afa394a2f2d427416602df69f99bcc89.ppt

- Количество слайдов: 30

IAPG Natural Gas Congress Molecular Sieves: is your regeneration procedure optimized? CECA – VETEK Author Peter Meyer Presenter Bob Davenport

IAPG Natural Gas Congress Molecular Sieves: is your regeneration procedure optimized? CECA – VETEK Author Peter Meyer Presenter Bob Davenport

Why optimize the regeneration procedure? Ø A non optimized regeneration procedure can harm the molecular sieves and reduce significantly their life time Ø New unit: if the regeneration gas is recycled the recycled water content has to be taken in account, if the regeneration gas flow rate is too short the unit will not work Ø Knowing how to optimize the procedure can help debottlenecking a unit IAPG 2008

Why optimize the regeneration procedure? Ø A non optimized regeneration procedure can harm the molecular sieves and reduce significantly their life time Ø New unit: if the regeneration gas is recycled the recycled water content has to be taken in account, if the regeneration gas flow rate is too short the unit will not work Ø Knowing how to optimize the procedure can help debottlenecking a unit IAPG 2008

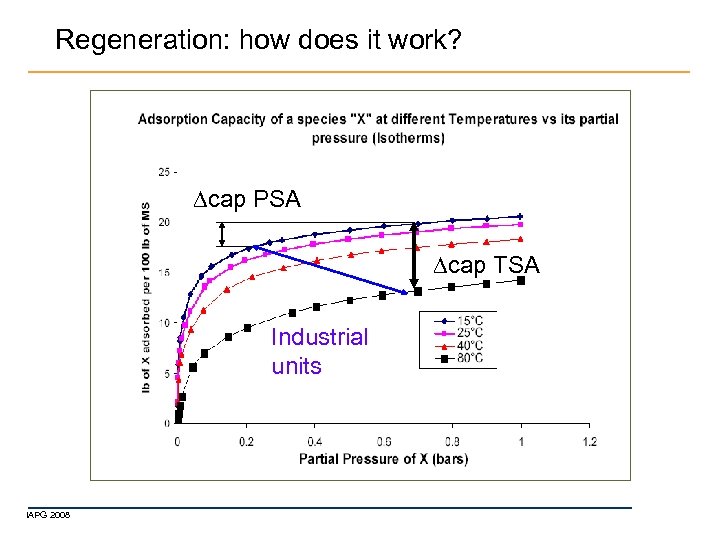

Regeneration: how does it work? cap PSA cap TSA Industrial units IAPG 2008

Regeneration: how does it work? cap PSA cap TSA Industrial units IAPG 2008

TSA Regeneration: how does it work? This presentation will focus on Natural Gas Drying regenerated by Thermal Swing Adsorption (TSA). Regeneration procedure: 1) Switch including possibly pressure change (depress. ) 2) Heating (Purge? Two step heating? Heating ramp? ) 3) Cooling (dry/wet gas? ) 4) Switch including possibly pressure change (repress. ) IAPG 2008

TSA Regeneration: how does it work? This presentation will focus on Natural Gas Drying regenerated by Thermal Swing Adsorption (TSA). Regeneration procedure: 1) Switch including possibly pressure change (depress. ) 2) Heating (Purge? Two step heating? Heating ramp? ) 3) Cooling (dry/wet gas? ) 4) Switch including possibly pressure change (repress. ) IAPG 2008

Regeneration: parameters Heating step: how much heat? - Heat up the molecular sieves - Heat up the vessel (internal/external insulation) - Remove water - Push out desorbed water IAPG 2008

Regeneration: parameters Heating step: how much heat? - Heat up the molecular sieves - Heat up the vessel (internal/external insulation) - Remove water - Push out desorbed water IAPG 2008

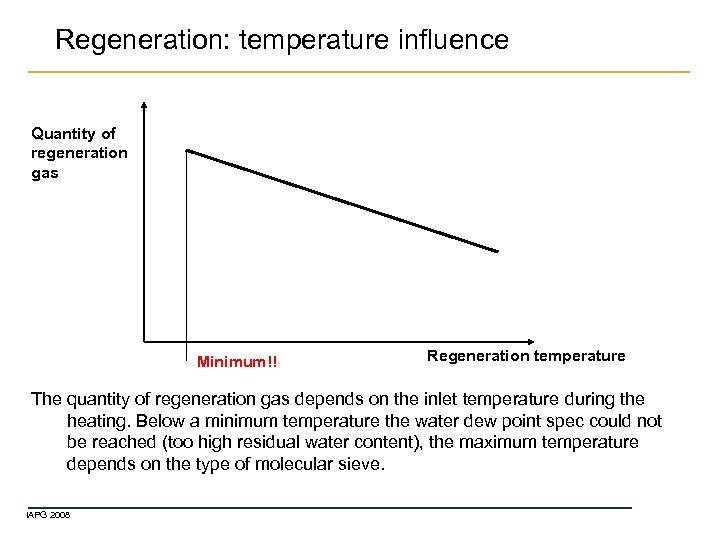

Regeneration: temperature influence Quantity of regeneration gas Minimum!! Regeneration temperature The quantity of regeneration gas depends on the inlet temperature during the heating. Below a minimum temperature the water dew point spec could not be reached (too high residual water content), the maximum temperature depends on the type of molecular sieve. IAPG 2008

Regeneration: temperature influence Quantity of regeneration gas Minimum!! Regeneration temperature The quantity of regeneration gas depends on the inlet temperature during the heating. Below a minimum temperature the water dew point spec could not be reached (too high residual water content), the maximum temperature depends on the type of molecular sieve. IAPG 2008

