ae0ee0c42a05fa5828cbee125b1929a1.ppt

- Количество слайдов: 62

Improving Electrical System Reliability © 2002 Eaton Corporation. All rights reserved.

Blackout News Headlines

Situation Analysis l Fact # 1: The aggregate economic loss of electrical power disruptions has climbed to more than $100 billion per year or more than 1% of U. S. Gross Domestic Product! n Recent events have demonstrated the fragility of our aging power grid. With transmission networks operating close to their stability limits, minor faults can cause cascading outages. Capacity limitations in several regions can lead to economic losses that cascade through the economy, causing loses for not only residential, but also commercial and industrial institutions.

Situation Analysis (Page 2) l Fact # 2: The recent power outages have been in the works for the last several years! n U. S utilities have always taken pride in their uptime and system performance. Over the past several years, due to industry-wide deregulation, market pressures for rate reductions, business restructuring and downsizing, overall investment in infrastructure has not been at traditional levels. The decoupling of transmission, distribution and generation has caused disruption in traditional business models and industry workings (i. e. the vertically integrated utility no longer exists in deregulated markets)

Situational Analysis (Page 3) l Fact # 3: De-regulation has contributed to loss of stability. n When the Federal Energy Regulatory Commission dictated that the electrical transmission network was to be opened to the free market, it allowed anyone to transmit power over any transmission line. This allowed generators outside a customer’s service area to bid on a distant customer’s power requirements and be guaranteed access to that customer over the transmission system. As a result, the owners of the transmission lines lost some of their ability to maintain stability since these lines now carry power generated outside their control. As demand has continued to increase at an average 2% per year and because few will accept new transmission lines in their backyard, grid stability continues to degrade over time.

Situational Analysis (Page 4) l Fact # 4: The 2000 dotcom implosion and the resultant relaxation of electrical demand has temporarily relaxed the demands placed on electrical transmission system, but the problem remains. n The recent retraction of the economy has reduced electrical demand temporarily. However little or no new transmission has been constructed during this economic downturn. When electrical demand returns to historic levels, we can only expect the problem to return and even become worse as the economy expands to more robust levels.

Conclusion l This problem will worsen before it improves l Companies must take action themselves

What Can Be Done? l Protect Yourself From External Problems 1. Install Local Backup Power • Eaton/CAT Solutions - Natural Gas, LPG, Diesel from 18 k. W to 2000+ MW 2. Install Voltage Correction • • • Eaton SAG Correction Equipment Eaton Supplied UPS Eaton Capacitors 3. Cutler-Hammer Engineering Services and Systems (CHESS) • • Audits Site Supervision, Equipment Commissioning Turnkey Installation

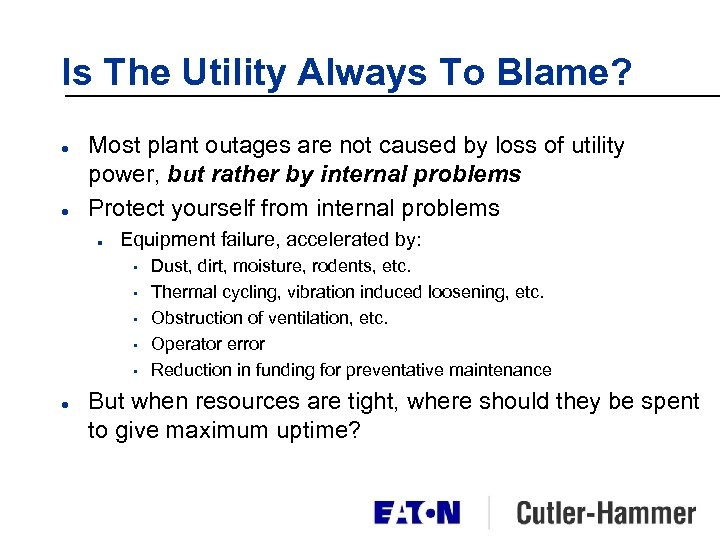

Is The Utility Always To Blame? l l Most plant outages are not caused by loss of utility power, but rather by internal problems Protect yourself from internal problems n Equipment failure, accelerated by: • • • l Dust, dirt, moisture, rodents, etc. Thermal cycling, vibration induced loosening, etc. Obstruction of ventilation, etc. Operator error Reduction in funding for preventative maintenance But when resources are tight, where should they be spent to give maximum uptime?

What Can Be Done? l Protect Yourself From Internal Problems 1. Cutler-Hammer Engineering Services and Systems (CHESS) • • Harmonics Study • Site Survey (e. g. evaluation of on-site generation, UPS, calculation of reliability of existing system, etc. ) • 2. Coordination Study Thermography Predictive Diagnostics • Early warning of pending failure in MV Equipment

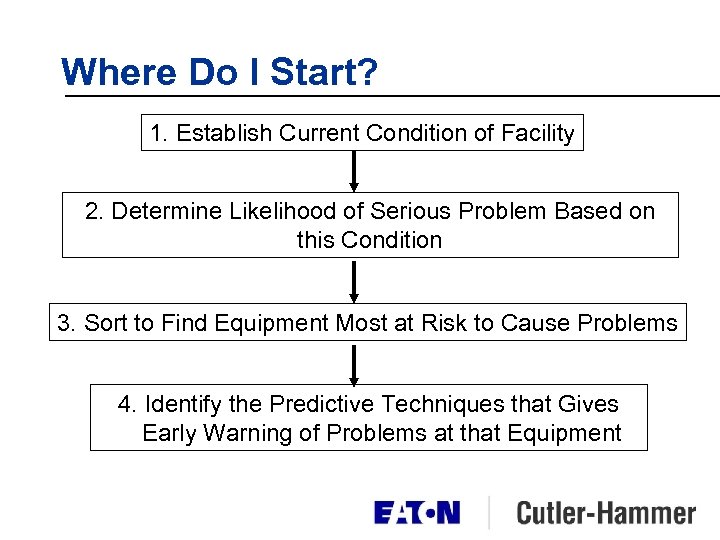

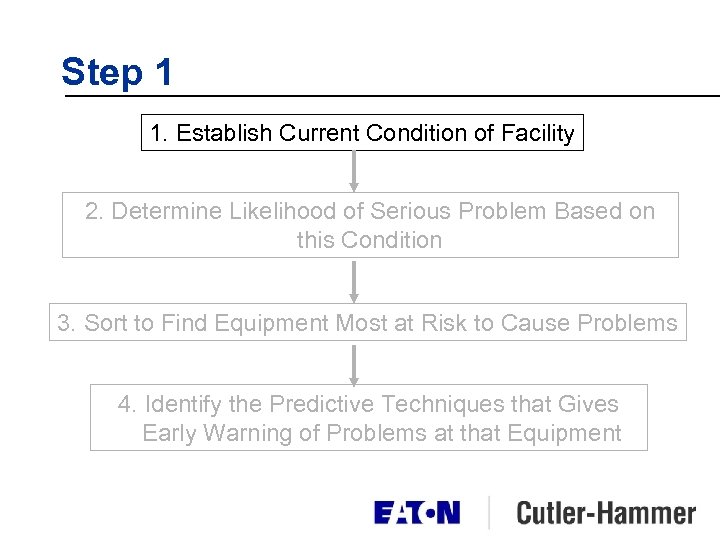

Where Do I Start? 1. Establish Current Condition of Facility 2. Determine Likelihood of Serious Problem Based on this Condition 3. Sort to Find Equipment Most at Risk to Cause Problems 4. Identify the Predictive Techniques that Gives Early Warning of Problems at that Equipment

Internal Problems are Ticking Time Bombs… l The ‘Quiet Crisis’ Term created by Paul Hubbel, Deputy Director, Facilities and Services, Marine Corps. Government Executive Magazine, Sept 2002. When he was asked “why isn’t preventative maintenance adhered to more closely in government facilities? ” “We call it the ‘quiet crisis’ because a lot of maintenance problems take time to occur and are noticed until damage occurs”.

