94ff993b39d4454d1749c56dbb45367c.ppt

- Количество слайдов: 37

Hydrogen from Coal: The U. S. DOE’s Hydrogen from Coal Program - Why, What, and How National Hydrogen Association Annual Hydrogen Conference 2007 March 20, 2007 Daniel C. Cicero, Technology Manager, Hydrogen and Syngas, National Energy Technology Laboratory and Dilo Paul, Senior Scientist, Science Applications International Corporation National Energy Technology Laboratory

Hydrogen from Coal: The U. S. DOE’s Hydrogen from Coal Program - Why, What, and How National Hydrogen Association Annual Hydrogen Conference 2007 March 20, 2007 Daniel C. Cicero, Technology Manager, Hydrogen and Syngas, National Energy Technology Laboratory and Dilo Paul, Senior Scientist, Science Applications International Corporation National Energy Technology Laboratory

Presidential Initiatives for Hydrogen · $1. 2 billion dollars · Addresses storage, delivery, and production from a variety of sources · Aimed at future fuel cell vehicles Future. Gen One billion dollar, 10 -year project to create world’s first coal-based, zero-emission electricity and hydrogen plant President Bush, February 27, 2003 · · Produce lower cost hydrogen Produce electricity - nominally 275 MWe Sequester carbon dioxide Builds on DOE-sponsored Integrated Gasification Combined Cycle (IGCC) technology 2 NHA Annual Hydrogen Conference 2007

Presidential Initiatives for Hydrogen · $1. 2 billion dollars · Addresses storage, delivery, and production from a variety of sources · Aimed at future fuel cell vehicles Future. Gen One billion dollar, 10 -year project to create world’s first coal-based, zero-emission electricity and hydrogen plant President Bush, February 27, 2003 · · Produce lower cost hydrogen Produce electricity - nominally 275 MWe Sequester carbon dioxide Builds on DOE-sponsored Integrated Gasification Combined Cycle (IGCC) technology 2 NHA Annual Hydrogen Conference 2007

Rationale for Producing Hydrogen from Coal · Hydrogen could fundamentally transform U. S. energy system National Academy of Engineering Study · Fossil Fuels will be one of the principal sources of hydrogen …but carbon capture and storage technologies will be required · If energy security is primary driver, coal must be a significant component of R&D aimed at making very large amounts of hydrogen 3 NHA Annual Hydrogen Conference 2007

Rationale for Producing Hydrogen from Coal · Hydrogen could fundamentally transform U. S. energy system National Academy of Engineering Study · Fossil Fuels will be one of the principal sources of hydrogen …but carbon capture and storage technologies will be required · If energy security is primary driver, coal must be a significant component of R&D aimed at making very large amounts of hydrogen 3 NHA Annual Hydrogen Conference 2007

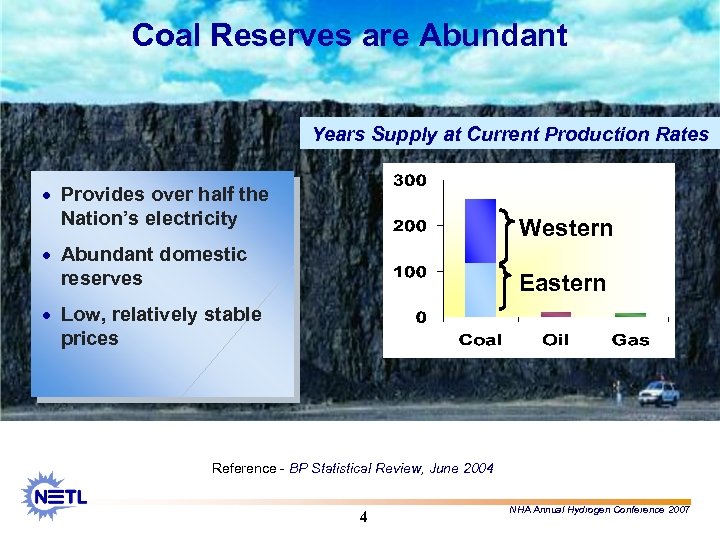

Coal Reserves are Abundant Years Supply at Current Production Rates · Provides over half the Nation’s electricity Western · Abundant domestic reserves Eastern · Low, relatively stable prices Reference - BP Statistical Review, June 2004 4 NHA Annual Hydrogen Conference 2007

Coal Reserves are Abundant Years Supply at Current Production Rates · Provides over half the Nation’s electricity Western · Abundant domestic reserves Eastern · Low, relatively stable prices Reference - BP Statistical Review, June 2004 4 NHA Annual Hydrogen Conference 2007

Possible Hydrogen Production from Coal The National Council estimates that, within 20 years, the nation could produce an additional 1300 million tons per year of coal that could be used for production of hydrogen, liquid fuels, substitute natural gas (SNG), and electricity Coal: America’s Energy Future, National Council, 2005 About 180 million tons per year of additional coal production could provide fuel for 100 million fuel cell vehicles (FCV) - Assumptions: · One ton of H 2 can be produced from 7. 3 tons of coal (Hydrogen from Coal, Mitretek Technical Paper MTR 2003 -31, July 2002) · · Carbon is sequestered FCVs achieve 60 miles per kg of H 2 5 NHA Annual Hydrogen Conference 2007

Possible Hydrogen Production from Coal The National Council estimates that, within 20 years, the nation could produce an additional 1300 million tons per year of coal that could be used for production of hydrogen, liquid fuels, substitute natural gas (SNG), and electricity Coal: America’s Energy Future, National Council, 2005 About 180 million tons per year of additional coal production could provide fuel for 100 million fuel cell vehicles (FCV) - Assumptions: · One ton of H 2 can be produced from 7. 3 tons of coal (Hydrogen from Coal, Mitretek Technical Paper MTR 2003 -31, July 2002) · · Carbon is sequestered FCVs achieve 60 miles per kg of H 2 5 NHA Annual Hydrogen Conference 2007

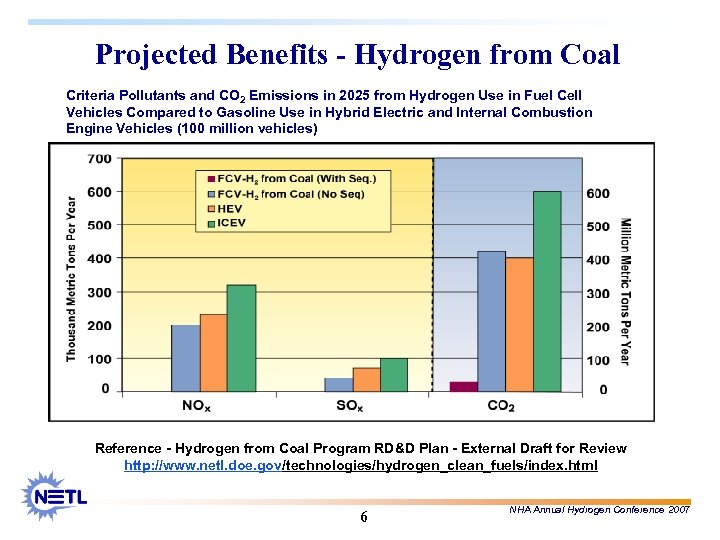

Projected Benefits - Hydrogen from Coal Criteria Pollutants and CO 2 Emissions in 2025 from Hydrogen Use in Fuel Cell Vehicles Compared to Gasoline Use in Hybrid Electric and Internal Combustion Engine Vehicles (100 million vehicles) Reference - Hydrogen from Coal Program RD&D Plan - External Draft for Review http: //www. netl. doe. gov/technologies/hydrogen_clean_fuels/index. html 6 NHA Annual Hydrogen Conference 2007

Projected Benefits - Hydrogen from Coal Criteria Pollutants and CO 2 Emissions in 2025 from Hydrogen Use in Fuel Cell Vehicles Compared to Gasoline Use in Hybrid Electric and Internal Combustion Engine Vehicles (100 million vehicles) Reference - Hydrogen from Coal Program RD&D Plan - External Draft for Review http: //www. netl. doe. gov/technologies/hydrogen_clean_fuels/index. html 6 NHA Annual Hydrogen Conference 2007

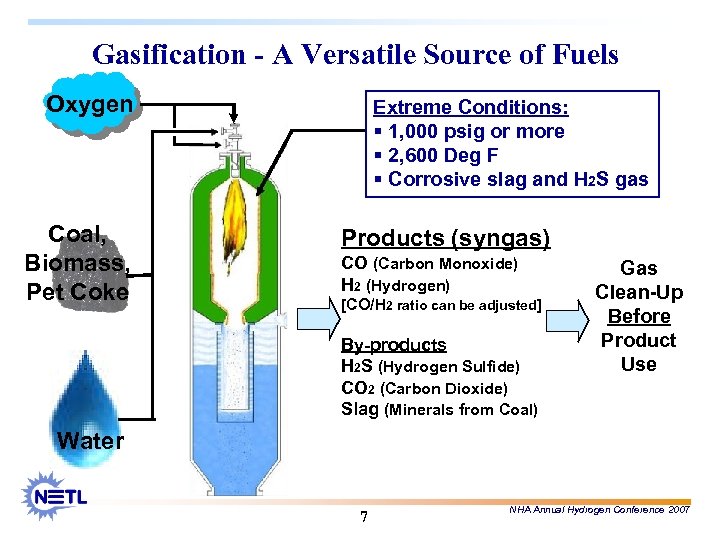

Gasification - A Versatile Source of Fuels Oxygen Coal, Biomass, Pet Coke Extreme Conditions: § 1, 000 psig or more § 2, 600 Deg F § Corrosive slag and H 2 S gas Products (syngas) CO (Carbon Monoxide) H 2 (Hydrogen) [CO/H 2 ratio can be adjusted] By-products H 2 S (Hydrogen Sulfide) CO 2 (Carbon Dioxide) Slag (Minerals from Coal) Gas Clean-Up Before Product Use Water 7 NHA Annual Hydrogen Conference 2007

