9b0fc1cd18124d6f8fd6bce43ac9b27d.ppt

- Количество слайдов: 58

Hydrogen Internal Combustion Engines (“HICEs”)

Hydrogen Policy Described • Mandate the CAA CFFP • program nationwide • Mandate the CPP nationwide • • Tax incentives for auto companies to: develop HICE vehicles, engage in R • & D partnerships, and establish a H 2 • infrastructure Funded research into H 2 production and storage More funding for HICE R&D H 2 as a natural gas additive – 15% pipelines Fossil fuel disincentives

Problems H 2 policy should address: • Consumer access to a H 2/ LH 2 infrastructure (centralized or decentralized) • Government investment into HICE vehicle development • Government funding for H 2 production • Establishment of uniform safety rules for H 2 production, storage, and handling

CONCLUSIONS • HICEs are a viable alternative for bridging the gap to the H 2 fuel cell economy • HICEs may be a viable long-term possibility as the ICE has undergone 100 years of refinement • To lessen greenhouse gases and foreign oil dependence, the government should encourage the transition to the H 2 economy with large investments in R&D, subsidies and tax incentives, and CAA amendments

Encouraging HICEs Empirically • Today’s safer, cleaner vehicles are the result of regulations Subsidies vs. Taxes: • Auto companies’ ability to absorb further costs • Loss of revenues from fossil fuel taxes • Tech-forcing

Status Quo HICE Policy • • February, 2003 proposal DOE-EU agreement Senator Dorgan’s proposal Freedom car – – – Demonstrated refueling Commercial codes, standards H cost equivalent to gas H ICEs Improved manufacturing

Foreign Oil Dependence • Imported oil comprises 55% of U. S. consumption • Transportation comprises 2/3 of 20 million bbl/day in U. S. • H 2 vehicles would reduce consumption by 11 million bbl/day by 2040 (EU plans 20% by 2020)

EARLY HISTORY OF H 2 • 1800: Electrolysis • 1820: Reverend W. Cecil proposes HICE • 1874: Jules Verne • 1860 -70’s: N. A. Otto uses ICEs and mixed H fuel • 1930 -40’s: Rudolf Erren develops HICEs • 1950: Francis T. Bacon

Military Research into H Vehicles • 1943: Air Force investigates LH 2 fuel • 1956: Lockheed • 1960’s: ‘Nuclear Powered Energy Depot’ A B-57 B airplane that flew with one engine fueled by liquid hydrogen

The Modern Era of HICEs • 1972: Urban Vehicle Design Competition – UCLA Gremlin wins • 1972 -3: International H 2 indenburg society • 1980’s: H-fueled airplanes (NASA continues to study FC airplanes)

MODERN H 2 VEHICLES • 1993: Ballard FC bus developed • 1995+ – CTA FC buses – Royal Dutch/ Shell – FC prototype cars – BMW HICE vehicles – H refueling stations open Ballard phase 3 FC buses, in Vancouver and Chicago

1990’S SOLAR H 2 PRODUCTION 1990: Solar-Wasserstoff. Bayern 1992: Freiburg solar plant Produces, stores H 2, LH 2 1994: HYSOLAR Saudi. German plant

Companies making HICE prototypes • Daimler-Benz: hydride HICEs, 19848 • GM has created a HICE prototypes Mazda hydride HR-X prototype • Mazda, Cadillac: HICEs and hydride HICEs Cadillac prototype HICE

Ford & BMW HICEs • BMW: 1999 fifth generation prototype, LH 2 commercially available • Ford: 1999 announced P 2000 HICE (H 2, LH 2)

H Refueling Stations Honda solar H 2 station in Torrance, Ca. LH 2 refueling station, Munich airport 2003: • Shell plans a H 2 refueling station in Luxemburg; others in California, Iceland, Japan, Holland, Norway • California, Arizona, Nevada, Illinois H 2 refueling stations • Washington, D. C. demo refueling project planned • EC International Hydrofueler Project • Reykjavik, Iceland H 2 bus refueling station opens • 1999: Hamburg, Munich, Dearborn

