23bacc232f410643fb60cc97009eebe0.ppt

- Количество слайдов: 25

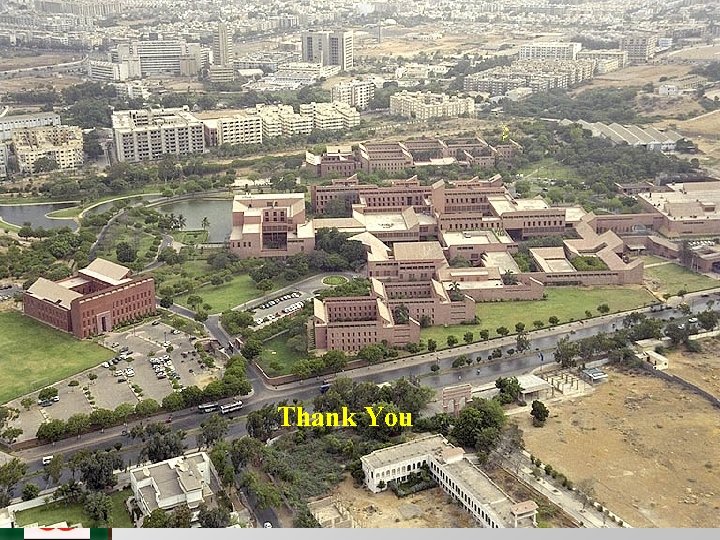

Improving Efficiency in Clinical Laboratory Dr Farooq Ghani Aga Khan University

Over 70% of Healthcare Decisions are based on Medical Tests

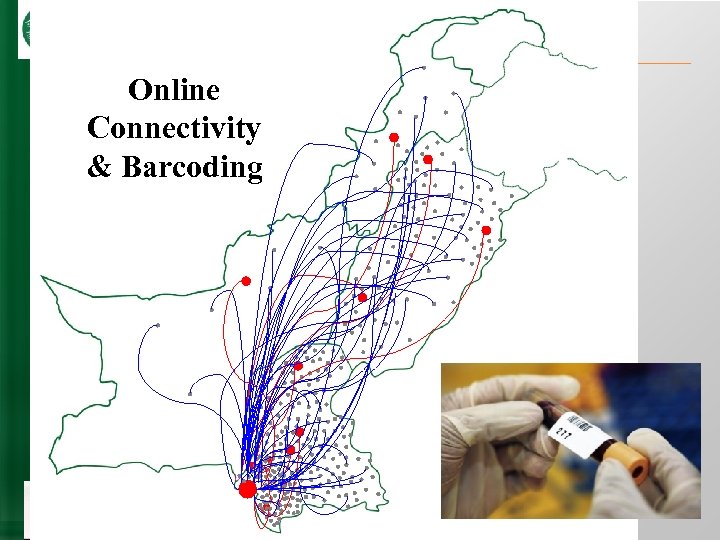

Clinical Lab Process Improvement • Online connectivity of the main lab to 11 regional labs and 187 phlebotomy centers throughout the country • Barcoding samples at collection site • Lab Automation

