983b9a837d927f8c923e5896c1d335f6.ppt

- Количество слайдов: 26

“ If Logisticians Can Cook” Logistics Assist Visit Concepts Edlouie S. Ortega, MSM, CDFM, CPFM Equipment and Technology Management Medical Equipment and Logistics Solutions Naval Medical Logistics Command

“ If Logisticians Can Cook” Logistics Assist Visit Concepts Edlouie S. Ortega, MSM, CDFM, CPFM Equipment and Technology Management Medical Equipment and Logistics Solutions Naval Medical Logistics Command

How do you measure success? • Do you believe in key performance indicators (KPI)? • How do you know which KPI to track? • Should all KPI measureable?

How do you measure success? • Do you believe in key performance indicators (KPI)? • How do you know which KPI to track? • Should all KPI measureable?

Who do you agree with? “Tell me how you measure me, and I'll tell you how I will behave. ” - Eli Goldratt " Tell me how you’ll measure me, and I’ll tell what damn fool things I’ll do to make the measurement look good. " - Tony Rizzo

Who do you agree with? “Tell me how you measure me, and I'll tell you how I will behave. ” - Eli Goldratt " Tell me how you’ll measure me, and I’ll tell what damn fool things I’ll do to make the measurement look good. " - Tony Rizzo

Restaurant Industry…What we measure • Cash flow. Restaurants are very cash-intensive, forking over money for fresh inventory and tipping out servers and other staff on a daily basis. • Percentage of repeat customers. The National Restaurant Association estimates that three-quarters of most restaurants' sales come from repeat customers. • Staff turnover. On average, management turnover rates run around 20% annually for table-service restaurants, while hourly workers turn over at roughly a 150% clip Forbes. com

Restaurant Industry…What we measure • Cash flow. Restaurants are very cash-intensive, forking over money for fresh inventory and tipping out servers and other staff on a daily basis. • Percentage of repeat customers. The National Restaurant Association estimates that three-quarters of most restaurants' sales come from repeat customers. • Staff turnover. On average, management turnover rates run around 20% annually for table-service restaurants, while hourly workers turn over at roughly a 150% clip Forbes. com

Other KPIs we measure • Table-turn over rate. How many times table is filled with customer. How fast tables empty and fill during a shift. • Order-throughput time. How long before a meal goes out to the customer. Drinks – appetizer – main course – dessert. • Table-turn time. How long did the table remain empty and how long did it stayed filled.

Other KPIs we measure • Table-turn over rate. How many times table is filled with customer. How fast tables empty and fill during a shift. • Order-throughput time. How long before a meal goes out to the customer. Drinks – appetizer – main course – dessert. • Table-turn time. How long did the table remain empty and how long did it stayed filled.

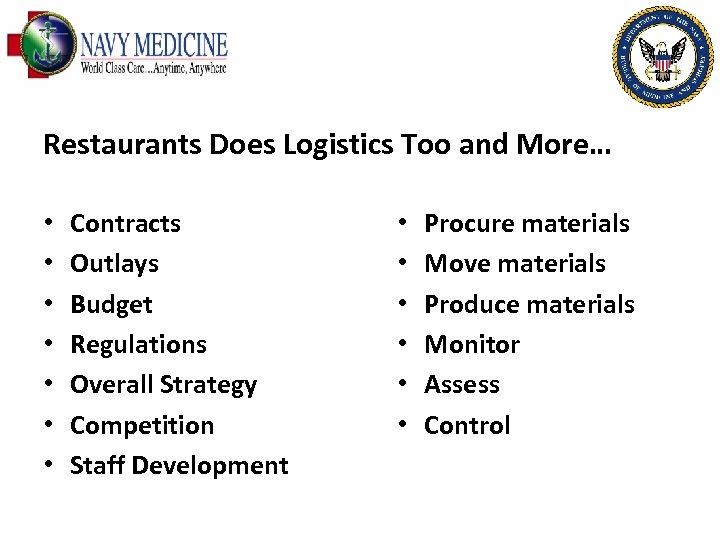

Restaurants Does Logistics Too and More… • • Contracts Outlays Budget Regulations Overall Strategy Competition Staff Development • • • Procure materials Move materials Produce materials Monitor Assess Control

