02826142a0279c5aad15fd37347f5f73.ppt

- Количество слайдов: 52

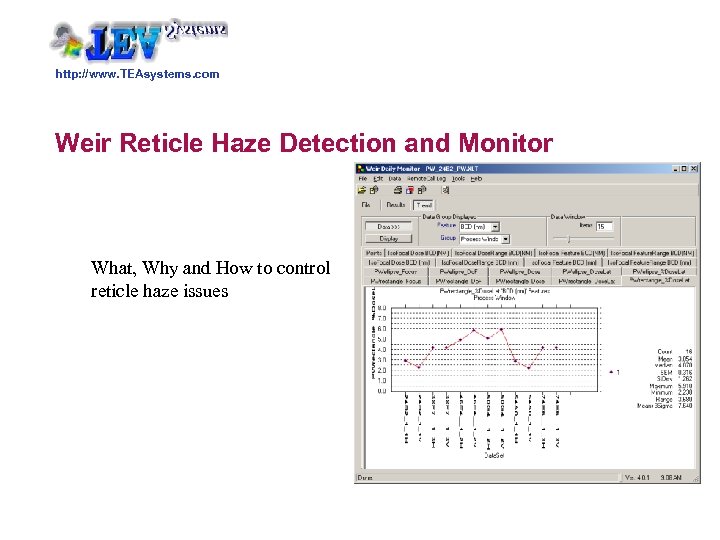

http: //www. TEAsystems. com Weir Reticle Haze Detection and Monitor What, Why and How to control reticle haze issues

http: //www. TEAsystems. com Weir Reticle Haze Detection and Monitor What, Why and How to control reticle haze issues

Sections n Reticle Haze Concepts n Base Method of Weir Haze Detection n Weir PW Characterization n Weir DM macro setup of Weir PW method n Weir DMA automation of input & output data 2 TEA Systems Yield Enhancement thru Modeling

Sections n Reticle Haze Concepts n Base Method of Weir Haze Detection n Weir PW Characterization n Weir DM macro setup of Weir PW method n Weir DMA automation of input & output data 2 TEA Systems Yield Enhancement thru Modeling

Reticle Haze Detection with Weir PW & Weir DMA n Haze formation on reticle continues to be a significant problem for the semiconductor industry. n Haze can be formed on the outside pellicle and on the quartz back side of the reticle. n Major component of the haze is known to be aluminum sulfate that comes from the reticle cleaning process and Deep Ultra Violet interactions with residue. n The reticle materials, the exposure wavelength, roughness of photomask and this haze will affect the resolution and process latitude. 3 TEA Systems Yield Enhancement thru Modeling

Reticle Haze Detection with Weir PW & Weir DMA n Haze formation on reticle continues to be a significant problem for the semiconductor industry. n Haze can be formed on the outside pellicle and on the quartz back side of the reticle. n Major component of the haze is known to be aluminum sulfate that comes from the reticle cleaning process and Deep Ultra Violet interactions with residue. n The reticle materials, the exposure wavelength, roughness of photomask and this haze will affect the resolution and process latitude. 3 TEA Systems Yield Enhancement thru Modeling

Reticle Haze Sources n n Mask making materials Process residues Reticle container Fab or Scanner environment 4 TEA Systems Yield Enhancement thru Modeling

Reticle Haze Sources n n Mask making materials Process residues Reticle container Fab or Scanner environment 4 TEA Systems Yield Enhancement thru Modeling

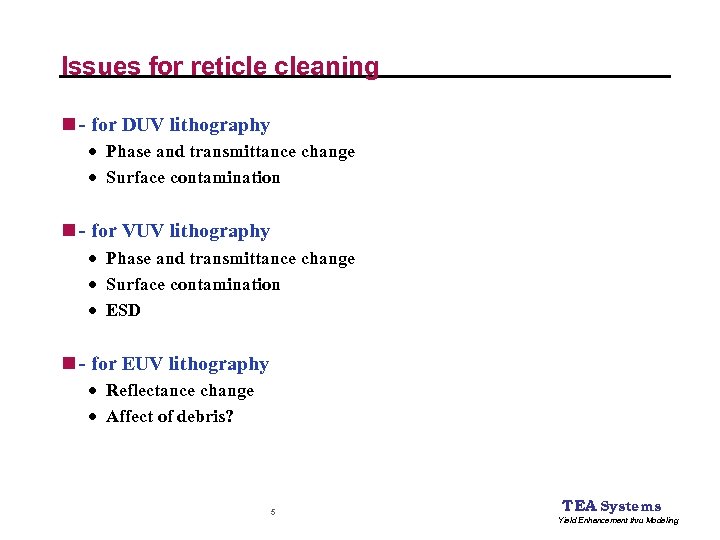

Issues for reticle cleaning n - for DUV lithography · Phase and transmittance change · Surface contamination n - for VUV lithography · Phase and transmittance change · Surface contamination · ESD n - for EUV lithography · Reflectance change · Affect of debris? 5 TEA Systems Yield Enhancement thru Modeling

Issues for reticle cleaning n - for DUV lithography · Phase and transmittance change · Surface contamination n - for VUV lithography · Phase and transmittance change · Surface contamination · ESD n - for EUV lithography · Reflectance change · Affect of debris? 5 TEA Systems Yield Enhancement thru Modeling

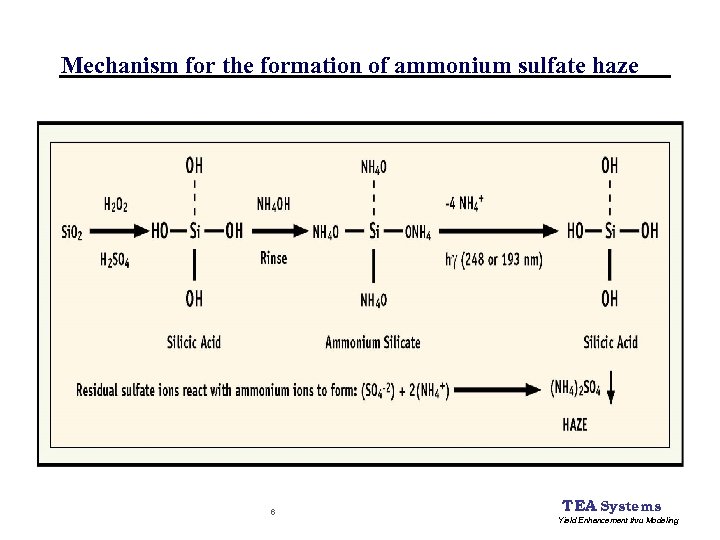

Mechanism for the formation of ammonium sulfate haze 6 TEA Systems Yield Enhancement thru Modeling

Mechanism for the formation of ammonium sulfate haze 6 TEA Systems Yield Enhancement thru Modeling

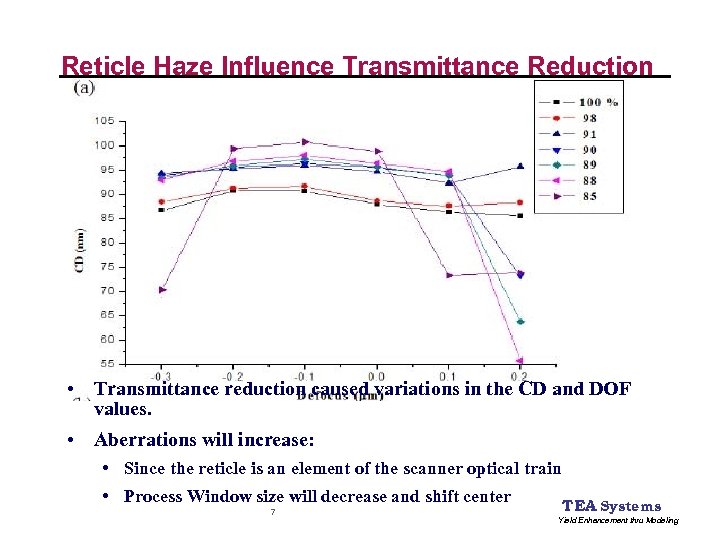

Reticle Haze Influence Transmittance Reduction • Transmittance reduction caused variations in the CD and DOF values. • Aberrations will increase: • Since the reticle is an element of the scanner optical train • Process Window size will decrease and shift center 7 TEA Systems Yield Enhancement thru Modeling

Reticle Haze Influence Transmittance Reduction • Transmittance reduction caused variations in the CD and DOF values. • Aberrations will increase: • Since the reticle is an element of the scanner optical train • Process Window size will decrease and shift center 7 TEA Systems Yield Enhancement thru Modeling

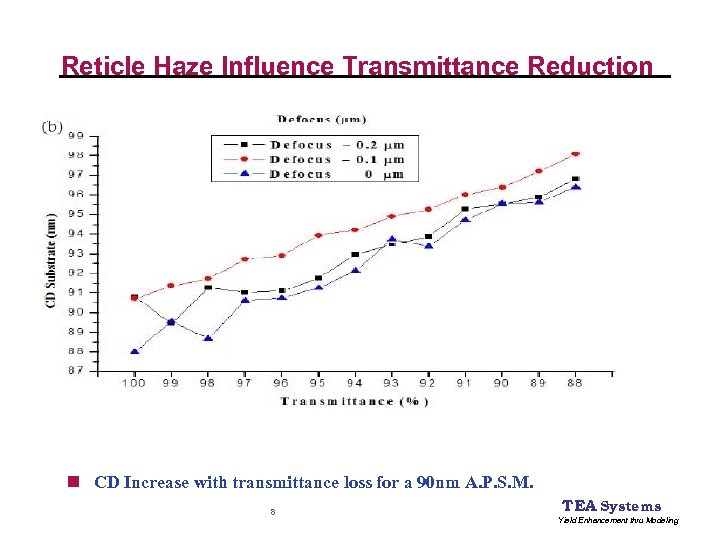

Reticle Haze Influence Transmittance Reduction n CD Increase with transmittance loss for a 90 nm A. P. S. M. 8 TEA Systems Yield Enhancement thru Modeling

Reticle Haze Influence Transmittance Reduction n CD Increase with transmittance loss for a 90 nm A. P. S. M. 8 TEA Systems Yield Enhancement thru Modeling

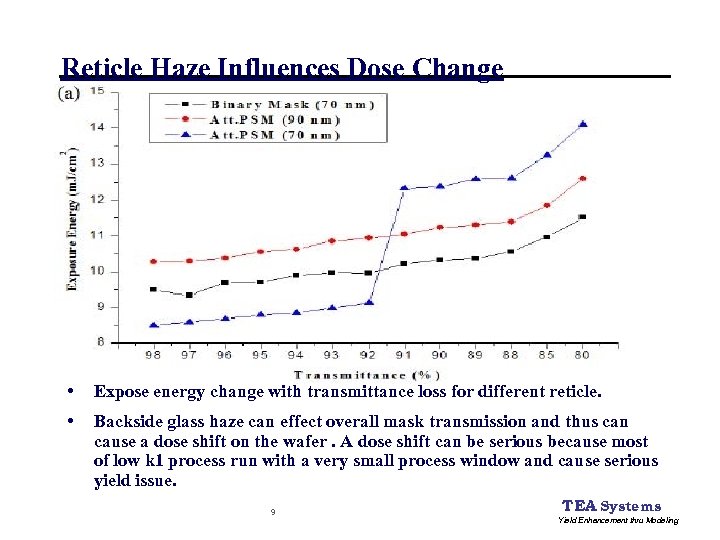

Reticle Haze Influences Dose Change • Expose energy change with transmittance loss for different reticle. • Backside glass haze can effect overall mask transmission and thus can cause a dose shift on the wafer. A dose shift can be serious because most of low k 1 process run with a very small process window and cause serious yield issue. 9 TEA Systems Yield Enhancement thru Modeling