Online Connectivity & Barcoding

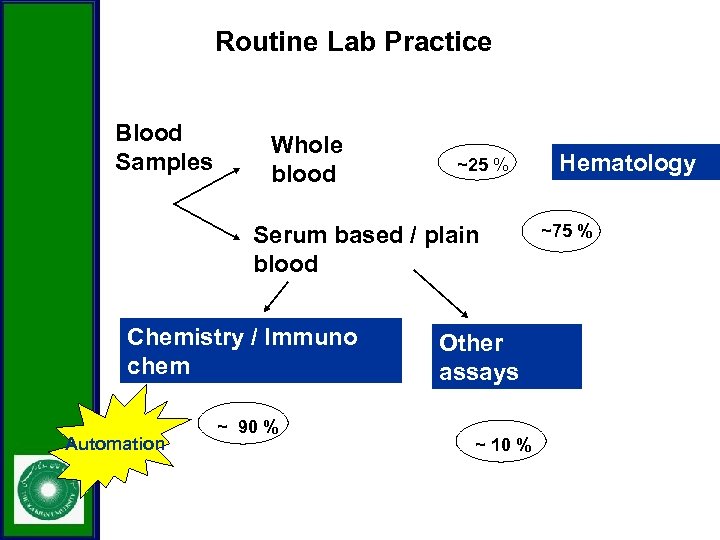

Routine Lab Practice Blood Samples Whole blood ~25 % Serum based / plain blood Chemistry / Immuno chem Automation ~ 90 % Other assays ~ 10 % Hematology ~75 %

• “The first rule of any technology used in an organization is that automation applied to an efficient operation will magnify the efficiency. The second is that automation applied to an inefficient operation will magnify the inefficiency” Bill Gates

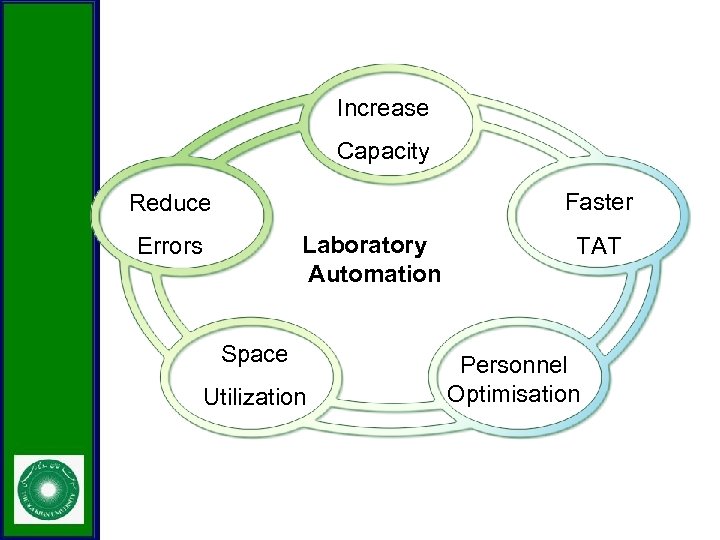

Increase Capacity Faster Reduce Laboratory Automation Errors Space Utilization TAT Personnel Optimisation