Restaurants Does Logistics Too and More… • • Contracts Outlays Budget Regulations Overall Strategy Competition Staff Development • • • Procure materials Move materials Produce materials Monitor Assess Control

What we can learn from a Cook It’s all about the… o food o presentation o timing o customer service o dish washer o work flow And sometimes it’s not all about measurable KPI…

What we can learn from a Cook It’s all about the… o food o presentation o timing o customer service o dish washer o work flow And sometimes it’s not all about measurable KPI…

What we can learn from a Cook Front of the House – Back of the House - Expedite!!! o Assurance: The act of giving confidence, the state of being certain or the act of making certain. o Control: An evaluation to indicate needed corrective responses; the act of guiding a process in which variability is attributable to a constant system of chance causes.

What we can learn from a Cook Front of the House – Back of the House - Expedite!!! o Assurance: The act of giving confidence, the state of being certain or the act of making certain. o Control: An evaluation to indicate needed corrective responses; the act of guiding a process in which variability is attributable to a constant system of chance causes.

What we can learn from a Cook o Quality Assurance: The planned and systematic activities implemented in a quality system so that quality requirements for a product or service will be fulfilled. o Quality Control: The observation techniques and activities used to fulfill requirements for quality. Standard processes/quality products… not to make measurements look good.

What we can learn from a Cook o Quality Assurance: The planned and systematic activities implemented in a quality system so that quality requirements for a product or service will be fulfilled. o Quality Control: The observation techniques and activities used to fulfill requirements for quality. Standard processes/quality products… not to make measurements look good.

What we can learn from a Cook o Outputs Defined as the goods or services produced (e. g. , patient admissions, bed days, work orders, receipts). o Outcomes Defined as the impacts on indicators arising from the delivery of outputs (e. g. , fill rate, turn-over ratio, SOS Due-in rate, maintenance completions rate, unable to locate). “More focused on Effectiveness than Efficiency”

What we can learn from a Cook o Outputs Defined as the goods or services produced (e. g. , patient admissions, bed days, work orders, receipts). o Outcomes Defined as the impacts on indicators arising from the delivery of outputs (e. g. , fill rate, turn-over ratio, SOS Due-in rate, maintenance completions rate, unable to locate). “More focused on Effectiveness than Efficiency”

Define Logistics o Logistics The planning, implementation, and coordination of the details of a business or other material operations. o Medical Logistics Is the logistic of pharmaceuticals, medical and surgical supplies, medical devices and equipment, and other products needed to support doctors, nurses, and other health and dental care providers. Because its final customers are responsible for the lives and health of their patients, medical logistics is unique in that it seeks to optimize effectiveness rather than efficiency.

Define Logistics o Logistics The planning, implementation, and coordination of the details of a business or other material operations. o Medical Logistics Is the logistic of pharmaceuticals, medical and surgical supplies, medical devices and equipment, and other products needed to support doctors, nurses, and other health and dental care providers. Because its final customers are responsible for the lives and health of their patients, medical logistics is unique in that it seeks to optimize effectiveness rather than efficiency.

Logistics Assist Visit Purpose: q Assist Logisticians to achieve Total Asset Management (TAM) and improve internal management control of accountable equipment. q Evaluate the effectiveness of the Equipment, Technology Material Management (ETM) processes from materiel procurement planning to eventual property disposal q Evaluate the effectiveness of the Purchasing Management, Acquisition Planning and Requirements Development, and Contracting Officer’s Representative (COR) Programs q The Logistics Assist Visit is NOT an inspection, this is strictly an assist visit to help your staff identify strengths and weaknesses and to provide them with the tools that they need to successfully carry out their mission.

Logistics Assist Visit Purpose: q Assist Logisticians to achieve Total Asset Management (TAM) and improve internal management control of accountable equipment. q Evaluate the effectiveness of the Equipment, Technology Material Management (ETM) processes from materiel procurement planning to eventual property disposal q Evaluate the effectiveness of the Purchasing Management, Acquisition Planning and Requirements Development, and Contracting Officer’s Representative (COR) Programs q The Logistics Assist Visit is NOT an inspection, this is strictly an assist visit to help your staff identify strengths and weaknesses and to provide them with the tools that they need to successfully carry out their mission.

