Презентация на конкурс.pptx

- Количество слайдов: 19

HIGH TECH RECYCLING INTER-UNIVERSITY RESEARCH CENTER Hydro. WEEE demo project Prof. Francesco Vegliò ESSEM COST Action ES 1407 European network for innovative recovery strategies of rare earth and other critical metals from electric and electronic waste (Re. Creew)

HIGH TECH RECYCLING INTER-UNIVERSITY RESEARCH CENTER Hydro. WEEE demo project Prof. Francesco Vegliò ESSEM COST Action ES 1407 European network for innovative recovery strategies of rare earth and other critical metals from electric and electronic waste (Re. Creew)

Motivation è Waste from Electrical and Electronic Equipment (WEEE) is the fastest growing waste stream (2 -5% per annum) in Europe. è Electr(on)ic products consist of a high amount of diverse metals, the precious and rare metals in very small quantities. è Regardless of their low amount in specific electronic components there are some metals which are highly preferred or are even essential for the present technology.

Motivation è Waste from Electrical and Electronic Equipment (WEEE) is the fastest growing waste stream (2 -5% per annum) in Europe. è Electr(on)ic products consist of a high amount of diverse metals, the precious and rare metals in very small quantities. è Regardless of their low amount in specific electronic components there are some metals which are highly preferred or are even essential for the present technology.

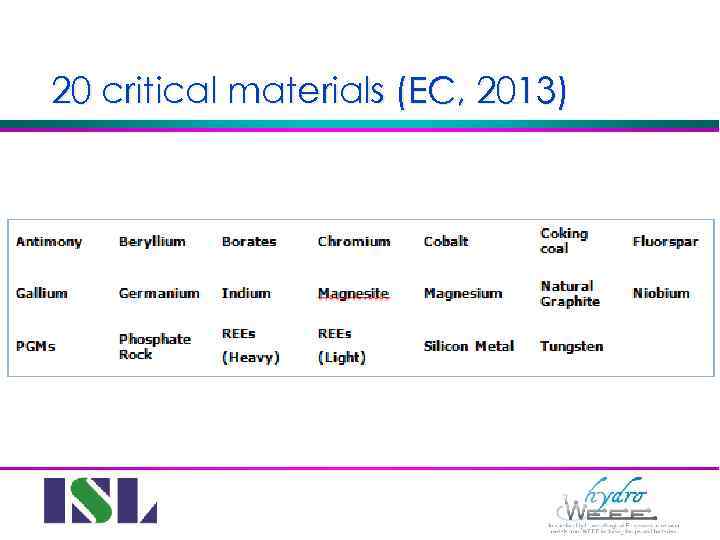

20 critical materials (EC, 2013)

20 critical materials (EC, 2013)

Main Goal To recover rare and precious metals from WEEE including lamps hydrometallurgical processes

Main Goal To recover rare and precious metals from WEEE including lamps hydrometallurgical processes

Demonstration Objectives • to design, build and demonstrate the first innovative industrial-like stationary Hydro. WEEE plant to recycle precious and rare metals. It will focus mainly on the processing of CRT- and lamps-powder as well as LCDs • to design, build and demonstrate the first full-scale, industrial mobile Hydro. WEEE plant that will be capable of processing all fractions (CRT, lamps, LCDs, Li-batteries, printed circuit boards, …) in 2 or more containers

Demonstration Objectives • to design, build and demonstrate the first innovative industrial-like stationary Hydro. WEEE plant to recycle precious and rare metals. It will focus mainly on the processing of CRT- and lamps-powder as well as LCDs • to design, build and demonstrate the first full-scale, industrial mobile Hydro. WEEE plant that will be capable of processing all fractions (CRT, lamps, LCDs, Li-batteries, printed circuit boards, …) in 2 or more containers

Research Objectives • The previously developed processes of extracting yttrium, indium, lithium, cobalt, zinc, copper, gold, silver, nickel, lead, tin will be optimised even more. • Processes to recover additional metals (e. g. Cerium, Platinum, Palladium, Europium, Lanthanum, Terbium, …) from the same 5 fractions (CRT, lamps, LCDs, Li-batteries and printed circuit boards) from WEEE and catalysts will be developed. • innovative solutions for the integrated treatment of waste water and the other solid wastes have to be found.

