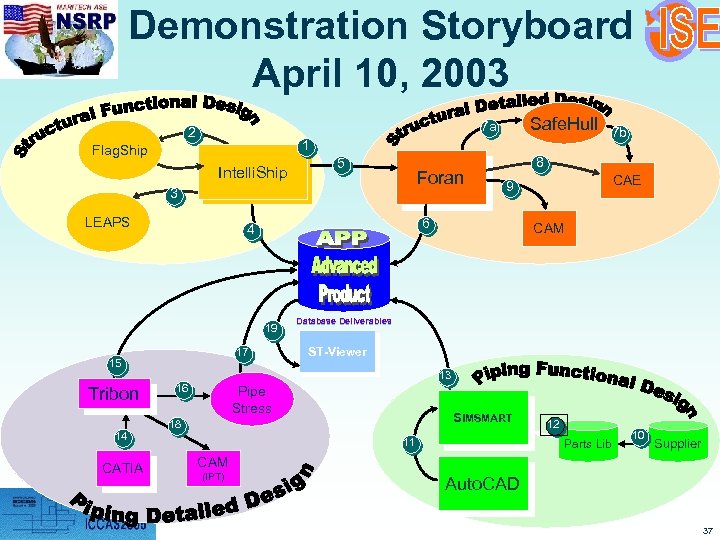

Demonstration Storyboard April 10, 2003 1 Flag. Ship Intelli. Ship 5 Foran 3 LEAPS 17 15 14 CATIA 7 b 8 CAE 9 6 4 19 Tribon Safe. Hull 7 a 2 CAM Database Deliverables ST-Viewer 13 16 Pipe Stress SIMSMART 18 11 12 Parts Lib 10 Supplier CAM (IPT) Auto. CAD 37

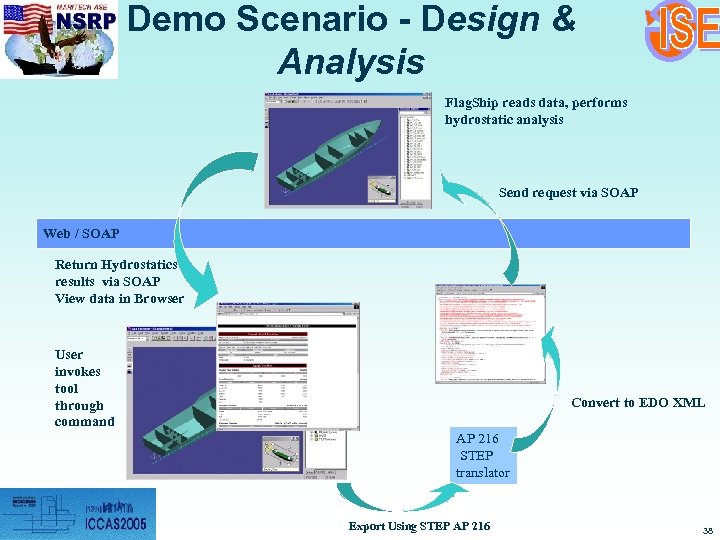

Demo Scenario - Design & Analysis Flag. Ship reads data, performs hydrostatic analysis Send request via SOAP Web / SOAP Return Hydrostatics results via SOAP View data in Browser User invokes tool through command Convert to EDO XML AP 216 STEP translator Export Using STEP AP 216 38