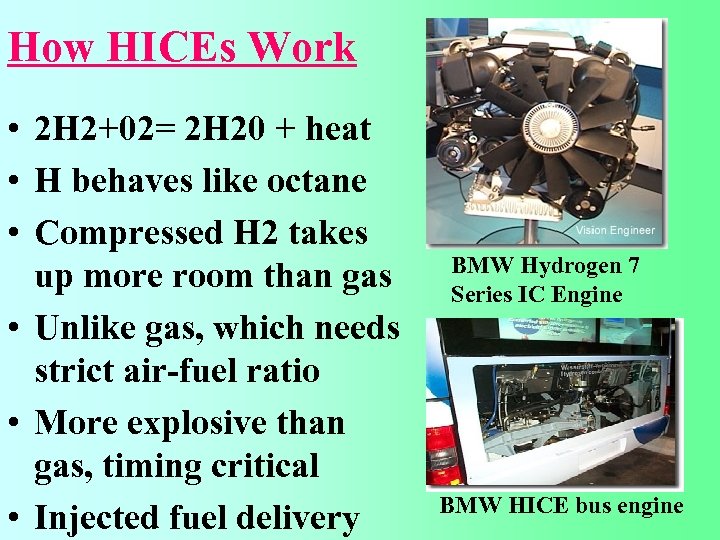

How HICEs Work • 2 H 2+02= 2 H 20 + heat • H behaves like octane • Compressed H 2 takes up more room than gas • Unlike gas, which needs strict air-fuel ratio • More explosive than gas, timing critical • Injected fuel delivery BMW Hydrogen 7 Series IC Engine BMW HICE bus engine

Converting ICEs to HICEs • Same basic design • Minimum cost: 1, 000$ • Other modifications needed for power, safety, efficiency • Limited availability • 1994 CAN Project

H-Gas Mixtures • H 2 can be used as an additive - pipelines • HYTHANE: commercially available, 20%H, 80% CH 4. Higher percentages of H require engine modifications • separately to blend with other fuels; mixed in gaseous state before injection (impractical) • Low boiling point causes fuel ice

H Onboard Storage Issues • EFFICIENCY: Gasoline is the benchmark • Ambient state demands binding H to a hydride, gas compression, or cryogenic cooling • No consensus • Infrastructure cost vs. onboard extraction • CARB vs. Ford Metal Hydride

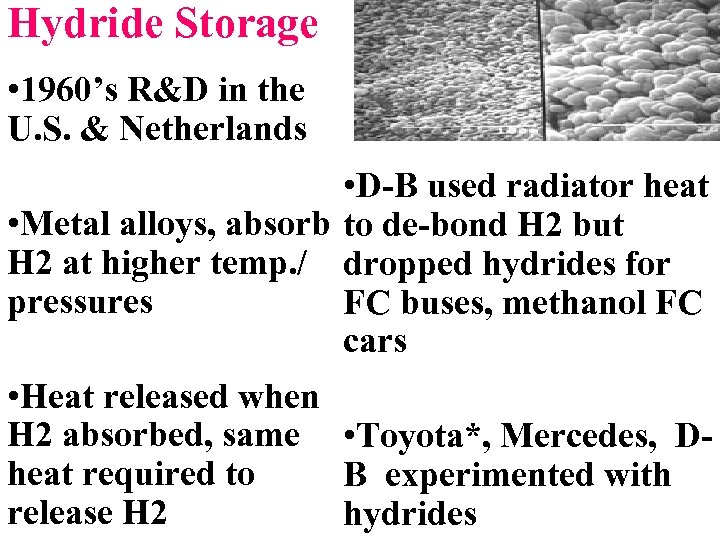

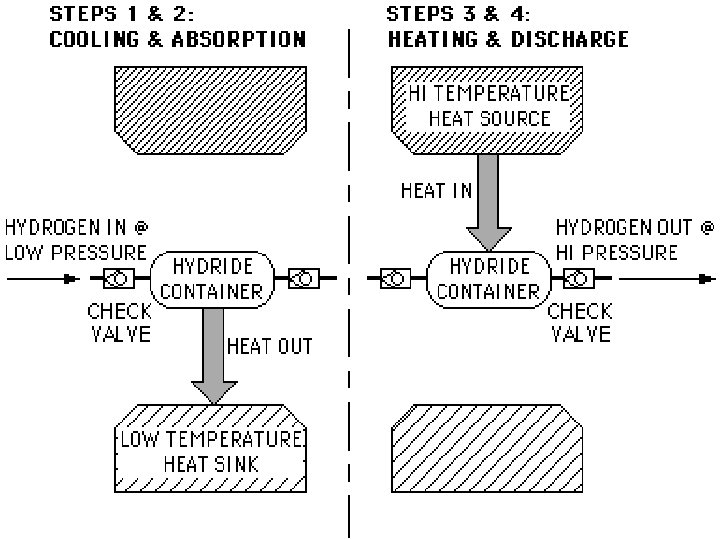

Hydride Storage • 1960’s R&D in the U. S. & Netherlands • D-B used radiator heat • Metal alloys, absorb to de-bond H 2 but H 2 at higher temp. / dropped hydrides for pressures FC buses, methanol FC cars • Heat released when H 2 absorbed, same • Toyota*, Mercedes, Dheat required to B experimented with release H 2 hydrides

