e04fb165399c311730991ea4efee2a39.ppt

- Количество слайдов: 15

IAQG STANDARDS IMPLEMENTATION AT ROCKWELL COLLINS GOALS, BENEFITS AND LESSONS LEARNED Primus Ridgeway, Jr. Vice-President, Enterprise Product Assurance Rockwell - Collins Inc. I

n Rockwell Collins (NYSE: COL) - A Leader In Aviation/Aerospace Advanced Communication, Navigation And Surveillance Electronics For Government And Commercial Applications. We Provide Product To The World's Aircraft Manufacturers And More Than 400 Airline Customers, As Well As The World's Military Forces. We Have Manufacturing Operations In The United States, Europe, Australia And Mexico, And >60 Service Centers And Service Bases Worldwide. — 2004 - $3. 1 Billion in Sales — ~ 15, 000 Employees — AS 9100, ISO 9001, ISO 14000, FAA Certified — Headquarters: Cedar Rapids, Iowa

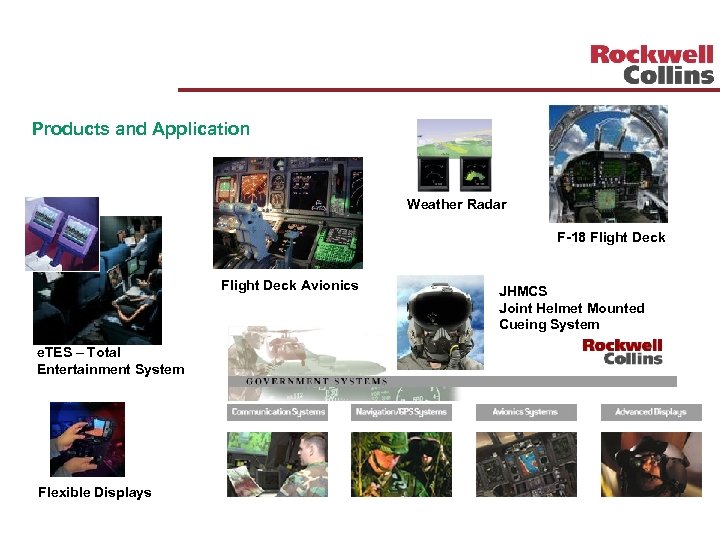

Products and Application Weather Radar F-18 Flight Deck Avionics e. TES – Total Entertainment System Flexible Displays JHMCS Joint Helmet Mounted Cueing System

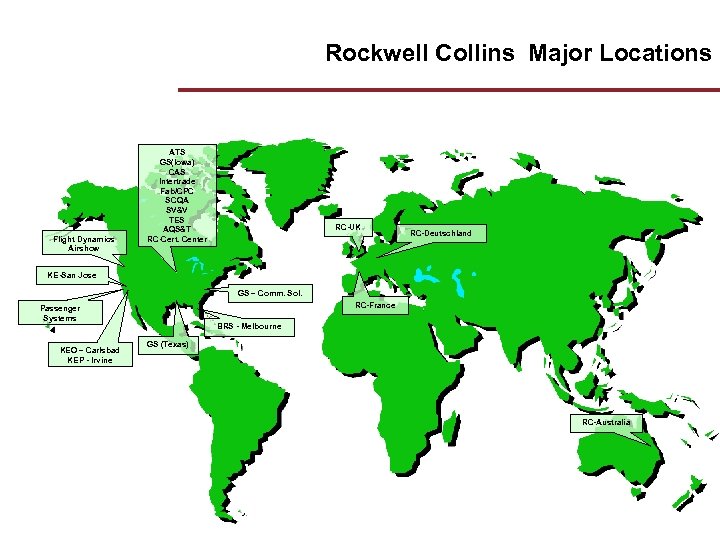

Rockwell Collins Major Locations Flight Dynamics Airshow ATS GS(Iowa) CAS Intertrade Fab/CPC SCQA SV&V TES AQS&T RC-Cert. Center RC-UK RC-Deutschland KE-San Jose GS – Comm. Sol. RC-France Passenger Systems KEO – Carlsbad KEP - Irvine BRS - Melbourne GS (Texas) RC-Australia

