bb792fea9bea41d926d1b5d432254865.ppt

- Количество слайдов: 35

Implementing a Lean/Six Sigma Culture to Transform Your Organization … and Drive Sustainability Wendy A. Kouba Vice President, Operations Management Bio Innovation Leader’s Summit London February 23, 2010 1

Implementing a Lean/Six Sigma Culture to Transform Your Organization … and Drive Sustainability Wendy A. Kouba Vice President, Operations Management Bio Innovation Leader’s Summit London February 23, 2010 1

Leading the Way to a Healthier World

Leading the Way to a Healthier World

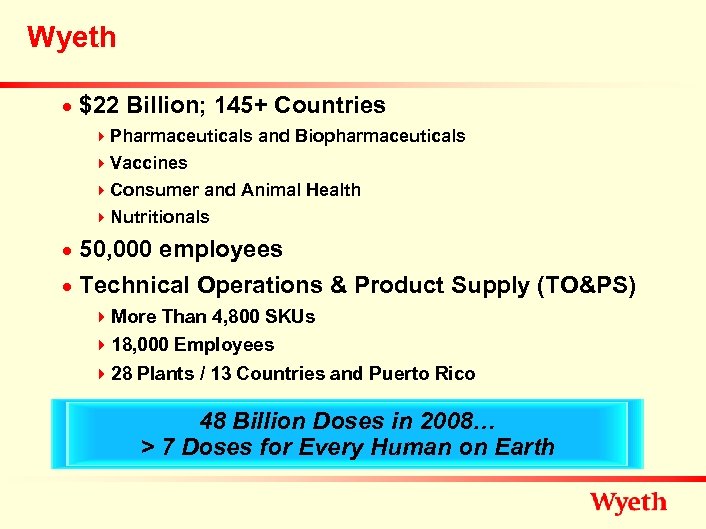

Wyeth n $22 Billion; 145+ Countries 4 Pharmaceuticals and Biopharmaceuticals 4 Vaccines 4 Consumer and Animal Health 4 Nutritionals 50, 000 employees n Technical Operations & Product Supply (TO&PS) n 4 More Than 4, 800 SKUs 418, 000 Employees 428 Plants / 13 Countries and Puerto Rico 48 Billion Doses in 2008… > 7 Doses for Every Human on Earth

Wyeth n $22 Billion; 145+ Countries 4 Pharmaceuticals and Biopharmaceuticals 4 Vaccines 4 Consumer and Animal Health 4 Nutritionals 50, 000 employees n Technical Operations & Product Supply (TO&PS) n 4 More Than 4, 800 SKUs 418, 000 Employees 428 Plants / 13 Countries and Puerto Rico 48 Billion Doses in 2008… > 7 Doses for Every Human on Earth

Our Story Begins in 2007 Changing industry environment Delayed new products Challenges to product exclusivity Changing regulatory environment – stricter requirements for new drugs n Decreasing R&D productivity n Significant generic penetration n Large product litigations n n Product approvals and contributions from new products delayed relative to expectations ~$6 B revenue exposed due to upcoming patent expirations December 2007: accelerated at-risk launch of generic

Our Story Begins in 2007 Changing industry environment Delayed new products Challenges to product exclusivity Changing regulatory environment – stricter requirements for new drugs n Decreasing R&D productivity n Significant generic penetration n Large product litigations n n Product approvals and contributions from new products delayed relative to expectations ~$6 B revenue exposed due to upcoming patent expirations December 2007: accelerated at-risk launch of generic

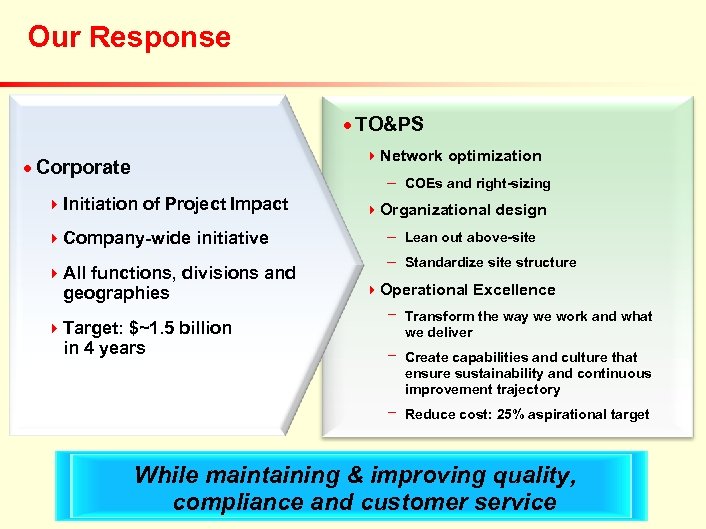

Our Response n n TO&PS 4 Network optimization Corporate – COEs and right-sizing 4 Initiation of Project Impact 4 Company-wide initiative 4 All functions, divisions and geographies 4 Target: $~1. 5 billion in 4 years 4 Organizational design – Lean out above-site – Standardize site structure 4 Operational Excellence − Transform the way we work and what we deliver − Create capabilities and culture that ensure sustainability and continuous improvement trajectory − Reduce cost: 25% aspirational target While maintaining & improving quality, compliance and customer service

Our Response n n TO&PS 4 Network optimization Corporate – COEs and right-sizing 4 Initiation of Project Impact 4 Company-wide initiative 4 All functions, divisions and geographies 4 Target: $~1. 5 billion in 4 years 4 Organizational design – Lean out above-site – Standardize site structure 4 Operational Excellence − Transform the way we work and what we deliver − Create capabilities and culture that ensure sustainability and continuous improvement trajectory − Reduce cost: 25% aspirational target While maintaining & improving quality, compliance and customer service

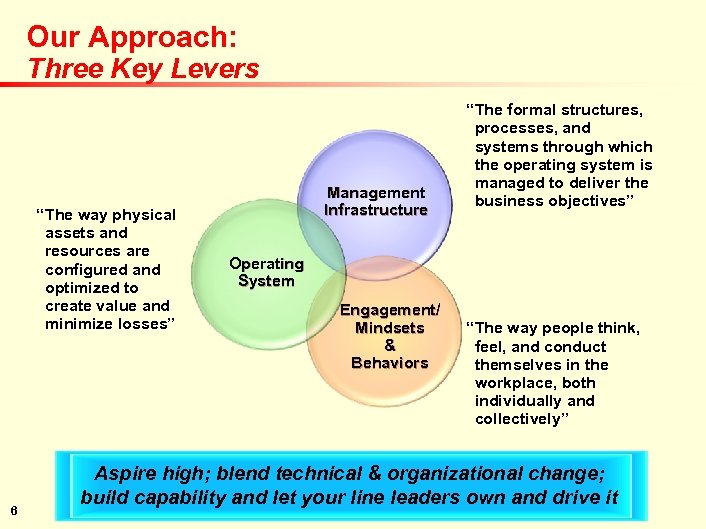

Our Approach: Three Key Levers “The way physical assets and resources are configured and optimized to create value and minimize losses” 6 Management Infrastructure “The formal structures, processes, and systems through which the operating system is managed to deliver the business objectives” Operating System Engagement/ Mindsets & Behaviors “The way people think, feel, and conduct themselves in the workplace, both individually and collectively” Aspire high; blend technical & organizational change; build capability and let your line leaders own and drive it

Our Approach: Three Key Levers “The way physical assets and resources are configured and optimized to create value and minimize losses” 6 Management Infrastructure “The formal structures, processes, and systems through which the operating system is managed to deliver the business objectives” Operating System Engagement/ Mindsets & Behaviors “The way people think, feel, and conduct themselves in the workplace, both individually and collectively” Aspire high; blend technical & organizational change; build capability and let your line leaders own and drive it

What Differentiated Our Approach? n Combines deep technical changes with cultural change 4 How people think and act: key to sustainability n n “Bias for action / tolerance for ambiguity” Led by local senior management engaging the people who do the work 4 They own it 4 Learning drives continuous improvement n Requires personal transformation and objective review to revitalize the organization 4 “Go and See” transforms our understanding of current state n Requires major upgrade in capabilities 4 Makes the changes sustainable n Changes the “daily work” of the majority of the workforce Process starts with a comprehensive site diagnostic…

What Differentiated Our Approach? n Combines deep technical changes with cultural change 4 How people think and act: key to sustainability n n “Bias for action / tolerance for ambiguity” Led by local senior management engaging the people who do the work 4 They own it 4 Learning drives continuous improvement n Requires personal transformation and objective review to revitalize the organization 4 “Go and See” transforms our understanding of current state n Requires major upgrade in capabilities 4 Makes the changes sustainable n Changes the “daily work” of the majority of the workforce Process starts with a comprehensive site diagnostic…

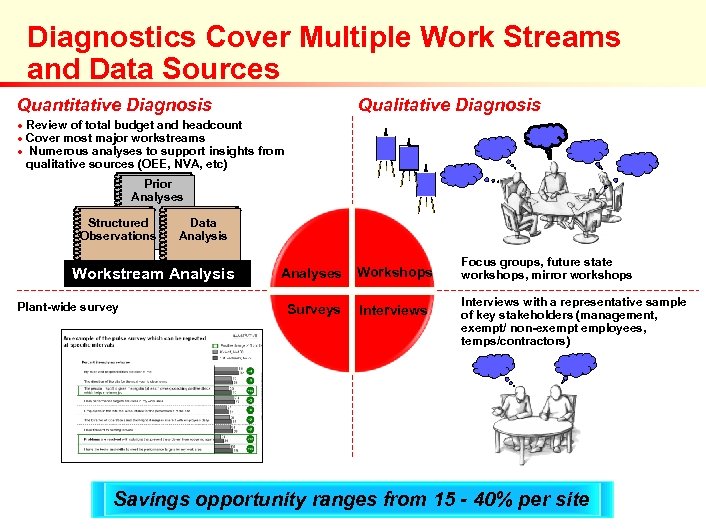

Diagnostics Cover Multiple Work Streams and Data Sources Quantitative Diagnosis Qualitative Diagnosis Review of total budget and headcount Cover most major workstreams n Numerous analyses to support insights from qualitative sources (OEE, NVA, etc) n n Prior Analyses Structured Observations Data Analysis Workstream Analysis Plant-wide survey Analyses Workshops Surveys Interviews Focus groups, future state workshops, mirror workshops Interviews with a representative sample of key stakeholders (management, exempt/ non-exempt employees, temps/contractors) Savings opportunity ranges from 15 - 40% per site

