057dab943029a0188d4367a9d7920ac8.ppt

- Количество слайдов: 18

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Chem. Cristina CIAMA, EHS Manager, Mihail GEORGESCU, Safety Inspector S. C EUROPHARM S. A Brașov

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Chem. Cristina CIAMA, EHS Manager, Mihail GEORGESCU, Safety Inspector S. C EUROPHARM S. A Brașov

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) • Issue ► Many of the Active Pharmaceutical Ingredients (API) used in the pharmaceutical production industry have the potential of causing occupational illness (e. g. skin rash, dermatitis, asthma, etc). ► Using the right tools and process to assess the chemical risk at workplace • Problem ► Employees working in pharmaceutical industry are exposed to pharmaceutical substances causing risk to their health. The ways of exposure to the chemical substance are various as skin, respiratory, ingestion, eye. ► The company set up Key Performance Indicators (KPI) on occupational health injuries and illnesses to monitor the performance on employees’ health and safety ► 3 potential allergies at skin level have been reported

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) • Issue ► Many of the Active Pharmaceutical Ingredients (API) used in the pharmaceutical production industry have the potential of causing occupational illness (e. g. skin rash, dermatitis, asthma, etc). ► Using the right tools and process to assess the chemical risk at workplace • Problem ► Employees working in pharmaceutical industry are exposed to pharmaceutical substances causing risk to their health. The ways of exposure to the chemical substance are various as skin, respiratory, ingestion, eye. ► The company set up Key Performance Indicators (KPI) on occupational health injuries and illnesses to monitor the performance on employees’ health and safety ► 3 potential allergies at skin level have been reported

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) • Solution ► Investigation § Following the reporting, an investigation committee has been set-up in order to find out the root cause of incidents § Tools used during investigation: • ROOT CAUSE ANALYSIS (RCA) • FISH BONE ANALYSIS • GEMBA tour ► Root Cause § Chemical Risk Assessment undertook is addressing few aspects and does not take into consideration the risk of employees’ exposure to chemical substances

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) • Solution ► Investigation § Following the reporting, an investigation committee has been set-up in order to find out the root cause of incidents § Tools used during investigation: • ROOT CAUSE ANALYSIS (RCA) • FISH BONE ANALYSIS • GEMBA tour ► Root Cause § Chemical Risk Assessment undertook is addressing few aspects and does not take into consideration the risk of employees’ exposure to chemical substances

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) ► Project Steps § Step 1 Establish the target • Improvement of Chemical Risk Assessment § Step 2 Set-up the project team • with members from all relevant departments § Step 3 Identify the best solutions • • • Introduce information about ways of exposure: inhalation/ingestion and skin contact Introduce a risk quantification Introduce types of chemical contact Introduce R phrases Link between risk assessment and occupational monitoring Involvement of operators in chemical risk assessment process § Step 4 Implement the new WOW • Training of the employees on CRA methodology • Training on chemical effects • Deployment of new CRA

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) ► Project Steps § Step 1 Establish the target • Improvement of Chemical Risk Assessment § Step 2 Set-up the project team • with members from all relevant departments § Step 3 Identify the best solutions • • • Introduce information about ways of exposure: inhalation/ingestion and skin contact Introduce a risk quantification Introduce types of chemical contact Introduce R phrases Link between risk assessment and occupational monitoring Involvement of operators in chemical risk assessment process § Step 4 Implement the new WOW • Training of the employees on CRA methodology • Training on chemical effects • Deployment of new CRA

