8c668988e47172cc87538fca4c0be2d3.ppt

- Количество слайдов: 32

Impact of Bonding Requirements for CSST on LP-Gas Piping Systems April 2009

Lightning Statistics • Ave. number lightning flashes/year in US: 25, 000 • Average annual number of U. S. home fires* by cause: - Fires caused by lightning: 4, 800 - Fires caused by natural gas: 2, 100 - Fires caused by lightning/fuel gas: 180 - Fires caused by lightning/wires: 260 - Fires caused by electric distribution: 24, 000 Lightning damage to gas piping is an uncommon event compared to other causes of fires. * NFPA data

Energizing Metallic Piping Systems • Direct lightning strike on the structure • Lightning that branches from nearby strike • Lightning energy conducted through the soil and underground metallic systems or through overhead power lines • Lightning current takes all pathways of electrical resistance to ground and not just the path of “least resistance”.

Lightning Induced Piping Damage • Lightning does not discriminate. It will damage all piping materials and systems. • Damage is attributed to arcing caused by a difference in voltage build-up between the grounded electrical system and any other electrically conductive pathway. • Gas system components typically damaged: – Perforations of PE pipe with copper tracer wire – Perforations of CSST wall – Flow/loss of pipe dope between threaded joints – Failure of flexible connectors on steel pipe system – Failure of copper tubing/pipe – Failure of gas burning equipment components

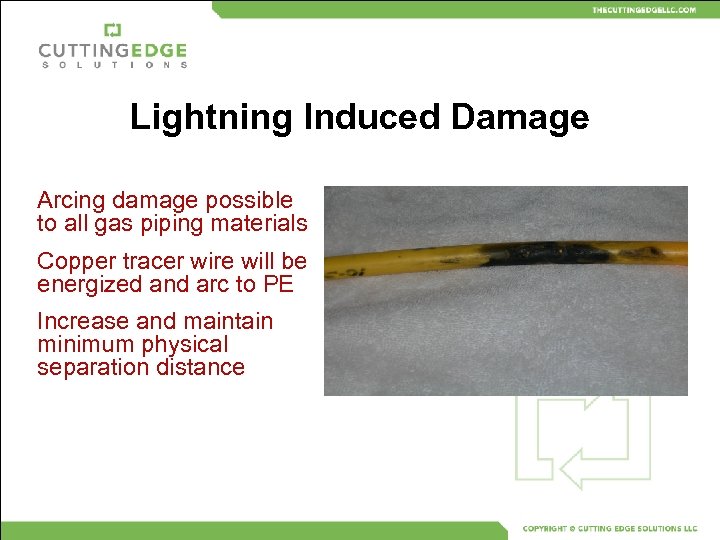

Lightning Induced Damage Arcing damage possible to all gas piping materials Copper tracer wire will be energized and arc to PE Increase and maintain minimum physical separation distance

Grounding verses Bonding • A conducting connection between an electrical circuit or equipment and the earth that limits the voltage imposed upon it. Only the premise wiring system is grounded. • The permanent joining of metallic parts to form an effective electrical path that ensures continuity and the capacity to safely conduct any current likely to be imposed. Gas piping is bonded.

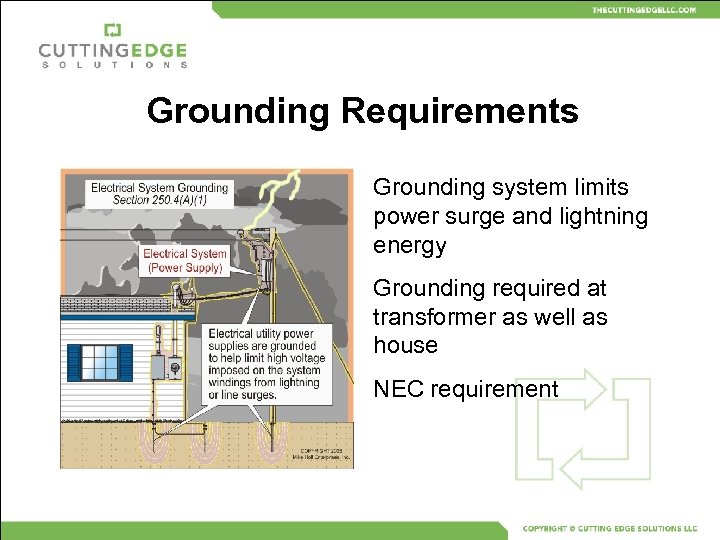

Grounding Requirements Grounding system limits power surge and lightning energy Grounding required at transformer as well as house NEC requirement

Grounding Requirements Grounding not required for LP storage containers.