Your Facility? l l Okay, so maybe some think they may be more reactive than proactive… but what about you? What happens if the power goes out at your facility for an extended period of time? For example, we would expect that critical facilities (such as prisons) won’t have power outage problems!

Maximum Security Prison l WASCO State Prison, California Department of Corrections “Wasco suffered an electrical failure in April 1999 that caused a total power outage lasting almost seven hoursa problem that Wasco could have prevented had management made certain that staff repaired previously identified flaws in the electrical system. ” California State Auditor/Bureau of State Audits Summary of Report Number 99118 - October 1999

Municipal Detention Center l Yolo County Sheriff’s Detention Facility, California On Tuesday, July 9 th 2002, the Sheriff’s Department experienced a power outage. Normally, this is not a major problem as our backup generator provides electrical power in the event of an outage. However, this was not the case on July 9 th, and the detention facilities did not have electrical power four hours. ” http: //www. yolocountysheriff. com/myweb 5/Sheriff%20 Final/2002%20 Commendation%20 Awards/Tina%20 Day. pdf

State Penitentiary l Riverside Correctional Facility, Michigan “…however, in April 1998, RCF lost its main power source and the emergency generator failed to start. This resulted in an emergency situation for RCF. ” Performance Audit, Michigan Department of Corrections, Feb 1999

Why is Maintenance Skipped? l l l Clearly there are problems, but why? Budget Cuts / Management Redirection of Maintenance Funds This results in “Crisis Mode Operation” or “Fix What’s Broke and Skip the Rest” mentality But how do you guess what will break next and where money should be targeted? Is there an analytical way of targeting scarce resources?

Step 1 1. Establish Current Condition of Facility 2. Determine Likelihood of Serious Problem Based on this Condition 3. Sort to Find Equipment Most at Risk to Cause Problems 4. Identify the Predictive Techniques that Gives Early Warning of Problems at that Equipment

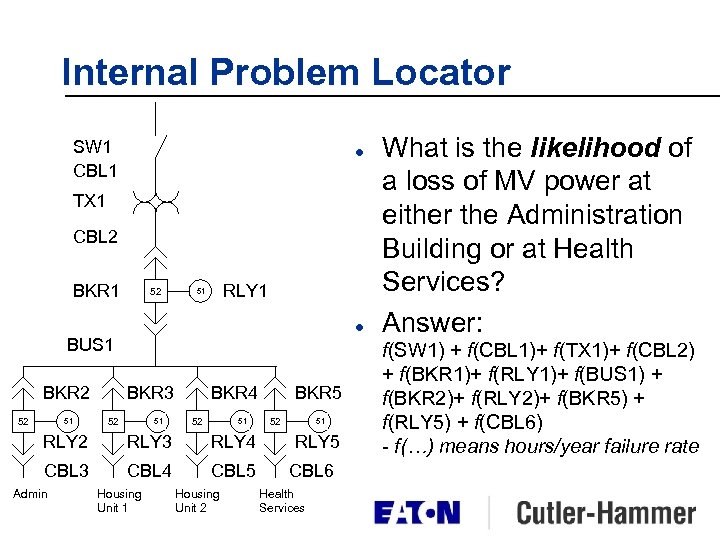

Internal Problem Locator SW 1 CBL 1 l TX 1 CBL 2 BKR 1 52 RLY 1 51 l BUS 1 BKR 2 52 51 BKR 3 52 51 BKR 4 52 51 RLY 2 RLY 3 RLY 4 CBL 3 CBL 4 CBL 5 Admin Housing Unit 1 Housing Unit 2 BKR 5 52 51 RLY 5 CBL 6 Health Services What is the likelihood of a loss of MV power at either the Administration Building or at Health Services? Answer: f(SW 1) + f(CBL 1)+ f(TX 1)+ f(CBL 2) + f(BKR 1)+ f(RLY 1)+ f(BUS 1) + f(BKR 2)+ f(RLY 2)+ f(BKR 5) + f(RLY 5) + f(CBL 6) - f(…) means hours/year failure rate

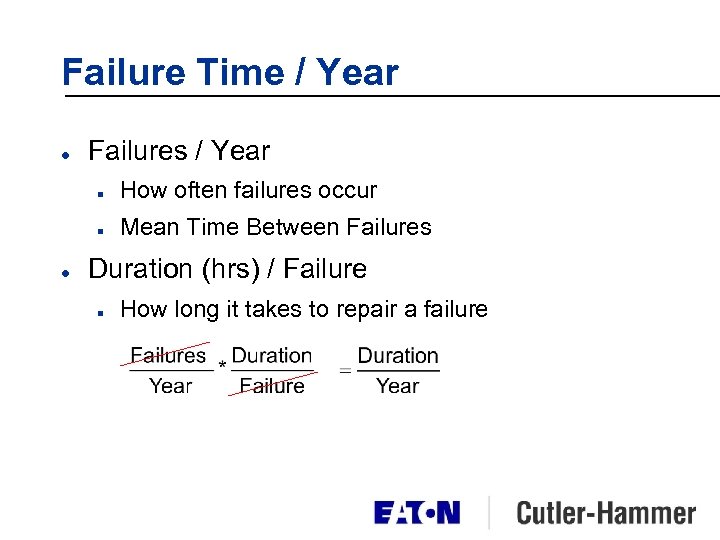

Failure Time / Year l Failures / Year n n l How often failures occur Mean Time Between Failures Duration (hrs) / Failure n How long it takes to repair a failure

Step 2 1. Establish Current Condition of Facility 2. Determine Likelihood of Serious Problem Based on this Condition 3. Sort to Find Equipment Most at Risk to Cause Problems 4. Identify the Predictive Techniques that Gives Early Warning of Problems at that Equipment