Gasification - A Versatile Source of Fuels Oxygen Coal, Biomass, Pet Coke Extreme Conditions: § 1, 000 psig or more § 2, 600 Deg F § Corrosive slag and H 2 S gas Products (syngas) CO (Carbon Monoxide) H 2 (Hydrogen) [CO/H 2 ratio can be adjusted] By-products H 2 S (Hydrogen Sulfide) CO 2 (Carbon Dioxide) Slag (Minerals from Coal) Gas Clean-Up Before Product Use Water 7 NHA Annual Hydrogen Conference 2007

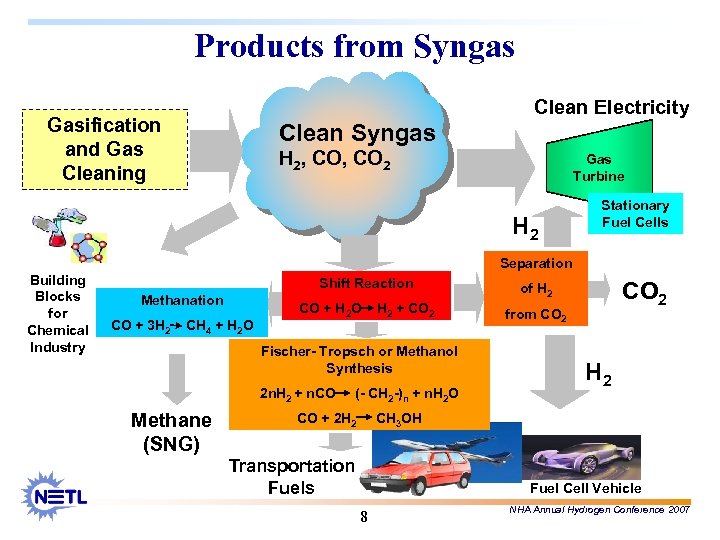

Products from Syngas Clean Electricity Gasification and Gas Cleaning Clean Syngas H 2, CO 2 Gas Turbine H 2 Stationary Fuel Cells Separation Building Blocks for Chemical Industry Shift Reaction Methanation CO + 3 H 2 CH 4 + H 2 O CO + H 2 O H 2 + CO 2 Fischer- Tropsch or Methanol Synthesis 2 n. H 2 + n. CO Methane (SNG) (- CH 2 -)n + n. H 2 O CO + 2 H 2 CO 2 of H 2 from CO 2 H 2 CH 3 OH Transportation Fuels Fuel Cell Vehicle 8 NHA Annual Hydrogen Conference 2007

Products from Syngas Clean Electricity Gasification and Gas Cleaning Clean Syngas H 2, CO 2 Gas Turbine H 2 Stationary Fuel Cells Separation Building Blocks for Chemical Industry Shift Reaction Methanation CO + 3 H 2 CH 4 + H 2 O CO + H 2 O H 2 + CO 2 Fischer- Tropsch or Methanol Synthesis 2 n. H 2 + n. CO Methane (SNG) (- CH 2 -)n + n. H 2 O CO + 2 H 2 CO 2 of H 2 from CO 2 H 2 CH 3 OH Transportation Fuels Fuel Cell Vehicle 8 NHA Annual Hydrogen Conference 2007

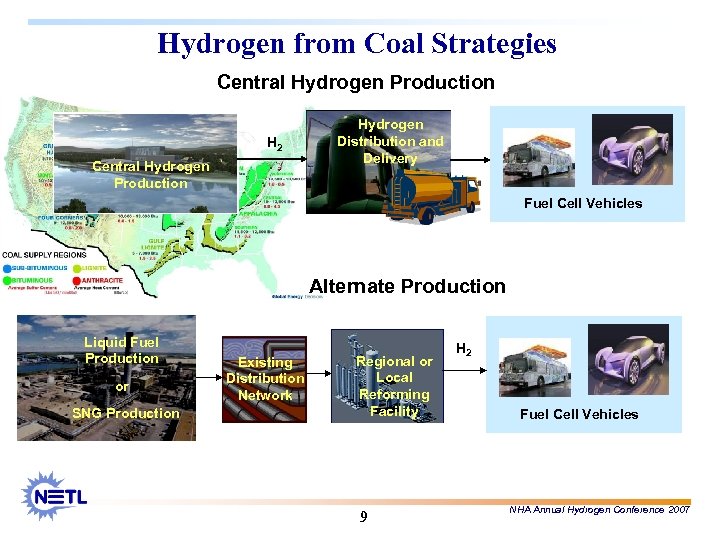

Hydrogen from Coal Strategies Central Hydrogen Production H 2 Central Hydrogen Production Hydrogen Distribution and Delivery Fuel Cell Vehicles Alternate Production Liquid Fuel Production or SNG Production Existing Distribution Network Regional or Local Reforming Facility 9 H 2 Fuel Cell Vehicles NHA Annual Hydrogen Conference 2007

Hydrogen from Coal Strategies Central Hydrogen Production H 2 Central Hydrogen Production Hydrogen Distribution and Delivery Fuel Cell Vehicles Alternate Production Liquid Fuel Production or SNG Production Existing Distribution Network Regional or Local Reforming Facility 9 H 2 Fuel Cell Vehicles NHA Annual Hydrogen Conference 2007

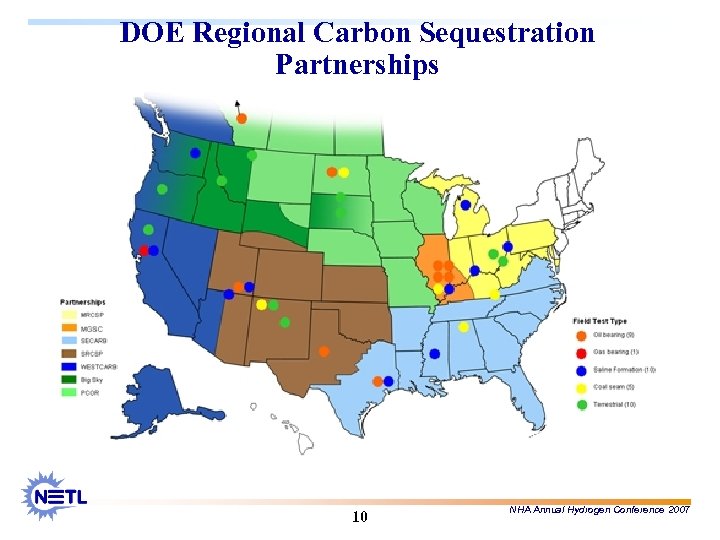

DOE Regional Carbon Sequestration Partnerships 10 NHA Annual Hydrogen Conference 2007

DOE Regional Carbon Sequestration Partnerships 10 NHA Annual Hydrogen Conference 2007

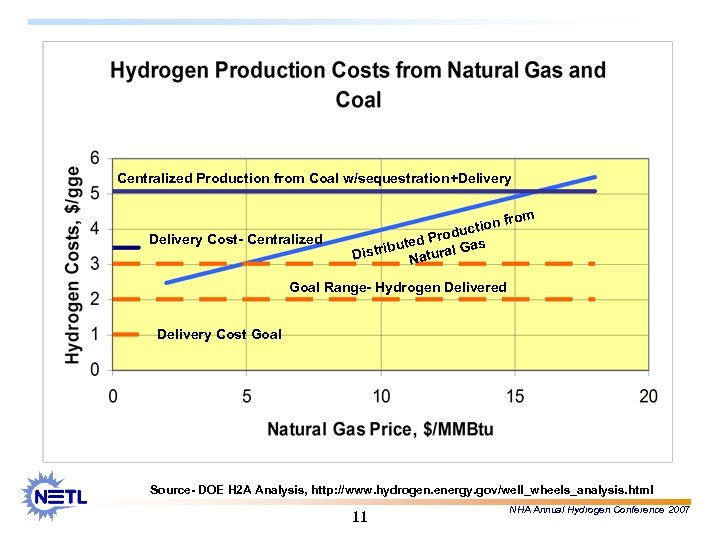

Centralized Production from Coal w/sequestration+Delivery Cost- Centralized n from uctio Prod uted al Gas ib Distr Natur Goal Range- Hydrogen Delivered Delivery Cost Goal Source- DOE H 2 A Analysis, http: //www. hydrogen. energy. gov/well_wheels_analysis. html 11 NHA Annual Hydrogen Conference 2007

Centralized Production from Coal w/sequestration+Delivery Cost- Centralized n from uctio Prod uted al Gas ib Distr Natur Goal Range- Hydrogen Delivered Delivery Cost Goal Source- DOE H 2 A Analysis, http: //www. hydrogen. energy. gov/well_wheels_analysis. html 11 NHA Annual Hydrogen Conference 2007

