51b8b9a6c701350b3af11f45723f8c9e.ppt

- Количество слайдов: 16

Implementation of a MPC on a deethanizer Thanks to: Elvira Aske and Stig Strand, Statoil 1

Implementation of a MPC on a deethanizer Thanks to: Elvira Aske and Stig Strand, Statoil 1

MPC implementation at Kårstø gas processing plant • Mainly distillation columns • In-house MPC technology (“SEPTIC”) • Karsto: So far 9 distillation column with MPC – 11 to go, plus MPC on some other systems, like steam production. 2

MPC implementation at Kårstø gas processing plant • Mainly distillation columns • In-house MPC technology (“SEPTIC”) • Karsto: So far 9 distillation column with MPC – 11 to go, plus MPC on some other systems, like steam production. 2

Stepwise approach for implementation 1. 2. 3. 4. 5. 6. 7. 8. 3 Check and possible retuning of the existing controllers (PID). Choose CV, MV and DV for the application Logic connections to the process interface placed and tested Develop estimators Model identification. Step tests, (Have used: Tai-Ji ID tool) Control specifications priorities Tuning and model verifications Operation under surveillance and operator training

Stepwise approach for implementation 1. 2. 3. 4. 5. 6. 7. 8. 3 Check and possible retuning of the existing controllers (PID). Choose CV, MV and DV for the application Logic connections to the process interface placed and tested Develop estimators Model identification. Step tests, (Have used: Tai-Ji ID tool) Control specifications priorities Tuning and model verifications Operation under surveillance and operator training

1. Base control (PIDs) • • • Stabilize pressure: Use vapor draw-off (partial condenser) Stabilize liquid levels: Use “LV”-configuration Stabilize temperature profile: Control temperature at bottom Note: This is a multicomponent separation with non-keys in the bottom, so temperature changes a lot towards the bottom 4

1. Base control (PIDs) • • • Stabilize pressure: Use vapor draw-off (partial condenser) Stabilize liquid levels: Use “LV”-configuration Stabilize temperature profile: Control temperature at bottom Note: This is a multicomponent separation with non-keys in the bottom, so temperature changes a lot towards the bottom 4

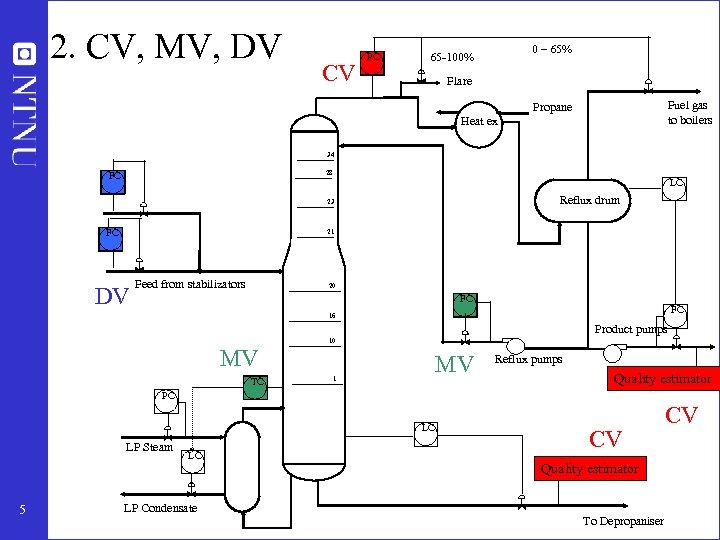

2. CV, MV, DV CV PC 0 – 65% 65 -100% Flare Fuel gas to boilers Propane Heat ex 34 28 FC LC Reflux drum 23 FC 21 DV Feed from stabilizators 20 FC FC 16 Product pumps 10 MV TC MV 1 Reflux pumps Quality estimator PC LC LP Steam 5 LC LP Condensate CV Quality estimator To Depropaniser CV

2. CV, MV, DV CV PC 0 – 65% 65 -100% Flare Fuel gas to boilers Propane Heat ex 34 28 FC LC Reflux drum 23 FC 21 DV Feed from stabilizators 20 FC FC 16 Product pumps 10 MV TC MV 1 Reflux pumps Quality estimator PC LC LP Steam 5 LC LP Condensate CV Quality estimator To Depropaniser CV

