4df65665d10000d62d31f47030187cfb.ppt

- Количество слайдов: 14

Implementation of MPC in a deethanizer at the Kårstø Gas plant Elvira Marie B. Aske*, ** Stig Strand** Sigurd Skogestad* *Department of Chemical Engineering, Norwegian University of Science and Technology, Trondheim, Norway ** Statoil R&D, Process Control, Trondheim, Norway 1

Implementation of MPC in a deethanizer at the Kårstø Gas plant Elvira Marie B. Aske*, ** Stig Strand** Sigurd Skogestad* *Department of Chemical Engineering, Norwegian University of Science and Technology, Trondheim, Norway ** Statoil R&D, Process Control, Trondheim, Norway 1

Outline • About the Kårstø gas plant • Motivation for MPC implementation • MPC implementation – – – Design Estimator development Model development Tuning Results • Conclusions and further work 2

Outline • About the Kårstø gas plant • Motivation for MPC implementation • MPC implementation – – – Design Estimator development Model development Tuning Results • Conclusions and further work 2

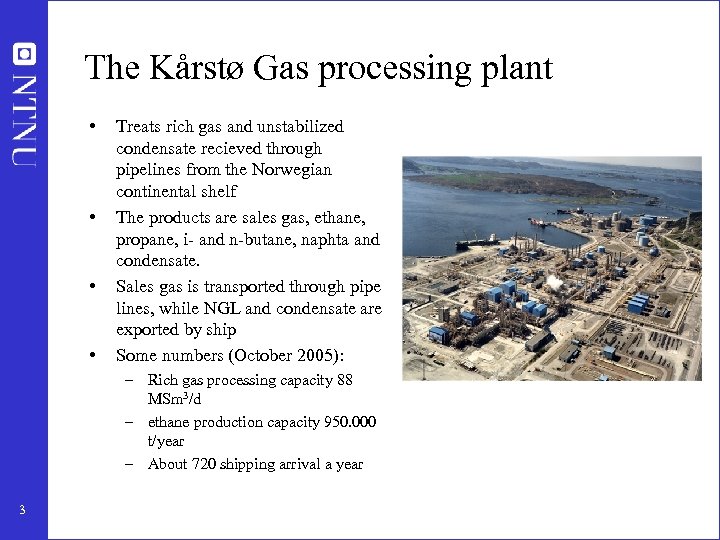

The Kårstø Gas processing plant • • Treats rich gas and unstabilized condensate recieved through pipelines from the Norwegian continental shelf The products are sales gas, ethane, propane, i- and n-butane, naphta and condensate. Sales gas is transported through pipe lines, while NGL and condensate are exported by ship Some numbers (October 2005): – Rich gas processing capacity 88 MSm 3/d – ethane production capacity 950. 000 t/year – About 720 shipping arrival a year 3

The Kårstø Gas processing plant • • Treats rich gas and unstabilized condensate recieved through pipelines from the Norwegian continental shelf The products are sales gas, ethane, propane, i- and n-butane, naphta and condensate. Sales gas is transported through pipe lines, while NGL and condensate are exported by ship Some numbers (October 2005): – Rich gas processing capacity 88 MSm 3/d – ethane production capacity 950. 000 t/year – About 720 shipping arrival a year 3

Motivation for MPC implementation • Increased complexity at the plant due to extension projects – Larger degree of system integration – Systems build with different design – Crossovers between process trains • Higher demands to regularity and through-put due to new fields developments that narrows the margins • MPC is a part of the ”control revolution” at the plant 4

Motivation for MPC implementation • Increased complexity at the plant due to extension projects – Larger degree of system integration – Systems build with different design – Crossovers between process trains • Higher demands to regularity and through-put due to new fields developments that narrows the margins • MPC is a part of the ”control revolution” at the plant 4

