90af0df7eb5954cfdc4f5fc000032d99.ppt

- Количество слайдов: 23

Impact System Impact cylinders used for cleaning of heating surfaces at industrial and waste incineration plants Alexander Haug

Impact System Impact cylinders used for cleaning of heating surfaces at industrial and waste incineration plants Alexander Haug

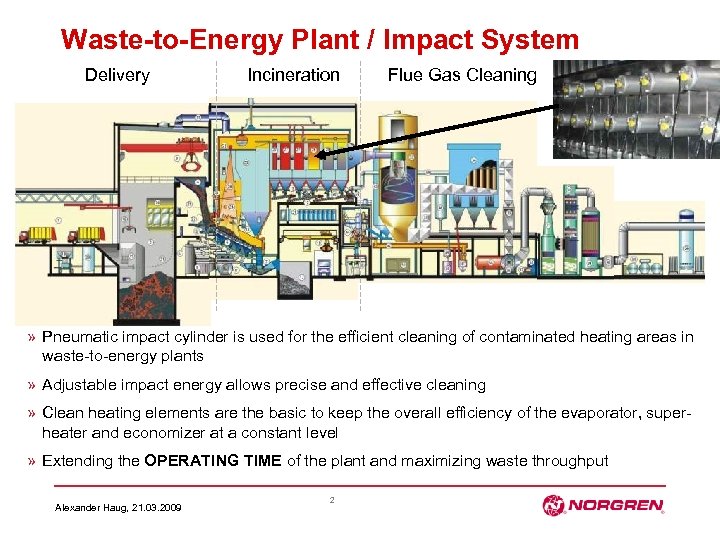

Waste-to-Energy Plant / Impact System Delivery Incineration Flue Gas Cleaning » Pneumatic impact cylinder is used for the efficient cleaning of contaminated heating areas in waste-to-energy plants » Adjustable impact energy allows precise and effective cleaning » Clean heating elements are the basic to keep the overall efficiency of the evaporator, superheater and economizer at a constant level » Extending the OPERATING TIME of the plant and maximizing waste throughput Alexander Haug, 21. 03. 2009 2

Waste-to-Energy Plant / Impact System Delivery Incineration Flue Gas Cleaning » Pneumatic impact cylinder is used for the efficient cleaning of contaminated heating areas in waste-to-energy plants » Adjustable impact energy allows precise and effective cleaning » Clean heating elements are the basic to keep the overall efficiency of the evaporator, superheater and economizer at a constant level » Extending the OPERATING TIME of the plant and maximizing waste throughput Alexander Haug, 21. 03. 2009 2

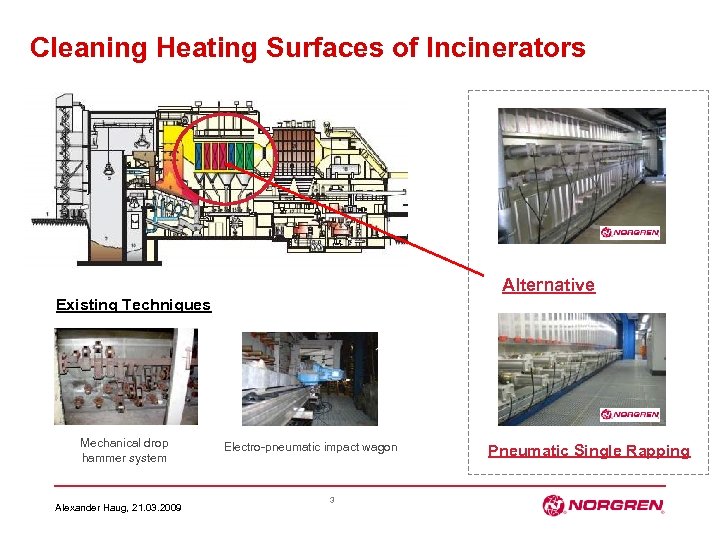

Cleaning Heating Surfaces of Incinerators Alternative Existing Techniques Mechanical drop hammer system Alexander Haug, 21. 03. 2009 Electro-pneumatic impact wagon 3 Pneumatic Single Rapping

Cleaning Heating Surfaces of Incinerators Alternative Existing Techniques Mechanical drop hammer system Alexander Haug, 21. 03. 2009 Electro-pneumatic impact wagon 3 Pneumatic Single Rapping

