954978f7d541d4d8436b28f81eb00a44.ppt

- Количество слайдов: 19

Hydrogen Fuel Injection to Improve Engine Efficiency March 2007 Ø Copyright Canadian Hydrogen Energy Company 2007 All rights reserved

Hydrogen Fuel Injection to Improve Engine Efficiency March 2007 Ø Copyright Canadian Hydrogen Energy Company 2007 All rights reserved

Changing Marketplace Dramatic economic growth in developing nations has created unprecedented demand for all commodities, particularly fuel stocks § Coupled with increased demand, it has become increasing expensive to find and recover fossil fuels, i. e. it will require fuel prices >$60/bbl for the processing of the oil sands in Canada to be commercially viable § Increased operating costs, particularly for transportation, have created unprecedented demand for increased fuel efficiency § § § Example, Wal-Mart, the world’s largest company, has demanded that all transport truck manufacturers double their fuel efficiency by 2012 The public is increasingly sensitive to environmental issues and there is an increased willingness to pay for “green” technologies § Time Magazine/ABC News poll in March 2006 revealed 88% of Americans believe global warming will threaten future generations

Changing Marketplace Dramatic economic growth in developing nations has created unprecedented demand for all commodities, particularly fuel stocks § Coupled with increased demand, it has become increasing expensive to find and recover fossil fuels, i. e. it will require fuel prices >$60/bbl for the processing of the oil sands in Canada to be commercially viable § Increased operating costs, particularly for transportation, have created unprecedented demand for increased fuel efficiency § § § Example, Wal-Mart, the world’s largest company, has demanded that all transport truck manufacturers double their fuel efficiency by 2012 The public is increasingly sensitive to environmental issues and there is an increased willingness to pay for “green” technologies § Time Magazine/ABC News poll in March 2006 revealed 88% of Americans believe global warming will threaten future generations

Regulatory Environment § Virtually all governments have instituted increasingly tougher regulations to promote fuel efficiency (i. e. CAFÉ standards); reduced vehicle emissions (EPA 2002, 2007, 2010; EURO 1 through 5; etc); and reduced GHG emissions from a wide variety of sources (Kyoto, “cap and trade” systems, etc) § Ironically, several of these regulatory initiatives have only accomplished environmental improvement at significant increases to capital or operating costs for industry § § I. E. to meet the 2007 EPA emissions standards, the average fuel efficiency of every North American made transport truck will decrease by 3. 5% - at precisely the time fuel prices have reached record levels Several countries have committed to the complete elimination of fossil fuels led by Iceland’s plan to ban fossil fuels by 2050

Regulatory Environment § Virtually all governments have instituted increasingly tougher regulations to promote fuel efficiency (i. e. CAFÉ standards); reduced vehicle emissions (EPA 2002, 2007, 2010; EURO 1 through 5; etc); and reduced GHG emissions from a wide variety of sources (Kyoto, “cap and trade” systems, etc) § Ironically, several of these regulatory initiatives have only accomplished environmental improvement at significant increases to capital or operating costs for industry § § I. E. to meet the 2007 EPA emissions standards, the average fuel efficiency of every North American made transport truck will decrease by 3. 5% - at precisely the time fuel prices have reached record levels Several countries have committed to the complete elimination of fossil fuels led by Iceland’s plan to ban fossil fuels by 2050

Hydrogen to the Rescue! § § § Hydrogen has, for many years, been considered a prime candidate for the final destination as the world moves away from fossil fuels. The combustion of hydrogen produces pure H 2 O, easily making hydrogen the ultimate in “green” fuels During the past 20 years, well over $2 Billion has been spent, in Canada, the U. S. , Europe and Japan, by companies and governments looking to utilize hydrogen fuel cells Despite that investment, which has yielded considerable technical progress, fuel cells remain far from commercial viability and to “hedge their bets” vehicle manufacturers have pursued hybrid technologies and other enhancements to traditional internal combustion engines (still using fossil fuels) to decrease emissions By focusing on fuel cells, the public and private sectors have largely overlooked more immediate roles hydrogen can play