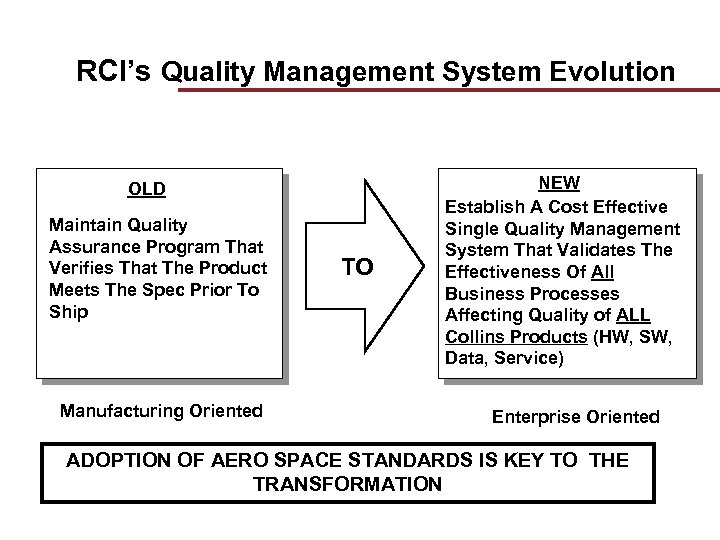

RCI’s Quality Management System Evolution OLD Maintain Quality Assurance Program That Verifies That The Product Meets The Spec Prior To Ship Manufacturing Oriented TO NEW Establish A Cost Effective Single Quality Management System That Validates The Effectiveness Of All Business Processes Affecting Quality of ALL Collins Products (HW, SW, Data, Service) Enterprise Oriented ADOPTION OF AERO SPACE STANDARDS IS KEY TO THE TRANSFORMATION

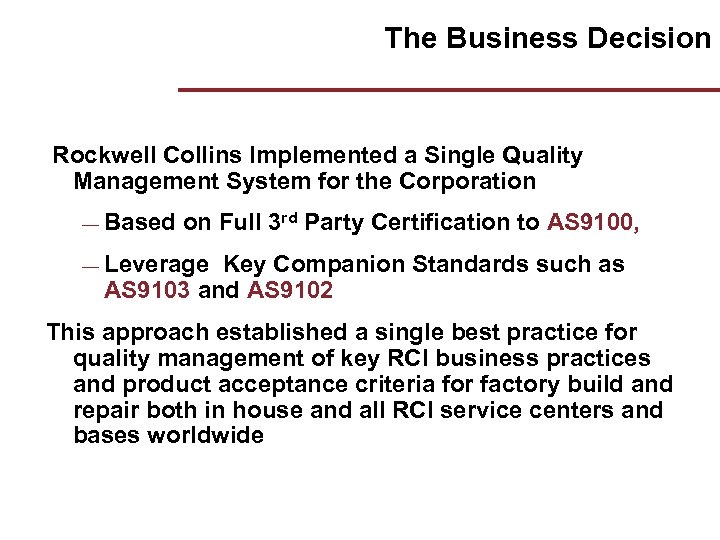

The Business Decision Rockwell Collins Implemented a Single Quality Management System for the Corporation — Based on Full 3 rd Party Certification to AS 9100, — Leverage Key Companion Standards such as AS 9103 and AS 9102 This approach established a single best practice for quality management of key RCI business practices and product acceptance criteria for factory build and repair both in house and all RCI service centers and bases worldwide

