1f0eec59d724694a95c003e72cf69a22.ppt

- Количество слайдов: 27

How to Specify an Electric Flight System A Simple Walk-through

How to Specify an Electric Flight System A Simple Walk-through

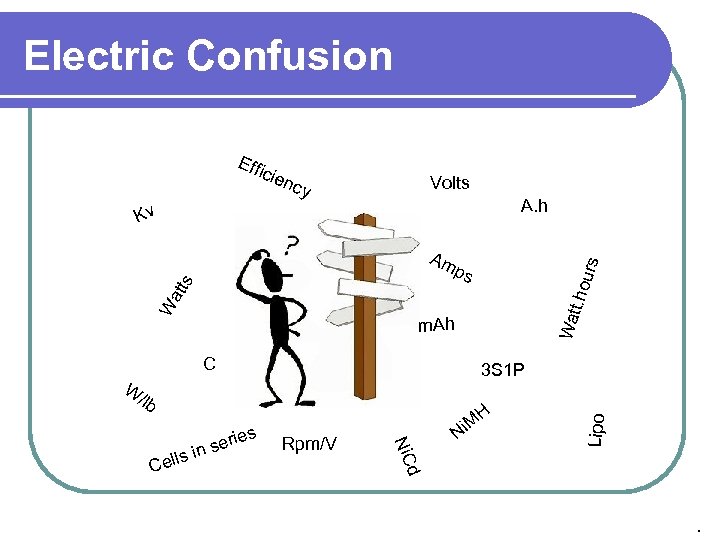

Electric Confusion cie ncy Volts A. h Kv urs t. ho Wat W att s Am ps m. Ah C 3 S 1 P W /lb H Rpm/V Ni. C d C i ells s erie ns M Ni Lipo Effi .

Electric Confusion cie ncy Volts A. h Kv urs t. ho Wat W att s Am ps m. Ah C 3 S 1 P W /lb H Rpm/V Ni. C d C i ells s erie ns M Ni Lipo Effi .

The I. C. Engine Approach l Most I. C. aircraft have a specified engine size, whether building from a plan, kit, or ARF, E. g. l l l 0. 46 – 0. 61 2 -stroke 0. 61 – 0. 91 4 -stroke This worked because all engine makes & models developed roughly the same power per cubic capacity. l l Through years of trial and error modellers had developed a feel for engine size vs aircraft size + flying style E. g. 2. 5 kg sport-model intended for aerobatics will fly well with 0. 40 C. I. 2 -stroke Each engine came with a recommended propeller size + fuel type l Install the right engine with the recommended prop, use the right fuel, and success was virtually guaranteed l .

The I. C. Engine Approach l Most I. C. aircraft have a specified engine size, whether building from a plan, kit, or ARF, E. g. l l l 0. 46 – 0. 61 2 -stroke 0. 61 – 0. 91 4 -stroke This worked because all engine makes & models developed roughly the same power per cubic capacity. l l Through years of trial and error modellers had developed a feel for engine size vs aircraft size + flying style E. g. 2. 5 kg sport-model intended for aerobatics will fly well with 0. 40 C. I. 2 -stroke Each engine came with a recommended propeller size + fuel type l Install the right engine with the recommended prop, use the right fuel, and success was virtually guaranteed l .

The Electric Conundrum Electric Motors have a multitude of “rating numbers” l However, the same fundamental rule applies: Each model will require a certain amount of power to achieve a certain flying style l A powered aircraft needs thrust to fly, and thrust is proportional to power l l l Most IC modellers are not aware how much power their engines develop Manufacturers specs are usually optimistic, e. g. 1. 6 BHP @ 16, 000 rpm, open exhaust!.

The Electric Conundrum Electric Motors have a multitude of “rating numbers” l However, the same fundamental rule applies: Each model will require a certain amount of power to achieve a certain flying style l A powered aircraft needs thrust to fly, and thrust is proportional to power l l l Most IC modellers are not aware how much power their engines develop Manufacturers specs are usually optimistic, e. g. 1. 6 BHP @ 16, 000 rpm, open exhaust!.

So all we need is Power? Fundamentally YES. . . l BUT… there are MANY variables we must correctly specify to make a system work: l l l Battery voltage Battery capacity and C-rating Speed Controller size (voltage and current capacity) Motor speed constant (Kv) Propeller size No aircraft comes with all of these items covered, and usually they are not covered at all! l To specify an electric power system you need to be prepared to apply some simple MATH l .

So all we need is Power? Fundamentally YES. . . l BUT… there are MANY variables we must correctly specify to make a system work: l l l Battery voltage Battery capacity and C-rating Speed Controller size (voltage and current capacity) Motor speed constant (Kv) Propeller size No aircraft comes with all of these items covered, and usually they are not covered at all! l To specify an electric power system you need to be prepared to apply some simple MATH l .