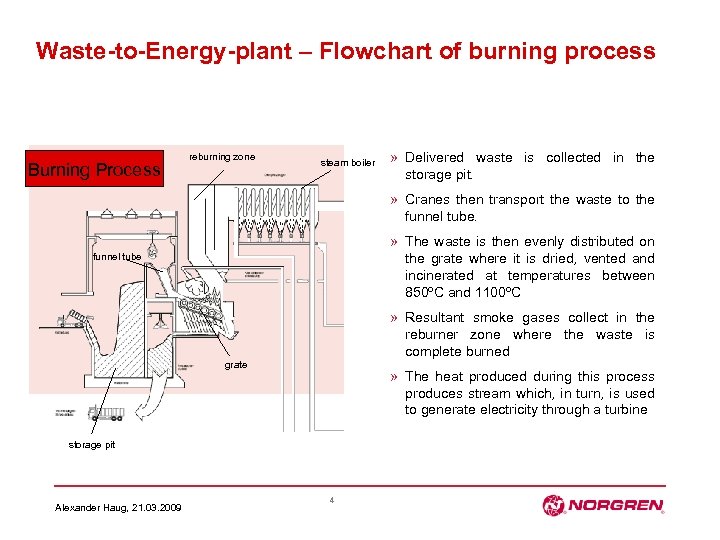

Waste-to-Energy-plant – Flowchart of burning process Burning Process reburning zone steam boiler » Delivered waste is collected in the storage pit. » Cranes then transport the waste to the funnel tube. » The waste is then evenly distributed on the grate where it is dried, vented and incinerated at temperatures between 850ºC and 1100ºC funnel tube » Resultant smoke gases collect in the reburner zone where the waste is complete burned grate » The heat produced during this process produces stream which, in turn, is used to generate electricity through a turbine storage pit Alexander Haug, 21. 03. 2009 4

Waste-to-Energy-plant – Flowchart of burning process Burning Process reburning zone steam boiler » Delivered waste is collected in the storage pit. » Cranes then transport the waste to the funnel tube. » The waste is then evenly distributed on the grate where it is dried, vented and incinerated at temperatures between 850ºC and 1100ºC funnel tube » Resultant smoke gases collect in the reburner zone where the waste is complete burned grate » The heat produced during this process produces stream which, in turn, is used to generate electricity through a turbine storage pit Alexander Haug, 21. 03. 2009 4

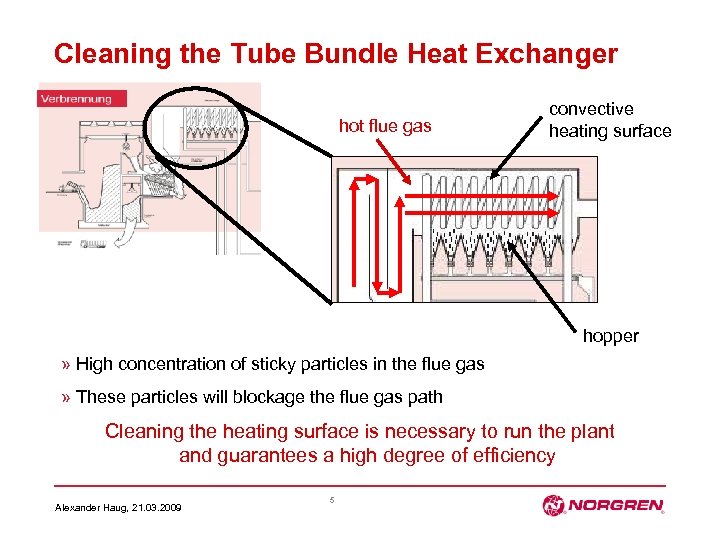

Cleaning the Tube Bundle Heat Exchanger hot flue gas convective heating surface hopper » High concentration of sticky particles in the flue gas » These particles will blockage the flue gas path Cleaning the heating surface is necessary to run the plant and guarantees a high degree of efficiency Alexander Haug, 21. 03. 2009 5

Cleaning the Tube Bundle Heat Exchanger hot flue gas convective heating surface hopper » High concentration of sticky particles in the flue gas » These particles will blockage the flue gas path Cleaning the heating surface is necessary to run the plant and guarantees a high degree of efficiency Alexander Haug, 21. 03. 2009 5