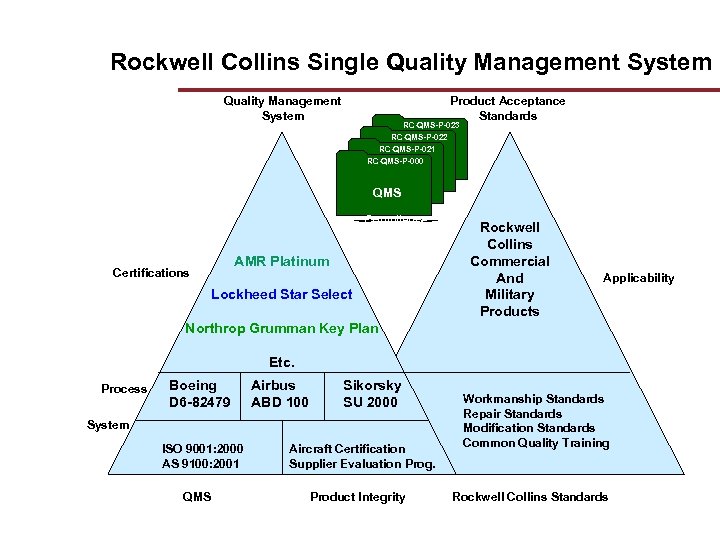

Rockwell Collins Single Quality Management System Product Acceptance Standards RC-QMS-P-023 RC-QMS-P-022 RC-QMS-P-021 RC-QMS-P-000 QMS Compliance AMR Platinum Certifications Lockheed Star Select Rockwell Collins Commercial And Military Products Applicability Northrop Grumman Key Plan Etc. Process Boeing D 6 -82479 Airbus ABD 100 Sikorsky SU 2000 System ISO 9001: 2000 AS 9100: 2001 QMS Aircraft Certification Supplier Evaluation Prog. Product Integrity Workmanship Standards Repair Standards Modification Standards Common Quality Training Rockwell Collins Standards

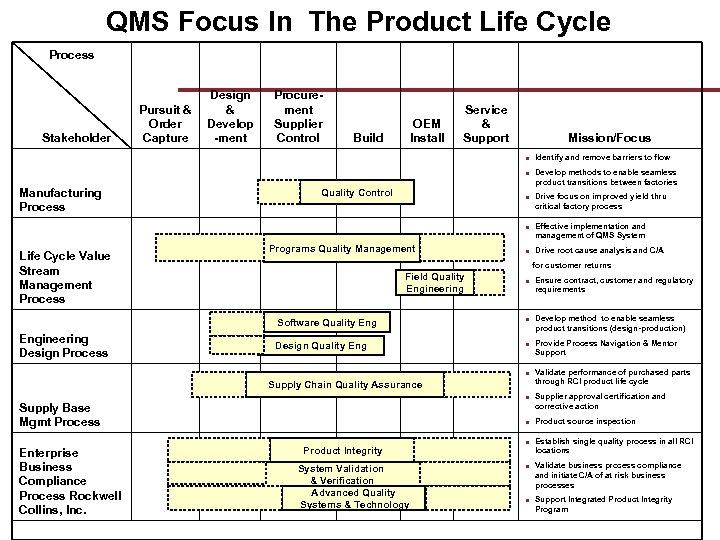

QMS Focus In The Product Life Cycle Process Stakeholder Design Pursuit & & Order Develop Capture -ment Procurement Supplier Control Build OEM Install Service & Support Mission/Focus n n Quality Control Programs Quality Management Life Cycle Value Stream Management Process Develop methods to enable seamless product transitions between factories Drive focus on improved yield thru critical factory process n Manufacturing Process Identify and remove barriers to flow n Effective implementation and management of QMS System n Drive root cause analysis and C/A for customer returns Field Quality Engineering Ensure contract, customer and regulatory requirements Software Quality Eng n Develop method to enable seamless product transitions (design-production) Design Quality Eng n Provide Process Navigation & Mentor Support n Validate performance of purchased parts through RCI product life cycle n Supplier approval certification and corrective action n Engineering Design Process n Product source inspection n Establish single quality process in all RCI locations n Validate business process compliance and initiate C/A of at risk business processes n Support Integrated Product Integrity Program Supply Chain Quality Assurance Supply Base Mgmt Process Enterprise Business Compliance Process Rockwell Collins, Inc. Product Integrity System Validation & Verification Advanced Quality Systems & Technology

Continuous Improvement Focus in Design n The Continuous Improvement Focus Of RCI Single QMS Is Identification And Reduction of Process Variability In The Life Cycle Value Stream Of Our Products. In The Design Phase This Means Identification And Management Of Key Process Characteristics AS 9103 Provides An Effective Guide For Application Of Industry Best Practices For RCI AS 9103 provided an effective baseline to attack Co. NC in the design Process

