4d2271eeabfb187c33eec27e2997498f.ppt

- Количество слайдов: 41

Hybrid Organic-Inorganic, POSS Materials Lecture 4 & Quiz September 28 th

Today First hour: • Some definitions • Strategies for making Hybrids Second hour: • Quiz • Discussion of quiz answers

Course website • For lecture slides and other info. • Not at HIT website, at Loy research website: http: //www. loyresearchgroup. com/ • Go to loy research group home page and select “courses” on menu at top. • Class website “Harbin Institute of Technology, Hybrid Materials Course” is the first entry. Direct url: http: //www. loyresearchgroup. com/harbininstitute-technology---hybrid-materialscourse. html

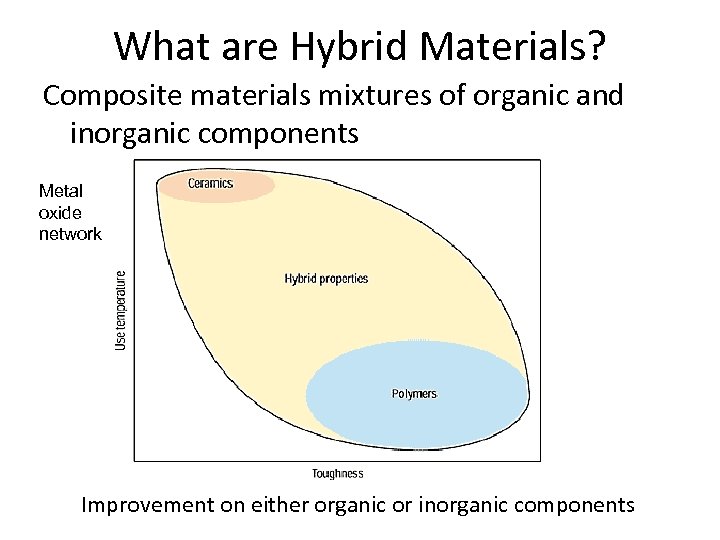

What are Hybrid Materials? Composite materials mixtures of organic and inorganic components Metal oxide network Improvement on either organic or inorganic components

Introduction to polysilsesquioxanes Network of Si-O-Si Organic group (alkyl, aryl, alkenyl) attached through Si-C bond Fully condensed: 1. 5 oxygens per Si Three siloxane bonds per silicon

Where are the organic and inorganic phases? • Segregation only at sub-molecular length scales. • Hybrid, synergistic properties come from very high surface area contact between phases

Silsesquioxane Silicon 1. 5 Oxygens Polysilsesquioxane Many generally means more than 10, 000 Dalto

Oligosilsesquioxane A few Silicon 1. 5 Oxygens Oligo means > 1 and < 50 -100 (depends on Mw or R group)

Nomenclature of silsesquioxanes • Polymers: poly(name of organic-silsesquioxane) eg. R = Ph or phenyl poly(phenylsilsesquioxane)

Nomenclature of silsesquioxanes • oligomers: oligo(name of organic-silsesquioxane) eg. R = Ph or phenyl poly(oligosilsesquioxane)