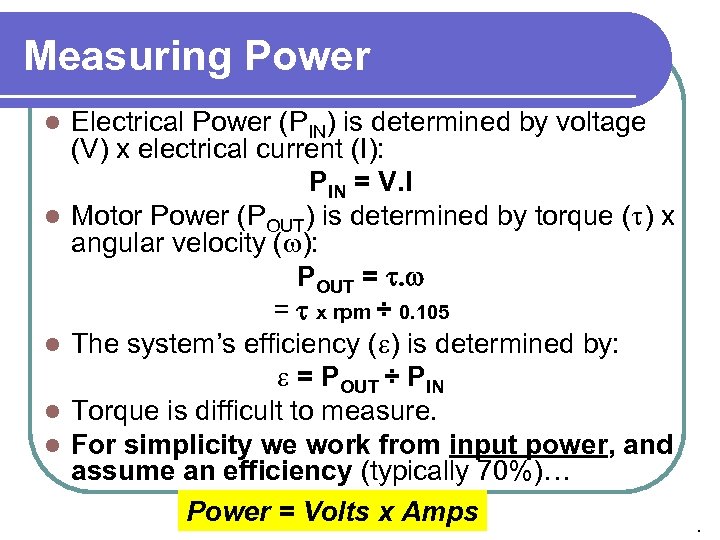

Measuring Power l l l Electrical Power (PIN) is determined by voltage (V) x electrical current (I): PIN = V. I Motor Power (POUT) is determined by torque (t) x angular velocity (w): POUT = t. w = t x rpm ÷ 0. 105 The system’s efficiency (e) is determined by: e = POUT ÷ PIN Torque is difficult to measure. For simplicity we work from input power, and assume an efficiency (typically 70%)… Power = Volts x Amps .

Measuring Power l l l Electrical Power (PIN) is determined by voltage (V) x electrical current (I): PIN = V. I Motor Power (POUT) is determined by torque (t) x angular velocity (w): POUT = t. w = t x rpm ÷ 0. 105 The system’s efficiency (e) is determined by: e = POUT ÷ PIN Torque is difficult to measure. For simplicity we work from input power, and assume an efficiency (typically 70%)… Power = Volts x Amps .

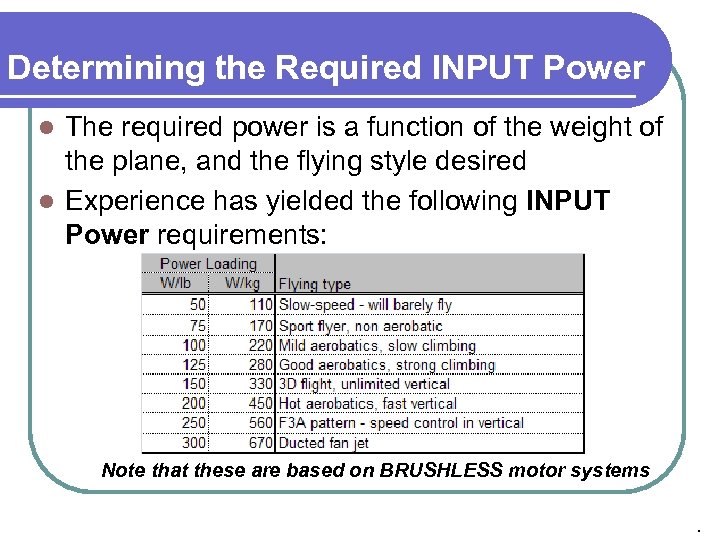

Determining the Required INPUT Power The required power is a function of the weight of the plane, and the flying style desired l Experience has yielded the following INPUT Power requirements: l Note that these are based on BRUSHLESS motor systems.

Determining the Required INPUT Power The required power is a function of the weight of the plane, and the flying style desired l Experience has yielded the following INPUT Power requirements: l Note that these are based on BRUSHLESS motor systems.

Case Study l. A modeller purchases an ARF electric powered aerobatic plane, and wants unlimited vertical l The instructions come with no details about the necessary power system l The model specifications say the plane should weigh 2. 0 kg ready to fly .

Case Study l. A modeller purchases an ARF electric powered aerobatic plane, and wants unlimited vertical l The instructions come with no details about the necessary power system l The model specifications say the plane should weigh 2. 0 kg ready to fly .

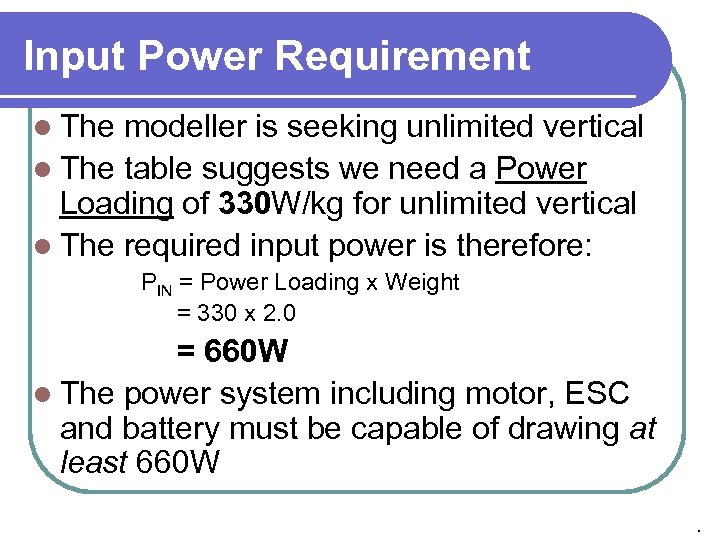

Input Power Requirement l The modeller is seeking unlimited vertical l The table suggests we need a Power Loading of 330 W/kg for unlimited vertical l The required input power is therefore: PIN = Power Loading x Weight = 330 x 2. 0 = 660 W l The power system including motor, ESC and battery must be capable of drawing at least 660 W.

Input Power Requirement l The modeller is seeking unlimited vertical l The table suggests we need a Power Loading of 330 W/kg for unlimited vertical l The required input power is therefore: PIN = Power Loading x Weight = 330 x 2. 0 = 660 W l The power system including motor, ESC and battery must be capable of drawing at least 660 W.