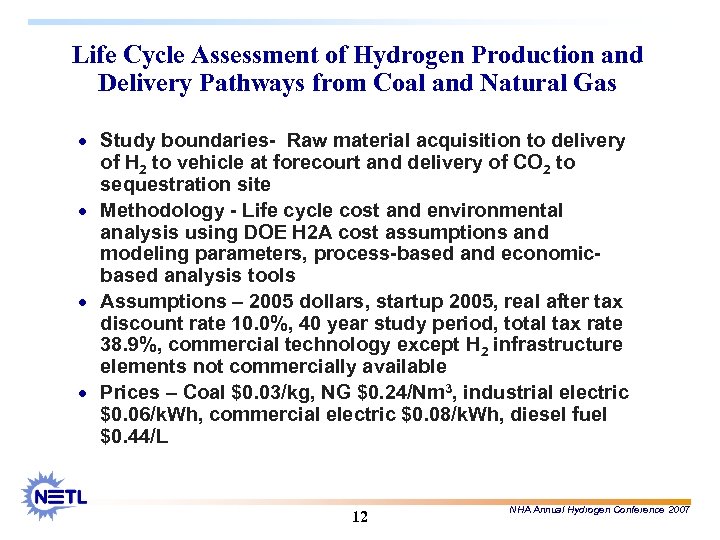

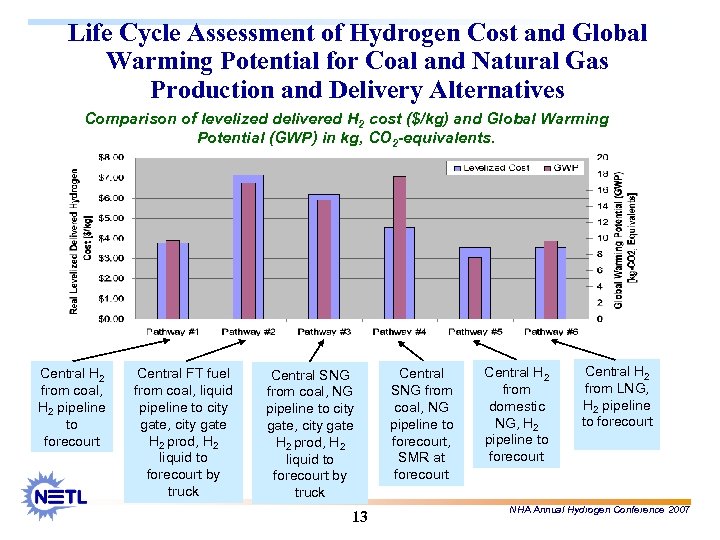

Life Cycle Assessment of Hydrogen Production and Delivery Pathways from Coal and Natural Gas · Study boundaries- Raw material acquisition to delivery of H 2 to vehicle at forecourt and delivery of CO 2 to sequestration site · Methodology - Life cycle cost and environmental analysis using DOE H 2 A cost assumptions and modeling parameters, process-based and economicbased analysis tools · Assumptions – 2005 dollars, startup 2005, real after tax discount rate 10. 0%, 40 year study period, total tax rate 38. 9%, commercial technology except H 2 infrastructure elements not commercially available · Prices – Coal $0. 03/kg, NG $0. 24/Nm 3, industrial electric $0. 06/k. Wh, commercial electric $0. 08/k. Wh, diesel fuel $0. 44/L 12 NHA Annual Hydrogen Conference 2007

Life Cycle Assessment of Hydrogen Production and Delivery Pathways from Coal and Natural Gas · Study boundaries- Raw material acquisition to delivery of H 2 to vehicle at forecourt and delivery of CO 2 to sequestration site · Methodology - Life cycle cost and environmental analysis using DOE H 2 A cost assumptions and modeling parameters, process-based and economicbased analysis tools · Assumptions – 2005 dollars, startup 2005, real after tax discount rate 10. 0%, 40 year study period, total tax rate 38. 9%, commercial technology except H 2 infrastructure elements not commercially available · Prices – Coal $0. 03/kg, NG $0. 24/Nm 3, industrial electric $0. 06/k. Wh, commercial electric $0. 08/k. Wh, diesel fuel $0. 44/L 12 NHA Annual Hydrogen Conference 2007

Life Cycle Assessment of Hydrogen Cost and Global Warming Potential for Coal and Natural Gas Production and Delivery Alternatives Comparison of levelized delivered H 2 cost ($/kg) and Global Warming Potential (GWP) in kg, CO 2 -equivalents. Central H 2 from coal, H 2 pipeline to forecourt Central FT fuel from coal, liquid pipeline to city gate, city gate H 2 prod, H 2 liquid to forecourt by truck Central SNG from coal, NG pipeline to city gate, city gate H 2 prod, H 2 liquid to forecourt by truck 13 Central SNG from coal, NG pipeline to forecourt, SMR at forecourt Central H 2 from domestic NG, H 2 pipeline to forecourt Central H 2 from LNG, H 2 pipeline to forecourt NHA Annual Hydrogen Conference 2007

Life Cycle Assessment of Hydrogen Cost and Global Warming Potential for Coal and Natural Gas Production and Delivery Alternatives Comparison of levelized delivered H 2 cost ($/kg) and Global Warming Potential (GWP) in kg, CO 2 -equivalents. Central H 2 from coal, H 2 pipeline to forecourt Central FT fuel from coal, liquid pipeline to city gate, city gate H 2 prod, H 2 liquid to forecourt by truck Central SNG from coal, NG pipeline to city gate, city gate H 2 prod, H 2 liquid to forecourt by truck 13 Central SNG from coal, NG pipeline to forecourt, SMR at forecourt Central H 2 from domestic NG, H 2 pipeline to forecourt Central H 2 from LNG, H 2 pipeline to forecourt NHA Annual Hydrogen Conference 2007

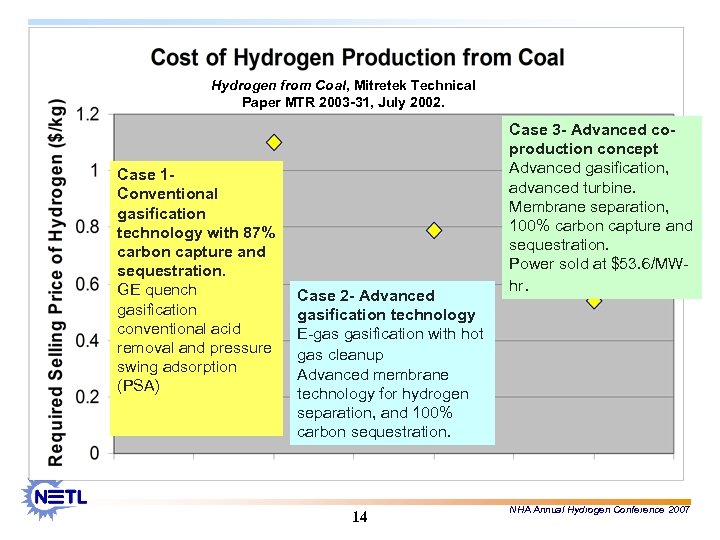

Hydrogen from Coal, Mitretek Technical Paper MTR 2003 -31, July 2002. Case 1 Conventional gasification technology with 87% carbon capture and sequestration. GE quench gasification conventional acid removal and pressure swing adsorption (PSA) Case 2 - Advanced gasification technology E-gas gasification with hot gas cleanup Advanced membrane technology for hydrogen separation, and 100% carbon sequestration. 14 Case 3 - Advanced coproduction concept Advanced gasification, advanced turbine. Membrane separation, 100% carbon capture and sequestration. Power sold at $53. 6/MWhr. NHA Annual Hydrogen Conference 2007

Hydrogen from Coal, Mitretek Technical Paper MTR 2003 -31, July 2002. Case 1 Conventional gasification technology with 87% carbon capture and sequestration. GE quench gasification conventional acid removal and pressure swing adsorption (PSA) Case 2 - Advanced gasification technology E-gas gasification with hot gas cleanup Advanced membrane technology for hydrogen separation, and 100% carbon sequestration. 14 Case 3 - Advanced coproduction concept Advanced gasification, advanced turbine. Membrane separation, 100% carbon capture and sequestration. Power sold at $53. 6/MWhr. NHA Annual Hydrogen Conference 2007

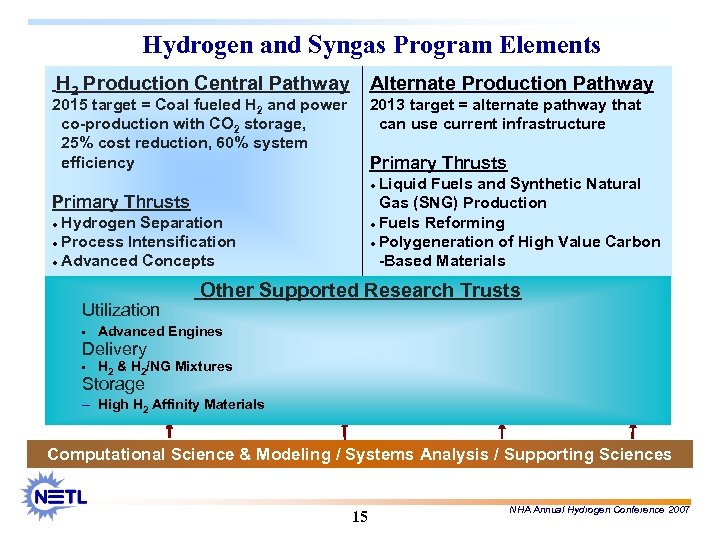

Hydrogen and Syngas Program Elements H 2 Production Central Pathway Alternate Production Pathway 2015 target = Coal fueled H 2 and power co-production with CO 2 storage, 25% cost reduction, 60% system efficiency 2013 target = alternate pathway that can use current infrastructure Primary Thrusts · Liquid Fuels and Synthetic Natural Gas (SNG) Production · Fuels Reforming · Polygeneration of High Value Carbon -Based Materials Primary Thrusts · Hydrogen Separation · Process Intensification · Advanced Concepts Utilization • Other Supported Research Trusts Advanced Engines Delivery • H 2 & H 2/NG Mixtures Storage - High H 2 Affinity Materials Computational Science & Modeling / Systems Analysis / Supporting Sciences 15 NHA Annual Hydrogen Conference 2007

Hydrogen and Syngas Program Elements H 2 Production Central Pathway Alternate Production Pathway 2015 target = Coal fueled H 2 and power co-production with CO 2 storage, 25% cost reduction, 60% system efficiency 2013 target = alternate pathway that can use current infrastructure Primary Thrusts · Liquid Fuels and Synthetic Natural Gas (SNG) Production · Fuels Reforming · Polygeneration of High Value Carbon -Based Materials Primary Thrusts · Hydrogen Separation · Process Intensification · Advanced Concepts Utilization • Other Supported Research Trusts Advanced Engines Delivery • H 2 & H 2/NG Mixtures Storage - High H 2 Affinity Materials Computational Science & Modeling / Systems Analysis / Supporting Sciences 15 NHA Annual Hydrogen Conference 2007