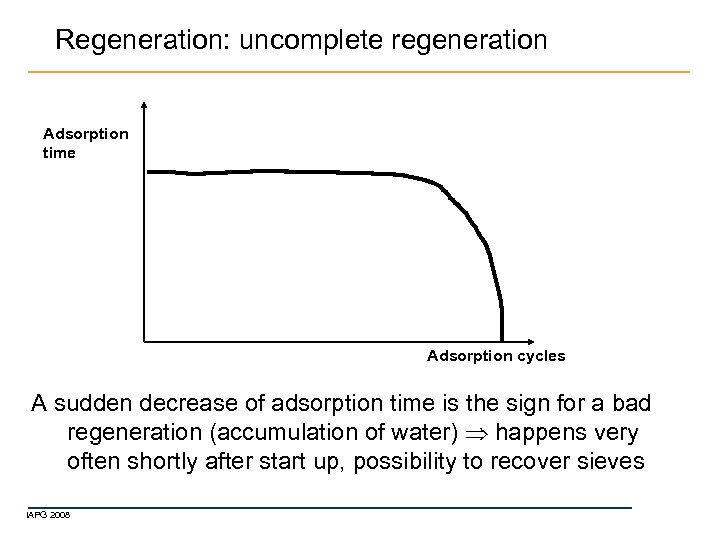

Regeneration: uncomplete regeneration Adsorption time Adsorption cycles A sudden decrease of adsorption time is the sign for a bad regeneration (accumulation of water) happens very often shortly after start up, possibility to recover sieves IAPG 2008

Regeneration: uncomplete regeneration Adsorption time Adsorption cycles A sudden decrease of adsorption time is the sign for a bad regeneration (accumulation of water) happens very often shortly after start up, possibility to recover sieves IAPG 2008

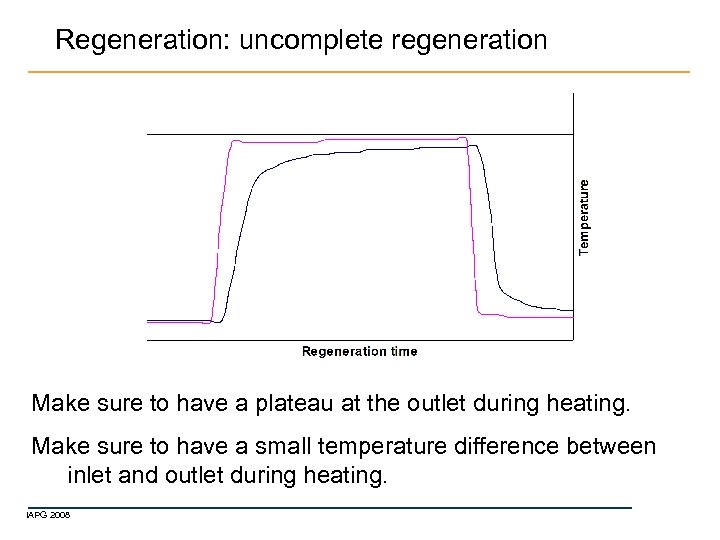

Regeneration: uncomplete regeneration Make sure to have a plateau at the outlet during heating. Make sure to have a small temperature difference between inlet and outlet during heating. IAPG 2008

Regeneration: uncomplete regeneration Make sure to have a plateau at the outlet during heating. Make sure to have a small temperature difference between inlet and outlet during heating. IAPG 2008

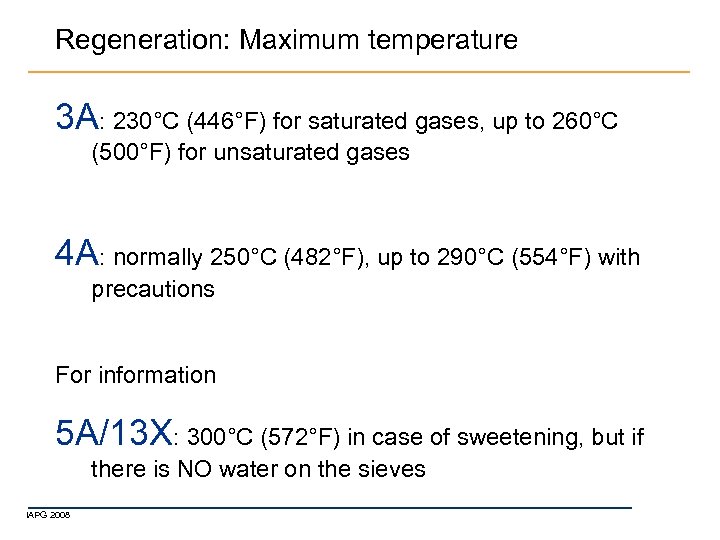

Regeneration: Maximum temperature 3 A: 230°C (446°F) for saturated gases, up to 260°C (500°F) for unsaturated gases 4 A: normally 250°C (482°F), up to 290°C (554°F) with precautions For information 5 A/13 X: 300°C (572°F) in case of sweetening, but if there is NO water on the sieves IAPG 2008

Regeneration: Maximum temperature 3 A: 230°C (446°F) for saturated gases, up to 260°C (500°F) for unsaturated gases 4 A: normally 250°C (482°F), up to 290°C (554°F) with precautions For information 5 A/13 X: 300°C (572°F) in case of sweetening, but if there is NO water on the sieves IAPG 2008

Regeneration: pressure influence More regeneration gas (quantity) is needed if the regeneration pressure is at a high pressure. Two cases for pressure range: Low pressure – heating limited The regeneration gas has to bring in the energy for heating and desorption (regeneration temperature above boiling temperature of water at regeneration pressure) High pressure – stripping limited The regeneration gas has additionally to strip off (push out) the desorbed water. The limit between both is around 30 -35 bars. Example: a regeneration at 60 bar (870 psia) may require perhaps 25% more regeneration gas quantity. IAPG 2008

Regeneration: pressure influence More regeneration gas (quantity) is needed if the regeneration pressure is at a high pressure. Two cases for pressure range: Low pressure – heating limited The regeneration gas has to bring in the energy for heating and desorption (regeneration temperature above boiling temperature of water at regeneration pressure) High pressure – stripping limited The regeneration gas has additionally to strip off (push out) the desorbed water. The limit between both is around 30 -35 bars. Example: a regeneration at 60 bar (870 psia) may require perhaps 25% more regeneration gas quantity. IAPG 2008

