6a818fa359108688383958623ae8a37b.ppt

- Количество слайдов: 53

Implementing a Quality Management System Presented by USDA GRAIN INSPECTION, PACKERS AND STOCKYARDS ADMINISTRATION

What is a QMS? The short answer: Say what you do (documentation) n Do what you say (implementation) n Prove what you do (records) n Review and improve (continuous improvement) n

QMS Definitions A Quality Management System is: n System for managing the quality of an organization n Includes everything in the organization that relates to quality: n Products and services n Processes n Operations n Customer Satisfaction

QMS Description As required by ISO 9000: n n The Quality System is well documented, implemented, understood, maintained and continually improved Emphasis is placed on problem prevention rather than inspection Quality planning is required The PROCESS APPROACH to management is encouraged

QMS Description Quality Standard or Regulation ISO 9001: 2000 Process Verified ISO Guide 65 Quality System Assessment Program National Organic Program Product or Service Consistent quality feed Identity Preserved livestock or grain Consulting Service Organic Certification and Organic Production Beef Export Verification (BEV)

What makes it so special? n Process Approach to management n Integration of processes into a System/ Interrelation of all activities n Continual Improvement at all levels n Communication among all employees and management that leads to full utilization of everyone’s talents

DEFINITION “A desired result is achieved more efficiently when activities and related resources are managed as a process. ” n PROCESS – collection of interrelated activities that transform inputs into outputs

DEFINITION “Identifying, understanding, and managing interrelated processes as a system contributes to the organization’s effectiveness and efficiency in achieving its objective. ” n SYSTEM – a collection of interrelated processes with a common set of objectives and outputs.

Yes, more DEFINITIONS n PROCESS CHAMPION – member of top management who has interest in promoting the control and improvement of a specific process. n PROCESS OWNER – the head of one of the key functions involved in the actual operation of the process and is responsible for ensuring that the process is understood, documented, implemented, controlled, and improved.

Last of the DEFINITIONS n VERIFICATION – the confirmation that specified requirements have been met n VALIDATION – confirmation through the provision of objective evidence that the requirements for a specific intended use or application have been fulfilled

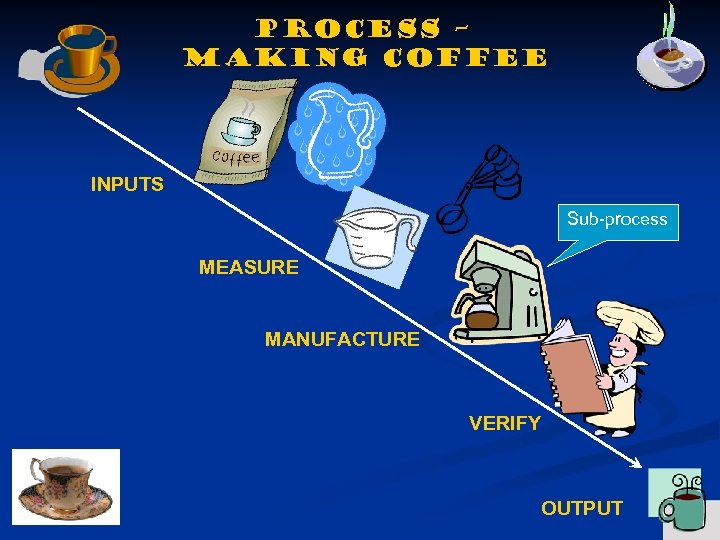

Process – making coffee INPUTS Sub-process MEASURE MANUFACTURE VERIFY OUTPUT

Process – making coffee VALIDATION

SYSTEMMAKING BREAKFAST COFFEE BACON & EGGS ORANGE JUICE TOAST

SYSTEM – making BREAKFAST VALIDATION

VERTCAL MANAGEMENT vs. QUALITY MANAGEMENT SYSTEM

Vertical Management Inputs Administration/Management Marketing Research and Development Purchasing Production Outputs