Hydrogen to the Rescue! § § § Hydrogen has, for many years, been considered a prime candidate for the final destination as the world moves away from fossil fuels. The combustion of hydrogen produces pure H 2 O, easily making hydrogen the ultimate in “green” fuels During the past 20 years, well over $2 Billion has been spent, in Canada, the U. S. , Europe and Japan, by companies and governments looking to utilize hydrogen fuel cells Despite that investment, which has yielded considerable technical progress, fuel cells remain far from commercial viability and to “hedge their bets” vehicle manufacturers have pursued hybrid technologies and other enhancements to traditional internal combustion engines (still using fossil fuels) to decrease emissions By focusing on fuel cells, the public and private sectors have largely overlooked more immediate roles hydrogen can play

Aren’t Fuel Cells the Only Answer? § § § There are other, currently more cost effective, means of utilizing H 2 in transportation applications BMW, Toyota and others are developing Hydrogen Internal Combustion Engines (HICE) as one solution Ford Motor Co. has recently commenced commercial production of an HICE engine for mid-range applications, such as delivery trucks Other companies, such as Westport Cummins, are pursuing the blending of hydrogen and natural gas - but this requires special storage tanks and sources of pure H 2 As an alternative to commercially dispensed NG, Hythane Ltd. blends H 2 and natural gas, which is then used in NG engines But all of these applications deal with new engines – what’s being done to improve the billion internal combustion engines already in use?

Aren’t Fuel Cells the Only Answer? § § § There are other, currently more cost effective, means of utilizing H 2 in transportation applications BMW, Toyota and others are developing Hydrogen Internal Combustion Engines (HICE) as one solution Ford Motor Co. has recently commenced commercial production of an HICE engine for mid-range applications, such as delivery trucks Other companies, such as Westport Cummins, are pursuing the blending of hydrogen and natural gas - but this requires special storage tanks and sources of pure H 2 As an alternative to commercially dispensed NG, Hythane Ltd. blends H 2 and natural gas, which is then used in NG engines But all of these applications deal with new engines – what’s being done to improve the billion internal combustion engines already in use?

Another Application – Hydrogen Fuel Injection Fully Patented ETV Verified Hydrogen Market Leader Installed on 150 fleets 5 th Generation Product Only hydrogen product with fuel saving guarantee Only commercially viable hydrogen product today Works with any fuel type – gasoline, diesel, NG, propane

Another Application – Hydrogen Fuel Injection Fully Patented ETV Verified Hydrogen Market Leader Installed on 150 fleets 5 th Generation Product Only hydrogen product with fuel saving guarantee Only commercially viable hydrogen product today Works with any fuel type – gasoline, diesel, NG, propane

The Inspiration for HFI § § § Hydrogen is the most energy efficient element in the universe, carrying over 3 times the energy, by weight, of gasoline Vast quantities of hydrogen have been used, safely, for decades, in a wide variety of industrial processes, but with almost no consumer exposure What is publicly “known” about hydrogen includes a variety of misinformation relating to its safety (Hindenburg syndrome) Tremendous cost to change to 100% hydrogen uses. What was needed was an application of hydrogen that could serve as a bridge between the fossil-fuel infrastructure in place today and the all-hydrogen fuelled future – a hydrogen hybrid, in essence With electrolysis, hydrogen is available without having to store it in expensive and heavy cylinders, indeed, without having to store the hydrogen, at all, so there are no safety considerations

The Inspiration for HFI § § § Hydrogen is the most energy efficient element in the universe, carrying over 3 times the energy, by weight, of gasoline Vast quantities of hydrogen have been used, safely, for decades, in a wide variety of industrial processes, but with almost no consumer exposure What is publicly “known” about hydrogen includes a variety of misinformation relating to its safety (Hindenburg syndrome) Tremendous cost to change to 100% hydrogen uses. What was needed was an application of hydrogen that could serve as a bridge between the fossil-fuel infrastructure in place today and the all-hydrogen fuelled future – a hydrogen hybrid, in essence With electrolysis, hydrogen is available without having to store it in expensive and heavy cylinders, indeed, without having to store the hydrogen, at all, so there are no safety considerations

The HFI Technology § A high-performance, on-board hydrogen electrolyser § Splits distilled water into hydrogen and oxygen, then injects those gases directly into the air intake of the engine. § Faster flame speed causes: § § An increase in the efficiency of the combustion Reduced emissions of HC, PM, CO Shorter burn duration results in lower NOx System is incredibly safe: § § § No hydrogen is ever stored onboard Gases are not produced unless the engine is running Use of HFI will not void any engine warranty § Operates in any weather condition § Only maintenance required is the addition of 2. 5 litres of distilled water every 65 hours of engine operation.