Logistics Assist Visit Focus: q Assessment of continued suitability as it applies to aging technology. q Assessment of effective use of the logistics information system as a tool for improving materials management operations. q Collect information to develop technical criteria for use as basis for acquisition actions across BSO-18. q Assessment of accountable equipment records with an acquisition cost of $25, 000 and greater. q Assessment of Material Management q Assessment of Acquisition Management

Logistics Assist Visit Focus: q Assessment of continued suitability as it applies to aging technology. q Assessment of effective use of the logistics information system as a tool for improving materials management operations. q Collect information to develop technical criteria for use as basis for acquisition actions across BSO-18. q Assessment of accountable equipment records with an acquisition cost of $25, 000 and greater. q Assessment of Material Management q Assessment of Acquisition Management

Logistics Assist Visit Assessment Methodology 1. 2. 3. Use of existing data and focus on establishing the baseline between the site and the "Best Practices" in BSO-18 claimancy and in the industry. Incorporate training, database management, material management, technology management and acquisition management site visits. Provide feedback to the site regarding LAV findings and recommendations that will help the site focus on its strengths and immediate improvement.

Logistics Assist Visit Assessment Methodology 1. 2. 3. Use of existing data and focus on establishing the baseline between the site and the "Best Practices" in BSO-18 claimancy and in the industry. Incorporate training, database management, material management, technology management and acquisition management site visits. Provide feedback to the site regarding LAV findings and recommendations that will help the site focus on its strengths and immediate improvement.

Logistics Assist Visit Assessment Elements 1. Evaluate synchronization of the Navy business practices, policies, and logistics and acquisition information systems. 2. Validation Processes (Management Assertion) 3. Evaluate training requirements and provide just-in-time training as needed.

Logistics Assist Visit Assessment Elements 1. Evaluate synchronization of the Navy business practices, policies, and logistics and acquisition information systems. 2. Validation Processes (Management Assertion) 3. Evaluate training requirements and provide just-in-time training as needed.

Logistics Assist Visit Assessment Elements 1. Evaluate synchronization of business practices, policies and systems. n n n n Review current policies. Analyze data; focus on trends. Evaluate site’s business practice. Evaluate site’s appropriate use of business systems. Identify processes requiring BUMED-wide standardization. Identify change requirements to the logistics information systems. Identify change requirements to the policies.

Logistics Assist Visit Assessment Elements 1. Evaluate synchronization of business practices, policies and systems. n n n n Review current policies. Analyze data; focus on trends. Evaluate site’s business practice. Evaluate site’s appropriate use of business systems. Identify processes requiring BUMED-wide standardization. Identify change requirements to the logistics information systems. Identify change requirements to the policies.

Logistics Assist Visit Assessment Elements 2. Validation Process (Management Assertion): § § § Valuation. Test all contributing factors (device code, life expectancy, useful life, acceptance date, acquisition cost, etc). Completeness. Test to ensure that maintenance significant equipment and personal properties are entered in DMLSS. Accountability. Test if the equipment found on site belongs to the entity. Replacement Plan. Test for proper equipment selection and requisition process. Due-in Receipt. Test to ensure that due-in materials are properly receipted and properly recorded.

Logistics Assist Visit Assessment Elements 2. Validation Process (Management Assertion): § § § Valuation. Test all contributing factors (device code, life expectancy, useful life, acceptance date, acquisition cost, etc). Completeness. Test to ensure that maintenance significant equipment and personal properties are entered in DMLSS. Accountability. Test if the equipment found on site belongs to the entity. Replacement Plan. Test for proper equipment selection and requisition process. Due-in Receipt. Test to ensure that due-in materials are properly receipted and properly recorded.

Logistics Assist Visit Assessment Elements 3. Evaluate training requirements and provide just-in-time training as needed. n Identify functionality gaps. n Identify execution gaps. n Identify process gaps. n Identify current workload and productivity. n Identify additional training requirements.

Logistics Assist Visit Assessment Elements 3. Evaluate training requirements and provide just-in-time training as needed. n Identify functionality gaps. n Identify execution gaps. n Identify process gaps. n Identify current workload and productivity. n Identify additional training requirements.

