31770e47bcc8767a1e9e33174ce4add5.ppt

- Количество слайдов: 10

IFR detector mechanics W. Baldini on behalf of the Ferrara IFR Group XXVII Super. B Workshop and Kick off Meeting Isola d’Elba May 28 - June 02 2011

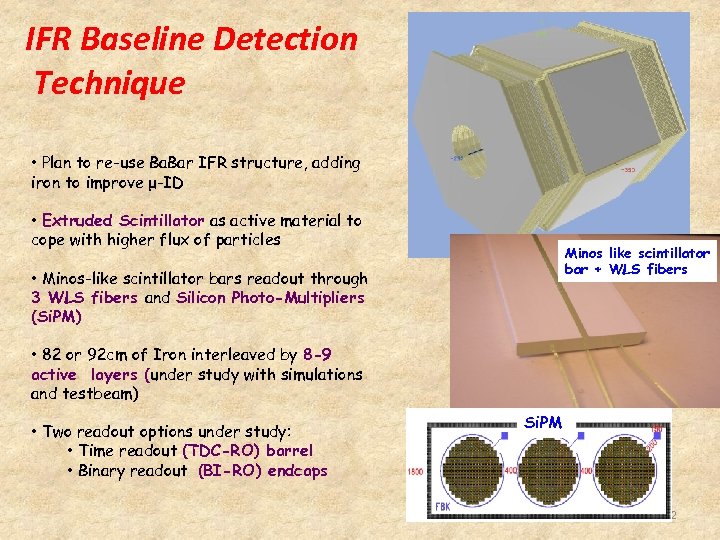

IFR Baseline Detection Technique • Plan to re-use Ba. Bar IFR structure, adding iron to improve μ-ID • Extruded Scintillator as active material to cope with higher flux of particles Minos like scintillator bar + WLS fibers • Minos-like scintillator bars readout through 3 WLS fibers and Silicon Photo-Multipliers (Si. PM) • 82 or 92 cm of Iron interleaved by 8 -9 active layers (under study with simulations and testbeam) • Two readout options under study: • Time readout (TDC-RO) barrel • Binary readout (BI-RO) endcaps Si. PM 2

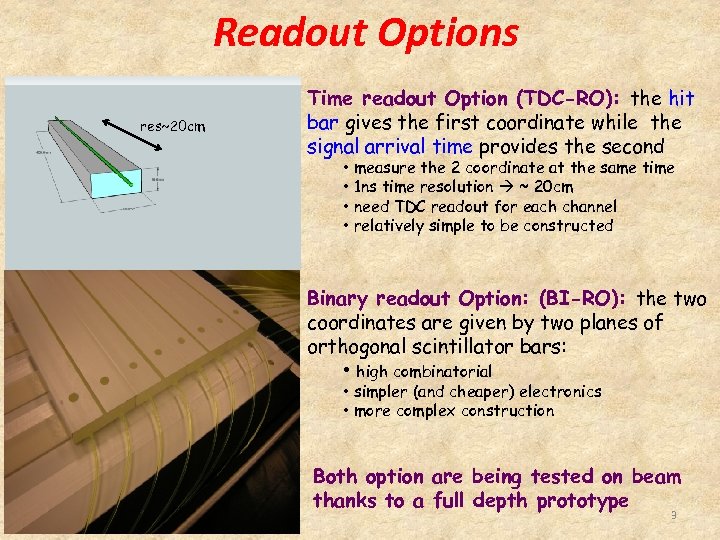

Readout Options res~20 cm Time readout Option (TDC-RO): the hit bar gives the first coordinate while the signal arrival time provides the second • measure the 2 coordinate at the same time • 1 ns time resolution ~ 20 cm • need TDC readout for each channel • relatively simple to be constructed Binary readout Option: (BI-RO): the two coordinates are given by two planes of orthogonal scintillator bars: • high combinatorial • simpler (and cheaper) electronics • more complex construction Both option are being tested on beam thanks to a full depth prototype 3