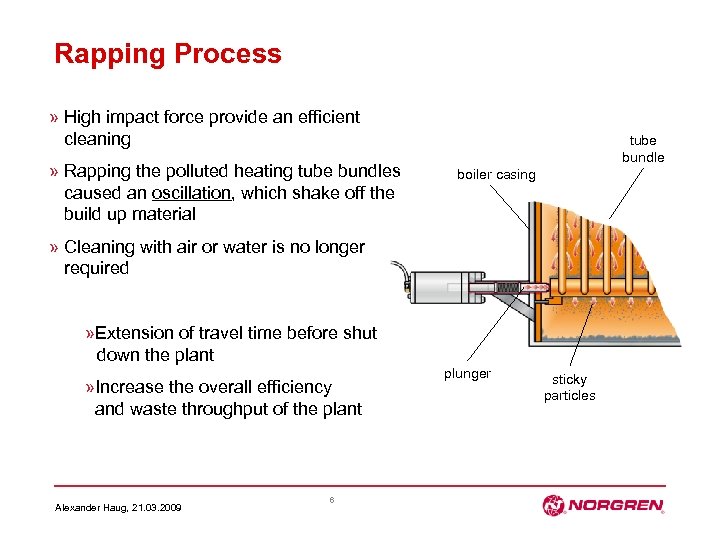

Rapping Process » High impact force provide an efficient cleaning » Rapping the polluted heating tube bundles caused an oscillation, which shake off the build up material tube bundle boiler casing » Cleaning with air or water is no longer required » Extension of travel time before shut down the plant » Increase the overall efficiency and waste throughput of the plant Alexander Haug, 21. 03. 2009 6 plunger sticky particles

Rapping Process » High impact force provide an efficient cleaning » Rapping the polluted heating tube bundles caused an oscillation, which shake off the build up material tube bundle boiler casing » Cleaning with air or water is no longer required » Extension of travel time before shut down the plant » Increase the overall efficiency and waste throughput of the plant Alexander Haug, 21. 03. 2009 6 plunger sticky particles

Demand of the customers Optimization of the cleaning system » Optimal cleaning of the heat exchange surfaces to optimize the absolute efficiency » Subsequent and Individual adjustment of the impact force » Reducing maintenance costs » Reducing the construction volume » Feedback to control room of the cleaning activity » Check the wear and inform about failures » Process stability » Guarantee maximum travel time Alexander Haug, 21. 03. 2009 7

Demand of the customers Optimization of the cleaning system » Optimal cleaning of the heat exchange surfaces to optimize the absolute efficiency » Subsequent and Individual adjustment of the impact force » Reducing maintenance costs » Reducing the construction volume » Feedback to control room of the cleaning activity » Check the wear and inform about failures » Process stability » Guarantee maximum travel time Alexander Haug, 21. 03. 2009 7

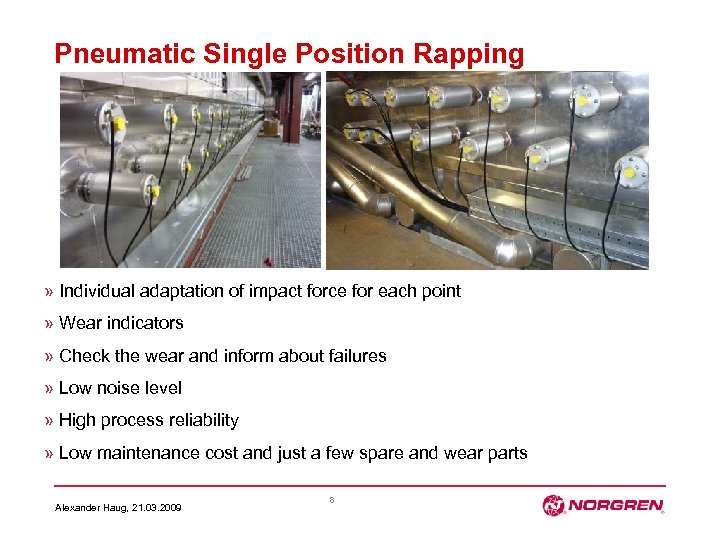

Pneumatic Single Position Rapping » Individual adaptation of impact force for each point » Wear indicators » Check the wear and inform about failures » Low noise level » High process reliability » Low maintenance cost and just a few spare and wear parts Alexander Haug, 21. 03. 2009 8

Pneumatic Single Position Rapping » Individual adaptation of impact force for each point » Wear indicators » Check the wear and inform about failures » Low noise level » High process reliability » Low maintenance cost and just a few spare and wear parts Alexander Haug, 21. 03. 2009 8

Norgren Impact System » Elements of the Norgren Impact System - Project » Product Impact Cylinder » Control Cabinet SPS (S 7) Profibus DP S 7 Touch Panel Coupler for Profibus or Fibre Optic Cable Valve Islands (3/2 way function) » Software » Engineering/Documentation » Installation » Commissioning » Optional » Mounting flanges with plungers and springs Alexander Haug, 21. 03. 2009 9