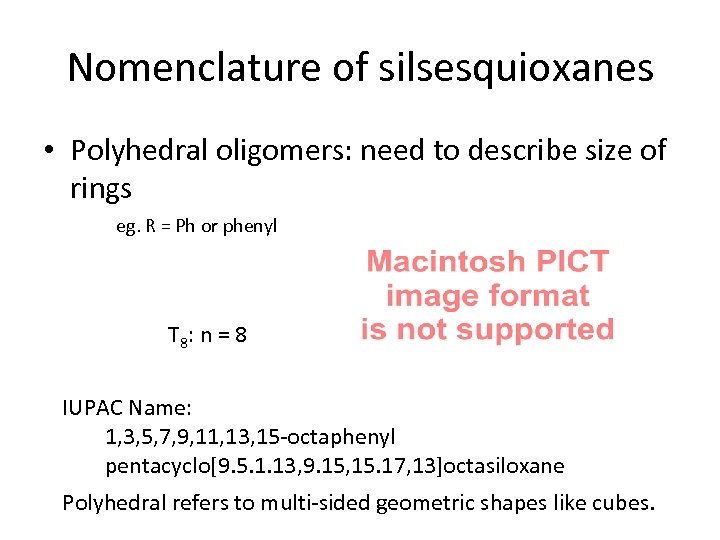

Nomenclature of silsesquioxanes • Polyhedral oligomers: need to describe size of rings eg. R = Ph or phenyl T 8 : n = 8 IUPAC Name: 1, 3, 5, 7, 9, 11, 13, 15 -octaphenyl pentacyclo[9. 5. 1. 13, 9. 15, 15. 17, 13]octasiloxane Polyhedral refers to multi-sided geometric shapes like cubes.

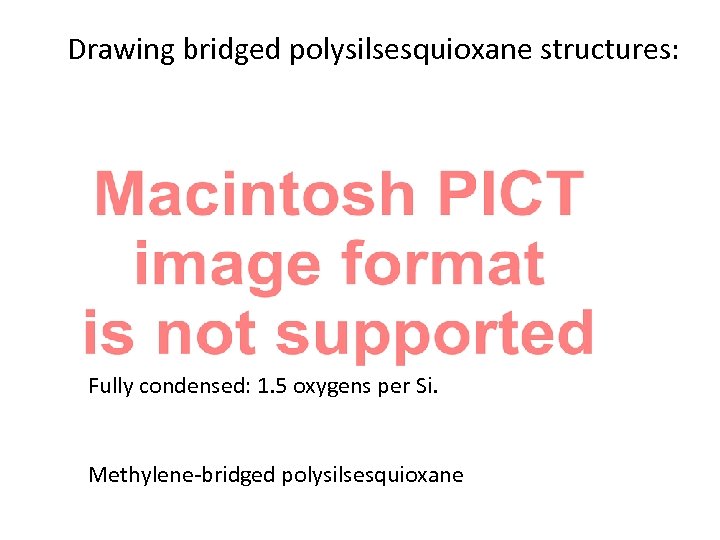

Drawing bridged polysilsesquioxane structures: Fully condensed: 1. 5 oxygens per Si. Methylene-bridged polysilsesquioxane

bridged polysilsesquioxane nomenclature: Methylene-bridged polysilsesquioxane Not “methane-bridged” These are not silicas Not “methano-bridged” These are not silicates Not “methano-silica” Not “methylene modified silicate”

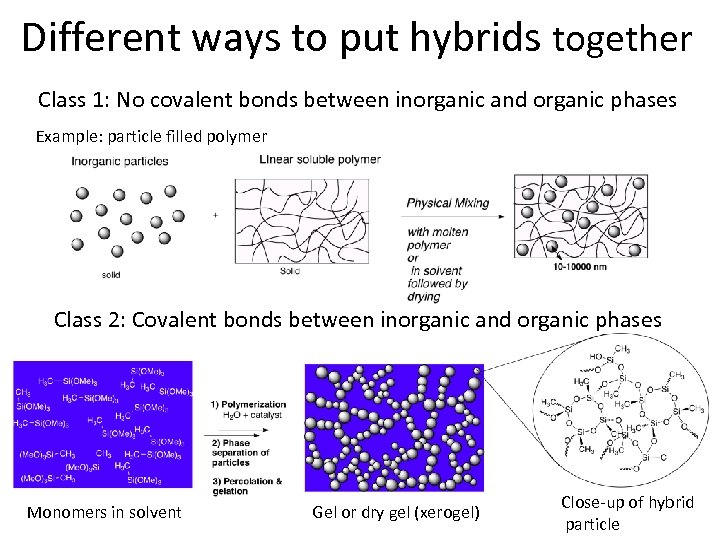

Different ways to put hybrids together Class 1: No covalent bonds between inorganic and organic phases Example: particle filled polymer Class 2: Covalent bonds between inorganic and organic phases Monomers in solvent Gel or dry gel (xerogel) Close-up of hybrid particle

