88d58a7afd3722e95e1026188f6054fc.ppt

- Количество слайдов: 33

Hour 5: ERP System Installation Special IS Project In-house: massive IS project, heavy system design features

Hour 5: ERP System Installation Special IS Project In-house: massive IS project, heavy system design features

ERP Implementation Project • If vendor system – Much less system design than otherwise – Vendor software already programmed • Only need interfaces – Have help from vendor, consultants – Opportunities to outsource

ERP Implementation Project • If vendor system – Much less system design than otherwise – Vendor software already programmed • Only need interfaces – Have help from vendor, consultants – Opportunities to outsource

ERP as an IS Project • At least 7 optional ways to implement ERP • Outsourcing (ASP) the easiest – But risky • Next easiest is single vendor source without modifications – Not necessarily least expensive, nor greatest benefits • All others involve significant IS project

ERP as an IS Project • At least 7 optional ways to implement ERP • Outsourcing (ASP) the easiest – But risky • Next easiest is single vendor source without modifications – Not necessarily least expensive, nor greatest benefits • All others involve significant IS project

![Relative Use of ERP Implementation Strategies Mabert et al. [2000] Strategy % Single vendor Relative Use of ERP Implementation Strategies Mabert et al. [2000] Strategy % Single vendor](https://present5.com/presentation/88d58a7afd3722e95e1026188f6054fc/image-4.jpg) Relative Use of ERP Implementation Strategies Mabert et al. [2000] Strategy % Single vendor package-internal modifications 50 Single vendor package 40 Vendor packages-internal modifications 5 Best-of-Breed 4 In-house plus special packages 1 Total in-house development 0. 5

Relative Use of ERP Implementation Strategies Mabert et al. [2000] Strategy % Single vendor package-internal modifications 50 Single vendor package 40 Vendor packages-internal modifications 5 Best-of-Breed 4 In-house plus special packages 1 Total in-house development 0. 5

Implementation Strategy Use • Dominant strategy in manufacturing: – Single vendor – Over half added internal modifications • Very few best-of-breed • Almost none developed totally in-house

Implementation Strategy Use • Dominant strategy in manufacturing: – Single vendor – Over half added internal modifications • Very few best-of-breed • Almost none developed totally in-house

IS/IT Project Management Results • Conventional IS/IT projects have trouble with time, budget, functionality • ERP projects have slightly more structure, but still face problems – Underestimation of required time common – Vendors have made easier & faster – Enhancement of systems another trend • Reintroduces time problem

IS/IT Project Management Results • Conventional IS/IT projects have trouble with time, budget, functionality • ERP projects have slightly more structure, but still face problems – Underestimation of required time common – Vendors have made easier & faster – Enhancement of systems another trend • Reintroduces time problem

Systems Failure Method • systematic method for analysis of failure • successfully applied - wide variety of situations • by reviewing past failures, avoid future failure • as organizations rely more on computers, there is a corresponding increase in significant business interruptions • yet of 300, 000 large & mid-sized computer system installations, <3% had disaster

Systems Failure Method • systematic method for analysis of failure • successfully applied - wide variety of situations • by reviewing past failures, avoid future failure • as organizations rely more on computers, there is a corresponding increase in significant business interruptions • yet of 300, 000 large & mid-sized computer system installations, <3% had disaster

Failures in Planning • negative disasters: decision culminating in physical result, later substantially modified, reversed or abandoned after heavy resource commitment – power generation facility on campus • positive disasters: decision culminating in physical results implemented despite heavy criticism, subsequently felt by many informed people to have been a mistake – Anglo-French SST; BART in San Francisco

Failures in Planning • negative disasters: decision culminating in physical result, later substantially modified, reversed or abandoned after heavy resource commitment – power generation facility on campus • positive disasters: decision culminating in physical results implemented despite heavy criticism, subsequently felt by many informed people to have been a mistake – Anglo-French SST; BART in San Francisco

Failures of Projects • information technology • 1992 - London Ambulance Service – 1. 5 million pound system on line 26 Oct 1992 – immediately lost ambulances – <20% of dispatched ambulances reached destinations within 15 minutes of summons – (before system, 65% met 15 minute standard)