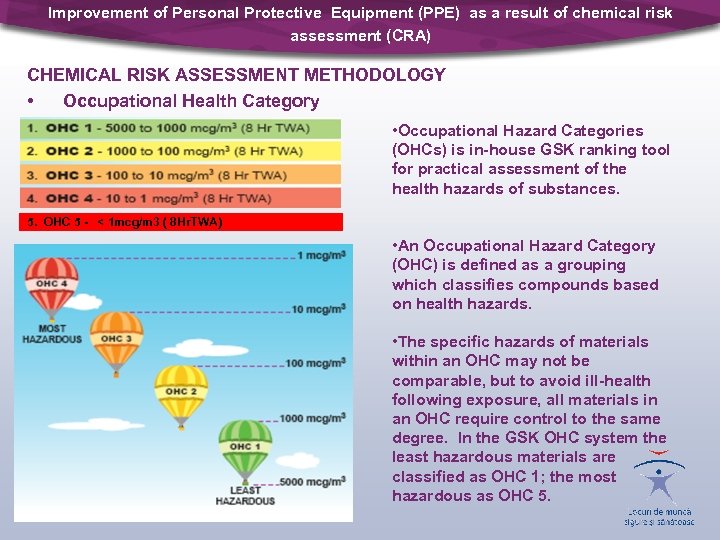

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CHEMICAL RISK ASSESSMENT METHODOLOGY • Occupational Health Category • Occupational Hazard Categories (OHCs) is in-house GSK ranking tool for practical assessment of the health hazards of substances. 5. OHC 5 - < 1 mcg/m 3 ( 8 Hr. TWA) • An Occupational Hazard Category (OHC) is defined as a grouping which classifies compounds based on health hazards. • The specific hazards of materials within an OHC may not be comparable, but to avoid ill-health following exposure, all materials in an OHC require control to the same degree. In the GSK OHC system the least hazardous materials are classified as OHC 1; the most hazardous as OHC 5.

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CHEMICAL RISK ASSESSMENT METHODOLOGY • Occupational Health Category • Occupational Hazard Categories (OHCs) is in-house GSK ranking tool for practical assessment of the health hazards of substances. 5. OHC 5 - < 1 mcg/m 3 ( 8 Hr. TWA) • An Occupational Hazard Category (OHC) is defined as a grouping which classifies compounds based on health hazards. • The specific hazards of materials within an OHC may not be comparable, but to avoid ill-health following exposure, all materials in an OHC require control to the same degree. In the GSK OHC system the least hazardous materials are classified as OHC 1; the most hazardous as OHC 5.

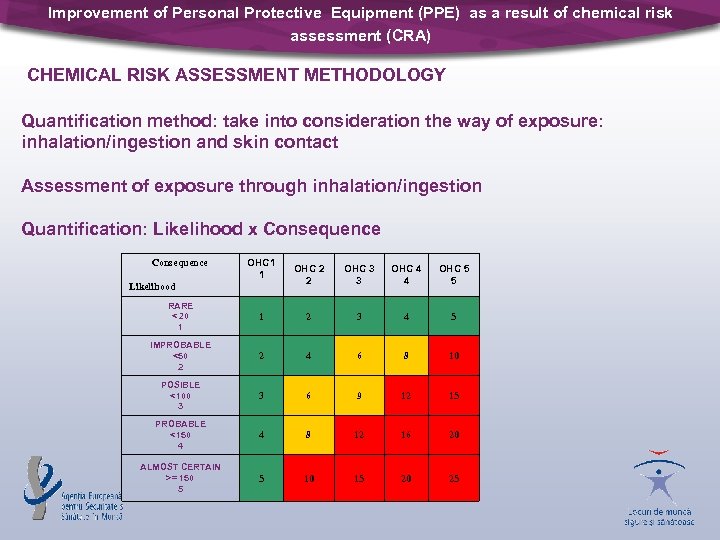

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CHEMICAL RISK ASSESSMENT METHODOLOGY Quantification method: take into consideration the way of exposure: inhalation/ingestion and skin contact Assessment of exposure through inhalation/ingestion Quantification: Likelihood x Consequence OHC 1 1 Likelihood OHC 2 2 OHC 3 3 OHC 4 4 OHC 5 5 RARE < 20 1 1 2 3 4 5 IMPROBABLE <50 2 2 4 6 8 10 POSIBLE <100 3 3 6 9 12 15 PROBABLE <150 4 4 8 12 16 20 ALMOST CERTAIN >= 150 5 5 10 15 20 25

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CHEMICAL RISK ASSESSMENT METHODOLOGY Quantification method: take into consideration the way of exposure: inhalation/ingestion and skin contact Assessment of exposure through inhalation/ingestion Quantification: Likelihood x Consequence OHC 1 1 Likelihood OHC 2 2 OHC 3 3 OHC 4 4 OHC 5 5 RARE < 20 1 1 2 3 4 5 IMPROBABLE <50 2 2 4 6 8 10 POSIBLE <100 3 3 6 9 12 15 PROBABLE <150 4 4 8 12 16 20 ALMOST CERTAIN >= 150 5 5 10 15 20 25