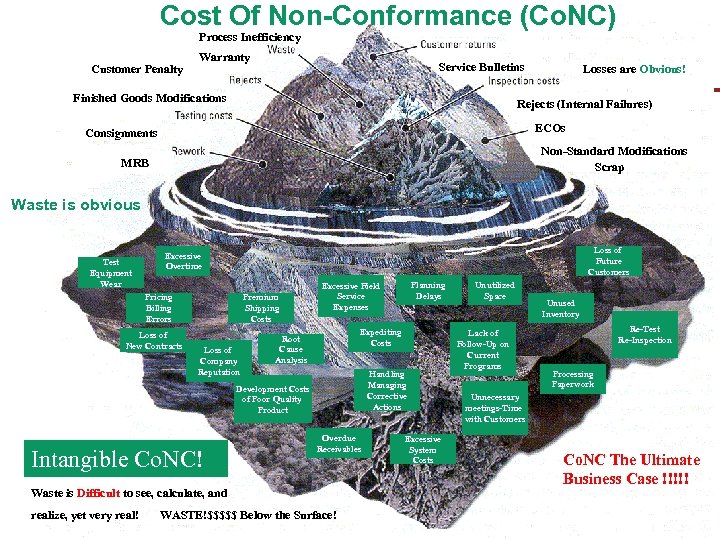

Cost Of Non-Conformance (Co. NC) Process Inefficiency Customer Penalty Warranty Service Bulletins Finished Goods Modifications Losses are Obvious! Rejects (Internal Failures) ECOs Consignments Non-Standard Modifications Scrap MRB Waste is obvious Test Equipment Wear Loss of Future Customers Excessive Overtime Pricing Billing Errors Loss of New Contracts Premium Shipping Costs Loss of Company Reputation Expediting Costs Root Cause Analysis Handling Managing Corrective Actions Development Costs of Poor Quality Product Intangible Co. NC! Overdue Receivables Waste is Difficult to see, calculate, and realize, yet very real! Planning Delays Excessive Field Service Expenses WASTE!$$$$$ Below the Surface! Excessive System Costs Unutilized Space Lack of Follow-Up on Current Programs Unused Inventory Re-Test Re-Inspection Processing Paperwork Unnecessary meetings-Time with Customers Co. NC The Ultimate Business Case !!!!!

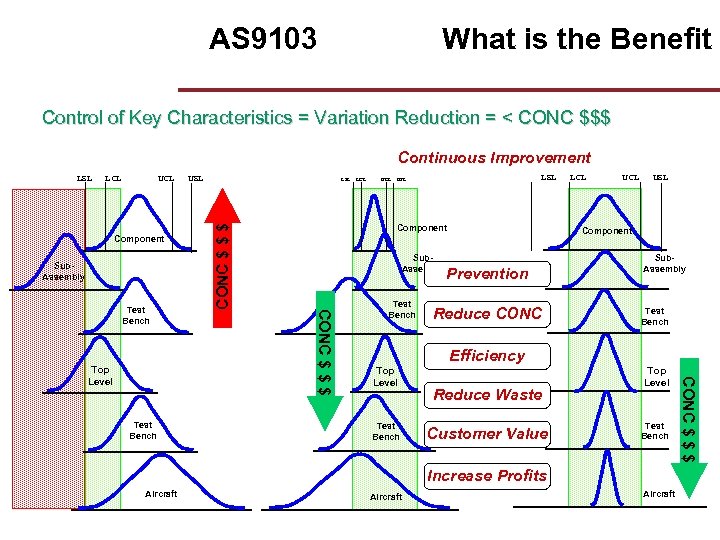

AS 9103 What is the Benefit Control of Key Characteristics = Variation Reduction = < CONC $$$ Continuous Improvement LCL UCL Component Sub. Assembly Test Bench UCL LSL USL Component Sub. Assembly Test Bench LCL USL Component Prevention Reduce CONC Sub. Assembly Test Bench Efficiency Top Level Test Bench Reduce Waste Customer Value Top Level Test Bench Increase Profits Aircraft CONC $ $ $ Top Level LSL LCL CONC $ $ $ Test Bench USL CONC $ $ $ LSL