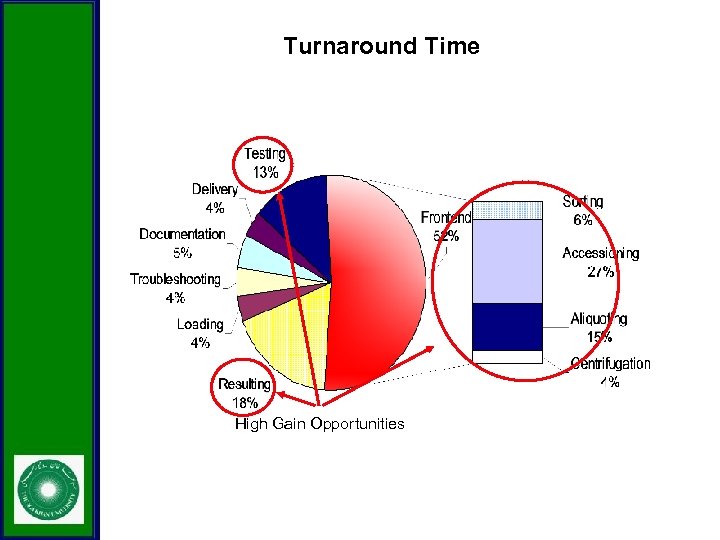

Turnaround Time High Gain Opportunities

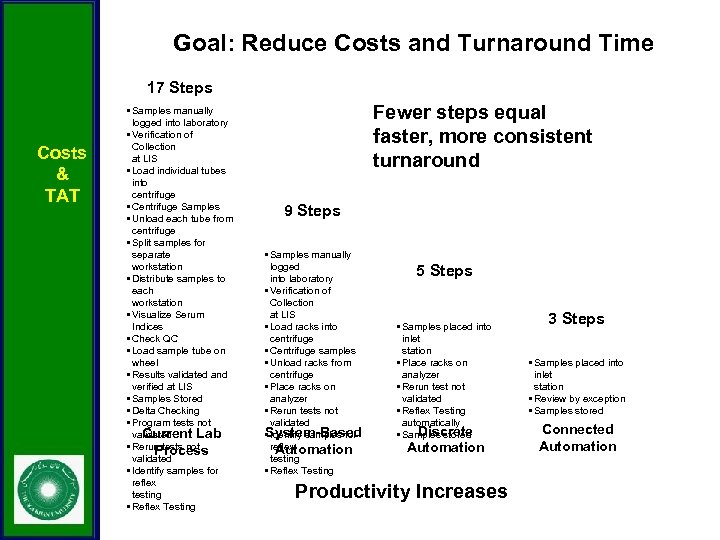

Goal: Reduce Costs and Turnaround Time 17 Steps Costs & TAT • Samples manually logged into laboratory • Verification of Collection at LIS • Load individual tubes into centrifuge • Centrifuge Samples • Unload each tube from centrifuge • Split samples for separate workstation • Distribute samples to each workstation • Visualize Serum Indices • Check QC • Load sample tube on wheel • Results validated and verified at LIS • Samples Stored • Delta Checking • Program tests not validated Current Lab • Rerun tests not Process validated • Identify samples for reflex testing • Reflex Testing Fewer steps equal faster, more consistent turnaround 9 Steps • Samples manually logged into laboratory • Verification of Collection at LIS • Load racks into centrifuge • Centrifuge samples • Unload racks from centrifuge • Place racks on analyzer • Rerun tests not validated System-Based • Identify samples for reflex Automation testing • Reflex Testing 5 Steps • Samples placed into inlet station • Place racks on analyzer • Rerun test not validated • Reflex Testing automatically Discrete • Samples stored Automation Productivity Increases 3 Steps • Samples placed into inlet station • Review by exception • Samples stored Connected Automation

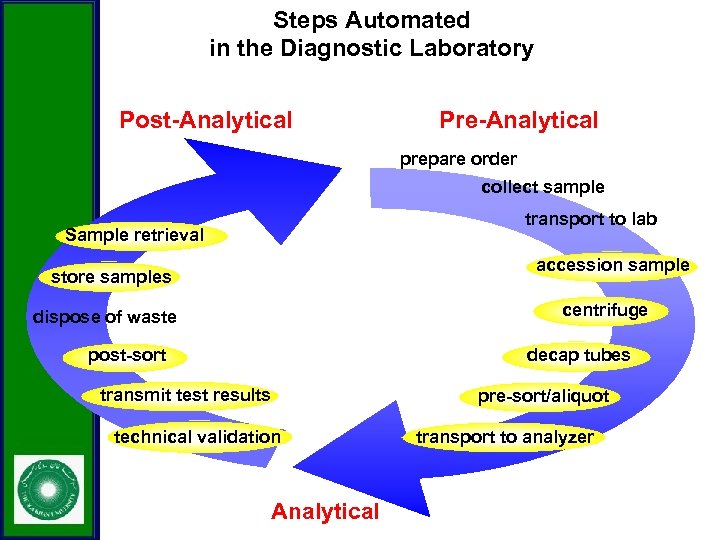

Steps Automated in the Diagnostic Laboratory Post-Analytical Pre-Analytical prepare order collect sample transport to lab Sample retrieval accession sample store samples centrifuge dispose of waste decap tubes post-sort transmit test results technical validation Analytical pre-sort/aliquot transport to analyzer