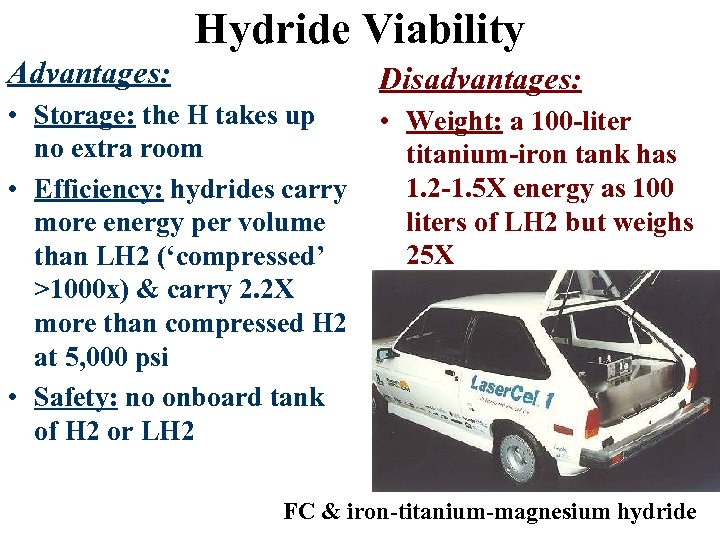

Hydride Viability Advantages: Disadvantages: • Storage: the H takes up no extra room • Efficiency: hydrides carry more energy per volume than LH 2 (‘compressed’ >1000 x) & carry 2. 2 X more than compressed H 2 at 5, 000 psi • Safety: no onboard tank of H 2 or LH 2 • Weight: a 100 -liter titanium-iron tank has 1. 2 -1. 5 X energy as 100 liters of LH 2 but weighs 25 X FC & iron-titanium-magnesium hydride

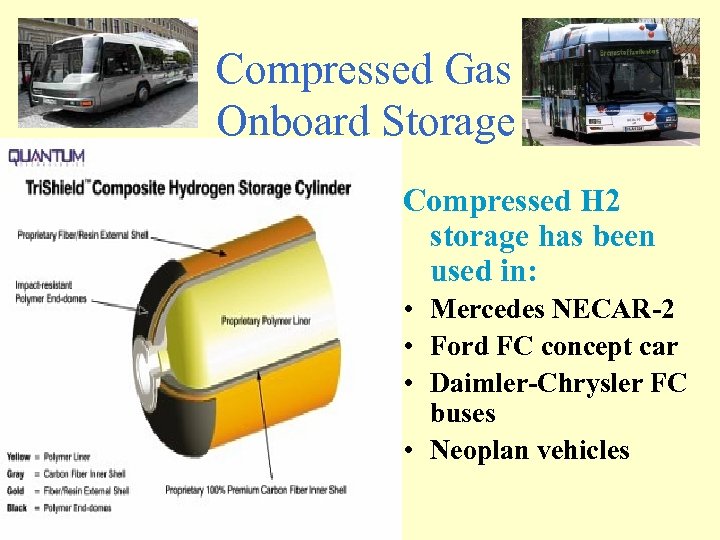

Compressed Gas Onboard Storage Compressed H 2 storage has been used in: • Mercedes NECAR-2 • Ford FC concept car • Daimler-Chrysler FC buses • Neoplan vehicles

