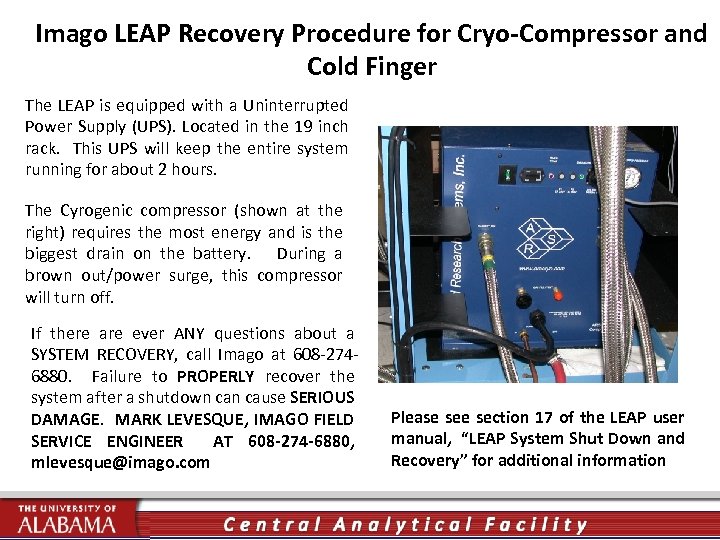

Imago LEAP Recovery Procedure for Cryo-Compressor and Cold Finger The LEAP is equipped with a Uninterrupted Power Supply (UPS). Located in the 19 inch rack. This UPS will keep the entire system running for about 2 hours. The Cyrogenic compressor (shown at the right) requires the most energy and is the biggest drain on the battery. During a brown out/power surge, this compressor will turn off. If there are ever ANY questions about a SYSTEM RECOVERY, call Imago at 608 -2746880. Failure to PROPERLY recover the system after a shutdown cause SERIOUS DAMAGE. MARK LEVESQUE, IMAGO FIELD SERVICE ENGINEER AT 608 -274 -6880, mlevesque@imago. com Please section 17 of the LEAP user manual, “LEAP System Shut Down and Recovery” for additional information

Imago LEAP Recovery Procedure for Cryo-Compressor and Cold Finger The LEAP is equipped with a Uninterrupted Power Supply (UPS). Located in the 19 inch rack. This UPS will keep the entire system running for about 2 hours. The Cyrogenic compressor (shown at the right) requires the most energy and is the biggest drain on the battery. During a brown out/power surge, this compressor will turn off. If there are ever ANY questions about a SYSTEM RECOVERY, call Imago at 608 -2746880. Failure to PROPERLY recover the system after a shutdown cause SERIOUS DAMAGE. MARK LEVESQUE, IMAGO FIELD SERVICE ENGINEER AT 608 -274 -6880, mlevesque@imago. com Please section 17 of the LEAP user manual, “LEAP System Shut Down and Recovery” for additional information

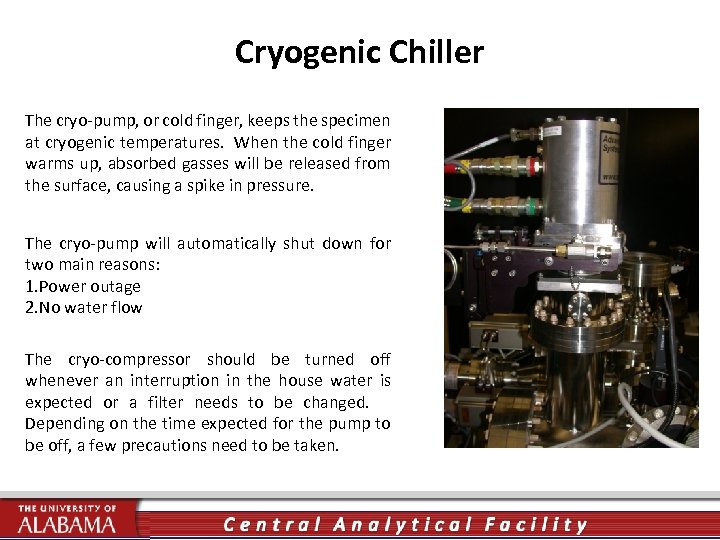

Cryogenic Chiller The cryo-pump, or cold finger, keeps the specimen at cryogenic temperatures. When the cold finger warms up, absorbed gasses will be released from the surface, causing a spike in pressure. The cryo-pump will automatically shut down for two main reasons: 1. Power outage 2. No water flow The cryo-compressor should be turned off whenever an interruption in the house water is expected or a filter needs to be changed. Depending on the time expected for the pump to be off, a few precautions need to be taken.