Assessment Candidates Equipment Receipt Inventory Management/UID Five Year Equipment Replacement Plan Device Code Assignment Property/Item Decrease/Loss Document Control Maintenance Plan and Procedures Repair Parts Request and Issue Service Contracts Material Due-ins Emergency Management Plan/CBRNE/IPP COR Appointment, Training and Management ECAT Orders

Assessment Candidates Equipment Receipt Inventory Management/UID Five Year Equipment Replacement Plan Device Code Assignment Property/Item Decrease/Loss Document Control Maintenance Plan and Procedures Repair Parts Request and Issue Service Contracts Material Due-ins Emergency Management Plan/CBRNE/IPP COR Appointment, Training and Management ECAT Orders

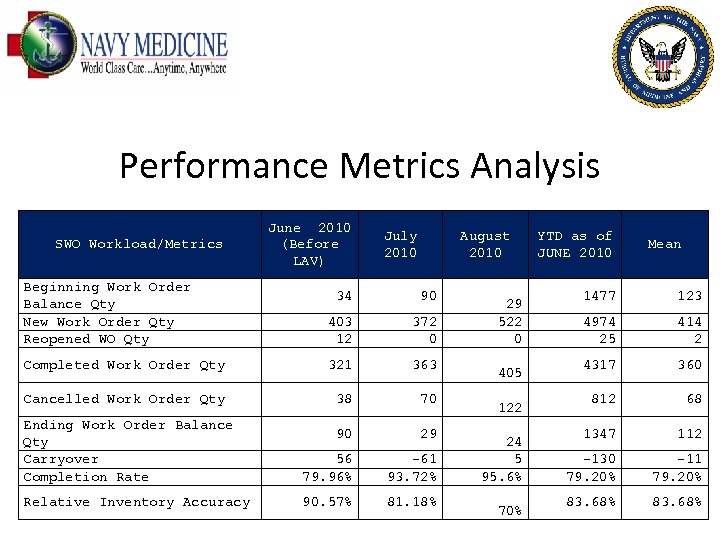

Performance Metrics Analysis SWO Workload/Metrics June 2010 (Before LAV) July 2010 Beginning Work Order Balance Qty New Work Order Qty Reopened WO Qty 34 90 403 12 372 0 Completed Work Order Qty 321 363 Cancelled Work Order Qty 38 70 Ending Work Order Balance Qty Carryover Completion Rate 90 29 56 79. 96% -61 93. 72% Relative Inventory Accuracy 90. 57% 81. 18% August 2010 29 522 0 405 122 24 5 95. 6% 70% YTD as of JUNE 2010 Mean 1477 123 4974 25 414 2 4317 360 812 68 1347 112 -130 79. 20% -11 79. 20% 83. 68%

Performance Metrics Analysis SWO Workload/Metrics June 2010 (Before LAV) July 2010 Beginning Work Order Balance Qty New Work Order Qty Reopened WO Qty 34 90 403 12 372 0 Completed Work Order Qty 321 363 Cancelled Work Order Qty 38 70 Ending Work Order Balance Qty Carryover Completion Rate 90 29 56 79. 96% -61 93. 72% Relative Inventory Accuracy 90. 57% 81. 18% August 2010 29 522 0 405 122 24 5 95. 6% 70% YTD as of JUNE 2010 Mean 1477 123 4974 25 414 2 4317 360 812 68 1347 112 -130 79. 20% -11 79. 20% 83. 68%