Diagnostics Cover Multiple Work Streams and Data Sources Quantitative Diagnosis Qualitative Diagnosis Review of total budget and headcount Cover most major workstreams n Numerous analyses to support insights from qualitative sources (OEE, NVA, etc) n n Prior Analyses Structured Observations Data Analysis Workstream Analysis Plant-wide survey Analyses Workshops Surveys Interviews Focus groups, future state workshops, mirror workshops Interviews with a representative sample of key stakeholders (management, exempt/ non-exempt employees, temps/contractors) Savings opportunity ranges from 15 - 40% per site

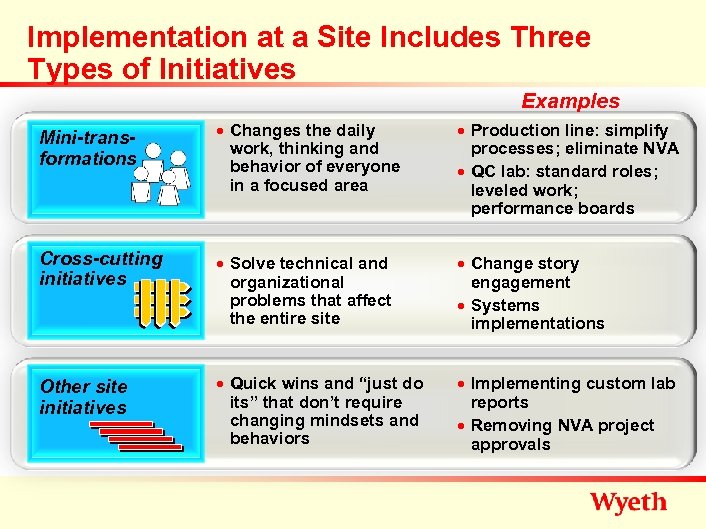

Implementation at a Site Includes Three Types of Initiatives Examples Mini-transformations Cross-cutting initiatives Other site initiatives n n n Changes the daily work, thinking and behavior of everyone in a focused area Solve technical and organizational problems that affect the entire site Quick wins and “just do its” that don’t require changing mindsets and behaviors Production line: simplify processes; eliminate NVA n QC lab: standard roles; leveled work; performance boards n Change story engagement n Systems implementations n Implementing custom lab reports n Removing NVA project approvals n

Implementation at a Site Includes Three Types of Initiatives Examples Mini-transformations Cross-cutting initiatives Other site initiatives n n n Changes the daily work, thinking and behavior of everyone in a focused area Solve technical and organizational problems that affect the entire site Quick wins and “just do its” that don’t require changing mindsets and behaviors Production line: simplify processes; eliminate NVA n QC lab: standard roles; leveled work; performance boards n Change story engagement n Systems implementations n Implementing custom lab reports n Removing NVA project approvals n

We Changed the Way We Think & Work n Data-driven decision making and acting on fact 4 Improvements in OEE 4 Elimination of non-value added meetings 4 Increased capacity from significant reduction in changeover time n Dedicated production trains and rhythm wheels 4 Tailored to velocity of product and value-streams 4 Lean Labs n Improvements in yield from technical changes 4 Awareness of cost and implications of waste n “Hot-seat” swapping and shift huddles n Visual management through performance boards n “Get out and Gemba” n Building capability 4 Forum and field

We Changed the Way We Think & Work n Data-driven decision making and acting on fact 4 Improvements in OEE 4 Elimination of non-value added meetings 4 Increased capacity from significant reduction in changeover time n Dedicated production trains and rhythm wheels 4 Tailored to velocity of product and value-streams 4 Lean Labs n Improvements in yield from technical changes 4 Awareness of cost and implications of waste n “Hot-seat” swapping and shift huddles n Visual management through performance boards n “Get out and Gemba” n Building capability 4 Forum and field

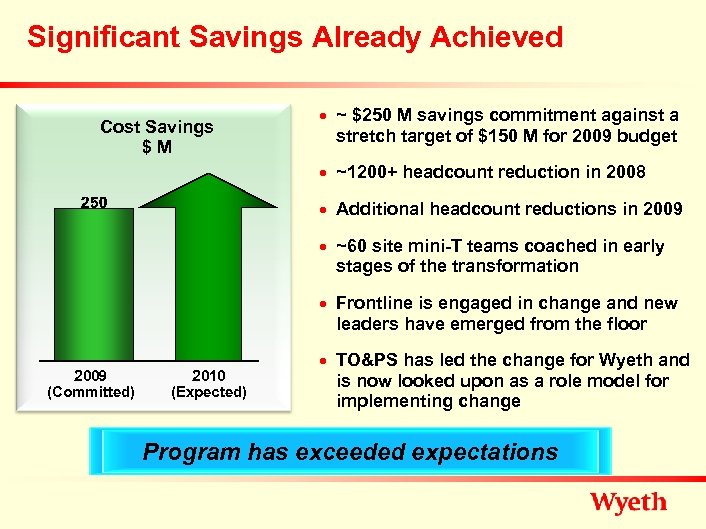

Significant Savings Already Achieved Cost Savings $M n ~ $250 M savings commitment against a stretch target of $150 M for 2009 budget n ~1200+ headcount reduction in 2008 n Additional headcount reductions in 2009 n n 2009 (Committed) 2010 (Expected) n ~60 site mini-T teams coached in early stages of the transformation Frontline is engaged in change and new leaders have emerged from the floor TO&PS has led the change for Wyeth and is now looked upon as a role model for implementing change Program has exceeded expectations

Significant Savings Already Achieved Cost Savings $M n ~ $250 M savings commitment against a stretch target of $150 M for 2009 budget n ~1200+ headcount reduction in 2008 n Additional headcount reductions in 2009 n n 2009 (Committed) 2010 (Expected) n ~60 site mini-T teams coached in early stages of the transformation Frontline is engaged in change and new leaders have emerged from the floor TO&PS has led the change for Wyeth and is now looked upon as a role model for implementing change Program has exceeded expectations

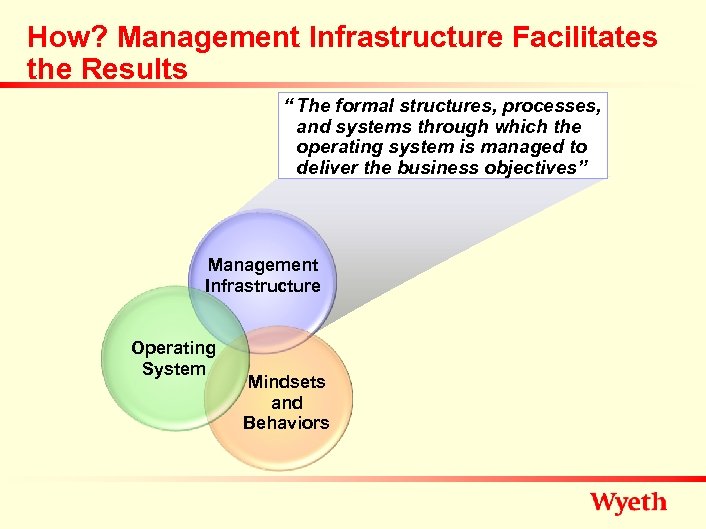

How? Management Infrastructure Facilitates the Results “ The formal structures, processes, and systems through which the operating system is managed to deliver the business objectives” Management Infrastructure Operating System Mindsets and Behaviors

How? Management Infrastructure Facilitates the Results “ The formal structures, processes, and systems through which the operating system is managed to deliver the business objectives” Management Infrastructure Operating System Mindsets and Behaviors

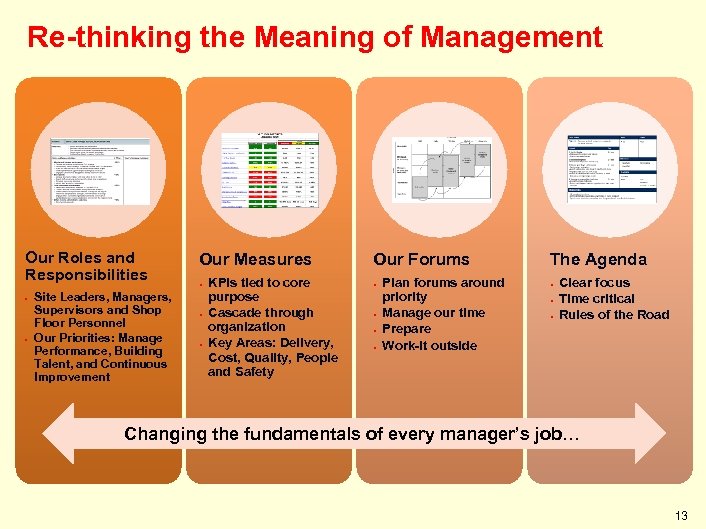

Re-thinking the Meaning of Management Our Roles and Responsibilities • • Site Leaders, Managers, Supervisors and Shop Floor Personnel Our Priorities: Manage Performance, Building Talent, and Continuous Improvement Our Measures • • • KPIs tied to core purpose Cascade through organization Key Areas: Delivery, Cost, Quality, People and Safety Our Forums • • Plan forums around priority Manage our time Prepare Work-it outside The Agenda • • • Clear focus Time critical Rules of the Road Changing the fundamentals of every manager’s job… 13

