bbfd08659be9379285eceb27686a1819.ppt

- Количество слайдов: 30

HFT Technology and Mechanical Design Wieman RNC LBNL TAC Review Wed. 11: 30 – 12: 05 15 -Mar-2006 1

Topics § Requirements and features § CMOS APS Detector Technology u APS Introduction u Basis for Technology Choice u Development history u Efficiency vs Accidentals based on electron beam measurements u R&D plan, a 4 ms chip followed by a 0. 2 ms chip u Detector Verification in STAR Environment § Mechanical Concept u Minimum mass ladders u Single end support § Stable reproducible spatial alignment § Rapid insertion and removal u Thin beam pipe system § Conclude with summary of R&D issues 2

Requirement Detect low momentum D’s in the environment of high multiplicity heavy ion collisions and high luminosity at RHIC in the most effective manner consistent with available resources 3

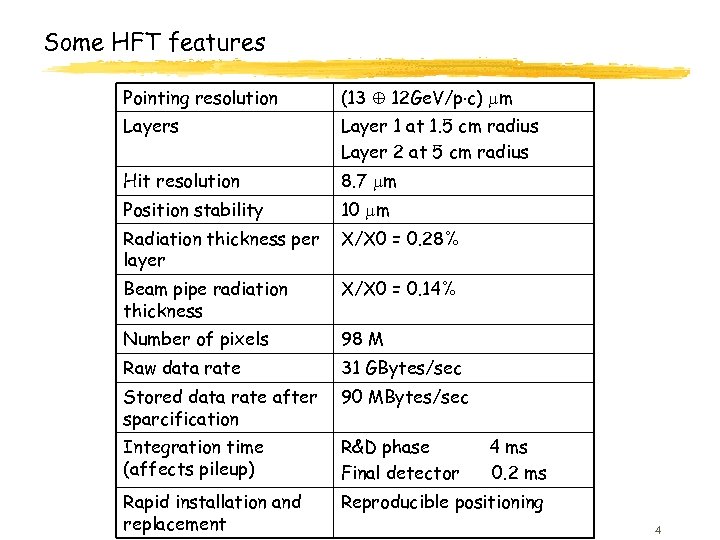

Some HFT features Pointing resolution (13 12 Ge. V/p c) m Layers Layer 1 at 1. 5 cm radius Layer 2 at 5 cm radius Hit resolution 8. 7 m Position stability 10 m Radiation thickness per layer X/X 0 = 0. 28% Beam pipe radiation thickness X/X 0 = 0. 14% Number of pixels 98 M Raw data rate 31 GBytes/sec Stored data rate after sparcification 90 MBytes/sec Integration time (affects pileup) R&D phase Final detector Rapid installation and replacement Reproducible positioning 4 ms 0. 2 ms 4