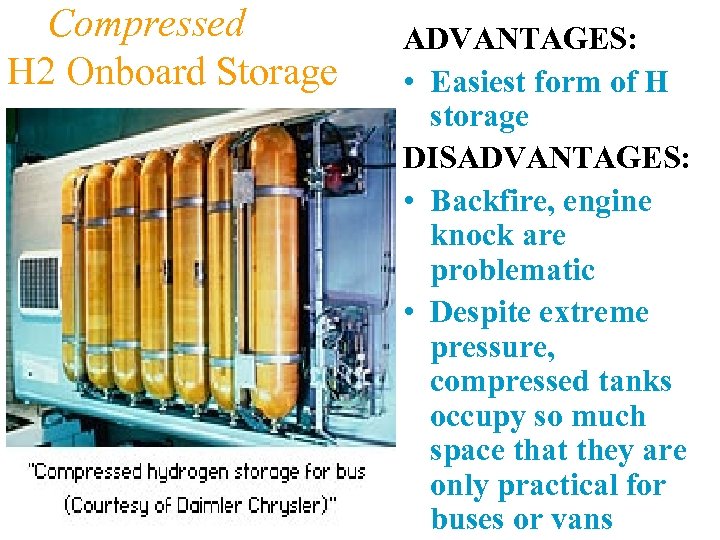

Compressed H 2 Onboard Storage ADVANTAGES: • Easiest form of H storage DISADVANTAGES: • Backfire, engine knock are problematic • Despite extreme pressure, compressed tanks occupy so much space that they are only practical for buses or vans

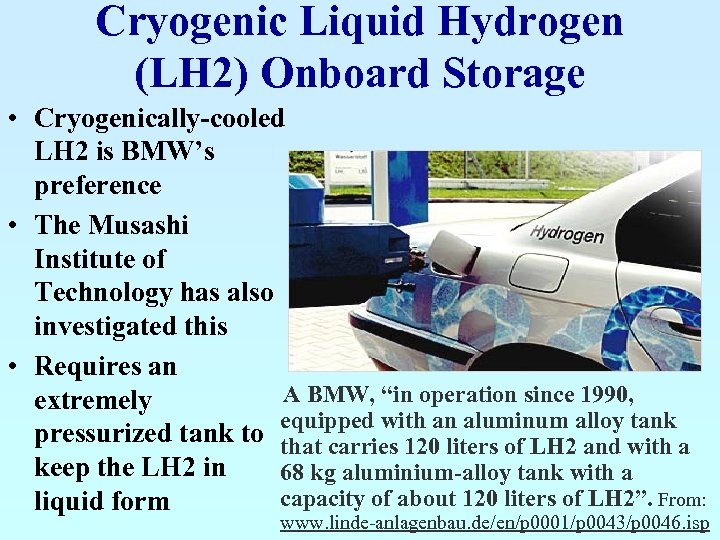

Cryogenic Liquid Hydrogen (LH 2) Onboard Storage • Cryogenically-cooled LH 2 is BMW’s preference • The Musashi Institute of Technology has also investigated this • Requires an A BMW, “in operation since 1990, extremely equipped with an aluminum alloy tank pressurized tank to that carries 120 liters of LH 2 and with a keep the LH 2 in 68 kg aluminium-alloy tank with a capacity of about 120 liters of LH 2”. From: liquid form www. linde-anlagenbau. de/en/p 0001/p 0043/p 0046. isp

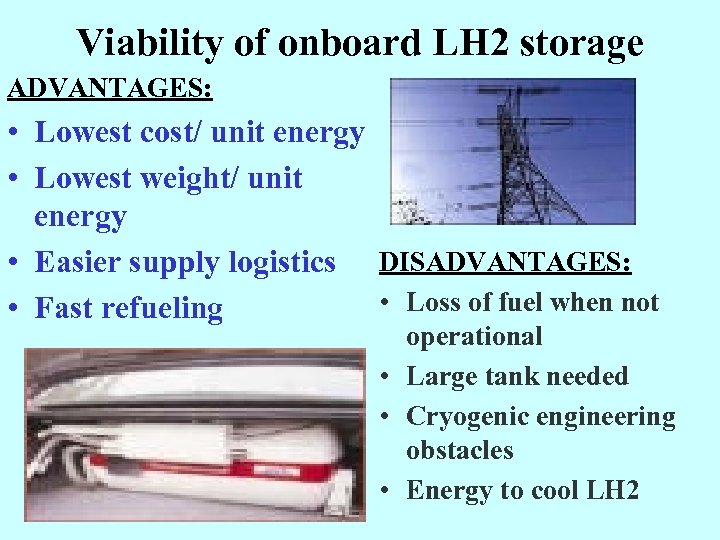

Viability of onboard LH 2 storage ADVANTAGES: • Lowest cost/ unit energy • Lowest weight/ unit energy • Easier supply logistics DISADVANTAGES: • Loss of fuel when not • Fast refueling operational • Large tank needed • Cryogenic engineering obstacles • Energy to cool LH 2