Failures of Projects • information technology • 1992 - London Ambulance Service – 1. 5 million pound system on line 26 Oct 1992 – immediately lost ambulances – <20% of dispatched ambulances reached destinations within 15 minutes of summons – (before system, 65% met 15 minute standard)

Failures of Projects • • Some never work others over budget, very late, or both others perform less than design others meet design specifications, but maintenance & enhancement nightmares

Failures of Projects • • Some never work others over budget, very late, or both others perform less than design others meet design specifications, but maintenance & enhancement nightmares

System Failure Method • failure is regarded as an output of transformation processed from system • place trial system boundaries around situation – experiment with various configurations – reach conclusion about system – need to model system in some detail • at different levels • be careful not to make too fine, lose important interrelationships

System Failure Method • failure is regarded as an output of transformation processed from system • place trial system boundaries around situation – experiment with various configurations – reach conclusion about system – need to model system in some detail • at different levels • be careful not to make too fine, lose important interrelationships

common results failure commonly a result of • organizational structure deficiencies – lack of performance-measuring, control • no clear statements of purpose • subsystem deficiencies • lack of effective communication between subsystems • inadequate design • insufficient consideration of environment; insufficient resources • imbalance of resources production quantity; test quality

common results failure commonly a result of • organizational structure deficiencies – lack of performance-measuring, control • no clear statements of purpose • subsystem deficiencies • lack of effective communication between subsystems • inadequate design • insufficient consideration of environment; insufficient resources • imbalance of resources production quantity; test quality

Fox. Meyer Drug Large drug distributor Wanted to implement ERP

Fox. Meyer Drug Large drug distributor Wanted to implement ERP

Fox. Meyer Corp • Holding company in health care services • wholesale distribution of drugs & beauty aids • served drug stores, chains, hospitals, care facilities • US: 23 distribution centers • Sought market niches, such as home health care

Fox. Meyer Corp • Holding company in health care services • wholesale distribution of drugs & beauty aids • served drug stores, chains, hospitals, care facilities • US: 23 distribution centers • Sought market niches, such as home health care

Fox. Meyer • Due to aging population & growth in health care, expected high growth • Market had extreme price competition, threatening margins • Long-term strategies: – – efficiently manage inventory lower operating expenses strengthen sales & marketing expand services

Fox. Meyer • Due to aging population & growth in health care, expected high growth • Market had extreme price competition, threatening margins • Long-term strategies: – – efficiently manage inventory lower operating expenses strengthen sales & marketing expand services

Prior Fox. Meyer IS • 3 data processing centers, linked • included electronic order entry, invoice preparation, inventory tracking • 1992 began migration of core systems • Benefits not realized until system fully integrated

Prior Fox. Meyer IS • 3 data processing centers, linked • included electronic order entry, invoice preparation, inventory tracking • 1992 began migration of core systems • Benefits not realized until system fully integrated

Fox. Meyer Process • Customer fills out electronic order • Order sent to 1 of the 3 data processing centers • Orders sent to the appropriate distribution center (within 24 hours) • Orders filled manually and packaged • Had just completed national distribution center with multiple carousels & automated picking • Could track inventory to secondary locations

Fox. Meyer Process • Customer fills out electronic order • Order sent to 1 of the 3 data processing centers • Orders sent to the appropriate distribution center (within 24 hours) • Orders filled manually and packaged • Had just completed national distribution center with multiple carousels & automated picking • Could track inventory to secondary locations