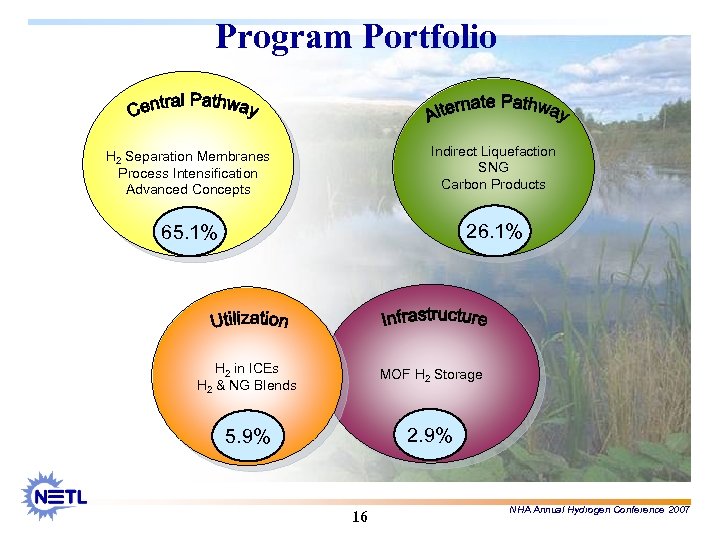

Program Portfolio H 2 Separation Membranes Process Intensification Advanced Concepts Indirect Liquefaction SNG Carbon Products 65. 1% 26. 1% H 2 in ICEs H 2 & NG Blends MOF H 2 Storage 5. 9% 2. 9% 16 NHA Annual Hydrogen Conference 2007

Program Portfolio H 2 Separation Membranes Process Intensification Advanced Concepts Indirect Liquefaction SNG Carbon Products 65. 1% 26. 1% H 2 in ICEs H 2 & NG Blends MOF H 2 Storage 5. 9% 2. 9% 16 NHA Annual Hydrogen Conference 2007

Central Production Pathway Milestones: · By end of 2007, downselect the most promising membrane separation technologies · By end of 2008, make go/no-go decision on further development of advanced WGS reaction technologies · By end of 2011, complete development of preengineering modules for producing high-purity hydrogen, based on integrated process studies · By end of 2013, complete design & construction of engineering scale modules for hydrogen production from coal gasification combined-cycle co-production plant · By end of 2015, demonstrate hydrogen modules integrated into a near-zero emission plant concept producing hydrogen and electric power with sequestration at a 25 percent lower cost for hydrogen 17 NHA Annual Hydrogen Conference 2007

Central Production Pathway Milestones: · By end of 2007, downselect the most promising membrane separation technologies · By end of 2008, make go/no-go decision on further development of advanced WGS reaction technologies · By end of 2011, complete development of preengineering modules for producing high-purity hydrogen, based on integrated process studies · By end of 2013, complete design & construction of engineering scale modules for hydrogen production from coal gasification combined-cycle co-production plant · By end of 2015, demonstrate hydrogen modules integrated into a near-zero emission plant concept producing hydrogen and electric power with sequestration at a 25 percent lower cost for hydrogen 17 NHA Annual Hydrogen Conference 2007

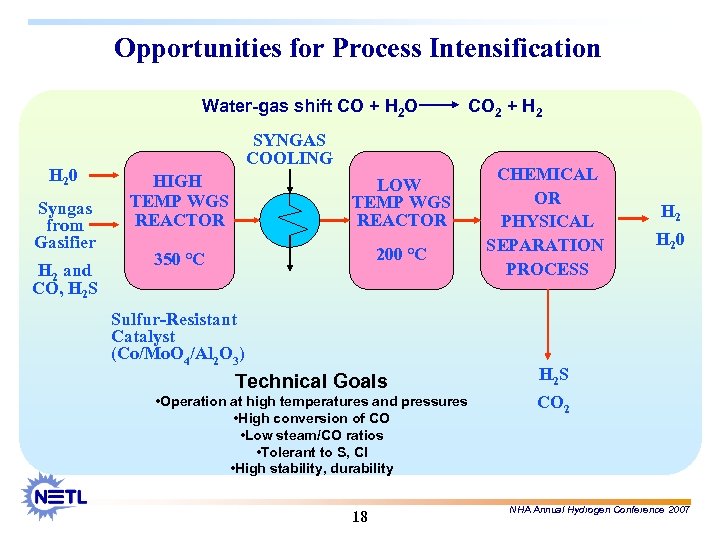

Opportunities for Process Intensification Water-gas shift CO + H 2 O H 2 0 Syngas from Gasifier H 2 and CO, H 2 S SYNGAS COOLING HIGH TEMP WGS REACTOR LOW TEMP WGS REACTOR 350 °C 200 °C Sulfur-Resistant Catalyst (Co/Mo. O 4/Al 2 O 3) CO 2 + H 2 CHEMICAL OR PHYSICAL SEPARATION PROCESS Technical Goals H 2 0 H 2 S • Operation at high temperatures and pressures • High conversion of CO • Low steam/CO ratios • Tolerant to S, Cl • High stability, durability H 2 CO 2 18 NHA Annual Hydrogen Conference 2007

Opportunities for Process Intensification Water-gas shift CO + H 2 O H 2 0 Syngas from Gasifier H 2 and CO, H 2 S SYNGAS COOLING HIGH TEMP WGS REACTOR LOW TEMP WGS REACTOR 350 °C 200 °C Sulfur-Resistant Catalyst (Co/Mo. O 4/Al 2 O 3) CO 2 + H 2 CHEMICAL OR PHYSICAL SEPARATION PROCESS Technical Goals H 2 0 H 2 S • Operation at high temperatures and pressures • High conversion of CO • Low steam/CO ratios • Tolerant to S, Cl • High stability, durability H 2 CO 2 18 NHA Annual Hydrogen Conference 2007

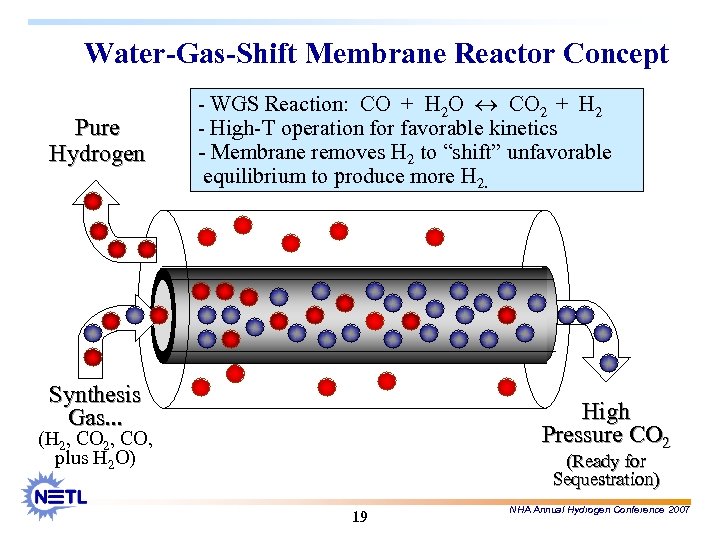

Water-Gas-Shift Membrane Reactor Concept Pure Hydrogen - WGS Reaction: CO + H 2 O CO 2 + H 2 - High-T operation for favorable kinetics - Membrane removes H 2 to “shift” unfavorable equilibrium to produce more H 2. Synthesis Gas. . . High Pressure CO 2 (H 2, CO, plus H 2 O) (Ready for Sequestration) 19 NHA Annual Hydrogen Conference 2007

Water-Gas-Shift Membrane Reactor Concept Pure Hydrogen - WGS Reaction: CO + H 2 O CO 2 + H 2 - High-T operation for favorable kinetics - Membrane removes H 2 to “shift” unfavorable equilibrium to produce more H 2. Synthesis Gas. . . High Pressure CO 2 (H 2, CO, plus H 2 O) (Ready for Sequestration) 19 NHA Annual Hydrogen Conference 2007

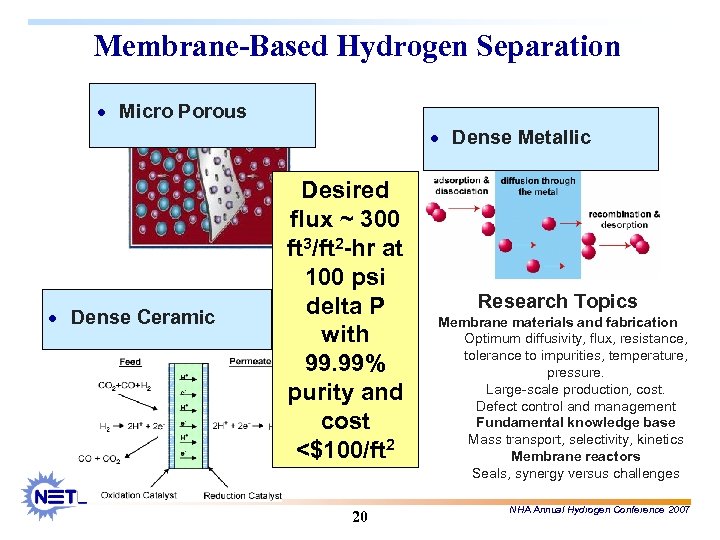

Membrane-Based Hydrogen Separation · Micro Porous · Dense Metallic · Dense Ceramic Desired flux ~ 300 ft 3/ft 2 -hr at 100 psi delta P with 99. 99% purity and cost <$100/ft 2 20 Research Topics Membrane materials and fabrication Optimum diffusivity, flux, resistance, tolerance to impurities, temperature, pressure. Large-scale production, cost. Defect control and management Fundamental knowledge base Mass transport, selectivity, kinetics Membrane reactors Seals, synergy versus challenges NHA Annual Hydrogen Conference 2007