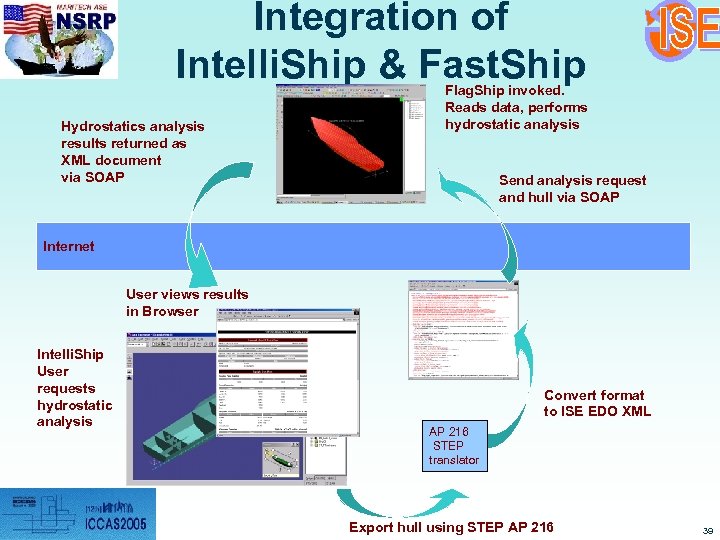

Integration of Intelli. Ship & Fast. Ship Hydrostatics analysis results returned as XML document via SOAP Flag. Ship invoked. Reads data, performs hydrostatic analysis Send analysis request and hull via SOAP Internet User views results in Browser Intelli. Ship User requests hydrostatic analysis Convert format to ISE EDO XML AP 216 STEP translator Export hull using STEP AP 216 39

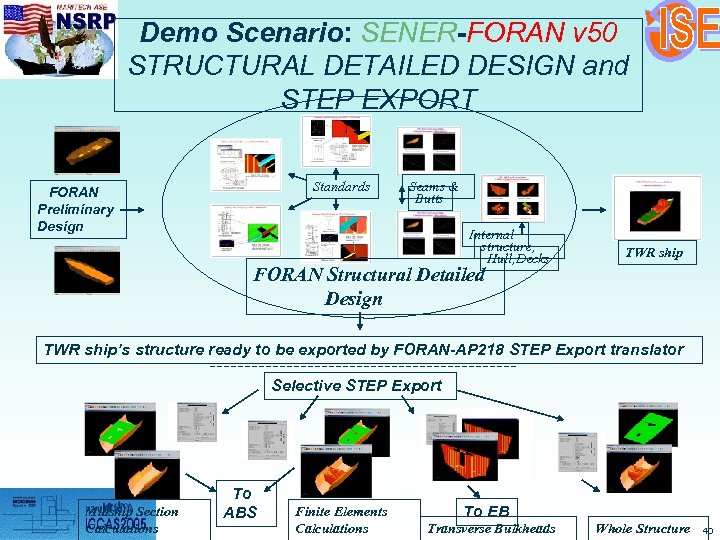

Demo Scenario: SENER-FORAN v 50 STRUCTURAL DETAILED DESIGN and STEP EXPORT Standards FORAN Preliminary Design Seams & Butts Internal structure, Hull, Decks TWR ship FORAN Structural Detailed Design TWR ship’s structure ready to be exported by FORAN-AP 218 STEP Export translator Selective STEP Export Midship Section Calculations To ABS Finite Elements Calculations To EB Transverse Bulkheads Whole Structure 40

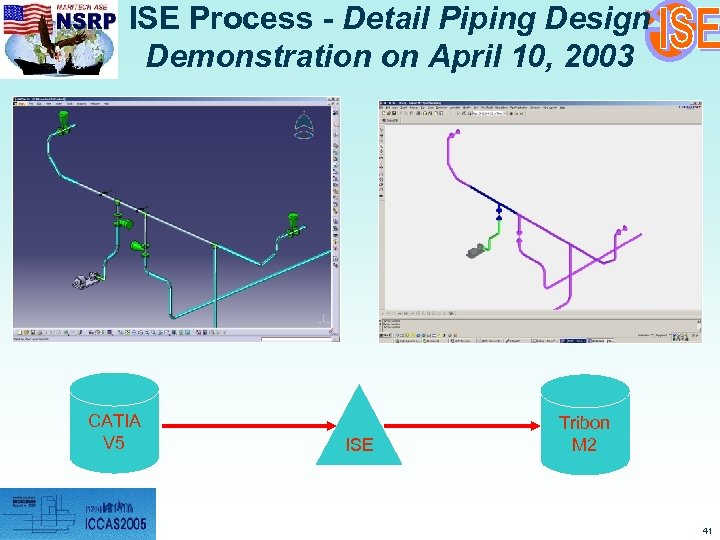

ISE Process - Detail Piping Design Demonstration on April 10, 2003 CATIA V 5 ISE Tribon M 2 41