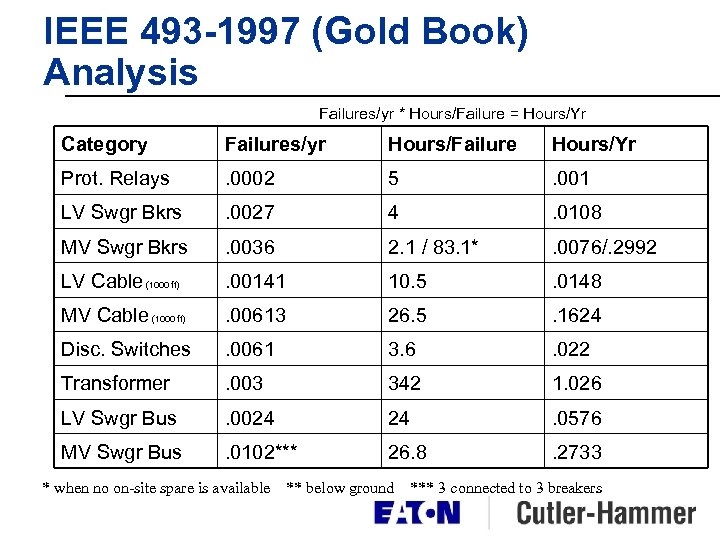

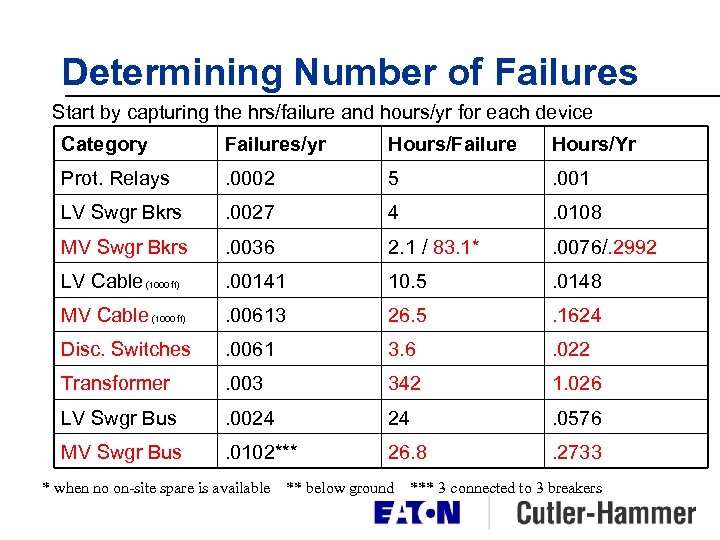

IEEE 493 -1997 (Gold Book) Analysis IEEE Std 493 -1997, Table 7 -1 Failures/yr * Hours/Failure = Hours/Yr Category Failures/yr Hours/Failure Hours/Yr Prot. Relays . 0002 5 . 001 LV Swgr Bkrs . 0027 4 . 0108 MV Swgr Bkrs . 0036 2. 1 / 83. 1* . 0076/. 2992 LV Cable (1000 ft) . 00141 10. 5 . 0148 MV Cable (1000 ft) . 00613 26. 5 . 1624 Disc. Switches . 0061 3. 6 . 022 Transformer . 003 342 1. 026 LV Swgr Bus . 0024 24 . 0576 MV Swgr Bus . 0102*** 26. 8 . 2733 * when no on-site spare is available ** below ground *** 3 connected to 3 breakers

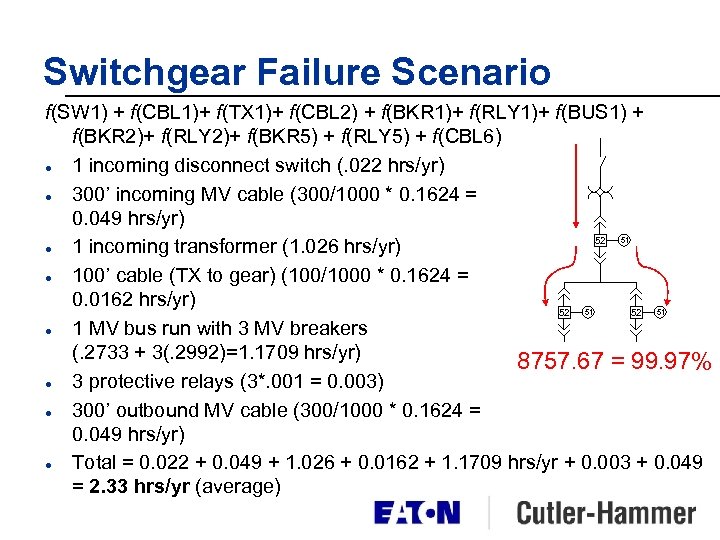

Switchgear Failure Scenario f(SW 1) + f(CBL 1)+ f(TX 1)+ f(CBL 2) + f(BKR 1)+ f(RLY 1)+ f(BUS 1) + f(BKR 2)+ f(RLY 2)+ f(BKR 5) + f(RLY 5) + f(CBL 6) l 1 incoming disconnect switch (. 022 hrs/yr) l 300’ incoming MV cable (300/1000 * 0. 1624 = 0. 049 hrs/yr) 52 l 1 incoming transformer (1. 026 hrs/yr) l 100’ cable (TX to gear) (100/1000 * 0. 1624 = 0. 0162 hrs/yr) 52 52 l 1 MV bus run with 3 MV breakers (. 2733 + 3(. 2992)=1. 1709 hrs/yr) ? % – 2. 33 8757. 67 = 99. 97% 8760 uptime l 3 protective relays (3*. 001 = 0. 003) l 300’ outbound MV cable (300/1000 * 0. 1624 = 0. 049 hrs/yr) l Total = 0. 022 + 0. 049 + 1. 026 + 0. 0162 + 1. 1709 hrs/yr + 0. 003 + 0. 049 = 2. 33 hrs/yr (average) 51 51 51

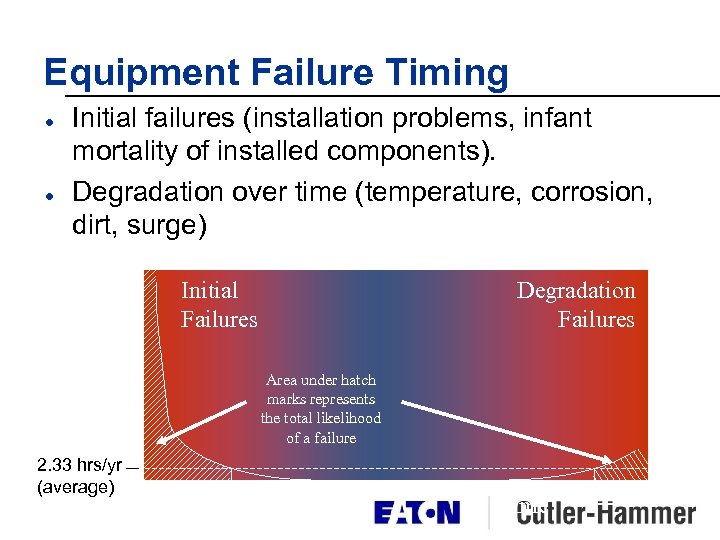

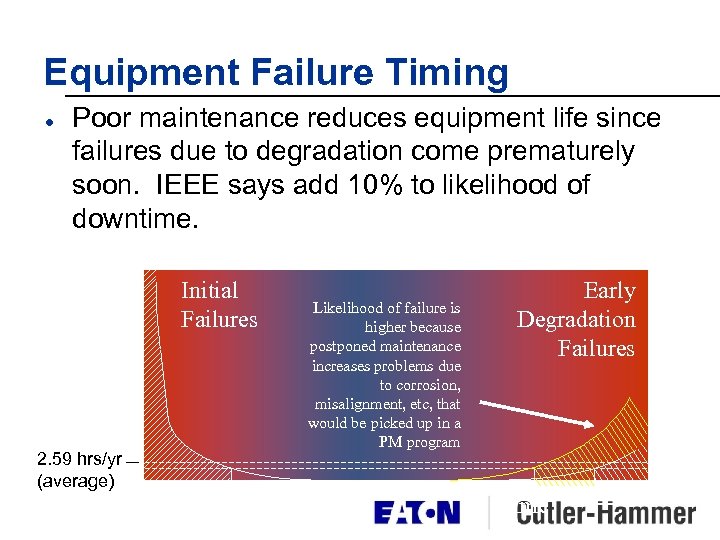

Equipment Failure Timing l l Initial failures (installation problems, infant mortality of installed components). Degradation over time (temperature, corrosion, dirt, surge) Likelihood Of Failure 2. 33 hrs/yr (average) Initial Failures Degradation Failures Area under hatch marks represents the total likelihood of a failure Time

Equipment Failure Timing l Poor maintenance reduces equipment life since failures due to degradation come prematurely soon. IEEE says add 10% to likelihood of downtime. Likelihood Of Failure 2. 59 hrs/yr (average) Initial Failures Likelihood of failure is higher because postponed maintenance increases problems due to corrosion, misalignment, etc, that would be picked up in a PM program Early Degradation Failures Time

Results l Fair Maintenance = 2. 59 hrs/year downtime l Good Maintenance = 2. 33 hrs/year downtime l 2. 59 – 2. 33 = 0. 26 hr/yr less downtime l 16 minutes per year more downtime Is that worth spending any time fixing? … but this is only a simple example