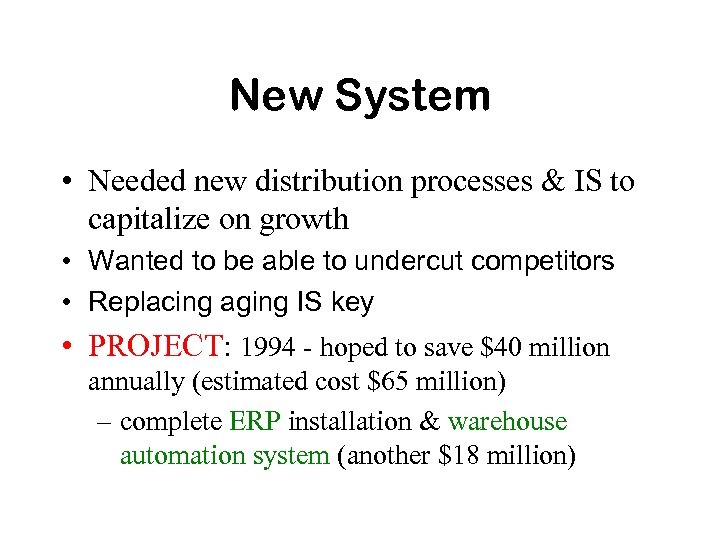

New System • Needed new distribution processes & IS to capitalize on growth • Wanted to be able to undercut competitors • Replacing aging IS key • PROJECT: 1994 - hoped to save $40 million annually (estimated cost $65 million) – complete ERP installation & warehouse automation system (another $18 million)

New System • Needed new distribution processes & IS to capitalize on growth • Wanted to be able to undercut competitors • Replacing aging IS key • PROJECT: 1994 - hoped to save $40 million annually (estimated cost $65 million) – complete ERP installation & warehouse automation system (another $18 million)

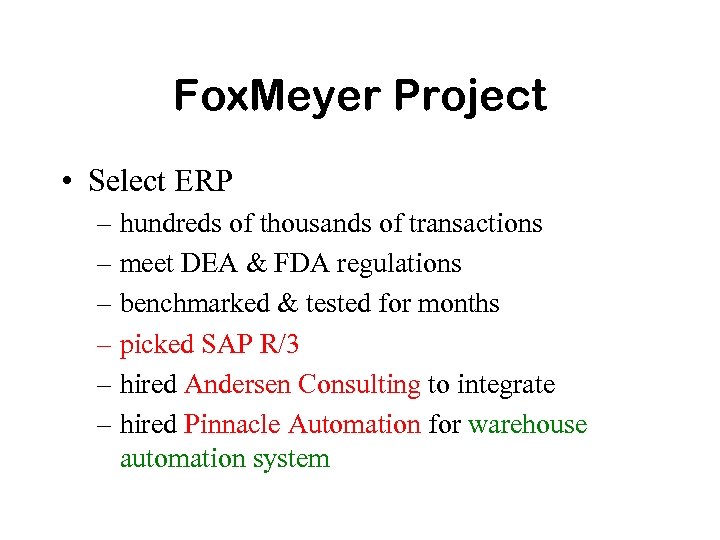

Fox. Meyer Project • Select ERP – hundreds of thousands of transactions – meet DEA & FDA regulations – benchmarked & tested for months – picked SAP R/3 – hired Andersen Consulting to integrate – hired Pinnacle Automation for warehouse automation system

Fox. Meyer Project • Select ERP – hundreds of thousands of transactions – meet DEA & FDA regulations – benchmarked & tested for months – picked SAP R/3 – hired Andersen Consulting to integrate – hired Pinnacle Automation for warehouse automation system

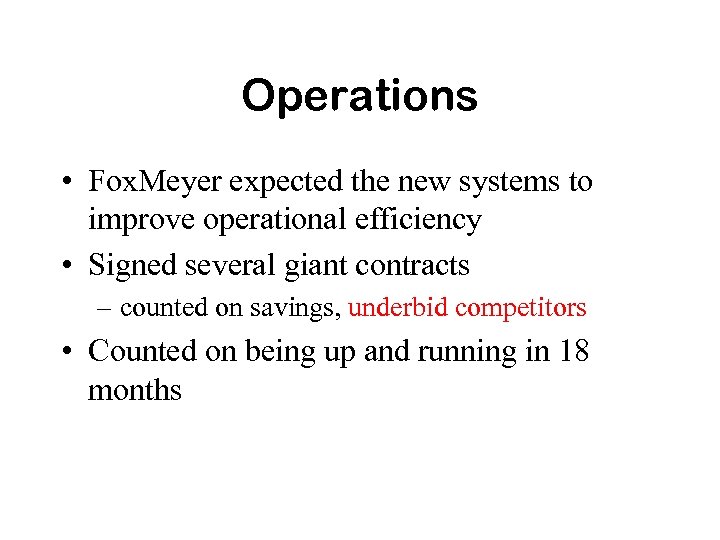

Operations • Fox. Meyer expected the new systems to improve operational efficiency • Signed several giant contracts – counted on savings, underbid competitors • Counted on being up and running in 18 months