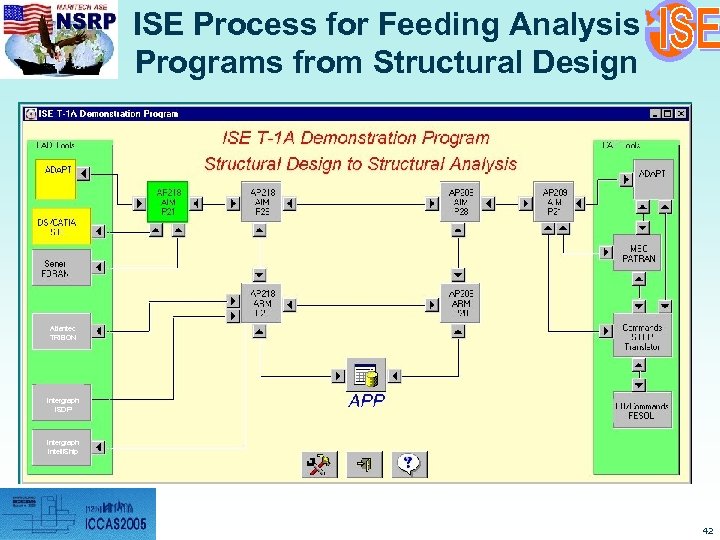

ISE Process for Feeding Analysis Programs from Structural Design Atlantec TRIBON Intergraph ISDP Intergraph Intelli. Ship 42

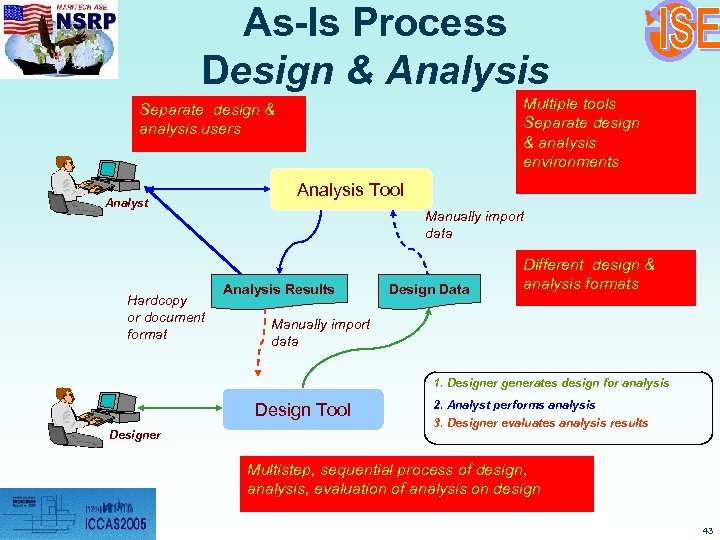

As-Is Process Design & Analysis Multiple tools Separate design & analysis environments Separate design & analysis users Analyst Hardcopy or document format Analysis Tool Manually import data Analysis Results Design Data Different design & analysis formats Manually import data 1. Designer generates design for analysis Design Tool Designer 2. Analyst performs analysis 3. Designer evaluates analysis results Multistep, sequential process of design, analysis, evaluation of analysis on design 43

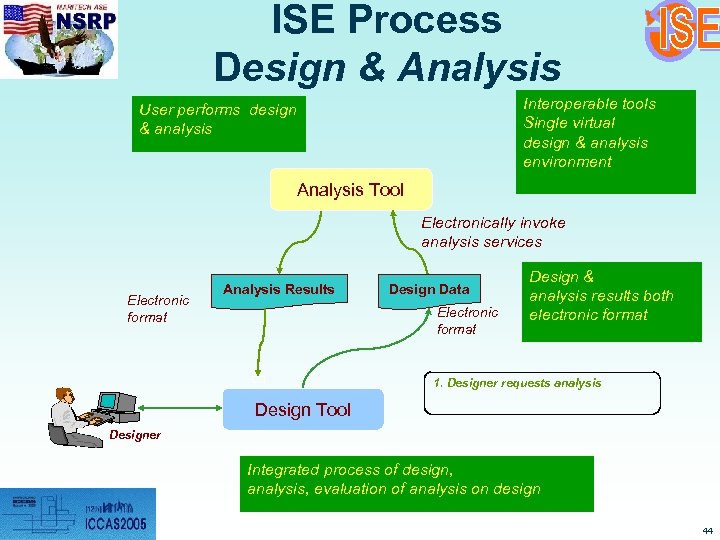

ISE Process Design & Analysis Interoperable tools Single virtual design & analysis environment User performs design & analysis Analysis Tool Electronically invoke analysis services Electronic format Analysis Results Design Data Electronic format Design & analysis results both electronic format 1. Designer requests analysis Design Tool Designer Integrated process of design, analysis, evaluation of analysis on design 44