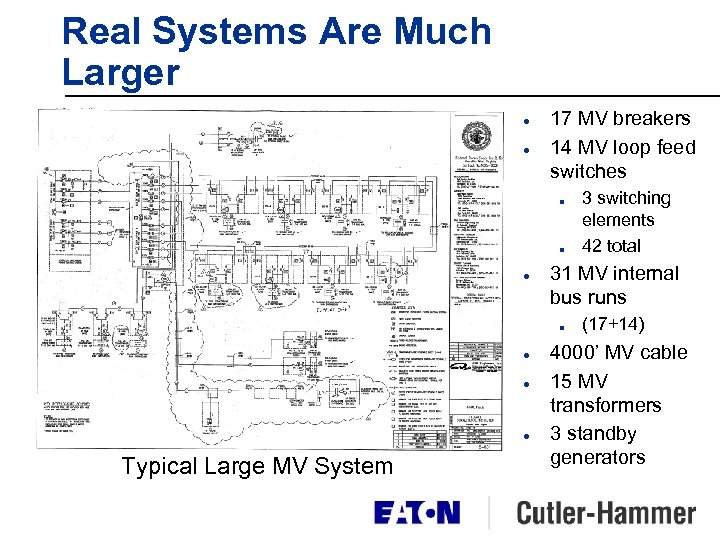

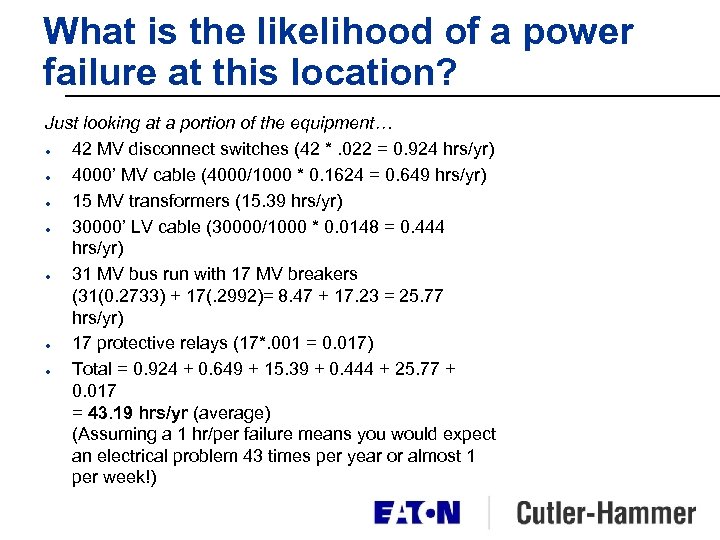

Real Systems Are Much Larger l l 17 MV breakers 14 MV loop feed switches n n l 31 MV internal bus runs n l l l Typical Large MV System 3 switching elements 42 total (17+14) 4000’ MV cable 15 MV transformers 3 standby generators

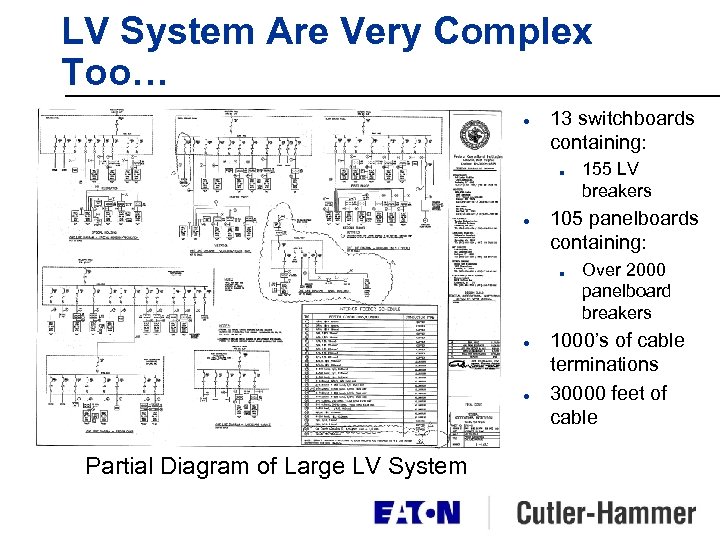

LV System Are Very Complex Too… l 13 switchboards containing: n l 105 panelboards containing: n l l Partial Diagram of Large LV System 155 LV breakers Over 2000 panelboard breakers 1000’s of cable terminations 30000 feet of cable

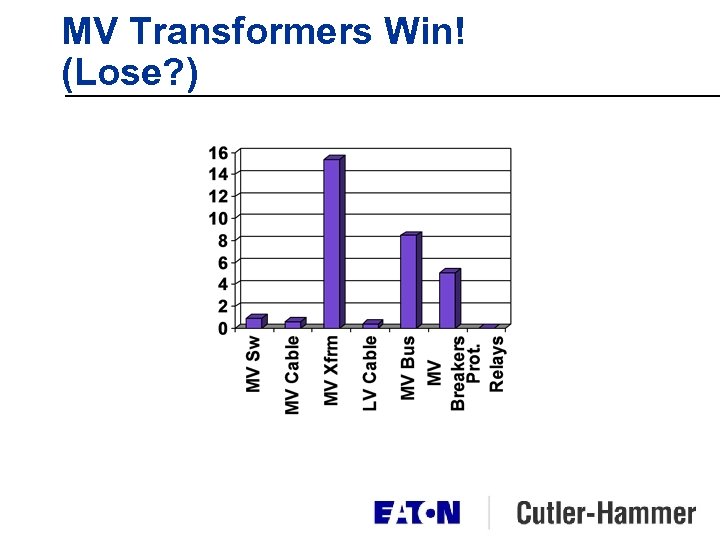

What is the likelihood of a power failure at this location? Just looking at a portion of the equipment… l 42 MV disconnect switches (42 *. 022 = 0. 924 hrs/yr) l 4000’ MV cable (4000/1000 * 0. 1624 = 0. 649 hrs/yr) l 15 MV transformers (15. 39 hrs/yr) l 30000’ LV cable (30000/1000 * 0. 0148 = 0. 444 hrs/yr) l 31 MV bus run with 17 MV breakers (31(0. 2733) + 17(. 2992)= 8. 47 + 17. 23 = 25. 77 hrs/yr) l 17 protective relays (17*. 001 = 0. 017) l Total = 0. 924 + 0. 649 + 15. 39 + 0. 444 + 25. 77 + 0. 017 = 43. 19 hrs/yr (average) (Assuming a 1 hr/per failure means you would expect an electrical problem 43 times per year or almost 1 per week!)

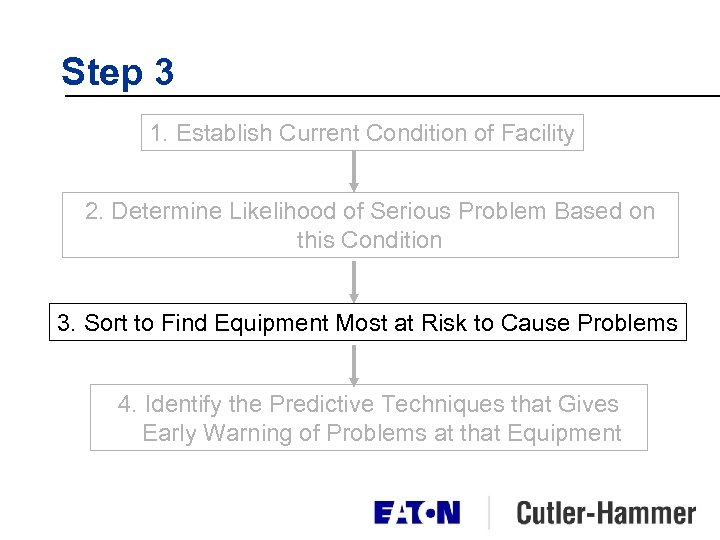

Step 3 1. Establish Current Condition of Facility 2. Determine Likelihood of Serious Problem Based on this Condition 3. Sort to Find Equipment Most at Risk to Cause Problems 4. Identify the Predictive Techniques that Gives Early Warning of Problems at that Equipment

MV Transformers Win! (Lose? )

Step 4 1. Establish Current Condition of Facility 2. Determine Likelihood of Serious Problem Based on this Condition 3. Sort to Find Equipment Most at Risk to Cause Problems 4. Identify the Predictive Techniques that Gives Early Warning of Problems at that Equipment

Now What? l l l We now know how to figure “how many minutes of outage will occur each year” for each device. But how do we reduce that value? We can recognize that failures can be predicted if we recognize the early warning signs n l The so-called “Predictive Indicator” Once we know that, we can identify the likely cause and fix the problem before it is serious.