Norgren Impact System » Elements of the Norgren Impact System - Project » Product Impact Cylinder » Control Cabinet SPS (S 7) Profibus DP S 7 Touch Panel Coupler for Profibus or Fibre Optic Cable Valve Islands (3/2 way function) » Software » Engineering/Documentation » Installation » Commissioning » Optional » Mounting flanges with plungers and springs Alexander Haug, 21. 03. 2009 9

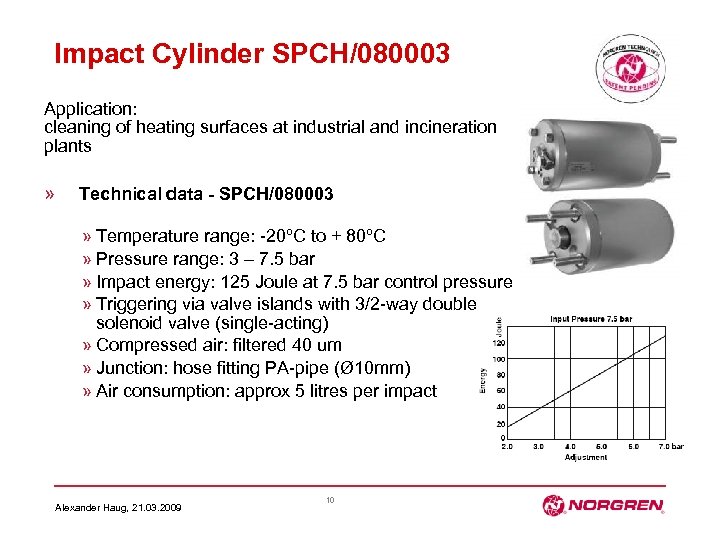

Impact Cylinder SPCH/080003 Application: cleaning of heating surfaces at industrial and incineration plants » Technical data - SPCH/080003 » Temperature range: -20ºC to + 80ºC » Pressure range: 3 – 7. 5 bar » Impact energy: 125 Joule at 7. 5 bar control pressure » Triggering via valve islands with 3/2 -way double solenoid valve (single-acting) » Compressed air: filtered 40 um » Junction: hose fitting PA-pipe (Ø 10 mm) » Air consumption: approx 5 litres per impact Alexander Haug, 21. 03. 2009 10

Impact Cylinder SPCH/080003 Application: cleaning of heating surfaces at industrial and incineration plants » Technical data - SPCH/080003 » Temperature range: -20ºC to + 80ºC » Pressure range: 3 – 7. 5 bar » Impact energy: 125 Joule at 7. 5 bar control pressure » Triggering via valve islands with 3/2 -way double solenoid valve (single-acting) » Compressed air: filtered 40 um » Junction: hose fitting PA-pipe (Ø 10 mm) » Air consumption: approx 5 litres per impact Alexander Haug, 21. 03. 2009 10