Operations • Fox. Meyer expected the new systems to improve operational efficiency • Signed several giant contracts – counted on savings, underbid competitors • Counted on being up and running in 18 months

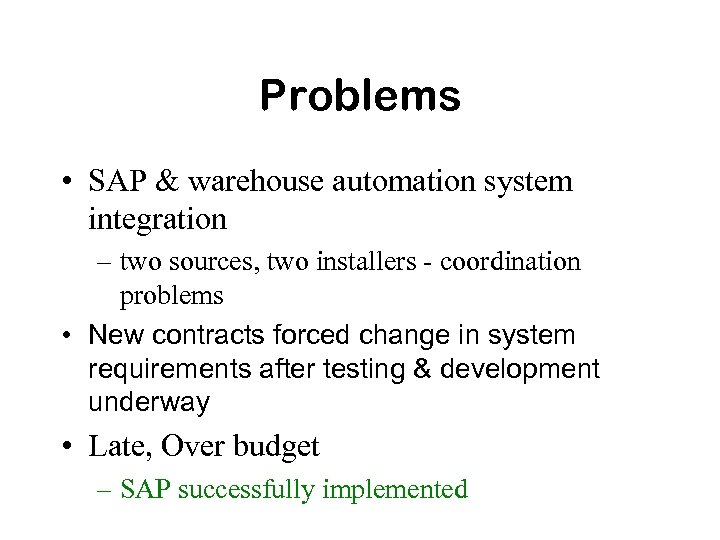

Problems • SAP & warehouse automation system integration – two sources, two installers - coordination problems • New contracts forced change in system requirements after testing & development underway • Late, Over budget – SAP successfully implemented

Problems • SAP & warehouse automation system integration – two sources, two installers - coordination problems • New contracts forced change in system requirements after testing & development underway • Late, Over budget – SAP successfully implemented

Outcomes • Lost key customer - 15% of sales • To recoup, signed new customer, expected $40 million benefit from ERP immediately - pushed ERP project deadline ahead 90 days, no time to reengineer • Warehouse system consistently failed – late orders, incorrect shipment, lost shipments – losses of over $15 million • August 1996 filed for Chapter 11

Outcomes • Lost key customer - 15% of sales • To recoup, signed new customer, expected $40 million benefit from ERP immediately - pushed ERP project deadline ahead 90 days, no time to reengineer • Warehouse system consistently failed – late orders, incorrect shipment, lost shipments – losses of over $15 million • August 1996 filed for Chapter 11

Mc. Kesson Followup • Mid-1990 s started implementation of SAP R/3 – Cancelled project in 1996 after spending $15 million • 1997 acquired Fox. Meyer – – – Carefully designed new R/3 implementation Dropped a number of modules Implemented modules one at a time Cautious rollout schedule, rigorously followed Separate testing group formed At last report $50 million system on time, in budget

Mc. Kesson Followup • Mid-1990 s started implementation of SAP R/3 – Cancelled project in 1996 after spending $15 million • 1997 acquired Fox. Meyer – – – Carefully designed new R/3 implementation Dropped a number of modules Implemented modules one at a time Cautious rollout schedule, rigorously followed Separate testing group formed At last report $50 million system on time, in budget

Mc. Kesson • Massive changes in 3, 000 end user jobs • Careful analysis of changes – Surveys – Focus groups – Demonstrations – Computer-based training

Mc. Kesson • Massive changes in 3, 000 end user jobs • Careful analysis of changes – Surveys – Focus groups – Demonstrations – Computer-based training

Lesson • Implementing ERP a major undertaking • Can easily bankrupt a company • However, it can also be done – Opportunity for great benefits

Lesson • Implementing ERP a major undertaking • Can easily bankrupt a company • However, it can also be done – Opportunity for great benefits

System Architecture & ERP • System architecture displays computer systems used to support organization • Open systems architecture allows greater integration possibilities – Important in supply chains, e-business • ERP systems initially quite closed

System Architecture & ERP • System architecture displays computer systems used to support organization • Open systems architecture allows greater integration possibilities – Important in supply chains, e-business • ERP systems initially quite closed

Open Architecture • Many external systems being added to ERP – CRM – Supply chain – Internet for e-business • Need to integrate independent ERPs across organizations – Messaging services used