Membrane-Based Hydrogen Separation · Micro Porous · Dense Metallic · Dense Ceramic Desired flux ~ 300 ft 3/ft 2 -hr at 100 psi delta P with 99. 99% purity and cost <$100/ft 2 20 Research Topics Membrane materials and fabrication Optimum diffusivity, flux, resistance, tolerance to impurities, temperature, pressure. Large-scale production, cost. Defect control and management Fundamental knowledge base Mass transport, selectivity, kinetics Membrane reactors Seals, synergy versus challenges NHA Annual Hydrogen Conference 2007

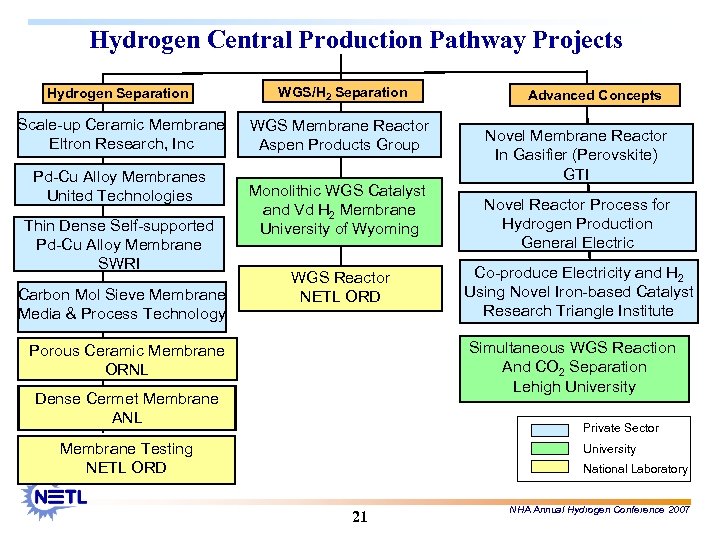

Hydrogen Central Production Pathway Projects Hydrogen Separation WGS/H 2 Separation Scale-up Ceramic Membrane Eltron Research, Inc WGS Membrane Reactor Aspen Products Group Pd-Cu Alloy Membranes United Technologies Thin Dense Self-supported Pd-Cu Alloy Membrane SWRI Carbon Mol Sieve Membrane Media & Process Technology Monolithic WGS Catalyst and Vd H 2 Membrane University of Wyoming WGS Reactor NETL ORD Advanced Concepts Novel Membrane Reactor In Gasifier (Perovskite) GTI Novel Reactor Process for Hydrogen Production General Electric Co-produce Electricity and H 2 Using Novel Iron-based Catalyst Research Triangle Institute Simultaneous WGS Reaction And CO 2 Separation Lehigh University Porous Ceramic Membrane ORNL Dense Cermet Membrane ANL Private Sector Membrane Testing NETL ORD University National Laboratory 21 NHA Annual Hydrogen Conference 2007

Hydrogen Central Production Pathway Projects Hydrogen Separation WGS/H 2 Separation Scale-up Ceramic Membrane Eltron Research, Inc WGS Membrane Reactor Aspen Products Group Pd-Cu Alloy Membranes United Technologies Thin Dense Self-supported Pd-Cu Alloy Membrane SWRI Carbon Mol Sieve Membrane Media & Process Technology Monolithic WGS Catalyst and Vd H 2 Membrane University of Wyoming WGS Reactor NETL ORD Advanced Concepts Novel Membrane Reactor In Gasifier (Perovskite) GTI Novel Reactor Process for Hydrogen Production General Electric Co-produce Electricity and H 2 Using Novel Iron-based Catalyst Research Triangle Institute Simultaneous WGS Reaction And CO 2 Separation Lehigh University Porous Ceramic Membrane ORNL Dense Cermet Membrane ANL Private Sector Membrane Testing NETL ORD University National Laboratory 21 NHA Annual Hydrogen Conference 2007

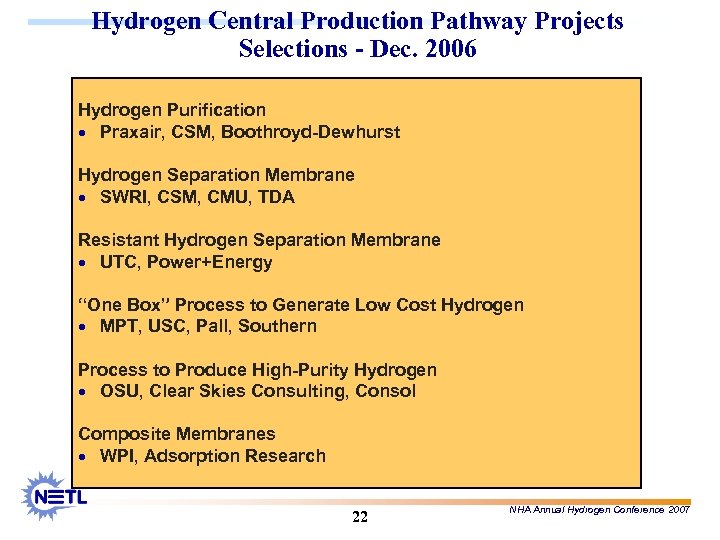

Hydrogen Central Production Pathway Projects Selections - Dec. 2006 Hydrogen Purification · Praxair, CSM, Boothroyd-Dewhurst Hydrogen Separation Membrane · SWRI, CSM, CMU, TDA Resistant Hydrogen Separation Membrane · UTC, Power+Energy “One Box” Process to Generate Low Cost Hydrogen · MPT, USC, Pall, Southern Process to Produce High-Purity Hydrogen · OSU, Clear Skies Consulting, Consol Composite Membranes · WPI, Adsorption Research 22 NHA Annual Hydrogen Conference 2007

Hydrogen Central Production Pathway Projects Selections - Dec. 2006 Hydrogen Purification · Praxair, CSM, Boothroyd-Dewhurst Hydrogen Separation Membrane · SWRI, CSM, CMU, TDA Resistant Hydrogen Separation Membrane · UTC, Power+Energy “One Box” Process to Generate Low Cost Hydrogen · MPT, USC, Pall, Southern Process to Produce High-Purity Hydrogen · OSU, Clear Skies Consulting, Consol Composite Membranes · WPI, Adsorption Research 22 NHA Annual Hydrogen Conference 2007

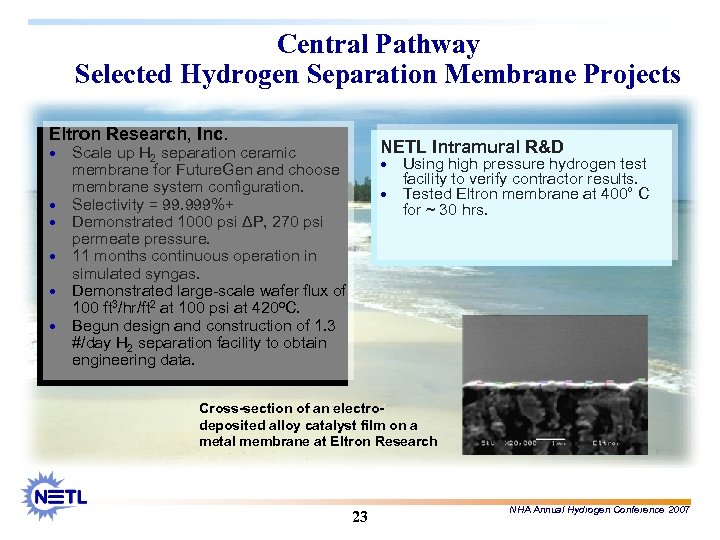

Central Pathway Selected Hydrogen Separation Membrane Projects Eltron Research, Inc. · · · NETL Intramural R&D Scale up H 2 separation ceramic membrane for Future. Gen and choose membrane system configuration. Selectivity = 99. 999%+ Demonstrated 1000 psi ΔP, 270 psi permeate pressure. 11 months continuous operation in simulated syngas. Demonstrated large-scale wafer flux of 100 ft 3/hr/ft 2 at 100 psi at 420 o. C. Begun design and construction of 1. 3 #/day H 2 separation facility to obtain engineering data. · Using high pressure hydrogen test facility to verify contractor results. · Tested Eltron membrane at 400° C for ~ 30 hrs. Cross-section of an electrodeposited alloy catalyst film on a metal membrane at Eltron Research 23 NHA Annual Hydrogen Conference 2007

Central Pathway Selected Hydrogen Separation Membrane Projects Eltron Research, Inc. · · · NETL Intramural R&D Scale up H 2 separation ceramic membrane for Future. Gen and choose membrane system configuration. Selectivity = 99. 999%+ Demonstrated 1000 psi ΔP, 270 psi permeate pressure. 11 months continuous operation in simulated syngas. Demonstrated large-scale wafer flux of 100 ft 3/hr/ft 2 at 100 psi at 420 o. C. Begun design and construction of 1. 3 #/day H 2 separation facility to obtain engineering data. · Using high pressure hydrogen test facility to verify contractor results. · Tested Eltron membrane at 400° C for ~ 30 hrs. Cross-section of an electrodeposited alloy catalyst film on a metal membrane at Eltron Research 23 NHA Annual Hydrogen Conference 2007