The HFI Technology § A high-performance, on-board hydrogen electrolyser § Splits distilled water into hydrogen and oxygen, then injects those gases directly into the air intake of the engine. § Faster flame speed causes: § § An increase in the efficiency of the combustion Reduced emissions of HC, PM, CO Shorter burn duration results in lower NOx System is incredibly safe: § § § No hydrogen is ever stored onboard Gases are not produced unless the engine is running Use of HFI will not void any engine warranty § Operates in any weather condition § Only maintenance required is the addition of 2. 5 litres of distilled water every 65 hours of engine operation.

H 2 Effects on Combustion • Assumption: hydrogen: HC at full load, big diesel, is 1: 100 (by moles). • Our ultimate effect is to increase the adiabatic efficiency of the engine. Modern diesels run around 35 -40% efficiency, and older engines can be as low as 25 -30%. To increase fuel efficiency by 10%, note that the adiabatic efficiency needs be increased only 3. 5 -4%, or on older engines only 2. 5 -3%. • The main mechanism by which the hydrogen effects the combustion in a way that contributes to increased adiabatic efficiency, is best described in terms of the initial evaporating droplets that provide the start to the combustion pathway. It is this model, of evaporating droplets of Cn. H 2 n+1, in a cloud of weak concentrations of H 2, that seems to be the proper theoretical framework. • Assuming that a droplet is roughly 20 micro-meters cubic, then there approximately 1013 molecules of fuel in that droplet, and so approximately 1011 hydrogen molecules surrounding that droplet at full load. In terms of evaporated HC molecules, only 10% is evaporated during the pre-ignition phase, only 10% of the spray is on the outer layer, and only 10% of that is involved in pre-flame oxidation. Thus, our 1% hydrogen: HC at full load increases to 1000% in terms of this particular phase of the combustion reaction, for example.

H 2 Effects on Combustion • Assumption: hydrogen: HC at full load, big diesel, is 1: 100 (by moles). • Our ultimate effect is to increase the adiabatic efficiency of the engine. Modern diesels run around 35 -40% efficiency, and older engines can be as low as 25 -30%. To increase fuel efficiency by 10%, note that the adiabatic efficiency needs be increased only 3. 5 -4%, or on older engines only 2. 5 -3%. • The main mechanism by which the hydrogen effects the combustion in a way that contributes to increased adiabatic efficiency, is best described in terms of the initial evaporating droplets that provide the start to the combustion pathway. It is this model, of evaporating droplets of Cn. H 2 n+1, in a cloud of weak concentrations of H 2, that seems to be the proper theoretical framework. • Assuming that a droplet is roughly 20 micro-meters cubic, then there approximately 1013 molecules of fuel in that droplet, and so approximately 1011 hydrogen molecules surrounding that droplet at full load. In terms of evaporated HC molecules, only 10% is evaporated during the pre-ignition phase, only 10% of the spray is on the outer layer, and only 10% of that is involved in pre-flame oxidation. Thus, our 1% hydrogen: HC at full load increases to 1000% in terms of this particular phase of the combustion reaction, for example.

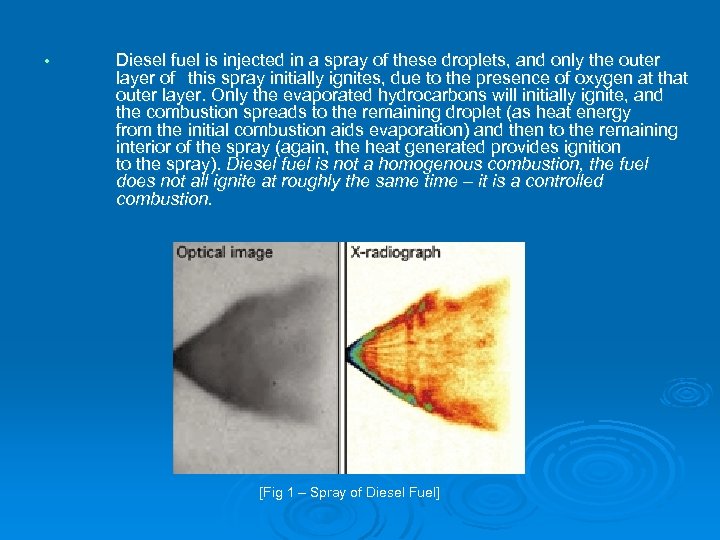

• Diesel fuel is injected in a spray of these droplets, and only the outer layer of this spray initially ignites, due to the presence of oxygen at that outer layer. Only the evaporated hydrocarbons will initially ignite, and the combustion spreads to the remaining droplet (as heat energy from the initial combustion aids evaporation) and then to the remaining interior of the spray (again, the heat generated provides ignition to the spray). Diesel fuel is not a homogenous combustion, the fuel does not all ignite at roughly the same time – it is a controlled combustion. [Fig 1 – Spray of Diesel Fuel]