Re-thinking the Meaning of Management Our Roles and Responsibilities • • Site Leaders, Managers, Supervisors and Shop Floor Personnel Our Priorities: Manage Performance, Building Talent, and Continuous Improvement Our Measures • • • KPIs tied to core purpose Cascade through organization Key Areas: Delivery, Cost, Quality, People and Safety Our Forums • • Plan forums around priority Manage our time Prepare Work-it outside The Agenda • • • Clear focus Time critical Rules of the Road Changing the fundamentals of every manager’s job… 13

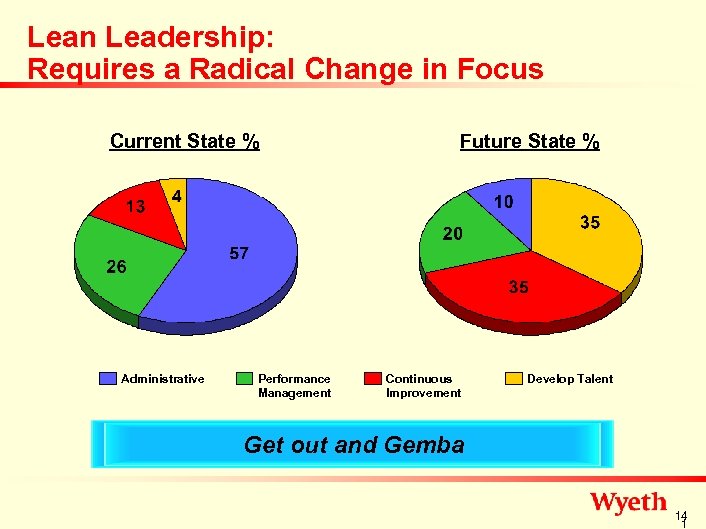

Lean Leadership: Requires a Radical Change in Focus Current State % Administrative Performance Management Future State % Continuous Improvement Develop Talent Get out and Gemba 14 1

Lean Leadership: Requires a Radical Change in Focus Current State % Administrative Performance Management Future State % Continuous Improvement Develop Talent Get out and Gemba 14 1

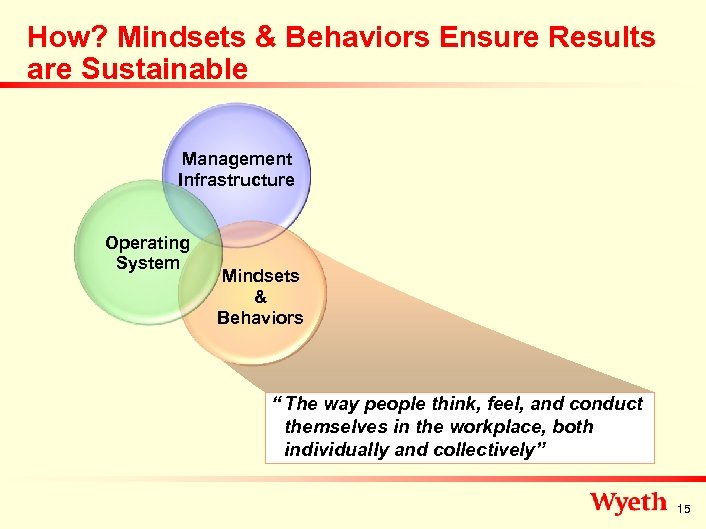

How? Mindsets & Behaviors Ensure Results are Sustainable Management Infrastructure Operating System Mindsets & Behaviors “ The way people think, feel, and conduct themselves in the workplace, both individually and collectively” 15

How? Mindsets & Behaviors Ensure Results are Sustainable Management Infrastructure Operating System Mindsets & Behaviors “ The way people think, feel, and conduct themselves in the workplace, both individually and collectively” 15

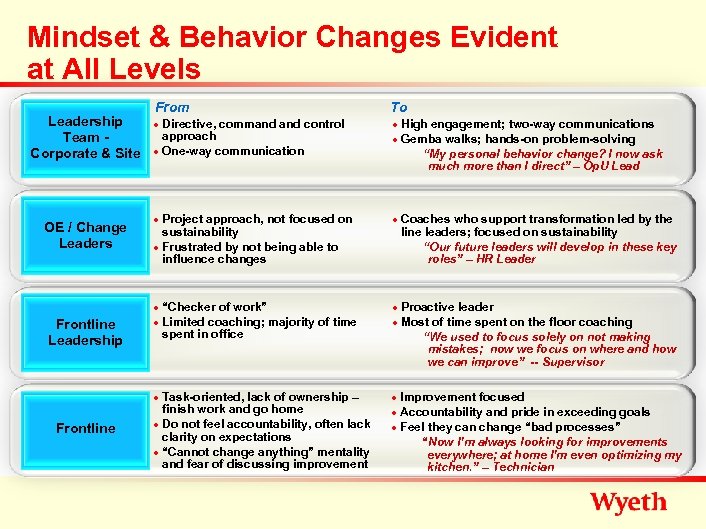

Mindset & Behavior Changes Evident at All Levels Leadership Team Corporate & Site OE / Change Leaders From Directive, command control approach n One-way communication n Project approach, not focused on sustainability n Frustrated by not being able to influence changes n “Checker of work” n Limited coaching; majority of time spent in office n Frontline Leadership Task-oriented, lack of ownership – finish work and go home n Do not feel accountability, often lack clarity on expectations n “Cannot change anything” mentality and fear of discussing improvement n Frontline To n n n High engagement; two-way communications Gemba walks; hands-on problem-solving “My personal behavior change? I now ask much more than I direct” – Op. U Lead Coaches who support transformation led by the line leaders; focused on sustainability “Our future leaders will develop in these key roles” – HR Leader Proactive leader n Most of time spent on the floor coaching “We used to focus solely on not making mistakes; now we focus on where and how we can improve” -- Supervisor n Improvement focused n Accountability and pride in exceeding goals n Feel they can change “bad processes” “Now I’m always looking for improvements everywhere; at home I’m even optimizing my kitchen. ” – Technician n

Mindset & Behavior Changes Evident at All Levels Leadership Team Corporate & Site OE / Change Leaders From Directive, command control approach n One-way communication n Project approach, not focused on sustainability n Frustrated by not being able to influence changes n “Checker of work” n Limited coaching; majority of time spent in office n Frontline Leadership Task-oriented, lack of ownership – finish work and go home n Do not feel accountability, often lack clarity on expectations n “Cannot change anything” mentality and fear of discussing improvement n Frontline To n n n High engagement; two-way communications Gemba walks; hands-on problem-solving “My personal behavior change? I now ask much more than I direct” – Op. U Lead Coaches who support transformation led by the line leaders; focused on sustainability “Our future leaders will develop in these key roles” – HR Leader Proactive leader n Most of time spent on the floor coaching “We used to focus solely on not making mistakes; now we focus on where and how we can improve” -- Supervisor n Improvement focused n Accountability and pride in exceeding goals n Feel they can change “bad processes” “Now I’m always looking for improvements everywhere; at home I’m even optimizing my kitchen. ” – Technician n

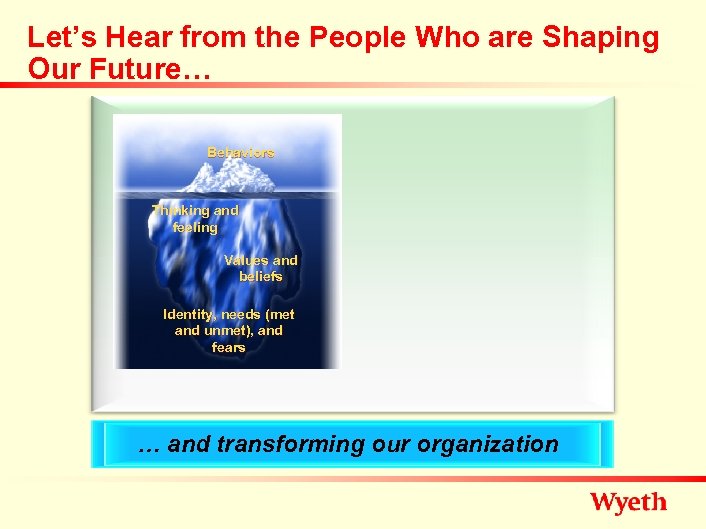

Let’s Hear from the People Who are Shaping Our Future… Behaviors Thinking and feeling Values and beliefs Identity, needs (met and unmet), and fears … and transforming our organization

Let’s Hear from the People Who are Shaping Our Future… Behaviors Thinking and feeling Values and beliefs Identity, needs (met and unmet), and fears … and transforming our organization