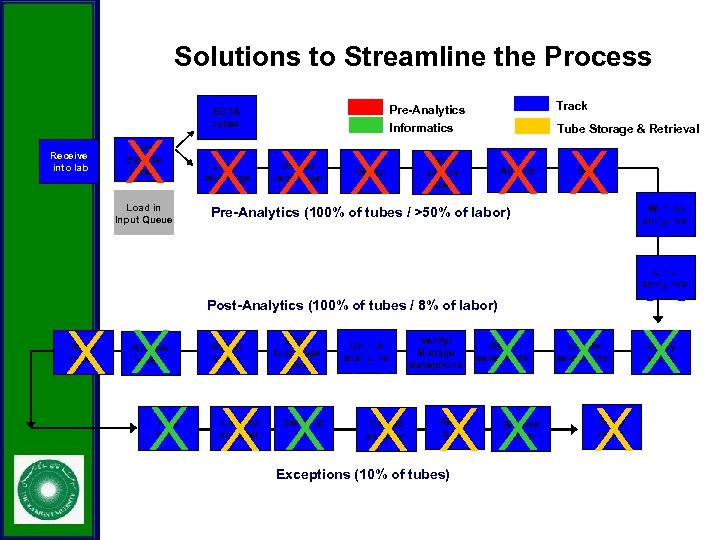

Solutions to Streamline the Process Receive into lab Track Pre-Analytics Informatics EDTA tubes Tube Storage & Retrieval X X X X Sort Sample tubes Load centrifuge Unload centrifuge Decap Label aliquot tubes Aliquot Sort X X X XX X Load in Input Queue Pre-Analytics (100% of tubes / >50% of labor) Walk to analyzers Load analyzers Post-Analytics (100% of tubes / 8% of labor) Store racks Archive tubes Find tube Recap tubes Load on analyzer Walk to storage area Verify at LIS Unload analyzers Unload analyzer Verify/ Manage exceptions Recap tube Exceptions (10% of tubes) Rerun exceptions Archive tubes Locate exceptions Store racks Verify at LIS

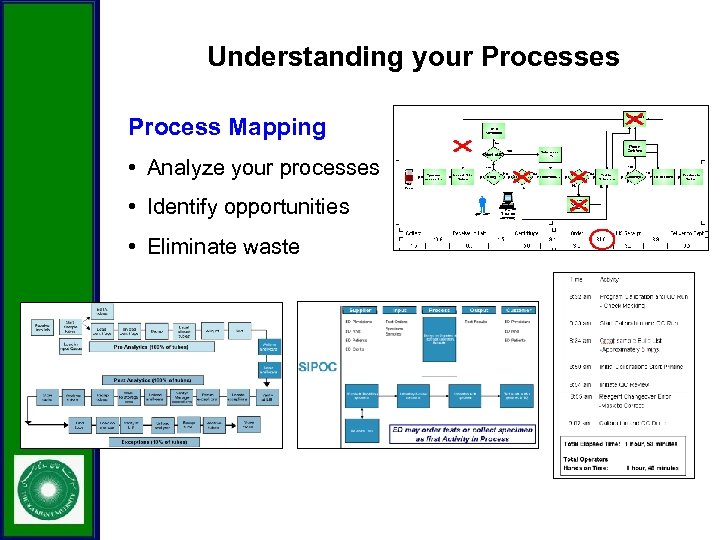

Understanding your Processes Process Mapping • Analyze your processes • Identify opportunities • Eliminate waste