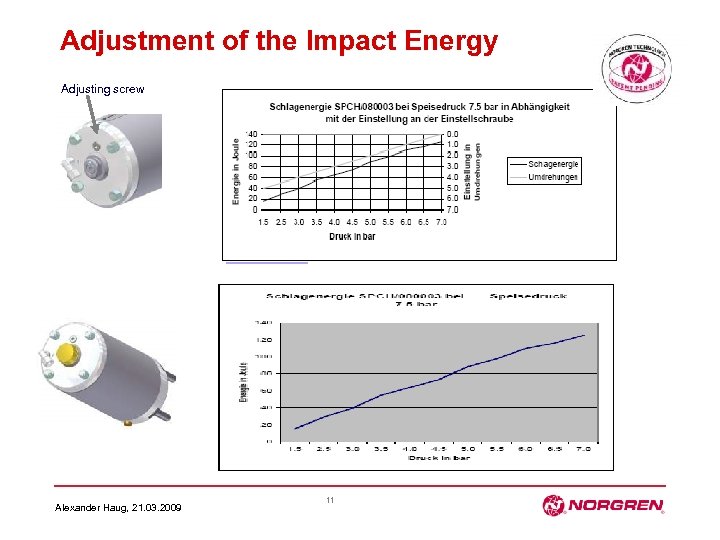

Adjustment of the Impact Energy Adjusting screw Alexander Haug, 21. 03. 2009 11

Adjustment of the Impact Energy Adjusting screw Alexander Haug, 21. 03. 2009 11

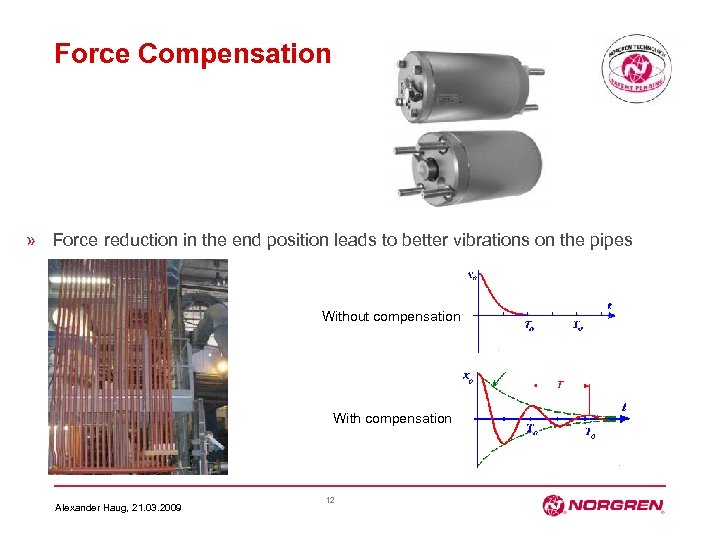

Force Compensation » Force reduction in the end position leads to better vibrations on the pipes Without compensation With compensation Alexander Haug, 21. 03. 2009 12

Force Compensation » Force reduction in the end position leads to better vibrations on the pipes Without compensation With compensation Alexander Haug, 21. 03. 2009 12

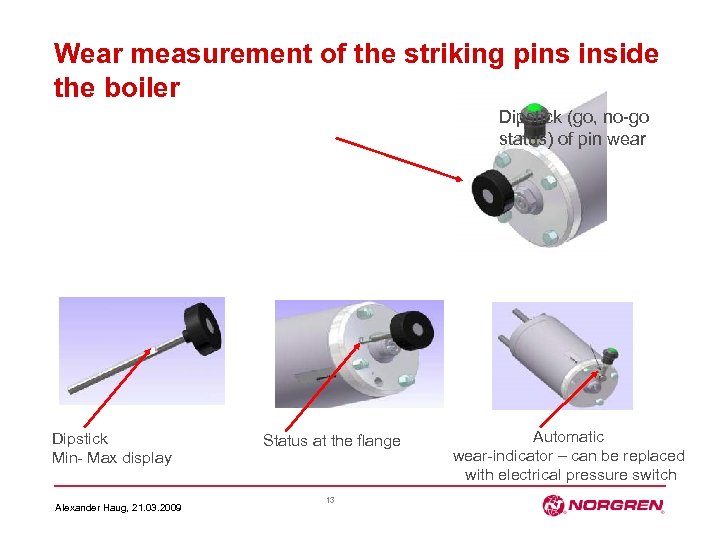

Wear measurement of the striking pins inside the boiler Dipstick (go, no-go status) of pin wear Dipstick Min- Max display Alexander Haug, 21. 03. 2009 Status at the flange 13 Automatic wear-indicator – can be replaced with electrical pressure switch

Wear measurement of the striking pins inside the boiler Dipstick (go, no-go status) of pin wear Dipstick Min- Max display Alexander Haug, 21. 03. 2009 Status at the flange 13 Automatic wear-indicator – can be replaced with electrical pressure switch

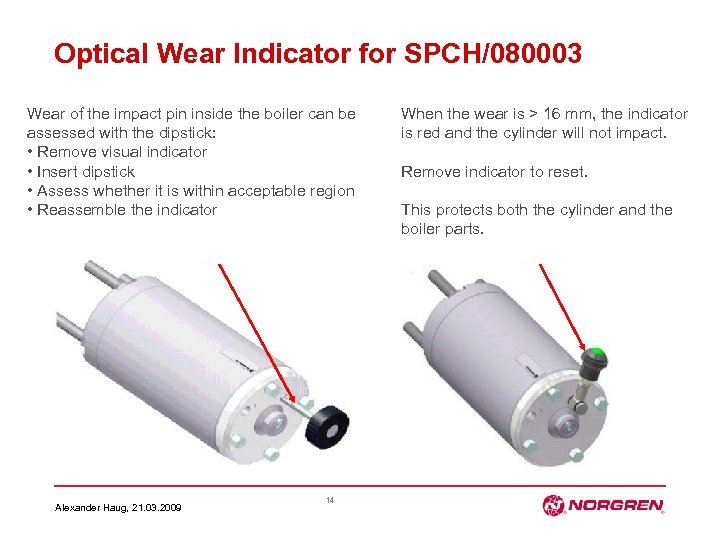

Optical Wear Indicator for SPCH/080003 Wear of the impact pin inside the boiler can be assessed with the dipstick: • Remove visual indicator • Insert dipstick • Assess whether it is within acceptable region • Reassemble the indicator Alexander Haug, 21. 03. 2009 14 When the wear is > 16 mm, the indicator is red and the cylinder will not impact. Remove indicator to reset. This protects both the cylinder and the boiler parts.