Reticle Haze Influences Dose Change • Expose energy change with transmittance loss for different reticle. • Backside glass haze can effect overall mask transmission and thus can cause a dose shift on the wafer. A dose shift can be serious because most of low k 1 process run with a very small process window and cause serious yield issue. 9 TEA Systems Yield Enhancement thru Modeling

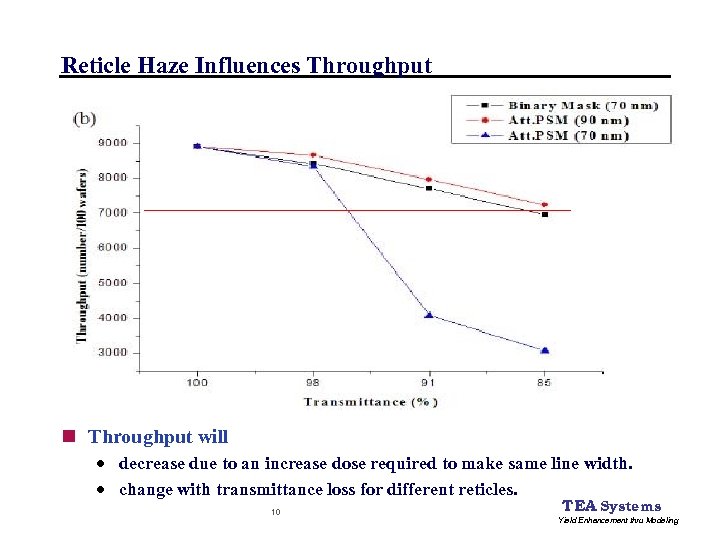

Reticle Haze Influences Throughput n Throughput will · decrease due to an increase dose required to make same line width. · change with transmittance loss for different reticles. 10 TEA Systems Yield Enhancement thru Modeling

Reticle Haze Influences Throughput n Throughput will · decrease due to an increase dose required to make same line width. · change with transmittance loss for different reticles. 10 TEA Systems Yield Enhancement thru Modeling

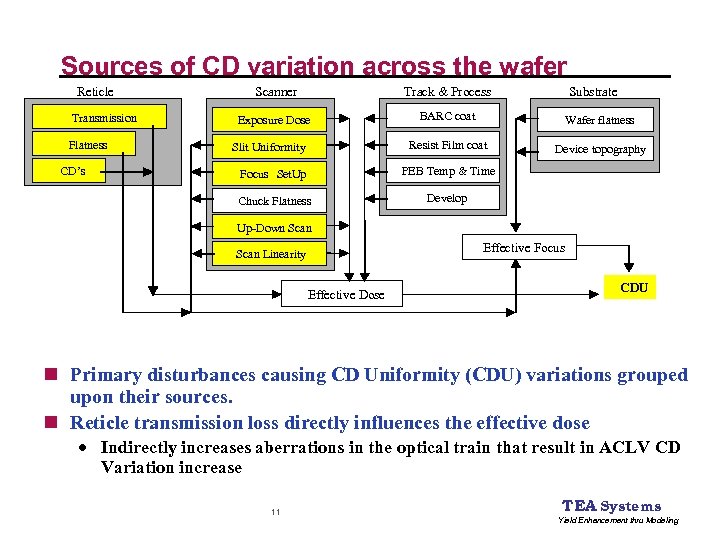

Sources of CD variation across the wafer Reticle Transmission Flatness CD’s Scanner Track & Process Exposure Dose BARC coat Wafer flatness Resist Film coat Device topography Slit Uniformity Focus Set. Up PEB Temp & Time Chuck Flatness Substrate Develop Up-Down Scan Effective Focus Scan Linearity Effective Dose CDU n Primary disturbances causing CD Uniformity (CDU) variations grouped upon their sources. n Reticle transmission loss directly influences the effective dose · Indirectly increases aberrations in the optical train that result in ACLV CD Variation increase 11 TEA Systems Yield Enhancement thru Modeling

Sources of CD variation across the wafer Reticle Transmission Flatness CD’s Scanner Track & Process Exposure Dose BARC coat Wafer flatness Resist Film coat Device topography Slit Uniformity Focus Set. Up PEB Temp & Time Chuck Flatness Substrate Develop Up-Down Scan Effective Focus Scan Linearity Effective Dose CDU n Primary disturbances causing CD Uniformity (CDU) variations grouped upon their sources. n Reticle transmission loss directly influences the effective dose · Indirectly increases aberrations in the optical train that result in ACLV CD Variation increase 11 TEA Systems Yield Enhancement thru Modeling

http: //www. TEAsystems. com Monitoring the process for Reticle Haze n Haze is formed around the pellicle, on the quartz side of the mask and on the chrome side of the mask.

http: //www. TEAsystems. com Monitoring the process for Reticle Haze n Haze is formed around the pellicle, on the quartz side of the mask and on the chrome side of the mask.

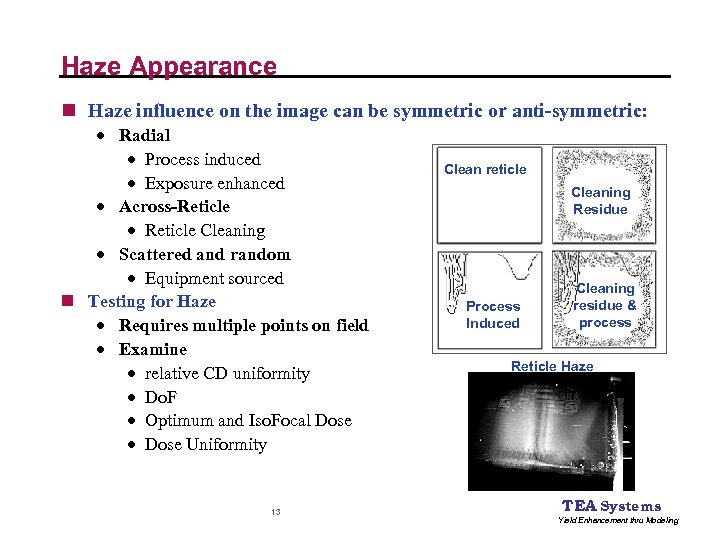

Haze Appearance n Haze influence on the image can be symmetric or anti-symmetric: · Radial · Process induced · Exposure enhanced · Across-Reticle · Reticle Cleaning · Scattered and random · Equipment sourced n Testing for Haze · Requires multiple points on field · Examine · relative CD uniformity · Do. F · Optimum and Iso. Focal Dose · Dose Uniformity 13 Clean reticle Cleaning Residue Process Induced Cleaning residue & process Reticle Haze TEA Systems Yield Enhancement thru Modeling

Haze Appearance n Haze influence on the image can be symmetric or anti-symmetric: · Radial · Process induced · Exposure enhanced · Across-Reticle · Reticle Cleaning · Scattered and random · Equipment sourced n Testing for Haze · Requires multiple points on field · Examine · relative CD uniformity · Do. F · Optimum and Iso. Focal Dose · Dose Uniformity 13 Clean reticle Cleaning Residue Process Induced Cleaning residue & process Reticle Haze TEA Systems Yield Enhancement thru Modeling

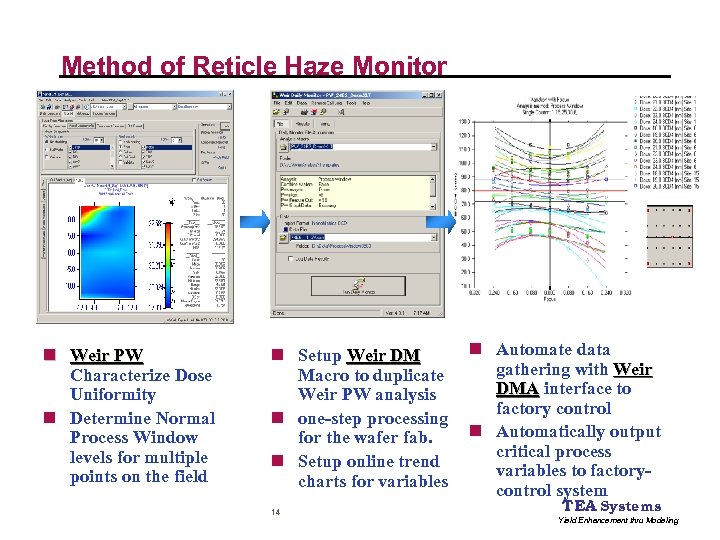

Method of Reticle Haze Monitor n Weir PW Characterize Dose Uniformity n Determine Normal Process Window levels for multiple points on the field n Setup Weir DM Macro to duplicate Weir PW analysis n one-step processing for the wafer fab. n Setup online trend charts for variables 14 n Automate data gathering with Weir DMA interface to factory control n Automatically output critical process variables to factorycontrol system TEA Systems Yield Enhancement thru Modeling

Method of Reticle Haze Monitor n Weir PW Characterize Dose Uniformity n Determine Normal Process Window levels for multiple points on the field n Setup Weir DM Macro to duplicate Weir PW analysis n one-step processing for the wafer fab. n Setup online trend charts for variables 14 n Automate data gathering with Weir DMA interface to factory control n Automatically output critical process variables to factorycontrol system TEA Systems Yield Enhancement thru Modeling

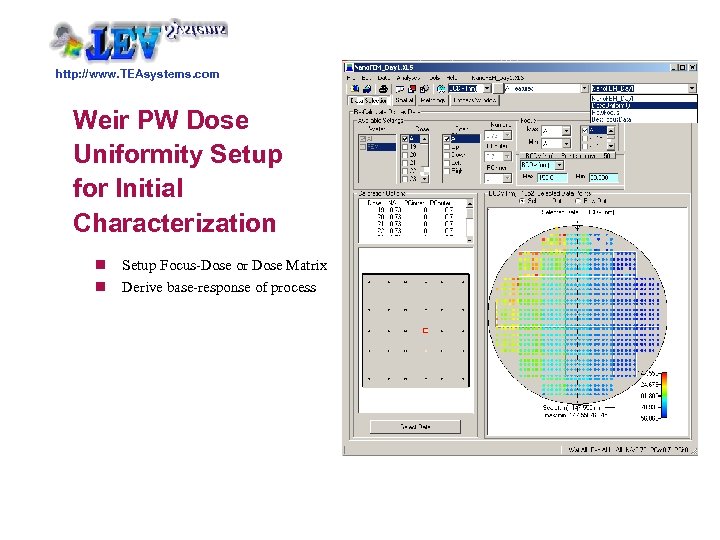

http: //www. TEAsystems. com Weir PW Dose Uniformity Setup for Initial Characterization n Setup Focus-Dose or Dose Matrix n Derive base-response of process

http: //www. TEAsystems. com Weir PW Dose Uniformity Setup for Initial Characterization n Setup Focus-Dose or Dose Matrix n Derive base-response of process