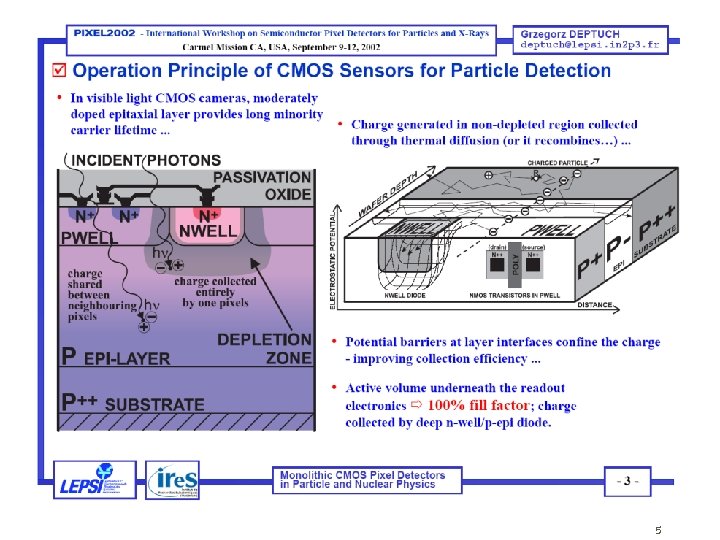

5

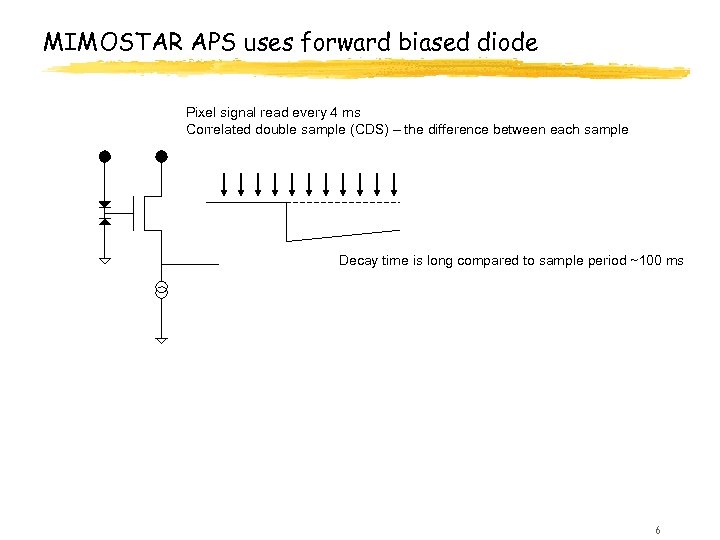

MIMOSTAR APS uses forward biased diode Pixel signal read every 4 ms Correlated double sample (CDS) – the difference between each sample Decay time is long compared to sample period ~100 ms 6

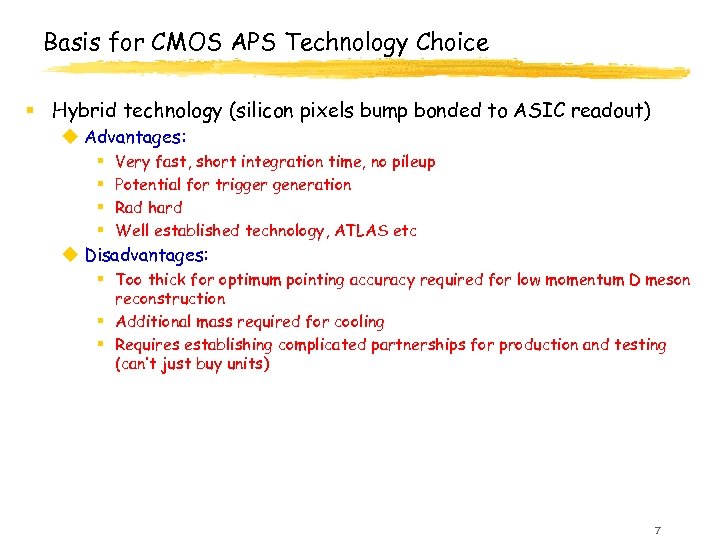

Basis for CMOS APS Technology Choice § Hybrid technology (silicon pixels bump bonded to ASIC readout) u Advantages: § § Very fast, short integration time, no pileup Potential for trigger generation Rad hard Well established technology, ATLAS etc u Disadvantages: § Too thick for optimum pointing accuracy required for low momentum D meson reconstruction § Additional mass required for cooling § Requires establishing complicated partnerships for production and testing (can’t just buy units) 7

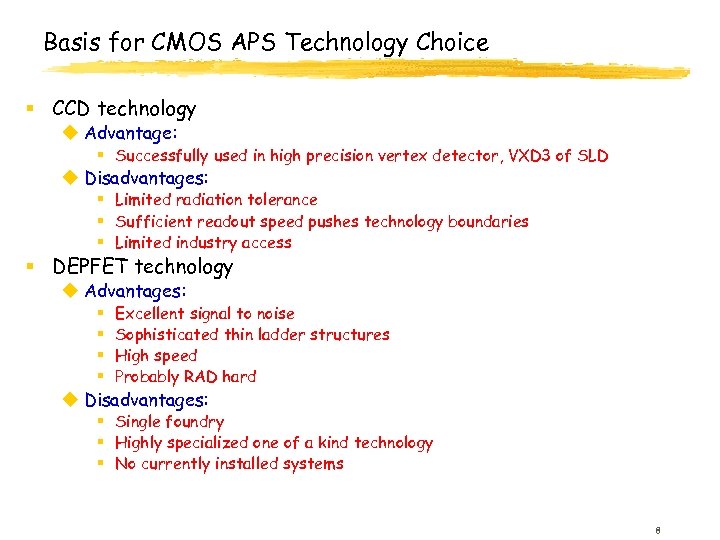

Basis for CMOS APS Technology Choice § CCD technology u Advantage: § Successfully used in high precision vertex detector, VXD 3 of SLD u Disadvantages: § Limited radiation tolerance § Sufficient readout speed pushes technology boundaries § Limited industry access § DEPFET technology u Advantages: § § Excellent signal to noise Sophisticated thin ladder structures High speed Probably RAD hard u Disadvantages: § Single foundry § Highly specialized one of a kind technology § No currently installed systems 8