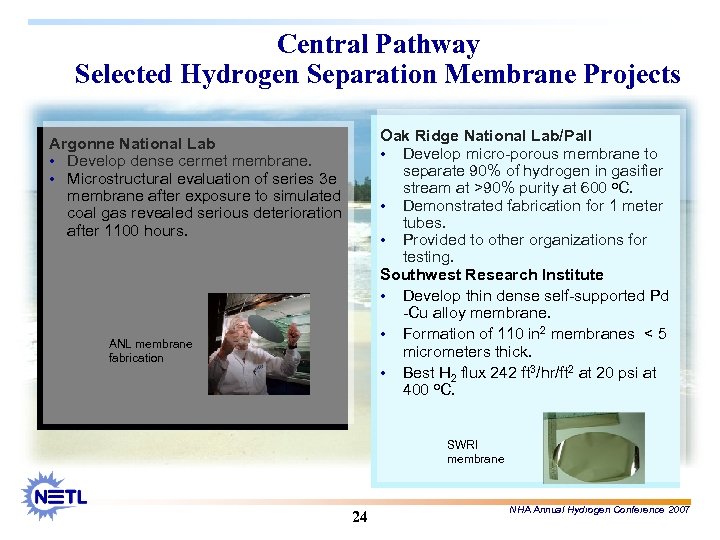

Central Pathway Selected Hydrogen Separation Membrane Projects Oak Ridge National Lab/Pall • Develop micro-porous membrane to separate 90% of hydrogen in gasifier stream at >90% purity at 600 o. C. • Demonstrated fabrication for 1 meter tubes. • Provided to other organizations for testing. Southwest Research Institute • Develop thin dense self-supported Pd -Cu alloy membrane. • Formation of 110 in 2 membranes < 5 micrometers thick. • Best H 2 flux 242 ft 3/hr/ft 2 at 20 psi at 400 o. C. Argonne National Lab • Develop dense cermet membrane. • Microstructural evaluation of series 3 e membrane after exposure to simulated coal gas revealed serious deterioration after 1100 hours. ANL membrane fabrication SWRI membrane 24 NHA Annual Hydrogen Conference 2007

Central Pathway Selected Hydrogen Separation Membrane Projects Oak Ridge National Lab/Pall • Develop micro-porous membrane to separate 90% of hydrogen in gasifier stream at >90% purity at 600 o. C. • Demonstrated fabrication for 1 meter tubes. • Provided to other organizations for testing. Southwest Research Institute • Develop thin dense self-supported Pd -Cu alloy membrane. • Formation of 110 in 2 membranes < 5 micrometers thick. • Best H 2 flux 242 ft 3/hr/ft 2 at 20 psi at 400 o. C. Argonne National Lab • Develop dense cermet membrane. • Microstructural evaluation of series 3 e membrane after exposure to simulated coal gas revealed serious deterioration after 1100 hours. ANL membrane fabrication SWRI membrane 24 NHA Annual Hydrogen Conference 2007

Central Pathway Selected WGS Reactor/Hydrogen Separation Membrane Projects Aspen Products Group • Develop a robust WGS membrane reactor using contaminant-tolerant, highly active WGS catalyst and Pd/Cu coated Ta membrane. • Demonstrated that a low-cost nanosized WGS catalyst is active and stable in 300 -500 °C range. • Fabricated 26 tubular membranes with different catalyst coatings and layer thicknesses • Demonstrated high H 2 permeability in presence of H 2 S and water. Media & Process Technology • Construct commercially-ready membrane reactor for CO 2 capture with low parasitic energy. • Achieved complete conversion of CO and concentration of CO 2 in single-stage WGS-MR at low shift -T and stoichiometric steam/CO ratio. • Excellent H 2 permeance and selectivity in presence of contaminants • Superior performance and costs relative to program goals. 25 NHA Annual Hydrogen Conference 2007

Central Pathway Selected WGS Reactor/Hydrogen Separation Membrane Projects Aspen Products Group • Develop a robust WGS membrane reactor using contaminant-tolerant, highly active WGS catalyst and Pd/Cu coated Ta membrane. • Demonstrated that a low-cost nanosized WGS catalyst is active and stable in 300 -500 °C range. • Fabricated 26 tubular membranes with different catalyst coatings and layer thicknesses • Demonstrated high H 2 permeability in presence of H 2 S and water. Media & Process Technology • Construct commercially-ready membrane reactor for CO 2 capture with low parasitic energy. • Achieved complete conversion of CO and concentration of CO 2 in single-stage WGS-MR at low shift -T and stoichiometric steam/CO ratio. • Excellent H 2 permeance and selectivity in presence of contaminants • Superior performance and costs relative to program goals. 25 NHA Annual Hydrogen Conference 2007

Central Pathway Selected WGS Reactor/Hydrogen Separation Membrane Projects United Technologies, Corp. • Identify Pd-Cu tri-metallic alloy membranes with high stability and hydrogen permeation: synthesize S and Cl tolerant WGS catalyst. • Two materials selected for study. • Selected composition range of 1. 0 to 1. 5 % for G 5 alloy. Permeation projected > B 2 bcc Pd-Cu. • Nine candidate WGS catalysts prepared analyzed; six selected for testing. University of Wyoming/WRI • Develop improved monolithic WGS catalyst and a vanadium alloy hydrogen separation membrane. Gas Technology Institute • Develop novel reactor to combine sulfur removal, WGS, and H 2/CO 2 separation using dual-phase nonporous membranes. • Constructed HTHP test unit. • Fabricated two membrane types. • One type had selectivity ~2000 for H 2 S over CO 2. • Another type showed CO 2 flux up to 0. 02 cc. STP/cm 2/min with selectivity over He. GTI supported membrane tube 26 NHA Annual Hydrogen Conference 2007

Central Pathway Selected WGS Reactor/Hydrogen Separation Membrane Projects United Technologies, Corp. • Identify Pd-Cu tri-metallic alloy membranes with high stability and hydrogen permeation: synthesize S and Cl tolerant WGS catalyst. • Two materials selected for study. • Selected composition range of 1. 0 to 1. 5 % for G 5 alloy. Permeation projected > B 2 bcc Pd-Cu. • Nine candidate WGS catalysts prepared analyzed; six selected for testing. University of Wyoming/WRI • Develop improved monolithic WGS catalyst and a vanadium alloy hydrogen separation membrane. Gas Technology Institute • Develop novel reactor to combine sulfur removal, WGS, and H 2/CO 2 separation using dual-phase nonporous membranes. • Constructed HTHP test unit. • Fabricated two membrane types. • One type had selectivity ~2000 for H 2 S over CO 2. • Another type showed CO 2 flux up to 0. 02 cc. STP/cm 2/min with selectivity over He. GTI supported membrane tube 26 NHA Annual Hydrogen Conference 2007

NETL Office of Research and Development (ORD) Computational chemistry and lab testing of sulfur-resistant Pd-alloys for WGS membrane reactor • Pd and 80 wt% Pd-Cu alloy exhibit significant catalytic effect on WGSR. • Above ~635 °C, all Pd-Cu alloys studied exhibited no detectable permeability loss on exposure to 1000 ppm H 2 S. All compositions are fcc above this temperature. • Major WGS gases have little effect on H 2 flux of 80/20 Pd-Cu membranes. Certain gas combinations and temperatures affect the membrane surface. • Completed study of 5 -day exposures to 1000 ppm H 2 S on Pd-Cu alloys (100, 80, 60, 53% Pd). • 60 wt%Pd-Cu alloy exhibited highest permeability at temperatures below ~500 o. C, little sulfur tolerance due to the bcc phase. • 80 wt%Pd-Cu alloy exhibited highest permeability at temperatures above ~500 o. C; sulfur tolerant due to the fcc phase. NETL Hydrogen Membrane Test Unit Inset- membrane reactor 27 NHA Annual Hydrogen Conference 2007

NETL Office of Research and Development (ORD) Computational chemistry and lab testing of sulfur-resistant Pd-alloys for WGS membrane reactor • Pd and 80 wt% Pd-Cu alloy exhibit significant catalytic effect on WGSR. • Above ~635 °C, all Pd-Cu alloys studied exhibited no detectable permeability loss on exposure to 1000 ppm H 2 S. All compositions are fcc above this temperature. • Major WGS gases have little effect on H 2 flux of 80/20 Pd-Cu membranes. Certain gas combinations and temperatures affect the membrane surface. • Completed study of 5 -day exposures to 1000 ppm H 2 S on Pd-Cu alloys (100, 80, 60, 53% Pd). • 60 wt%Pd-Cu alloy exhibited highest permeability at temperatures below ~500 o. C, little sulfur tolerance due to the bcc phase. • 80 wt%Pd-Cu alloy exhibited highest permeability at temperatures above ~500 o. C; sulfur tolerant due to the fcc phase. NETL Hydrogen Membrane Test Unit Inset- membrane reactor 27 NHA Annual Hydrogen Conference 2007

Alternate Hydrogen Production Pathway Milestones: · By the end of 2010, hydrogen-rich liquid fuels and SNG from coal technologies are feasible as an alternate hydrogen from coal production pathway and are able to meet the hydrogen cost target. · By the end of 2013, optimize, integrate and make available an alternate hydrogen production pathway and reforming system to produce decentralized hydrogen. 28 NHA Annual Hydrogen Conference 2007

Alternate Hydrogen Production Pathway Milestones: · By the end of 2010, hydrogen-rich liquid fuels and SNG from coal technologies are feasible as an alternate hydrogen from coal production pathway and are able to meet the hydrogen cost target. · By the end of 2013, optimize, integrate and make available an alternate hydrogen production pathway and reforming system to produce decentralized hydrogen. 28 NHA Annual Hydrogen Conference 2007