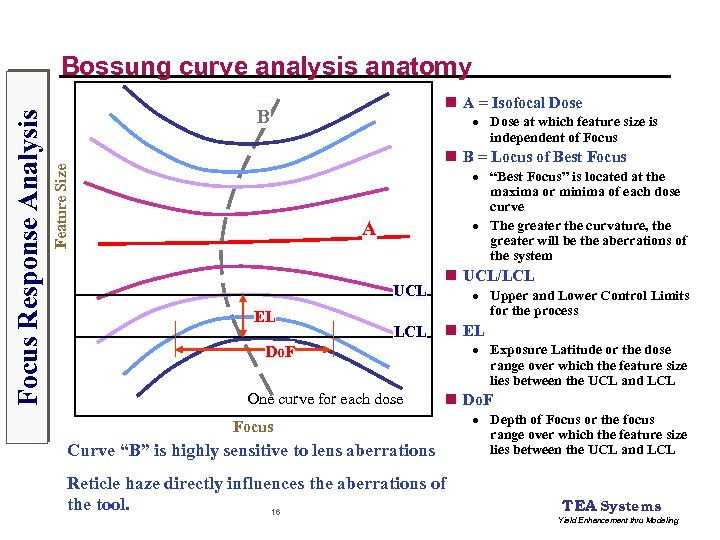

n A = Isofocal Dose B · Dose at which feature size is independent of Focus n B = Locus of Best Focus Feature Size Focus Response Analysis Bossung curve analysis anatomy · “Best Focus” is located at the maxima or minima of each dose curve · The greater the curvature, the greater will be the aberrations of the system A UCL EL LCL n UCL/LCL · Upper and Lower Control Limits for the process n EL · Exposure Latitude or the dose range over which the feature size lies between the UCL and LCL Do. F One curve for each dose n Do. F Focus Curve “B” is highly sensitive to lens aberrations Reticle haze directly influences the aberrations of the tool. 16 · Depth of Focus or the focus range over which the feature size lies between the UCL and LCL TEA Systems Yield Enhancement thru Modeling

n A = Isofocal Dose B · Dose at which feature size is independent of Focus n B = Locus of Best Focus Feature Size Focus Response Analysis Bossung curve analysis anatomy · “Best Focus” is located at the maxima or minima of each dose curve · The greater the curvature, the greater will be the aberrations of the system A UCL EL LCL n UCL/LCL · Upper and Lower Control Limits for the process n EL · Exposure Latitude or the dose range over which the feature size lies between the UCL and LCL Do. F One curve for each dose n Do. F Focus Curve “B” is highly sensitive to lens aberrations Reticle haze directly influences the aberrations of the tool. 16 · Depth of Focus or the focus range over which the feature size lies between the UCL and LCL TEA Systems Yield Enhancement thru Modeling

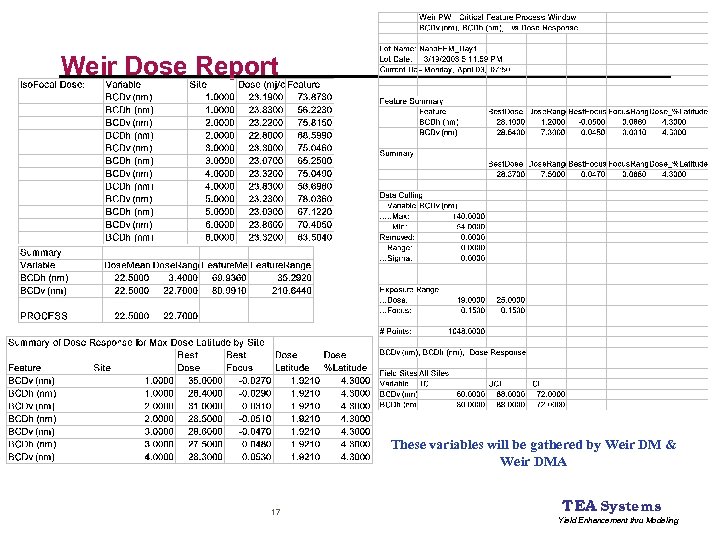

Weir Dose Report These variables will be gathered by Weir DM & Weir DMA 17 TEA Systems Yield Enhancement thru Modeling

Weir Dose Report These variables will be gathered by Weir DM & Weir DMA 17 TEA Systems Yield Enhancement thru Modeling

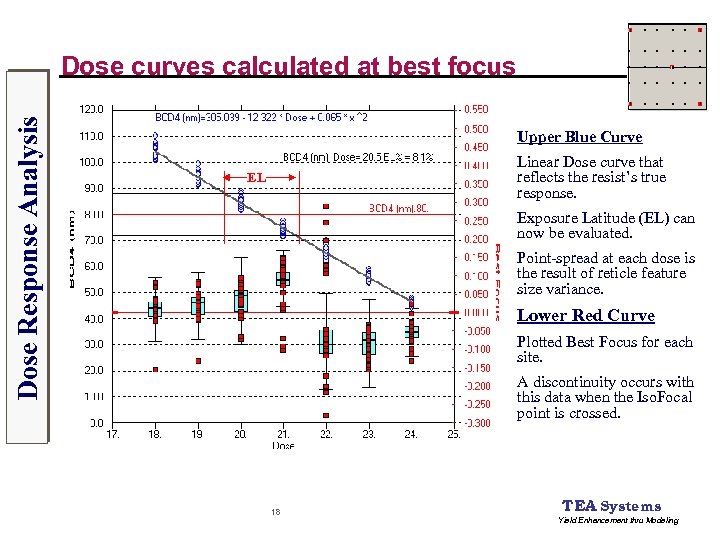

Dose Response Analysis Dose curves calculated at best focus Upper Blue Curve Linear Dose curve that reflects the resist’s true response. EL Exposure Latitude (EL) can now be evaluated. Point-spread at each dose is the result of reticle feature size variance. Lower Red Curve Plotted Best Focus for each site. A discontinuity occurs with this data when the Iso. Focal point is crossed. 18 TEA Systems Yield Enhancement thru Modeling

Dose Response Analysis Dose curves calculated at best focus Upper Blue Curve Linear Dose curve that reflects the resist’s true response. EL Exposure Latitude (EL) can now be evaluated. Point-spread at each dose is the result of reticle feature size variance. Lower Red Curve Plotted Best Focus for each site. A discontinuity occurs with this data when the Iso. Focal point is crossed. 18 TEA Systems Yield Enhancement thru Modeling

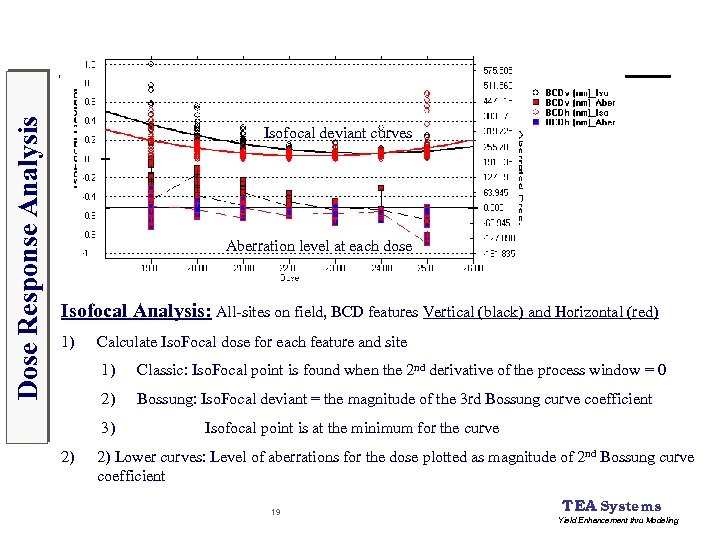

Dose Response Analysis Isofocal deviant curves Aberration level at each dose Isofocal Analysis: All-sites on field, BCD features Vertical (black) and Horizontal (red) 1) Calculate Iso. Focal dose for each feature and site 1) Classic: Iso. Focal point is found when the 2 nd derivative of the process window = 0 2) Bossung: Iso. Focal deviant = the magnitude of the 3 rd Bossung curve coefficient 3) 2) Isofocal point is at the minimum for the curve 2) Lower curves: Level of aberrations for the dose plotted as magnitude of 2 nd Bossung curve coefficient 19 TEA Systems Yield Enhancement thru Modeling

Dose Response Analysis Isofocal deviant curves Aberration level at each dose Isofocal Analysis: All-sites on field, BCD features Vertical (black) and Horizontal (red) 1) Calculate Iso. Focal dose for each feature and site 1) Classic: Iso. Focal point is found when the 2 nd derivative of the process window = 0 2) Bossung: Iso. Focal deviant = the magnitude of the 3 rd Bossung curve coefficient 3) 2) Isofocal point is at the minimum for the curve 2) Lower curves: Level of aberrations for the dose plotted as magnitude of 2 nd Bossung curve coefficient 19 TEA Systems Yield Enhancement thru Modeling

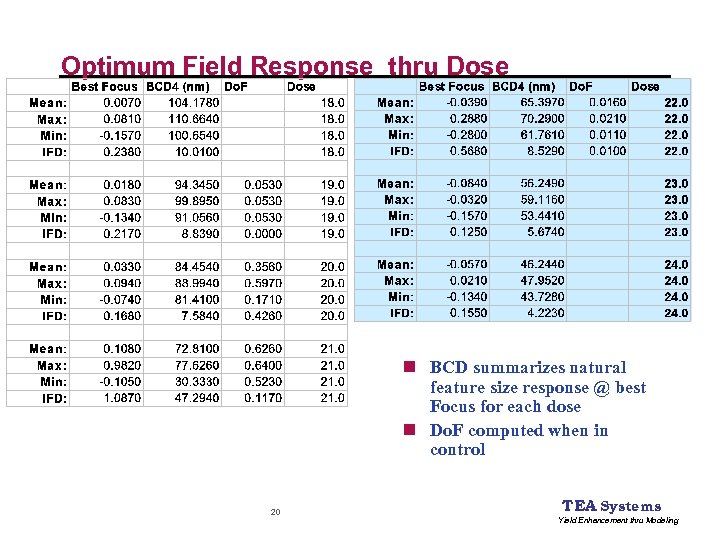

Optimum Field Response thru Dose n BCD summarizes natural feature size response @ best Focus for each dose n Do. F computed when in control 20 TEA Systems Yield Enhancement thru Modeling

Optimum Field Response thru Dose n BCD summarizes natural feature size response @ best Focus for each dose n Do. F computed when in control 20 TEA Systems Yield Enhancement thru Modeling

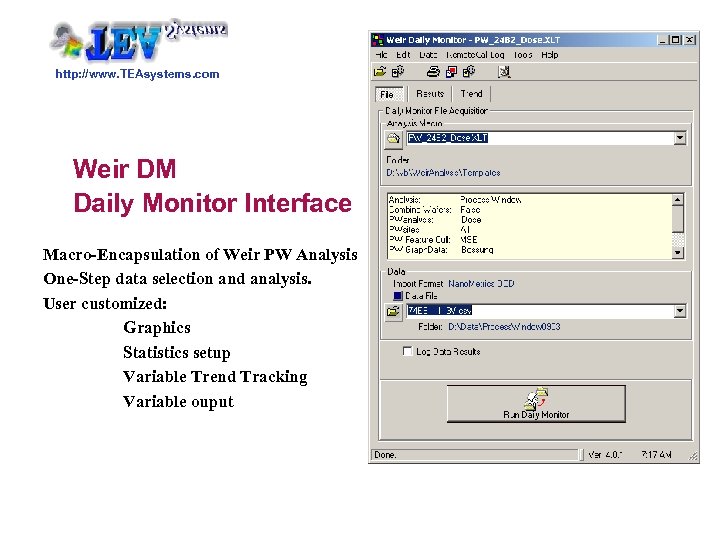

http: //www. TEAsystems. com Weir DM Daily Monitor Interface Macro-Encapsulation of Weir PW Analysis One-Step data selection and analysis. User customized: Graphics Statistics setup Variable Trend Tracking Variable ouput

http: //www. TEAsystems. com Weir DM Daily Monitor Interface Macro-Encapsulation of Weir PW Analysis One-Step data selection and analysis. User customized: Graphics Statistics setup Variable Trend Tracking Variable ouput