4. Composition (quality) estimators • Quality estimators to estimate the top and bottom compositions • Based on a combination of temperatures in the column x = i ki Ti Use log transformations on temperatures (T) and compositions (c) • Coefficients ki identified using ARX model fitting of dynamic test data. • Typical column: – “Binary end” (usually top) impurity needs about 2 temperatures – in general easy to establish – “Multicomponent end” (usually bottom) impurity needs 3 -4 temperatures and in general more difficult to identify – test period often needed to get data with enough variation 6

4. Composition (quality) estimators • Quality estimators to estimate the top and bottom compositions • Based on a combination of temperatures in the column x = i ki Ti Use log transformations on temperatures (T) and compositions (c) • Coefficients ki identified using ARX model fitting of dynamic test data. • Typical column: – “Binary end” (usually top) impurity needs about 2 temperatures – in general easy to establish – “Multicomponent end” (usually bottom) impurity needs 3 -4 temperatures and in general more difficult to identify – test period often needed to get data with enough variation 6

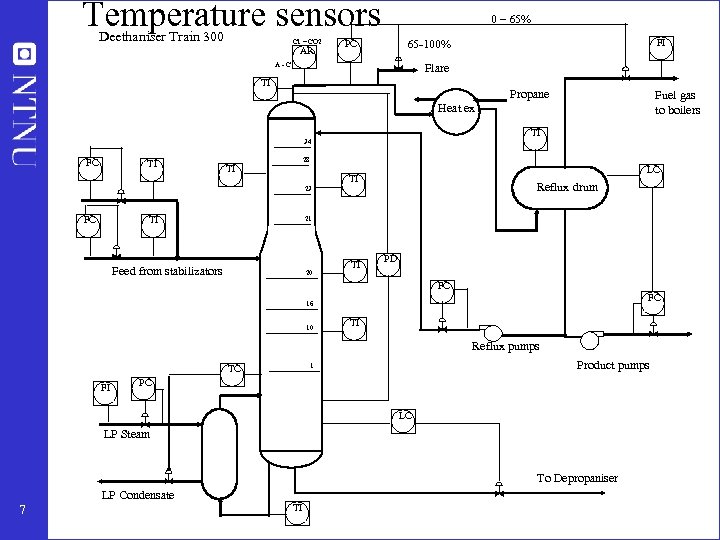

Temperature sensors Deethaniser Train 300 C 1 – CO 2 AR 0 – 65% FI 65 -100% PC Flare A-C TI Propane Fuel gas to boilers Heat ex TI 34 FC TI 28 TI LC TI Reflux drum 23 FC TI 21 Feed from stabilizators 20 TI PD FC FC 16 10 TI Reflux pumps FI Product pumps 1 TC PC LC LP Steam To Depropaniser 7 LP Condensate TI

Temperature sensors Deethaniser Train 300 C 1 – CO 2 AR 0 – 65% FI 65 -100% PC Flare A-C TI Propane Fuel gas to boilers Heat ex TI 34 FC TI 28 TI LC TI Reflux drum 23 FC TI 21 Feed from stabilizators 20 TI PD FC FC 16 10 TI Reflux pumps FI Product pumps 1 TC PC LC LP Steam To Depropaniser 7 LP Condensate TI