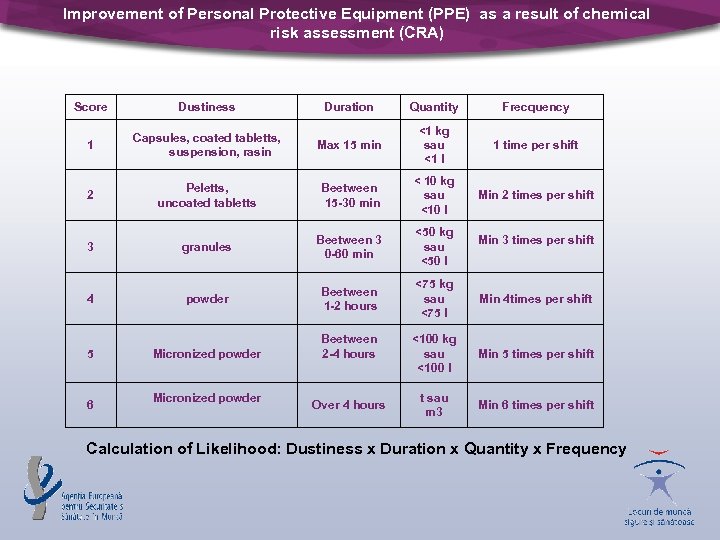

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Score Dustiness Duration Quantity Frecquency 1 Capsules, coated tabletts, suspension, rasin Max 15 min <1 kg sau <1 l 1 time per shift 2 Peletts, uncoated tabletts Beetween 15 -30 min < 10 kg sau <10 l Min 2 times per shift 3 granules Beetween 3 0 -60 min <50 kg sau <50 l 4 powder Beetween 1 -2 hours <75 kg sau <75 l Min 4 times per shift <100 kg sau <100 l Min 5 times per shift t sau m 3 Min 6 times per shift 5 6 Micronized powder Beetween 2 -4 hours Over 4 hours Min 3 times per shift Calculation of Likelihood: Dustiness x Duration x Quantity x Frequency

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Score Dustiness Duration Quantity Frecquency 1 Capsules, coated tabletts, suspension, rasin Max 15 min <1 kg sau <1 l 1 time per shift 2 Peletts, uncoated tabletts Beetween 15 -30 min < 10 kg sau <10 l Min 2 times per shift 3 granules Beetween 3 0 -60 min <50 kg sau <50 l 4 powder Beetween 1 -2 hours <75 kg sau <75 l Min 4 times per shift <100 kg sau <100 l Min 5 times per shift t sau m 3 Min 6 times per shift 5 6 Micronized powder Beetween 2 -4 hours Over 4 hours Min 3 times per shift Calculation of Likelihood: Dustiness x Duration x Quantity x Frequency

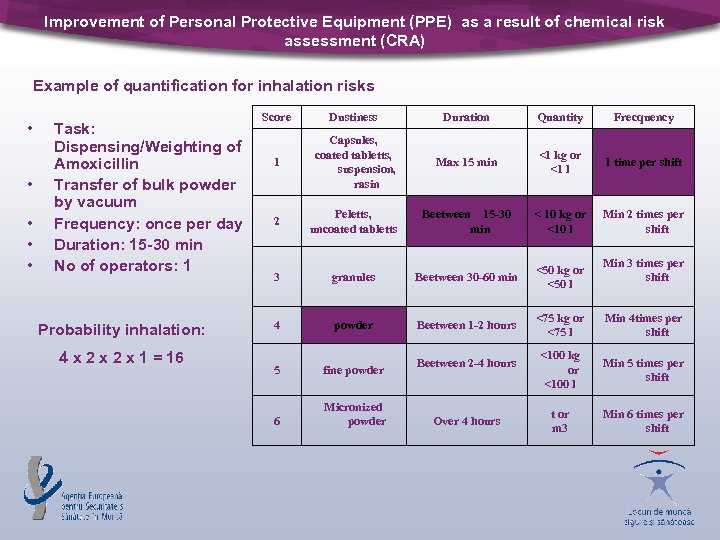

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Example of quantification for inhalation risks • • • Task: Dispensing/Weighting of Amoxicillin Transfer of bulk powder by vacuum Frequency: once per day Duration: 15 -30 min No of operators: 1 Probability inhalation: 4 x 2 x 1 = 16 Score Dustiness Duration Quantity Frecquency 1 Capsules, coated tabletts, suspension, rasin Max 15 min <1 kg or <1 l 1 time per shift 2 Peletts, uncoated tabletts Beetween 15 -30 min < 10 kg or <10 l Min 2 times per shift Min 3 times per shift 3 granules Beetween 30 -60 min <50 kg or <50 l 4 powder Beetween 1 -2 hours <75 kg or <75 l Min 4 times per shift <100 kg or <100 l Min 5 times per shift t or m 3 Min 6 times per shift 5 fine powder 6 Micronized powder Beetween 2 -4 hours Over 4 hours