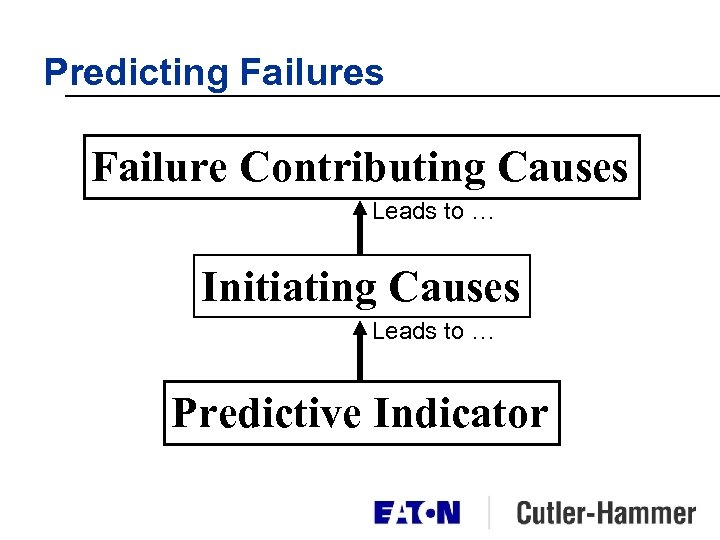

Predicting Failures Failure Contributing Causes Leads to … Initiating Causes Leads to … Predictive Indicator

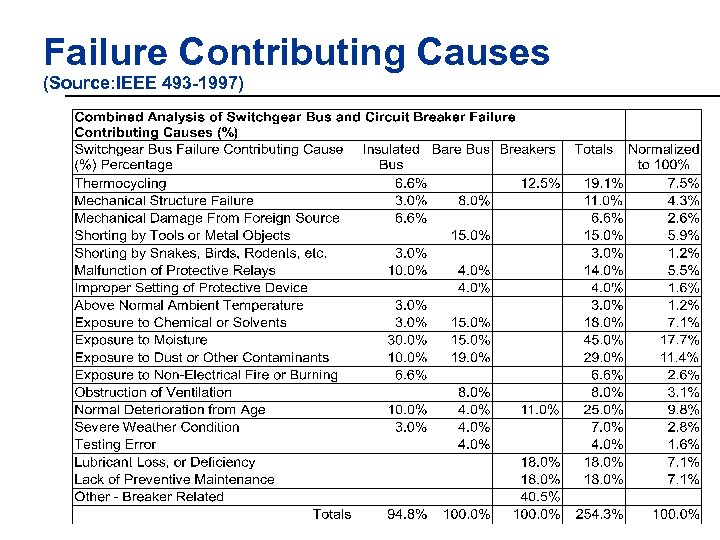

Failure Contributing Causes (Source: IEEE 493 -1997)

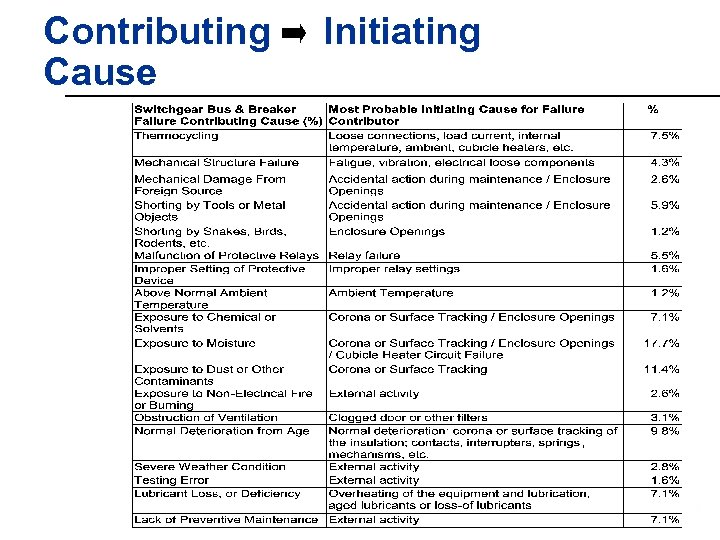

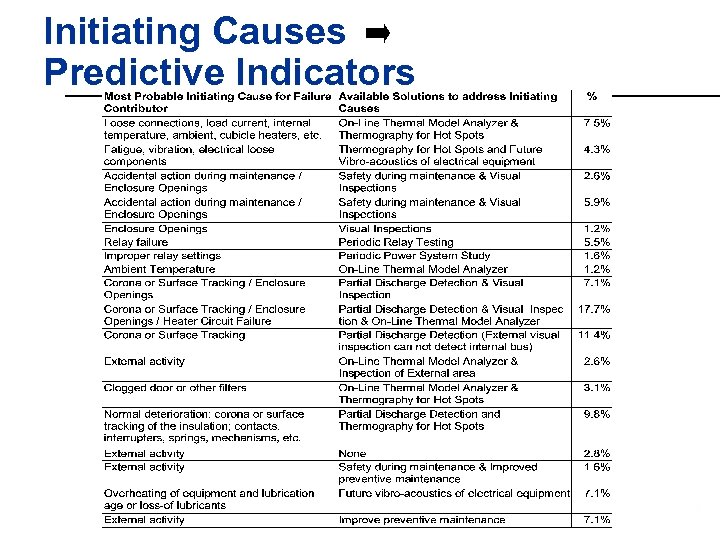

Contributing Cause Initiating

Initiating Causes Predictive Indicators

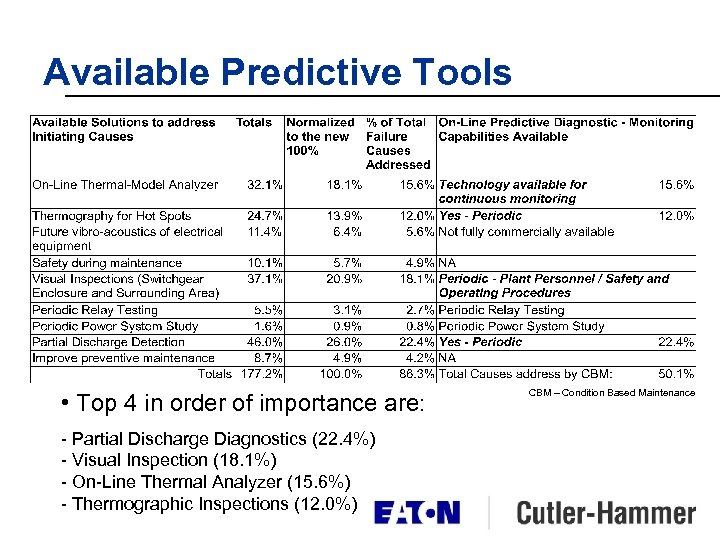

Available Predictive Tools • Top 4 in order of importance are: - Partial Discharge Diagnostics (22. 4%) - Visual Inspection (18. 1%) - On-Line Thermal Analyzer (15. 6%) - Thermographic Inspections (12. 0%) CBM – Condition Based Maintenance