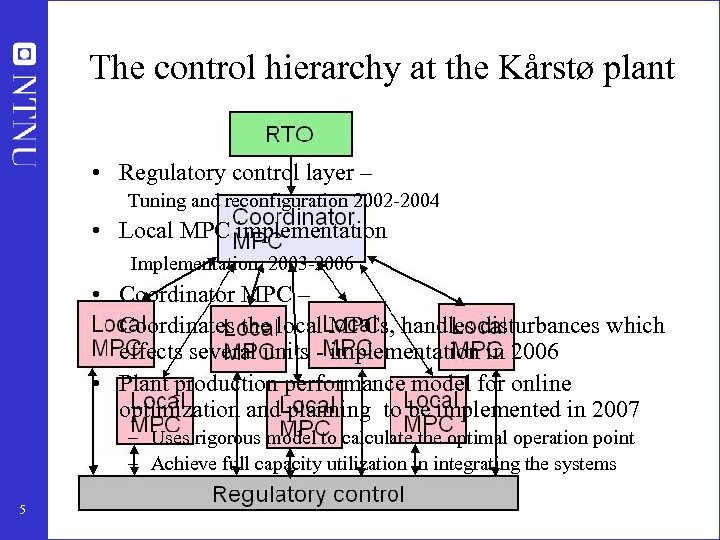

The control hierarchy at the Kårstø plant • Regulatory control layer – Tuning and reconfiguration 2002 -2004 • Local MPC implementation Implementation 2003 -2006 • Coordinator MPC – Coordinates the local MPCs, handles disturbances which effects several units - implementation in 2006 • Plant production performance model for online optimization and planning to be implemented in 2007 – Uses rigorous model to calculate the optimal operation point – Achieve full capacity utilization in integrating the systems 5

The control hierarchy at the Kårstø plant • Regulatory control layer – Tuning and reconfiguration 2002 -2004 • Local MPC implementation Implementation 2003 -2006 • Coordinator MPC – Coordinates the local MPCs, handles disturbances which effects several units - implementation in 2006 • Plant production performance model for online optimization and planning to be implemented in 2007 – Uses rigorous model to calculate the optimal operation point – Achieve full capacity utilization in integrating the systems 5

MPC implementation on a deethanizer • A typical implementation case for a distillation column at the Kårstø plant • Includes the stages in an MPC implementation: – – design estimator development model development tuning • Using the in-house developed MPC software SEPTIC (Statoil Estimation and Prediction Tool for Identification and Control) • Implementation done by plant engineers together with engineers from Statoil Research Centre 6

MPC implementation on a deethanizer • A typical implementation case for a distillation column at the Kårstø plant • Includes the stages in an MPC implementation: – – design estimator development model development tuning • Using the in-house developed MPC software SEPTIC (Statoil Estimation and Prediction Tool for Identification and Control) • Implementation done by plant engineers together with engineers from Statoil Research Centre 6

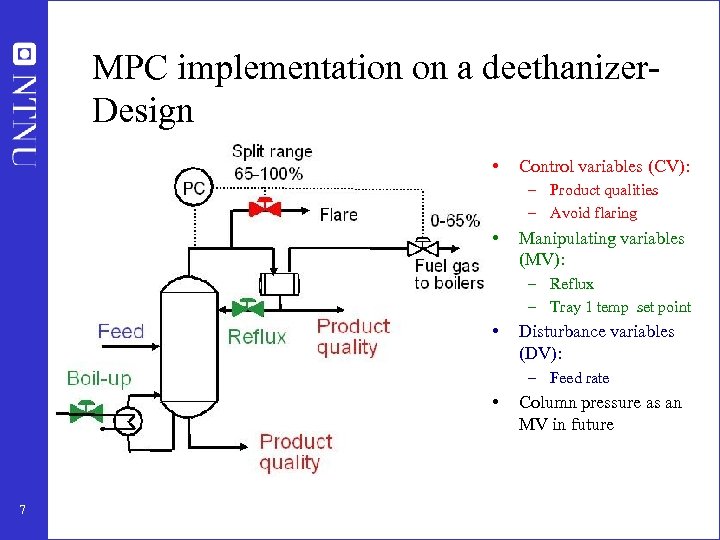

MPC implementation on a deethanizer. Design • Control variables (CV): – Product qualities – Avoid flaring • Manipulating variables (MV): – Reflux – Tray 1 temp set point • Disturbance variables (DV): – Feed rate • 7 Column pressure as an MV in future