• Diesel fuel is injected in a spray of these droplets, and only the outer layer of this spray initially ignites, due to the presence of oxygen at that outer layer. Only the evaporated hydrocarbons will initially ignite, and the combustion spreads to the remaining droplet (as heat energy from the initial combustion aids evaporation) and then to the remaining interior of the spray (again, the heat generated provides ignition to the spray). Diesel fuel is not a homogenous combustion, the fuel does not all ignite at roughly the same time – it is a controlled combustion. [Fig 1 – Spray of Diesel Fuel]

• Mechanism 1: Pre-Ignition: Although hydrogen has a much higher auto-ignition temperature (temperature to sustain combustion) it has much lower ignition energy than diesel (by an order of magnitude) – therefore the hydrogen surrounding the evaporating droplets will pre-ignite and provide an initial impetus to get the combustion started. This is probably the dominant effect in newer engines. • Mechanism 2: Hydro-cracking : The hydrogen alters the kinetic chemical path through which the fuel combusts, as some of the initial hydrocarbons are split in to smaller, more easily combustible elements by the presence of hydrogen under high pressure. • Mechanism 3: Pre-Flame Oxidation: We effectively increase the Pre-Flame Oxidation phase, as hydrogen is available to participate; the increase of which would increase overall efficiency. Pre-Flame Oxidation is when the hydrocarbons are oxidizing, but the mixture has not yet reached auto-ignition temperatures. • Mechanism 4: Engine Friction Losses and Carbon Presence: On older engines, we clean the carbon off the cylinder walls and injection pumps, increasing combustion efficiency significantly. The mechanism responsible for this effect is the low ‘quenching gap’ of hydrogen – it will burn very close to the cylinder walls. This is undoubtedly the dominant mechanism on older engines. • The net effect of these three mechanisms is to alter the Pressure-Crank Angle to enable a faster rise of pressure, and a smoother top pressure characteristic (but limiting the peak pressures and thereby mitigating NOx). This change in the pressure diagram leads directly to the efficiency gains.

• Mechanism 1: Pre-Ignition: Although hydrogen has a much higher auto-ignition temperature (temperature to sustain combustion) it has much lower ignition energy than diesel (by an order of magnitude) – therefore the hydrogen surrounding the evaporating droplets will pre-ignite and provide an initial impetus to get the combustion started. This is probably the dominant effect in newer engines. • Mechanism 2: Hydro-cracking : The hydrogen alters the kinetic chemical path through which the fuel combusts, as some of the initial hydrocarbons are split in to smaller, more easily combustible elements by the presence of hydrogen under high pressure. • Mechanism 3: Pre-Flame Oxidation: We effectively increase the Pre-Flame Oxidation phase, as hydrogen is available to participate; the increase of which would increase overall efficiency. Pre-Flame Oxidation is when the hydrocarbons are oxidizing, but the mixture has not yet reached auto-ignition temperatures. • Mechanism 4: Engine Friction Losses and Carbon Presence: On older engines, we clean the carbon off the cylinder walls and injection pumps, increasing combustion efficiency significantly. The mechanism responsible for this effect is the low ‘quenching gap’ of hydrogen – it will burn very close to the cylinder walls. This is undoubtedly the dominant mechanism on older engines. • The net effect of these three mechanisms is to alter the Pressure-Crank Angle to enable a faster rise of pressure, and a smoother top pressure characteristic (but limiting the peak pressures and thereby mitigating NOx). This change in the pressure diagram leads directly to the efficiency gains.