Grounding Electrode System Various types of electrodes permitted Grounding electrode conductor and bonding conductor are different Do not install separate electrode for LP-gas service

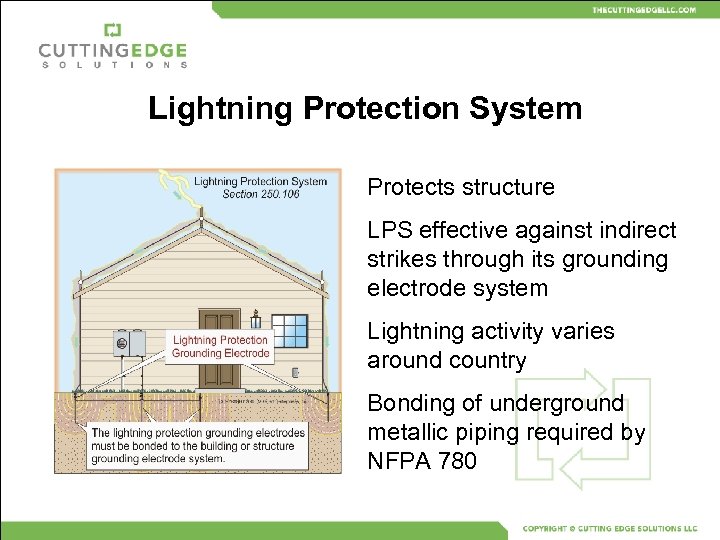

Lightning Protection System Protects structure LPS effective against indirect strikes through its grounding electrode system Lightning activity varies around country Bonding of underground metallic piping required by NFPA 780

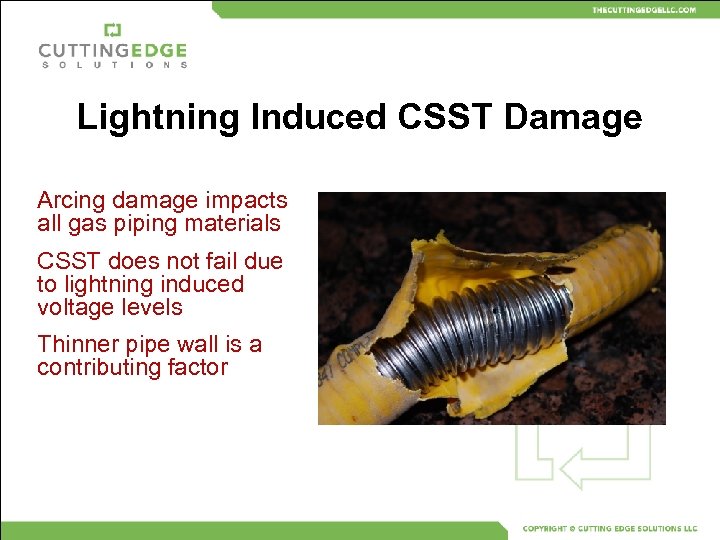

Lightning Induced CSST Damage Arcing damage impacts all gas piping materials CSST does not fail due to lightning induced voltage levels Thinner pipe wall is a contributing factor

CSST Solution • Increase robustness of bonding connection beyond minimum required by NEC. • Bonding at service entrance to divert energy off gas piping system and lower voltage level. • Increase jumper size to reduce the difference in voltage build-up between other electrically conductive pathways and minimize potential for arcing. • Equi-potential bonding of all metallic systems will further reduce the chances for arcing by balancing the voltage levels in all connected systems. • Maintain physical separation as much as practical

Applicable Codes and Standards

NFPA 58/54/70/780 Requirements 6. 9. 3. 15 LP-Gas piping shall not be used as a grounding electrode. (also NFPA 54 and 70) 6. 22. 1. 3 Grounding and bonding shall not be required on LP-Gas systems. 7. 13. 4 Lightning Protection Systems. Where a lightning protection system is installed, the bonding of the gas piping shall be in accordance with NFPA 780 requires the bonding of any underground conductive piping to the grounding electrode system at or near the entry point into the structure.