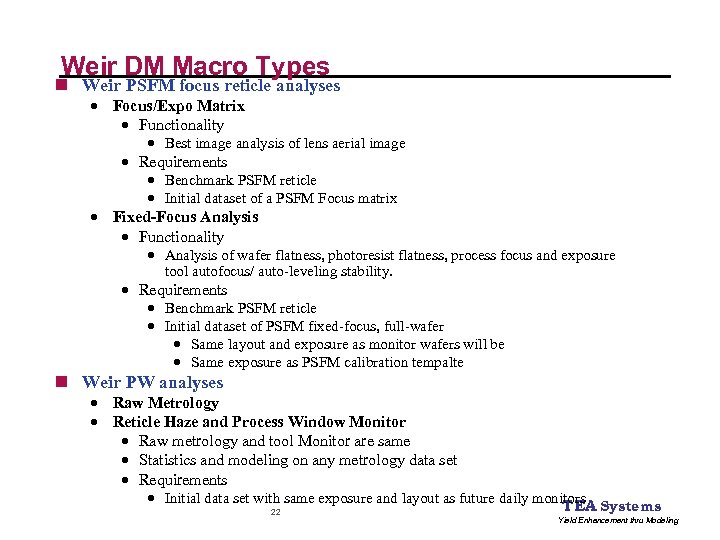

Weir DM Macro Types n Weir PSFM focus reticle analyses · Focus/Expo Matrix · Functionality · Best image analysis of lens aerial image · Requirements · Benchmark PSFM reticle · Initial dataset of a PSFM Focus matrix · Fixed-Focus Analysis · Functionality · Analysis of wafer flatness, photoresist flatness, process focus and exposure tool autofocus/ auto-leveling stability. · Requirements · Benchmark PSFM reticle · Initial dataset of PSFM fixed-focus, full-wafer · Same layout and exposure as monitor wafers will be · Same exposure as PSFM calibration tempalte n Weir PW analyses · Raw Metrology · Reticle Haze and Process Window Monitor · Raw metrology and tool Monitor are same · Statistics and modeling on any metrology data set · Requirements · Initial data set with same exposure and layout as future daily monitors TEA Systems 22 Yield Enhancement thru Modeling

Weir DM Macro Types n Weir PSFM focus reticle analyses · Focus/Expo Matrix · Functionality · Best image analysis of lens aerial image · Requirements · Benchmark PSFM reticle · Initial dataset of a PSFM Focus matrix · Fixed-Focus Analysis · Functionality · Analysis of wafer flatness, photoresist flatness, process focus and exposure tool autofocus/ auto-leveling stability. · Requirements · Benchmark PSFM reticle · Initial dataset of PSFM fixed-focus, full-wafer · Same layout and exposure as monitor wafers will be · Same exposure as PSFM calibration tempalte n Weir PW analyses · Raw Metrology · Reticle Haze and Process Window Monitor · Raw metrology and tool Monitor are same · Statistics and modeling on any metrology data set · Requirements · Initial data set with same exposure and layout as future daily monitors TEA Systems 22 Yield Enhancement thru Modeling

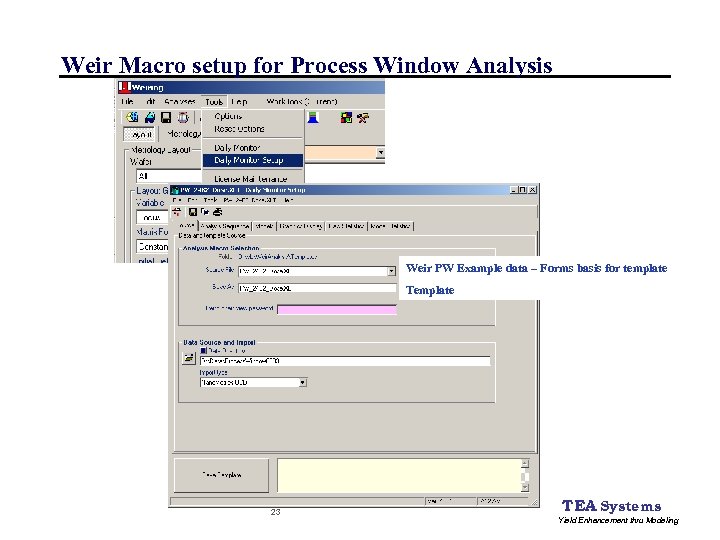

Weir Macro setup for Process Window Analysis Weir PW Example data – Forms basis for template Template 23 TEA Systems Yield Enhancement thru Modeling

Weir Macro setup for Process Window Analysis Weir PW Example data – Forms basis for template Template 23 TEA Systems Yield Enhancement thru Modeling

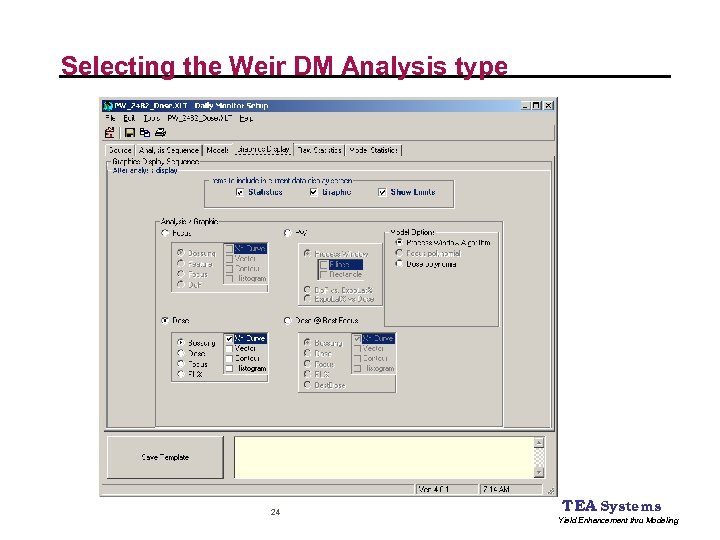

Selecting the Weir DM Analysis type 24 TEA Systems Yield Enhancement thru Modeling

Selecting the Weir DM Analysis type 24 TEA Systems Yield Enhancement thru Modeling

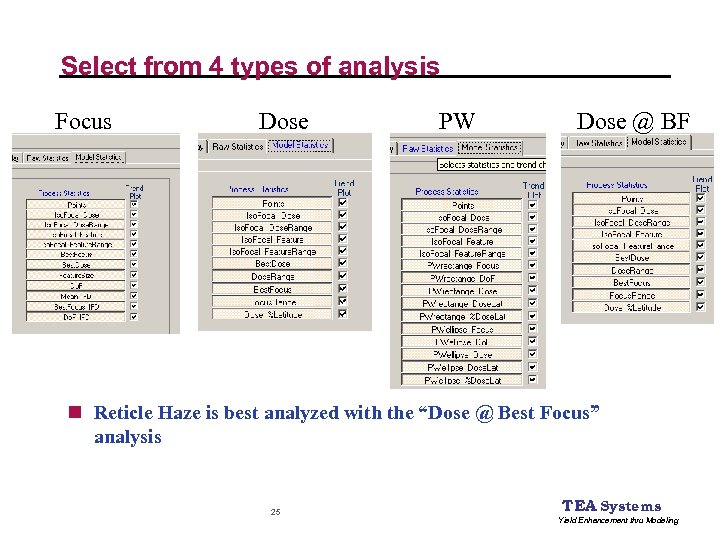

Select from 4 types of analysis Focus Dose PW Dose @ BF n Reticle Haze is best analyzed with the “Dose @ Best Focus” analysis 25 TEA Systems Yield Enhancement thru Modeling

Select from 4 types of analysis Focus Dose PW Dose @ BF n Reticle Haze is best analyzed with the “Dose @ Best Focus” analysis 25 TEA Systems Yield Enhancement thru Modeling

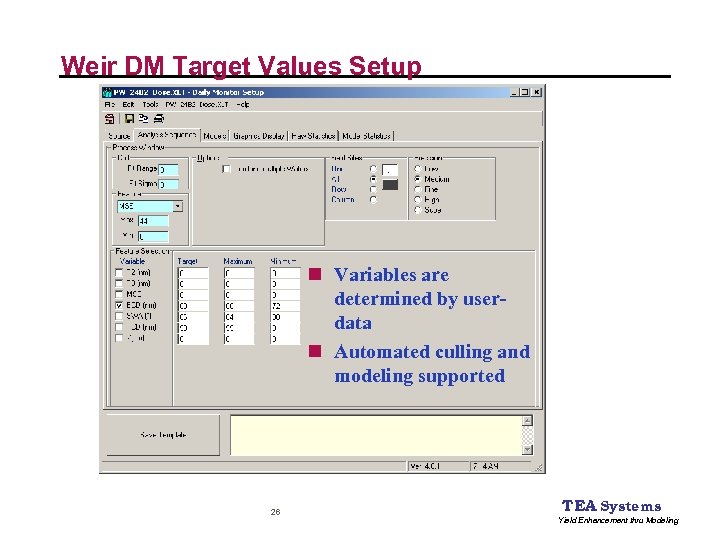

Weir DM Target Values Setup n Variables are determined by userdata n Automated culling and modeling supported 26 TEA Systems Yield Enhancement thru Modeling

Weir DM Target Values Setup n Variables are determined by userdata n Automated culling and modeling supported 26 TEA Systems Yield Enhancement thru Modeling

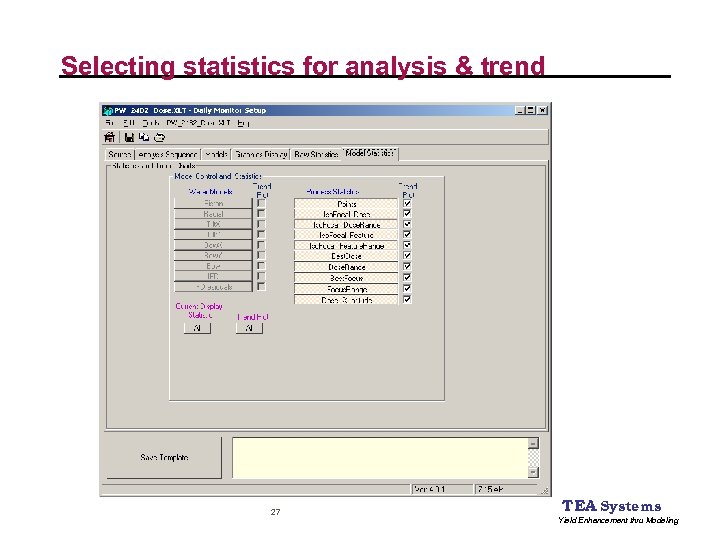

Selecting statistics for analysis & trend 27 TEA Systems Yield Enhancement thru Modeling

Selecting statistics for analysis & trend 27 TEA Systems Yield Enhancement thru Modeling