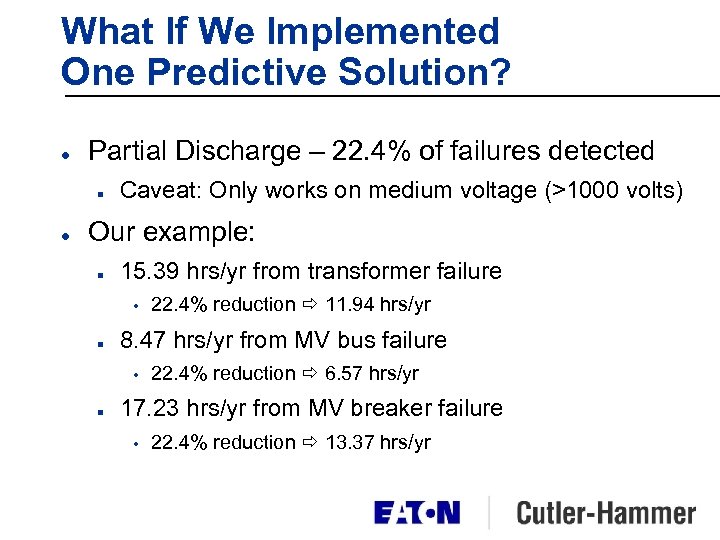

What If We Implemented One Predictive Solution? l Partial Discharge – 22. 4% of failures detected n l Caveat: Only works on medium voltage (>1000 volts) Our example: n 15. 39 hrs/yr from transformer failure • n 8. 47 hrs/yr from MV bus failure • n 22. 4% reduction 11. 94 hrs/yr 22. 4% reduction 6. 57 hrs/yr 17. 23 hrs/yr from MV breaker failure • 22. 4% reduction 13. 37 hrs/yr

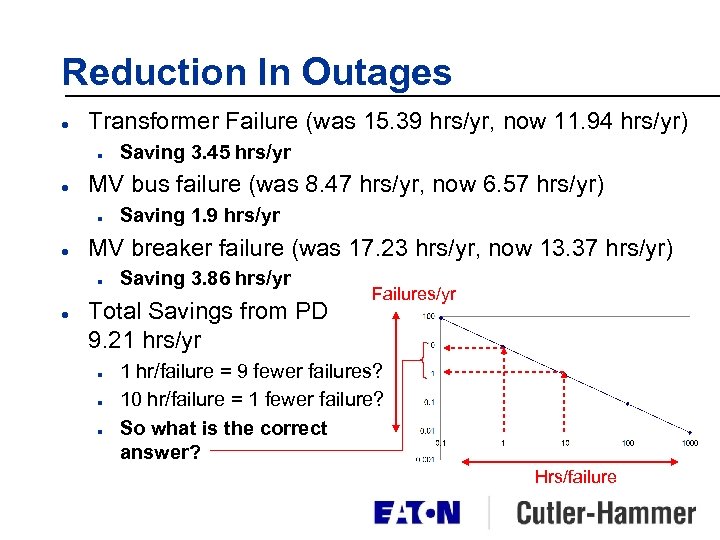

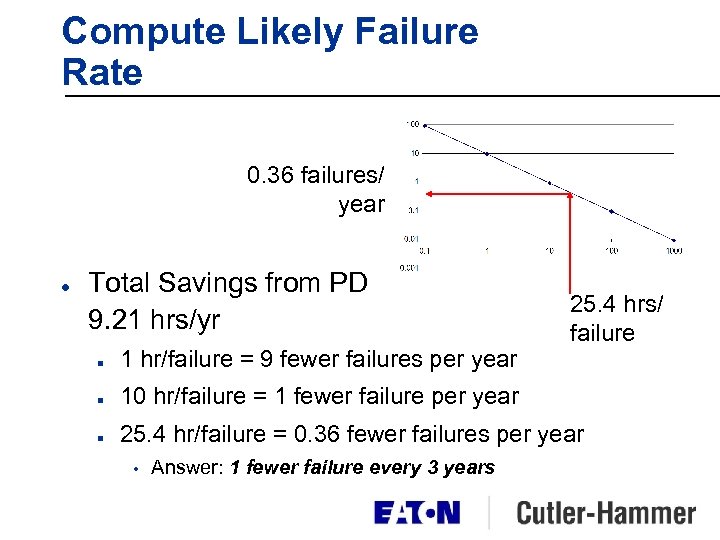

Reduction In Outages l Transformer Failure (was 15. 39 hrs/yr, now 11. 94 hrs/yr) n l MV bus failure (was 8. 47 hrs/yr, now 6. 57 hrs/yr) n l Saving 1. 9 hrs/yr MV breaker failure (was 17. 23 hrs/yr, now 13. 37 hrs/yr) n l Saving 3. 45 hrs/yr Saving 3. 86 hrs/yr Total Savings from PD 9. 21 hrs/yr n n n Failures/yr 1 hr/failure = 9 fewer failures? 10 hr/failure = 1 fewer failure? So what is the correct answer? Hrs/failure

Determining Number of Failures Start by capturing the hrs/failure and hours/yr for each device Category Failures/yr Hours/Failure Hours/Yr Prot. Relays . 0002 5 . 001 LV Swgr Bkrs . 0027 4 . 0108 MV Swgr Bkrs . 0036 2. 1 / 83. 1* . 0076/. 2992 LV Cable (1000 ft) . 00141 10. 5 . 0148 MV Cable (1000 ft) . 00613 26. 5 . 1624 Disc. Switches . 0061 3. 6 . 022 Transformer . 003 342 1. 026 LV Swgr Bus . 0024 24 . 0576 MV Swgr Bus . 0102*** 26. 8 . 2733 * when no on-site spare is available ** below ground *** 3 connected to 3 breakers

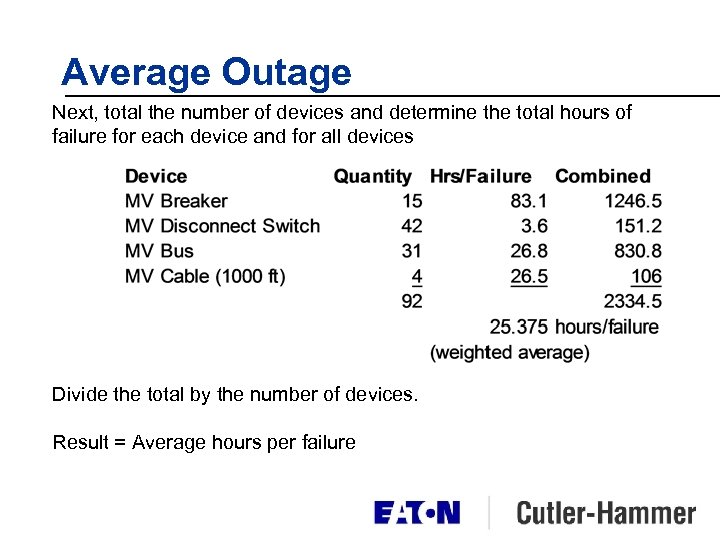

Average Outage Next, total the number of devices and determine the total hours of failure for each device and for all devices Divide the total by the number of devices. Result = Average hours per failure

Compute Likely Failure Rate 0. 36 failures/ year l Total Savings from PD 9. 21 hrs/yr 25. 4 hrs/ failure n 1 hr/failure = 9 fewer failures per year n 10 hr/failure = 1 fewer failure per year n 25. 4 hr/failure = 0. 36 fewer failures per year • Answer: 1 fewer failure every 3 years