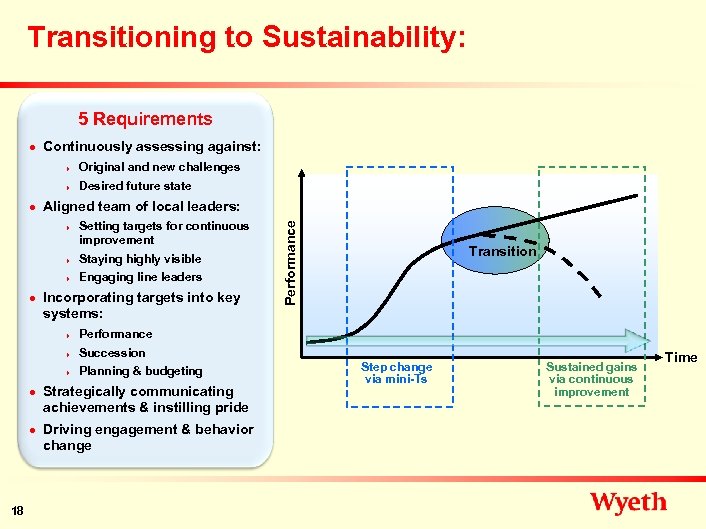

Transitioning to Sustainability: 5 Requirements Continuously assessing against: 4 4 n Original and new challenges Desired future state Aligned team of local leaders: 4 Setting targets for continuous improvement 4 4 n Staying highly visible Engaging line leaders Incorporating targets into key systems: 4 n n 18 Succession 4 Planning & budgeting Transition Performance 4 Performance n Strategically communicating achievements & instilling pride Driving engagement & behavior change Step change via mini-Ts Sustained gains via continuous improvement Time

Transitioning to Sustainability: 5 Requirements Continuously assessing against: 4 4 n Original and new challenges Desired future state Aligned team of local leaders: 4 Setting targets for continuous improvement 4 4 n Staying highly visible Engaging line leaders Incorporating targets into key systems: 4 n n 18 Succession 4 Planning & budgeting Transition Performance 4 Performance n Strategically communicating achievements & instilling pride Driving engagement & behavior change Step change via mini-Ts Sustained gains via continuous improvement Time

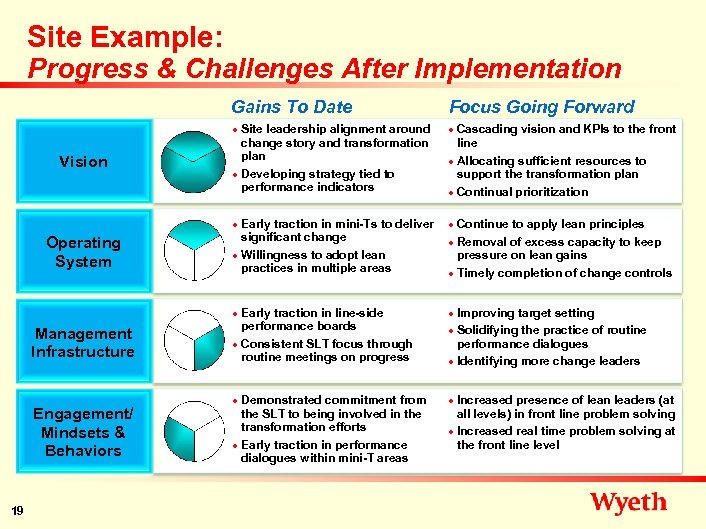

Site Example: Progress & Challenges After Implementation Gains To Date Site leadership alignment around change story and transformation plan n Developing strategy tied to performance indicators n Vision Early traction in mini-Ts to deliver significant change n Willingness to adopt lean practices in multiple areas n Operating System Early traction in line-side performance boards n Consistent SLT focus through routine meetings on progress n Management Infrastructure Engagement/ Mindsets & Behaviors 19 Demonstrated commitment from the SLT to being involved in the transformation efforts n Early traction in performance dialogues within mini-T areas n Focus Going Forward Cascading vision and KPIs to the front line n Allocating sufficient resources to support the transformation plan n Continual prioritization n Continue to apply lean principles n Removal of excess capacity to keep pressure on lean gains n Timely completion of change controls n Improving target setting n Solidifying the practice of routine performance dialogues n Identifying more change leaders n Increased presence of lean leaders (at all levels) in front line problem solving n Increased real time problem solving at the front line level n

Site Example: Progress & Challenges After Implementation Gains To Date Site leadership alignment around change story and transformation plan n Developing strategy tied to performance indicators n Vision Early traction in mini-Ts to deliver significant change n Willingness to adopt lean practices in multiple areas n Operating System Early traction in line-side performance boards n Consistent SLT focus through routine meetings on progress n Management Infrastructure Engagement/ Mindsets & Behaviors 19 Demonstrated commitment from the SLT to being involved in the transformation efforts n Early traction in performance dialogues within mini-T areas n Focus Going Forward Cascading vision and KPIs to the front line n Allocating sufficient resources to support the transformation plan n Continual prioritization n Continue to apply lean principles n Removal of excess capacity to keep pressure on lean gains n Timely completion of change controls n Improving target setting n Solidifying the practice of routine performance dialogues n Identifying more change leaders n Increased presence of lean leaders (at all levels) in front line problem solving n Increased real time problem solving at the front line level n

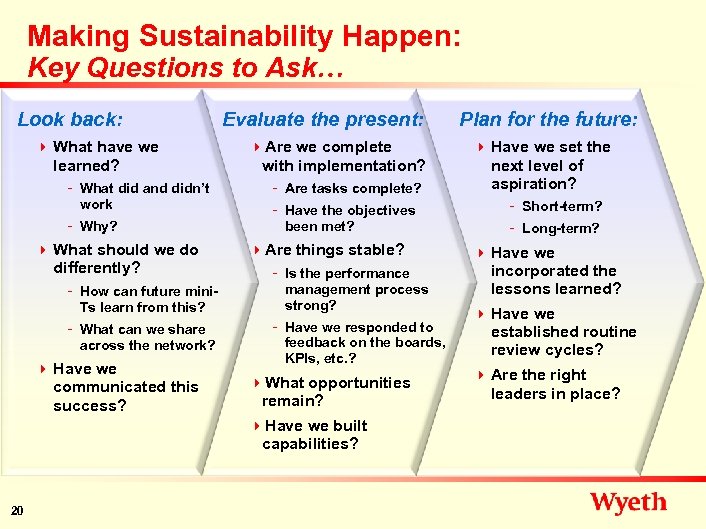

Making Sustainability Happen: Key Questions to Ask Look back: 4 What have we learned? - What did and didn’t work - Why? 4 What should we do differently? - How can future mini. Ts learn from this? - What can we share across the network? 4 Have we communicated this success? Evaluate the present: 4 Are we complete with implementation? - Are tasks complete? - Have the objectives been met? 4 Are things stable? - Is the performance management process strong? - Have we responded to feedback on the boards, KPIs, etc. ? 4 What opportunities remain? 4 Have we built capabilities? 20 Plan for the future: 4 Have we set the next level of aspiration? - Short-term? - Long-term? 4 Have we incorporated the lessons learned? 4 Have we established routine review cycles? 4 Are the right leaders in place?

Making Sustainability Happen: Key Questions to Ask Look back: 4 What have we learned? - What did and didn’t work - Why? 4 What should we do differently? - How can future mini. Ts learn from this? - What can we share across the network? 4 Have we communicated this success? Evaluate the present: 4 Are we complete with implementation? - Are tasks complete? - Have the objectives been met? 4 Are things stable? - Is the performance management process strong? - Have we responded to feedback on the boards, KPIs, etc. ? 4 What opportunities remain? 4 Have we built capabilities? 20 Plan for the future: 4 Have we set the next level of aspiration? - Short-term? - Long-term? 4 Have we incorporated the lessons learned? 4 Have we established routine review cycles? 4 Are the right leaders in place?

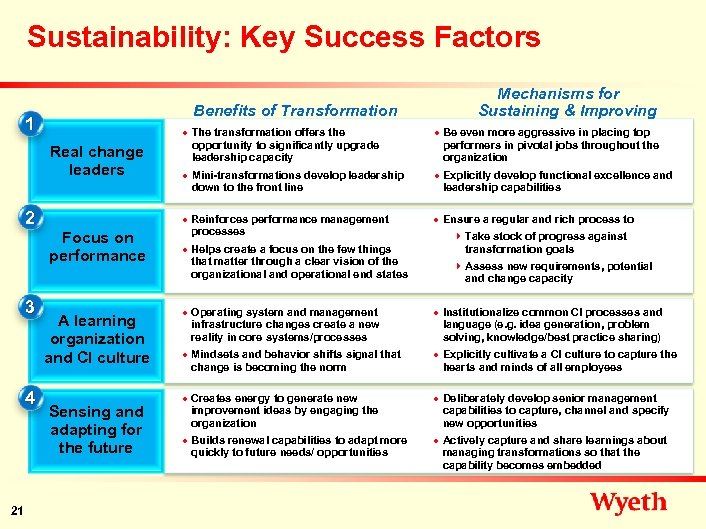

Sustainability: Key Success Factors Benefits of Transformation 1 n Real change leaders 2 4 21 n n Focus on performance 3 Mechanisms for Sustaining & Improving A learning organization and CI culture Sensing and adapting for the future n n n The transformation offers the opportunity to significantly upgrade leadership capacity Mini-transformations develop leadership down to the front line Reinforces performance management processes n n n Mindsets and behavior shifts signal that change is becoming the norm Creates energy to generate new improvement ideas by engaging the organization Builds renewal capabilities to adapt more quickly to future needs/ opportunities Explicitly develop functional excellence and leadership capabilities Ensure a regular and rich process to 4 Take stock of progress against Helps create a focus on the few things that matter through a clear vision of the organizational and operational end states Operating system and management infrastructure changes create a new reality in core systems/processes Be even more aggressive in placing top performers in pivotal jobs throughout the organization transformation goals 4 Assess new requirements, potential and change capacity n n Institutionalize common CI processes and language (e. g. idea generation, problem solving, knowledge/best practice sharing) Explicitly cultivate a CI culture to capture the hearts and minds of all employees Deliberately develop senior management capabilities to capture, channel and specify new opportunities Actively capture and share learnings about managing transformations so that the capability becomes embedded