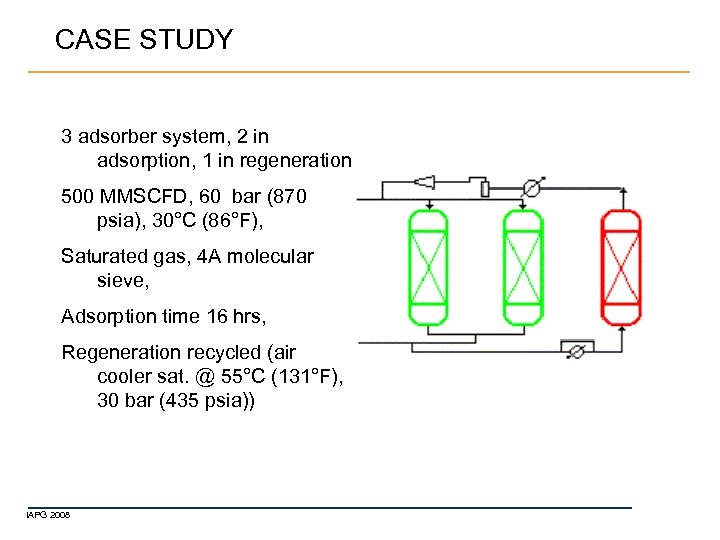

CASE STUDY 3 adsorber system, 2 in adsorption, 1 in regeneration 500 MMSCFD, 60 bar (870 psia), 30°C (86°F), Saturated gas, 4 A molecular sieve, Adsorption time 16 hrs, Regeneration recycled (air cooler sat. @ 55°C (131°F), 30 bar (435 psia)) IAPG 2008

CASE STUDY 3 adsorber system, 2 in adsorption, 1 in regeneration 500 MMSCFD, 60 bar (870 psia), 30°C (86°F), Saturated gas, 4 A molecular sieve, Adsorption time 16 hrs, Regeneration recycled (air cooler sat. @ 55°C (131°F), 30 bar (435 psia)) IAPG 2008