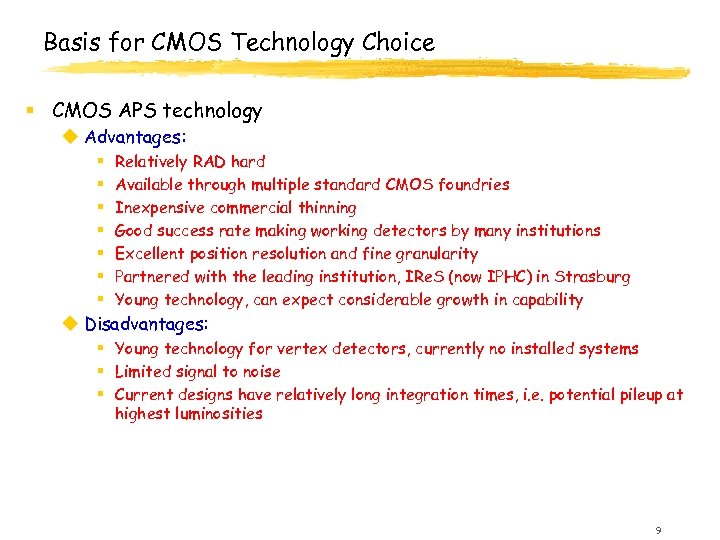

Basis for CMOS Technology Choice § CMOS APS technology u Advantages: § § § § Relatively RAD hard Available through multiple standard CMOS foundries Inexpensive commercial thinning Good success rate making working detectors by many institutions Excellent position resolution and fine granularity Partnered with the leading institution, IRe. S (now IPHC) in Strasburg Young technology, can expect considerable growth in capability u Disadvantages: § Young technology for vertex detectors, currently no installed systems § Limited signal to noise § Current designs have relatively long integration times, i. e. potential pileup at highest luminosities 9

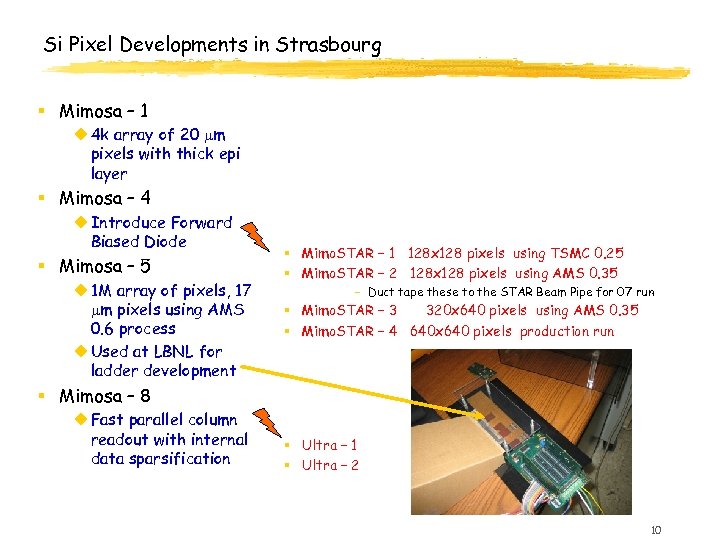

Si Pixel Developments in Strasbourg § Mimosa – 1 u 4 k array of 20 m pixels with thick epi layer § Mimosa – 4 u Introduce Forward Biased Diode § Mimosa – 5 u 1 M array of pixels, 17 m pixels using AMS 0. 6 process u Used at LBNL for ladder development § Mimo. STAR – 1 128 x 128 pixels using TSMC 0. 25 § Mimo. STAR – 2 128 x 128 pixels using AMS 0. 35 – Duct tape these to the STAR Beam Pipe for 07 run § Mimo. STAR – 3 320 x 640 pixels using AMS 0. 35 § Mimo. STAR – 4 640 x 640 pixels production run § Mimosa – 8 u Fast parallel column readout with internal data sparsification § Ultra – 1 § Ultra – 2 10