Simulation and Modeling of Shipboard Piping Systems 3/15/2018 45

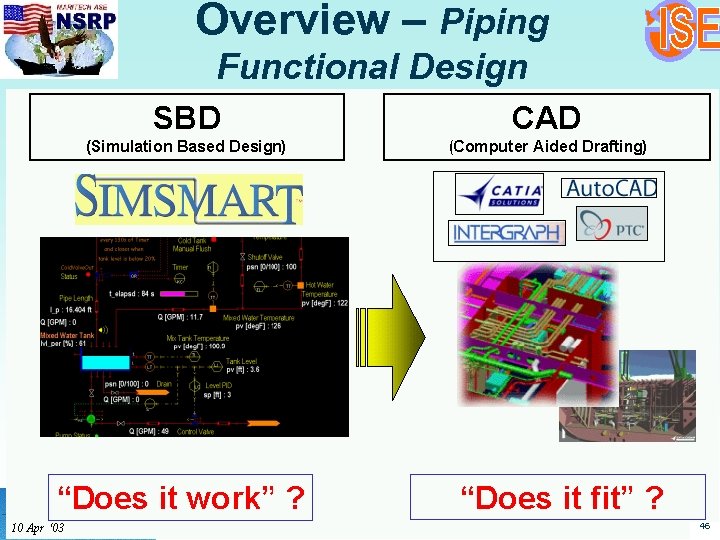

Overview – Piping Functional Design 46 46

Additional Benefits § Validated As-Built model can be used to: • Validate the design and ensure that all requirements are met • Evaluate different design alternatives • Form a basis for creating an On Board Training System (OBTS) and schoolhouse training system • Evaluate refits and upgrades throughout the lifecycle of the vessel • Validate control system algorithms • Test the control system prior to delivery • Perform manning analyses 47