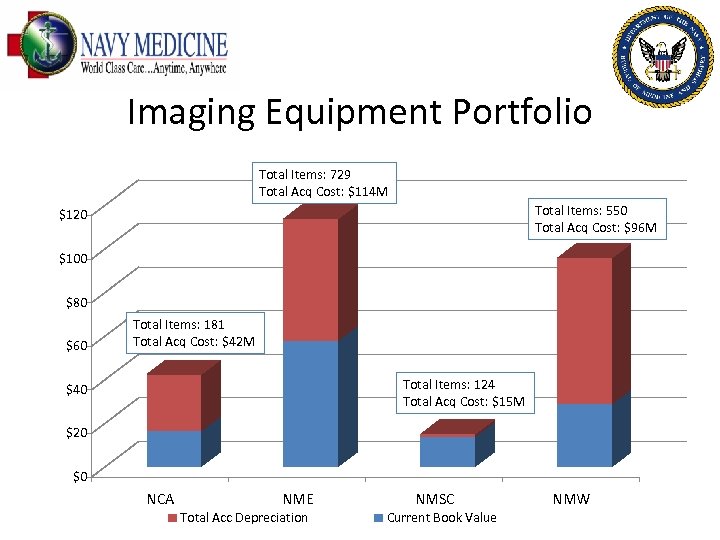

Imaging Equipment Portfolio Total Items: 729 Total Acq Cost: $114 M Total Items: 550 Total Acq Cost: $96 M $120 $100 $80 $60 Total Items: 181 Total Acq Cost: $42 M Total Items: 124 Total Acq Cost: $15 M $40 $20 $0 NCA NME Total Acc Depreciation NMSC Current Book Value NMW

Imaging Equipment Portfolio Total Items: 729 Total Acq Cost: $114 M Total Items: 550 Total Acq Cost: $96 M $120 $100 $80 $60 Total Items: 181 Total Acq Cost: $42 M Total Items: 124 Total Acq Cost: $15 M $40 $20 $0 NCA NME Total Acc Depreciation NMSC Current Book Value NMW

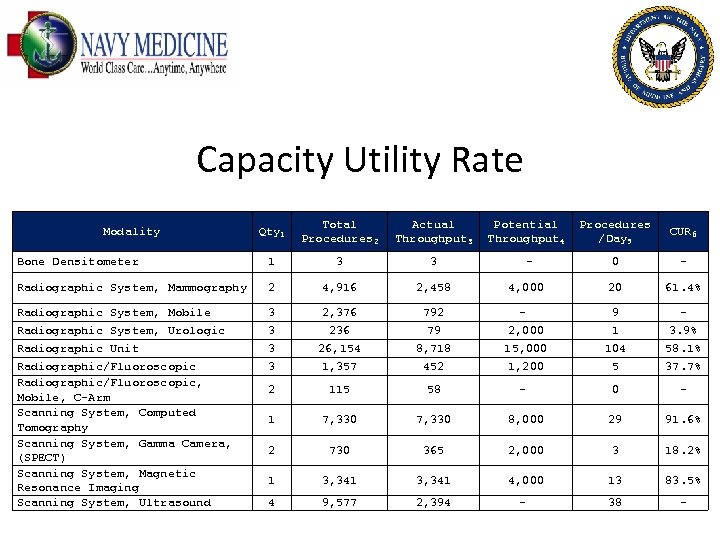

Capacity Utility Rate Qty₁ Total Procedures₂ Actual Throughput₃ Potential Throughput₄ Bone Densitometer 1 3 3 - 0 - Radiographic System, Mammography 2 4, 916 2, 458 4, 000 20 61. 4% Radiographic System, Mobile Radiographic System, Urologic Radiographic Unit Radiographic/Fluoroscopic, Mobile, C-Arm Scanning System, Computed Tomography Scanning System, Gamma Camera, (SPECT) Scanning System, Magnetic Resonance Imaging Scanning System, Ultrasound 3 3 2, 376 236 26, 154 1, 357 792 79 8, 718 452 - 2, 000 15, 000 1, 200 9 1 104 5 3. 9% 58. 1% 37. 7% 2 115 58 - 0 - 1 7, 330 8, 000 29 91. 6% 2 730 365 2, 000 3 18. 2% 1 3, 341 4, 000 13 83. 5% 4 9, 577 2, 394 - 38 - Modality Procedures CUR₆ /Day₅

Capacity Utility Rate Qty₁ Total Procedures₂ Actual Throughput₃ Potential Throughput₄ Bone Densitometer 1 3 3 - 0 - Radiographic System, Mammography 2 4, 916 2, 458 4, 000 20 61. 4% Radiographic System, Mobile Radiographic System, Urologic Radiographic Unit Radiographic/Fluoroscopic, Mobile, C-Arm Scanning System, Computed Tomography Scanning System, Gamma Camera, (SPECT) Scanning System, Magnetic Resonance Imaging Scanning System, Ultrasound 3 3 2, 376 236 26, 154 1, 357 792 79 8, 718 452 - 2, 000 15, 000 1, 200 9 1 104 5 3. 9% 58. 1% 37. 7% 2 115 58 - 0 - 1 7, 330 8, 000 29 91. 6% 2 730 365 2, 000 3 18. 2% 1 3, 341 4, 000 13 83. 5% 4 9, 577 2, 394 - 38 - Modality Procedures CUR₆ /Day₅

