456704e09667d1172686646656e93cce.ppt

- Количество слайдов: 13

HIGH GENERATION RATE OF UNIFORM OIL-INWATER DROPLETS FORMED BY MULTI-STAGE DIVERGENCE MICROFLOW DEVICE Y. Murakami 1, T. Arakawa 1, E. H. Jeong 2, J. S. Go 2 and S. Shoji 1 1 Major in Nano-science and Nano-engineering, Waseda University Ohkubo Shinjuku, Tokyo, Japan 2 School of Mechanical Engineering, Pusan National University Instructor: Professor 劉承賢 CHENG-HSIEN LIU Reporter : 9733593 葉致成 CHIH-CHENG YEH TRANDUCERS & EUROSENSORS’ 07 The 14 th international Conference on Solid-State Sensor. Actuator and Microsystems, Lyon. France. June 10 -14, 2007

HIGH GENERATION RATE OF UNIFORM OIL-INWATER DROPLETS FORMED BY MULTI-STAGE DIVERGENCE MICROFLOW DEVICE Y. Murakami 1, T. Arakawa 1, E. H. Jeong 2, J. S. Go 2 and S. Shoji 1 1 Major in Nano-science and Nano-engineering, Waseda University Ohkubo Shinjuku, Tokyo, Japan 2 School of Mechanical Engineering, Pusan National University Instructor: Professor 劉承賢 CHENG-HSIEN LIU Reporter : 9733593 葉致成 CHIH-CHENG YEH TRANDUCERS & EUROSENSORS’ 07 The 14 th international Conference on Solid-State Sensor. Actuator and Microsystems, Lyon. France. June 10 -14, 2007

METHODS TO GENERATE THE SMALLER SIZE OF DROPLETS Flow focusing geometry. Geometrically mediated breakup of droplets.

METHODS TO GENERATE THE SMALLER SIZE OF DROPLETS Flow focusing geometry. Geometrically mediated breakup of droplets.

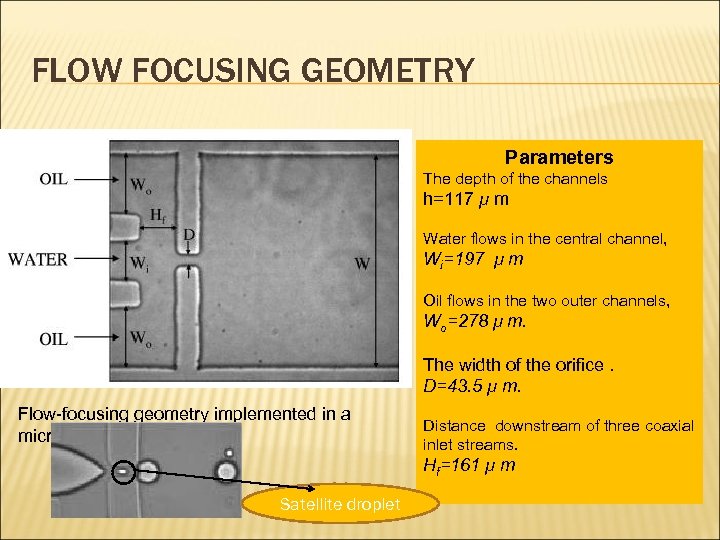

FLOW FOCUSING GEOMETRY Parameters The depth of the channels h=117 μ m Water flows in the central channel, Wi=197 μ m Oil flows in the two outer channels, Wo=278 μ m. The width of the orifice. D=43. 5 μ m. Flow-focusing geometry implemented in a microfluidic device Distance downstream of three coaxial inlet streams. Hf=161 μ m Satellite droplet

FLOW FOCUSING GEOMETRY Parameters The depth of the channels h=117 μ m Water flows in the central channel, Wi=197 μ m Oil flows in the two outer channels, Wo=278 μ m. The width of the orifice. D=43. 5 μ m. Flow-focusing geometry implemented in a microfluidic device Distance downstream of three coaxial inlet streams. Hf=161 μ m Satellite droplet