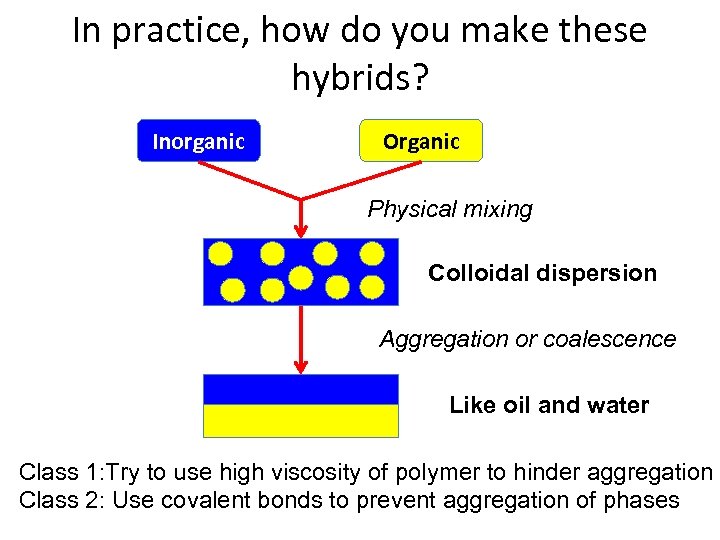

In practice, how do you make these hybrids? Inorganic Organic Physical mixing Colloidal dispersion Aggregation or coalescence Like oil and water Class 1: Try to use high viscosity of polymer to hinder aggregation Class 2: Use covalent bonds to prevent aggregation of phases

Making Hybrid Materials: Class 1 A (pre -formed particles and fibers) Physical mixing of particles in melt or solution Easiest hybrid to make