Sustainability: Key Success Factors Benefits of Transformation 1 n Real change leaders 2 4 21 n n Focus on performance 3 Mechanisms for Sustaining & Improving A learning organization and CI culture Sensing and adapting for the future n n n The transformation offers the opportunity to significantly upgrade leadership capacity Mini-transformations develop leadership down to the front line Reinforces performance management processes n n n Mindsets and behavior shifts signal that change is becoming the norm Creates energy to generate new improvement ideas by engaging the organization Builds renewal capabilities to adapt more quickly to future needs/ opportunities Explicitly develop functional excellence and leadership capabilities Ensure a regular and rich process to 4 Take stock of progress against Helps create a focus on the few things that matter through a clear vision of the organizational and operational end states Operating system and management infrastructure changes create a new reality in core systems/processes Be even more aggressive in placing top performers in pivotal jobs throughout the organization transformation goals 4 Assess new requirements, potential and change capacity n n Institutionalize common CI processes and language (e. g. idea generation, problem solving, knowledge/best practice sharing) Explicitly cultivate a CI culture to capture the hearts and minds of all employees Deliberately develop senior management capabilities to capture, channel and specify new opportunities Actively capture and share learnings about managing transformations so that the capability becomes embedded

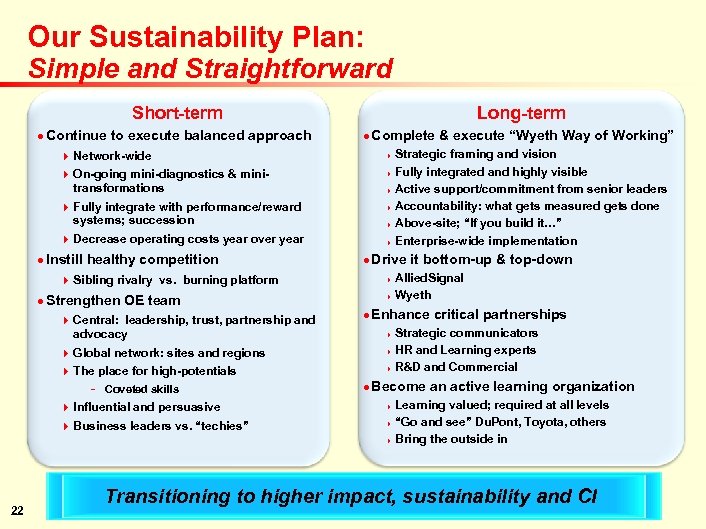

Our Sustainability Plan: Simple and Straightforward Short-term n Continue to execute balanced approach Long-term n Strategic framing and vision 4 Fully integrated and highly visible 4 Active support/commitment from senior leaders 4 Accountability: what gets measured gets done 4 Above-site; “If you build it…” 4 Enterprise-wide implementation 4 Network-wide 4 4 On-going mini-diagnostics & minitransformations 4 Fully integrate with performance/reward systems; succession 4 Decrease operating costs year over year n Instill healthy competition n 4 Strengthen OE team 4 Central: leadership, trust, partnership and advocacy n Strategic communicators 4 HR and Learning experts 4 R&D and Commercial 4 The place for high-potentials 4 Influential and persuasive 4 Business leaders vs. “techies” 22 Enhance critical partnerships 4 4 Global network: sites and regions - Coveted skills Drive it bottom-up & top-down Allied. Signal 4 Wyeth 4 Sibling rivalry vs. burning platform n Complete & execute “Wyeth Way of Working” n Become an active learning organization Learning valued; required at all levels 4 “Go and see” Du. Pont, Toyota, others 4 Bring the outside in 4 Transitioning to higher impact, sustainability and CI

Our Sustainability Plan: Simple and Straightforward Short-term n Continue to execute balanced approach Long-term n Strategic framing and vision 4 Fully integrated and highly visible 4 Active support/commitment from senior leaders 4 Accountability: what gets measured gets done 4 Above-site; “If you build it…” 4 Enterprise-wide implementation 4 Network-wide 4 4 On-going mini-diagnostics & minitransformations 4 Fully integrate with performance/reward systems; succession 4 Decrease operating costs year over year n Instill healthy competition n 4 Strengthen OE team 4 Central: leadership, trust, partnership and advocacy n Strategic communicators 4 HR and Learning experts 4 R&D and Commercial 4 The place for high-potentials 4 Influential and persuasive 4 Business leaders vs. “techies” 22 Enhance critical partnerships 4 4 Global network: sites and regions - Coveted skills Drive it bottom-up & top-down Allied. Signal 4 Wyeth 4 Sibling rivalry vs. burning platform n Complete & execute “Wyeth Way of Working” n Become an active learning organization Learning valued; required at all levels 4 “Go and see” Du. Pont, Toyota, others 4 Bring the outside in 4 Transitioning to higher impact, sustainability and CI

Key Tools and Processes n Diagnostic methodology n Capability deployment 4 SLT, FLS and Mini-T 23

Key Tools and Processes n Diagnostic methodology n Capability deployment 4 SLT, FLS and Mini-T 23

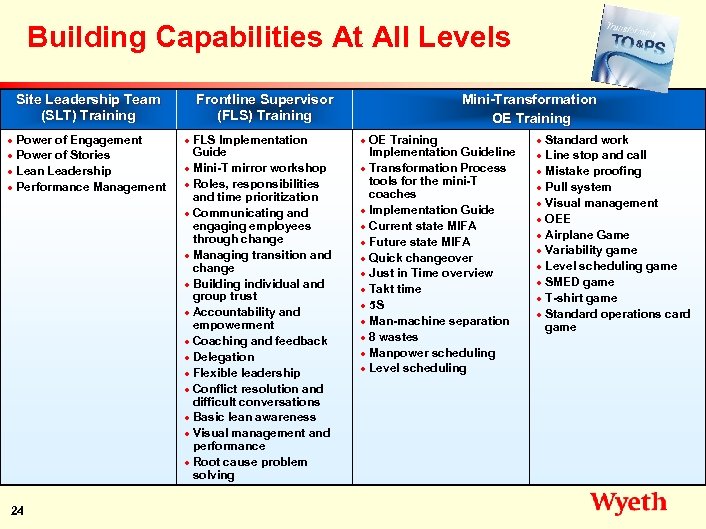

Building Capabilities At All Levels Site Leadership Team (SLT) Training Power of Engagement n Power of Stories n Leadership n Performance Management n 24 Frontline Supervisor (FLS) Training FLS Implementation Guide n Mini-T mirror workshop n Roles, responsibilities and time prioritization n Communicating and engaging employees through change n Managing transition and change n Building individual and group trust n Accountability and empowerment n Coaching and feedback n Delegation n Flexible leadership n Conflict resolution and difficult conversations n Basic lean awareness n Visual management and performance n Root cause problem solving n Mini-Transformation OE Training Implementation Guideline n Transformation Process tools for the mini-T coaches n Implementation Guide n Current state MIFA n Future state MIFA n Quick changeover n Just in Time overview n Takt time n 5 S n Man-machine separation n 8 wastes n Manpower scheduling n Level scheduling n Standard work n Line stop and call n Mistake proofing n Pull system n Visual management n OEE n Airplane Game n Variability game n Level scheduling game n SMED game n T-shirt game n Standard operations card game n

Building Capabilities At All Levels Site Leadership Team (SLT) Training Power of Engagement n Power of Stories n Leadership n Performance Management n 24 Frontline Supervisor (FLS) Training FLS Implementation Guide n Mini-T mirror workshop n Roles, responsibilities and time prioritization n Communicating and engaging employees through change n Managing transition and change n Building individual and group trust n Accountability and empowerment n Coaching and feedback n Delegation n Flexible leadership n Conflict resolution and difficult conversations n Basic lean awareness n Visual management and performance n Root cause problem solving n Mini-Transformation OE Training Implementation Guideline n Transformation Process tools for the mini-T coaches n Implementation Guide n Current state MIFA n Future state MIFA n Quick changeover n Just in Time overview n Takt time n 5 S n Man-machine separation n 8 wastes n Manpower scheduling n Level scheduling n Standard work n Line stop and call n Mistake proofing n Pull system n Visual management n OEE n Airplane Game n Variability game n Level scheduling game n SMED game n T-shirt game n Standard operations card game n

Key Tools and Processes n n Diagnostic methodology Capability deployment 4 SLT, FLS and Mini-T n Roadmaps 4 Transformation and Future State n n Site needs analysis and self-assessment Consulting tools 4 Waste walks, FL meetings, Performance Boards, 5 Whys? , and more n Structured knowledge management 4 Communities of Practice 4 Strategic communications n Global Recognition 4 Site Best Practices 4 Network Excellence Award n 25 Replication Process

Key Tools and Processes n n Diagnostic methodology Capability deployment 4 SLT, FLS and Mini-T n Roadmaps 4 Transformation and Future State n n Site needs analysis and self-assessment Consulting tools 4 Waste walks, FL meetings, Performance Boards, 5 Whys? , and more n Structured knowledge management 4 Communities of Practice 4 Strategic communications n Global Recognition 4 Site Best Practices 4 Network Excellence Award n 25 Replication Process