Other Possible Storage Methods: • CARBON-BASED FUEL EXTRACTION: depending on the availability of H 2/ LH 2, for both HICEs and FC vehicles, the onboard production of hydrogen is a possibility, from carbon-based fuels • NANOTECHNOLOGY: graphite nanofiber tubes store 65% H 2 by weight. -DOE funded, then withdrew -Ford continued the R&D -GM later questioned the 65%

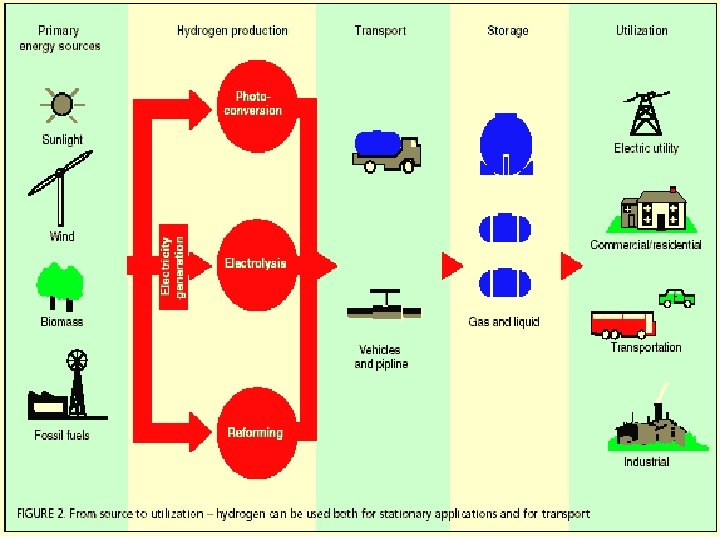

Hydrogen Sources • H is a common element but must be pried from other substances and thus is not an energy ‘source’ • A consensus exists that H 2 is an ideal fuel, but not about the ideal source • The best production alternative may vary by locality

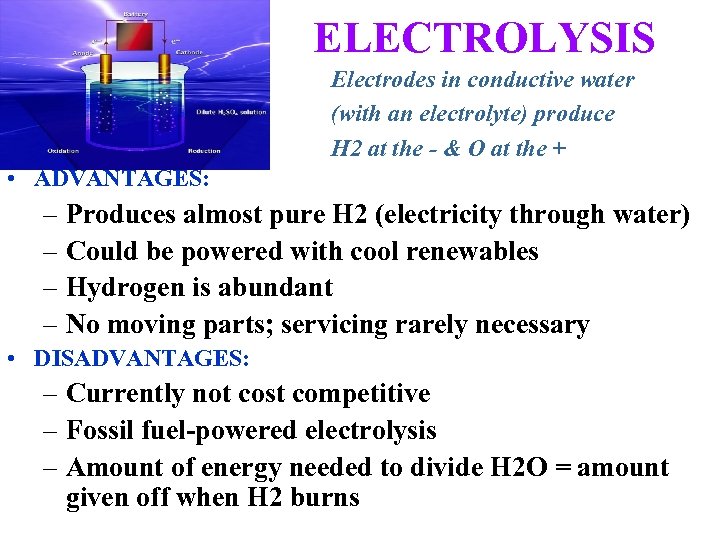

ELECTROLYSIS Electrodes in conductive water (with an electrolyte) produce H 2 at the - & O at the + • ADVANTAGES: – Produces almost pure H 2 (electricity through water) – Could be powered with cool renewables – Hydrogen is abundant – No moving parts; servicing rarely necessary • DISADVANTAGES: – Currently not cost competitive – Fossil fuel-powered electrolysis – Amount of energy needed to divide H 2 O = amount given off when H 2 burns

Solar-Powered Electrolysis • Honda doing this in Torrance, California • HYSOLAR: began making H 2 in 1994 • Solar-Wasserstoff-Bayern in Bavaria • CAN project

Nuclear-powered Electrolysis • It’s a feasible alternative • Anti-nuclear sentiment may prevent nuclear H 2 production • NRDC opposed; spent fuel

Making H 2 from Natural Gas • Stripping H 2 from natural gas is called ‘reforming’ • Reforming natural gas emits CO 2 • Outfitting a gas station with a machine to reform natural gas would cost $400, 000 (building a conventional gas station costs $1, 500, 000)