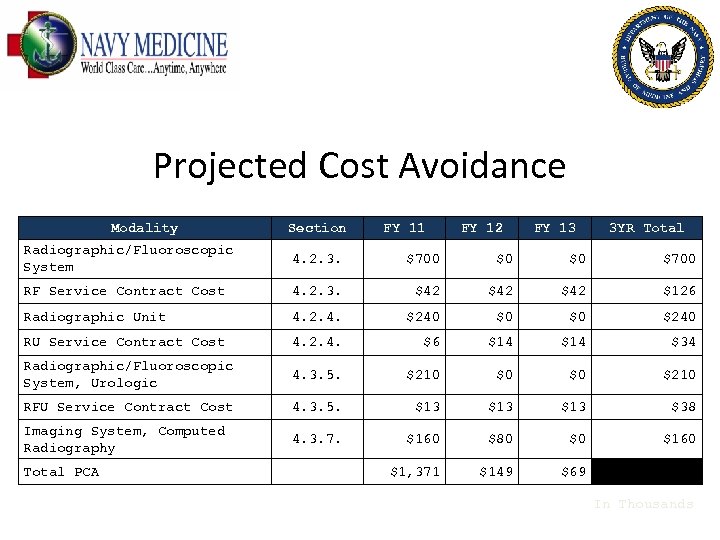

Projected Cost Avoidance Modality Section FY 11 FY 12 FY 13 3 YR Total Radiographic/Fluoroscopic System 4. 2. 3. $700 $0 $0 $700 RF Service Contract Cost 4. 2. 3. $42 $42 $126 Radiographic Unit 4. 2. 4. $240 $0 $0 $240 RU Service Contract Cost 4. 2. 4. $6 $14 $34 Radiographic/Fluoroscopic System, Urologic 4. 3. 5. $210 $0 $0 $210 RFU Service Contract Cost 4. 3. 5. $13 $13 $38 Imaging System, Computed Radiography 4. 3. 7. $160 $80 $0 $160 $1, 371 $149 $69 $1, 508 Total PCA In Thousands

Projected Cost Avoidance Modality Section FY 11 FY 12 FY 13 3 YR Total Radiographic/Fluoroscopic System 4. 2. 3. $700 $0 $0 $700 RF Service Contract Cost 4. 2. 3. $42 $42 $126 Radiographic Unit 4. 2. 4. $240 $0 $0 $240 RU Service Contract Cost 4. 2. 4. $6 $14 $34 Radiographic/Fluoroscopic System, Urologic 4. 3. 5. $210 $0 $0 $210 RFU Service Contract Cost 4. 3. 5. $13 $13 $38 Imaging System, Computed Radiography 4. 3. 7. $160 $80 $0 $160 $1, 371 $149 $69 $1, 508 Total PCA In Thousands