Optical Wear Indicator for SPCH/080003 Wear of the impact pin inside the boiler can be assessed with the dipstick: • Remove visual indicator • Insert dipstick • Assess whether it is within acceptable region • Reassemble the indicator Alexander Haug, 21. 03. 2009 14 When the wear is > 16 mm, the indicator is red and the cylinder will not impact. Remove indicator to reset. This protects both the cylinder and the boiler parts.

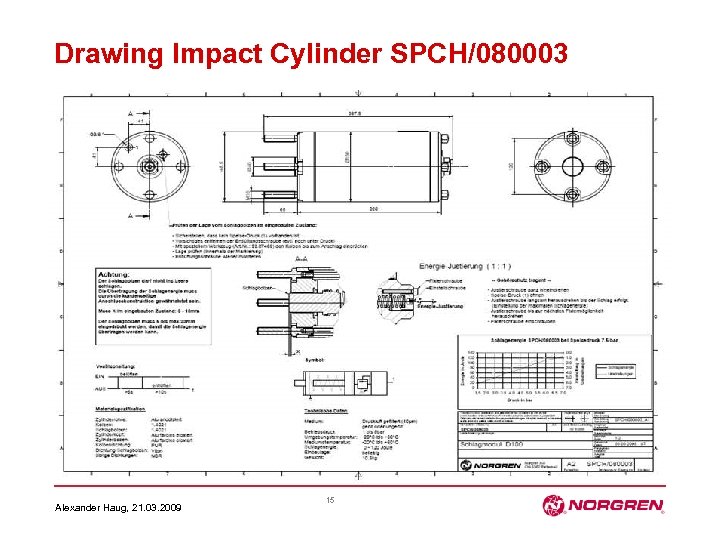

Drawing Impact Cylinder SPCH/080003 Alexander Haug, 21. 03. 2009 15

Drawing Impact Cylinder SPCH/080003 Alexander Haug, 21. 03. 2009 15

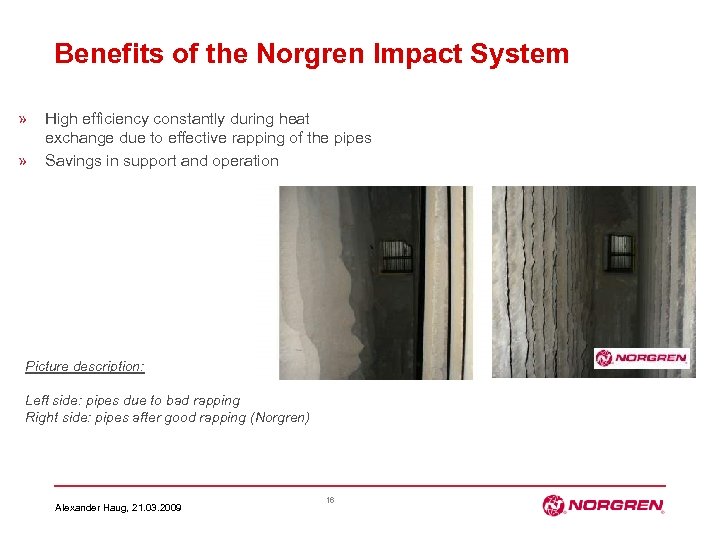

Benefits of the Norgren Impact System » » High efficiency constantly during heat exchange due to effective rapping of the pipes Savings in support and operation Picture description: Left side: pipes due to bad rapping Right side: pipes after good rapping (Norgren) Alexander Haug, 21. 03. 2009 16

Benefits of the Norgren Impact System » » High efficiency constantly during heat exchange due to effective rapping of the pipes Savings in support and operation Picture description: Left side: pipes due to bad rapping Right side: pipes after good rapping (Norgren) Alexander Haug, 21. 03. 2009 16

Reference List - Impact Systems Germany » MVA Leuna Boiler I + II » MVA Sonne (Großräschen) » MVA Premnitz » MVA Hameln » MVA Herten » MVA Mannheim International » WTE Dürnrohr Boiler I + II » WTE Dürnrohr Boiler III » WTE Pfaffenau » WTE Delfzijl Boiler I + II » KEBAG Emmenspitz » KVA Chevenez, Geneve » KVA Turgi Aarau » WTE Allington* » WTE Moskau* Built 2006 2008 2009 1982 2009 (Austria) (NL) (Switzerland) (UK) (Russia) *Impact wagon system Alexander Haug, 21. 03. 2009 17 2005 2009 2006 2002/2009 1996 2005 2007