Verification § Subject to numerous third party tests in Canada, the US and UK § First emission control technology in Canada (and the first hydrogen product worldwide) to receive Environmental Technology Verification (ETV) designation § Data from 100 million kms of applied use has been recorded using electronic control modules (on-board computers) on transport trucks § Ontario Drive Clean tests showed decreases in opacity ranging from 38% to 92% immediately after the HFI system was installed on ambulances in the City of Hamilton, Ontario § Testing of a London taxi cab by the Millbrook Emissions Testing Laboratory in the UK showed reductions in all noxious emissions (HC 53%, CO 47%, PM 47% and a 14% reduction in NOx)

Verification § Subject to numerous third party tests in Canada, the US and UK § First emission control technology in Canada (and the first hydrogen product worldwide) to receive Environmental Technology Verification (ETV) designation § Data from 100 million kms of applied use has been recorded using electronic control modules (on-board computers) on transport trucks § Ontario Drive Clean tests showed decreases in opacity ranging from 38% to 92% immediately after the HFI system was installed on ambulances in the City of Hamilton, Ontario § Testing of a London taxi cab by the Millbrook Emissions Testing Laboratory in the UK showed reductions in all noxious emissions (HC 53%, CO 47%, PM 47% and a 14% reduction in NOx)

Scientific Research • • • • • Houseman and Cerini, Jet Propulsion Lab. , California Institute of Technology, On-Board Hydrogen Generator for a Partial Hydrogen Cerini, Injection Internal Combustion Engine, August 1974, SAE Paper # 740600 Update Heavy-Duty Engine Emission Conversion Factors for Mobile 6: Analysis of BSFCs and Calculation of Heavy-Duty Engine Emission Conversion Factors, United States Environmental Protection Agency, EPA 420 -P-98 -015, May 1998 Lax and Rucker, Medium and Heavy Duty Truck Fuel Economy and Consumption Trends, Society of Automotive Engineers, SAE Technical Paper Series, Paper # 810023, February, 1981 Kong, Crane, Patel and Taylor, NOx Trap Regeneration with an On-Board Hydrogen Generation Device, March 2004, SAE Technical Paper Series, Paper # 2004 -01 -0582 Welch and Wallace, Ortech International and University of Toronto, Performance Characteristics of a Hydrogen-Fueled Diesel Engine with Ignition Assist , October 1990, SAE Technical Paper Series, Paper # 902070 Hoekstra, Van Blarigan and Mulligan, University of Central Florida, Sandia National Labs and Florida Solar Energy Center, NOx Emissions and Efficiency of Hydrogen, Natural Gas, and Hydrogen/Natural Gas Blended Fuels, , May 1996, SAE Technical Paper Series Paper # 961103 Tunestal et al. , Lund Institute of Technology and Swedish Gas Center, Hydrogen Addition For Improved Lean Burn Capability of Slow and Fast Burning Natural Gas Combustion Chambers, October 2002, SAE Technical Paper Series Paper # 2002 -01 -2686 Ochoa, Dwyer, Wallace and Brodrick, University of California at Davis, Emissions from Hydrogen Enriched CHG Production Brodrick, Engines, October 2002, SAE Technical Paper Series Paper # 2002 -01 -2687 Fontana, Galloni, Jannelli, and Minutillo, Department of Industrial Engineering, University of Cassino, Performance and Fuel Galloni, Jannelli, Minutillo, Cassino, Consumption Estimation of a Hydrogen Enriched Gasoline Engine at Part-Load Operation, July 2002, SAE Technical Paper Series Paper # 2002 -01 -2196 Tully and Heywood, General Motors and Massachusetts Institute of Technology, Lean-Burn Characteristics of a Gasoline Engine Enriched with Hydrogen from a Plasmatron Fuel Reformer, , March 2003, SAE Technical Paper Series Paper # 2003 -01 -0630 Natkin et al. , Ford Motor Company and University of California-Riverside, Hydrogen IC Engine Boosting Performance and NOx Study, SAE Technical Paper Series Paper # 2003 -01 -0631 Conte and Boulouchos, Swiss Federal Institute of Technology, Influence of Hydrogen-Rich-Gas Addition on Combustion, Pollutant Boulouchos, Formation and Efficiency of an IC-SI Engine, March 2004 SAE Technical Paper Series, Paper # 2004 -01 -0972 Allgeier et al. , Robert Bosch Gmbh, Swiss Federal Institute of Technology and HTI Biel, Advanced Emission and Fuel Economy Gmbh, Biel, Concept Using Combined Injection of Gasoline and Hydrogen in SI-Engines, March 2004, SAE Technical Paper Series, Paper # 2004 -01 -1270 Tomita, Kawahara, Piao, Fujita, and Hamamato; Hydrogen Combustion and Exhaust Emissions Ignited with Diesel Oil in a Dual Piao, Hamamato; Fuel Engine, September 2001, SAE Technical Paper Series Paper # 2001 -01 -3503 Ross, Internal Combustion Engine Kit with Electrolysis Cell, United States Patent and Trademark Office, Patent # 6, 209, 493 , April 3, 2001 Ross, Electrolysis Cell and Internal Combustion Engine Kit, , Canadian Intellectual Property Office, Patents # 2278917 & 2349508, July 27, 1998 & June 4, 2001 J. J. J. Louis, Shell Global Solutions, Well-to Wheel Energy Use and Greenhouse Gas Emissions for Various Vehicle Technologies, March 2001, SAE Technical Paper Series, Paper # 2001 -01 -1343 Hsu, Practical Diesel-Engine Combustion Analysis 2002 SAE International, SAE #R-327 ISBN: 0 -7860 -0914 -6