ISE-3: HVAC 3/15/2018 48

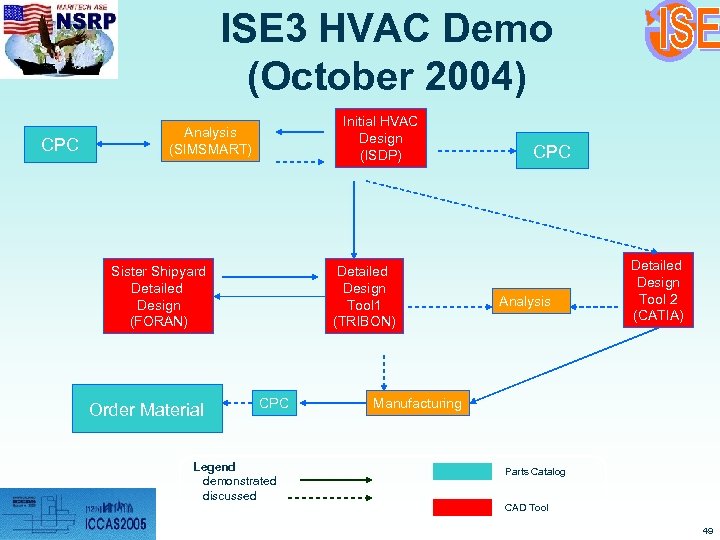

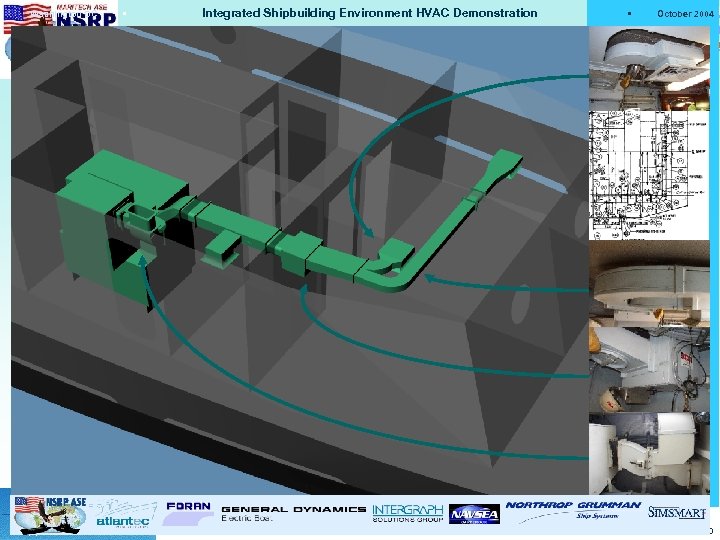

ISE 3 HVAC Demo (October 2004) CPC Initial HVAC Design (ISDP) Analysis (SIMSMART) Sister Shipyard Detailed Design (FORAN) Order Material Detailed Design Tool 1 (TRIBON) CPC Legend demonstrated discussed CPC Analysis Detailed Design Tool 2 (CATIA) Manufacturing Parts Catalog CAD Tool 49

Washington DC • Integrated Shipbuilding Environment HVAC Demonstration • October 2004 50

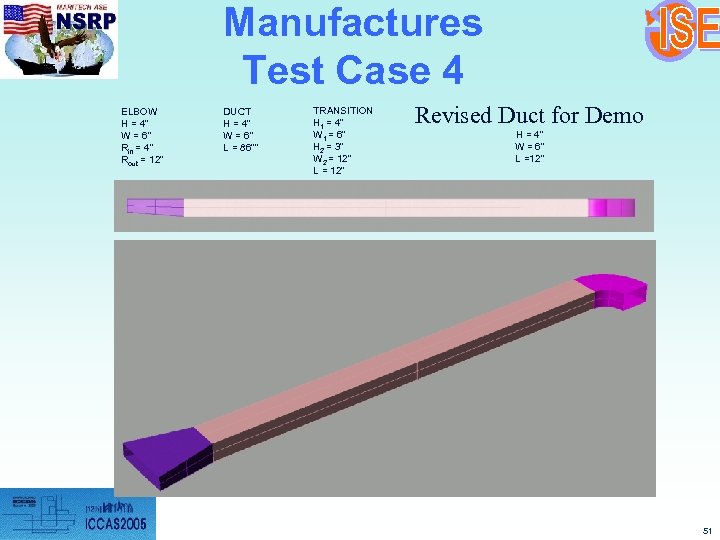

Manufactures Test Case 4 ELBOW H = 4” W = 6” Rin = 4” Rout = 12” DUCT H = 4” W = 6” L = 86”” TRANSITION H 1 = 4” W 1 = 6” H 2 = 3” W 2 = 12” L = 12” Revised Duct for Demo H = 4” W = 6” L =12” 51

ISE-4: Steel Processing, Arrangements, Electrical, and Analysis 3/15/2018 52

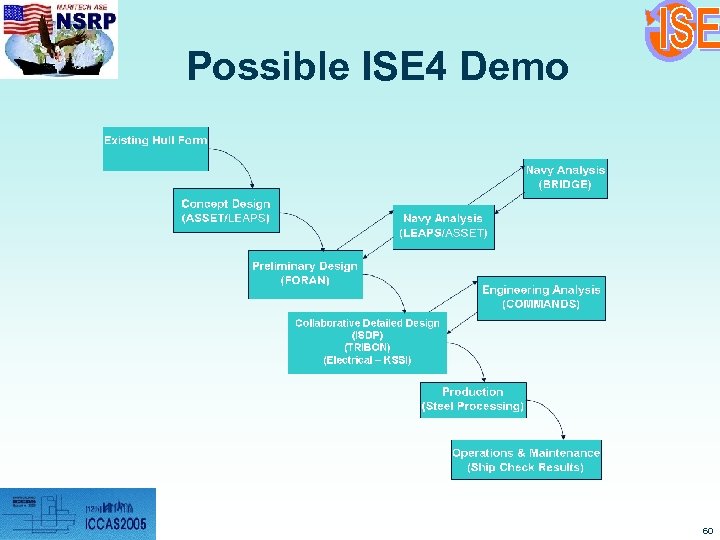

ISE 4 – New NSRP Project § Awarded – January 2005 § Includes • • Ship Arrangements (AP 215) Electrical (AP 212) Analysis (AP 209) Steel Processing (AP 218, 238, 240) 53