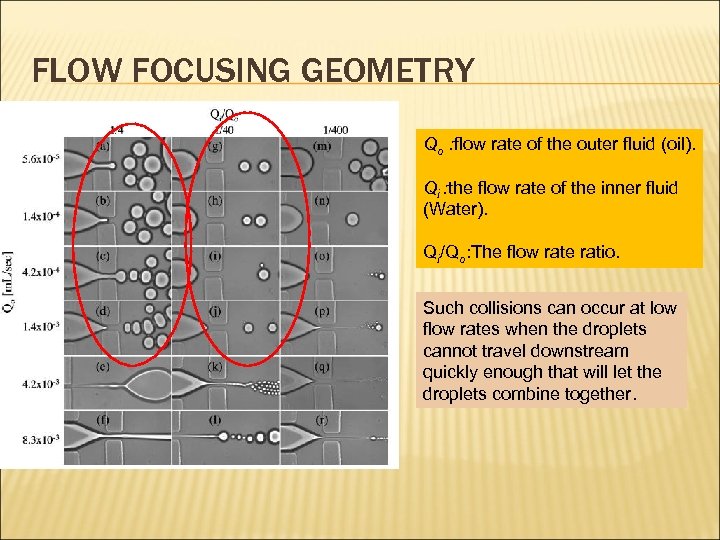

FLOW FOCUSING GEOMETRY Qo : flow rate of the outer fluid (oil). Qi : the flow rate of the inner fluid (Water). Qi/Qo: The flow rate ratio. Such collisions can occur at low flow rates when the droplets cannot travel downstream quickly enough that will let the droplets combine together.

FLOW FOCUSING GEOMETRY Qo : flow rate of the outer fluid (oil). Qi : the flow rate of the inner fluid (Water). Qi/Qo: The flow rate ratio. Such collisions can occur at low flow rates when the droplets cannot travel downstream quickly enough that will let the droplets combine together.

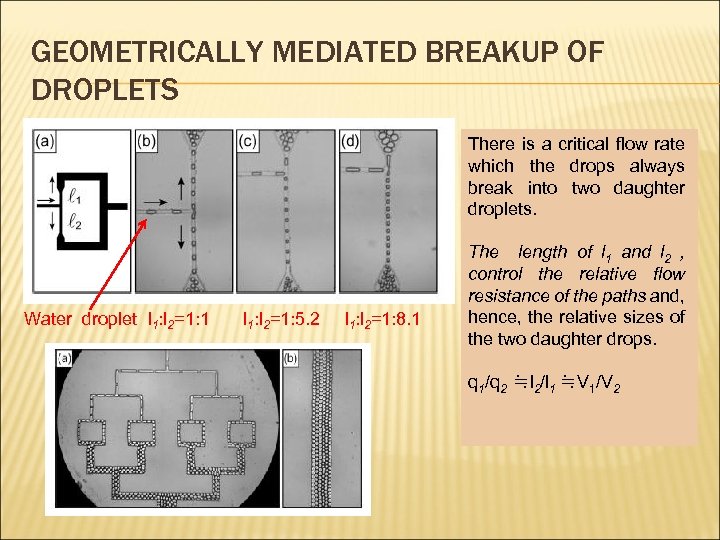

GEOMETRICALLY MEDIATED BREAKUP OF DROPLETS There is a critical flow rate which the drops always break into two daughter droplets. Water droplet l 1: l 2=1: 1 l 1: l 2=1: 5. 2 l 1: l 2=1: 8. 1 The length of l 1 and l 2 , control the relative flow resistance of the paths and, hence, the relative sizes of the two daughter drops. q 1/q 2 ≒l 2/l 1 ≒V 1/V 2

GEOMETRICALLY MEDIATED BREAKUP OF DROPLETS There is a critical flow rate which the drops always break into two daughter droplets. Water droplet l 1: l 2=1: 1 l 1: l 2=1: 5. 2 l 1: l 2=1: 8. 1 The length of l 1 and l 2 , control the relative flow resistance of the paths and, hence, the relative sizes of the two daughter drops. q 1/q 2 ≒l 2/l 1 ≒V 1/V 2