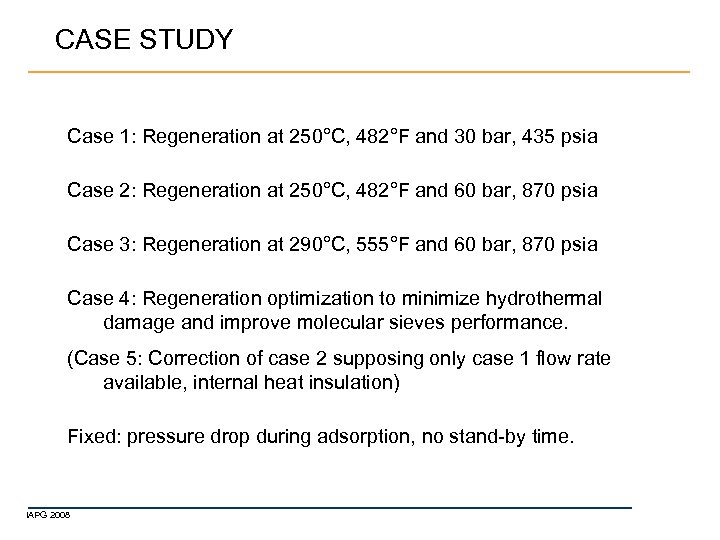

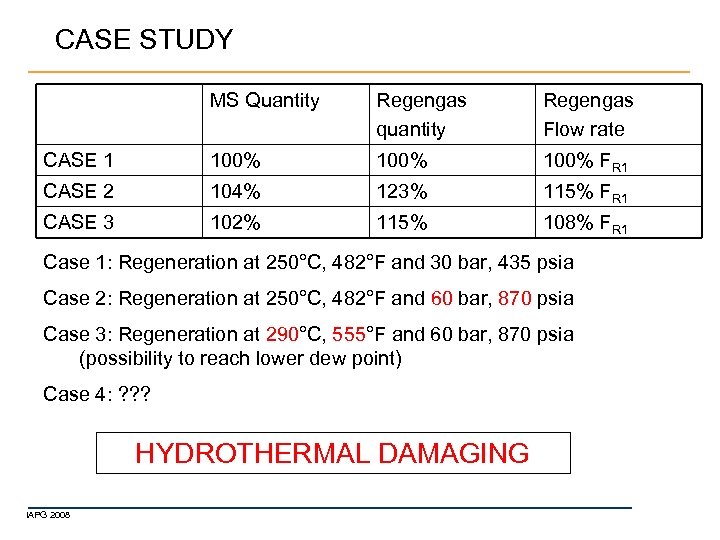

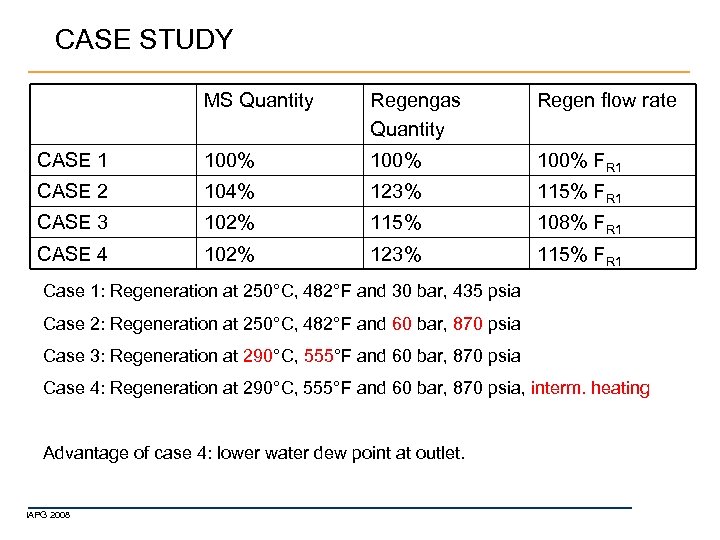

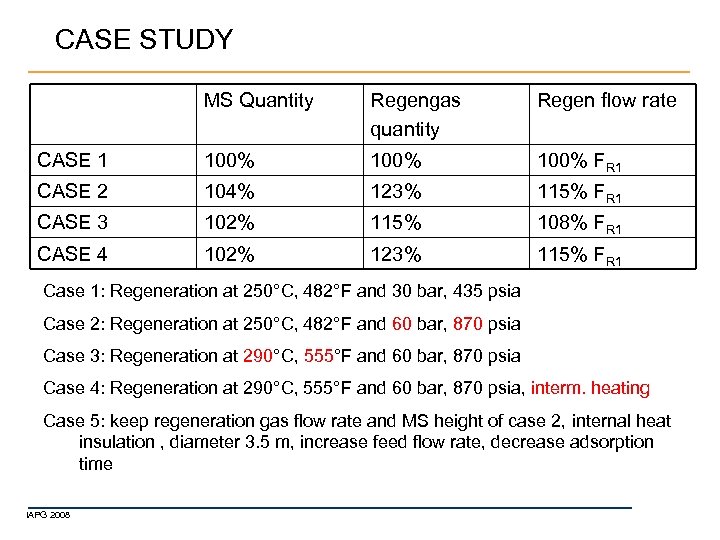

CASE STUDY Case 1: Regeneration at 250°C, 482°F and 30 bar, 435 psia Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Case 3: Regeneration at 290°C, 555°F and 60 bar, 870 psia Case 4: Regeneration optimization to minimize hydrothermal damage and improve molecular sieves performance. (Case 5: Correction of case 2 supposing only case 1 flow rate available, internal heat insulation) Fixed: pressure drop during adsorption, no stand-by time. IAPG 2008

CASE STUDY Case 1: Regeneration at 250°C, 482°F and 30 bar, 435 psia Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Case 3: Regeneration at 290°C, 555°F and 60 bar, 870 psia Case 4: Regeneration optimization to minimize hydrothermal damage and improve molecular sieves performance. (Case 5: Correction of case 2 supposing only case 1 flow rate available, internal heat insulation) Fixed: pressure drop during adsorption, no stand-by time. IAPG 2008

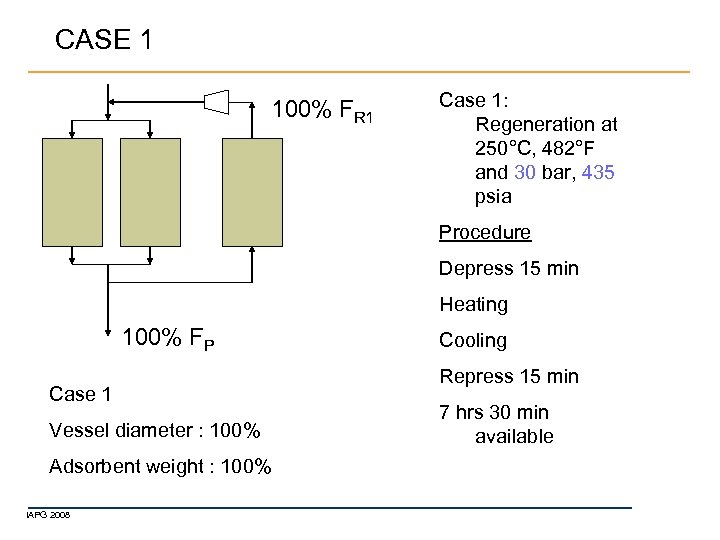

CASE 1 100% FR 1 Case 1: Regeneration at 250°C, 482°F and 30 bar, 435 psia Procedure Depress 15 min Heating 100% FP Case 1 Vessel diameter : 100% Adsorbent weight : 100% IAPG 2008 Cooling Repress 15 min 7 hrs 30 min available

CASE 1 100% FR 1 Case 1: Regeneration at 250°C, 482°F and 30 bar, 435 psia Procedure Depress 15 min Heating 100% FP Case 1 Vessel diameter : 100% Adsorbent weight : 100% IAPG 2008 Cooling Repress 15 min 7 hrs 30 min available

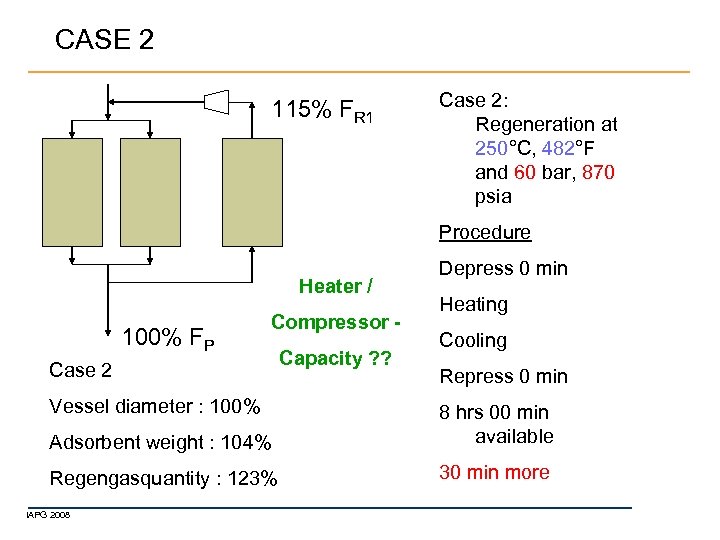

CASE 2 115% FR 1 Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Procedure Heater / 100% FP Compressor - Case 2 Vessel diameter : 100% Capacity ? ? Depress 0 min Heating Cooling Repress 0 min Adsorbent weight : 104% 8 hrs 00 min available Regengasquantity : 123% 30 min more IAPG 2008

CASE 2 115% FR 1 Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Procedure Heater / 100% FP Compressor - Case 2 Vessel diameter : 100% Capacity ? ? Depress 0 min Heating Cooling Repress 0 min Adsorbent weight : 104% 8 hrs 00 min available Regengasquantity : 123% 30 min more IAPG 2008