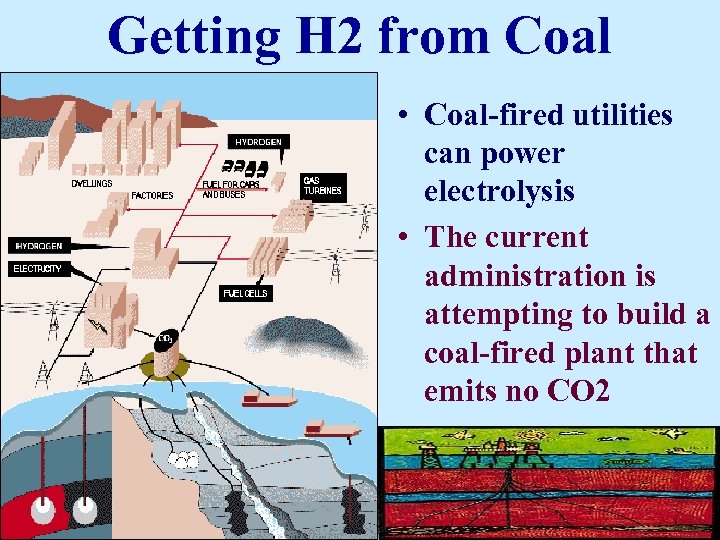

Getting H 2 from Coal • Coal-fired utilities can power electrolysis • The current administration is attempting to build a coal-fired plant that emits no CO 2

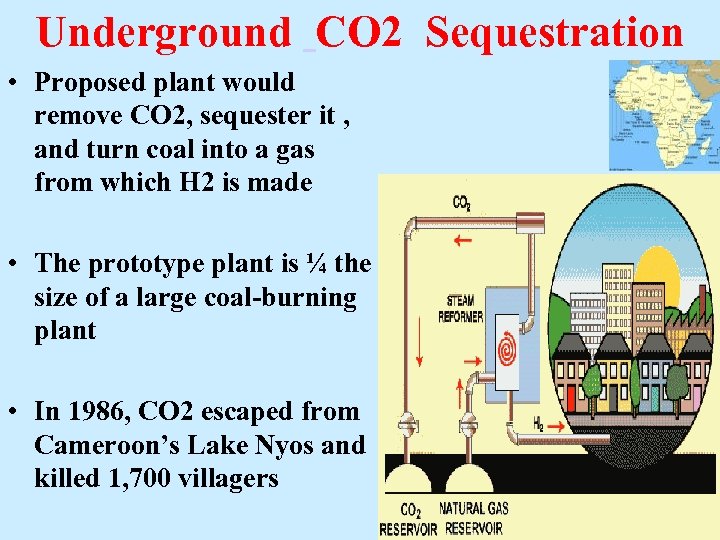

Underground CO 2 Sequestration • Proposed plant would remove CO 2, sequester it , and turn coal into a gas from which H 2 is made • The prototype plant is ¼ the size of a large coal-burning plant • In 1986, CO 2 escaped from Cameroon’s Lake Nyos and killed 1, 700 villagers

H 2 Production from Bacteria • Some anaerobic bacteria can produce H 2 at 20 times their volume per minute • When starved of sulfur, Chlamydomonas Reinhardtii makes H 2, one of ten most important discoveries in 2000 (popular science magazine)

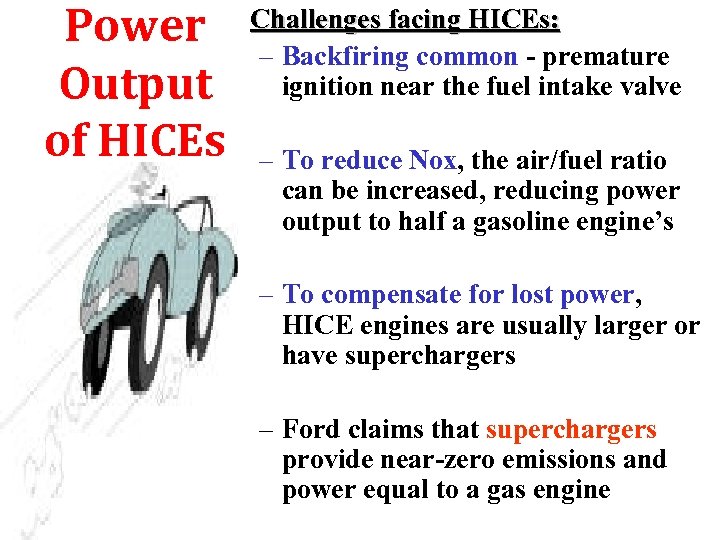

Power Output of HICEs Challenges facing HICEs: – Backfiring common - premature ignition near the fuel intake valve – To reduce Nox, the air/fuel ratio can be increased, reducing power output to half a gasoline engine’s – To compensate for lost power, HICE engines are usually larger or have superchargers – Ford claims that superchargers provide near-zero emissions and power equal to a gas engine