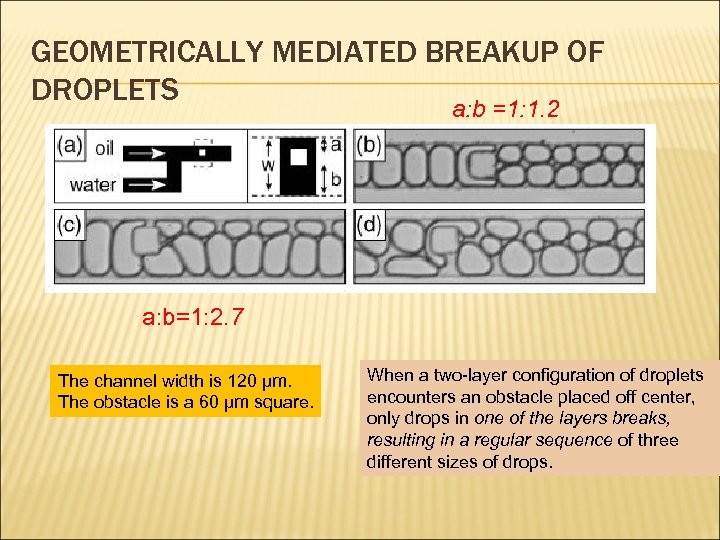

GEOMETRICALLY MEDIATED BREAKUP OF DROPLETS a: b =1: 1. 2 a: b=1: 2. 7 The channel width is 120 μm. The obstacle is a 60 μm square. When a two-layer configuration of droplets encounters an obstacle placed off center, only drops in one of the layers breaks, resulting in a regular sequence of three different sizes of drops.

GEOMETRICALLY MEDIATED BREAKUP OF DROPLETS a: b =1: 1. 2 a: b=1: 2. 7 The channel width is 120 μm. The obstacle is a 60 μm square. When a two-layer configuration of droplets encounters an obstacle placed off center, only drops in one of the layers breaks, resulting in a regular sequence of three different sizes of drops.

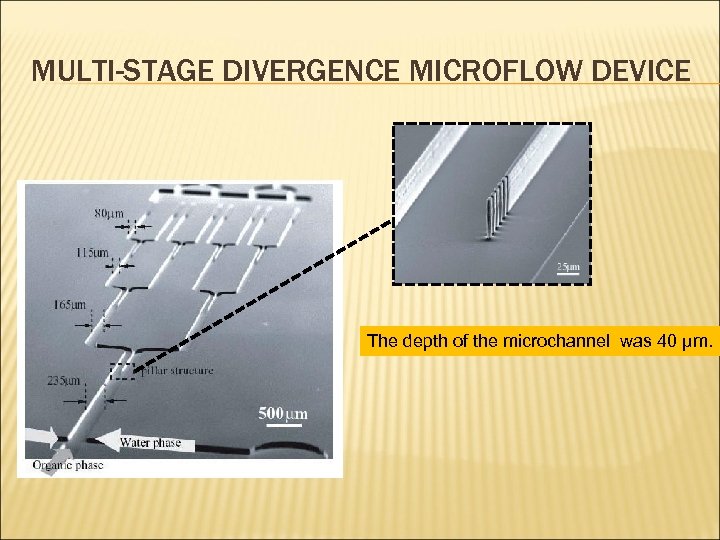

MULTI-STAGE DIVERGENCE MICROFLOW DEVICE The depth of the microchannel was 40 μm.

MULTI-STAGE DIVERGENCE MICROFLOW DEVICE The depth of the microchannel was 40 μm.

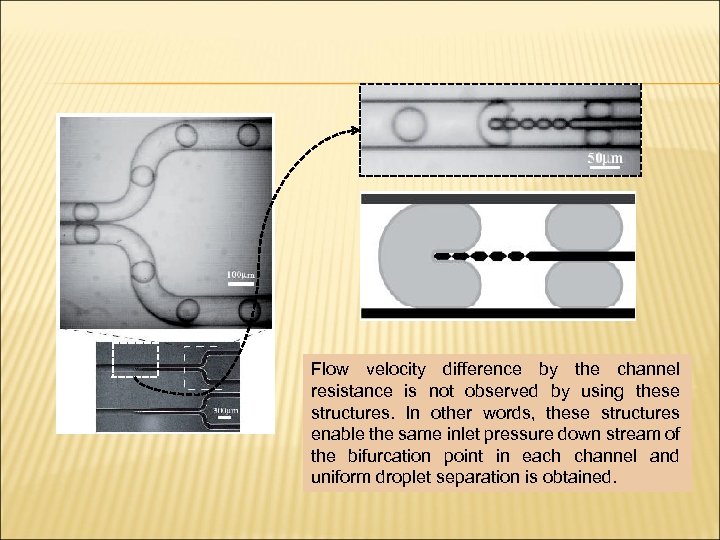

Flow velocity difference by the channel resistance is not observed by using these structures. In other words, these structures enable the same inlet pressure down stream of the bifurcation point in each channel and uniform droplet separation is obtained.

Flow velocity difference by the channel resistance is not observed by using these structures. In other words, these structures enable the same inlet pressure down stream of the bifurcation point in each channel and uniform droplet separation is obtained.