Cryogenic Chiller The cryo-pump, or cold finger, keeps the specimen at cryogenic temperatures. When the cold finger warms up, absorbed gasses will be released from the surface, causing a spike in pressure. The cryo-pump will automatically shut down for two main reasons: 1. Power outage 2. No water flow The cryo-compressor should be turned off whenever an interruption in the house water is expected or a filter needs to be changed. Depending on the time expected for the pump to be off, a few precautions need to be taken.

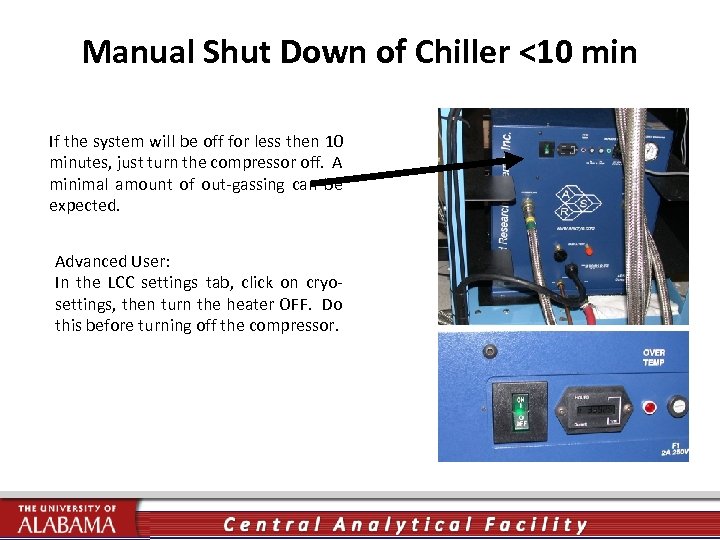

Manual Shut Down of Chiller <10 min If the system will be off for less then 10 minutes, just turn the compressor off. A minimal amount of out-gassing can be expected. Advanced User: In the LCC settings tab, click on cryosettings, then turn the heater OFF. Do this before turning off the compressor.

Manual Shut Down of Chiller <10 min If the system will be off for less then 10 minutes, just turn the compressor off. A minimal amount of out-gassing can be expected. Advanced User: In the LCC settings tab, click on cryosettings, then turn the heater OFF. Do this before turning off the compressor.