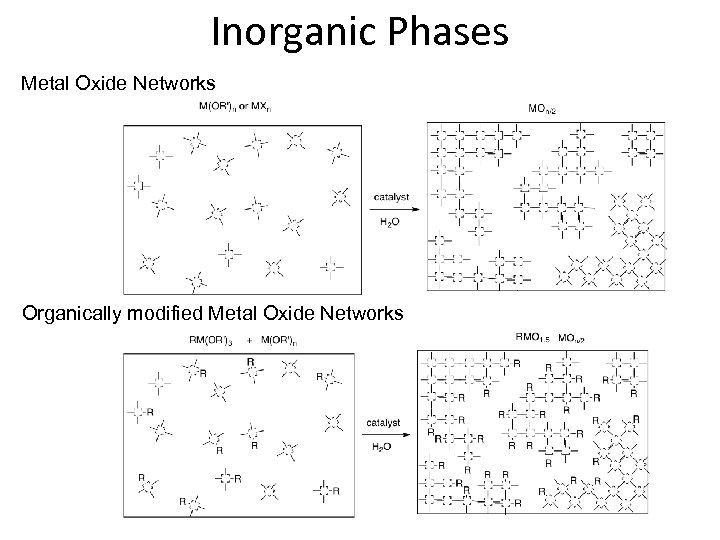

Inorganic Phases Metal Oxide Networks Organically modified Metal Oxide Networks

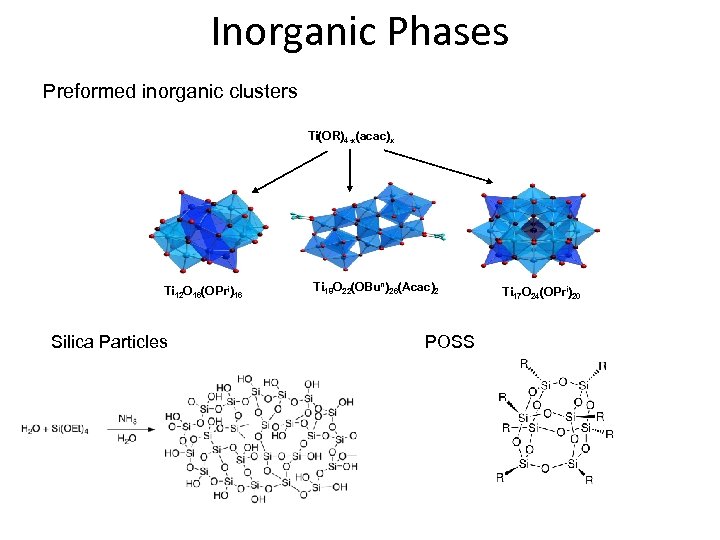

Inorganic Phases Preformed inorganic clusters Ti(OR)4 -x(acac)x Ti 12 O 16(OPri)16 Silica Particles Ti 18 O 22(OBun)26(Acac)2 POSS Ti 17 O 24(OPri)20

Making silsesquioxanes as inorganic phase Surface modified inorganic

Class 1 A: POSS physically dispersed in polypropylene

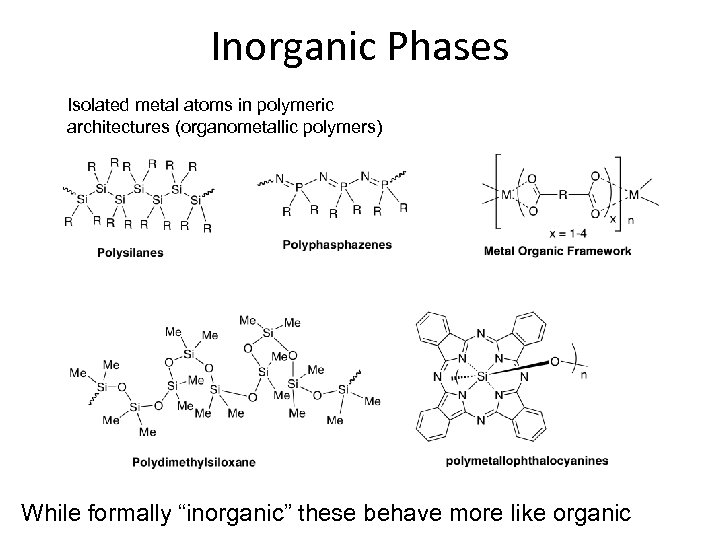

Inorganic Phases Isolated metal atoms in polymeric architectures (organometallic polymers) While formally “inorganic” these behave more like organic

Organic phases: Polymers Commercially available from Dow, BASF or from research chemical vendors: Aldrich or Polyscience

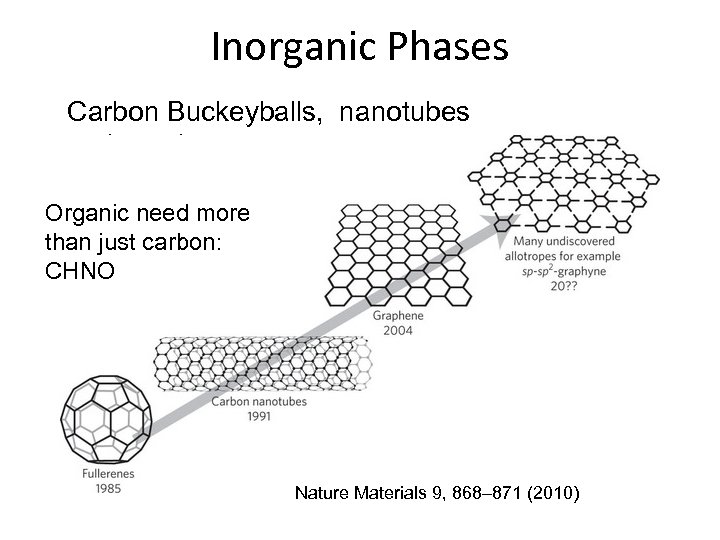

Inorganic Phases Carbon Buckeyballs, nanotubes and graphene Organic need more than just carbon: CHNO Nature Materials 9, 868– 871 (2010)

Class 1: No covalent bonds between inorganic and organic phase (easiest hybrid to prepare) Example: particle filled polymer 1) First need to prepare or buy inorganic particles 2) then, depending on polymer melting point, mix into melt or solution of polymer 3) Cool (if melt) or evaporate solvent (if solution) If you were making this hybrid, what would you be worrying about? And how would you check experimentally?