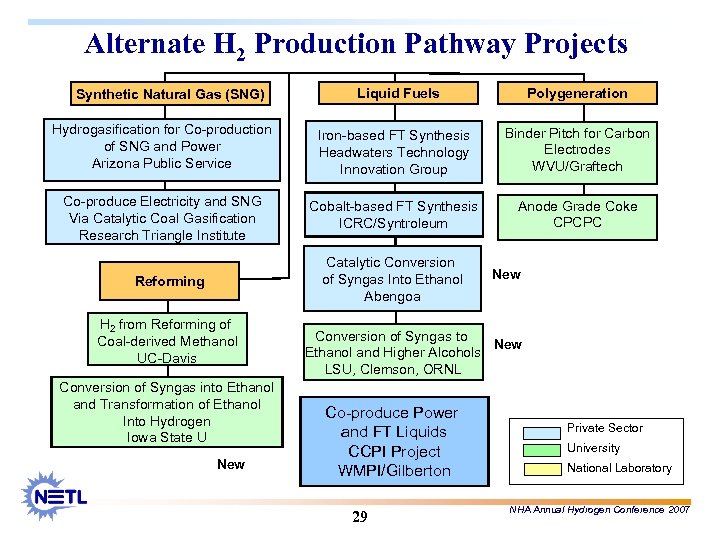

Alternate H 2 Production Pathway Projects Synthetic Natural Gas (SNG) Liquid Fuels Polygeneration Hydrogasification for Co-production of SNG and Power Arizona Public Service Iron-based FT Synthesis Headwaters Technology Innovation Group Binder Pitch for Carbon Electrodes WVU/Graftech Co-produce Electricity and SNG Via Catalytic Coal Gasification Research Triangle Institute Cobalt-based FT Synthesis ICRC/Syntroleum Anode Grade Coke CPCPC Catalytic Conversion of Syngas Into Ethanol Abengoa Reforming H 2 from Reforming of Coal-derived Methanol UC-Davis Conversion of Syngas into Ethanol and Transformation of Ethanol Into Hydrogen Iowa State U New Conversion of Syngas to New Ethanol and Higher Alcohols LSU, Clemson, ORNL Co-produce Power and FT Liquids CCPI Project WMPI/Gilberton 29 Private Sector University National Laboratory NHA Annual Hydrogen Conference 2007

Alternate H 2 Production Pathway Projects Synthetic Natural Gas (SNG) Liquid Fuels Polygeneration Hydrogasification for Co-production of SNG and Power Arizona Public Service Iron-based FT Synthesis Headwaters Technology Innovation Group Binder Pitch for Carbon Electrodes WVU/Graftech Co-produce Electricity and SNG Via Catalytic Coal Gasification Research Triangle Institute Cobalt-based FT Synthesis ICRC/Syntroleum Anode Grade Coke CPCPC Catalytic Conversion of Syngas Into Ethanol Abengoa Reforming H 2 from Reforming of Coal-derived Methanol UC-Davis Conversion of Syngas into Ethanol and Transformation of Ethanol Into Hydrogen Iowa State U New Conversion of Syngas to New Ethanol and Higher Alcohols LSU, Clemson, ORNL Co-produce Power and FT Liquids CCPI Project WMPI/Gilberton 29 Private Sector University National Laboratory NHA Annual Hydrogen Conference 2007

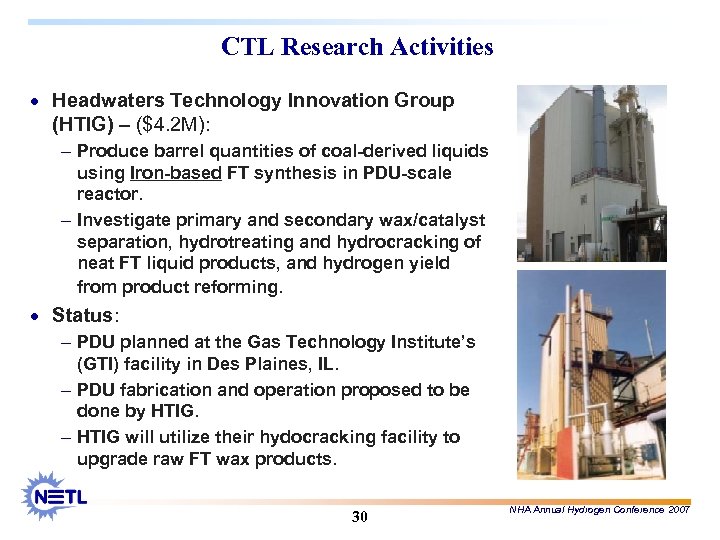

CTL Research Activities · Headwaters Technology Innovation Group (HTIG) – ($4. 2 M): - Produce barrel quantities of coal-derived liquids using Iron-based FT synthesis in PDU-scale reactor. - Investigate primary and secondary wax/catalyst separation, hydrotreating and hydrocracking of neat FT liquid products, and hydrogen yield from product reforming. · Status: - PDU planned at the Gas Technology Institute’s (GTI) facility in Des Plaines, IL. - PDU fabrication and operation proposed to be done by HTIG. - HTIG will utilize their hydocracking facility to upgrade raw FT wax products. 30 NHA Annual Hydrogen Conference 2007

CTL Research Activities · Headwaters Technology Innovation Group (HTIG) – ($4. 2 M): - Produce barrel quantities of coal-derived liquids using Iron-based FT synthesis in PDU-scale reactor. - Investigate primary and secondary wax/catalyst separation, hydrotreating and hydrocracking of neat FT liquid products, and hydrogen yield from product reforming. · Status: - PDU planned at the Gas Technology Institute’s (GTI) facility in Des Plaines, IL. - PDU fabrication and operation proposed to be done by HTIG. - HTIG will utilize their hydocracking facility to upgrade raw FT wax products. 30 NHA Annual Hydrogen Conference 2007

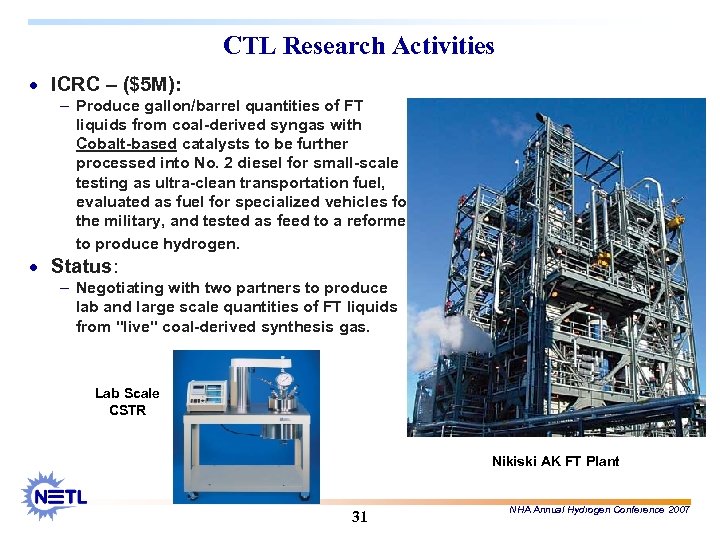

CTL Research Activities · ICRC – ($5 M): - Produce gallon/barrel quantities of FT liquids from coal-derived syngas with Cobalt-based catalysts to be further processed into No. 2 diesel for small-scale testing as ultra-clean transportation fuel, evaluated as fuel for specialized vehicles for the military, and tested as feed to a reformer to produce hydrogen. · Status: - Negotiating with two partners to produce lab and large scale quantities of FT liquids from "live" coal-derived synthesis gas. Lab Scale CSTR Nikiski AK FT Plant 31 NHA Annual Hydrogen Conference 2007

CTL Research Activities · ICRC – ($5 M): - Produce gallon/barrel quantities of FT liquids from coal-derived syngas with Cobalt-based catalysts to be further processed into No. 2 diesel for small-scale testing as ultra-clean transportation fuel, evaluated as fuel for specialized vehicles for the military, and tested as feed to a reformer to produce hydrogen. · Status: - Negotiating with two partners to produce lab and large scale quantities of FT liquids from "live" coal-derived synthesis gas. Lab Scale CSTR Nikiski AK FT Plant 31 NHA Annual Hydrogen Conference 2007

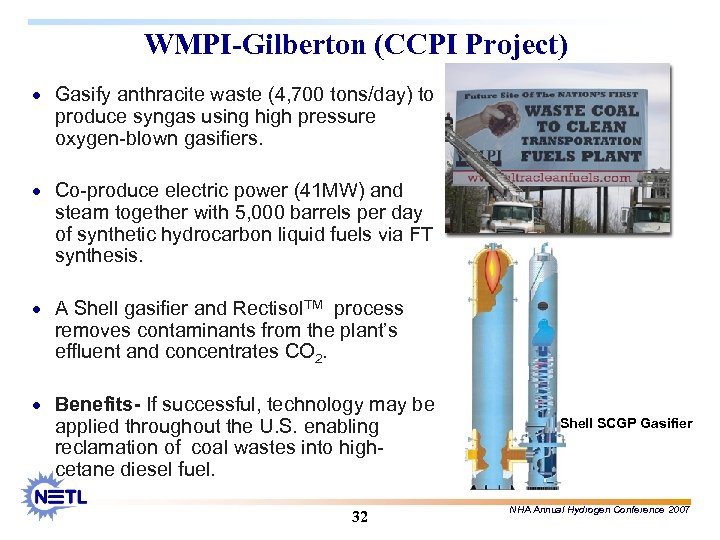

WMPI-Gilberton (CCPI Project) · Gasify anthracite waste (4, 700 tons/day) to produce syngas using high pressure oxygen-blown gasifiers. · Co-produce electric power (41 MW) and steam together with 5, 000 barrels per day of synthetic hydrocarbon liquid fuels via FT synthesis. · A Shell gasifier and Rectisol. TM process removes contaminants from the plant’s effluent and concentrates CO 2. · Benefits- If successful, technology may be applied throughout the U. S. enabling reclamation of coal wastes into highcetane diesel fuel. 32 Shell SCGP Gasifier NHA Annual Hydrogen Conference 2007

WMPI-Gilberton (CCPI Project) · Gasify anthracite waste (4, 700 tons/day) to produce syngas using high pressure oxygen-blown gasifiers. · Co-produce electric power (41 MW) and steam together with 5, 000 barrels per day of synthetic hydrocarbon liquid fuels via FT synthesis. · A Shell gasifier and Rectisol. TM process removes contaminants from the plant’s effluent and concentrates CO 2. · Benefits- If successful, technology may be applied throughout the U. S. enabling reclamation of coal wastes into highcetane diesel fuel. 32 Shell SCGP Gasifier NHA Annual Hydrogen Conference 2007