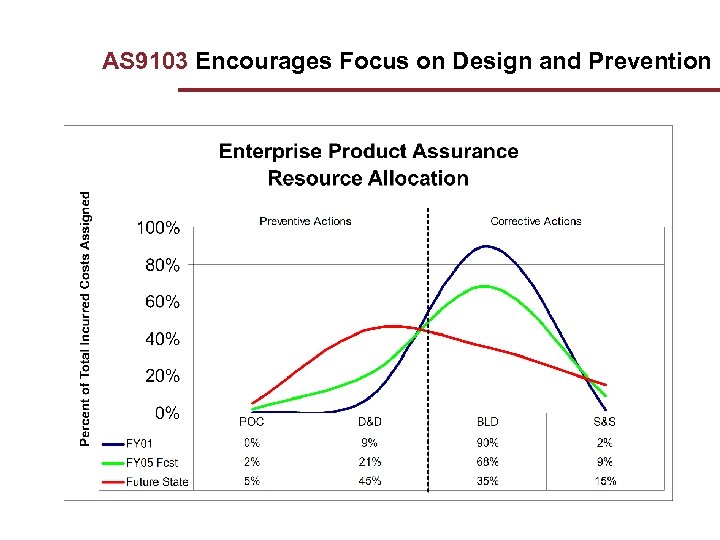

AS 9103 Encourages Focus on Design and Prevention

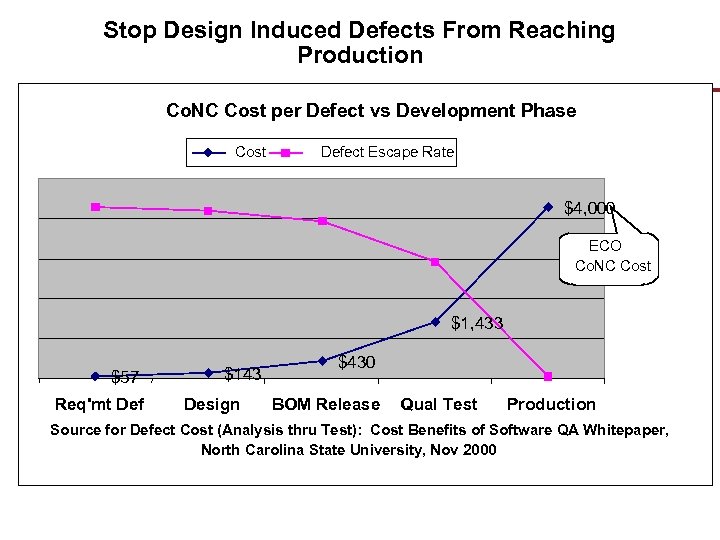

Stop Design Induced Defects From Reaching Production Co. NC Cost per Defect vs Development Phase Cost Defect Escape Rate $4, 000 ECO Co. NC Cost $1, 433 $57 Req'mt Def $143 Design $430 BOM Release Qual Test Production Source for Defect Cost (Analysis thru Test): Cost Benefits of Software QA Whitepaper, North Carolina State University, Nov 2000

Lessons Learned n n IAQG Standards Are A Key Component To An Overall Continuous Improvement Plan Get Management Support – Define The Business Case — Reducing Cost of Non-Conformance is a good one! n n n Keep It Simple – Use An Understandable Continuous Improvement Model Show Return-On-Investment. Get Finance Dept To Validate The Savings Report Results: Improved Quality, Reduced Costs, Improved Delivery, etc. Advertise Successes!

Other Important Points For Successful Implementation n Remember To Address “Social” Issues Of Any Standards Implementation — — n Is The Business “Focused” On Developing a Best Practice Are There Unresolved Business Cultural Differences? (Mergers) Ensure The Foundations Are In Place — Right People, Willingness-To-Change, Commitment, Goals — Strong Communication and Training Plan

e04fb165399c311730991ea4efee2a39.ppt