Making Hybrid Materials: Class 1 B (in situ particle growth) No Solvent except for monomer(s) Generally uses low tg organic polymers or in polymer melts (< 100 °C). Viscous environment. Confined growth.

Making Hybrid Materials: Class 1 B (in situ particle growth) What must happen for this method to work?

Making Hybrid Materials: Class 1 C (Polymerizing in pores) • Porous metal oxide • Liquid monomer (no solvent) • UV, heat, radiation Non-porous composite material Same issues as in 1 B, but organic polymerization must not be chemically hindered by metal oxide What polymerization chemistry is incompatible with silica or silsesquioxanes? Why?

Making Hybrid Materials: Class 1 D (encapsulation of small organics) • Polymerize metal oxide around organic • pores must be small or leakage will occur • Solid state dye lasers, filters, colored glass Describe how the starting materials must behave for this to work © Asahi. Kirin

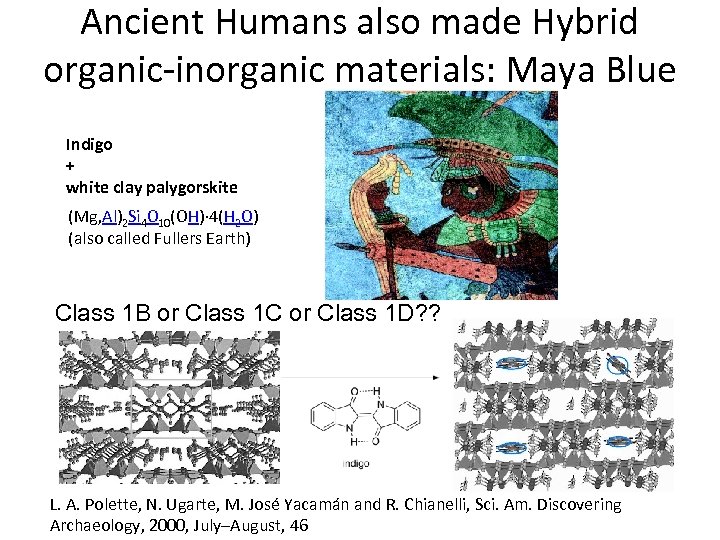

Ancient Humans also made Hybrid organic-inorganic materials: Maya Blue Indigo + white clay palygorskite (Mg, Al)2 Si 4 O 10(OH)· 4(H 2 O) (also called Fullers Earth) Class 1 B or Class 1 C or Class 1 D? ? L. A. Polette, N. Ugarte, M. José Yacamán and R. Chianelli, Sci. Am. Discovering Archaeology, 2000, July–August, 46

Making Hybrid Materials: Class 1 E (Interpenetrating network) • Both organic and inorganic phases grow simultaneously • Timing is more difficult • Reproducibility is a challenge • May need to use crosslinking organic monomers to ensure solid product What does this assume about the reaction kinetics?

Making Hybrid Materials: Class 2 A (Covalent links at molecular level) • Organic group is attached to network at molecular level • Hypercrosslinking is possible • Pendant or bridging monomers • Bridging groups can be small or macromolecule • This class also includes the organometallic polymers Chromatographic Materials Photoresists for Lithography Low K Dielectrics

Making Hybrid Materials: Class 2 B (Covalent links at polymer level) • ligands attached to polymer • Reaction rates slow unless in sol. or melt

Making Hybrid Materials: Class 2 C Templating with block copolymers and surfactants Self-assembly surfactant into 3 -D biphase system then polymerize in one of the phases (usually in the water phase)