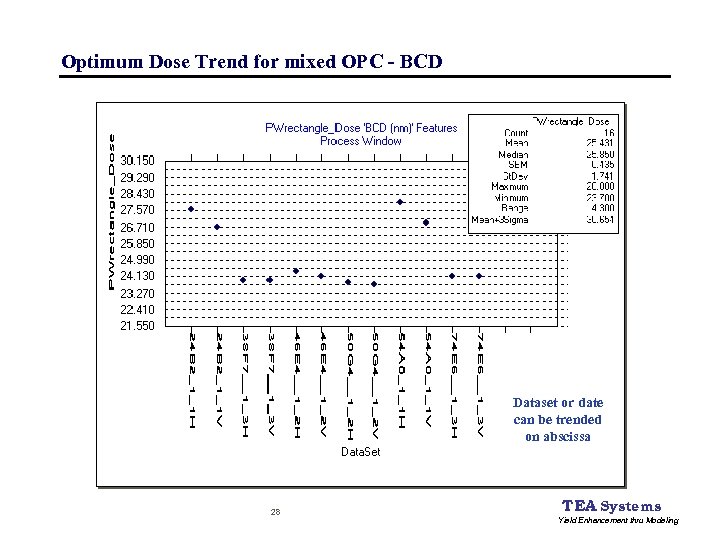

Optimum Dose Trend for mixed OPC - BCD Dataset or date can be trended on abscissa 28 TEA Systems Yield Enhancement thru Modeling

Optimum Dose Trend for mixed OPC - BCD Dataset or date can be trended on abscissa 28 TEA Systems Yield Enhancement thru Modeling

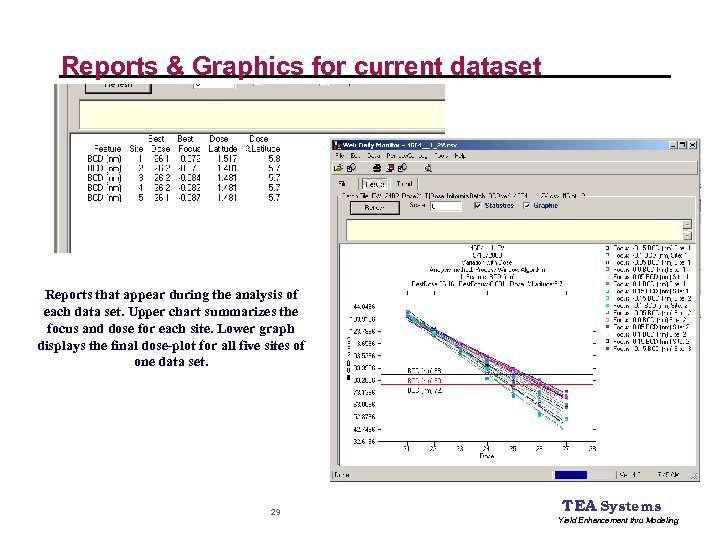

Reports & Graphics for current dataset Reports that appear during the analysis of each data set. Upper chart summarizes the focus and dose for each site. Lower graph displays the final dose-plot for all five sites of one data set. 29 TEA Systems Yield Enhancement thru Modeling

Reports & Graphics for current dataset Reports that appear during the analysis of each data set. Upper chart summarizes the focus and dose for each site. Lower graph displays the final dose-plot for all five sites of one data set. 29 TEA Systems Yield Enhancement thru Modeling

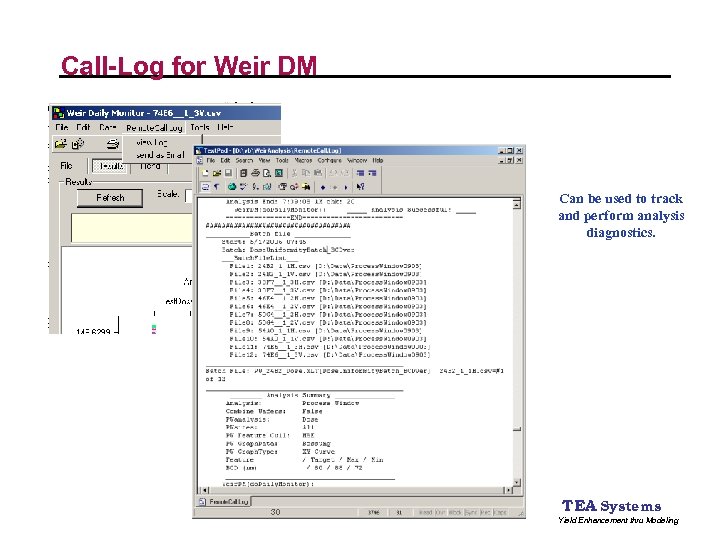

Call-Log for Weir DM Can be used to track and perform analysis diagnostics. 30 TEA Systems Yield Enhancement thru Modeling

Call-Log for Weir DM Can be used to track and perform analysis diagnostics. 30 TEA Systems Yield Enhancement thru Modeling

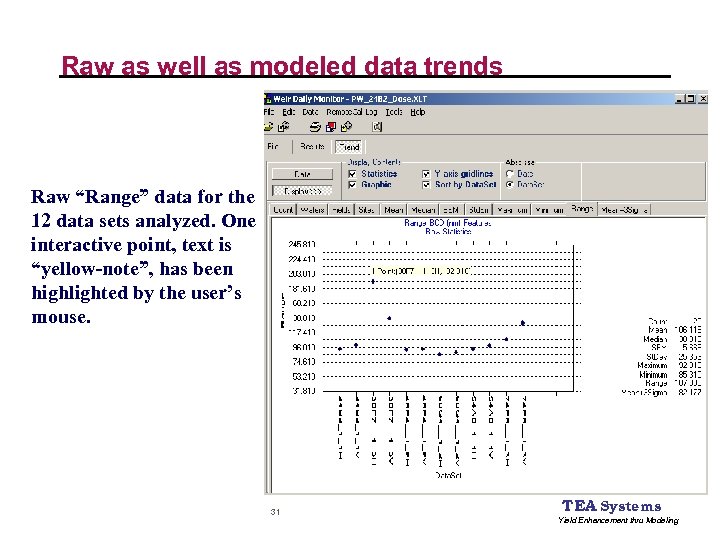

Raw as well as modeled data trends Raw “Range” data for the 12 data sets analyzed. One interactive point, text is “yellow-note”, has been highlighted by the user’s mouse. 31 TEA Systems Yield Enhancement thru Modeling

Raw as well as modeled data trends Raw “Range” data for the 12 data sets analyzed. One interactive point, text is “yellow-note”, has been highlighted by the user’s mouse. 31 TEA Systems Yield Enhancement thru Modeling

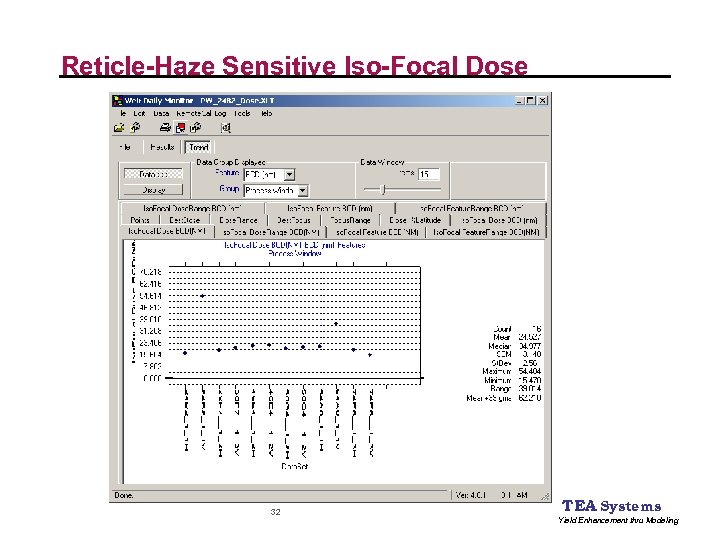

Reticle-Haze Sensitive Iso-Focal Dose 32 TEA Systems Yield Enhancement thru Modeling

Reticle-Haze Sensitive Iso-Focal Dose 32 TEA Systems Yield Enhancement thru Modeling

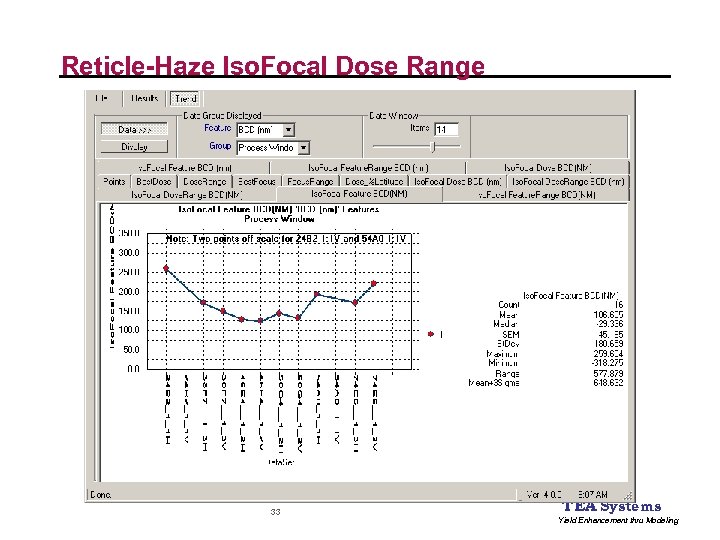

Reticle-Haze Iso. Focal Dose Range 33 TEA Systems Yield Enhancement thru Modeling

Reticle-Haze Iso. Focal Dose Range 33 TEA Systems Yield Enhancement thru Modeling

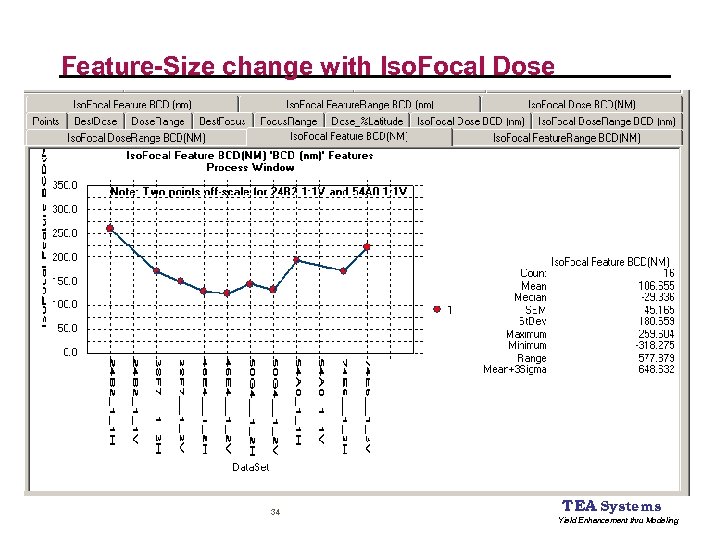

Feature-Size change with Iso. Focal Dose 34 TEA Systems Yield Enhancement thru Modeling

Feature-Size change with Iso. Focal Dose 34 TEA Systems Yield Enhancement thru Modeling

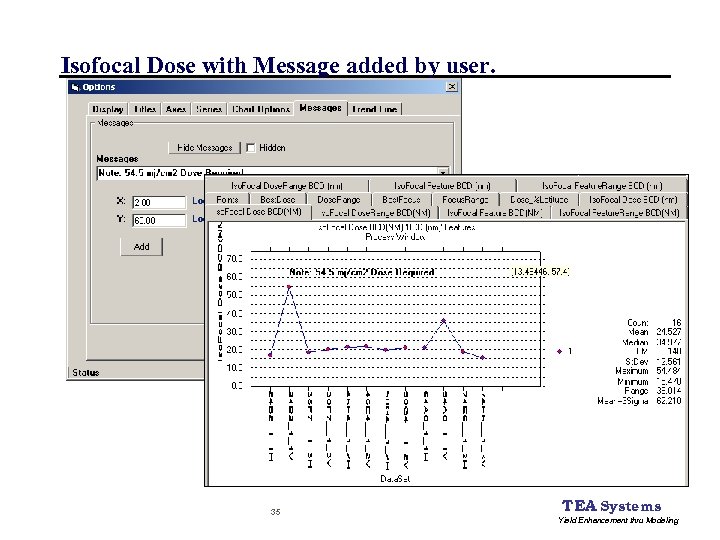

Isofocal Dose with Message added by user. 35 TEA Systems Yield Enhancement thru Modeling