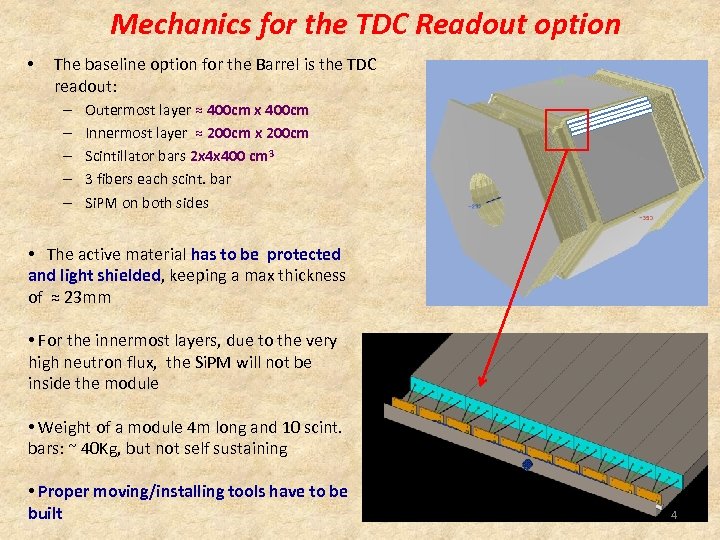

Mechanics for the TDC Readout option • The baseline option for the Barrel is the TDC readout: – – – Outermost layer ≈ 400 cm x 400 cm Innermost layer ≈ 200 cm x 200 cm Scintillator bars 2 x 4 x 400 cm 3 3 fibers each scint. bar Si. PM on both sides • The active material has to be protected and light shielded, keeping a max thickness of ≈ 23 mm • For the innermost layers, due to the very high neutron flux, the Si. PM will not be inside the module • Weight of a module 4 m long and 10 scint. bars: ~ 40 Kg, but not self sustaining • Proper moving/installing tools have to be built 4

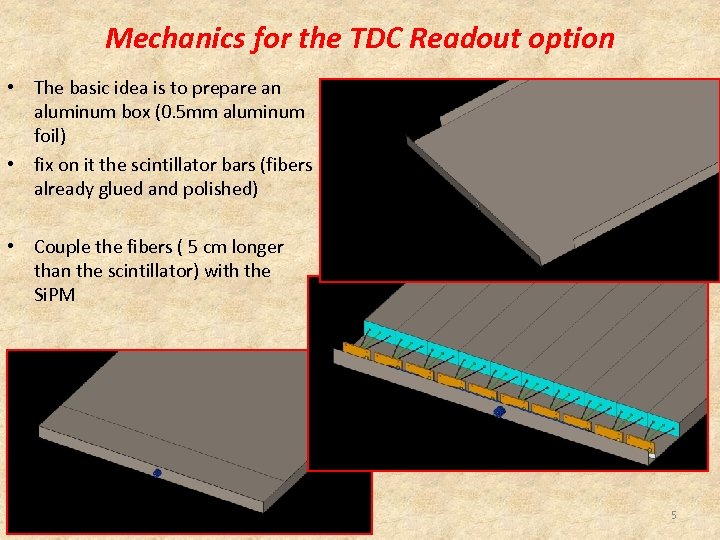

Mechanics for the TDC Readout option • The basic idea is to prepare an aluminum box (0. 5 mm aluminum foil) • fix on it the scintillator bars (fibers already glued and polished) • Couple the fibers ( 5 cm longer than the scintillator) with the Si. PM 5

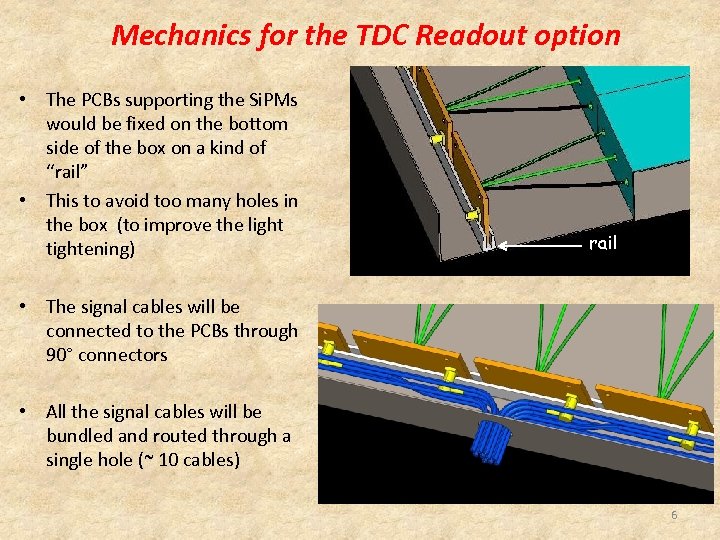

Mechanics for the TDC Readout option • The PCBs supporting the Si. PMs would be fixed on the bottom side of the box on a kind of “rail” • This to avoid too many holes in the box (to improve the light tightening) rail • The signal cables will be connected to the PCBs through 90° connectors • All the signal cables will be bundled and routed through a single hole (~ 10 cables) 6