MPC implementation on a deethanizer. Design • Control variables (CV): – Product qualities – Avoid flaring • Manipulating variables (MV): – Reflux – Tray 1 temp set point • Disturbance variables (DV): – Feed rate • 7 Column pressure as an MV in future

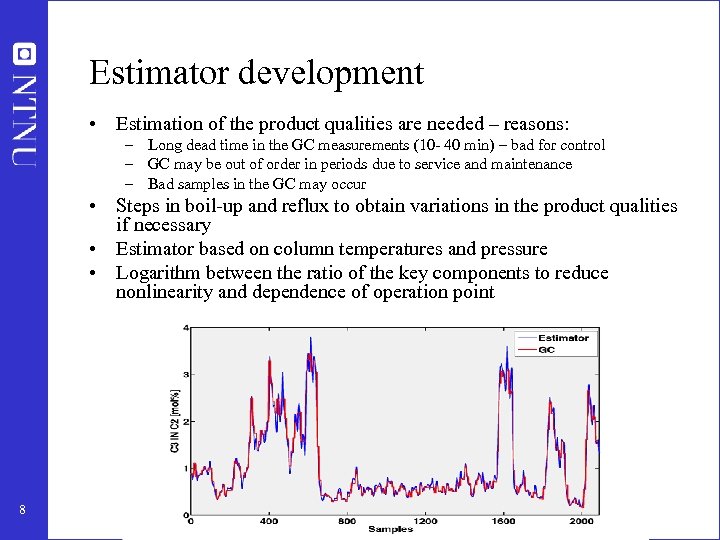

Estimator development • Estimation of the product qualities are needed – reasons: – Long dead time in the GC measurements (10 - 40 min) – bad for control – GC may be out of order in periods due to service and maintenance – Bad samples in the GC may occur • Steps in boil-up and reflux to obtain variations in the product qualities if necessary • Estimator based on column temperatures and pressure • Logarithm between the ratio of the key components to reduce nonlinearity and dependence of operation point 8

Estimator development • Estimation of the product qualities are needed – reasons: – Long dead time in the GC measurements (10 - 40 min) – bad for control – GC may be out of order in periods due to service and maintenance – Bad samples in the GC may occur • Steps in boil-up and reflux to obtain variations in the product qualities if necessary • Estimator based on column temperatures and pressure • Logarithm between the ratio of the key components to reduce nonlinearity and dependence of operation point 8

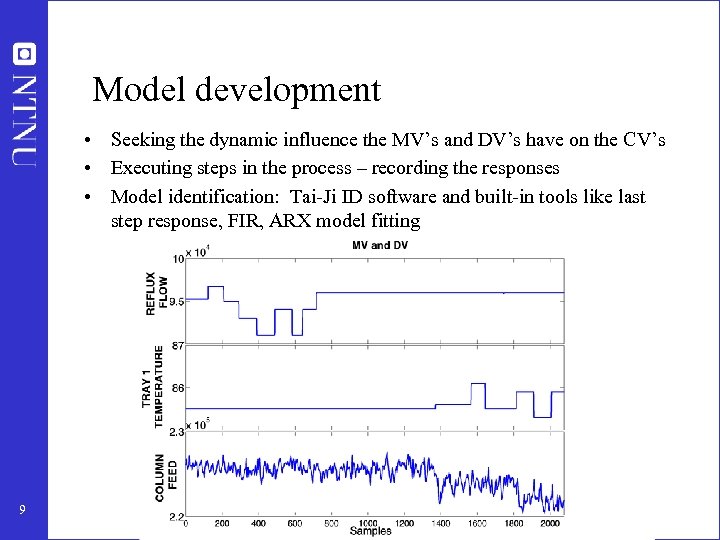

Model development • Seeking the dynamic influence the MV’s and DV’s have on the CV’s • Executing steps in the process – recording the responses • Model identification: Tai-Ji ID software and built-in tools like last step response, FIR, ARX model fitting 9