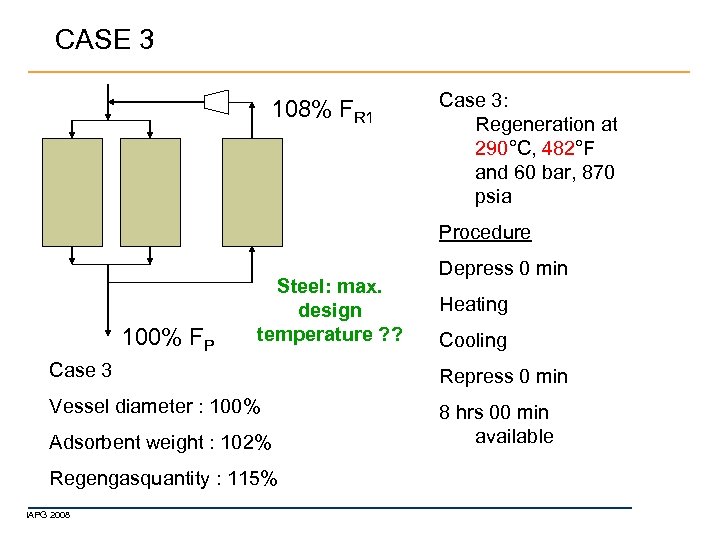

CASE 3 108% FR 1 Case 3: Regeneration at 290°C, 482°F and 60 bar, 870 psia Procedure 100% FP Steel: max. design temperature ? ? Depress 0 min Heating Cooling Case 3 Repress 0 min Vessel diameter : 100% 8 hrs 00 min available Adsorbent weight : 102% Regengasquantity : 115% IAPG 2008

CASE 3 108% FR 1 Case 3: Regeneration at 290°C, 482°F and 60 bar, 870 psia Procedure 100% FP Steel: max. design temperature ? ? Depress 0 min Heating Cooling Case 3 Repress 0 min Vessel diameter : 100% 8 hrs 00 min available Adsorbent weight : 102% Regengasquantity : 115% IAPG 2008

CASE STUDY MS Quantity Regengas quantity Regengas Flow rate CASE 1 100% FR 1 CASE 2 104% 123% 115% FR 1 CASE 3 102% 115% 108% FR 1 Case 1: Regeneration at 250°C, 482°F and 30 bar, 435 psia Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Case 3: Regeneration at 290°C, 555°F and 60 bar, 870 psia (possibility to reach lower dew point) Case 4: ? ? ? HYDROTHERMAL DAMAGING IAPG 2008

CASE STUDY MS Quantity Regengas quantity Regengas Flow rate CASE 1 100% FR 1 CASE 2 104% 123% 115% FR 1 CASE 3 102% 115% 108% FR 1 Case 1: Regeneration at 250°C, 482°F and 30 bar, 435 psia Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Case 3: Regeneration at 290°C, 555°F and 60 bar, 870 psia (possibility to reach lower dew point) Case 4: ? ? ? HYDROTHERMAL DAMAGING IAPG 2008

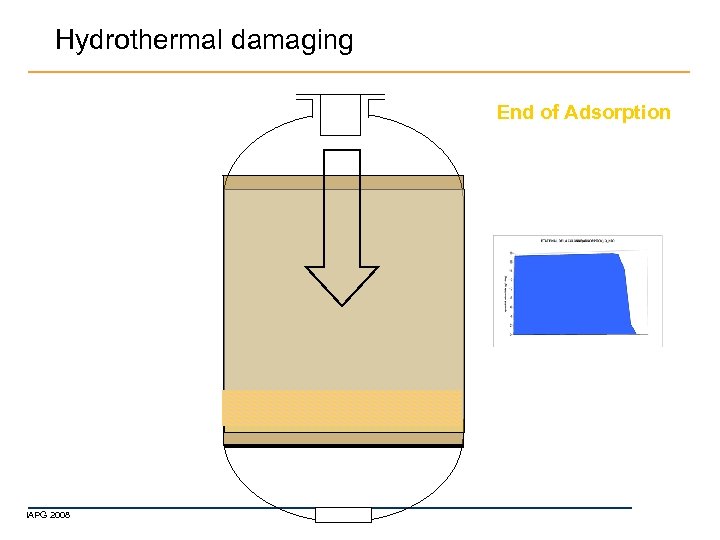

Hydrothermal damaging End of Adsorption IAPG 2008

Hydrothermal damaging End of Adsorption IAPG 2008

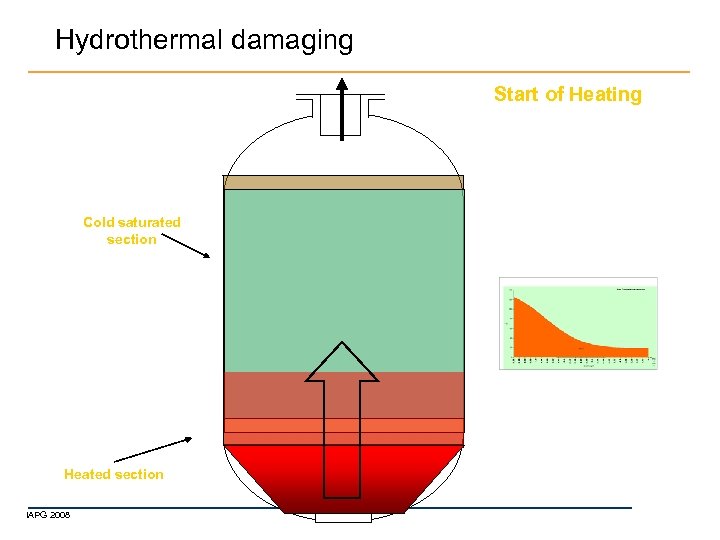

Hydrothermal damaging Start of Heating Cold saturated section Heated section IAPG 2008

Hydrothermal damaging Start of Heating Cold saturated section Heated section IAPG 2008

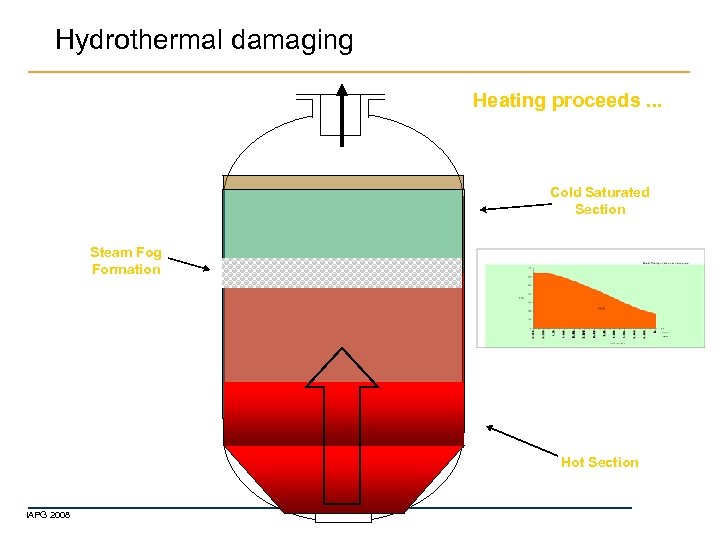

Hydrothermal damaging Heating proceeds. . . Cold Saturated Section Steam Fog Formation Hot Section IAPG 2008