Scientific Research • • • • • Houseman and Cerini, Jet Propulsion Lab. , California Institute of Technology, On-Board Hydrogen Generator for a Partial Hydrogen Cerini, Injection Internal Combustion Engine, August 1974, SAE Paper # 740600 Update Heavy-Duty Engine Emission Conversion Factors for Mobile 6: Analysis of BSFCs and Calculation of Heavy-Duty Engine Emission Conversion Factors, United States Environmental Protection Agency, EPA 420 -P-98 -015, May 1998 Lax and Rucker, Medium and Heavy Duty Truck Fuel Economy and Consumption Trends, Society of Automotive Engineers, SAE Technical Paper Series, Paper # 810023, February, 1981 Kong, Crane, Patel and Taylor, NOx Trap Regeneration with an On-Board Hydrogen Generation Device, March 2004, SAE Technical Paper Series, Paper # 2004 -01 -0582 Welch and Wallace, Ortech International and University of Toronto, Performance Characteristics of a Hydrogen-Fueled Diesel Engine with Ignition Assist , October 1990, SAE Technical Paper Series, Paper # 902070 Hoekstra, Van Blarigan and Mulligan, University of Central Florida, Sandia National Labs and Florida Solar Energy Center, NOx Emissions and Efficiency of Hydrogen, Natural Gas, and Hydrogen/Natural Gas Blended Fuels, , May 1996, SAE Technical Paper Series Paper # 961103 Tunestal et al. , Lund Institute of Technology and Swedish Gas Center, Hydrogen Addition For Improved Lean Burn Capability of Slow and Fast Burning Natural Gas Combustion Chambers, October 2002, SAE Technical Paper Series Paper # 2002 -01 -2686 Ochoa, Dwyer, Wallace and Brodrick, University of California at Davis, Emissions from Hydrogen Enriched CHG Production Brodrick, Engines, October 2002, SAE Technical Paper Series Paper # 2002 -01 -2687 Fontana, Galloni, Jannelli, and Minutillo, Department of Industrial Engineering, University of Cassino, Performance and Fuel Galloni, Jannelli, Minutillo, Cassino, Consumption Estimation of a Hydrogen Enriched Gasoline Engine at Part-Load Operation, July 2002, SAE Technical Paper Series Paper # 2002 -01 -2196 Tully and Heywood, General Motors and Massachusetts Institute of Technology, Lean-Burn Characteristics of a Gasoline Engine Enriched with Hydrogen from a Plasmatron Fuel Reformer, , March 2003, SAE Technical Paper Series Paper # 2003 -01 -0630 Natkin et al. , Ford Motor Company and University of California-Riverside, Hydrogen IC Engine Boosting Performance and NOx Study, SAE Technical Paper Series Paper # 2003 -01 -0631 Conte and Boulouchos, Swiss Federal Institute of Technology, Influence of Hydrogen-Rich-Gas Addition on Combustion, Pollutant Boulouchos, Formation and Efficiency of an IC-SI Engine, March 2004 SAE Technical Paper Series, Paper # 2004 -01 -0972 Allgeier et al. , Robert Bosch Gmbh, Swiss Federal Institute of Technology and HTI Biel, Advanced Emission and Fuel Economy Gmbh, Biel, Concept Using Combined Injection of Gasoline and Hydrogen in SI-Engines, March 2004, SAE Technical Paper Series, Paper # 2004 -01 -1270 Tomita, Kawahara, Piao, Fujita, and Hamamato; Hydrogen Combustion and Exhaust Emissions Ignited with Diesel Oil in a Dual Piao, Hamamato; Fuel Engine, September 2001, SAE Technical Paper Series Paper # 2001 -01 -3503 Ross, Internal Combustion Engine Kit with Electrolysis Cell, United States Patent and Trademark Office, Patent # 6, 209, 493 , April 3, 2001 Ross, Electrolysis Cell and Internal Combustion Engine Kit, , Canadian Intellectual Property Office, Patents # 2278917 & 2349508, July 27, 1998 & June 4, 2001 J. J. J. Louis, Shell Global Solutions, Well-to Wheel Energy Use and Greenhouse Gas Emissions for Various Vehicle Technologies, March 2001, SAE Technical Paper Series, Paper # 2001 -01 -1343 Hsu, Practical Diesel-Engine Combustion Analysis 2002 SAE International, SAE #R-327 ISBN: 0 -7860 -0914 -6