Isofocal Dose with Message added by user. 35 TEA Systems Yield Enhancement thru Modeling

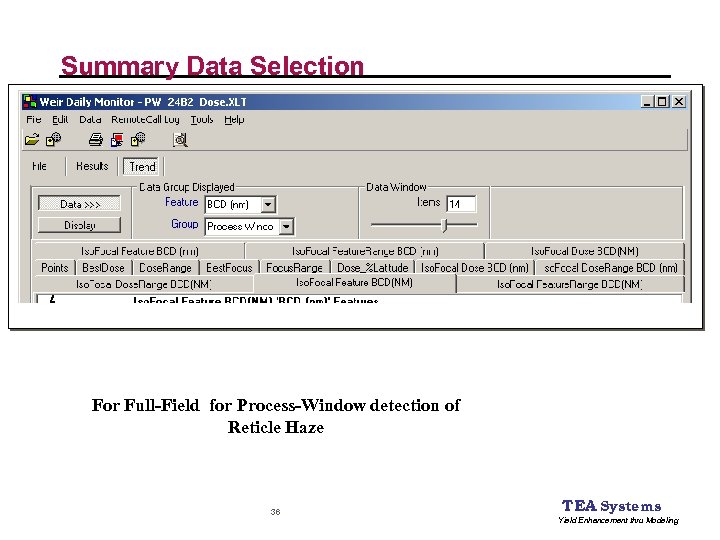

Summary Data Selection For Full-Field for Process-Window detection of Reticle Haze 36 TEA Systems Yield Enhancement thru Modeling

Summary Data Selection For Full-Field for Process-Window detection of Reticle Haze 36 TEA Systems Yield Enhancement thru Modeling

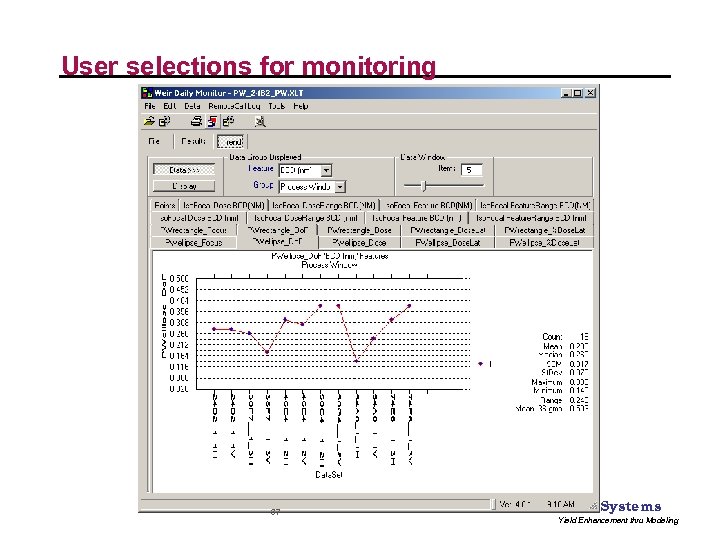

User selections for monitoring 37 TEA Systems Yield Enhancement thru Modeling

User selections for monitoring 37 TEA Systems Yield Enhancement thru Modeling

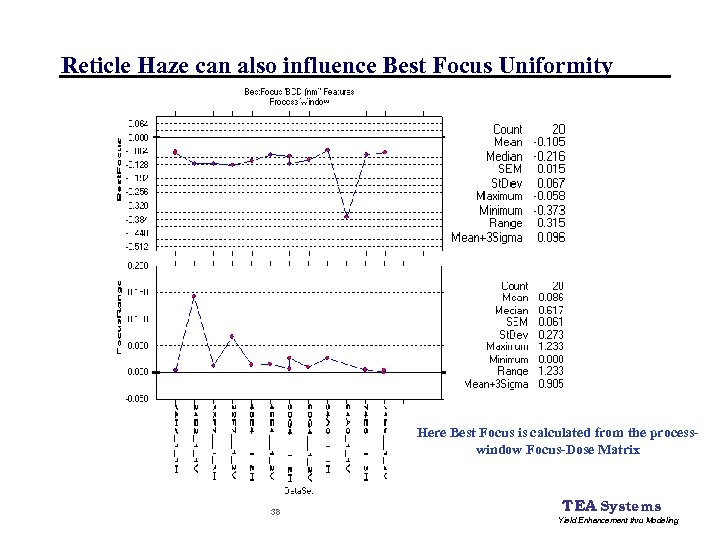

Reticle Haze can also influence Best Focus Uniformity Here Best Focus is calculated from the processwindow Focus-Dose Matrix 38 TEA Systems Yield Enhancement thru Modeling

Reticle Haze can also influence Best Focus Uniformity Here Best Focus is calculated from the processwindow Focus-Dose Matrix 38 TEA Systems Yield Enhancement thru Modeling

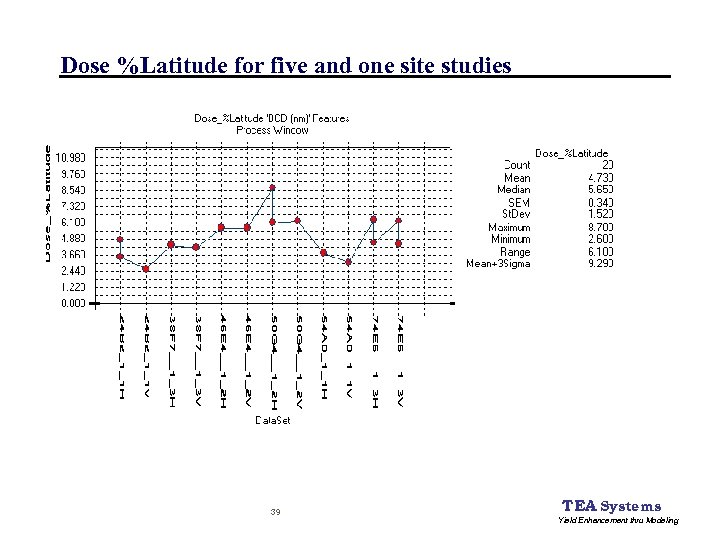

Dose %Latitude for five and one site studies 39 TEA Systems Yield Enhancement thru Modeling

Dose %Latitude for five and one site studies 39 TEA Systems Yield Enhancement thru Modeling

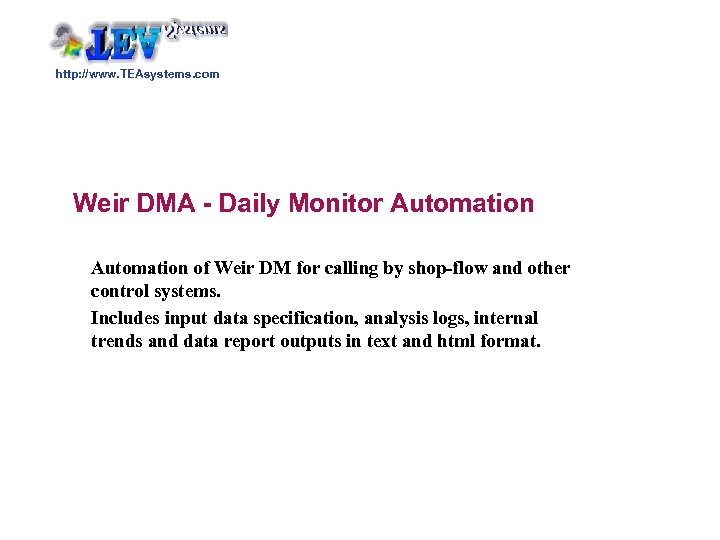

http: //www. TEAsystems. com Weir DMA - Daily Monitor Automation of Weir DM for calling by shop-flow and other control systems. Includes input data specification, analysis logs, internal trends and data report outputs in text and html format.

http: //www. TEAsystems. com Weir DMA - Daily Monitor Automation of Weir DM for calling by shop-flow and other control systems. Includes input data specification, analysis logs, internal trends and data report outputs in text and html format.

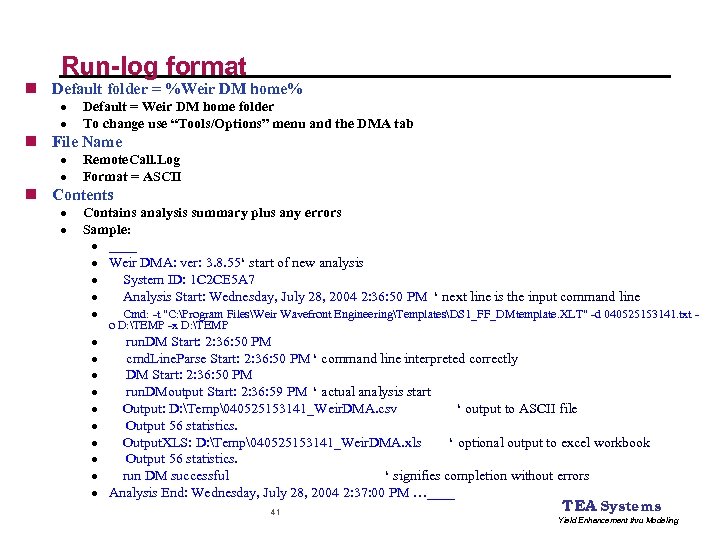

Run-log format n Default folder = %Weir DM home% · · Default = Weir DM home folder To change use “Tools/Options” menu and the DMA tab n File Name · · Remote. Call. Log Format = ASCII n Contents · · Contains analysis summary plus any errors Sample: · ____ · Weir DMA: ver: 3. 8. 55‘ start of new analysis · System ID: 1 C 2 CE 5 A 7 · Analysis Start: Wednesday, July 28, 2004 2: 36: 50 PM ‘ next line is the input command line · Cmd: -t "C: Program FilesWeir Wavefront EngineeringTemplatesDS 1_FF_DMtemplate. XLT" -d 040525153141. txt o D: TEMP -x D: TEMP · run. DM Start: 2: 36: 50 PM · cmd. Line. Parse Start: 2: 36: 50 PM ‘ command line interpreted correctly · DM Start: 2: 36: 50 PM · run. DMoutput Start: 2: 36: 59 PM ‘ actual analysis start · Output: D: Temp�40525153141_Weir. DMA. csv ‘ output to ASCII file · Output 56 statistics. · Output. XLS: D: Temp�40525153141_Weir. DMA. xls ‘ optional output to excel workbook · Output 56 statistics. · run DM successful ‘ signifies completion without errors · Analysis End: Wednesday, July 28, 2004 2: 37: 00 PM …____ TEA Systems 41 Yield Enhancement thru Modeling

Run-log format n Default folder = %Weir DM home% · · Default = Weir DM home folder To change use “Tools/Options” menu and the DMA tab n File Name · · Remote. Call. Log Format = ASCII n Contents · · Contains analysis summary plus any errors Sample: · ____ · Weir DMA: ver: 3. 8. 55‘ start of new analysis · System ID: 1 C 2 CE 5 A 7 · Analysis Start: Wednesday, July 28, 2004 2: 36: 50 PM ‘ next line is the input command line · Cmd: -t "C: Program FilesWeir Wavefront EngineeringTemplatesDS 1_FF_DMtemplate. XLT" -d 040525153141. txt o D: TEMP -x D: TEMP · run. DM Start: 2: 36: 50 PM · cmd. Line. Parse Start: 2: 36: 50 PM ‘ command line interpreted correctly · DM Start: 2: 36: 50 PM · run. DMoutput Start: 2: 36: 59 PM ‘ actual analysis start · Output: D: Temp�40525153141_Weir. DMA. csv ‘ output to ASCII file · Output 56 statistics. · Output. XLS: D: Temp�40525153141_Weir. DMA. xls ‘ optional output to excel workbook · Output 56 statistics. · run DM successful ‘ signifies completion without errors · Analysis End: Wednesday, July 28, 2004 2: 37: 00 PM …____ TEA Systems 41 Yield Enhancement thru Modeling