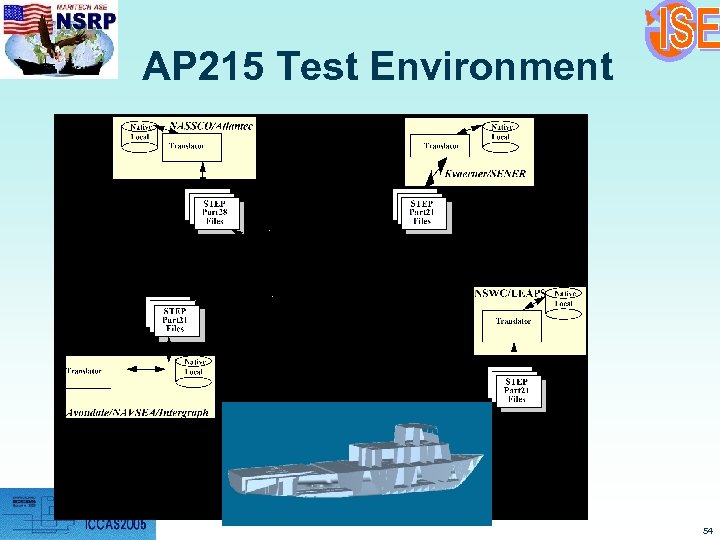

AP 215 Test Environment 54

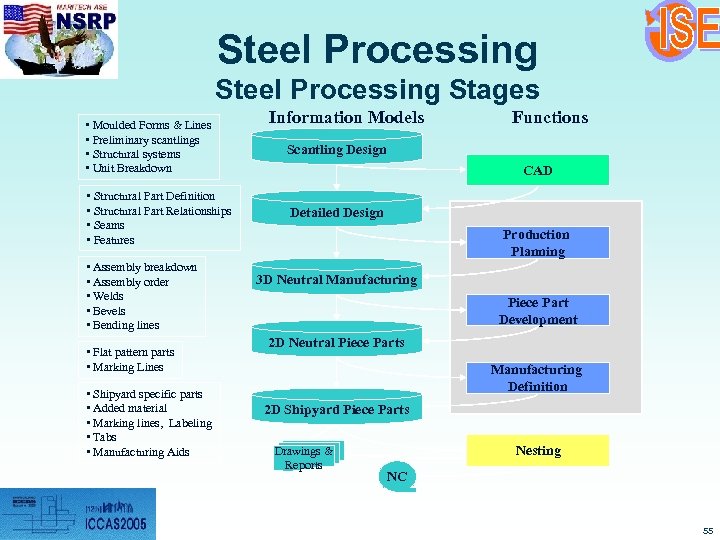

Steel Processing Stages • Moulded Forms & Lines • Preliminary scantlings • Structural systems • Unit Breakdown • Structural Part Definition • Structural Part Relationships • Seams • Features • Assembly breakdown • Assembly order • Welds • Bevels • Bending lines • Flat pattern parts • Marking Lines • Shipyard specific parts • Added material • Marking lines, Labeling • Tabs • Manufacturing Aids Information Models Functions Scantling Design CAD Detailed Design Production Planning 3 D Neutral Manufacturing Piece Part Development 2 D Neutral Piece Parts Manufacturing Definition 2 D Shipyard Piece Parts Drawings & Reports Nesting NC 55