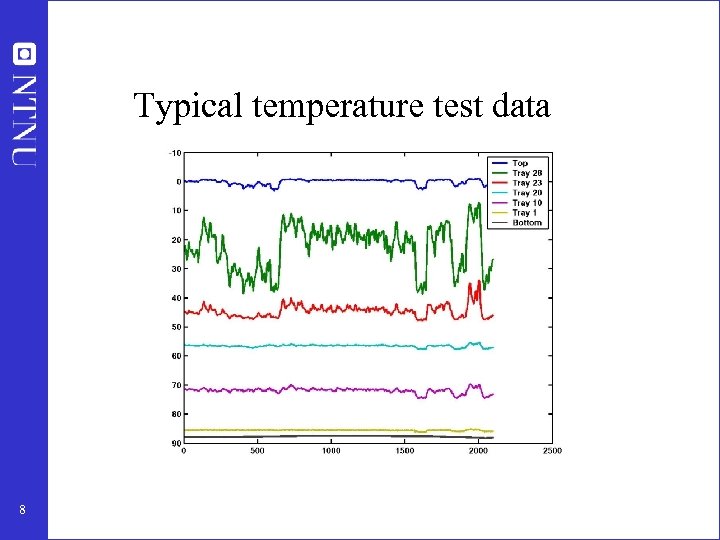

Typical temperature test data 8

Typical temperature test data 8

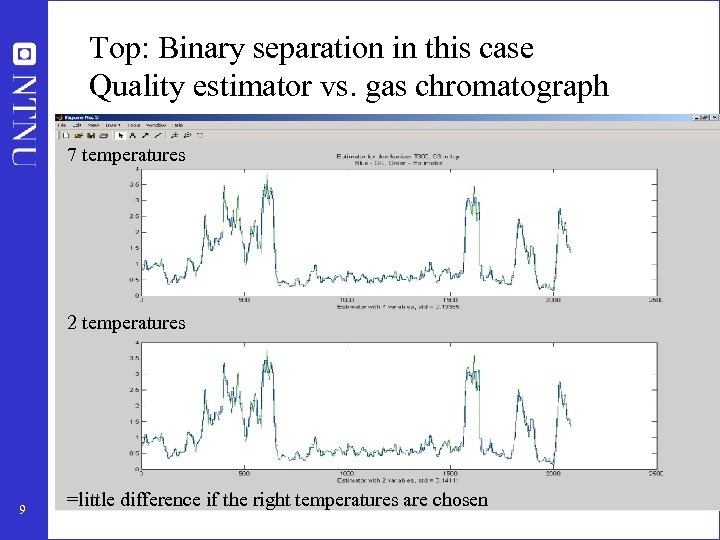

Top: Binary separation in this case Quality estimator vs. gas chromatograph 7 temperatures 2 temperatures 9 =little difference if the right temperatures are chosen

Top: Binary separation in this case Quality estimator vs. gas chromatograph 7 temperatures 2 temperatures 9 =little difference if the right temperatures are chosen

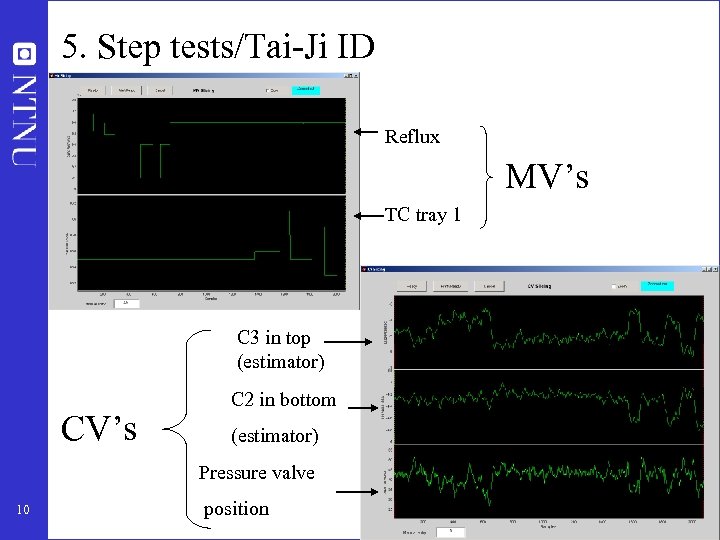

5. Step tests/Tai-Ji ID Reflux MV’s TC tray 1 C 3 in top (estimator) CV’s C 2 in bottom (estimator) Pressure valve 10 position

5. Step tests/Tai-Ji ID Reflux MV’s TC tray 1 C 3 in top (estimator) CV’s C 2 in bottom (estimator) Pressure valve 10 position