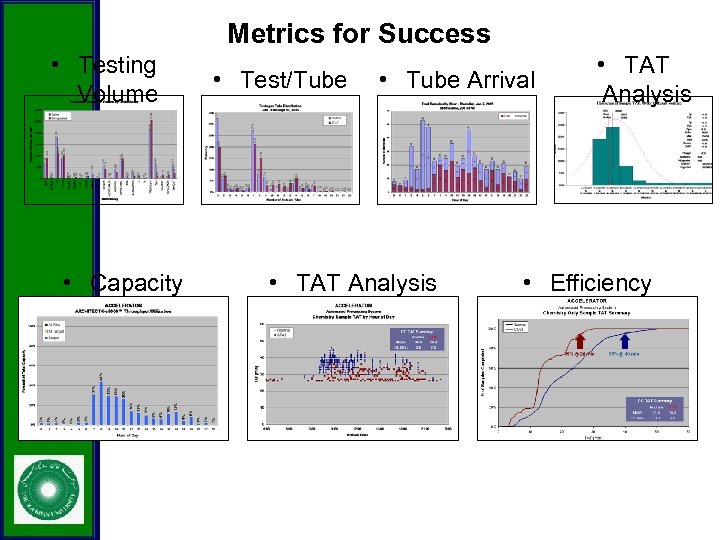

Metrics for Success • Testing Volume • Capacity Planning • Test/Tube • Tube Arrival • TAT Analysis • Efficiency