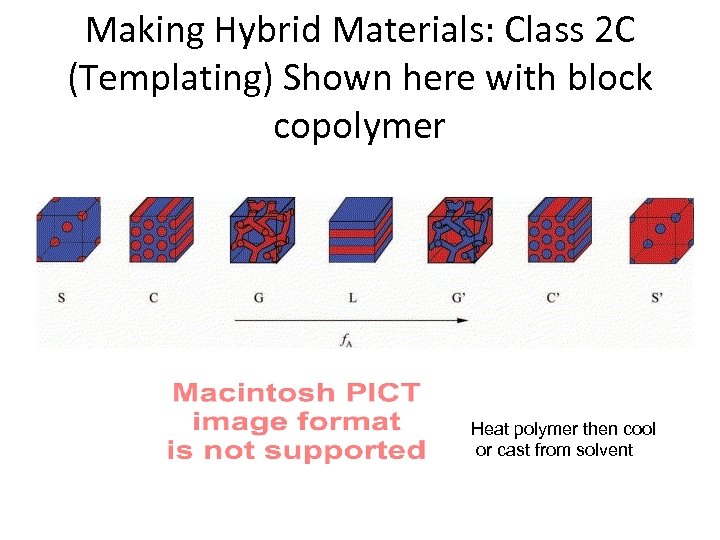

Making Hybrid Materials: Class 2 C (Templating) Shown here with block copolymer Heat polymer then cool or cast from solvent

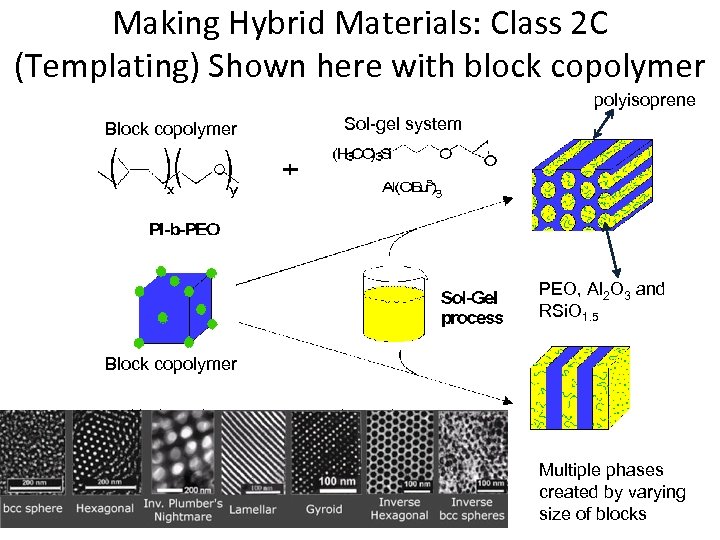

Making Hybrid Materials: Class 2 C (Templating) Shown here with block copolymer polyisoprene Block copolymer Sol-gel system PEO, Al 2 O 3 and RSi. O 1. 5 Block copolymer Multiple phases created by varying size of blocks