Region UIC Unit Name BWO NWO RWO CWO XWO EWO Risk 1 UTL Risk 2 -4 UTL % PMCR NME N 32185 NHC New England 0 196 0 191 5 0 0 5 2. 55% 100. 00% NME N 39163 USNH Sigonella 1 127 3 127 4 0 0 4 3. 15% 100. 00% NMW N 68095 NH Bremerton 2 240 1 234 9 0 0 9 3. 75% 100. 00% NME N 66094 NHC Cherry Point 0 26 0 20 6 0 0 6 23. 08% 100. 00% NME N 00232 NH Jacksonville 109 731 9 847 1 1 0. 14% 99. 88% NME N 68084 NHC Charleston 35 114 0 143 4 2 0 4 3. 51% 98. 66% NMW N 66097 NH Oak Harbor 1 95 2 88 8 2 0 8 8. 42% 97. 96% NME N 00211 NHC Great Lakes 0 153 3 145 7 4 0 7 4. 58% 97. 44% NMW N 68292 USNH Yokosuka 16 304 4 294 21 9 0 21 6. 91% 97. 22% NMW N 66095 NH Lemoore 1 128 0 114 11 4 0 11 8. 59% 96. 90% NME N 66096 USNH Naples 0 114 0 110 0 4 0 0 0. 00% 96. 49% NME N 00183 NMC Portsmouth 63 1064 2 995 87 47 1 87 8. 27% 95. 84% NME N 68093 NH Camp Lejeune 18 341 1 321 24 15 0 24 7. 04% 95. 83% NCA N 00168 Walter Reed NMMC 188 1542 45 951 685 139 44 685 47. 28% 92. 17% NMW N 68096 USNH Guam 33 152 1 169 1 16 0 1 0. 66% 91. 40% NME N 00285 NHC Corpus Christi 0 21 1 20 0 2 0 0 0. 00% 90. 91% NMW N 00259 NMC San Diego 85 1109 49 1001 103 139 3 103 9. 56% 88. 82% NME N 66101 USNH Rota 22 55 0 62 6 9 0 6 10. 91% 88. 31% NMW N 68470 USNH Okinawa 65 355 1 315 44 62 3 44 13. 24% 85. 27% NME N 00203 NH Pensacola 48 300 2 245 50 55 0 50 16. 67% 84. 29% NME N 61337 NH Beaufort 3 317 2 257 14 51 0 14 4. 42% 84. 16% NMW N 68098 NHC Hawaii 70 100 39 31 0 39 39. 00% 81. 76% NMW N 68094 NH Camp Pendleton 278 362 1 504 14 123 12 14 7. 18% 80. 81% NMW N 35949 NH Twentynine Palms 1 172 0 95 27 51 0 27 15. 70% 70. 52% NCA N 00162 NHC Annapolis 198 0 0 0 198 100. 00% VALIDATE NCA N 00231 NHC Quantico 39 0 0 1 38 0 0 38 97. 44% VALIDATE NCA N 66098 NHC PAX River 2 0 0 0 2 100. 00% VALIDATE TOTAL BUMED-WIDE 1278 8118 127 7349 1408 766 63 1408 18. 12% 91. 96%

Region UIC Unit Name BWO NWO RWO CWO XWO EWO Risk 1 UTL Risk 2 -4 UTL % PMCR NME N 32185 NHC New England 0 196 0 191 5 0 0 5 2. 55% 100. 00% NME N 39163 USNH Sigonella 1 127 3 127 4 0 0 4 3. 15% 100. 00% NMW N 68095 NH Bremerton 2 240 1 234 9 0 0 9 3. 75% 100. 00% NME N 66094 NHC Cherry Point 0 26 0 20 6 0 0 6 23. 08% 100. 00% NME N 00232 NH Jacksonville 109 731 9 847 1 1 0. 14% 99. 88% NME N 68084 NHC Charleston 35 114 0 143 4 2 0 4 3. 51% 98. 66% NMW N 66097 NH Oak Harbor 1 95 2 88 8 2 0 8 8. 42% 97. 96% NME N 00211 NHC Great Lakes 0 153 3 145 7 4 0 7 4. 58% 97. 44% NMW N 68292 USNH Yokosuka 16 304 4 294 21 9 0 21 6. 91% 97. 22% NMW N 66095 NH Lemoore 1 128 0 114 11 4 0 11 8. 59% 96. 90% NME N 66096 USNH Naples 0 114 0 110 0 4 0 0 0. 00% 96. 49% NME N 00183 NMC Portsmouth 63 1064 2 995 87 47 1 87 8. 27% 95. 84% NME N 68093 NH Camp Lejeune 18 341 1 321 24 15 0 24 7. 04% 95. 83% NCA N 00168 Walter Reed NMMC 188 1542 45 951 685 139 44 685 47. 28% 92. 17% NMW N 68096 USNH Guam 33 152 1 169 1 16 0 1 0. 66% 91. 40% NME N 00285 NHC Corpus Christi 0 21 1 20 0 2 0 0 0. 00% 90. 91% NMW N 00259 NMC San Diego 85 1109 49 1001 103 139 3 103 9. 56% 88. 82% NME N 66101 USNH Rota 22 55 0 62 6 9 0 6 10. 91% 88. 31% NMW N 68470 USNH Okinawa 65 355 1 315 44 62 3 44 13. 24% 85. 27% NME N 00203 NH Pensacola 48 300 2 245 50 55 0 50 16. 67% 84. 29% NME N 61337 NH Beaufort 3 317 2 257 14 51 0 14 4. 42% 84. 16% NMW N 68098 NHC Hawaii 70 100 39 31 0 39 39. 00% 81. 76% NMW N 68094 NH Camp Pendleton 278 362 1 504 14 123 12 14 7. 18% 80. 81% NMW N 35949 NH Twentynine Palms 1 172 0 95 27 51 0 27 15. 70% 70. 52% NCA N 00162 NHC Annapolis 198 0 0 0 198 100. 00% VALIDATE NCA N 00231 NHC Quantico 39 0 0 1 38 0 0 38 97. 44% VALIDATE NCA N 66098 NHC PAX River 2 0 0 0 2 100. 00% VALIDATE TOTAL BUMED-WIDE 1278 8118 127 7349 1408 766 63 1408 18. 12% 91. 96%