Research Objectives • The previously developed processes of extracting yttrium, indium, lithium, cobalt, zinc, copper, gold, silver, nickel, lead, tin will be optimised even more. • Processes to recover additional metals (e. g. Cerium, Platinum, Palladium, Europium, Lanthanum, Terbium, …) from the same 5 fractions (CRT, lamps, LCDs, Li-batteries and printed circuit boards) from WEEE and catalysts will be developed. • innovative solutions for the integrated treatment of waste water and the other solid wastes have to be found.

Work package Overview

Work package Overview

Our pilot plant (previous project)

Our pilot plant (previous project)

Project design and realisation of the pilot plant Layout of the pilot plant

Project design and realisation of the pilot plant Layout of the pilot plant

Our mobile plant

Our mobile plant

Spent fluorescent lamps process CHARACTERIZATION OF THE INITIAL MATERIALS Rare Earths content Y % La Ce Eu Gd Tb 14 0, 001 0, 002 0, 88 0, 001 0, 013 Other main elements Ca % Ba Hg Si 12 1. 4 0. 02 2. 5 XRF analysis

Spent fluorescent lamps process CHARACTERIZATION OF THE INITIAL MATERIALS Rare Earths content Y % La Ce Eu Gd Tb 14 0, 001 0, 002 0, 88 0, 001 0, 013 Other main elements Ca % Ba Hg Si 12 1. 4 0. 02 2. 5 XRF analysis

Hydrometallurgical process for lamps RE 2 O 3 + 3 H 2 SO 4 RE 2(SO 4)3 + 3 H 2 O (1) RE 2(SO 4)3 + 3(COOH)2 RE 2(C 2 O 4)3 + 3 H 2 SO 4 (2) The research activities included: laboratory, pilot and industrial tests, simulation of the processes and process analysis. At the first the processes were developed in the small scale, after are studied in the pilot scale using the Hydro. WEEE pilot plant Laboratory scale Pilot scale

Hydrometallurgical process for lamps RE 2 O 3 + 3 H 2 SO 4 RE 2(SO 4)3 + 3 H 2 O (1) RE 2(SO 4)3 + 3(COOH)2 RE 2(C 2 O 4)3 + 3 H 2 SO 4 (2) The research activities included: laboratory, pilot and industrial tests, simulation of the processes and process analysis. At the first the processes were developed in the small scale, after are studied in the pilot scale using the Hydro. WEEE pilot plant Laboratory scale Pilot scale

Industrial tests RECOVERIES YIELDS = 93 % Y, Eu PURITY OF OXIDES = 96% 88% OF RECYCLE OF SOLUTIONS Composition of final product from lamps Y 2 O 3 % Eu 2 O 3 Tb 4 O 7 La 2 O 3 Ce 2 O 3 Gd 2 O 3 86. 35 5. 73 0. 82 0. 002 1. 16 2. 12 Actual implementations -Modifications of the process conditions to increase the Tb recovery The preliminary tests showed that with little modification is it possible increase the amount of Tb (>2%) in the final oxide

Industrial tests RECOVERIES YIELDS = 93 % Y, Eu PURITY OF OXIDES = 96% 88% OF RECYCLE OF SOLUTIONS Composition of final product from lamps Y 2 O 3 % Eu 2 O 3 Tb 4 O 7 La 2 O 3 Ce 2 O 3 Gd 2 O 3 86. 35 5. 73 0. 82 0. 002 1. 16 2. 12 Actual implementations -Modifications of the process conditions to increase the Tb recovery The preliminary tests showed that with little modification is it possible increase the amount of Tb (>2%) in the final oxide

Thank you for your attention…. . Prof. Ing. Francesco Vegliò francesco. veglio@univaq. it Department of Industrial and Information Engineering and Economics, University of L'Aquila, Via Giovanni Gronchi 18, 67100 L'Aquila, Italy

Thank you for your attention…. . Prof. Ing. Francesco Vegliò francesco. veglio@univaq. it Department of Industrial and Information Engineering and Economics, University of L'Aquila, Via Giovanni Gronchi 18, 67100 L'Aquila, Italy