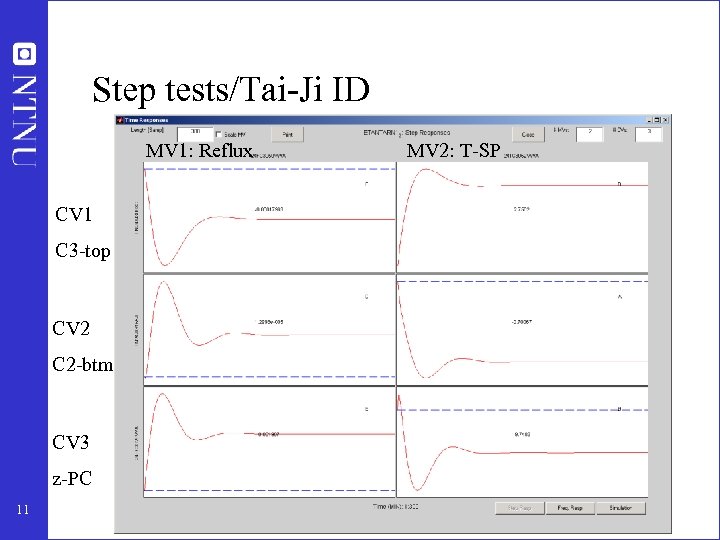

Step tests/Tai-Ji ID MV 1: Reflux CV 1 C 3 -top CV 2 C 2 -btm CV 3 z-PC 11 MV 2: T-SP

Step tests/Tai-Ji ID MV 1: Reflux CV 1 C 3 -top CV 2 C 2 -btm CV 3 z-PC 11 MV 2: T-SP

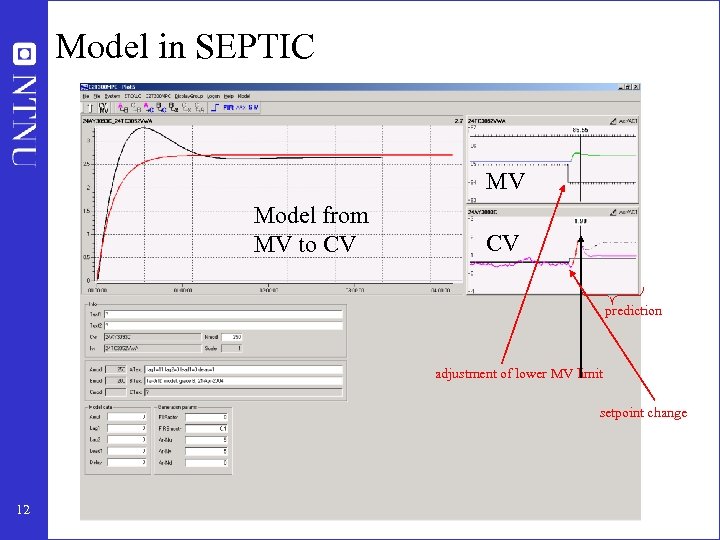

Model in SEPTIC MV Model from MV to CV CV prediction adjustment of lower MV limit setpoint change 12

Model in SEPTIC MV Model from MV to CV CV prediction adjustment of lower MV limit setpoint change 12

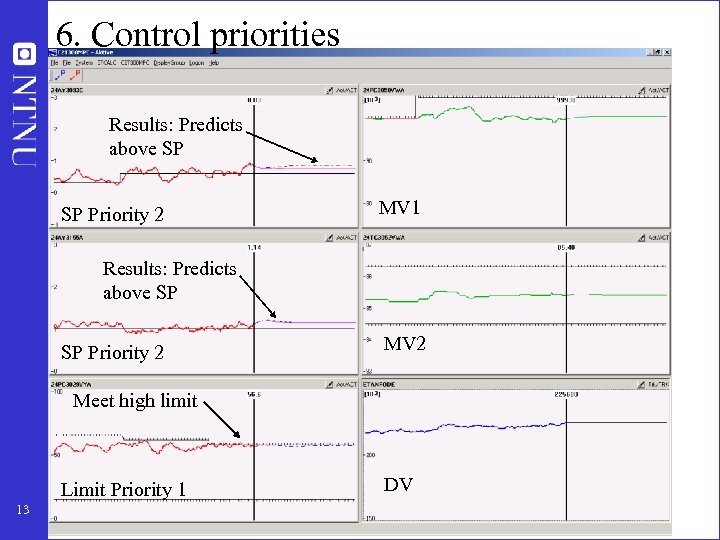

6. Control priorities Results: Predicts above SP SP Priority 2 MV 1 Results: Predicts above SP SP Priority 2 MV 2 Meet high limit Limit Priority 1 13 DV