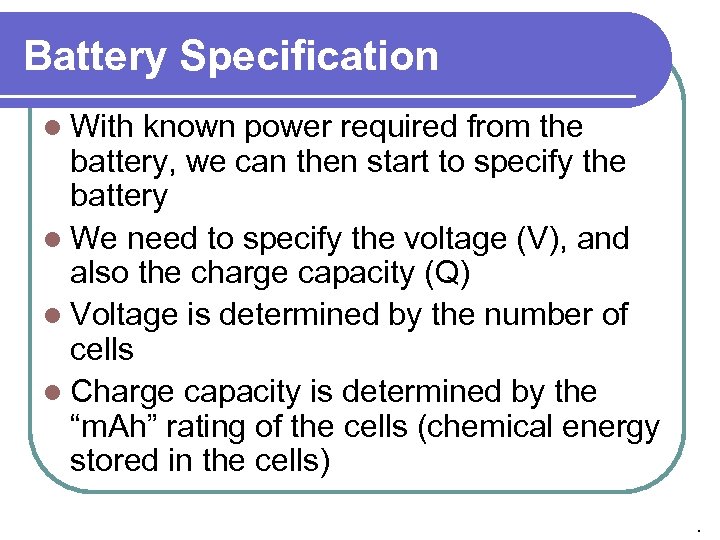

Battery Specification l With known power required from the battery, we can then start to specify the battery l We need to specify the voltage (V), and also the charge capacity (Q) l Voltage is determined by the number of cells l Charge capacity is determined by the “m. Ah” rating of the cells (chemical energy stored in the cells).

Battery Specification l With known power required from the battery, we can then start to specify the battery l We need to specify the voltage (V), and also the charge capacity (Q) l Voltage is determined by the number of cells l Charge capacity is determined by the “m. Ah” rating of the cells (chemical energy stored in the cells).

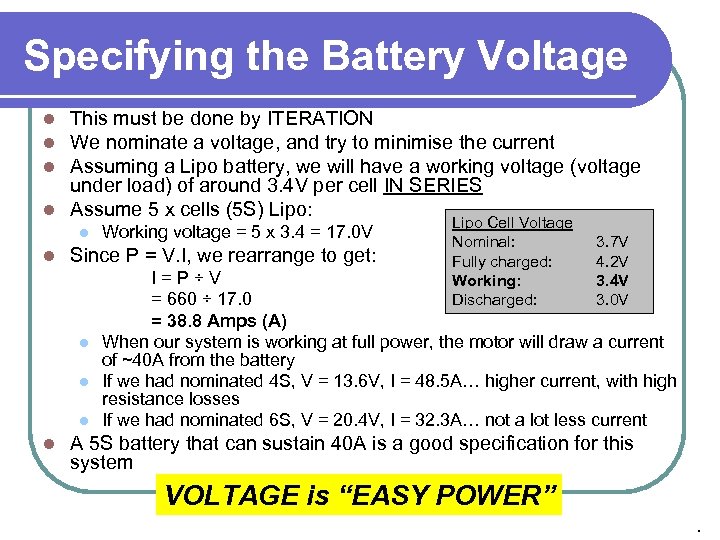

Specifying the Battery Voltage This must be done by ITERATION We nominate a voltage, and try to minimise the current Assuming a Lipo battery, we will have a working voltage (voltage under load) of around 3. 4 V per cell IN SERIES l Assume 5 x cells (5 S) Lipo: l l l Since P = V. I, we rearrange to get: l l Working voltage = 5 x 3. 4 = 17. 0 V Lipo Cell Voltage Nominal: Fully charged: Working: Discharged: 3. 7 V 4. 2 V 3. 4 V 3. 0 V I=P÷V = 660 ÷ 17. 0 = 38. 8 Amps (A) When our system is working at full power, the motor will draw a current of ~40 A from the battery If we had nominated 4 S, V = 13. 6 V, I = 48. 5 A… higher current, with high resistance losses If we had nominated 6 S, V = 20. 4 V, I = 32. 3 A… not a lot less current A 5 S battery that can sustain 40 A is a good specification for this system VOLTAGE is “EASY POWER”.

Specifying the Battery Voltage This must be done by ITERATION We nominate a voltage, and try to minimise the current Assuming a Lipo battery, we will have a working voltage (voltage under load) of around 3. 4 V per cell IN SERIES l Assume 5 x cells (5 S) Lipo: l l l Since P = V. I, we rearrange to get: l l Working voltage = 5 x 3. 4 = 17. 0 V Lipo Cell Voltage Nominal: Fully charged: Working: Discharged: 3. 7 V 4. 2 V 3. 4 V 3. 0 V I=P÷V = 660 ÷ 17. 0 = 38. 8 Amps (A) When our system is working at full power, the motor will draw a current of ~40 A from the battery If we had nominated 4 S, V = 13. 6 V, I = 48. 5 A… higher current, with high resistance losses If we had nominated 6 S, V = 20. 4 V, I = 32. 3 A… not a lot less current A 5 S battery that can sustain 40 A is a good specification for this system VOLTAGE is “EASY POWER”.