Hydrothermal damaging Heating proceeds. . . Cold Saturated Section Steam Fog Formation Hot Section IAPG 2008

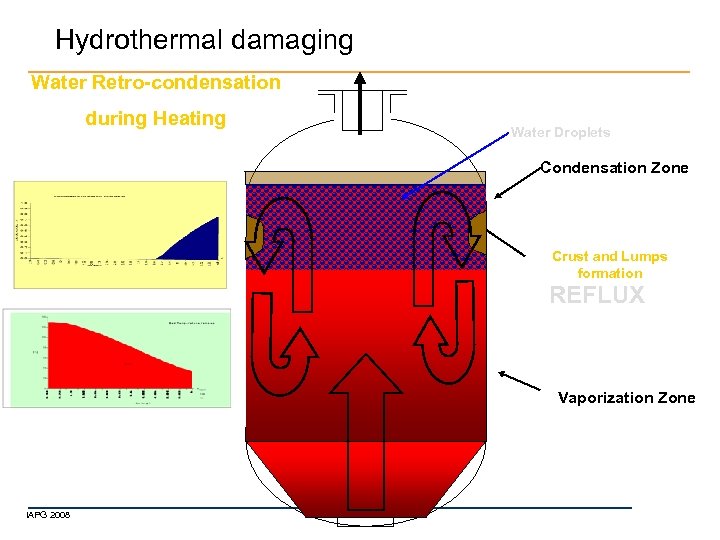

Hydrothermal damaging Water Retro-condensation during Heating Water Droplets Condensation Zone Crust and Lumps formation REFLUX Vaporization Zone IAPG 2008

Hydrothermal damaging Water Retro-condensation during Heating Water Droplets Condensation Zone Crust and Lumps formation REFLUX Vaporization Zone IAPG 2008

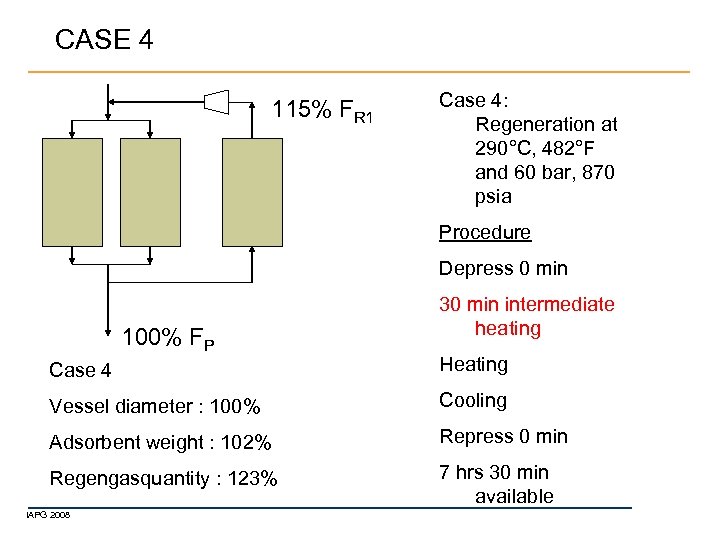

CASE 4 115% FR 1 Case 4: Regeneration at 290°C, 482°F and 60 bar, 870 psia Procedure Depress 0 min 100% FP 30 min intermediate heating Case 4 Heating Vessel diameter : 100% Cooling Adsorbent weight : 102% Repress 0 min Regengasquantity : 123% 7 hrs 30 min available IAPG 2008

CASE 4 115% FR 1 Case 4: Regeneration at 290°C, 482°F and 60 bar, 870 psia Procedure Depress 0 min 100% FP 30 min intermediate heating Case 4 Heating Vessel diameter : 100% Cooling Adsorbent weight : 102% Repress 0 min Regengasquantity : 123% 7 hrs 30 min available IAPG 2008

CASE STUDY MS Quantity Regengas Quantity Regen flow rate CASE 1 100% FR 1 CASE 2 104% 123% 115% FR 1 CASE 3 102% 115% 108% FR 1 CASE 4 102% 123% 115% FR 1 Case 1: Regeneration at 250°C, 482°F and 30 bar, 435 psia Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Case 3: Regeneration at 290°C, 555°F and 60 bar, 870 psia Case 4: Regeneration at 290°C, 555°F and 60 bar, 870 psia, interm. heating Advantage of case 4: lower water dew point at outlet. IAPG 2008

CASE STUDY MS Quantity Regengas Quantity Regen flow rate CASE 1 100% FR 1 CASE 2 104% 123% 115% FR 1 CASE 3 102% 115% 108% FR 1 CASE 4 102% 123% 115% FR 1 Case 1: Regeneration at 250°C, 482°F and 30 bar, 435 psia Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Case 3: Regeneration at 290°C, 555°F and 60 bar, 870 psia Case 4: Regeneration at 290°C, 555°F and 60 bar, 870 psia, interm. heating Advantage of case 4: lower water dew point at outlet. IAPG 2008

CASE STUDY MS Quantity Regengas quantity Regen flow rate CASE 1 100% FR 1 CASE 2 104% 123% 115% FR 1 CASE 3 102% 115% 108% FR 1 CASE 4 102% 123% 115% FR 1 Case 1: Regeneration at 250°C, 482°F and 30 bar, 435 psia Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Case 3: Regeneration at 290°C, 555°F and 60 bar, 870 psia Case 4: Regeneration at 290°C, 555°F and 60 bar, 870 psia, interm. heating Case 5: keep regeneration gas flow rate and MS height of case 2, internal heat insulation , diameter 3. 5 m, increase feed flow rate, decrease adsorption time IAPG 2008