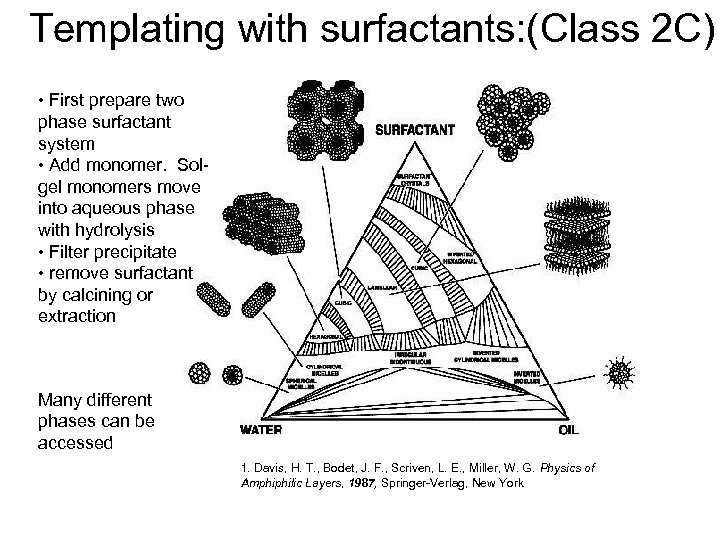

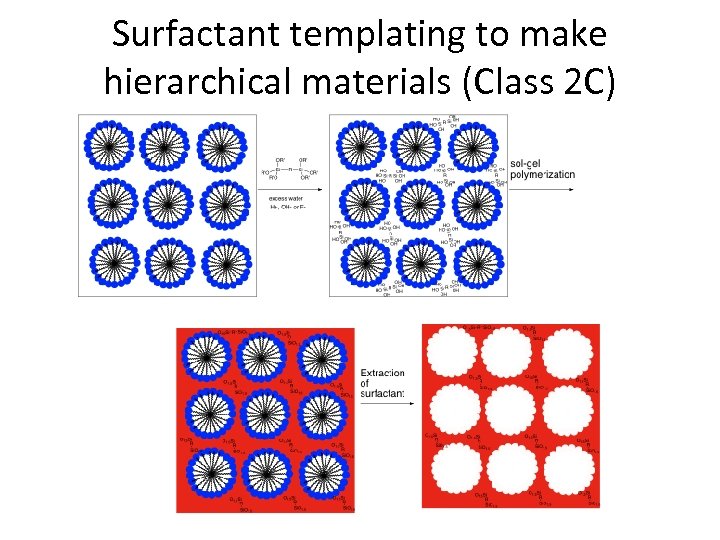

Templating with surfactants: (Class 2 C) • First prepare two phase surfactant system • Add monomer. Solgel monomers move into aqueous phase with hydrolysis • Filter precipitate • remove surfactant by calcining or extraction Many different phases can be accessed 1. Davis, H. T. , Bodet, J. F. , Scriven, L. E. , Miller, W. G. Physics of Amphiphilic Layers, 1987, Springer-Verlag, New York

Surfactant templating to make hierarchical materials (Class 2 C)

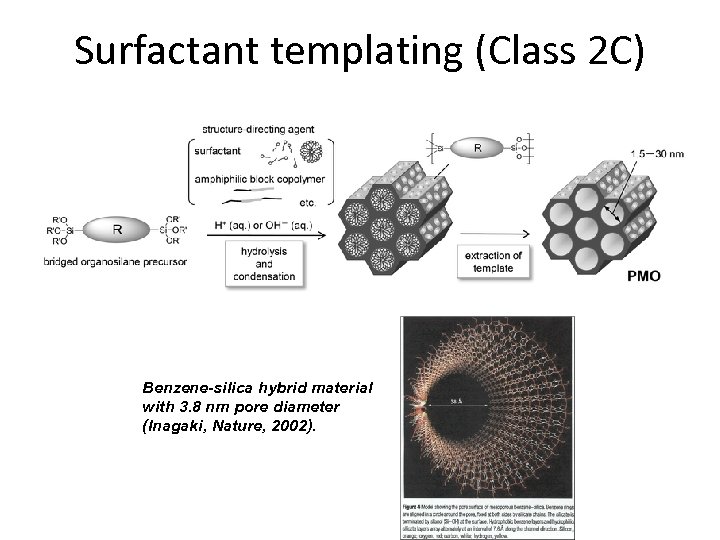

Surfactant templating (Class 2 C) Benzene-silica hybrid material with 3. 8 nm pore diameter (Inagaki, Nature, 2002).

Classes 2 D Covalent coupling agents Attaching organic group onto inorganic material

Classes 2 E Covalent coupling agents. Attaching inorganic group onto organic polymer For tough electrical wire coating & shrink fit wrap

Summary • Silsesquioxane nomenclature is hard to pronounce • Organosilica is improper nomenclature • Mixing polymer with anything is hard & may not work • Good mixing is necessary for hybrids • Surfactants can template hierarchical structures

4d2271eeabfb187c33eec27e2997498f.ppt