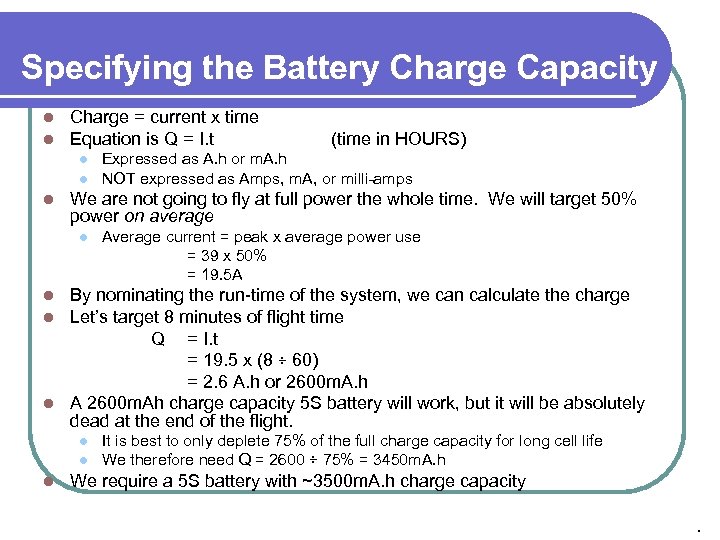

Specifying the Battery Charge Capacity l l Charge = current x time Equation is Q = I. t l l l (time in HOURS) Expressed as A. h or m. A. h NOT expressed as Amps, m. A, or milli-amps We are not going to fly at full power the whole time. We will target 50% power on average l Average current = peak x average power use = 39 x 50% = 19. 5 A By nominating the run-time of the system, we can calculate the charge Let’s target 8 minutes of flight time Q = I. t = 19. 5 x (8 ÷ 60) = 2. 6 A. h or 2600 m. A. h l A 2600 m. Ah charge capacity 5 S battery will work, but it will be absolutely dead at the end of the flight. l l l It is best to only deplete 75% of the full charge capacity for long cell life We therefore need Q = 2600 ÷ 75% = 3450 m. A. h We require a 5 S battery with ~3500 m. A. h charge capacity.

Specifying the Battery Charge Capacity l l Charge = current x time Equation is Q = I. t l l l (time in HOURS) Expressed as A. h or m. A. h NOT expressed as Amps, m. A, or milli-amps We are not going to fly at full power the whole time. We will target 50% power on average l Average current = peak x average power use = 39 x 50% = 19. 5 A By nominating the run-time of the system, we can calculate the charge Let’s target 8 minutes of flight time Q = I. t = 19. 5 x (8 ÷ 60) = 2. 6 A. h or 2600 m. A. h l A 2600 m. Ah charge capacity 5 S battery will work, but it will be absolutely dead at the end of the flight. l l l It is best to only deplete 75% of the full charge capacity for long cell life We therefore need Q = 2600 ÷ 75% = 3450 m. A. h We require a 5 S battery with ~3500 m. A. h charge capacity.

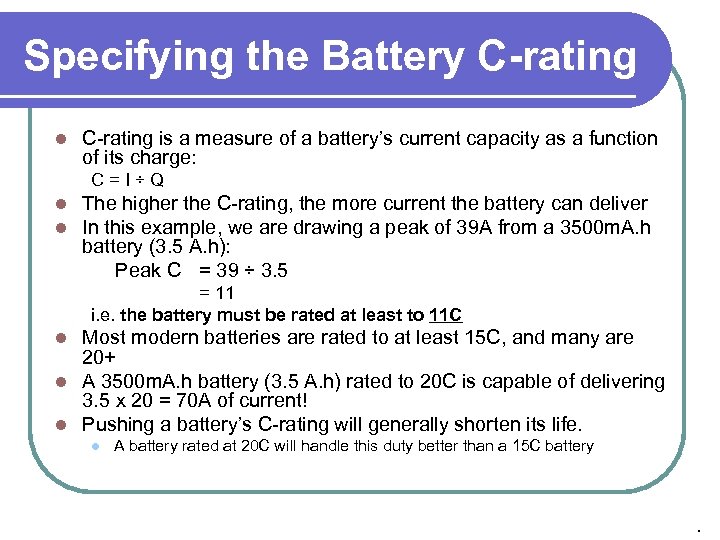

Specifying the Battery C-rating l C-rating is a measure of a battery’s current capacity as a function of its charge: C=I÷Q l l The higher the C-rating, the more current the battery can deliver In this example, we are drawing a peak of 39 A from a 3500 m. A. h battery (3. 5 A. h): Peak C = 39 ÷ 3. 5 = 11 i. e. the battery must be rated at least to 11 C Most modern batteries are rated to at least 15 C, and many are 20+ l A 3500 m. A. h battery (3. 5 A. h) rated to 20 C is capable of delivering 3. 5 x 20 = 70 A of current! l Pushing a battery’s C-rating will generally shorten its life. l l A battery rated at 20 C will handle this duty better than a 15 C battery .

Specifying the Battery C-rating l C-rating is a measure of a battery’s current capacity as a function of its charge: C=I÷Q l l The higher the C-rating, the more current the battery can deliver In this example, we are drawing a peak of 39 A from a 3500 m. A. h battery (3. 5 A. h): Peak C = 39 ÷ 3. 5 = 11 i. e. the battery must be rated at least to 11 C Most modern batteries are rated to at least 15 C, and many are 20+ l A 3500 m. A. h battery (3. 5 A. h) rated to 20 C is capable of delivering 3. 5 x 20 = 70 A of current! l Pushing a battery’s C-rating will generally shorten its life. l l A battery rated at 20 C will handle this duty better than a 15 C battery .