CASE STUDY MS Quantity Regengas quantity Regen flow rate CASE 1 100% FR 1 CASE 2 104% 123% 115% FR 1 CASE 3 102% 115% 108% FR 1 CASE 4 102% 123% 115% FR 1 Case 1: Regeneration at 250°C, 482°F and 30 bar, 435 psia Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Case 3: Regeneration at 290°C, 555°F and 60 bar, 870 psia Case 4: Regeneration at 290°C, 555°F and 60 bar, 870 psia, interm. heating Case 5: keep regeneration gas flow rate and MS height of case 2, internal heat insulation , diameter 3. 5 m, increase feed flow rate, decrease adsorption time IAPG 2008

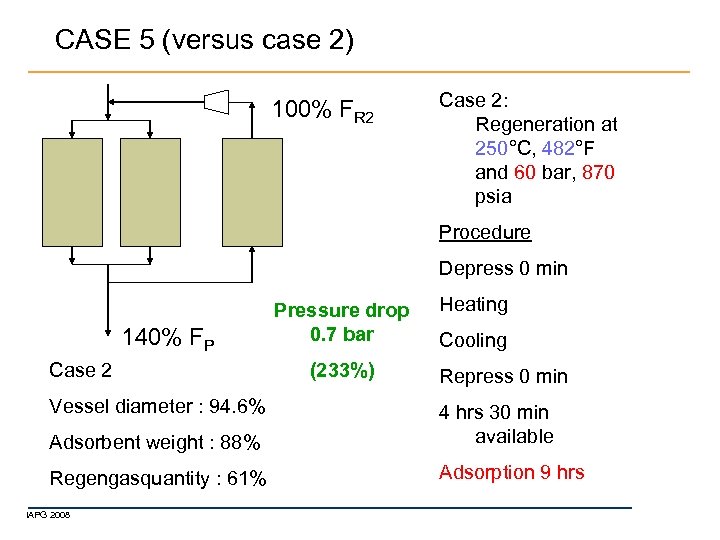

CASE 5 (versus case 2) 100% FR 2 Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Procedure Depress 0 min 140% FP Case 2 Vessel diameter : 94. 6% Pressure drop 0. 7 bar (233%) Heating Cooling Repress 0 min Adsorbent weight : 88% 4 hrs 30 min available Regengasquantity : 61% Adsorption 9 hrs IAPG 2008

CASE 5 (versus case 2) 100% FR 2 Case 2: Regeneration at 250°C, 482°F and 60 bar, 870 psia Procedure Depress 0 min 140% FP Case 2 Vessel diameter : 94. 6% Pressure drop 0. 7 bar (233%) Heating Cooling Repress 0 min Adsorbent weight : 88% 4 hrs 30 min available Regengasquantity : 61% Adsorption 9 hrs IAPG 2008

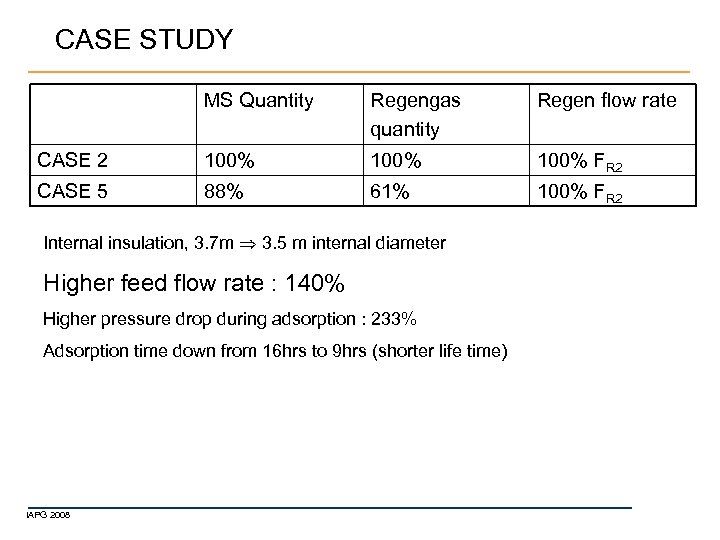

CASE STUDY MS Quantity Regengas quantity Regen flow rate CASE 2 100% FR 2 CASE 5 88% 61% 100% FR 2 Internal insulation, 3. 7 m 3. 5 m internal diameter Higher feed flow rate : 140% Higher pressure drop during adsorption : 233% Adsorption time down from 16 hrs to 9 hrs (shorter life time) IAPG 2008

CASE STUDY MS Quantity Regengas quantity Regen flow rate CASE 2 100% FR 2 CASE 5 88% 61% 100% FR 2 Internal insulation, 3. 7 m 3. 5 m internal diameter Higher feed flow rate : 140% Higher pressure drop during adsorption : 233% Adsorption time down from 16 hrs to 9 hrs (shorter life time) IAPG 2008