Model development • Seeking the dynamic influence the MV’s and DV’s have on the CV’s • Executing steps in the process – recording the responses • Model identification: Tai-Ji ID software and built-in tools like last step response, FIR, ARX model fitting 9

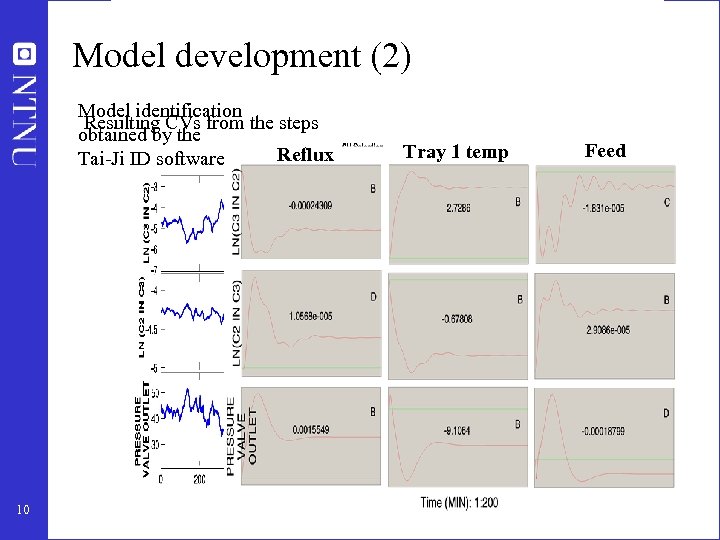

Model development (2) Model identification Resulting CVs from the steps obtained by the Reflux Tai-Ji ID software 10 Tray 1 temp Feed

Model development (2) Model identification Resulting CVs from the steps obtained by the Reflux Tai-Ji ID software 10 Tray 1 temp Feed

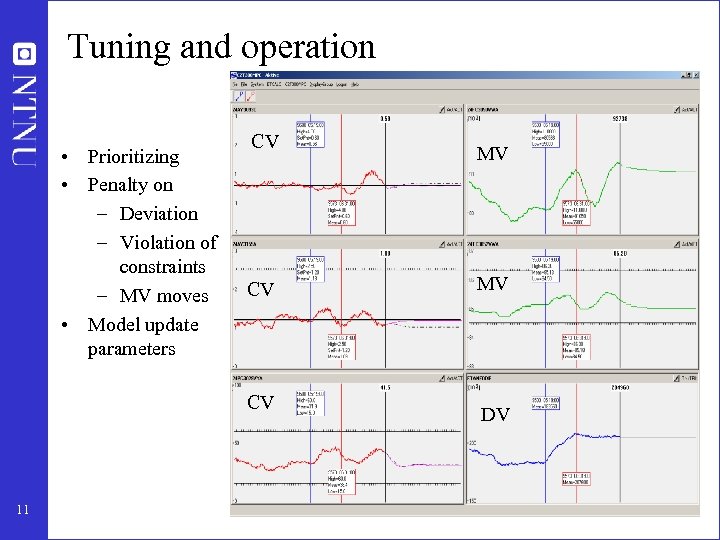

Tuning and operation • Prioritizing • Penalty on – Deviation – Violation of constraints – MV moves • Model update parameters CV CV CV 11 MV MV DV

Tuning and operation • Prioritizing • Penalty on – Deviation – Violation of constraints – MV moves • Model update parameters CV CV CV 11 MV MV DV