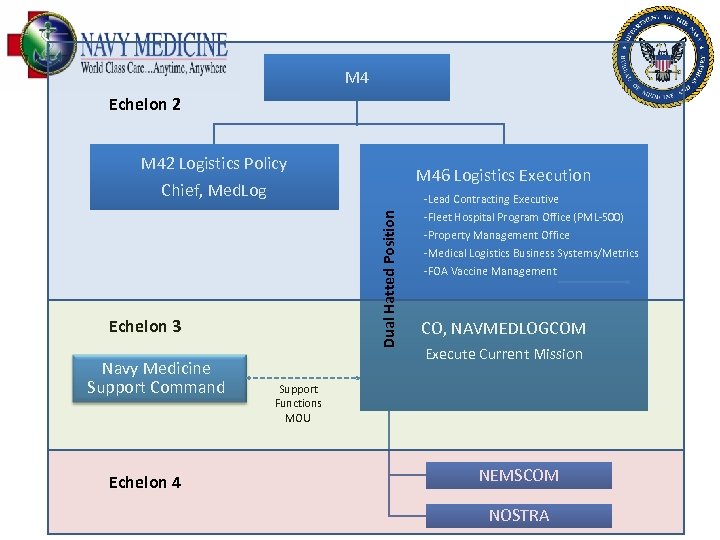

M 4 Echelon 2 M 42 Logistics Policy M 46 Logistics Execution Chief, Med. Log Dual Hatted Position -Lead Contracting Executive Echelon 3 Navy Medicine Support Command Echelon 4 -Fleet Hospital Program Office (PML-500) -Property Management Office -Medical Logistics Business Systems/Metrics -FOA Vaccine Management CO, NAVMEDLOGCOM Execute Current Mission Support Functions MOU NEMSCOM NOSTRA

M 4 Echelon 2 M 42 Logistics Policy M 46 Logistics Execution Chief, Med. Log Dual Hatted Position -Lead Contracting Executive Echelon 3 Navy Medicine Support Command Echelon 4 -Fleet Hospital Program Office (PML-500) -Property Management Office -Medical Logistics Business Systems/Metrics -FOA Vaccine Management CO, NAVMEDLOGCOM Execute Current Mission Support Functions MOU NEMSCOM NOSTRA

Related Sessions • LO-T-3 -B • LO-T-3 -C • LO-T-3 -D • LO-W-3 -C • LO-W-3 -D • LO-W-3 -E Equipment Management Self Assessment Conduct Your Own LAV Material Management Self Assessment Conduct Your Own LAV Maintenance Management Self Assessment Conduct Your Own LAV Automatic Identification Technologies (AIT) /IUID and RTLS Equipment Management Process Annual Inventory Process and Requirements 26

Related Sessions • LO-T-3 -B • LO-T-3 -C • LO-T-3 -D • LO-W-3 -C • LO-W-3 -D • LO-W-3 -E Equipment Management Self Assessment Conduct Your Own LAV Material Management Self Assessment Conduct Your Own LAV Maintenance Management Self Assessment Conduct Your Own LAV Automatic Identification Technologies (AIT) /IUID and RTLS Equipment Management Process Annual Inventory Process and Requirements 26