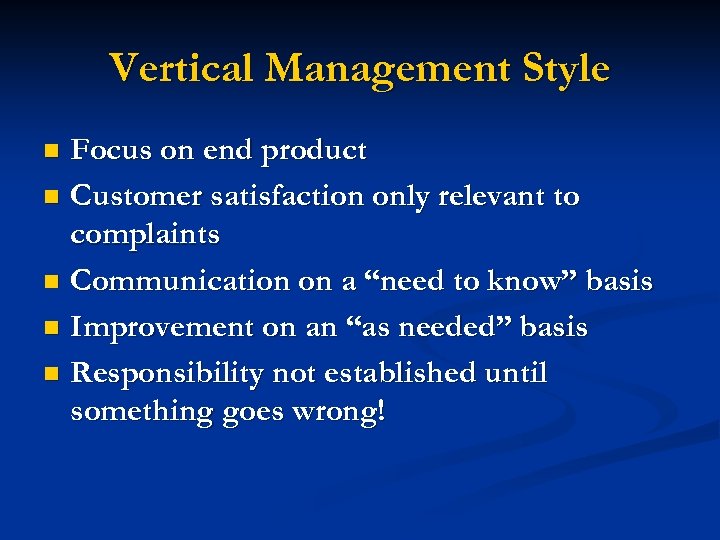

Vertical Management Style Focus on end product n Customer satisfaction only relevant to complaints n Communication on a “need to know” basis n Improvement on an “as needed” basis n Responsibility not established until something goes wrong! n

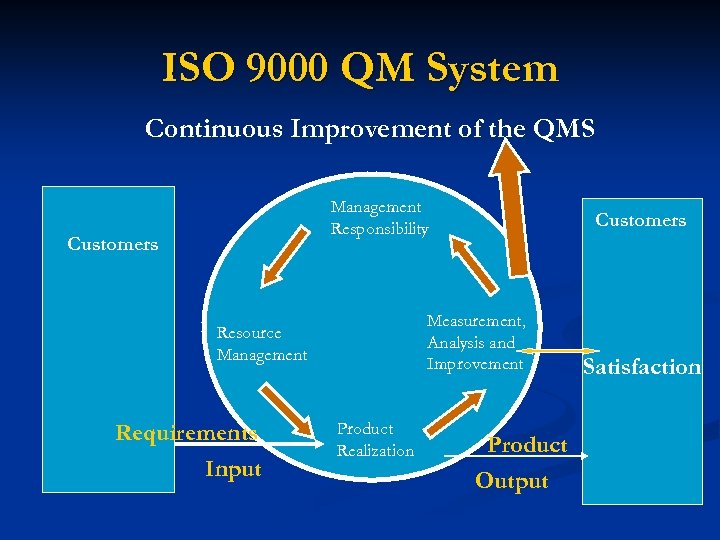

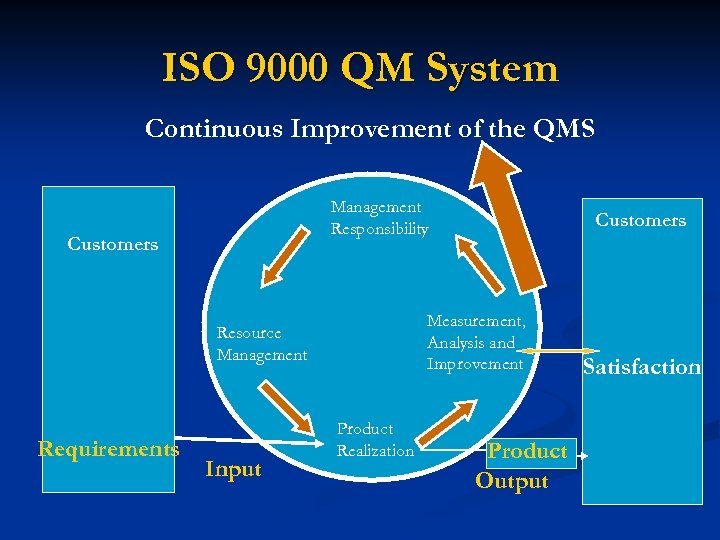

ISO 9000 QM System Continuous Improvement of the QMS Management Responsibility Customers Measurement, Analysis and Improvement Resource Management Requirements Input Customers Product Realization Product Output Satisfaction

Quality Management Style Focus on the entire system n Customer is main concern n Communication at all levels n Continuous Improvement n Responsibility assigned n

Why Implement a QMS? (ISO 9000) n n Ensure Customer Satisfaction Improve Quality System Enhance Control of Resources Improve Suppliers Performance

ISO 9000 REQUIREMENTS

ISO 9000 Requirements 1. SCOPE covers why the standard is used 2. APPLICATION states that the standard is generic and there can be exclusions from section 7 3. TERMS AND DEFINITIONS reference ISO 9000 and 9001 vocabulary

ISO 9000 Elements 4. General Requirements (Documentation requirements covered in earlier training) 5. Management Responsibility 6. Resource Management 7. Product Realization 8. Measurement, Analysis and Improvement

Just a Refresher n Documentation – The information used to provide a description of your operation and to record its activities Quality Manual, Work Instructions, Sales Invoices n Documents – work papers used for activities. They will change over time (living) Procedures, Forms, Policies n Records – historical material that will not change, but will be retained for reference (dead) Meeting minutes, Completed forms, Reports