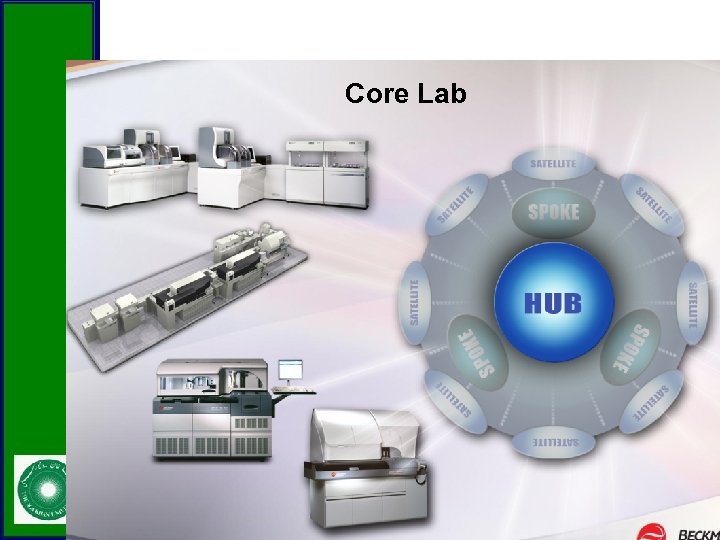

Core Lab

Regional Labs

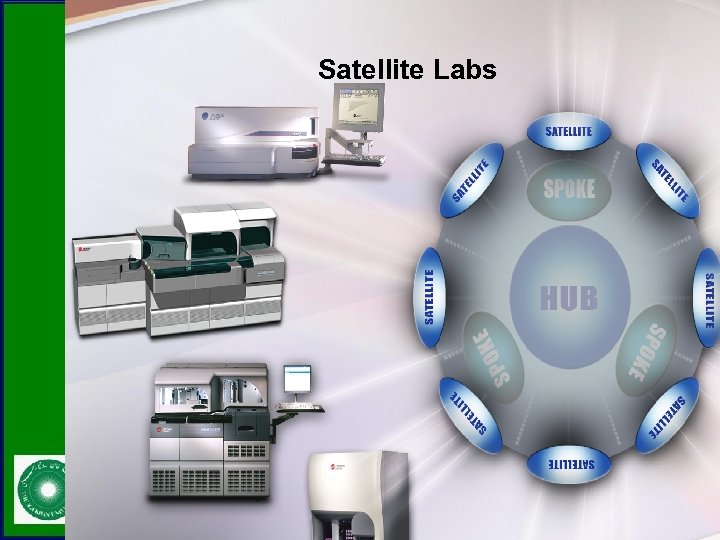

Satellite Labs

ADVIA® Automation

ADVIA® Automation

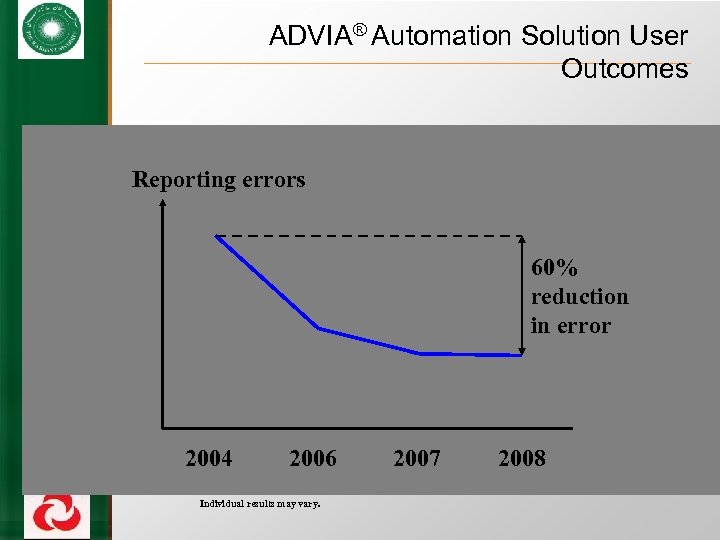

ADVIA® Automation Solution User Outcomes Reporting errors 60% reduction in error 2004 2006 Individual results may vary. 2007 2008

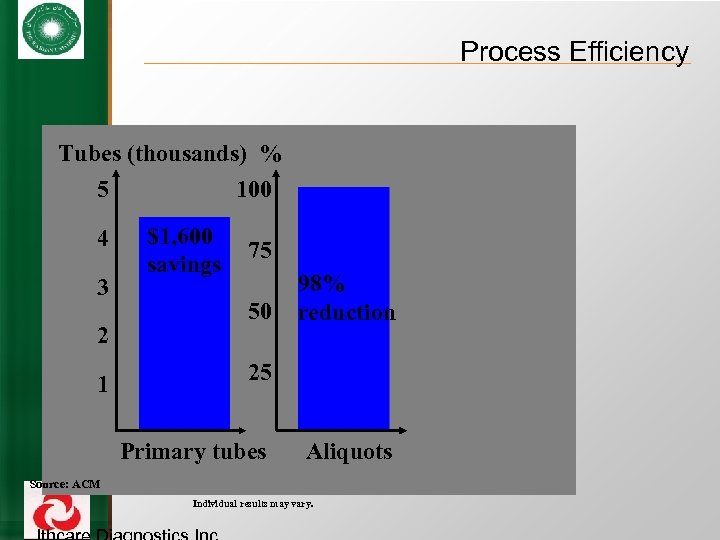

Process Efficiency Tubes (thousands) % 100 5 4 3 2 1 $1, 600 savings 75 50 98% reduction 25 Primary tubes Aliquots Source: ACM Individual results may vary.

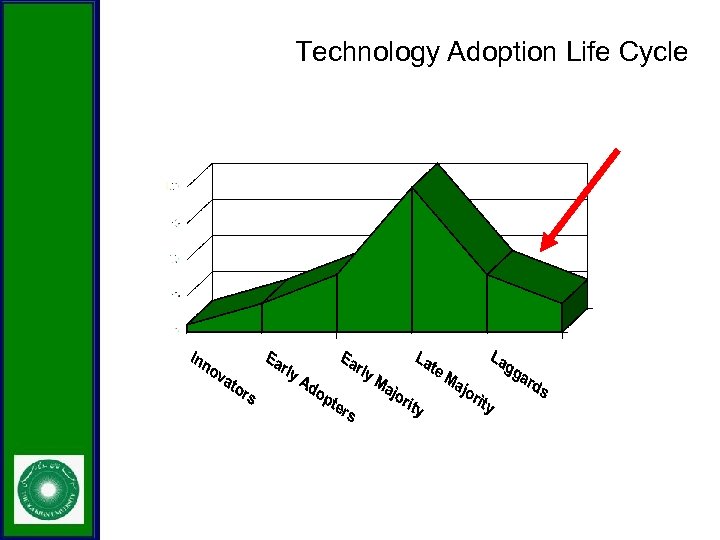

Technology Adoption Life Cycle

Thank You

23bacc232f410643fb60cc97009eebe0.ppt