Are HICEs unsafe at any speed? • H 2 is volatile and is 10 x more explosive than gasoline • H leaks and static present risks • Special sensors and ducts that pull in fresh air may be necessary whenever HICEs are parked indoors • Stringent, universal safety regulations are needed for storage, handling, and disposal of H 2

BMW Tests indicate HICEs are Safe • ’ 94 BMW: safety valves of double-walled LH 2 tanks were blocked, cooked, shaken, rammed with pole; slow LH 2 leak, no explosion • H 2 escaped after 10 minutes in open fire; burned with no effect on tank • OTHER TESTS: some tanks burst under extreme pressure buildup

Ford’s 2000 H 2, LH 2 vehicles • Model U concept car: 3 millimeter aluminum barrier tank, carbon-fiber structural casing, rated to a pressure of 10, 000 psi • P 2000 FUEL system - redundancy for safety: – fueling system under trunk – Triple redundant system based on natural gas, designed to use H 2 natural dispersion – H 2 ventilators – Sensors in engine, passenger and trunk compartments – Alarms triggered at concentrations below flammability – H 2 detected = fuel system/engine starter disable, roof opens, ventilation fans activate

H 2 Safety & the Hindenburg • The Public perception of H 2? • 1997, Addison Bain, former NASA H 2 program manager presented findings: – Static and flame accelerants (painted on the skin), not H 2, were causes – Based on Analysis of surviving Hindenburg remnants

Is Hydrogen Fuel Safer? Former Lockheed Manager: maintains air crashes involving kerosene fuel would have resulted in fewer deaths if H 2 were the fuel: –Radiated fire heat is less with H 2 –No smoke from H 2 fires –LH 2 safer upon impact than kerosene –H 2 volatile/ burns quickly –H 2 vaporizes/ disperses quickly –Less fire area

H 2 vs. CONVENTIONAL FUELS 1976 Stanford Research Institute: no clear answers; physical/ chemical properties of H 2 differ, comparisons are misleading 1974 NASA study: road transport of LH 2 presents fewer ignition risks First H 2 pipeline: ships H 2 to chemical plants, has operated safely for years, but the H 2 is only 95% pure, at low psi, in a narrow pipe

1993 German H 2 study H 2 SAFER: – Vaporization – Cloud formation – Fire, thermal emissivity H 2 RISKIER: –In enclosed rooms –Customer handling of H 2 demands technical safety measures (selfadjusting gas sensors linked to ventilation systems) UNRESOLVED: –Questions remain about pipeline embrittlement, feasibility of high pressure H 2 pipeline

HICEs & POLLUTION ADVANTAGES: DISADVANTAGES: • Emissions are a • High temperature H 2 fraction of convention combustion makes Nox ICE emissions • NOx emissions = ¼ that of gas, can be lessened with • Ford HICEs emit additional control almost no pollutants and are 25% more fuel equipment efficient than gas ICEs • Even without aftertreatment, NOx emissions • H 2/ CH 4 mixed fuel are low emits extremely low • Fossil fuel electrolysis NOx lessens pollution gains

Barriers to Commercial Availability • H 2/ LH 2 infrastructure needed • ICE-HICE conversion availability • Low cost H 2 production needed • Like current vehicles, H 2/LH 2 vehicle designs will likely vary • Economics of H 2 cars are ill-defined • Lack of uniform regulations of H 2

Commercial HICE Availability • Shell: “marathon, not a sprint, and the race has just begun, ” H 2 fuel network by 2030 -2050. Others estimate 10 -50 years to the H 2 economy • BMW’s HICE cars are available today • John C. Anderson, Pres. & CEO of AFS says: (1) the existing ICE infrastructure (2) the demand for clean emissions; & (3) H 2’s flammability characteristics make H 2 the “ultimate low cost fuel” which, when widely available, can be adapted to conventional autos and diesel engine vehicles

What if FCs are the future? • BMW’s future could be adversely affected • Unlikely soon: – FC engines 3 x as heavy as ICEs – No transport FC mass production – Most H 2 vehicles produced are HICEs • HICEs offer a good opportunity to improve the H 2 infrastructure as HICEs are “comparatively easy to produce” • HICEs can bridge the gap to H 2 -fueled transport that eventually incorporates fuel cells