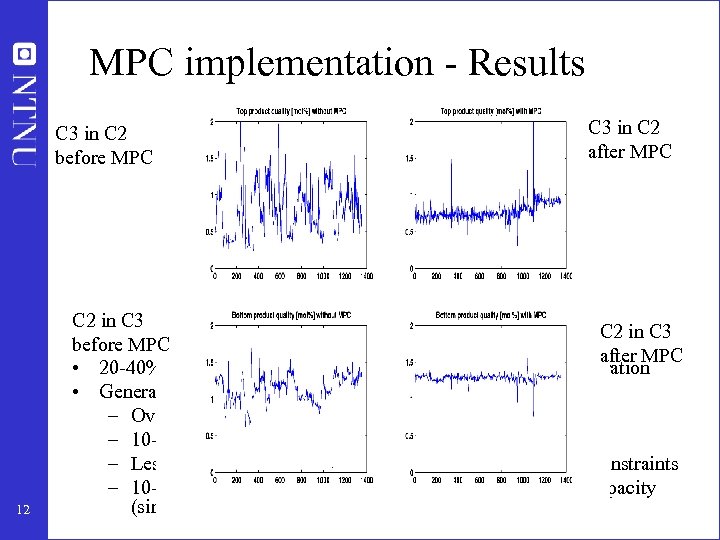

MPC implementation - Results C 3 in C 2 before MPC 12 C 3 in C 2 after MPC C 2 in C 3 before MPC after MPC • 20 -40% reduction in flaring frequency and has often shorter duration • General results from MPC implementations: – Overfractionation before introducing MPC – 10 -12% reduction in steam consumption – Less variation in product quality operate closer to the constraints – 10 -25% reduction in reflux flow rate increase column capacity (simulations show at least 10% increase)

MPC implementation - Results C 3 in C 2 before MPC 12 C 3 in C 2 after MPC C 2 in C 3 before MPC after MPC • 20 -40% reduction in flaring frequency and has often shorter duration • General results from MPC implementations: – Overfractionation before introducing MPC – 10 -12% reduction in steam consumption – Less variation in product quality operate closer to the constraints – 10 -25% reduction in reflux flow rate increase column capacity (simulations show at least 10% increase)

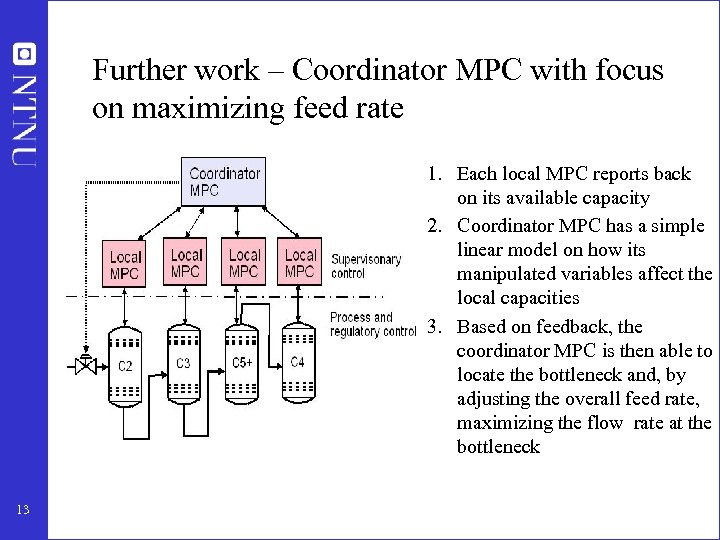

Further work – Coordinator MPC with focus on maximizing feed rate 1. Each local MPC reports back on its available capacity 2. Coordinator MPC has a simple linear model on how its manipulated variables affect the local capacities 3. Based on feedback, the coordinator MPC is then able to locate the bottleneck and, by adjusting the overall feed rate, maximizing the flow rate at the bottleneck 13

Further work – Coordinator MPC with focus on maximizing feed rate 1. Each local MPC reports back on its available capacity 2. Coordinator MPC has a simple linear model on how its manipulated variables affect the local capacities 3. Based on feedback, the coordinator MPC is then able to locate the bottleneck and, by adjusting the overall feed rate, maximizing the flow rate at the bottleneck 13

Conclusions • Better quality control – with the opportunity to specify the desired product quality • Reduced flaring frequency and shorter duration of the flaring • Operator uses less time to control the column, especially under feed disturbances Acknowledgements • Personnel working at the Kårstø gas plant, Norway • Gassco for financial support 14

Conclusions • Better quality control – with the opportunity to specify the desired product quality • Reduced flaring frequency and shorter duration of the flaring • Operator uses less time to control the column, especially under feed disturbances Acknowledgements • Personnel working at the Kårstø gas plant, Norway • Gassco for financial support 14