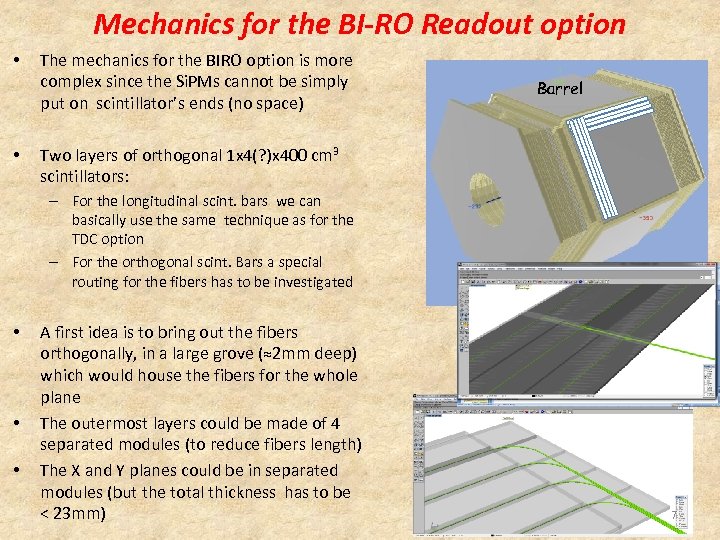

Mechanics for the BI-RO Readout option • • The mechanics for the BIRO option is more complex since the Si. PMs cannot be simply put on scintillator’s ends (no space) Barrel Two layers of orthogonal 1 x 4(? )x 400 cm 3 scintillators: – For the longitudinal scint. bars we can basically use the same technique as for the TDC option – For the orthogonal scint. Bars a special routing for the fibers has to be investigated • • • A first idea is to bring out the fibers orthogonally, in a large grove (≈2 mm deep) which would house the fibers for the whole plane The outermost layers could be made of 4 separated modules (to reduce fibers length) The X and Y planes could be in separated modules (but the total thickness has to be < 23 mm) 7

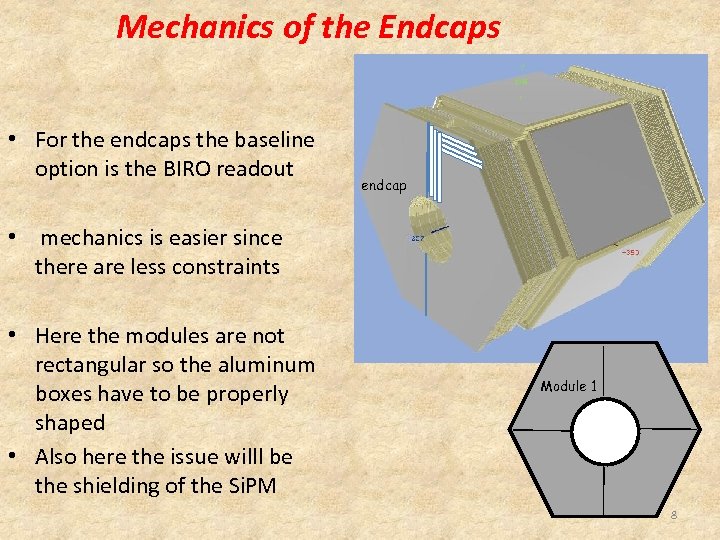

Mechanics of the Endcaps • For the endcaps the baseline option is the BIRO readout endcap • mechanics is easier since there are less constraints • Here the modules are not rectangular so the aluminum boxes have to be properly shaped • Also here the issue willl be the shielding of the Si. PM Module 1 8

Detector related Mechanical Activities • Aside to the active layer mechanics there are many other mechanical activities to be carried out • Tooling for the scintillator-fibers gluing (embedded holes or surface groves) • Given the non self sustaining structure of the active layers (aluminum foils very thin) a set of toolings have to be designed and built: – Supports to move the modules during the assembling and QC – Toolings for the movements and insertion of the modules in the flux return during the installation phase – Other tooling… • QC related toolings 9

Conclusions and next steps • The mechanics of the active layers is under definition • A present these are “conceptual” designs, we are now going through the details toward a “technical” design • Due to the high neutron flux an open issue is where to put the Si. PMs of the innermost layers of the barrel • It would be desirable to put the Si. PMs in accessible points, but this implies to use longer fibers… • We could consider the use of a few meters of clear fibers, in this case a proper coupling has to be done • Aside to the mechanics of the active layers there all the tools for the moving, QC, and installation 10

31770e47bcc8767a1e9e33174ce4add5.ppt