ISO 9000 Element 4 General ( Documentation) Covered in “Creating and Documenting a Quality Management System” n Managers and supervisors most likely would write or participate in writing documents: n procedures n forms n work instructions n n Managers and supervisors provide oversight of record creation, preservation, and retention

ISO 9000 Element 5 Management Responsibility Management Commitment n Customer Focus n Planning (Objectives & QMS) n Responsibility, Authority and Communication (Management Representative) n Management Review n

ISO 9000 Element 5 Management Responsibility Top Management is responsible for Meeting Customer Requirements, Policy, Objectives, Planning, Management Review, and Management Representative n Mid-level Managers and Supervisors are responsible for supporting Top Management’s Objectives, Fostering Communication at ALL Levels, and Building Enthusiasm for the QMS Throughout the Company n

ISO 9000 Element 6 Resource Management (Human, Infrastructure and Environment) n Provision of Resources n Human Resources n General n Competence, Awareness, and Training n Infrastructure n Work Environment

ISO 9000 Element 6 Resource Management (Human, Infrastructure and Environment) Mid-level Managers and Supervisors must: n Ensure that all employees are competent to do their jobs; strive for performance improvement n Be observant of buildings, machinery and property; make recommendations as appropriate n Follow all safety rules and make certain employees follow your example; make working conditions as comfortable as possible – including both physical and emotional comfort

ISO 9000 Element 7 Product Realization n 7. 1 Planning n 7. 2 Customer-Related Processes n 7. 3 Design and Development n 7. 4 Purchasing n 7. 5 Production and Service Provision n 7. 6 Control of Monitoring and Measuring Devices

ISO 9000 Element 7. 1 Product Realization Planning of Product Realization Plan and Develop Process n Planning Consistent with other processes must determine: n Quality Objectives and Requirements n New processes, documents and resources n Verification, validation, monitoring, inspection and testing n Records n Suitability n

ISO 9000 Element 7. 2 Product Realization Customer-Related Processes n Determination of requirements related to the product n Review requirements related to the product n Customer communication

ISO 9000 Element 7. 3 Product Realization Design and Development Planning n Inputs n Outputs n Review n Verification n Validation n Control of changes n

ISO 9000 Element 7. 4 Product Realization Purchasing Process n Purchasing Information n Verification of Purchased Product

ISO 9000 Element 7. 5 Product Realization Production and Service Provision n Control of Production and Service Provision n Validation of Processes n Identification and Traceability n Customer Property n Preservation of Product

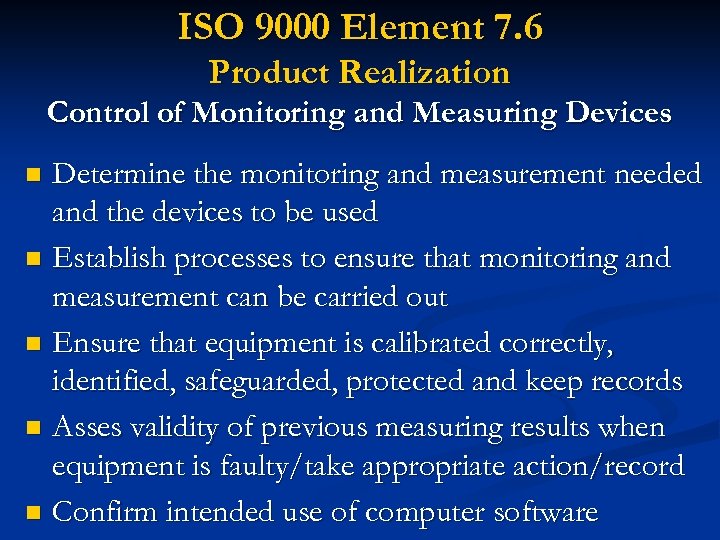

ISO 9000 Element 7. 6 Product Realization Control of Monitoring and Measuring Devices Determine the monitoring and measurement needed and the devices to be used n Establish processes to ensure that monitoring and measurement can be carried out n Ensure that equipment is calibrated correctly, identified, safeguarded, protected and keep records n Asses validity of previous measuring results when equipment is faulty/take appropriate action/record n Confirm intended use of computer software n