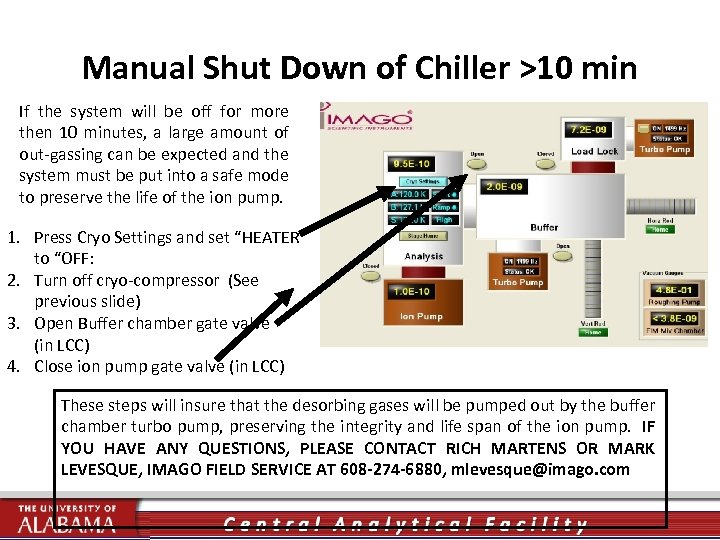

Manual Shut Down of Chiller >10 min If the system will be off for more then 10 minutes, a large amount of out-gassing can be expected and the system must be put into a safe mode to preserve the life of the ion pump. 1. Press Cryo Settings and set “HEATER to “OFF: 2. Turn off cryo-compressor (See previous slide) 3. Open Buffer chamber gate valve (in LCC) 4. Close ion pump gate valve (in LCC) These steps will insure that the desorbing gases will be pumped out by the buffer chamber turbo pump, preserving the integrity and life span of the ion pump. IF YOU HAVE ANY QUESTIONS, PLEASE CONTACT RICH MARTENS OR MARK LEVESQUE, IMAGO FIELD SERVICE AT 608 -274 -6880, mlevesque@imago. com

Manual Shut Down of Chiller >10 min If the system will be off for more then 10 minutes, a large amount of out-gassing can be expected and the system must be put into a safe mode to preserve the life of the ion pump. 1. Press Cryo Settings and set “HEATER to “OFF: 2. Turn off cryo-compressor (See previous slide) 3. Open Buffer chamber gate valve (in LCC) 4. Close ion pump gate valve (in LCC) These steps will insure that the desorbing gases will be pumped out by the buffer chamber turbo pump, preserving the integrity and life span of the ion pump. IF YOU HAVE ANY QUESTIONS, PLEASE CONTACT RICH MARTENS OR MARK LEVESQUE, IMAGO FIELD SERVICE AT 608 -274 -6880, mlevesque@imago. com

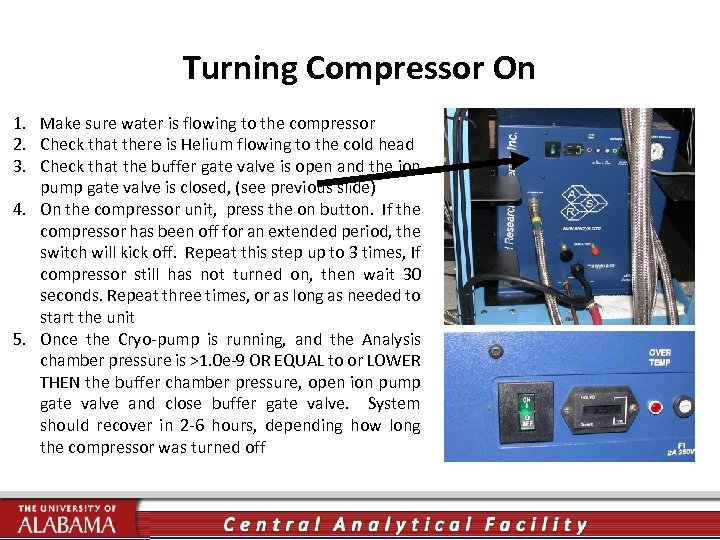

Turning Compressor On 1. Make sure water is flowing to the compressor 2. Check that there is Helium flowing to the cold head 3. Check that the buffer gate valve is open and the ion pump gate valve is closed, (see previous slide) 4. On the compressor unit, press the on button. If the compressor has been off for an extended period, the switch will kick off. Repeat this step up to 3 times, If compressor still has not turned on, then wait 30 seconds. Repeat three times, or as long as needed to start the unit 5. Once the Cryo-pump is running, and the Analysis chamber pressure is >1. 0 e-9 OR EQUAL to or LOWER THEN the buffer chamber pressure, open ion pump gate valve and close buffer gate valve. System should recover in 2 -6 hours, depending how long the compressor was turned off

Turning Compressor On 1. Make sure water is flowing to the compressor 2. Check that there is Helium flowing to the cold head 3. Check that the buffer gate valve is open and the ion pump gate valve is closed, (see previous slide) 4. On the compressor unit, press the on button. If the compressor has been off for an extended period, the switch will kick off. Repeat this step up to 3 times, If compressor still has not turned on, then wait 30 seconds. Repeat three times, or as long as needed to start the unit 5. Once the Cryo-pump is running, and the Analysis chamber pressure is >1. 0 e-9 OR EQUAL to or LOWER THEN the buffer chamber pressure, open ion pump gate valve and close buffer gate valve. System should recover in 2 -6 hours, depending how long the compressor was turned off