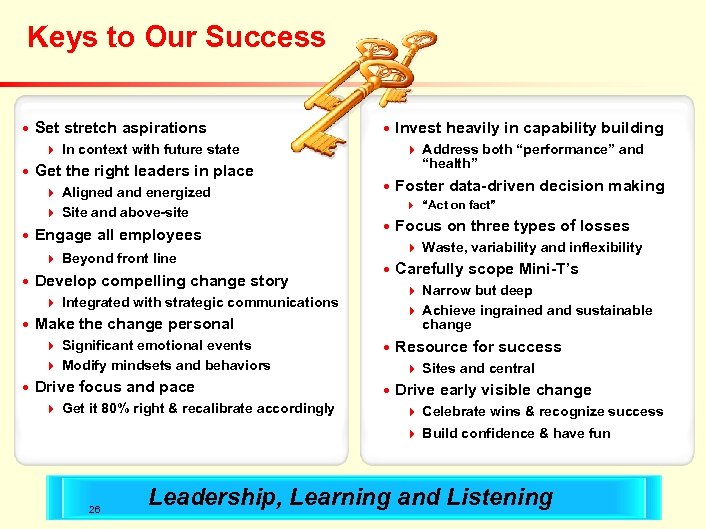

Keys to Our Success n Set stretch aspirations n 4 In context with future state n n Engage all employees 4 Beyond front line n 4 Address both “performance” and “health” Get the right leaders in place 4 Aligned and energized 4 Site and above-site Develop compelling change story n n n Drive focus and pace 4 Get it 80% right & recalibrate accordingly Focus on three types of losses 4 Waste, variability and inflexibility n Carefully scope Mini-T’s 4 Narrow but deep 4 Achieve ingrained and sustainable change Make the change personal 4 Significant emotional events 4 Modify mindsets and behaviors Foster data-driven decision making 4 “Act on fact” 4 Integrated with strategic communications n Invest heavily in capability building n Resource for success 4 Sites and central n Drive early visible change 4 Celebrate wins & recognize success 4 Build confidence & have fun 26 Leadership, Learning and Listening

Keys to Our Success n Set stretch aspirations n 4 In context with future state n n Engage all employees 4 Beyond front line n 4 Address both “performance” and “health” Get the right leaders in place 4 Aligned and energized 4 Site and above-site Develop compelling change story n n n Drive focus and pace 4 Get it 80% right & recalibrate accordingly Focus on three types of losses 4 Waste, variability and inflexibility n Carefully scope Mini-T’s 4 Narrow but deep 4 Achieve ingrained and sustainable change Make the change personal 4 Significant emotional events 4 Modify mindsets and behaviors Foster data-driven decision making 4 “Act on fact” 4 Integrated with strategic communications n Invest heavily in capability building n Resource for success 4 Sites and central n Drive early visible change 4 Celebrate wins & recognize success 4 Build confidence & have fun 26 Leadership, Learning and Listening

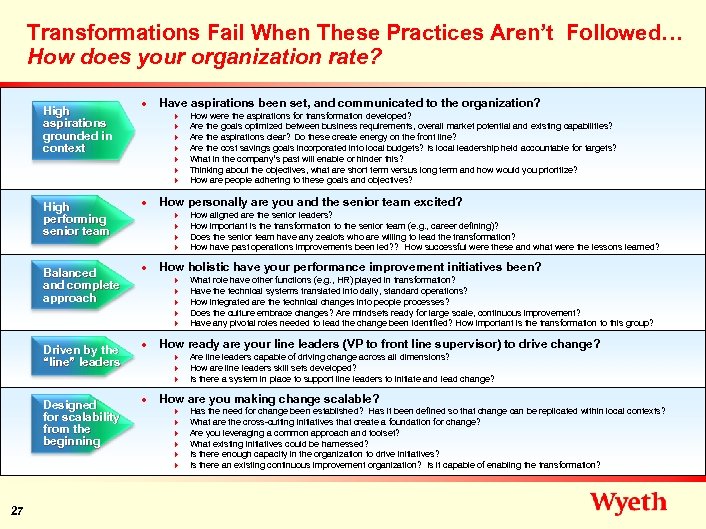

Transformations Fail When These Practices Aren’t Followed… How does your organization rate? High aspirations grounded in context n 4 4 4 4 High performing senior team n Balanced and complete approach n Driven by the “line” leaders n Designed for scalability from the beginning 27 Have aspirations been set, and communicated to the organization? n How were the aspirations for transformation developed? Are the goals optimized between business requirements, overall market potential and existing capabilities? Are the aspirations clear? Do these create energy on the front line? Are the cost savings goals incorporated into local budgets? Is local leadership held accountable for targets? What in the company’s past will enable or hinder this? Thinking about the objectives, what are short term versus long term and how would you prioritize? How are people adhering to these goals and objectives? How personally are you and the senior team excited? 4 4 How aligned are the senior leaders? How important is the transformation to the senior team (e. g. , career defining)? Does the senior team have any zealots who are willing to lead the transformation? How have past operations improvements been led? ? How successful were these and what were the lessons learned? How holistic have your performance improvement initiatives been? 4 4 4 What role have other functions (e. g. , HR) played in transformation? Have the technical systems translated into daily, standard operations? How integrated are the technical changes into people processes? Does the culture embrace changes? Are mindsets ready for large scale, continuous improvement? Have any pivotal roles needed to lead the change been identified? How important is the transformation to this group? How ready are your line leaders (VP to front line supervisor) to drive change? 4 Are line leaders capable of driving change across all dimensions? 4 How are line leaders skill sets developed? 4 Is there a system in place to support line leaders to initiate and lead change? How are you making change scalable? 4 4 4 Has the need for change been established? Has it been defined so that change can be replicated within local contexts? What are the cross-cutting initiatives that create a foundation for change? Are you leveraging a common approach and toolset? What existing initiatives could be harnessed? Is there enough capacity in the organization to drive initiatives? Is there an existing continuous improvement organization? Is it capable of enabling the transformation?

Transformations Fail When These Practices Aren’t Followed… How does your organization rate? High aspirations grounded in context n 4 4 4 4 High performing senior team n Balanced and complete approach n Driven by the “line” leaders n Designed for scalability from the beginning 27 Have aspirations been set, and communicated to the organization? n How were the aspirations for transformation developed? Are the goals optimized between business requirements, overall market potential and existing capabilities? Are the aspirations clear? Do these create energy on the front line? Are the cost savings goals incorporated into local budgets? Is local leadership held accountable for targets? What in the company’s past will enable or hinder this? Thinking about the objectives, what are short term versus long term and how would you prioritize? How are people adhering to these goals and objectives? How personally are you and the senior team excited? 4 4 How aligned are the senior leaders? How important is the transformation to the senior team (e. g. , career defining)? Does the senior team have any zealots who are willing to lead the transformation? How have past operations improvements been led? ? How successful were these and what were the lessons learned? How holistic have your performance improvement initiatives been? 4 4 4 What role have other functions (e. g. , HR) played in transformation? Have the technical systems translated into daily, standard operations? How integrated are the technical changes into people processes? Does the culture embrace changes? Are mindsets ready for large scale, continuous improvement? Have any pivotal roles needed to lead the change been identified? How important is the transformation to this group? How ready are your line leaders (VP to front line supervisor) to drive change? 4 Are line leaders capable of driving change across all dimensions? 4 How are line leaders skill sets developed? 4 Is there a system in place to support line leaders to initiate and lead change? How are you making change scalable? 4 4 4 Has the need for change been established? Has it been defined so that change can be replicated within local contexts? What are the cross-cutting initiatives that create a foundation for change? Are you leveraging a common approach and toolset? What existing initiatives could be harnessed? Is there enough capacity in the organization to drive initiatives? Is there an existing continuous improvement organization? Is it capable of enabling the transformation?

“The culture of a company is the behavior of its leaders. Leaders get the behavior they exhibit and tolerate. You change the culture of a company by changing the behavior of its leaders. ” -- Larry Bossidy & Ram Charan Execution: The Discipline of Getting Things Done

“The culture of a company is the behavior of its leaders. Leaders get the behavior they exhibit and tolerate. You change the culture of a company by changing the behavior of its leaders. ” -- Larry Bossidy & Ram Charan Execution: The Discipline of Getting Things Done

Back up starts here….

Back up starts here….

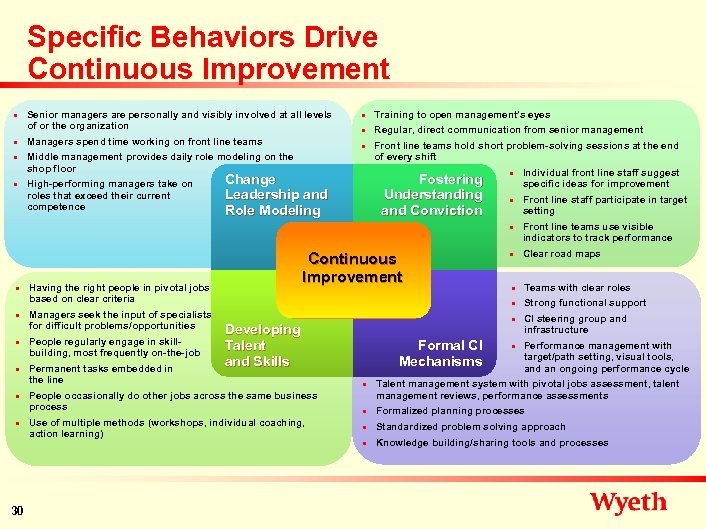

Specific Behaviors Drive Continuous Improvement n n Senior managers are personally and visibly involved at all levels of or the organization Managers spend time working on front line teams n Training to open management’s eyes n Regular, direct communication from senior management n Middle management provides daily role modeling on the shop floor High-performing managers take on roles that exceed their current competence Change Leadership and Role Modeling Front line teams hold short problem-solving sessions at the end of every shift Fostering Understanding and Conviction n n n n People regularly engage in skillbuilding, most frequently on-the-job Permanent tasks embedded in the line Front line staff participate in target setting Front line teams use visible indicators to track performance Clear road maps n Teams with clear roles Strong functional support n Developing Talent and Skills People occasionally do other jobs across the same business process n n Continuous Improvement Having the right people in pivotal jobs based on clear criteria Managers seek the input of specialists for difficult problems/opportunities Individual front line staff suggest specific ideas for improvement Formal CI Mechanisms n n CI steering group and infrastructure Performance management with target/path setting, visual tools, and an ongoing performance cycle Talent management system with pivotal jobs assessment, talent management reviews, performance assessments 30 Use of multiple methods (workshops, individual coaching, action learning) n Formalized planning processes n Standardized problem solving approach n n Knowledge building/sharing tools and processes