6. Control priorities Results: Predicts above SP SP Priority 2 MV 1 Results: Predicts above SP SP Priority 2 MV 2 Meet high limit Limit Priority 1 13 DV

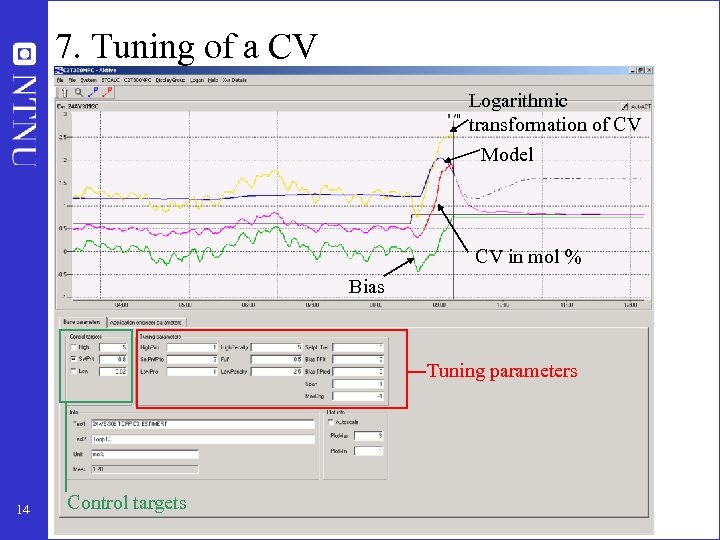

7. Tuning of a CV Logarithmic transformation of CV Model CV in mol % Bias Tuning parameters 14 Control targets

7. Tuning of a CV Logarithmic transformation of CV Model CV in mol % Bias Tuning parameters 14 Control targets

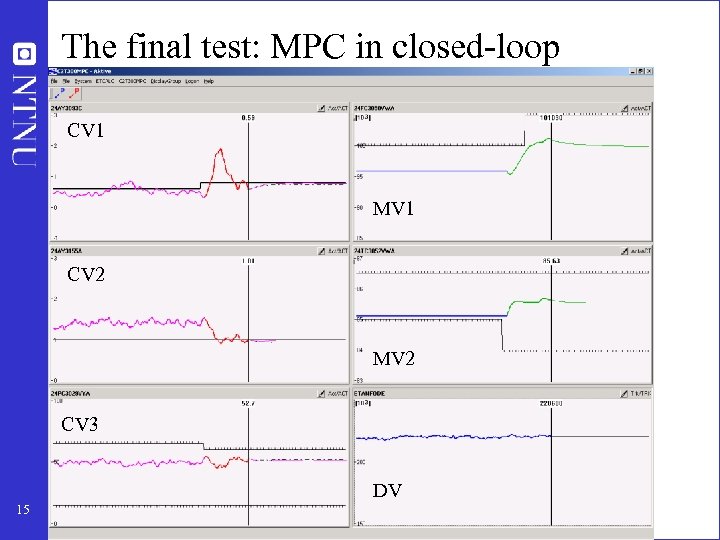

The final test: MPC in closed-loop CV 1 MV 1 CV 2 MV 2 CV 3 DV 15

The final test: MPC in closed-loop CV 1 MV 1 CV 2 MV 2 CV 3 DV 15

Conclusion MPC • Generally simpler than previous advanced control • Well accepted by operators • Use of in-house technology and expertise successful 16

Conclusion MPC • Generally simpler than previous advanced control • Well accepted by operators • Use of in-house technology and expertise successful 16