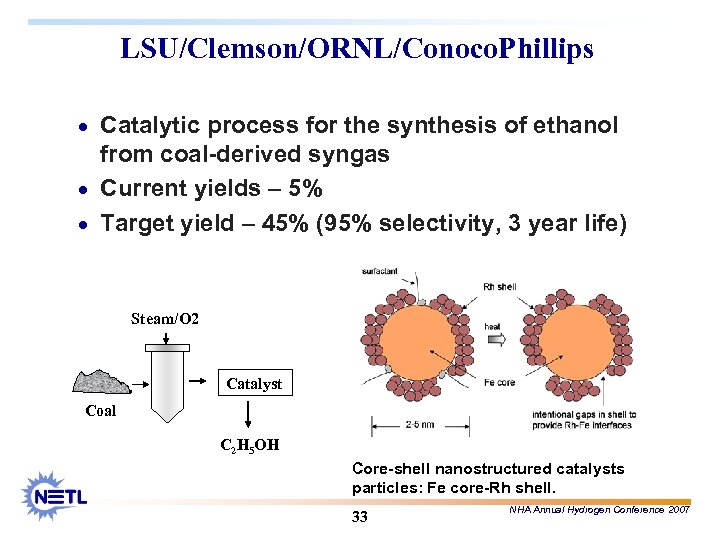

LSU/Clemson/ORNL/Conoco. Phillips · Catalytic process for the synthesis of ethanol from coal-derived syngas · Current yields – 5% · Target yield – 45% (95% selectivity, 3 year life) Steam/O 2 Catalyst Coal C 2 H 5 OH Core-shell nanostructured catalysts particles: Fe core-Rh shell. 33 NHA Annual Hydrogen Conference 2007

LSU/Clemson/ORNL/Conoco. Phillips · Catalytic process for the synthesis of ethanol from coal-derived syngas · Current yields – 5% · Target yield – 45% (95% selectivity, 3 year life) Steam/O 2 Catalyst Coal C 2 H 5 OH Core-shell nanostructured catalysts particles: Fe core-Rh shell. 33 NHA Annual Hydrogen Conference 2007

Utilization · Milestone: By the end of 2009, successfully complete small-scale research to modify and optimize advanced engine types fueled by hydrogen and/or hydrogen-natural gas mixtures. 34 NHA Annual Hydrogen Conference 2007

Utilization · Milestone: By the end of 2009, successfully complete small-scale research to modify and optimize advanced engine types fueled by hydrogen and/or hydrogen-natural gas mixtures. 34 NHA Annual Hydrogen Conference 2007

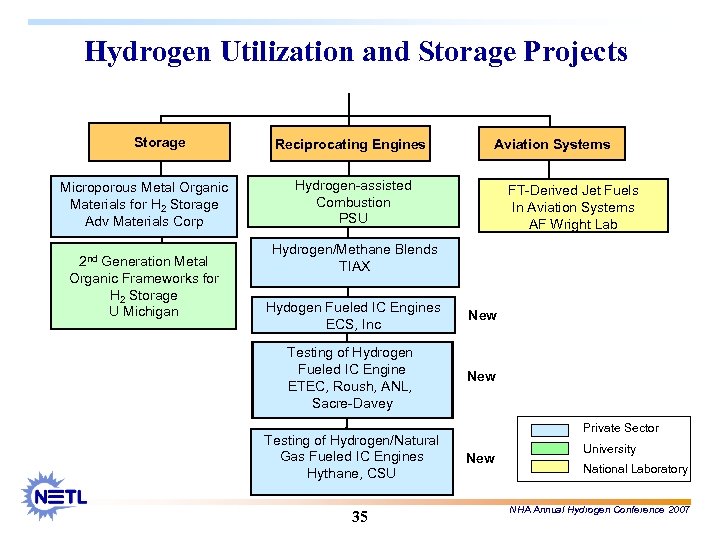

Hydrogen Utilization and Storage Projects Storage Microporous Metal Organic Materials for H 2 Storage Adv Materials Corp 2 nd Generation Metal Organic Frameworks for H 2 Storage U Michigan Reciprocating Engines Aviation Systems Hydrogen-assisted Combustion PSU FT-Derived Jet Fuels In Aviation Systems AF Wright Lab Hydrogen/Methane Blends TIAX Hydogen Fueled IC Engines ECS, Inc New Testing of Hydrogen Fueled IC Engine ETEC, Roush, ANL, Sacre-Davey New Testing of Hydrogen/Natural Gas Fueled IC Engines Hythane, CSU 35 Private Sector New University National Laboratory NHA Annual Hydrogen Conference 2007

Hydrogen Utilization and Storage Projects Storage Microporous Metal Organic Materials for H 2 Storage Adv Materials Corp 2 nd Generation Metal Organic Frameworks for H 2 Storage U Michigan Reciprocating Engines Aviation Systems Hydrogen-assisted Combustion PSU FT-Derived Jet Fuels In Aviation Systems AF Wright Lab Hydrogen/Methane Blends TIAX Hydogen Fueled IC Engines ECS, Inc New Testing of Hydrogen Fueled IC Engine ETEC, Roush, ANL, Sacre-Davey New Testing of Hydrogen/Natural Gas Fueled IC Engines Hythane, CSU 35 Private Sector New University National Laboratory NHA Annual Hydrogen Conference 2007

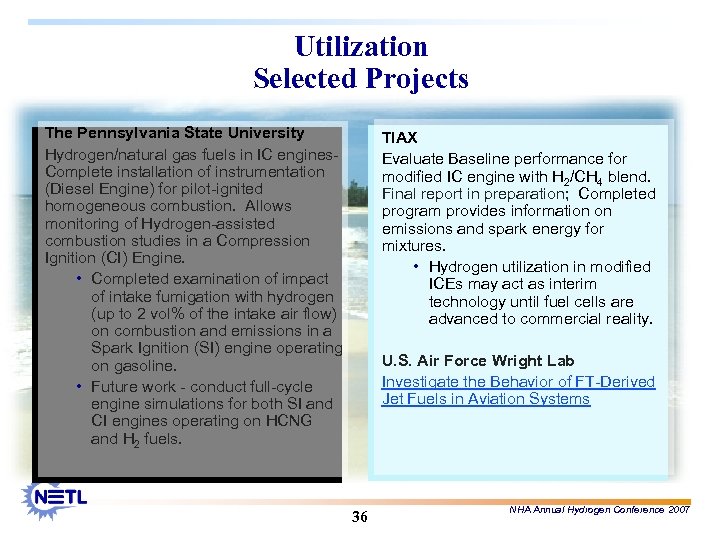

Utilization Selected Projects The Pennsylvania State University Hydrogen/natural gas fuels in IC engines. Complete installation of instrumentation (Diesel Engine) for pilot-ignited homogeneous combustion. Allows monitoring of Hydrogen-assisted combustion studies in a Compression Ignition (CI) Engine. • Completed examination of impact of intake fumigation with hydrogen (up to 2 vol% of the intake air flow) on combustion and emissions in a Spark Ignition (SI) engine operating on gasoline. • Future work - conduct full-cycle engine simulations for both SI and CI engines operating on HCNG and H 2 fuels. TIAX Evaluate Baseline performance for modified IC engine with H 2/CH 4 blend. Final report in preparation; Completed program provides information on emissions and spark energy for mixtures. • Hydrogen utilization in modified ICEs may act as interim technology until fuel cells are advanced to commercial reality. U. S. Air Force Wright Lab Investigate the Behavior of FT-Derived Jet Fuels in Aviation Systems 36 NHA Annual Hydrogen Conference 2007

Utilization Selected Projects The Pennsylvania State University Hydrogen/natural gas fuels in IC engines. Complete installation of instrumentation (Diesel Engine) for pilot-ignited homogeneous combustion. Allows monitoring of Hydrogen-assisted combustion studies in a Compression Ignition (CI) Engine. • Completed examination of impact of intake fumigation with hydrogen (up to 2 vol% of the intake air flow) on combustion and emissions in a Spark Ignition (SI) engine operating on gasoline. • Future work - conduct full-cycle engine simulations for both SI and CI engines operating on HCNG and H 2 fuels. TIAX Evaluate Baseline performance for modified IC engine with H 2/CH 4 blend. Final report in preparation; Completed program provides information on emissions and spark energy for mixtures. • Hydrogen utilization in modified ICEs may act as interim technology until fuel cells are advanced to commercial reality. U. S. Air Force Wright Lab Investigate the Behavior of FT-Derived Jet Fuels in Aviation Systems 36 NHA Annual Hydrogen Conference 2007

Summary · Hydrogen from coal can play a key role in future hydrogen economy and contribute to GHG emission reductions · When used in tandem with carbon sequestration, the central station production of hydrogen from coal would result in virtually no greenhouse gas and pollutant emissions · Hydrogen and Syngas Program R&D will reduce production costs and provide technology to test in Future. Gen - Goals are to reduce cost and complexity of processes, 25% cost reduction in hydrogen production cost is achievable · Initial bench-scale success in H 2 separation membranes achieved 2007 flux goal early · This R&D will contribute to improving hydrogen production from other resources such as biomass and natural gas · Alternate pathway provides options and contributes to CTL and SNG technology 37 NHA Annual Hydrogen Conference 2007

Summary · Hydrogen from coal can play a key role in future hydrogen economy and contribute to GHG emission reductions · When used in tandem with carbon sequestration, the central station production of hydrogen from coal would result in virtually no greenhouse gas and pollutant emissions · Hydrogen and Syngas Program R&D will reduce production costs and provide technology to test in Future. Gen - Goals are to reduce cost and complexity of processes, 25% cost reduction in hydrogen production cost is achievable · Initial bench-scale success in H 2 separation membranes achieved 2007 flux goal early · This R&D will contribute to improving hydrogen production from other resources such as biomass and natural gas · Alternate pathway provides options and contributes to CTL and SNG technology 37 NHA Annual Hydrogen Conference 2007