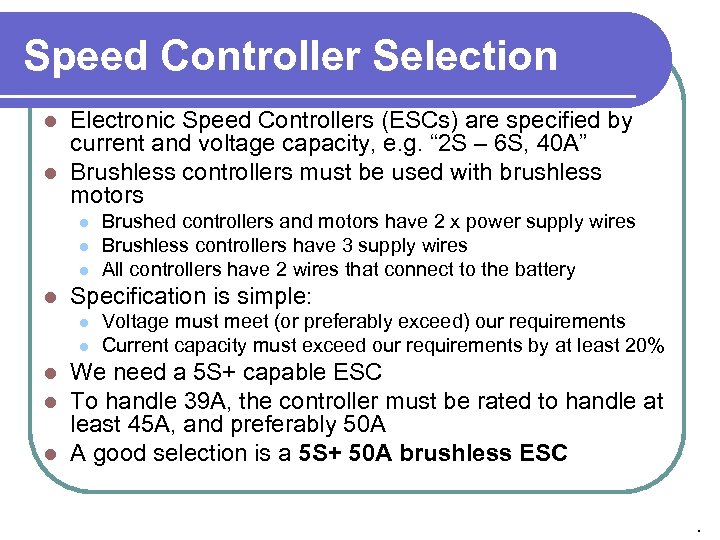

Speed Controller Selection Electronic Speed Controllers (ESCs) are specified by current and voltage capacity, e. g. “ 2 S – 6 S, 40 A” l Brushless controllers must be used with brushless motors l l l Brushed controllers and motors have 2 x power supply wires Brushless controllers have 3 supply wires All controllers have 2 wires that connect to the battery Specification is simple: l l Voltage must meet (or preferably exceed) our requirements Current capacity must exceed our requirements by at least 20% We need a 5 S+ capable ESC To handle 39 A, the controller must be rated to handle at least 45 A, and preferably 50 A l A good selection is a 5 S+ 50 A brushless ESC l l .

Speed Controller Selection Electronic Speed Controllers (ESCs) are specified by current and voltage capacity, e. g. “ 2 S – 6 S, 40 A” l Brushless controllers must be used with brushless motors l l l Brushed controllers and motors have 2 x power supply wires Brushless controllers have 3 supply wires All controllers have 2 wires that connect to the battery Specification is simple: l l Voltage must meet (or preferably exceed) our requirements Current capacity must exceed our requirements by at least 20% We need a 5 S+ capable ESC To handle 39 A, the controller must be rated to handle at least 45 A, and preferably 50 A l A good selection is a 5 S+ 50 A brushless ESC l l .

Motor Specification l Motors often have confusing specifications, e. g. : Graupner Speed 380 BB l Axi 2808/16 l Hi. Max C 3030 -1000 l l Most of these numbers are IRRELEVANT l We need only 2 x numbers: Rated Power l Speed Constant (Kv) l .

Motor Specification l Motors often have confusing specifications, e. g. : Graupner Speed 380 BB l Axi 2808/16 l Hi. Max C 3030 -1000 l l Most of these numbers are IRRELEVANT l We need only 2 x numbers: Rated Power l Speed Constant (Kv) l .

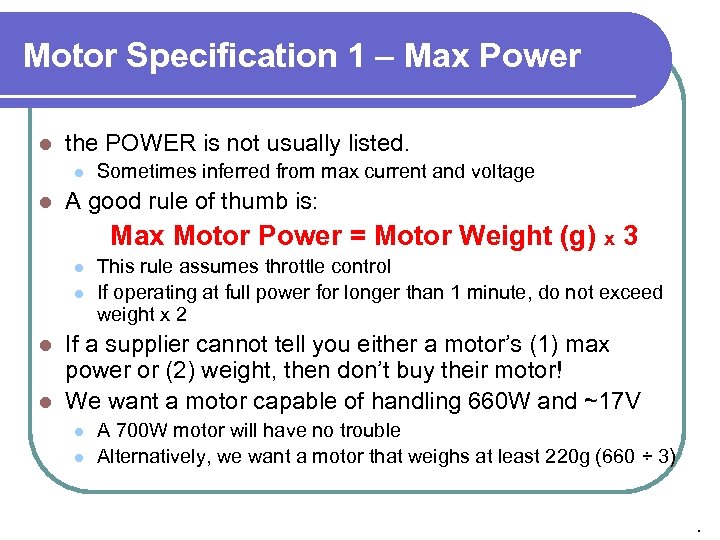

Motor Specification 1 – Max Power l the POWER is not usually listed. l l Sometimes inferred from max current and voltage A good rule of thumb is: Max Motor Power = Motor Weight (g) x 3 l l This rule assumes throttle control If operating at full power for longer than 1 minute, do not exceed weight x 2 If a supplier cannot tell you either a motor’s (1) max power or (2) weight, then don’t buy their motor! l We want a motor capable of handling 660 W and ~17 V l l l A 700 W motor will have no trouble Alternatively, we want a motor that weighs at least 220 g (660 ÷ 3).

Motor Specification 1 – Max Power l the POWER is not usually listed. l l Sometimes inferred from max current and voltage A good rule of thumb is: Max Motor Power = Motor Weight (g) x 3 l l This rule assumes throttle control If operating at full power for longer than 1 minute, do not exceed weight x 2 If a supplier cannot tell you either a motor’s (1) max power or (2) weight, then don’t buy their motor! l We want a motor capable of handling 660 W and ~17 V l l l A 700 W motor will have no trouble Alternatively, we want a motor that weighs at least 220 g (660 ÷ 3).