2009 Bonding Requirements* CSST gas piping systems shall be bonded to the electrical service grounding electrode system at the point where the gas service enters the building. The bonding jumper shall not be smaller than 6 AWG copper wire or equivalent. * 2009 NFPA 54, IFGC and UPC

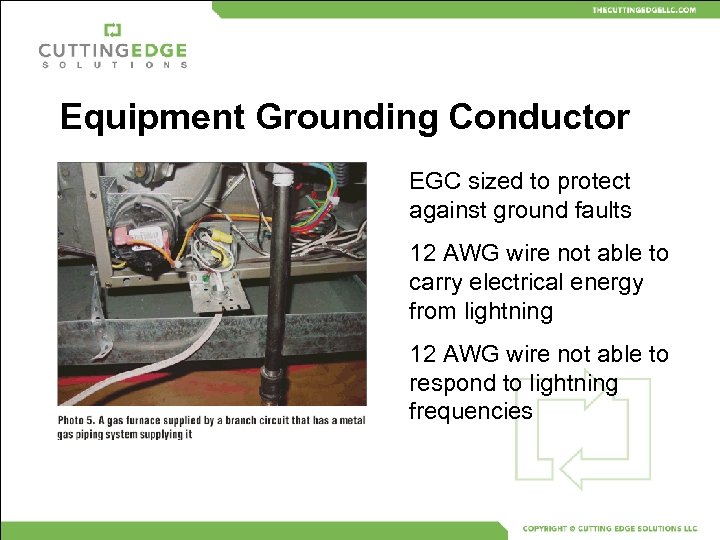

Equipment Grounding Conductor EGC sized to protect against ground faults 12 AWG wire not able to carry electrical energy from lightning 12 AWG wire not able to respond to lightning frequencies

2009 IFGC Electrical Isolation 404. 8. 1 Isolation. Metallic piping and metallic tubing that conveys fuel gas from an LP-gas storage container shall be provided with an approved dielectric fitting to electrically isolate the underground portion of the pipe or tube from the above ground portion that enters a building. Such dielectric fitting shall be installed above ground and outdoors. Same proposal submitted for 2011 NFPA 58.

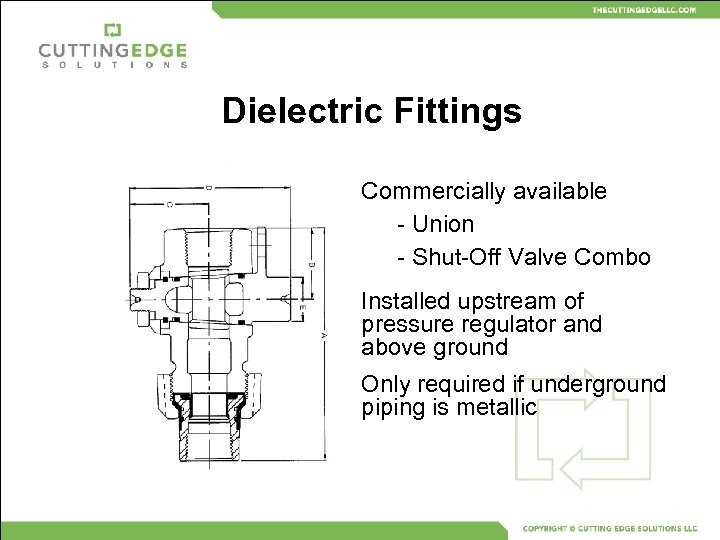

Dielectric Fittings Commercially available - Union - Shut-Off Valve Combo Installed upstream of pressure regulator and above ground Only required if underground piping is metallic

