Homework 3 Group Technology Design and Operational Scheduling Due on November 22, 2006 Maximum group size is 2 students

Homework 3 Group Technology Design and Operational Scheduling Due on November 22, 2006 Maximum group size is 2 students

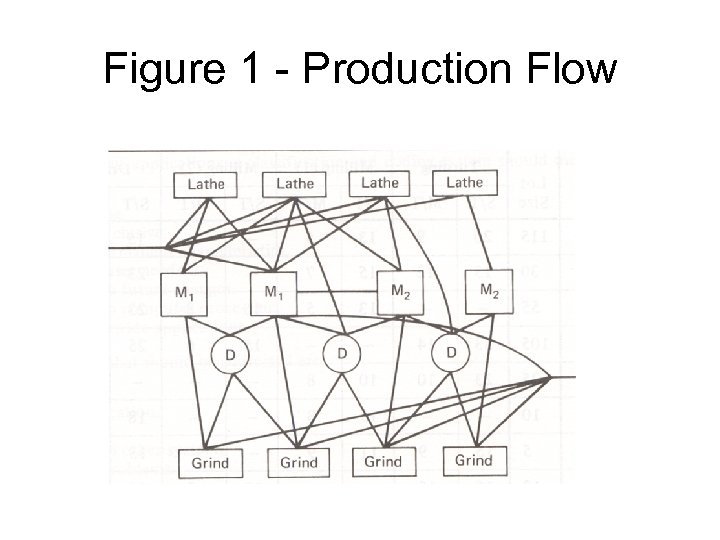

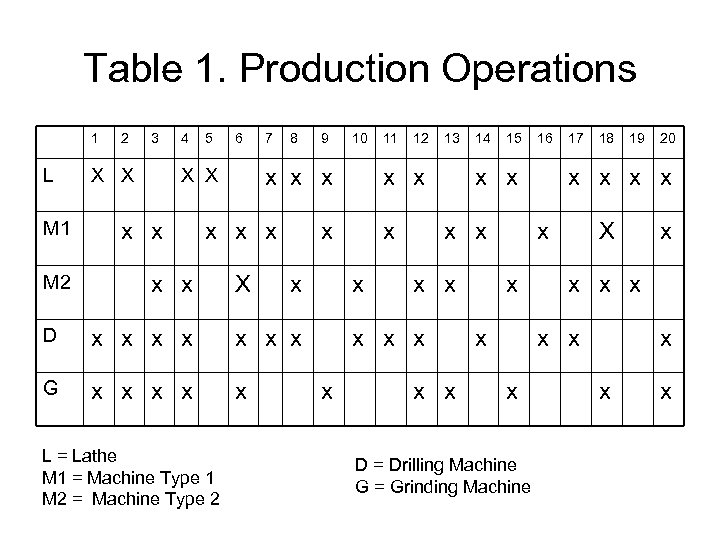

Question 1 • Assume that a machining operation produces 20 products with a machine and routing operation shown in Figure 1. • Consider the following production requirements for the 20 different part numbers given in Table 1. Develop a machine grouping plan to build the products in part families. • Illustrate the new layout and routing for the facility accounting for all machines.

Question 1 • Assume that a machining operation produces 20 products with a machine and routing operation shown in Figure 1. • Consider the following production requirements for the 20 different part numbers given in Table 1. Develop a machine grouping plan to build the products in part families. • Illustrate the new layout and routing for the facility accounting for all machines.

Figure 1 - Production Flow

Figure 1 - Production Flow

Table 1. Production Operations 1 L M 1 M 2 2 3 X X 4 5 6 X X x x 7 8 X x x x G x x x 12 x x x 11 13 x x x D L = Lathe M 1 = Machine Type 1 M 2 = Machine Type 2 10 x x x x 9 15 16 x x x x x 14 x x 17 x X D = Drilling Machine G = Grinding Machine 20 x x x x 19 x x x 18 x x x

Table 1. Production Operations 1 L M 1 M 2 2 3 X X 4 5 6 X X x x 7 8 X x x x G x x x 12 x x x 11 13 x x x D L = Lathe M 1 = Machine Type 1 M 2 = Machine Type 2 10 x x x x 9 15 16 x x x x x 14 x x 17 x X D = Drilling Machine G = Grinding Machine 20 x x x x 19 x x x 18 x x x