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Example of quantification for inhalation risks • • • Task: Dispensing/Weighting of Amoxicillin Transfer of bulk powder by vacuum Frequency: once per day Duration: 15 -30 min No of operators: 1 Probability inhalation: 4 x 2 x 1 = 16 Score Dustiness Duration Quantity Frecquency 1 Capsules, coated tabletts, suspension, rasin Max 15 min <1 kg or <1 l 1 time per shift 2 Peletts, uncoated tabletts Beetween 15 -30 min < 10 kg or <10 l Min 2 times per shift Min 3 times per shift 3 granules Beetween 30 -60 min <50 kg or <50 l 4 powder Beetween 1 -2 hours <75 kg or <75 l Min 4 times per shift <100 kg or <100 l Min 5 times per shift t or m 3 Min 6 times per shift 5 fine powder 6 Micronized powder Beetween 2 -4 hours Over 4 hours

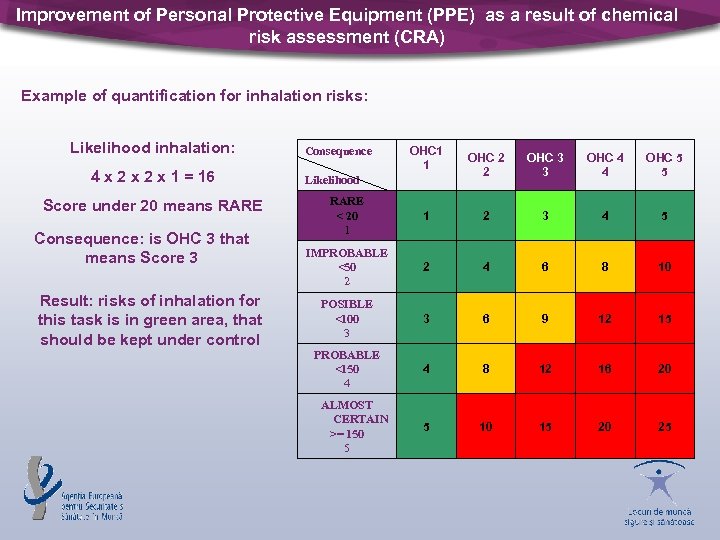

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Example of quantification for inhalation risks: Likelihood inhalation: 4 x 2 x 1 = 16 Score under 20 means RARE Consequence: is OHC 3 that means Score 3 Result: risks of inhalation for this task is in green area, that should be kept under control Consequence OHC 1 1 Likelihood OHC 2 2 OHC 3 3 OHC 4 4 OHC 5 5 RARE < 20 1 1 2 3 4 5 IMPROBABLE <50 2 2 4 6 8 10 POSIBLE <100 3 3 6 9 12 15 PROBABLE <150 4 4 8 12 16 20 5 10 15 20 25 ALMOST CERTAIN >= 150 5

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Example of quantification for inhalation risks: Likelihood inhalation: 4 x 2 x 1 = 16 Score under 20 means RARE Consequence: is OHC 3 that means Score 3 Result: risks of inhalation for this task is in green area, that should be kept under control Consequence OHC 1 1 Likelihood OHC 2 2 OHC 3 3 OHC 4 4 OHC 5 5 RARE < 20 1 1 2 3 4 5 IMPROBABLE <50 2 2 4 6 8 10 POSIBLE <100 3 3 6 9 12 15 PROBABLE <150 4 4 8 12 16 20 5 10 15 20 25 ALMOST CERTAIN >= 150 5