Impact on CSST Piping Systems Complete Piping System - Tubing - Fittings - Strike Plates Update ANSI Standard Installed in accordance with manufacturer’s instructions Uniform bonding practices

Six Manufacturers: One Approach Ward Mfg - Wardflex Parker - Par. Flex Omegaflex - Trac. Pipe Titeflex - Gastite Truflex - Pro-Flex Metal. Fab - Diamondback

CSST Bonding Instructions • Direct bonding of CSST to the grounding system is now required • All new CSST installations for all gas appliances • One-size-fits-all for most residential applications • Installation and sizing requirements consistent with NEC Section 250 for metallic piping and current edition of NFGC • Installed by person recognized by AHJ as qualified to perform such work • Do not bond any underground metallic piping upstream of second stage regulator (at service entrance)

KISS Principle • One simple, universal bonding approach • Effective and low cost • Consistent with NEC/NFGC requirements • Applies to all single family and low-rise multi-family • Commercial applications may require an engineered solution

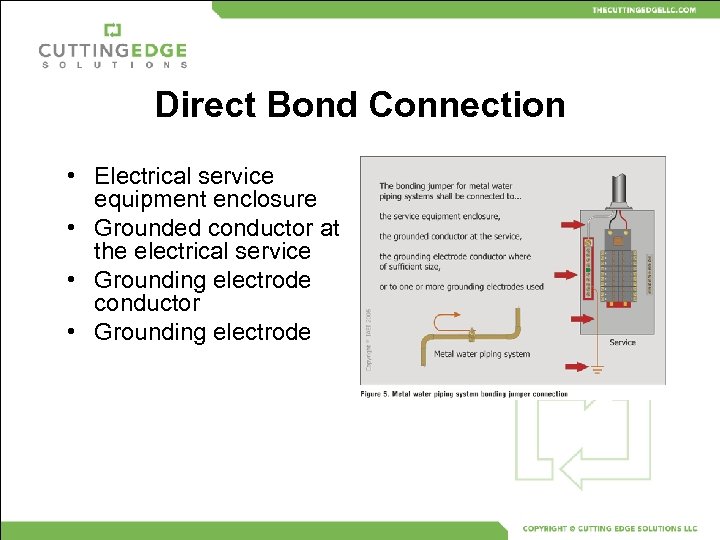

Direct Bond Connection • Electrical service equipment enclosure • Grounded conductor at the electrical service • Grounding electrode conductor • Grounding electrode

Bond Near the Gas Service • Customer side of meter • Downstream of 2 nd stage LP regulator • Indoors or outdoors • Upstream of first CSST fitting

Bonding Jumper • At least a 6 AWG copper wire or equivalent • Installed in accordance with NEC • Jacketed or bare • Above or below grade • Keep as short as possible

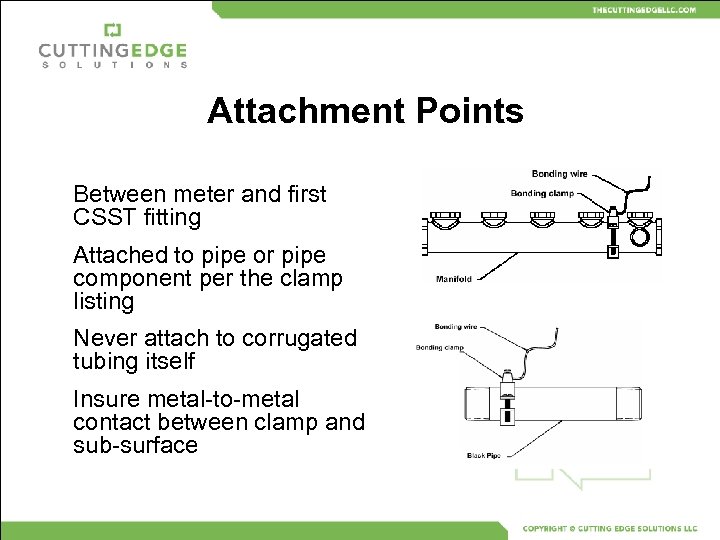

Attachment Points Between meter and first CSST fitting Attached to pipe or pipe component per the clamp listing Never attach to corrugated tubing itself Insure metal-to-metal contact between clamp and sub-surface