Reference List - Impact Systems Germany » MVA Leuna Boiler I + II » MVA Sonne (Großräschen) » MVA Premnitz » MVA Hameln » MVA Herten » MVA Mannheim International » WTE Dürnrohr Boiler I + II » WTE Dürnrohr Boiler III » WTE Pfaffenau » WTE Delfzijl Boiler I + II » KEBAG Emmenspitz » KVA Chevenez, Geneve » KVA Turgi Aarau » WTE Allington* » WTE Moskau* Built 2006 2008 2009 1982 2009 (Austria) (NL) (Switzerland) (UK) (Russia) *Impact wagon system Alexander Haug, 21. 03. 2009 17 2005 2009 2006 2002/2009 1996 2005 2007

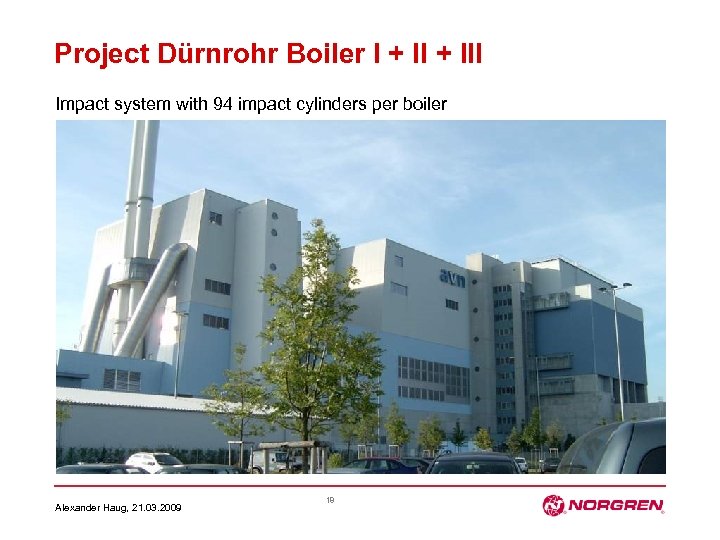

Project Dürnrohr Boiler I + III Impact system with 94 impact cylinders per boiler Alexander Haug, 21. 03. 2009 18

Project Dürnrohr Boiler I + III Impact system with 94 impact cylinders per boiler Alexander Haug, 21. 03. 2009 18

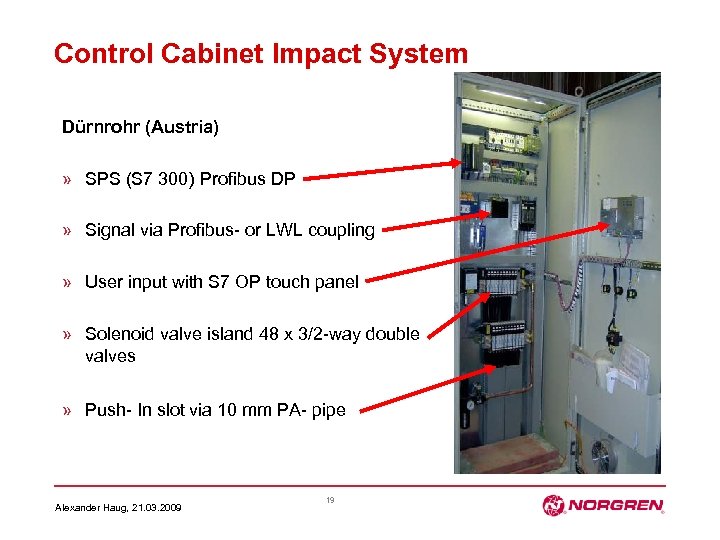

Control Cabinet Impact System Dürnrohr (Austria) » SPS (S 7 300) Profibus DP » Signal via Profibus- or LWL coupling » User input with S 7 OP touch panel » Solenoid valve island 48 x 3/2 -way double valves » Push- In slot via 10 mm PA- pipe Alexander Haug, 21. 03. 2009 19

Control Cabinet Impact System Dürnrohr (Austria) » SPS (S 7 300) Profibus DP » Signal via Profibus- or LWL coupling » User input with S 7 OP touch panel » Solenoid valve island 48 x 3/2 -way double valves » Push- In slot via 10 mm PA- pipe Alexander Haug, 21. 03. 2009 19