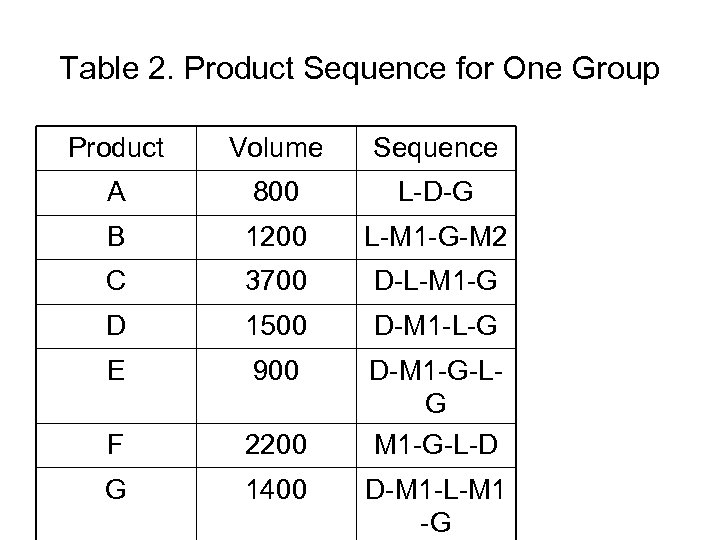

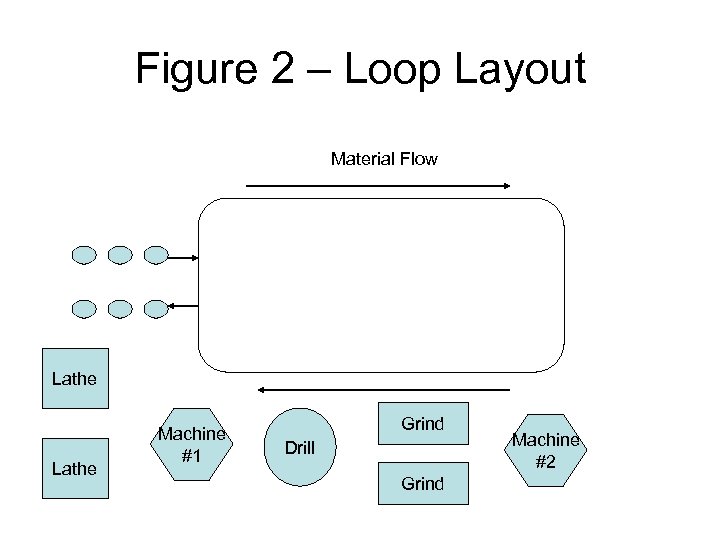

Question 2 • Next assume that production for each part in one group did not have the same processing routing sequence. The routing sequence for a series of parts is noted in the following Table 2. 2. A) For this operation, a loop operation using the diagram as shown in Figure 2 is proposed. Arrange the lathes, machine, drill, and grinder to minimize the flow for the loop conveyor. 2. B) If you are allowed to buy one more machine (i. e. machine duplication), which machine would you like to buy and why? What will be the new layout?

Question 2 • Next assume that production for each part in one group did not have the same processing routing sequence. The routing sequence for a series of parts is noted in the following Table 2. 2. A) For this operation, a loop operation using the diagram as shown in Figure 2 is proposed. Arrange the lathes, machine, drill, and grinder to minimize the flow for the loop conveyor. 2. B) If you are allowed to buy one more machine (i. e. machine duplication), which machine would you like to buy and why? What will be the new layout?

Table 2. Product Sequence for One Group Product Volume Sequence A 800 L-D-G B 1200 L-M 1 -G-M 2 C 3700 D-L-M 1 -G D 1500 D-M 1 -L-G E 900 F 2200 D-M 1 -G-LG M 1 -G-L-D G 1400 D-M 1 -L-M 1 -G

Table 2. Product Sequence for One Group Product Volume Sequence A 800 L-D-G B 1200 L-M 1 -G-M 2 C 3700 D-L-M 1 -G D 1500 D-M 1 -L-G E 900 F 2200 D-M 1 -G-LG M 1 -G-L-D G 1400 D-M 1 -L-M 1 -G