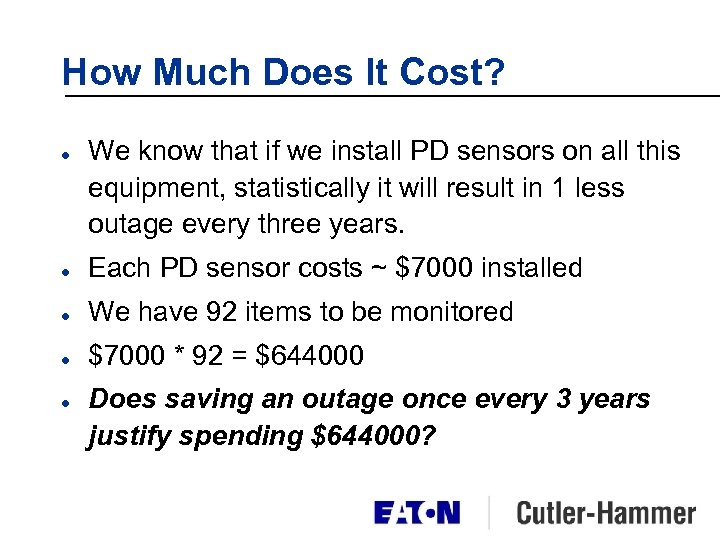

How Much Does It Cost? l We know that if we install PD sensors on all this equipment, statistically it will result in 1 less outage every three years. l Each PD sensor costs ~ $7000 installed l We have 92 items to be monitored l $7000 * 92 = $644000 l Does saving an outage once every 3 years justify spending $644000?

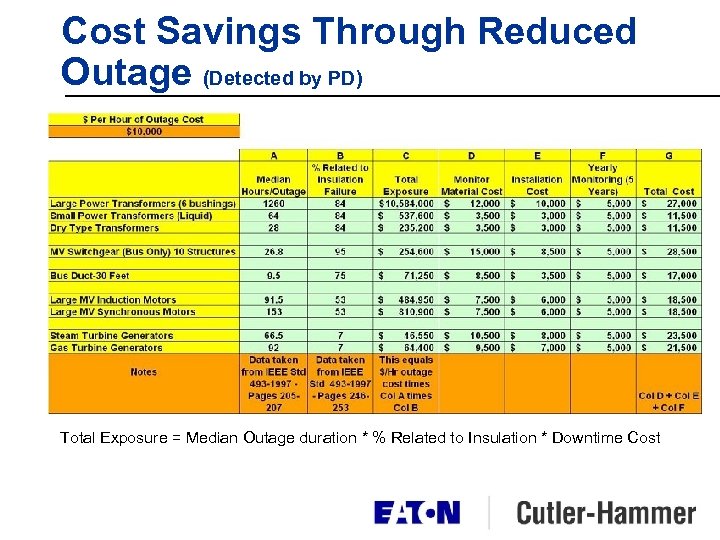

Cost Savings Through Reduced Outage (Detected by PD) Total Exposure = Median Outage duration * % Related to Insulation * Downtime Cost

Your Mileage May Vary… Using this $10000 assumption… l At $10, 000 / hour of downtime costs n Loss of one of the small power transformers would cost: • n $537000 of downtime ($240, 000 / day) Cost of a 1000 k. VA indoor dry, MV power transformer • • Assume labor $50/hr, 3 man-days labor • n Assume $18/k. VA or $18000 Total cost = (1000 * $18) + ($50 * 3 * 8) = $18000 + $1200 Total cost = $19200 Downtime and material = $537000 + $19200 Downtime and material = $556200

Compute Payback l l l Our cost is $644000 Our savings is $556200 once every 3 years or $185400 per year Assume we expect a 10% return on invested capital l Assume 10 year project life l Assume 2. 5% inflation rate

Compute Equivalent Payback l l Cost = $644 K, Savings = $185. 4/yr, N=10 years, inflation = 2. 5%, capital cost = 10% Is this a good investment? Simple Payback = $644 K/$185. 4 K = 3. 47 years (10 -3. 47)*$185. 4 - $644 K = = $567 K positive cash flow (life of project) Does this cover cost of capital (10%) considering the reduction in value of money over time (2. 5% inflation)?

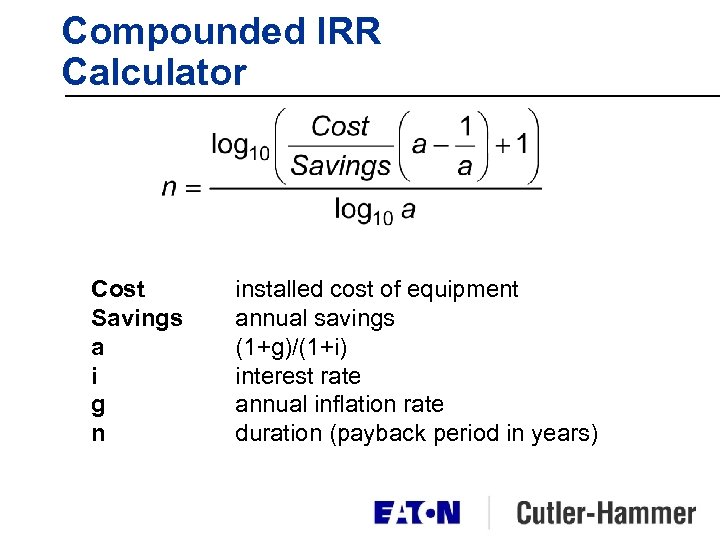

Compounded IRR Calculator Cost Savings a i g n installed cost of equipment annual savings (1+g)/(1+i) interest rate annual inflation rate duration (payback period in years)

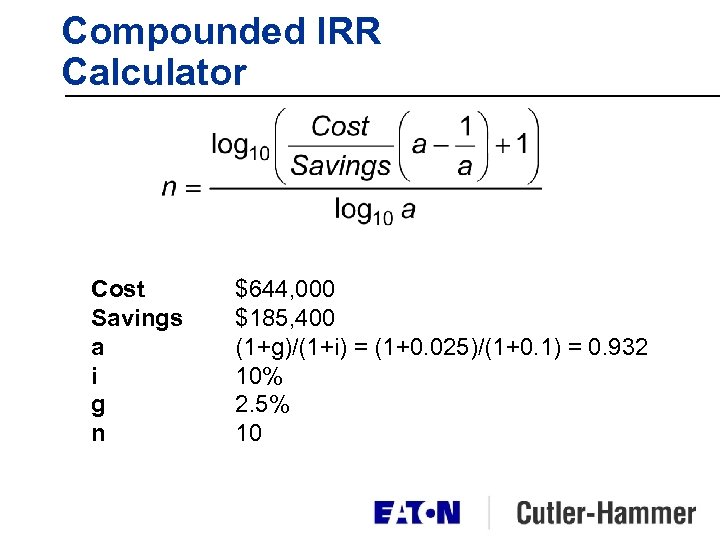

Compounded IRR Calculator Cost Savings a i g n $644, 000 $185, 400 (1+g)/(1+i) = (1+0. 025)/(1+0. 1) = 0. 932 10% 2. 5% 10