The Benefits Improved fuel economy • Minimum 10% improvement is guaranteed Increased horsepower and torque • Acting as an initiator, the heat given off from the combustion of the hydrogen ensures that a far greater percentage of the diesel combusts, and faster. Typically, torque and horsepower increase by 3% (5 -15 HP) Decreased maintenance expenses • More complete combustion produces less soot and ash, meaning longer oil change intervals and decreased engine wear Reduced emissions • • • § Higher initial heat is offset by a faster reaction time and better distribution of that heat as a result of the homogenous mixture of hydrogen in the fuel/air mix resulting in significant NOx reduction More complete combustion means a significant reduction in CO, PM and all Hydrocarbons Faster flame speed means a reduction in NOx Reduction in SO 2 and CO 2 = % reduction in fuel use

The Benefits Improved fuel economy • Minimum 10% improvement is guaranteed Increased horsepower and torque • Acting as an initiator, the heat given off from the combustion of the hydrogen ensures that a far greater percentage of the diesel combusts, and faster. Typically, torque and horsepower increase by 3% (5 -15 HP) Decreased maintenance expenses • More complete combustion produces less soot and ash, meaning longer oil change intervals and decreased engine wear Reduced emissions • • • § Higher initial heat is offset by a faster reaction time and better distribution of that heat as a result of the homogenous mixture of hydrogen in the fuel/air mix resulting in significant NOx reduction More complete combustion means a significant reduction in CO, PM and all Hydrocarbons Faster flame speed means a reduction in NOx Reduction in SO 2 and CO 2 = % reduction in fuel use

Current Uses § HFI represents the only viable hydrogen-based retrofit technology for heavy duty trucks and other engine applications § First model, the HT (heavy truck) was developed for long haul trucking (35 million globally, 9 million in North America) § With minor adaptations, the HT is also being used in bus, marine, motorhome and stationary generator applications § Second model, the LT (light truck) was developed for engines <7. 3 litres, and installed in high fuel use applications such as ambulances, delivery vehicles, refuse trucks, & school buses § Depending on fuel consumption, the technology typically offers a payback of 12 -15 months in most commercial uses

Current Uses § HFI represents the only viable hydrogen-based retrofit technology for heavy duty trucks and other engine applications § First model, the HT (heavy truck) was developed for long haul trucking (35 million globally, 9 million in North America) § With minor adaptations, the HT is also being used in bus, marine, motorhome and stationary generator applications § Second model, the LT (light truck) was developed for engines <7. 3 litres, and installed in high fuel use applications such as ambulances, delivery vehicles, refuse trucks, & school buses § Depending on fuel consumption, the technology typically offers a payback of 12 -15 months in most commercial uses

Examples of HFI Installations

Examples of HFI Installations

Concluding Thoughts • It is today’s engines which are causing today’s pollution which, in turn, causes today’s health consequences • The incidence of asthma in Canada has grown 5 fold in the last fifty years, making it the second largest health care expense and the #1 reason for hospital admissions for children • Governments and the private sector need to put far greater emphasis on cleaning existing vehicles and other emission sources • Hydrogen is the ultimate fuel, from an energy and environmental perspective, but the change to pure hydrogen applications will take decades and hundreds of billions of dollars • On the other hand, the addition of fractional amounts of hydrogen can achieve significant emission reductions, including CO 2, as well as operational savings. • As a bridge to the (possible) hydrogen future, HFI has the potential to extend the lifespan of the fossil fuel infrastructure which currently exists around the world • HFI is not a threat to fossil fuel production, rather it is arguably one of the best means of improving the image of diesel and other fuels and reduce the pressure on governments to use emissions as an excuse to promote alternative fuels