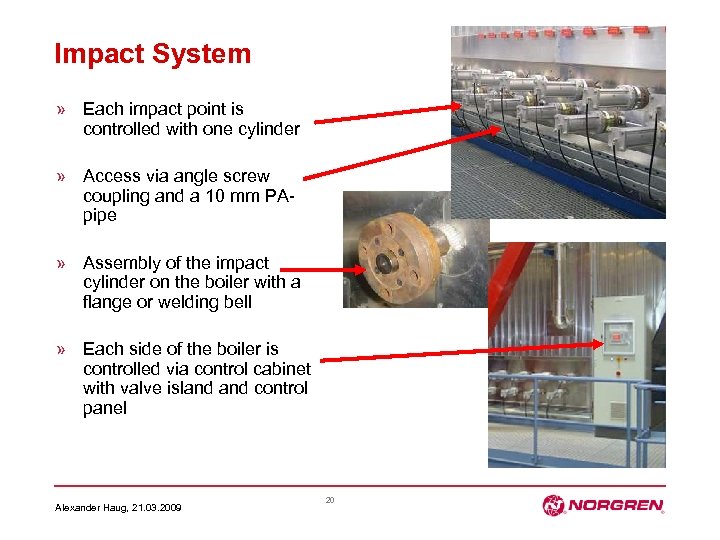

Impact System » Each impact point is controlled with one cylinder » Access via angle screw coupling and a 10 mm PApipe » Assembly of the impact cylinder on the boiler with a flange or welding bell » Each side of the boiler is controlled via control cabinet with valve island control panel Alexander Haug, 21. 03. 2009 20

Impact System » Each impact point is controlled with one cylinder » Access via angle screw coupling and a 10 mm PApipe » Assembly of the impact cylinder on the boiler with a flange or welding bell » Each side of the boiler is controlled via control cabinet with valve island control panel Alexander Haug, 21. 03. 2009 20

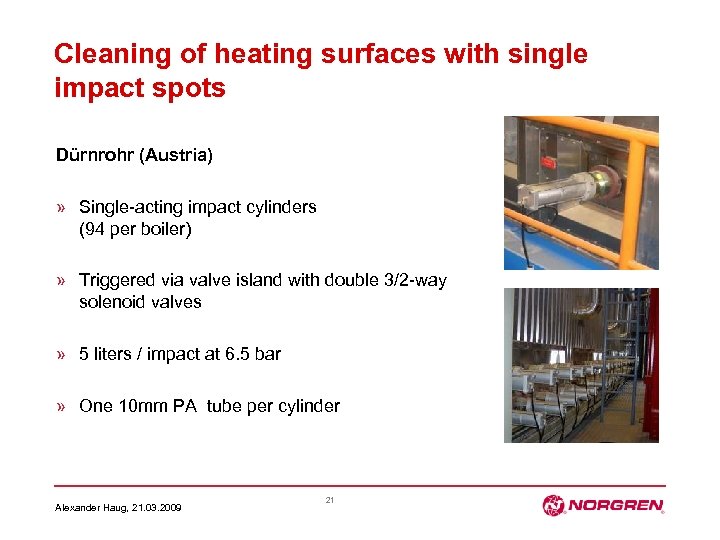

Cleaning of heating surfaces with single impact spots Dürnrohr (Austria) » Single-acting impact cylinders (94 per boiler) » Triggered via valve island with double 3/2 -way solenoid valves » 5 liters / impact at 6. 5 bar » One 10 mm PA tube per cylinder Alexander Haug, 21. 03. 2009 21

Cleaning of heating surfaces with single impact spots Dürnrohr (Austria) » Single-acting impact cylinders (94 per boiler) » Triggered via valve island with double 3/2 -way solenoid valves » 5 liters / impact at 6. 5 bar » One 10 mm PA tube per cylinder Alexander Haug, 21. 03. 2009 21

Key Advantages of Norgren Impact System » Optimal cleaning » Extend the maximum travel time of the plant » Guarantee high overall efficient » Maximize the waste throughput » Keep an “Eye” into the boiler » Check the wear and inform about failures » Subsequent adjustment of the cleaning system to your plant » In- / decrease the impact force » Change the iteration of the cylinder groups » Nearly no maintenance and no spare and wear parts » Comfortable operation and feedback to the control room Alexander Haug, 21. 03. 2009 22

Key Advantages of Norgren Impact System » Optimal cleaning » Extend the maximum travel time of the plant » Guarantee high overall efficient » Maximize the waste throughput » Keep an “Eye” into the boiler » Check the wear and inform about failures » Subsequent adjustment of the cleaning system to your plant » In- / decrease the impact force » Change the iteration of the cylinder groups » Nearly no maintenance and no spare and wear parts » Comfortable operation and feedback to the control room Alexander Haug, 21. 03. 2009 22

Contact www. norgren. com Alexander Haug, 21. 03. 2009 23

Contact www. norgren. com Alexander Haug, 21. 03. 2009 23