Power, Cooling and Throttle Control l The harder you push a motor, the hotter it will get l l l Cooling is essential: l l If efficiency is 70%, 30% of the supplied power is turning into heat! At 660 W, this means 200 W of heat! Cooling air inlets near the motor Clear flow past the ESC and battery Exit area larger than inlet area Use throttle control!.

Power, Cooling and Throttle Control l The harder you push a motor, the hotter it will get l l l Cooling is essential: l l If efficiency is 70%, 30% of the supplied power is turning into heat! At 660 W, this means 200 W of heat! Cooling air inlets near the motor Clear flow past the ESC and battery Exit area larger than inlet area Use throttle control!.

Motor Specification 2 – Speed Constant l Every electric motor will want to turn at a certain speed (rpm) depending on the applied voltage l l We will be sending 17. 0 V to the motor. Resulting motor speeds will be: l l This is expressed as a motor speed constant (Kv), e. g. 1000 rpm/V Motor Speed (rpm) = Kv x V 300 rpm/V will attempt to achieve 5100 rpm 500 rpm/V will attempt to achieve 8500 rpm 2000 rpm/V will attempt to achieve 34000 rpm!!! GREAT! Let’s go for 34000 rpm and select 2000 rpm/V… WRONG!.

Motor Specification 2 – Speed Constant l Every electric motor will want to turn at a certain speed (rpm) depending on the applied voltage l l We will be sending 17. 0 V to the motor. Resulting motor speeds will be: l l This is expressed as a motor speed constant (Kv), e. g. 1000 rpm/V Motor Speed (rpm) = Kv x V 300 rpm/V will attempt to achieve 5100 rpm 500 rpm/V will attempt to achieve 8500 rpm 2000 rpm/V will attempt to achieve 34000 rpm!!! GREAT! Let’s go for 34000 rpm and select 2000 rpm/V… WRONG!.

Motor Speed Constant vs Propeller Selection l The higher the rpm, the higher the load on the motor, and hence the greater the power draw l l For a given propeller, doubling the rpm increases the power draw by ~8 times!!! The “bigger” the propeller, the higher the motor load, and the greater the power draw l A 12 x 8 propeller will draw around twice the power of a 10 x 6 at the same rpm High revving propellers are less efficient than low revving propellers due to drag l Clearly we want to specify a propeller and a motor constant that will draw 660 W at full motor power, at reasonable efficiency l A good rule of thumb for electric is to target 6000 – 10, 000 rpm l l l Higher rpm is less efficient Lower rpm will need a big propeller to draw the power, and possibly give too little pitch speed .

Motor Speed Constant vs Propeller Selection l The higher the rpm, the higher the load on the motor, and hence the greater the power draw l l For a given propeller, doubling the rpm increases the power draw by ~8 times!!! The “bigger” the propeller, the higher the motor load, and the greater the power draw l A 12 x 8 propeller will draw around twice the power of a 10 x 6 at the same rpm High revving propellers are less efficient than low revving propellers due to drag l Clearly we want to specify a propeller and a motor constant that will draw 660 W at full motor power, at reasonable efficiency l A good rule of thumb for electric is to target 6000 – 10, 000 rpm l l l Higher rpm is less efficient Lower rpm will need a big propeller to draw the power, and possibly give too little pitch speed .

Motor Speed Constant Selection l The speed constant (Kv) is the UNLOADED speed of the motor l l l As the load increases, the motor will slow down – called SLIP, BUT it will draw more power (unlike IC) Slip is typically 10% - 30% The 600 rpm/V motor on 5 S will turn at 10, 200 rpm with no load, but at about 8000 rpm under load – IDEAL! .

Motor Speed Constant Selection l The speed constant (Kv) is the UNLOADED speed of the motor l l l As the load increases, the motor will slow down – called SLIP, BUT it will draw more power (unlike IC) Slip is typically 10% - 30% The 600 rpm/V motor on 5 S will turn at 10, 200 rpm with no load, but at about 8000 rpm under load – IDEAL! .

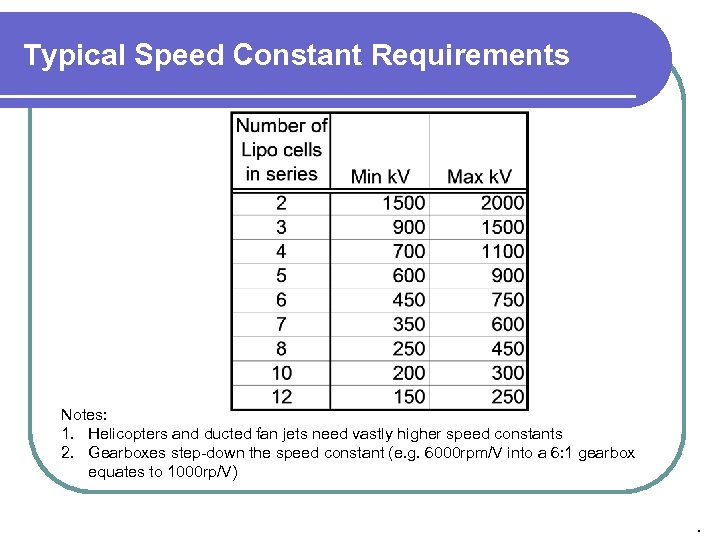

Typical Speed Constant Requirements Notes: 1. Helicopters and ducted fan jets need vastly higher speed constants 2. Gearboxes step-down the speed constant (e. g. 6000 rpm/V into a 6: 1 gearbox equates to 1000 rp/V) .