Figure 2 – Loop Layout Material Flow Lathe Machine #1 Grind Drill Grind Machine #2

Figure 2 – Loop Layout Material Flow Lathe Machine #1 Grind Drill Grind Machine #2

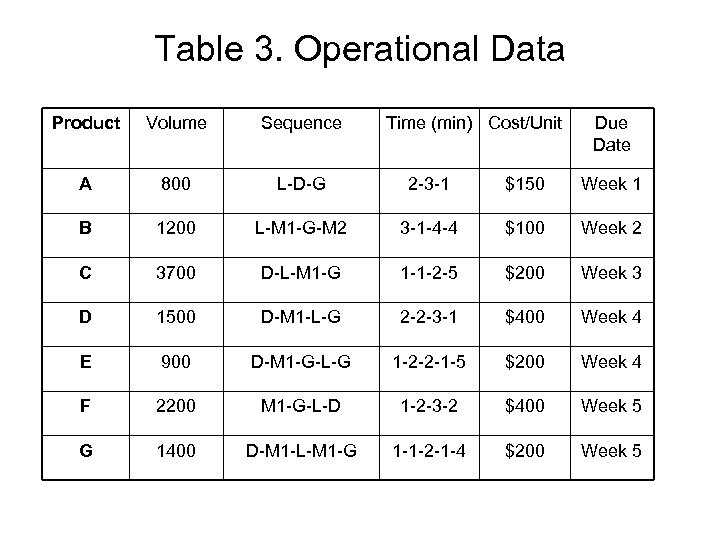

Question 3 • Assume that the following Table 3 provides a series of parts to be produced in the proposed cell. The dates show the required due date for production and the cost shows the tardiness cost per unit per week for each product. Develop a production schedule to produce the products while minimizing the total tardiness cost. • Assume that the available production time is 40 hours per week (or 8 hours per day) on each machine. The number of machines for each type are 2 Lathes, 1 Drill, 2 Grinders, 1 M 1 and 1 M 2. • Products A, B and C belong to Family 1, and Products D, E, F and G belong to Family 2. If you switch from one family to another one on any machine, the required setup time is 4 hours. There is no setup time for the products within the same family.

Question 3 • Assume that the following Table 3 provides a series of parts to be produced in the proposed cell. The dates show the required due date for production and the cost shows the tardiness cost per unit per week for each product. Develop a production schedule to produce the products while minimizing the total tardiness cost. • Assume that the available production time is 40 hours per week (or 8 hours per day) on each machine. The number of machines for each type are 2 Lathes, 1 Drill, 2 Grinders, 1 M 1 and 1 M 2. • Products A, B and C belong to Family 1, and Products D, E, F and G belong to Family 2. If you switch from one family to another one on any machine, the required setup time is 4 hours. There is no setup time for the products within the same family.

Table 3. Operational Data Product Volume Sequence Time (min) Cost/Unit Due Date A 800 L-D-G 2 -3 -1 $150 Week 1 B 1200 L-M 1 -G-M 2 3 -1 -4 -4 $100 Week 2 C 3700 D-L-M 1 -G 1 -1 -2 -5 $200 Week 3 D 1500 D-M 1 -L-G 2 -2 -3 -1 $400 Week 4 E 900 D-M 1 -G-L-G 1 -2 -2 -1 -5 $200 Week 4 F 2200 M 1 -G-L-D 1 -2 -3 -2 $400 Week 5 G 1400 D-M 1 -L-M 1 -G 1 -1 -2 -1 -4 $200 Week 5

Table 3. Operational Data Product Volume Sequence Time (min) Cost/Unit Due Date A 800 L-D-G 2 -3 -1 $150 Week 1 B 1200 L-M 1 -G-M 2 3 -1 -4 -4 $100 Week 2 C 3700 D-L-M 1 -G 1 -1 -2 -5 $200 Week 3 D 1500 D-M 1 -L-G 2 -2 -3 -1 $400 Week 4 E 900 D-M 1 -G-L-G 1 -2 -2 -1 -5 $200 Week 4 F 2200 M 1 -G-L-D 1 -2 -3 -2 $400 Week 5 G 1400 D-M 1 -L-M 1 -G 1 -1 -2 -1 -4 $200 Week 5