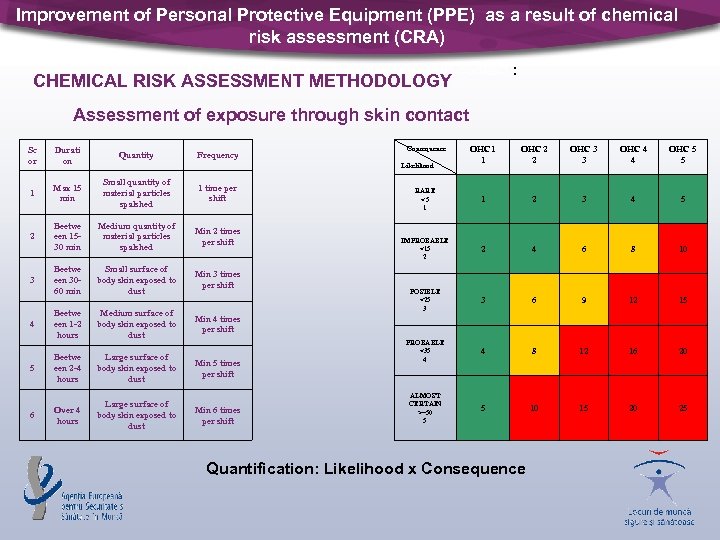

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Assessment of exposure through skin contact : CHEMICAL RISK ASSESSMENT METHODOLOGY Assessment of exposure through skin contact Sc or Durati on Quantity 1 Max 15 min Small quantity of material particles spalshed 1 time per shift 2 Beetwe een 1530 min Medium quantity of material particles spalshed Min 2 times per shift Beetwe een 3060 min Small surface of body skin exposed to dust Min 3 times per shift Beetwe een 1 -2 hours Medium surface of body skin exposed to dust Beetwe een 2 -4 hours Large surface of body skin exposed to dust Min 5 times per shift Over 4 hours Large surface of body skin exposed to dust OHC 1 1 OHC 2 2 OHC 3 3 OHC 4 4 OHC 5 5 RARE <5 1 1 2 3 4 5 IMPROBABLE <15 2 2 4 6 8 10 POSIBLE <25 3 3 6 9 12 15 PROBABLE <35 4 4 8 12 16 20 ALMOST CERTAIN >=50 5 5 10 15 20 25 Consequence Min 4 times per shift 3 4 5 6 Frequency Likelihood Min 6 times per shift Quantification: Likelihood x Consequence

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Assessment of exposure through skin contact : CHEMICAL RISK ASSESSMENT METHODOLOGY Assessment of exposure through skin contact Sc or Durati on Quantity 1 Max 15 min Small quantity of material particles spalshed 1 time per shift 2 Beetwe een 1530 min Medium quantity of material particles spalshed Min 2 times per shift Beetwe een 3060 min Small surface of body skin exposed to dust Min 3 times per shift Beetwe een 1 -2 hours Medium surface of body skin exposed to dust Beetwe een 2 -4 hours Large surface of body skin exposed to dust Min 5 times per shift Over 4 hours Large surface of body skin exposed to dust OHC 1 1 OHC 2 2 OHC 3 3 OHC 4 4 OHC 5 5 RARE <5 1 1 2 3 4 5 IMPROBABLE <15 2 2 4 6 8 10 POSIBLE <25 3 3 6 9 12 15 PROBABLE <35 4 4 8 12 16 20 ALMOST CERTAIN >=50 5 5 10 15 20 25 Consequence Min 4 times per shift 3 4 5 6 Frequency Likelihood Min 6 times per shift Quantification: Likelihood x Consequence