Typical Speed Constant Requirements Notes: 1. Helicopters and ducted fan jets need vastly higher speed constants 2. Gearboxes step-down the speed constant (e. g. 6000 rpm/V into a 6: 1 gearbox equates to 1000 rp/V) .

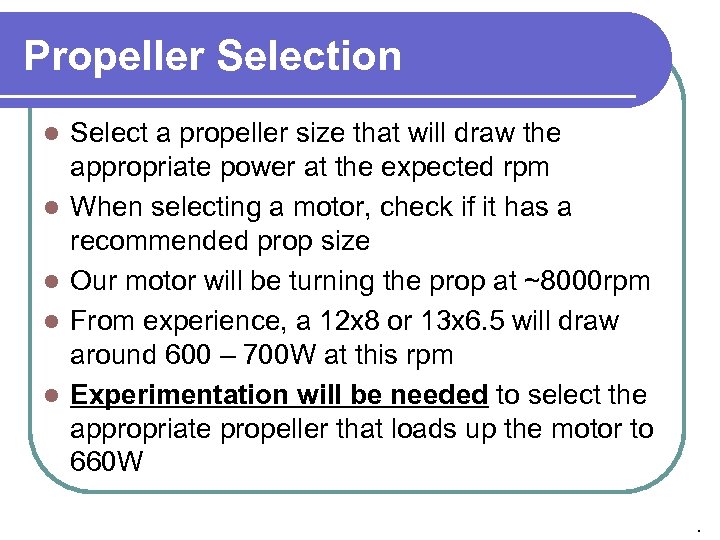

Propeller Selection l l l Select a propeller size that will draw the appropriate power at the expected rpm When selecting a motor, check if it has a recommended prop size Our motor will be turning the prop at ~8000 rpm From experience, a 12 x 8 or 13 x 6. 5 will draw around 600 – 700 W at this rpm Experimentation will be needed to select the appropriate propeller that loads up the motor to 660 W.

Propeller Selection l l l Select a propeller size that will draw the appropriate power at the expected rpm When selecting a motor, check if it has a recommended prop size Our motor will be turning the prop at ~8000 rpm From experience, a 12 x 8 or 13 x 6. 5 will draw around 600 – 700 W at this rpm Experimentation will be needed to select the appropriate propeller that loads up the motor to 660 W.

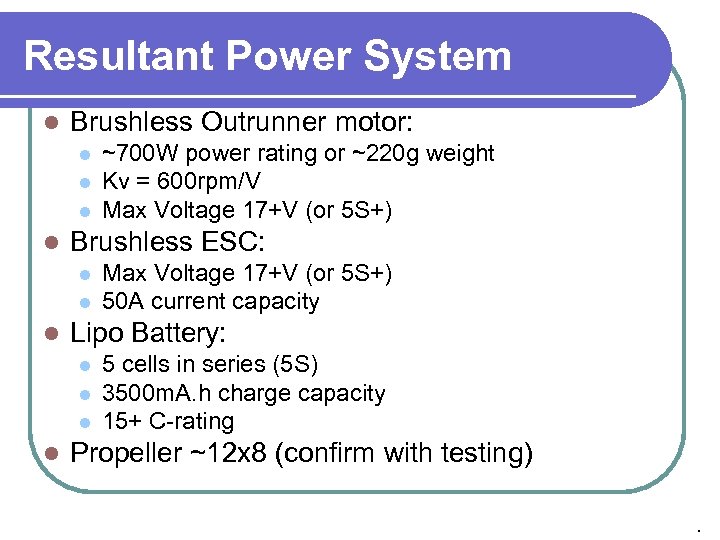

Resultant Power System l Brushless Outrunner motor: l l Brushless ESC: l l l Max Voltage 17+V (or 5 S+) 50 A current capacity Lipo Battery: l l ~700 W power rating or ~220 g weight Kv = 600 rpm/V Max Voltage 17+V (or 5 S+) 5 cells in series (5 S) 3500 m. A. h charge capacity 15+ C-rating Propeller ~12 x 8 (confirm with testing).

Resultant Power System l Brushless Outrunner motor: l l Brushless ESC: l l l Max Voltage 17+V (or 5 S+) 50 A current capacity Lipo Battery: l l ~700 W power rating or ~220 g weight Kv = 600 rpm/V Max Voltage 17+V (or 5 S+) 5 cells in series (5 S) 3500 m. A. h charge capacity 15+ C-rating Propeller ~12 x 8 (confirm with testing).

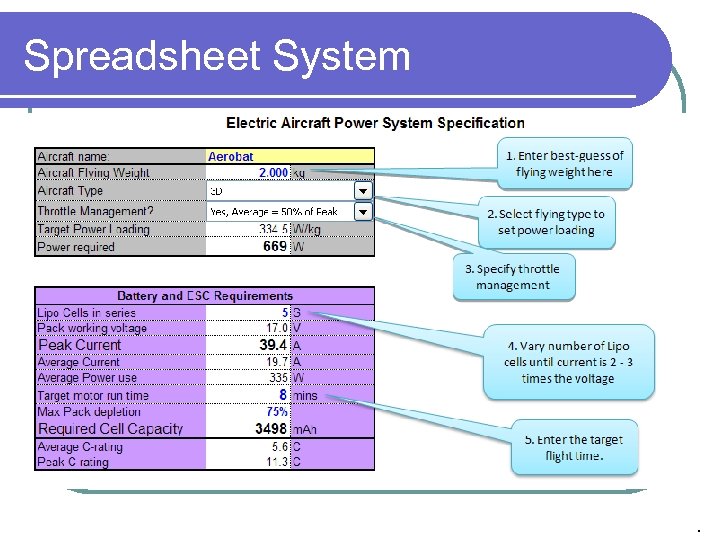

Spreadsheet System .