Open Architecture • Many external systems being added to ERP – CRM – Supply chain – Internet for e-business • Need to integrate independent ERPs across organizations – Messaging services used

Analysis & Design Control Frameworks • Traditional standards for application development • ERP implementation usually involves installation of vendor software – Still need for treatment as installation project • Early in project, extensive customization needed – The more system flexibility, the more difficulties in implementation – Object-oriented framework benefits extension, tailorability, customizability

Analysis & Design Control Frameworks • Traditional standards for application development • ERP implementation usually involves installation of vendor software – Still need for treatment as installation project • Early in project, extensive customization needed – The more system flexibility, the more difficulties in implementation – Object-oriented framework benefits extension, tailorability, customizability

Application Service Providers • Outsource ERP • Popular – Unocal pared IT staff 40% in two years – Focus on core competencies, shed cost centers • Many specific functions can be outsourced • Outsourcing benefits – Speed – Organization lacks IT skills • ASP the most popular way to outsource

Application Service Providers • Outsource ERP • Popular – Unocal pared IT staff 40% in two years – Focus on core competencies, shed cost centers • Many specific functions can be outsourced • Outsourcing benefits – Speed – Organization lacks IT skills • ASP the most popular way to outsource

ASP Risks • Your applications and data are controlled by others • Service failures out of your control • Confidentiality failure a possibility • Performance issues possible

ASP Risks • Your applications and data are controlled by others • Service failures out of your control • Confidentiality failure a possibility • Performance issues possible

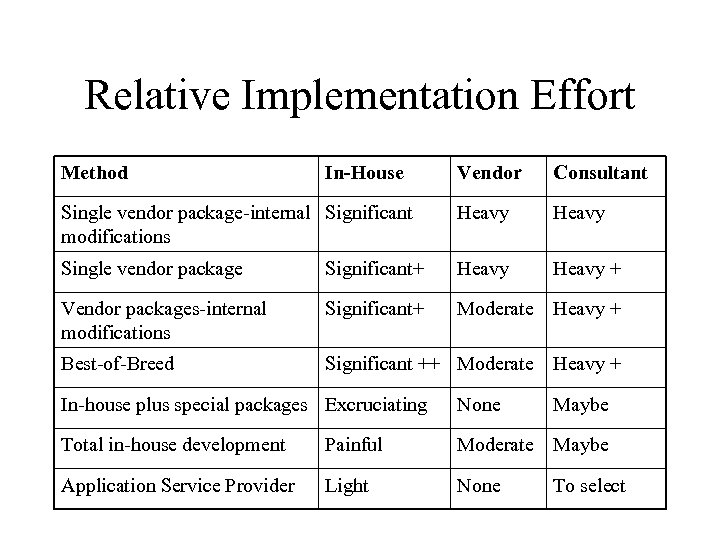

Relative Implementation Effort Method In-House Vendor Consultant Single vendor package-internal Significant modifications Heavy Single vendor package Significant+ Heavy + Vendor packages-internal modifications Significant+ Moderate Heavy + Best-of-Breed Significant ++ Moderate Heavy + In-house plus special packages Excruciating None Maybe Total in-house development Painful Moderate Maybe Application Service Provider Light None To select

Relative Implementation Effort Method In-House Vendor Consultant Single vendor package-internal Significant modifications Heavy Single vendor package Significant+ Heavy + Vendor packages-internal modifications Significant+ Moderate Heavy + Best-of-Breed Significant ++ Moderate Heavy + In-house plus special packages Excruciating None Maybe Total in-house development Painful Moderate Maybe Application Service Provider Light None To select

Implementation Effort • Implementing ERP places strain on in-house information systems groups • Consultants are expensive – Sometimes need special expertise • Tradeoff: control vs. time & cost

Implementation Effort • Implementing ERP places strain on in-house information systems groups • Consultants are expensive – Sometimes need special expertise • Tradeoff: control vs. time & cost

Summary • ERP driven by idea of quality software support • Software quality has long been important • Many ERP implementation strategies available • Tradeoff in control vs. time & cost

Summary • ERP driven by idea of quality software support • Software quality has long been important • Many ERP implementation strategies available • Tradeoff in control vs. time & cost