Concluding Thoughts • It is today’s engines which are causing today’s pollution which, in turn, causes today’s health consequences • The incidence of asthma in Canada has grown 5 fold in the last fifty years, making it the second largest health care expense and the #1 reason for hospital admissions for children • Governments and the private sector need to put far greater emphasis on cleaning existing vehicles and other emission sources • Hydrogen is the ultimate fuel, from an energy and environmental perspective, but the change to pure hydrogen applications will take decades and hundreds of billions of dollars • On the other hand, the addition of fractional amounts of hydrogen can achieve significant emission reductions, including CO 2, as well as operational savings. • As a bridge to the (possible) hydrogen future, HFI has the potential to extend the lifespan of the fossil fuel infrastructure which currently exists around the world • HFI is not a threat to fossil fuel production, rather it is arguably one of the best means of improving the image of diesel and other fuels and reduce the pressure on governments to use emissions as an excuse to promote alternative fuels

Mission Statement Canadian Hydrogen Energy Company Limited will continue to be the global leader in the development and manufacturing of hydrogen technology products that extend the lifespan of the fossil fuel infrastructure while leaving a legacy of improved air quality to future generations. Our products will revitalize the economics in transportation, power generation and heating markets and will create new wealth for our stakeholders as well as cost savings for customers. Our mission is to be recognized, globally, as the “Clean Energy Company”.

Mission Statement Canadian Hydrogen Energy Company Limited will continue to be the global leader in the development and manufacturing of hydrogen technology products that extend the lifespan of the fossil fuel infrastructure while leaving a legacy of improved air quality to future generations. Our products will revitalize the economics in transportation, power generation and heating markets and will create new wealth for our stakeholders as well as cost savings for customers. Our mission is to be recognized, globally, as the “Clean Energy Company”.

CANADIAN HYDROGEN ENERGY COMPANY With an R&D facility in Pickering and its main manufacturing centre in Bowmanville, Ontario, CHEC is a world leader in the development of on-board hydrogen electrolysers. The company and its staff have been active in the field since 1983 and the current family of HFI units was first introduced into the long-haul trucking market over 8 years ago. The HFI units are currently operating on over 150 fleets, in Canada and the U. S. , and the applications have expanded to include cars, light-duty trucks, SUV’s, motorhomes, boats, ambulances, municipal buses and natural gas boilers. The company expects to expand the range of applications into rail and marine markets in 2007. The company has a network of over 140 certified installation centers across Canada, the United States and Mexico. In late 2006, marketing of the HFI line commenced in Europe, Australia/NZ and the Caribbean, with worldwide release of the products expected by mid-2007. For more information, please visit our website at www. chechfi. com or contact Steve Gilchrist at sgilchrist@chechfi. com. Canadian Hydrogen Energy Company 182 Wellington St. W. , Suite 1, Bowmanville, ON, L 1 C 1 W 3 800 -550 -4066/905 -697 -7011 (ph) 905 -697 -7018 (fax) All rights reserved 2007

CANADIAN HYDROGEN ENERGY COMPANY With an R&D facility in Pickering and its main manufacturing centre in Bowmanville, Ontario, CHEC is a world leader in the development of on-board hydrogen electrolysers. The company and its staff have been active in the field since 1983 and the current family of HFI units was first introduced into the long-haul trucking market over 8 years ago. The HFI units are currently operating on over 150 fleets, in Canada and the U. S. , and the applications have expanded to include cars, light-duty trucks, SUV’s, motorhomes, boats, ambulances, municipal buses and natural gas boilers. The company expects to expand the range of applications into rail and marine markets in 2007. The company has a network of over 140 certified installation centers across Canada, the United States and Mexico. In late 2006, marketing of the HFI line commenced in Europe, Australia/NZ and the Caribbean, with worldwide release of the products expected by mid-2007. For more information, please visit our website at www. chechfi. com or contact Steve Gilchrist at sgilchrist@chechfi. com. Canadian Hydrogen Energy Company 182 Wellington St. W. , Suite 1, Bowmanville, ON, L 1 C 1 W 3 800 -550 -4066/905 -697 -7011 (ph) 905 -697 -7018 (fax) All rights reserved 2007