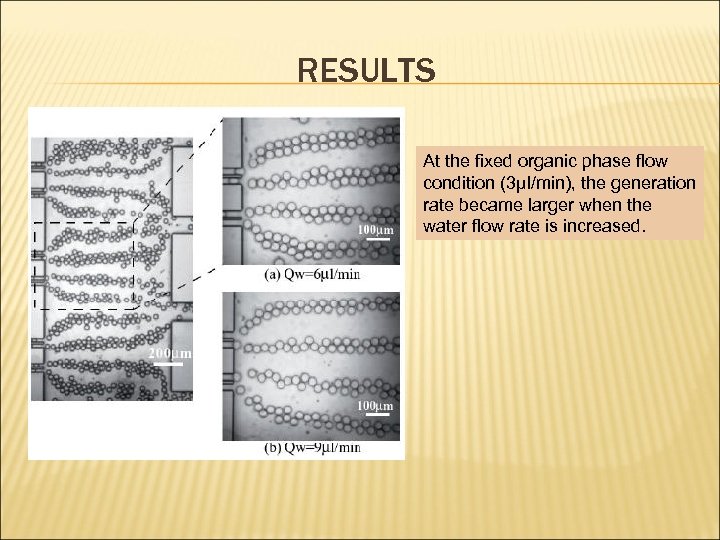

RESULTS At the fixed organic phase flow condition (3μl/min), the generation rate became larger when the water flow rate is increased.

RESULTS At the fixed organic phase flow condition (3μl/min), the generation rate became larger when the water flow rate is increased.

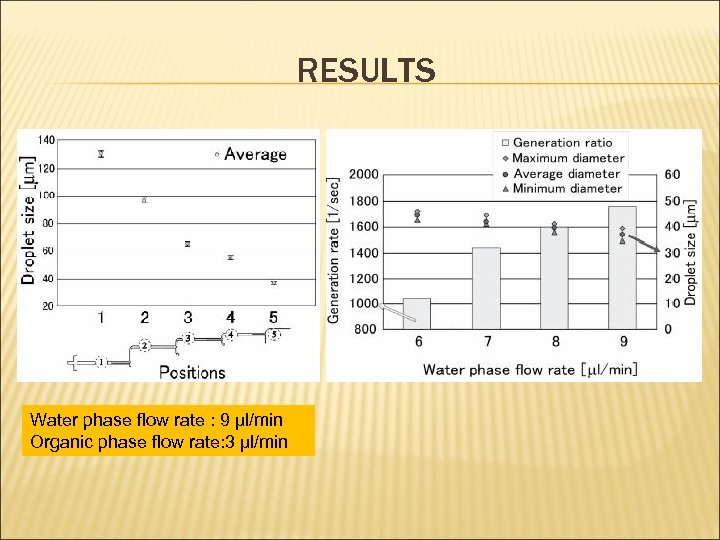

RESULTS Water phase flow rate : 9 μl/min Organic phase flow rate: 3 μl/min

RESULTS Water phase flow rate : 9 μl/min Organic phase flow rate: 3 μl/min

CONCLUSIONS High generation rate of uniform water-in-oil droplets was realized by multi-stage divergence microflow device. (Max generation rate was 1760 droplets/sec , and the droplets was 37 μm) This average diameter of the device can be applied to product microbeads and microcapsules which used in drug delivery.

CONCLUSIONS High generation rate of uniform water-in-oil droplets was realized by multi-stage divergence microflow device. (Max generation rate was 1760 droplets/sec , and the droplets was 37 μm) This average diameter of the device can be applied to product microbeads and microcapsules which used in drug delivery.

![REFERENCE [1] S. L. Anna, N. Bontoux, and H. A. Stone, REFERENCE [1] S. L. Anna, N. Bontoux, and H. A. Stone,](https://present5.com/presentation/456704e09667d1172686646656e93cce/image-12.jpg) REFERENCE [1] S. L. Anna, N. Bontoux, and H. A. Stone, "Formation of dispersions using “flow focusing” in microchannels, " Applied Physics Letters, vol. 82, pp. 364 -366, 2003. [2] D. R. Link, S. L. Anna, D. A. Weitz, and H. A. Stone, "Geometrically Mediated Breakup of Drops in Microfluidic Devices, " Physical Review Letters, vol. 92, p. 054503, 2004.

REFERENCE [1] S. L. Anna, N. Bontoux, and H. A. Stone, "Formation of dispersions using “flow focusing” in microchannels, " Applied Physics Letters, vol. 82, pp. 364 -366, 2003. [2] D. R. Link, S. L. Anna, D. A. Weitz, and H. A. Stone, "Geometrically Mediated Breakup of Drops in Microfluidic Devices, " Physical Review Letters, vol. 92, p. 054503, 2004.

THANKS FOR YOUR ATTENTION.

THANKS FOR YOUR ATTENTION.