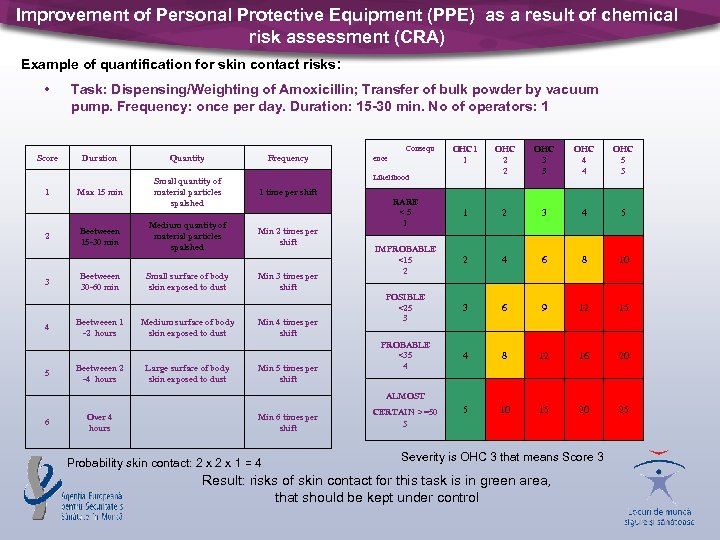

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Example of quantification for skin contact risks: • Task: Dispensing/Weighting of Amoxicillin; Transfer of bulk powder by vacuum pump. Frequency: once per day. Duration: 15 -30 min. No of operators: 1 Consequ Score 1 2 3 4 5 Duration Quantity Max 15 min Small quantity of material particles spalshed 1 time per shift Medium quantity of material particles spalshed Min 2 times per shift Beetweeen 15 -30 min Beetweeen 30 -60 min Beetweeen 1 -2 hours Beetweeen 2 -4 hours Small surface of body skin exposed to dust Medium surface of body skin exposed to dust Large surface of body skin exposed to dust Frequency OHC 1 1 OHC 2 2 OHC 3 3 OHC 4 4 OHC 5 5 RARE <5 1 1 2 3 4 5 IMPROBABLE <15 2 2 4 6 8 10 POSIBLE <25 3 3 6 9 12 15 PROBABLE <35 4 4 8 12 16 20 5 10 15 20 25 ence Likelihood Min 3 times per shift Min 4 times per shift Min 5 times per shift ALMOST 6 Over 4 hours Min 6 times per shift Probability skin contact: 2 x 1 = 4 CERTAIN >=50 5 Severity is OHC 3 that means Score 3 Result: risks of skin contact for this task is in green area, that should be kept under control

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) Example of quantification for skin contact risks: • Task: Dispensing/Weighting of Amoxicillin; Transfer of bulk powder by vacuum pump. Frequency: once per day. Duration: 15 -30 min. No of operators: 1 Consequ Score 1 2 3 4 5 Duration Quantity Max 15 min Small quantity of material particles spalshed 1 time per shift Medium quantity of material particles spalshed Min 2 times per shift Beetweeen 15 -30 min Beetweeen 30 -60 min Beetweeen 1 -2 hours Beetweeen 2 -4 hours Small surface of body skin exposed to dust Medium surface of body skin exposed to dust Large surface of body skin exposed to dust Frequency OHC 1 1 OHC 2 2 OHC 3 3 OHC 4 4 OHC 5 5 RARE <5 1 1 2 3 4 5 IMPROBABLE <15 2 2 4 6 8 10 POSIBLE <25 3 3 6 9 12 15 PROBABLE <35 4 4 8 12 16 20 5 10 15 20 25 ence Likelihood Min 3 times per shift Min 4 times per shift Min 5 times per shift ALMOST 6 Over 4 hours Min 6 times per shift Probability skin contact: 2 x 1 = 4 CERTAIN >=50 5 Severity is OHC 3 that means Score 3 Result: risks of skin contact for this task is in green area, that should be kept under control

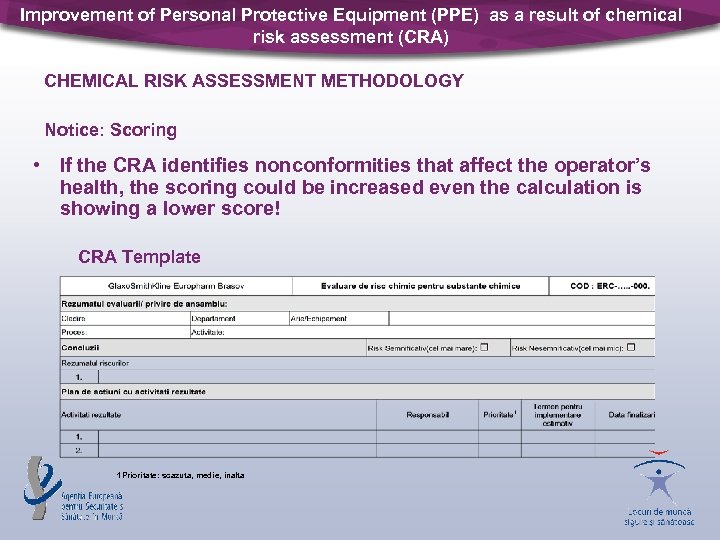

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CHEMICAL RISK ASSESSMENT METHODOLOGY Notice: Scoring • If the CRA identifies nonconformities that affect the operator’s health, the scoring could be increased even the calculation is showing a lower score! CRA Template 1 Prioritate: scazuta, medie, inalta