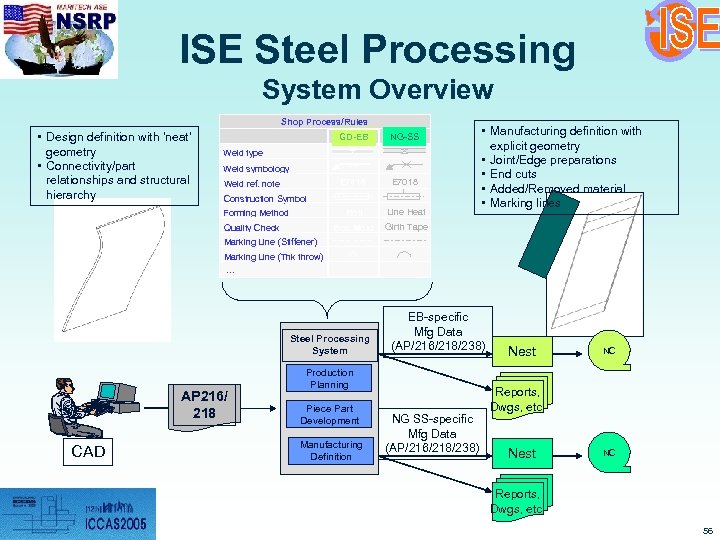

ISE Steel Processing System Overview Shop Process/Rules • Design definition with ‘neat’ geometry • Connectivity/part relationships and structural hierarchy GD-EB NG-SS E 7018 Roll Line Heat Box Mold Girth Tape Weld type Weld symbology Weld ref. note Construction Symbol Forming Method Quality Check • Manufacturing definition with explicit geometry • Joint/Edge preparations • End cuts • Added/Removed material • Marking lines Marking Line (Stiffener) Marking Line (Thk throw) … Steel Processing System AP 216/ 218 CAD EB-specific Mfg Data (AP/216/218/238) Production Planning Piece Part Development Manufacturing Definition NG SS-specific Mfg Data (AP/216/218/238) Nest NC Reports, Dwgs, etc. 56