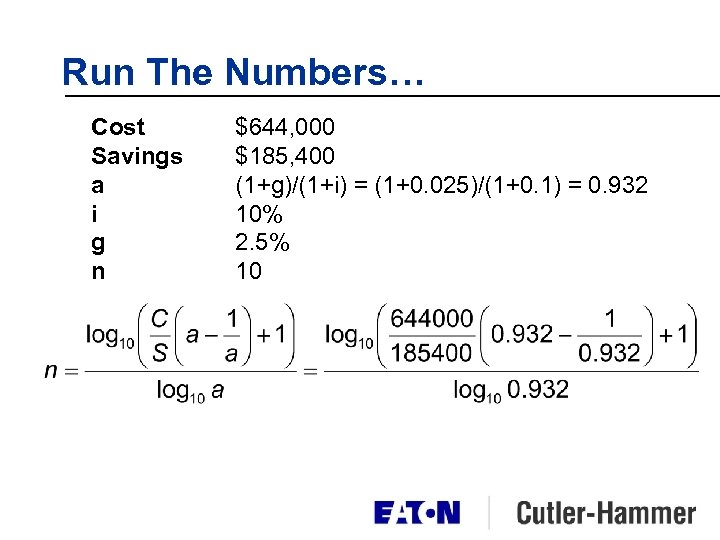

Run The Numbers… Cost Savings a i g n $644, 000 $185, 400 (1+g)/(1+i) = (1+0. 025)/(1+0. 1) = 0. 932 10% 2. 5% 10

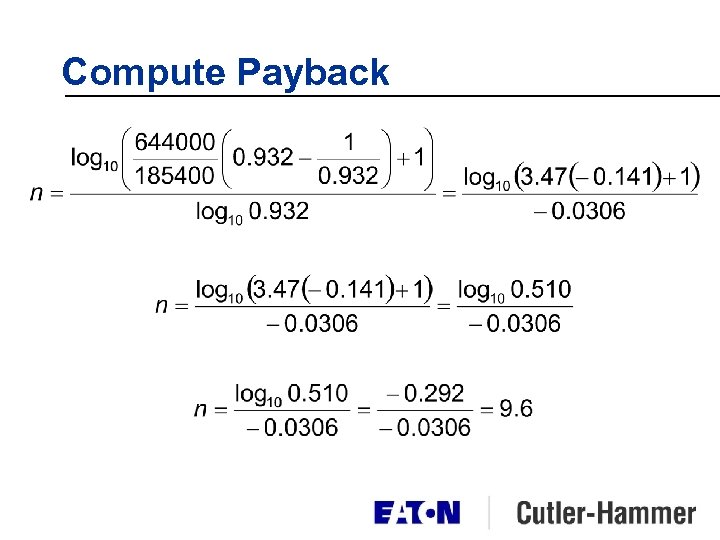

Compute Payback

What Does 9. 6 Mean? l Based on a cost of $644 K, an annual savings of $185. 4 K, a required rate of return of 10%, and inflation rate of 2. 5%… n n 9. 6 means a payback is achieved in 9. 6 years means that the payback is under 10 years Since our project life is 10 years …this project is financially viable. Said another way: l If you put $644 K into this investment, it will return 10% per year every year for 10 years plus enough additional cash to completely pay for the $644 K initial investment. l

Great, I’ve Found Problems, Now What? l l l You can certainly replace with new or… If you catch it before it fails catastrophically, you can rebuild Many old electrical devices can be rebuilt to like new condition

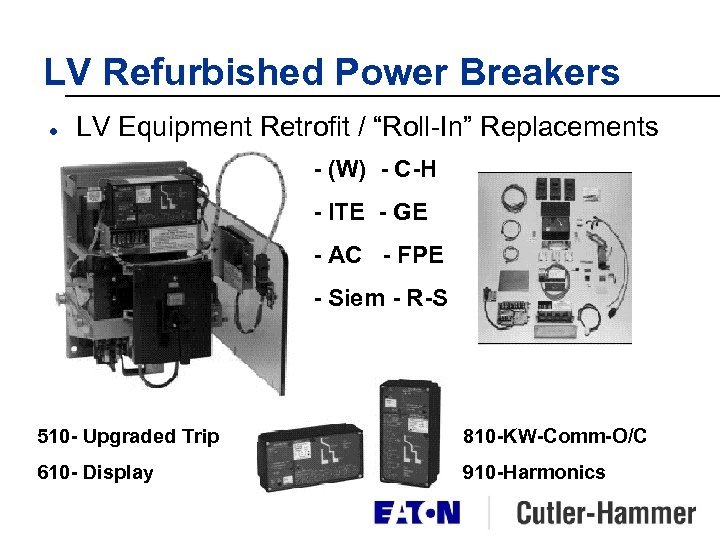

LV Refurbished Power Breakers l LV Equipment Retrofit / “Roll-In” Replacements - (W) - C-H - ITE - GE - AC - FPE - Siem - R-S 510 - Upgraded Trip 810 -KW-Comm-O/C 610 - Display 910 -Harmonics

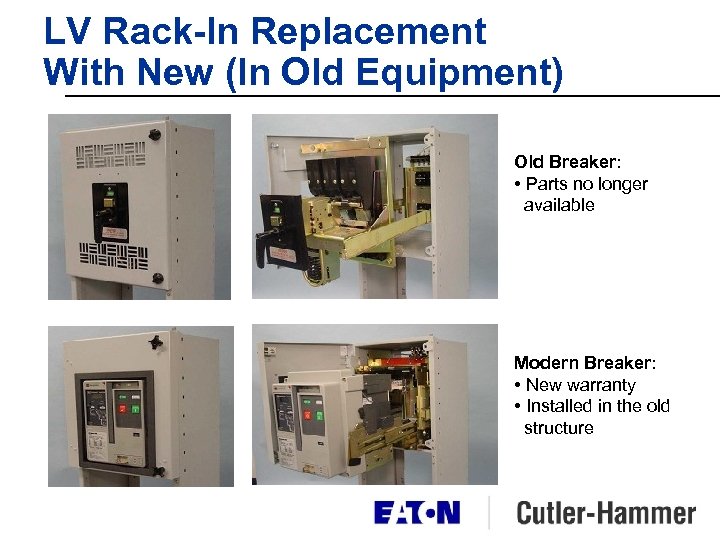

LV Rack-In Replacement With New (In Old Equipment) Old Breaker: • Parts no longer available Modern Breaker: • New warranty • Installed in the old structure

Motor Control Upgrades Breaker-to-Starter Conversions: - circuit breaker used to start motor - only good for 1000 or less operations - replace breaker with starter - now good for 1, 000 operations Continuous Partial Discharge Monitor MCC Bucket Retrofits - new breaker and starter

MV Vacuum Replacement • Vacuum replacement for Air Break in same space • Extensive Product Availability • ANSI Qualified Designs • 158 Designs • Non-Sliding Current Transfer • SURE CLOSE - Patented (MOC Switches) • 2 -Year Warranty - Dedicated Service • Factory Trained Commissioning Engineers • Full Design & Production Certification • ANSI C 37. 59 Conversion Standard • ANSI C 37. 09 Breaker Standard • ANSI C 37. 20 Switchgear Standard • Design Test Certificate Available on Request

Can’t Buy a Spare? Class 1 Recondition Instead l Receiving & Testing l Complete Disassembly l Detailed Inspection and Cleaning l New Parts l OEM Re-assembly l Testing l Data-Base Tracking

Spot Network Upgrade Network Protector Class 1 Recondition Network Relay Upgrades. . .

Transformer Oil Processing Other Services Available: • Samples Obtained On-Site • Mail-in Sampling Kits • Self Powering Generator • Complete Transformer Testing • On-Site. PCB & Dissolved Gas Analysis - PF, Testing & Analysis • Vacuum Filling & Start-up • Reclamation & Retesting • Samples Obtained On-Site On-Board Testing Dielectric Testing Karl Fischer Moisture Test Acid Titration Testing

For more information www. cutler-hammer. com (Coming Soon: a web based “Reliability Calculator” to simplify these calculations)

ae0ee0c42a05fa5828cbee125b1929a1.ppt