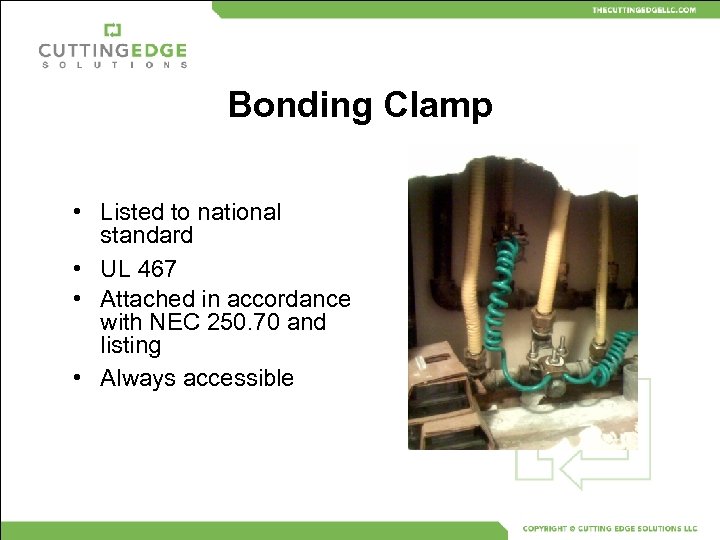

Bonding Clamp • Listed to national standard • UL 467 • Attached in accordance with NEC 250. 70 and listing • Always accessible

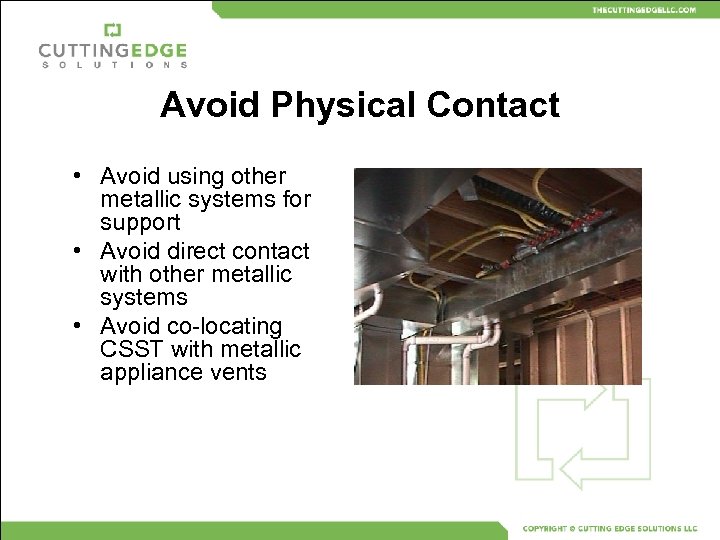

Avoid Physical Contact • Avoid using other metallic systems for support • Avoid direct contact with other metallic systems • Avoid co-locating CSST with metallic appliance vents

Summary • Direct bonding of gas piping will: – Lower voltage levels – Reduce differences in electrical potential – Minimize the possibility of arcing • Maintain physical separation where practical • Bonding together of all metallic systems • All CSST products require the same type of bonding in accordance with current edition of NFPA 54 or IFGC or UPC

Conclusions • No code or standards requirements mandating lightning resistance, protection or mitigation. • New bonding requirements above minimum of NEC. • Direct bonding will reduce impact of lightning strikes on gas piping system without effecting ground-fault protection. • New CSST bonding requires dielectric isolation • CSST industry requiring direct bonding on all new CSST installations with a “keep-it-simple” approach. • National model code change proposals are being developed. • CSST product standard being updated.

http: //thecuttingedgellc. com

Cutting Edge Solutions LLC 70 Flanagan Drive Framingham, MA 01701 (508) 877 -9239

8c668988e47172cc87538fca4c0be2d3.ppt