ARE FUEL CELLS BETTER? • Fuel cells are more efficient than HICEs but less efficient when operated on methane • Barriers exist to FCs as ‘dual fuel’ vehicles, and thus may be less feasible than HICEs in the near future unless H 2 onboard conversion materializes • FCs cars are the best for zero emissions • FC cars average 60 more mpg than BMW’s HICEs • FCs cars are far more costly than HICE vehicles

THE EU IS DOING MORE • March 2003 DOE-EU joint effort • EU: 20% alternate energy fuel sources by 2020, plans to develop H 2 tech while sharply tightening fuel efficiency standards

California Fuel Cell Partnership • Corporate members have 6 H 2 stations; at least 8 H 2 filling stations in southern California • 12 more planned • The partnership has cut the number of H 2 vehicles it plans to require car companies to produce

Centrally Fueled Fleet Program (CFFP) • H 2 is a CAA Clean Fuel • The CFFP applies to states with serious or worse O 3 nonattainment • Requires fleets to use a % of clean fuel vehicles • Not vigorously enforced; voluntary as of 1995 • EPA of 1992: CFV purchase incentives for public/private fleets & incentives for fuel suppliers

CAA California Pilot Program (CPP) • Increases CFV availability (requires 300, 000 yearly) • Credit program (excess CFVs or buy credits) • SIP mandates sufficient • Serious/ worse O 3 nonclean fuels be produced, distributed by fuel suppliers attainment states may opt in (profit incentive) • Opt-in states cannot • CARB’s LEV program mandate CFV sales or differs – clean fuels must be alternate fuel production available, not produced and availability (incentives instead)

H 2/LH 2 INFRASTRUCTURE • Centralized or decentralized? • Assuming a centralized infrastructure, oil companies estimate that consumer interest depends on a new fuel being available at 30% of gas stations • 180, 000 gas station in the U. S

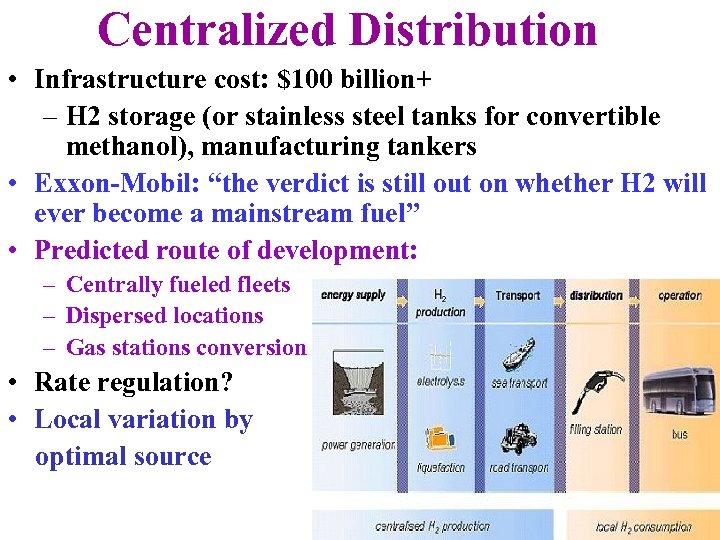

Centralized Distribution • Infrastructure cost: $100 billion+ – H 2 storage (or stainless steel tanks for convertible methanol), manufacturing tankers • Exxon-Mobil: “the verdict is still out on whether H 2 will ever become a mainstream fuel” • Predicted route of development: – Centrally fueled fleets – Dispersed locations – Gas stations conversion • Rate regulation? • Local variation by optimal source

REPAIR INFRASTRUCTURE • HICEs have the advantage over FC vehicles • Developed economies already have ready access to HICE repair • Adequately trained technicians and equipment still are needed for HICEs; ICE-HICE conversion not readily available

Decentralized H 2 Infrastructure • Retrofitting CH 4 pipelines favors centralization; long term localized production will favor decentralization • Honda & GM are discussing bypassing gas stations in favor of letting consumers buy/ lease home H 2 -fueling machines • For consumers, the ability to refuel at home may justify higher fuel costs • Some advocate onboard stripping of H 2 from carbon fuel to avoid H 2 transition difficulties

Conclusions • Regulatory mandates; CFFP, CPP nationally? • Tax incentives, subsidies for HICE R&D, investment • Incentives and regulatory mandates to develop a fueling infrastructure • Standardization of H 2 safety codes

9b0fc1cd18124d6f8fd6bce43ac9b27d.ppt