Specific Behaviors Drive Continuous Improvement n n Senior managers are personally and visibly involved at all levels of or the organization Managers spend time working on front line teams n Training to open management’s eyes n Regular, direct communication from senior management n Middle management provides daily role modeling on the shop floor High-performing managers take on roles that exceed their current competence Change Leadership and Role Modeling Front line teams hold short problem-solving sessions at the end of every shift Fostering Understanding and Conviction n n n n People regularly engage in skillbuilding, most frequently on-the-job Permanent tasks embedded in the line Front line staff participate in target setting Front line teams use visible indicators to track performance Clear road maps n Teams with clear roles Strong functional support n Developing Talent and Skills People occasionally do other jobs across the same business process n n Continuous Improvement Having the right people in pivotal jobs based on clear criteria Managers seek the input of specialists for difficult problems/opportunities Individual front line staff suggest specific ideas for improvement Formal CI Mechanisms n n CI steering group and infrastructure Performance management with target/path setting, visual tools, and an ongoing performance cycle Talent management system with pivotal jobs assessment, talent management reviews, performance assessments 30 Use of multiple methods (workshops, individual coaching, action learning) n Formalized planning processes n Standardized problem solving approach n n Knowledge building/sharing tools and processes

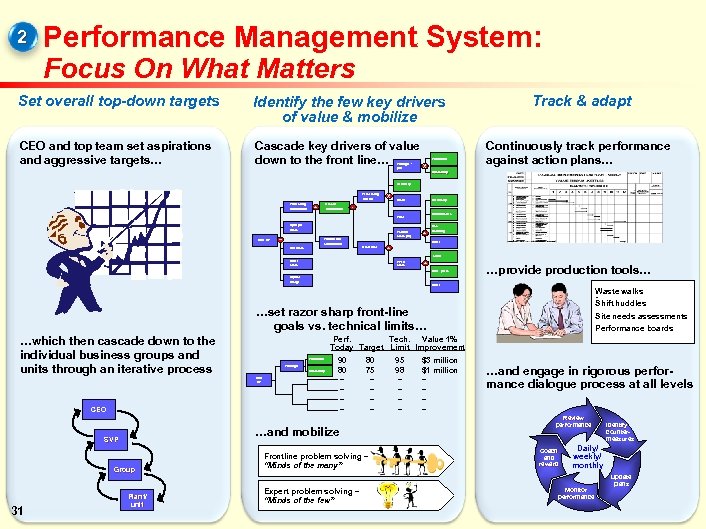

2 Performance Management System: Focus On What Matters Set overall top-down targets Identify the few key drivers of value & mobilize CEO and top team set aspirations and aggressive targets… Cascade key drivers of value down to the front line… X Through - put Tons per Tons/hour Track & adapt Continuously track performance against action plans… Availability Recovery Processing revenue X Roaster contribution + Grade Electricity Price Processing contribution Consumables - Open pit costs Mine EP – Variable costs ($/t) Wetmill /AC contribution U/G costs + Gas handling Other Cash cost + Labor Labour Other costs Fixed costs + Mtce parts Capital charge …provide production tools… Other Waste walks “ Shift huddles …set razor sharp front-line goals vs. technical limits… …which then cascade down to the individual business groups and units through an iterative process Tons/hour Through Availability Group 31 90 80 – – 80 75 – – …and mobilize SVP Plant/ unit Performance boards Value 1% Perf. Tech. Today Target Limit Improvement Mine EP CEO Site needs assessments Frontline problem solving – “Minds of the many” Expert problem solving – “Minds of the few” 95 98 – – $3 million $1 million – – …and engage in rigorous performance dialogue process at all levels Review performance Coach and reward Identify countermeasures Daily/ weekly/ monthly Monitor performance Update plans

2 Performance Management System: Focus On What Matters Set overall top-down targets Identify the few key drivers of value & mobilize CEO and top team set aspirations and aggressive targets… Cascade key drivers of value down to the front line… X Through - put Tons per Tons/hour Track & adapt Continuously track performance against action plans… Availability Recovery Processing revenue X Roaster contribution + Grade Electricity Price Processing contribution Consumables - Open pit costs Mine EP – Variable costs ($/t) Wetmill /AC contribution U/G costs + Gas handling Other Cash cost + Labor Labour Other costs Fixed costs + Mtce parts Capital charge …provide production tools… Other Waste walks “ Shift huddles …set razor sharp front-line goals vs. technical limits… …which then cascade down to the individual business groups and units through an iterative process Tons/hour Through Availability Group 31 90 80 – – 80 75 – – …and mobilize SVP Plant/ unit Performance boards Value 1% Perf. Tech. Today Target Limit Improvement Mine EP CEO Site needs assessments Frontline problem solving – “Minds of the many” Expert problem solving – “Minds of the few” 95 98 – – $3 million $1 million – – …and engage in rigorous performance dialogue process at all levels Review performance Coach and reward Identify countermeasures Daily/ weekly/ monthly Monitor performance Update plans

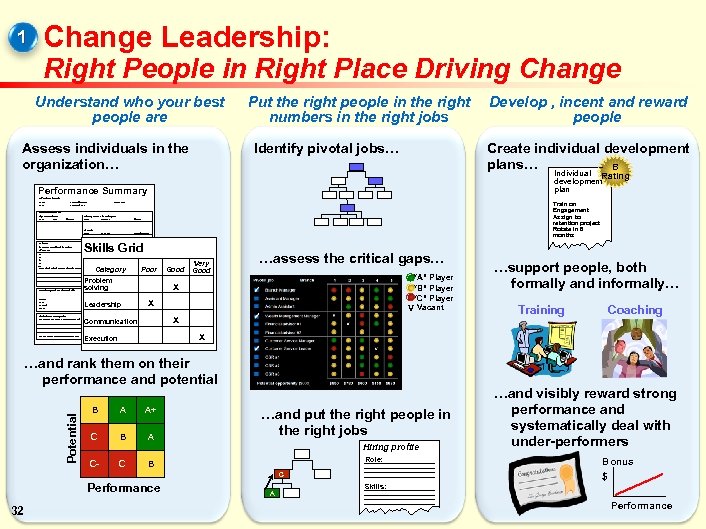

Change Leadership: 1 Right People in Right Place Driving Change Understand who your best people are Assess individuals in the organization… Put the right people in the right numbers in the right jobs Identify pivotal jobs… Create individual development plans… Individual B Rating development plan Performance Summary Rigorously plans and executes Really executes Develop , incent and reward people Stays focused on what counts Provides solutions, not excuses Makes tough decisions A. Personal Information Name: Current Position: Relishes Completed by: change Date: Supervisor: Train on Engagement Assign to retention project Rotate in 6 months Drives change Thinks outside the box _______ good ideas B. Historical Background Experience at Barrick Dates Site Position Work experience in other companies Rallies the troops Dates Company Inspires others Earns trust Positionleaders Develops Communicates effectively Education Dates Institution Represents the best of Barrick Degree/Diploma Recognizes excellence Acts with integrity Promotes safety, protects environment Contributes to community Focuses on shareholder value C. Results against KPIs and other goals KPI or goal Skills Grid Target 1. Result Comments 4 – Towering strength, role model to others 2. 3 – Solid, usually demonstrates 3. 4. Category 5. Other contributions during the course of this year D. Leadership attributes – Barrick’s 5 R’s Poor Problem solving Good Very Good …assess the critical gaps… “A” Player “B” Player “C” Player V Vacant X Rating 1 -4 Stretch Leadership Shine Succeed Search X X E. Individual career aspirations Communication Are there any changes in responsibility or development opportunities you would like in the next year or two? Are you willing to relocate to another site? No Maybe Potential …and rank them on their performance and potential B A A+ C B A …and put the right people in the right jobs Hiring profile C- C Role: B C Performance 32 Training Coaching X Execution Yes …support people, both formally and informally… A …and visibly reward strong performance and systematically deal with under-performers Bonus $ Skills: Performance

Change Leadership: 1 Right People in Right Place Driving Change Understand who your best people are Assess individuals in the organization… Put the right people in the right numbers in the right jobs Identify pivotal jobs… Create individual development plans… Individual B Rating development plan Performance Summary Rigorously plans and executes Really executes Develop , incent and reward people Stays focused on what counts Provides solutions, not excuses Makes tough decisions A. Personal Information Name: Current Position: Relishes Completed by: change Date: Supervisor: Train on Engagement Assign to retention project Rotate in 6 months Drives change Thinks outside the box _______ good ideas B. Historical Background Experience at Barrick Dates Site Position Work experience in other companies Rallies the troops Dates Company Inspires others Earns trust Positionleaders Develops Communicates effectively Education Dates Institution Represents the best of Barrick Degree/Diploma Recognizes excellence Acts with integrity Promotes safety, protects environment Contributes to community Focuses on shareholder value C. Results against KPIs and other goals KPI or goal Skills Grid Target 1. Result Comments 4 – Towering strength, role model to others 2. 3 – Solid, usually demonstrates 3. 4. Category 5. Other contributions during the course of this year D. Leadership attributes – Barrick’s 5 R’s Poor Problem solving Good Very Good …assess the critical gaps… “A” Player “B” Player “C” Player V Vacant X Rating 1 -4 Stretch Leadership Shine Succeed Search X X E. Individual career aspirations Communication Are there any changes in responsibility or development opportunities you would like in the next year or two? Are you willing to relocate to another site? No Maybe Potential …and rank them on their performance and potential B A A+ C B A …and put the right people in the right jobs Hiring profile C- C Role: B C Performance 32 Training Coaching X Execution Yes …support people, both formally and informally… A …and visibly reward strong performance and systematically deal with under-performers Bonus $ Skills: Performance