Spreadsheet System .

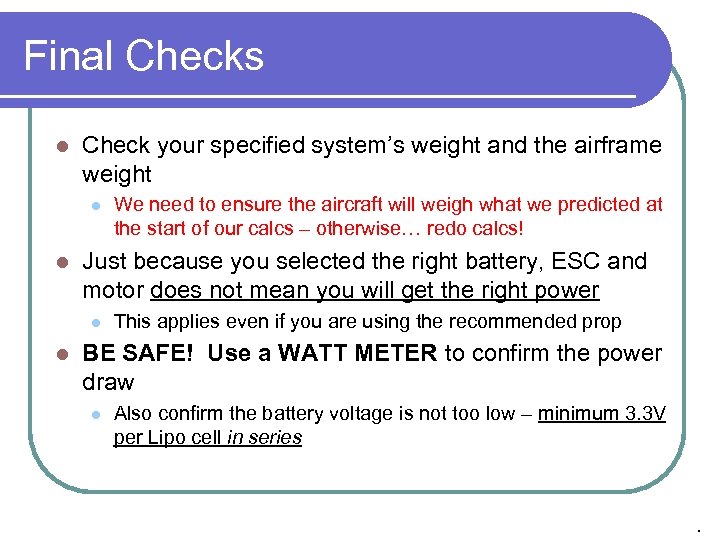

Final Checks l Check your specified system’s weight and the airframe weight l l Just because you selected the right battery, ESC and motor does not mean you will get the right power l l We need to ensure the aircraft will weigh what we predicted at the start of our calcs – otherwise… redo calcs! This applies even if you are using the recommended prop BE SAFE! Use a WATT METER to confirm the power draw l Also confirm the battery voltage is not too low – minimum 3. 3 V per Lipo cell in series .

Final Checks l Check your specified system’s weight and the airframe weight l l Just because you selected the right battery, ESC and motor does not mean you will get the right power l l We need to ensure the aircraft will weigh what we predicted at the start of our calcs – otherwise… redo calcs! This applies even if you are using the recommended prop BE SAFE! Use a WATT METER to confirm the power draw l Also confirm the battery voltage is not too low – minimum 3. 3 V per Lipo cell in series .

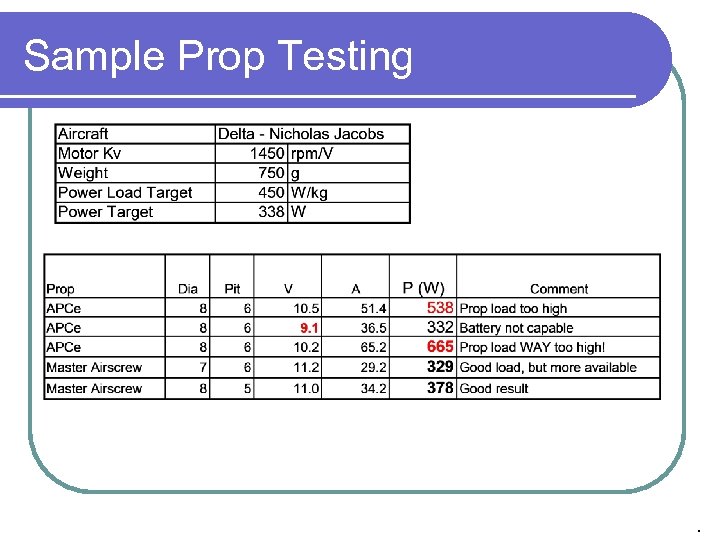

Sample Prop Testing .

Sample Prop Testing .

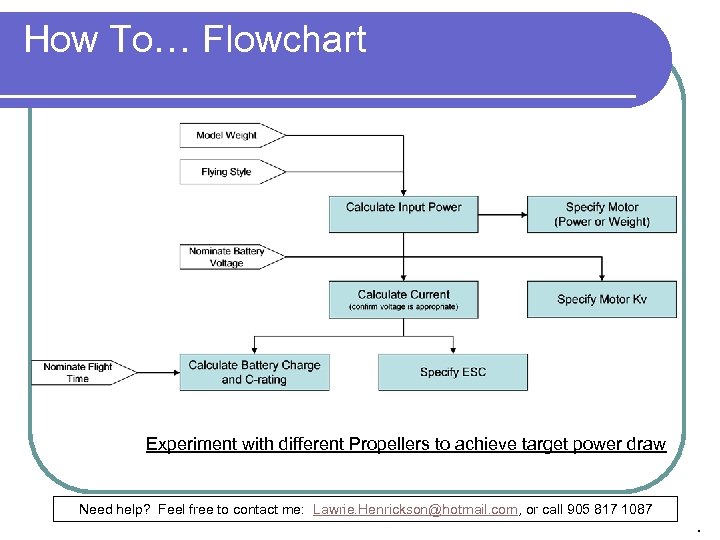

How To… Flowchart Experiment with different Propellers to achieve target power draw Need help? Feel free to contact me: Lawrie. Henrickson@hotmail. com, or call 905 817 1087 .

How To… Flowchart Experiment with different Propellers to achieve target power draw Need help? Feel free to contact me: Lawrie. Henrickson@hotmail. com, or call 905 817 1087 .