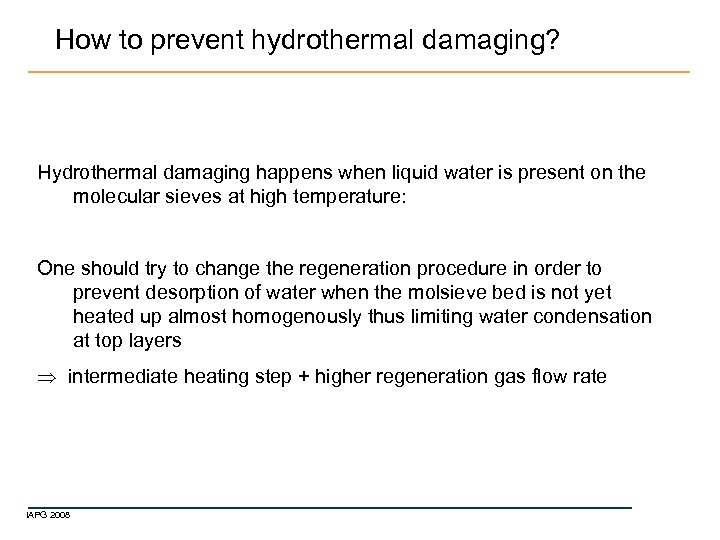

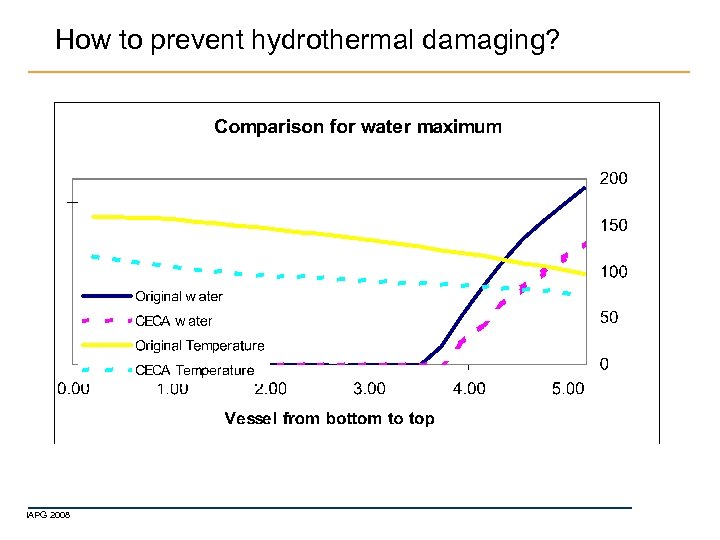

How to prevent hydrothermal damaging? Hydrothermal damaging happens when liquid water is present on the molecular sieves at high temperature: One should try to change the regeneration procedure in order to prevent desorption of water when the molsieve bed is not yet heated up almost homogenously thus limiting water condensation at top layers intermediate heating step + higher regeneration gas flow rate IAPG 2008

How to prevent hydrothermal damaging? Hydrothermal damaging happens when liquid water is present on the molecular sieves at high temperature: One should try to change the regeneration procedure in order to prevent desorption of water when the molsieve bed is not yet heated up almost homogenously thus limiting water condensation at top layers intermediate heating step + higher regeneration gas flow rate IAPG 2008

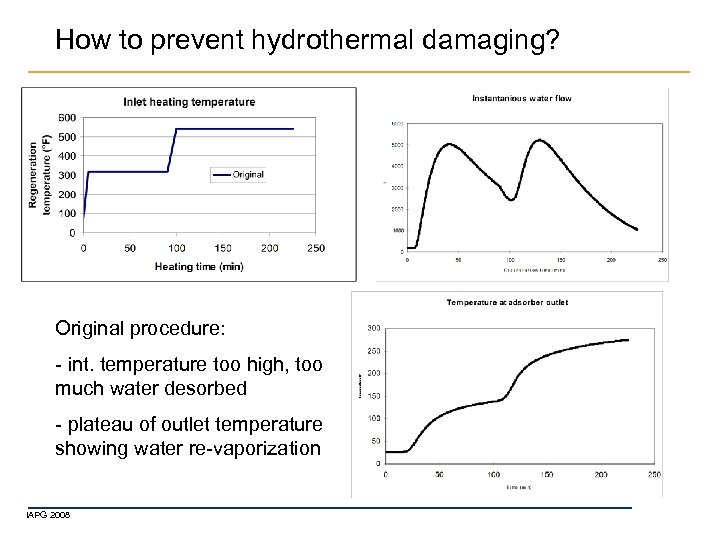

How to prevent hydrothermal damaging? Original procedure: - int. temperature too high, too much water desorbed - plateau of outlet temperature showing water re-vaporization IAPG 2008

How to prevent hydrothermal damaging? Original procedure: - int. temperature too high, too much water desorbed - plateau of outlet temperature showing water re-vaporization IAPG 2008

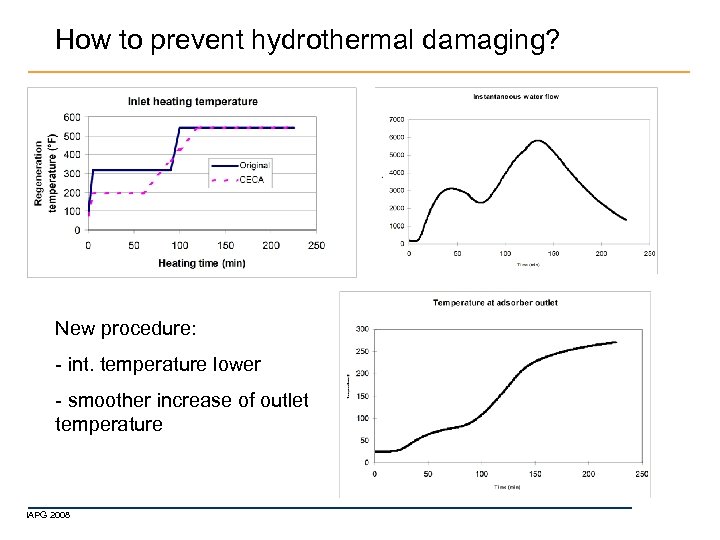

How to prevent hydrothermal damaging? New procedure: - int. temperature lower - smoother increase of outlet temperature IAPG 2008

How to prevent hydrothermal damaging? New procedure: - int. temperature lower - smoother increase of outlet temperature IAPG 2008

How to prevent hydrothermal damaging? IAPG 2008

How to prevent hydrothermal damaging? IAPG 2008

Conclusion When looking at your molecular sieve unit and its regeneration procedure: - Don’t underestimate the pressure influence on the regeneration gas quantity - Think about hydrothermal damaging - Optimization does not cost a lot but lengthens the life time of the molecular sieves Don’t hesitate to ask the nice and knowledgeable guys from CECA to help you. THANK YOU! IAPG 2008

Conclusion When looking at your molecular sieve unit and its regeneration procedure: - Don’t underestimate the pressure influence on the regeneration gas quantity - Think about hydrothermal damaging - Optimization does not cost a lot but lengthens the life time of the molecular sieves Don’t hesitate to ask the nice and knowledgeable guys from CECA to help you. THANK YOU! IAPG 2008