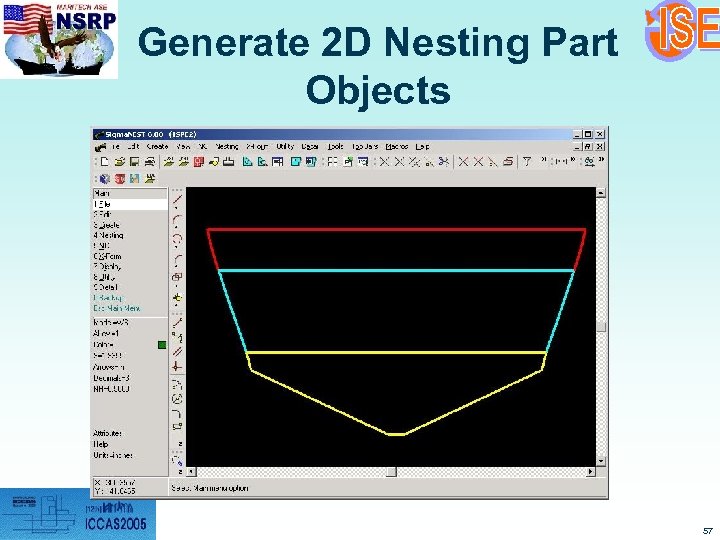

Generate 2 D Nesting Part Objects 57

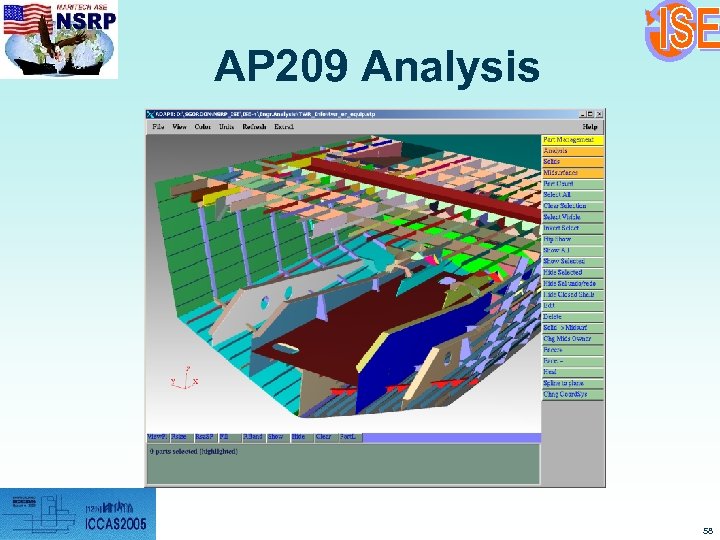

AP 209 Analysis 58

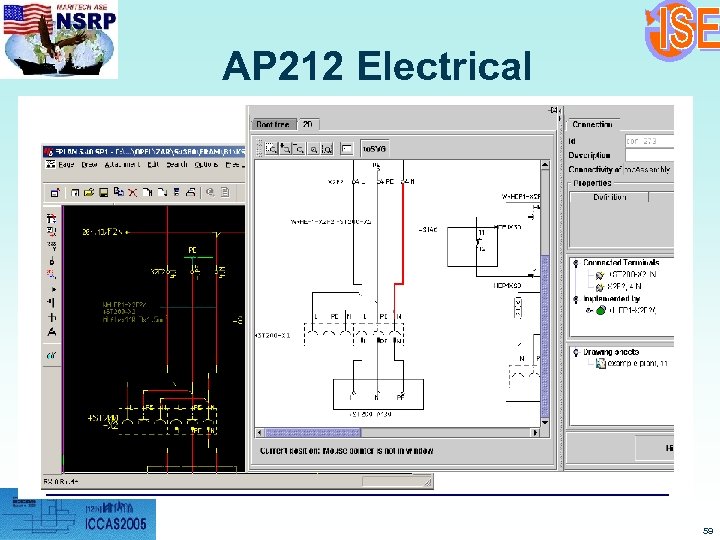

AP 212 Electrical 59

Possible ISE 4 Demo 60

STEP Shipbuilding Implementation Forum § A Testing Forum for the STEP Shipbuilding APs has been established § It is being run under the auspices of the NSRP Systems Technology Panel § It will test and validate implementations of the STEP Shipbuilding APs § Forum began in 2004 with AP 216 testing 61

Summary 3/15/2018 62

ISE Tools § Tools developed by the ISE Project are made available on the Web at: www. isetools. org § These include: • Formal information requirements published – – Ship Piping Ship Structures Ship HVAC CPC Interfaces • Translator generators for custom representations • XML schema generators – ISO 10303 -28 ed 2 • Automated test frameworks for conformance testing 63

Implement in Production § The goal of current and future efforts is to make these techniques and tools available in production and to all U. S. shipyards • STEP Shipbuilding Translators • XML Tools • Common Parts Catalog Interfaces § A Website is being established to contain the relevant software tools, schemas, etc. as provided by the ISE Project • www. isetools. org 64

Summary § ISE 1, 2 & 3 has successfully demonstrated the potential of standards based data exchange to LEAN design and construction processes for HVAC, molded forms, structures and piping. § ISE 4 is looking at Electrical, Ship Arrangements, Steel Processing, Analysis § Two major challenges lie ahead of us: • Commercialization of this technology • Continuing to prototype standards based data exchange in other application areas such as system engineering 65

Goal : Implement in Production § The ISE Project has developed tools and demonstrated interoperability between shipyards in the areas of: • • Structure Piping HVAC Common Parts Catalog Interfaces § The goal of current and future efforts is to make these techniques and tools available in production and to all U. S. shipyards • STEP Shipbuilding Translators • XML Tools • Common Parts Catalog Interfaces § A Website has been established to contain the relevant software tools, schemas, etc. as provided by the ISE Project • www. isetools. org 66

Conclusions § These testing, modeling, and simulation efforts are part of an attempt to develop a suite of product model data exchange tools that will enable U. S. Shipyards to become more productive § These efforts revolve around implementation of the ISO 10303 STEP Shipbuilding standards § The APs that enable these exchanges have completed their development and approval as International Standards § The focus is now shifting to testing and validating their implementations 67

Conclusions (cont’d) § In order to increase the availability and lower the price of production ready tools: • The ship owner / operator needs to insist that data be delivered in a system neutral format • The shipbuilder needs to insist that STEP functionality be an integral part of product § The next challenge is to move this technology into the mainstream and that the technology is mature enough to transition into commercial CAD and Product Modeling products 68

DISCUSSION 3/15/2018 69

0591ed73c7c673a14facfe3593133bb3.ppt