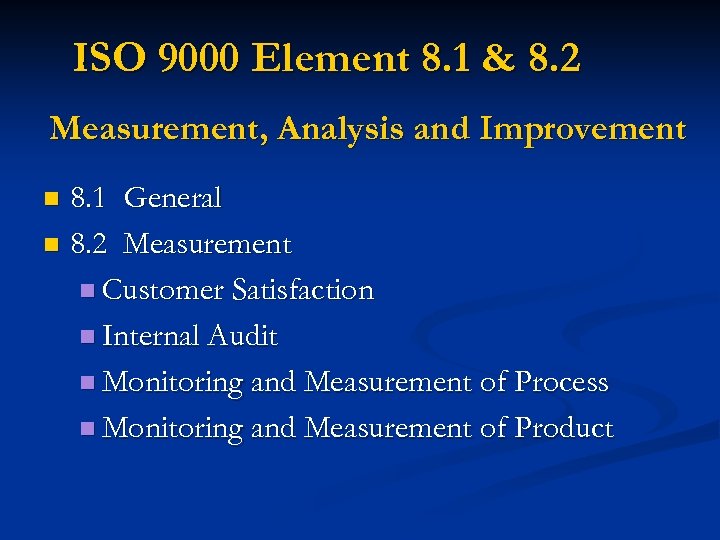

ISO 9000 Element 8 Measurement, Analysis and Improvement General n Monitoring and Measurement n Control of Nonconforming Product n Analysis of Data n Improvement n

ISO 9000 Element 8. 1 & 8. 2 Measurement, Analysis and Improvement 8. 1 General n 8. 2 Measurement n Customer Satisfaction n Internal Audit n Monitoring and Measurement of Process n Monitoring and Measurement of Product n

ISO 9000 Element 8. 3 & 8. 4 Measurement, Analysis and Improvement 8. 3 Control of Nonconforming Product n 8. 4 Analysis of Data n

ISO 9000 Element 8. 5 Measurement, Analysis and Improvement n Continual Improvement n Corrective Action n Preventive Action

ISO 9000 QM System Continuous Improvement of the QMS Management Responsibility Customers Measurement, Analysis and Improvement Resource Management Requirements Input Customers Product Realization Product Output Satisfaction

QUALITY MANAGEMENT PRINCIPLES

What are ISO 9000 Principles? Fundamental beliefs that form the foundation of the ISO requirements n Lead to quality excellence by following them n Are based on practical application n Can be applied at any level of the quality pyramid n Quality Control (QC) n Quality Management (QM) n Total Quality Management (TQM) n

ISO 9000 Principles n Customer Focus n Continual n Leadership Improvement n Factual Approach to Decision Making n Mutually beneficial supplier relationship n Involvement of People n Process Approach n Systems Approach to Management

ISO 9000 Principles 1. Customer Focus 2. QC -- understand meet basic requirements; little or no knowledge of customer perceptions 3. QM – better understanding of overall requirements; customer satisfaction tracked 4. TQM – customer information collected systematically throughout the company; knowledge of customer perception; ability to offer preferred products

ISO 9000 Principles 2. Leadership 3. QC – management provides resources sufficient for quality control 4. QM – management establishes policy, objectives and environment to control processes that ensure quality 5. TQM – managers provide personal examples that create customer satisfaction; quality is a strategic issue

ISO 9000 Principles 3. Involvement of people 4. QC – people must create and operate basic process; does not draw on full talents 5. QM – processes defined and personnel qualified; employees contribute to improvement 6. TQM – employees fully engaged & entirely involved; high level of

ISO 9000 Principles 4. Process Approach 5. QC – inspection and testing are common; controlled processes provide feedback 6. QM – movement from control of only process outputs to control of the process itself ; additional processes such as management review, corrective actions, etc. 7. TQM – optimizes resources, continually improves, uses process measures

ISO 9000 Principles 5. System Approach to Management QC – inspection and control systems work together but not integrated with the rest of the organization QM – moved to integrate the process for creating the product with verification of the final product; focus on customer satisfaction TQM – fully understands the interaction among the processes; continually improves

ISO 9000 Principles 6. Continual Improvement 7. QC – focus on improvements to ensure that the customer does not receive defective products 8. QM – focus on improving the effectiveness and efficiency of the QMS; mature corrective/preventive loop 9. TQM – focus on efficiently meeting customer needs through the QMS; leaders involved in improvement process

ISO 9000 Principles 7. Factual Approach to Decision Making 8. QC – uses data to distinguish nonconformities; statistical data ensure requirements are met; little use of data to measure trends 9. QM – facts and data used to make decisions regarding the QMS; focus on improvement 10. TQM – analysis used to improve market position; information gathered from all members of the organization

ISO 9000 Principles 8. Mutually Beneficial Supplier Relationship 9. QC – some validation of the suppliers product 10. QM – processes to define and document, review and evaluate; well developed and defined validation process 11. TQM – focus changes with established strategic alliances or partnerships; mutual commitment to customer satisfaction; focus

THANK YOU for Your Participation Beth Hayden, Process Verified Program Manager Grain Inspection, Packers and Stockyards Administration Beth. E. Hayden@usda. gov 202 205 -4007

6a818fa359108688383958623ae8a37b.ppt