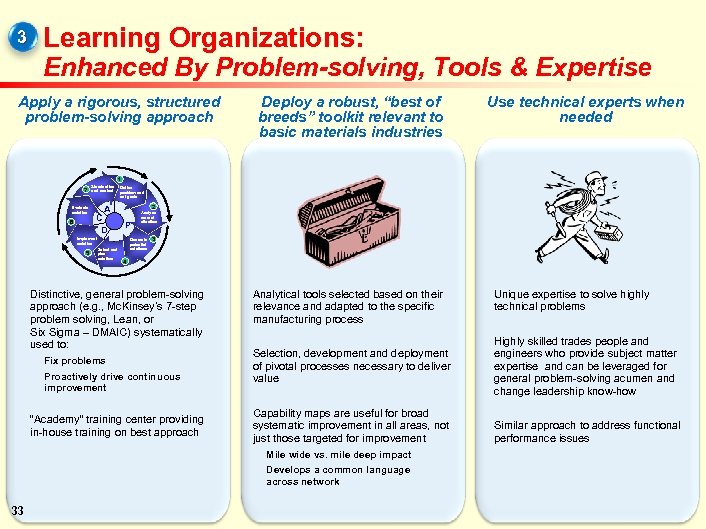

3 Learning Organizations: Enhanced By Problem-solving, Tools & Expertise Apply a rigorous, structured problem-solving approach Deploy a robust, “best of breeds” toolkit relevant to basic materials industries Use technical experts when needed 1 7 Evaluate solution 6 Standardize and control A C D Define problem and set goals 2 P Implement solution 5 Select and plan solution Analyze current situation Generate potential solutions 3 4 Distinctive, general problem-solving approach (e. g. , Mc. Kinsey’s 7 -step problem solving, Lean, or Six Sigma – DMAIC) systematically used to: Fix problems Proactively drive continuous improvement “Academy” training center providing in-house training on best approach Analytical tools selected based on their relevance and adapted to the specific manufacturing process Selection, development and deployment of pivotal processes necessary to deliver value Capability maps are useful for broad systematic improvement in all areas, not just those targeted for improvement Mile wide vs. mile deep impact Develops a common language across network 33 Unique expertise to solve highly technical problems Highly skilled trades people and engineers who provide subject matter expertise and can be leveraged for general problem-solving acumen and change leadership know-how Similar approach to address functional performance issues

3 Learning Organizations: Enhanced By Problem-solving, Tools & Expertise Apply a rigorous, structured problem-solving approach Deploy a robust, “best of breeds” toolkit relevant to basic materials industries Use technical experts when needed 1 7 Evaluate solution 6 Standardize and control A C D Define problem and set goals 2 P Implement solution 5 Select and plan solution Analyze current situation Generate potential solutions 3 4 Distinctive, general problem-solving approach (e. g. , Mc. Kinsey’s 7 -step problem solving, Lean, or Six Sigma – DMAIC) systematically used to: Fix problems Proactively drive continuous improvement “Academy” training center providing in-house training on best approach Analytical tools selected based on their relevance and adapted to the specific manufacturing process Selection, development and deployment of pivotal processes necessary to deliver value Capability maps are useful for broad systematic improvement in all areas, not just those targeted for improvement Mile wide vs. mile deep impact Develops a common language across network 33 Unique expertise to solve highly technical problems Highly skilled trades people and engineers who provide subject matter expertise and can be leveraged for general problem-solving acumen and change leadership know-how Similar approach to address functional performance issues

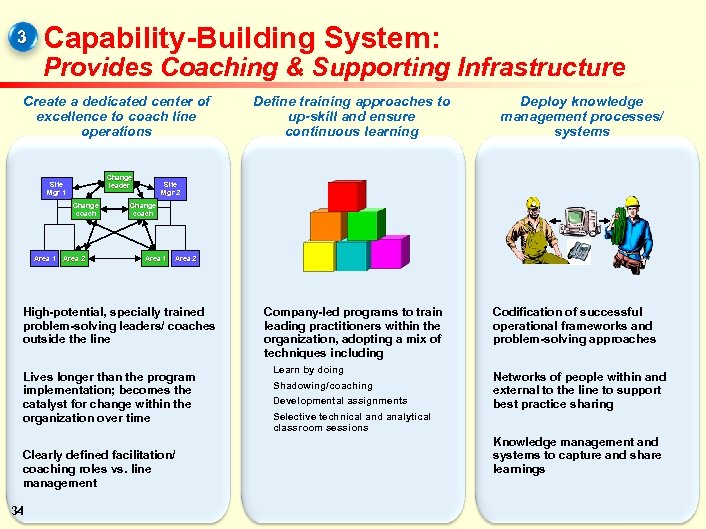

3 Capability-Building System: Provides Coaching & Supporting Infrastructure Create a dedicated center of excellence to coach line operations Change leader Site Mgr 1 Change coach Area 1 Area 2 Deploy knowledge management processes/ systems Site Mgr 2 Change coach Area 1 Area 2 High-potential, specially trained problem-solving leaders/ coaches outside the line Lives longer than the program implementation; becomes the catalyst for change within the organization over time Clearly defined facilitation/ coaching roles vs. line management 34 Define training approaches to up-skill and ensure continuous learning Company-led programs to train leading practitioners within the organization, adopting a mix of techniques including Learn by doing Shadowing/coaching Developmental assignments Codification of successful operational frameworks and problem-solving approaches Networks of people within and external to the line to support best practice sharing Selective technical and analytical classroom sessions Knowledge management and systems to capture and share learnings

3 Capability-Building System: Provides Coaching & Supporting Infrastructure Create a dedicated center of excellence to coach line operations Change leader Site Mgr 1 Change coach Area 1 Area 2 Deploy knowledge management processes/ systems Site Mgr 2 Change coach Area 1 Area 2 High-potential, specially trained problem-solving leaders/ coaches outside the line Lives longer than the program implementation; becomes the catalyst for change within the organization over time Clearly defined facilitation/ coaching roles vs. line management 34 Define training approaches to up-skill and ensure continuous learning Company-led programs to train leading practitioners within the organization, adopting a mix of techniques including Learn by doing Shadowing/coaching Developmental assignments Codification of successful operational frameworks and problem-solving approaches Networks of people within and external to the line to support best practice sharing Selective technical and analytical classroom sessions Knowledge management and systems to capture and share learnings

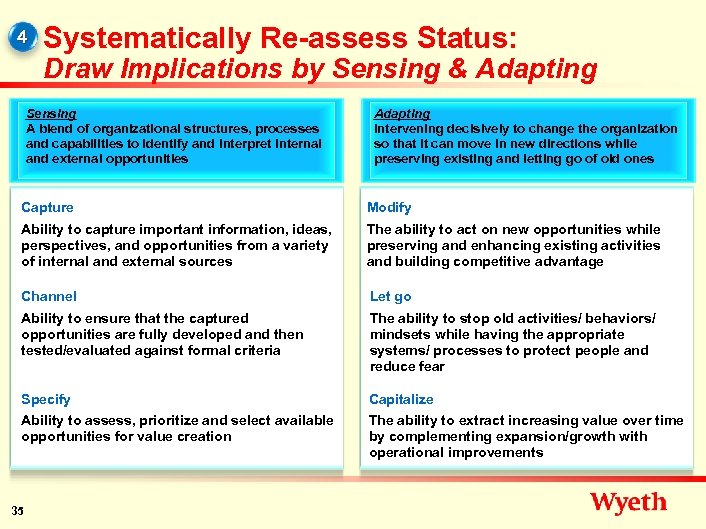

4 Systematically Re-assess Status: Draw Implications by Sensing & Adapting Sensing A blend of organizational structures, processes and capabilities to identify and interpret internal and external opportunities Adapting Intervening decisively to change the organization so that it can move in new directions while preserving existing and letting go of old ones Capture Modify Ability to capture important information, ideas, perspectives, and opportunities from a variety of internal and external sources The ability to act on new opportunities while preserving and enhancing existing activities and building competitive advantage Channel Let go Ability to ensure that the captured opportunities are fully developed and then tested/evaluated against formal criteria The ability to stop old activities/ behaviors/ mindsets while having the appropriate systems/ processes to protect people and reduce fear Specify Capitalize Ability to assess, prioritize and select available opportunities for value creation The ability to extract increasing value over time by complementing expansion/growth with operational improvements 35

4 Systematically Re-assess Status: Draw Implications by Sensing & Adapting Sensing A blend of organizational structures, processes and capabilities to identify and interpret internal and external opportunities Adapting Intervening decisively to change the organization so that it can move in new directions while preserving existing and letting go of old ones Capture Modify Ability to capture important information, ideas, perspectives, and opportunities from a variety of internal and external sources The ability to act on new opportunities while preserving and enhancing existing activities and building competitive advantage Channel Let go Ability to ensure that the captured opportunities are fully developed and then tested/evaluated against formal criteria The ability to stop old activities/ behaviors/ mindsets while having the appropriate systems/ processes to protect people and reduce fear Specify Capitalize Ability to assess, prioritize and select available opportunities for value creation The ability to extract increasing value over time by complementing expansion/growth with operational improvements 35