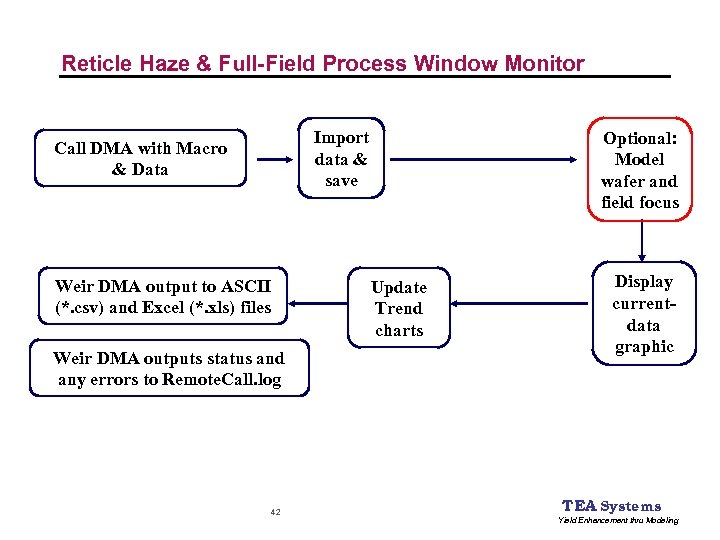

Reticle Haze & Full-Field Process Window Monitor Import data & save Call DMA with Macro & Data Weir DMA output to ASCII (*. csv) and Excel (*. xls) files Optional: Model wafer and field focus Update Trend charts Weir DMA outputs status and any errors to Remote. Call. log 42 Display currentdata graphic TEA Systems Yield Enhancement thru Modeling

Reticle Haze & Full-Field Process Window Monitor Import data & save Call DMA with Macro & Data Weir DMA output to ASCII (*. csv) and Excel (*. xls) files Optional: Model wafer and field focus Update Trend charts Weir DMA outputs status and any errors to Remote. Call. log 42 Display currentdata graphic TEA Systems Yield Enhancement thru Modeling

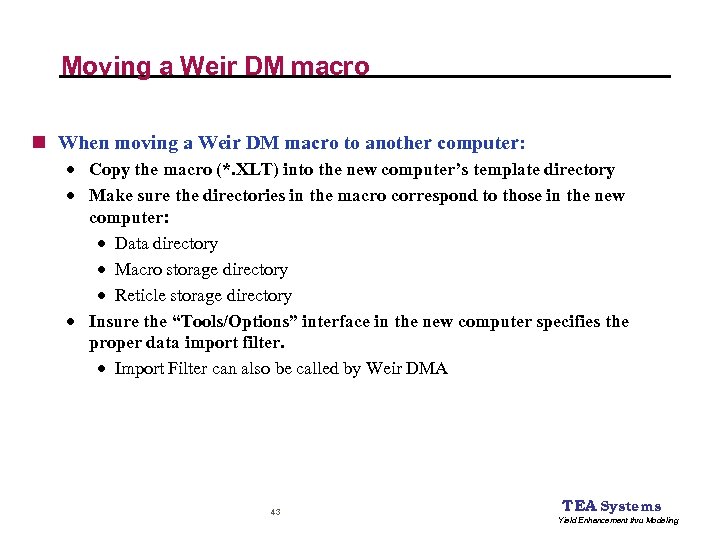

Moving a Weir DM macro n When moving a Weir DM macro to another computer: · Copy the macro (*. XLT) into the new computer’s template directory · Make sure the directories in the macro correspond to those in the new computer: · Data directory · Macro storage directory · Reticle storage directory · Insure the “Tools/Options” interface in the new computer specifies the proper data import filter. · Import Filter can also be called by Weir DMA 43 TEA Systems Yield Enhancement thru Modeling

Moving a Weir DM macro n When moving a Weir DM macro to another computer: · Copy the macro (*. XLT) into the new computer’s template directory · Make sure the directories in the macro correspond to those in the new computer: · Data directory · Macro storage directory · Reticle storage directory · Insure the “Tools/Options” interface in the new computer specifies the proper data import filter. · Import Filter can also be called by Weir DMA 43 TEA Systems Yield Enhancement thru Modeling

http: //www. TEAsystems. com Weir DMA Example Analysis

http: //www. TEAsystems. com Weir DMA Example Analysis

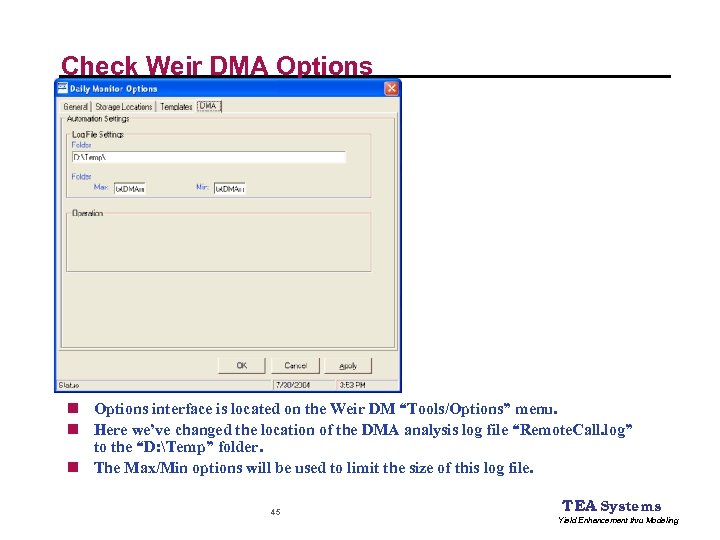

Check Weir DMA Options n Options interface is located on the Weir DM “Tools/Options” menu. n Here we’ve changed the location of the DMA analysis log file “Remote. Call. log” to the “D: Temp” folder. n The Max/Min options will be used to limit the size of this log file. 45 TEA Systems Yield Enhancement thru Modeling

Check Weir DMA Options n Options interface is located on the Weir DM “Tools/Options” menu. n Here we’ve changed the location of the DMA analysis log file “Remote. Call. log” to the “D: Temp” folder. n The Max/Min options will be used to limit the size of this log file. 45 TEA Systems Yield Enhancement thru Modeling

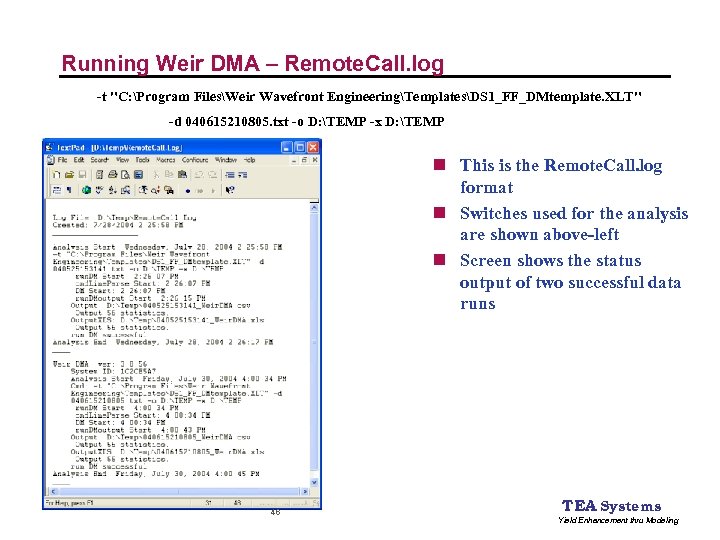

Running Weir DMA – Remote. Call. log -t "C: Program FilesWeir Wavefront EngineeringTemplatesDS 1_FF_DMtemplate. XLT" -d 040615210805. txt -o D: TEMP -x D: TEMP n This is the Remote. Call. log format n Switches used for the analysis are shown above-left n Screen shows the status output of two successful data runs 46 TEA Systems Yield Enhancement thru Modeling

Running Weir DMA – Remote. Call. log -t "C: Program FilesWeir Wavefront EngineeringTemplatesDS 1_FF_DMtemplate. XLT" -d 040615210805. txt -o D: TEMP -x D: TEMP n This is the Remote. Call. log format n Switches used for the analysis are shown above-left n Screen shows the status output of two successful data runs 46 TEA Systems Yield Enhancement thru Modeling

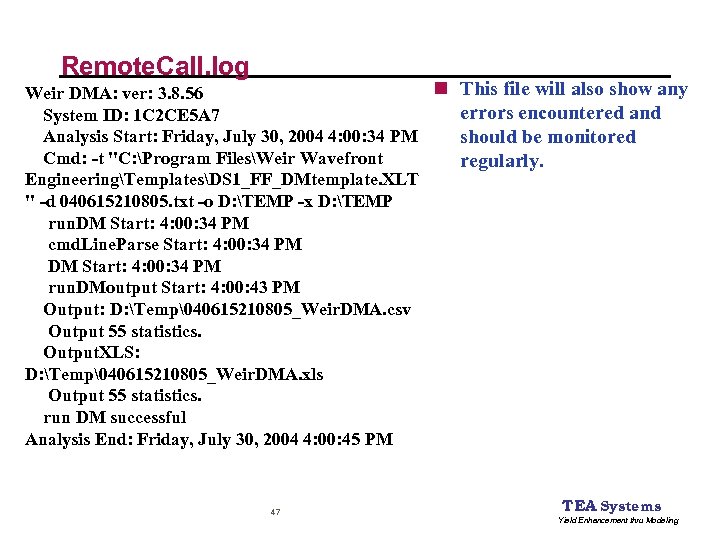

Remote. Call. log n This file will also show any Weir DMA: ver: 3. 8. 56 errors encountered and System ID: 1 C 2 CE 5 A 7 Analysis Start: Friday, July 30, 2004 4: 00: 34 PM should be monitored Cmd: -t "C: Program FilesWeir Wavefront regularly. EngineeringTemplatesDS 1_FF_DMtemplate. XLT " -d 040615210805. txt -o D: TEMP -x D: TEMP run. DM Start: 4: 00: 34 PM cmd. Line. Parse Start: 4: 00: 34 PM DM Start: 4: 00: 34 PM run. DMoutput Start: 4: 00: 43 PM Output: D: Temp�40615210805_Weir. DMA. csv Output 55 statistics. Output. XLS: D: Temp�40615210805_Weir. DMA. xls Output 55 statistics. run DM successful Analysis End: Friday, July 30, 2004 4: 00: 45 PM 47 TEA Systems Yield Enhancement thru Modeling

Remote. Call. log n This file will also show any Weir DMA: ver: 3. 8. 56 errors encountered and System ID: 1 C 2 CE 5 A 7 Analysis Start: Friday, July 30, 2004 4: 00: 34 PM should be monitored Cmd: -t "C: Program FilesWeir Wavefront regularly. EngineeringTemplatesDS 1_FF_DMtemplate. XLT " -d 040615210805. txt -o D: TEMP -x D: TEMP run. DM Start: 4: 00: 34 PM cmd. Line. Parse Start: 4: 00: 34 PM DM Start: 4: 00: 34 PM run. DMoutput Start: 4: 00: 43 PM Output: D: Temp�40615210805_Weir. DMA. csv Output 55 statistics. Output. XLS: D: Temp�40615210805_Weir. DMA. xls Output 55 statistics. run DM successful Analysis End: Friday, July 30, 2004 4: 00: 45 PM 47 TEA Systems Yield Enhancement thru Modeling