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CHEMICAL RISK ASSESSMENT METHODOLOGY Notice: Scoring • If the CRA identifies nonconformities that affect the operator’s health, the scoring could be increased even the calculation is showing a lower score! CRA Template 1 Prioritate: scazuta, medie, inalta

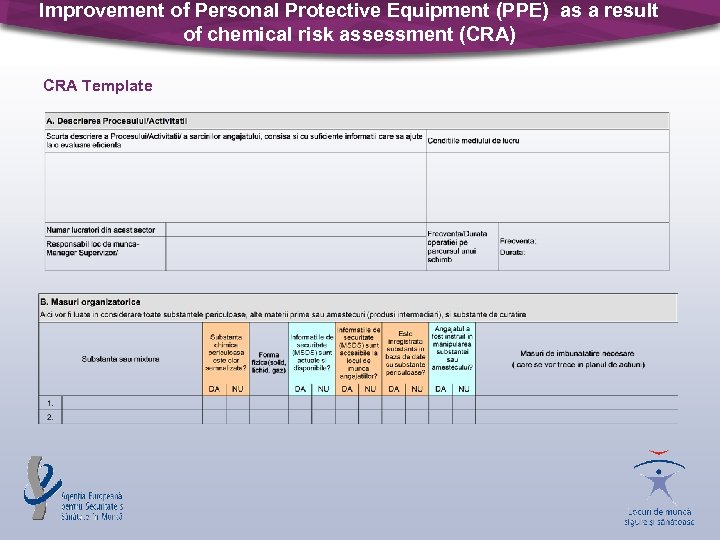

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CRA Template

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CRA Template

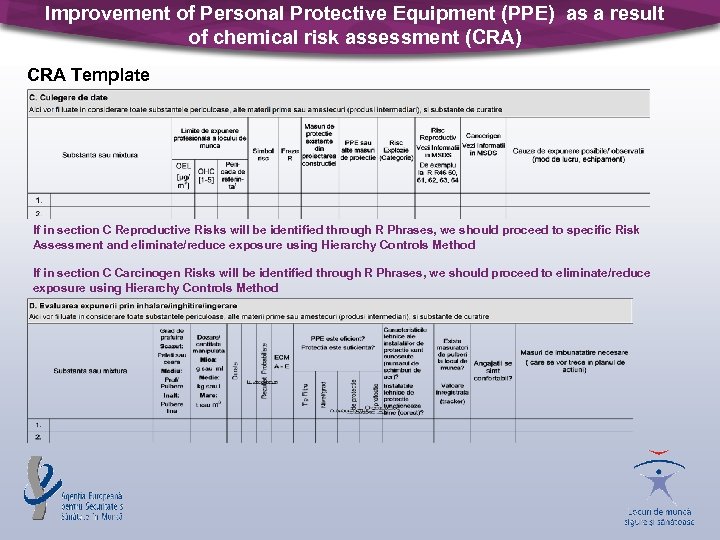

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CRA Template If in section C Reproductive Risks will be identified through R Phrases, we should proceed to specific Risk Assessment and eliminate/reduce exposure using Hierarchy Controls Method If in section C Carcinogen Risks will be identified through R Phrases, we should proceed to eliminate/reduce exposure using Hierarchy Controls Method

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CRA Template If in section C Reproductive Risks will be identified through R Phrases, we should proceed to specific Risk Assessment and eliminate/reduce exposure using Hierarchy Controls Method If in section C Carcinogen Risks will be identified through R Phrases, we should proceed to eliminate/reduce exposure using Hierarchy Controls Method