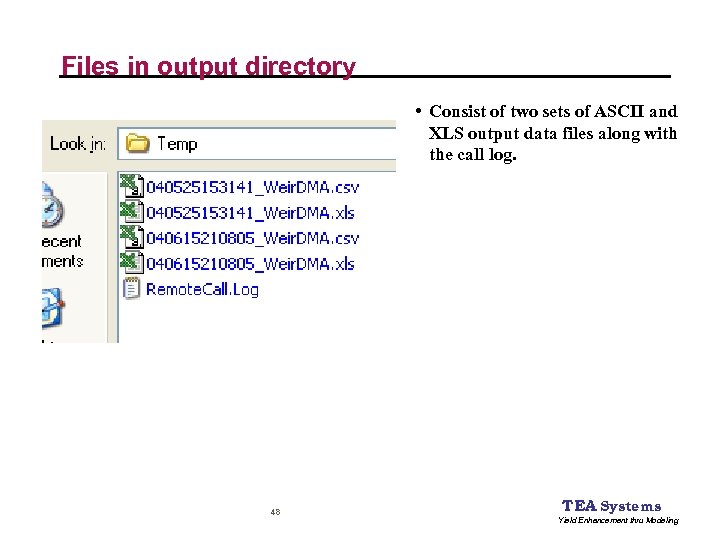

Files in output directory • Consist of two sets of ASCII and XLS output data files along with the call log. 48 TEA Systems Yield Enhancement thru Modeling

Files in output directory • Consist of two sets of ASCII and XLS output data files along with the call log. 48 TEA Systems Yield Enhancement thru Modeling

![Output Data File , [Data], , , Program: , Weir DMA, , , Data. Output Data File , [Data], , , Program: , Weir DMA, , , Data.](https://present5.com/presentation/02826142a0279c5aad15fd37347f5f73/image-49.jpg) Output Data File , [Data], , , Program: , Weir DMA, , , Data. File: , 040525153141. txt, , Data. Folder: , D: DataUMCWeir. DM Testing, , Template: , DS 1_FF_DMtemplate. XLT, , Template. Folder: , C: Program FilesWeir Wavefront EngineeringTemplates, , Analysis. Date: , 7/28/2004, , Analysis. Time: , 12: 00 AM, , Tool: , , , Wafers: , 1, , , [Header], , , Date. Template. Saved: , 7/27/2004, , Analysis: , Fixed Focus, , Focus. Template: , UMC DS 5 -Step 2, , Conversion. Method: , All Sites, , Model. Data: , True, , Statistics: , 1, , Graphic. Data: , 0, , Wafer. Field. Graphic: , Wafer, , Graphic. Plot: , Vector, , Graphic. Data. Format: , All Points, , Comments: , , , Summary: , Analysis: Fixed Focus: All Sites (UMC DS 5 -Step 2) 49 , Focus. Min: : , 0, , [End. Header], , , [Results], , , [Z (Mean)], , , Wafers: , 1, , Sites/Die: , 2, , #Dice: , 5, , IFD: , 0. 199, , BF(Fitted): , 0. 000, , X Tilt(urad): , 0. 000, , Y Tilt(urad): , 0. 000, , Astigmatism: , 0. 135, , Curv(nm/cm 2): , 0. 000, , IFDresid(um): , 0. 000, , St. DEVresid(um): , 0. 000, , Count: , 10, , Mean: , 0. 017, , Median: , 0. 036, , SEM: , 0. 018, , Maximum: , 0. 136, , Minimum: , -0. 063, , Range: , 0. 199, , Min. Max: , 0. 136, , St. Dev: , 0. 058, , Mean+3 Sigma: , 0. 190, , [End. Results], , , [END], , n Partial display of output file n Specifications are in the manual. n Each section of the data is summarized by a header line in “[]” brackets TEA Systems Yield Enhancement thru Modeling

Output Data File , [Data], , , Program: , Weir DMA, , , Data. File: , 040525153141. txt, , Data. Folder: , D: DataUMCWeir. DM Testing, , Template: , DS 1_FF_DMtemplate. XLT, , Template. Folder: , C: Program FilesWeir Wavefront EngineeringTemplates, , Analysis. Date: , 7/28/2004, , Analysis. Time: , 12: 00 AM, , Tool: , , , Wafers: , 1, , , [Header], , , Date. Template. Saved: , 7/27/2004, , Analysis: , Fixed Focus, , Focus. Template: , UMC DS 5 -Step 2, , Conversion. Method: , All Sites, , Model. Data: , True, , Statistics: , 1, , Graphic. Data: , 0, , Wafer. Field. Graphic: , Wafer, , Graphic. Plot: , Vector, , Graphic. Data. Format: , All Points, , Comments: , , , Summary: , Analysis: Fixed Focus: All Sites (UMC DS 5 -Step 2) 49 , Focus. Min: : , 0, , [End. Header], , , [Results], , , [Z (Mean)], , , Wafers: , 1, , Sites/Die: , 2, , #Dice: , 5, , IFD: , 0. 199, , BF(Fitted): , 0. 000, , X Tilt(urad): , 0. 000, , Y Tilt(urad): , 0. 000, , Astigmatism: , 0. 135, , Curv(nm/cm 2): , 0. 000, , IFDresid(um): , 0. 000, , St. DEVresid(um): , 0. 000, , Count: , 10, , Mean: , 0. 017, , Median: , 0. 036, , SEM: , 0. 018, , Maximum: , 0. 136, , Minimum: , -0. 063, , Range: , 0. 199, , Min. Max: , 0. 136, , St. Dev: , 0. 058, , Mean+3 Sigma: , 0. 190, , [End. Results], , , [END], , n Partial display of output file n Specifications are in the manual. n Each section of the data is summarized by a header line in “[]” brackets TEA Systems Yield Enhancement thru Modeling

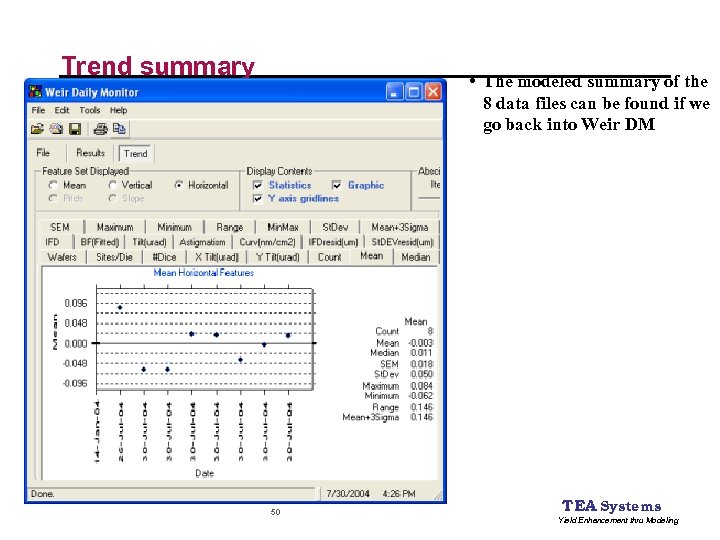

Trend summary • The modeled summary of the 8 data files can be found if we go back into Weir DM 50 TEA Systems Yield Enhancement thru Modeling

Trend summary • The modeled summary of the 8 data files can be found if we go back into Weir DM 50 TEA Systems Yield Enhancement thru Modeling

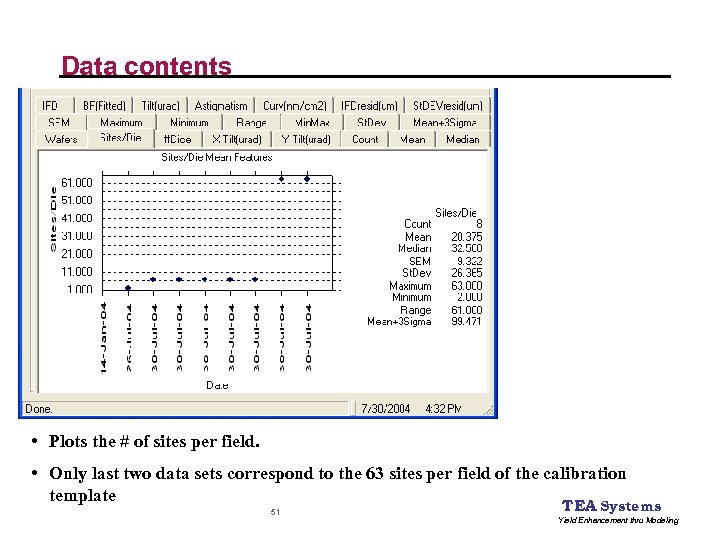

Data contents • Plots the # of sites per field. • Only last two data sets correspond to the 63 sites per field of the calibration template 51 TEA Systems Yield Enhancement thru Modeling

Data contents • Plots the # of sites per field. • Only last two data sets correspond to the 63 sites per field of the calibration template 51 TEA Systems Yield Enhancement thru Modeling

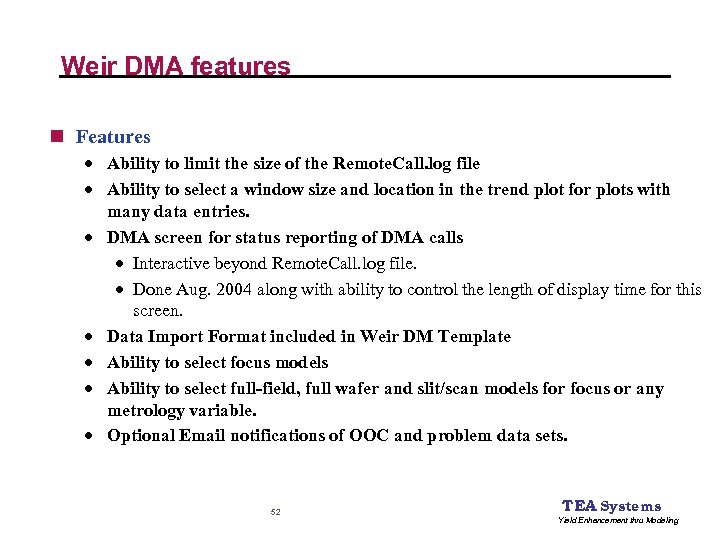

Weir DMA features n Features · Ability to limit the size of the Remote. Call. log file · Ability to select a window size and location in the trend plot for plots with many data entries. · DMA screen for status reporting of DMA calls · Interactive beyond Remote. Call. log file. · Done Aug. 2004 along with ability to control the length of display time for this screen. · Data Import Format included in Weir DM Template · Ability to select focus models · Ability to select full-field, full wafer and slit/scan models for focus or any metrology variable. · Optional Email notifications of OOC and problem data sets. 52 TEA Systems Yield Enhancement thru Modeling

Weir DMA features n Features · Ability to limit the size of the Remote. Call. log file · Ability to select a window size and location in the trend plot for plots with many data entries. · DMA screen for status reporting of DMA calls · Interactive beyond Remote. Call. log file. · Done Aug. 2004 along with ability to control the length of display time for this screen. · Data Import Format included in Weir DM Template · Ability to select focus models · Ability to select full-field, full wafer and slit/scan models for focus or any metrology variable. · Optional Email notifications of OOC and problem data sets. 52 TEA Systems Yield Enhancement thru Modeling