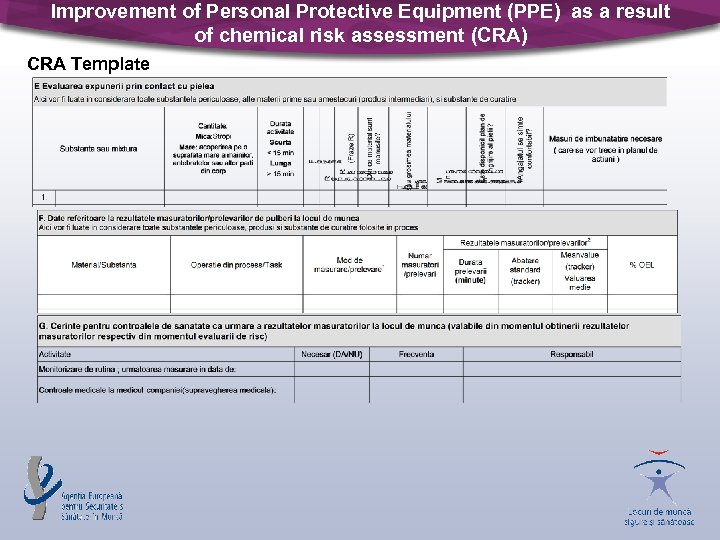

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CRA Template

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CRA Template

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CRA Template RESULTS • operators involvement in CRA process • cross reference with the OH monitoring results

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) CRA Template RESULTS • operators involvement in CRA process • cross reference with the OH monitoring results

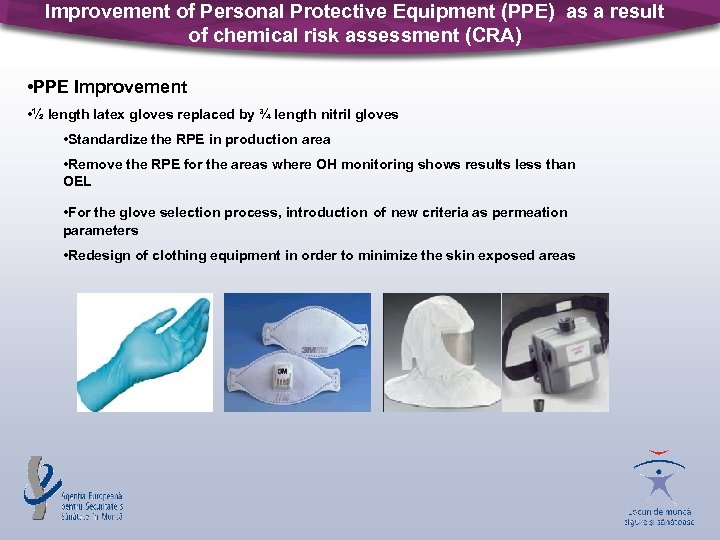

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) • PPE Improvement • ½ length latex gloves replaced by ¾ length nitril gloves • Standardize the RPE in production area • Remove the RPE for the areas where OH monitoring shows results less than OEL • For the glove selection process, introduction of new criteria as permeation parameters • Redesign of clothing equipment in order to minimize the skin exposed areas

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) • PPE Improvement • ½ length latex gloves replaced by ¾ length nitril gloves • Standardize the RPE in production area • Remove the RPE for the areas where OH monitoring shows results less than OEL • For the glove selection process, introduction of new criteria as permeation parameters • Redesign of clothing equipment in order to minimize the skin exposed areas

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) BENEFITS • a structured approach of CRA • Chemical 5 x 5 risk quantification system allows quick ranking of the risk and helps on action prioritization • increase the ownership and understanding at shop floor level of chemical risks COMMENTS Health and Safety of the employees is always an important part of GSK, and therefore it is important to find ways to minimise EHS risks and impacts to create and develop a healthy work-place. This CRA methodology has been recognized as Good Practice in the GSK network “In addition we aim to continue improving process safety and to move toward an environment where containment rather than respirator is the primary control of chemical exposure” (quote David Pulman, President Global Manufacturing and Supply GSK)

Improvement of Personal Protective Equipment (PPE) as a result of chemical risk assessment (CRA) BENEFITS • a structured approach of CRA • Chemical 5 x 5 risk quantification system allows quick ranking of the risk and helps on action prioritization • increase the ownership and understanding at shop floor level of chemical risks COMMENTS Health and Safety of the employees is always an important part of GSK, and therefore it is important to find ways to minimise EHS risks and impacts to create and develop a healthy work-place. This CRA methodology has been recognized as Good Practice in the GSK network “In addition we aim to continue improving process safety and to move toward an environment where containment rather than respirator is the primary control of chemical exposure” (quote David Pulman, President Global Manufacturing and Supply GSK)