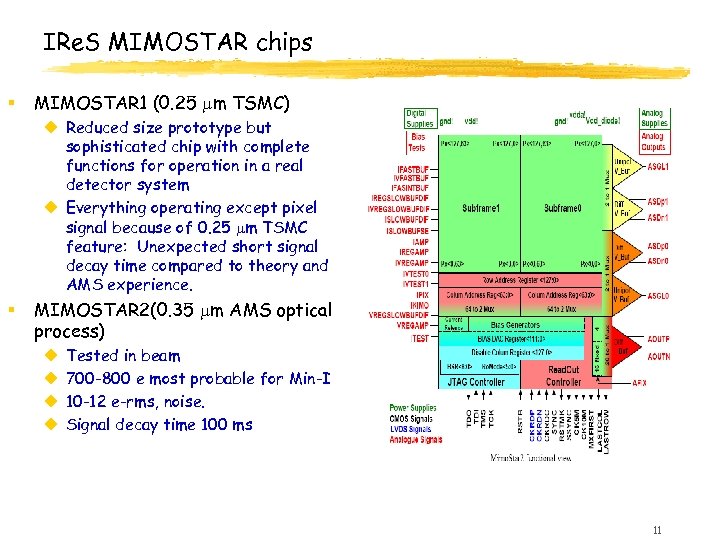

IRe. S MIMOSTAR chips § MIMOSTAR 1 (0. 25 m TSMC) u Reduced size prototype but sophisticated chip with complete functions for operation in a real detector system u Everything operating except pixel signal because of 0. 25 m TSMC feature: Unexpected short signal decay time compared to theory and AMS experience. § MIMOSTAR 2(0. 35 m AMS optical process) u u Tested in beam 700 -800 e most probable for Min-I 10 -12 e-rms, noise. Signal decay time 100 ms 11

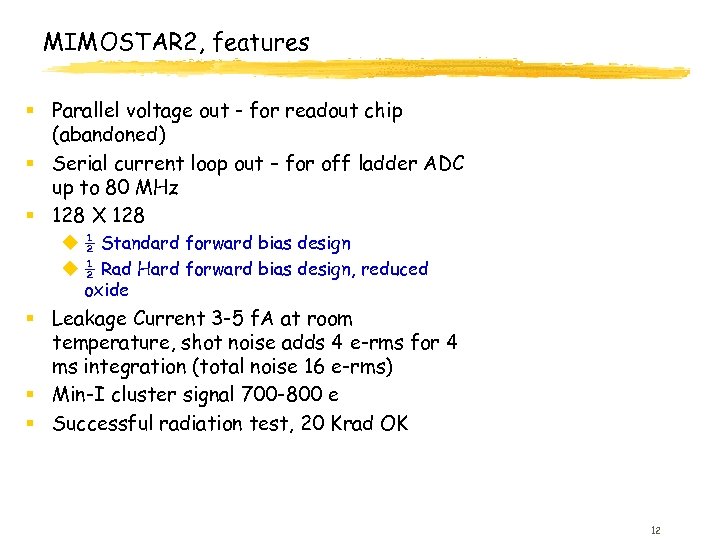

MIMOSTAR 2, features § Parallel voltage out - for readout chip (abandoned) § Serial current loop out – for off ladder ADC up to 80 MHz § 128 X 128 u ½ Standard forward bias design u ½ Rad Hard forward bias design, reduced oxide § Leakage Current 3 -5 f. A at room temperature, shot noise adds 4 e-rms for 4 ms integration (total noise 16 e-rms) § Min-I cluster signal 700 -800 e § Successful radiation test, 20 Krad OK 12

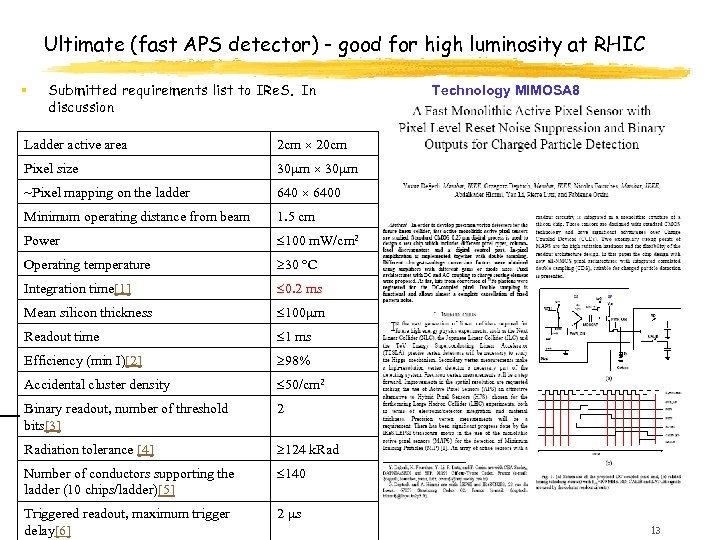

Ultimate (fast APS detector) - good for high luminosity at RHIC § Submitted requirements list to IRe. S. In discussion Ladder active area 2 cm 20 cm Pixel size 30 m ~Pixel mapping on the ladder 6400 Minimum operating distance from beam 1. 5 cm Power 100 m. W/cm 2 Operating temperature 30 C Integration time[1] 0. 2 ms Mean silicon thickness 100 m Readout time 1 ms Efficiency (min I)[2] 98% Accidental cluster density 50/cm 2 Binary readout, number of threshold bits[3] 2 Radiation tolerance [4] 124 k. Rad Number of conductors supporting the ladder (10 chips/ladder)[5] 140 Triggered readout, maximum trigger delay[6] Technology MIMOSA 8 2 s 13

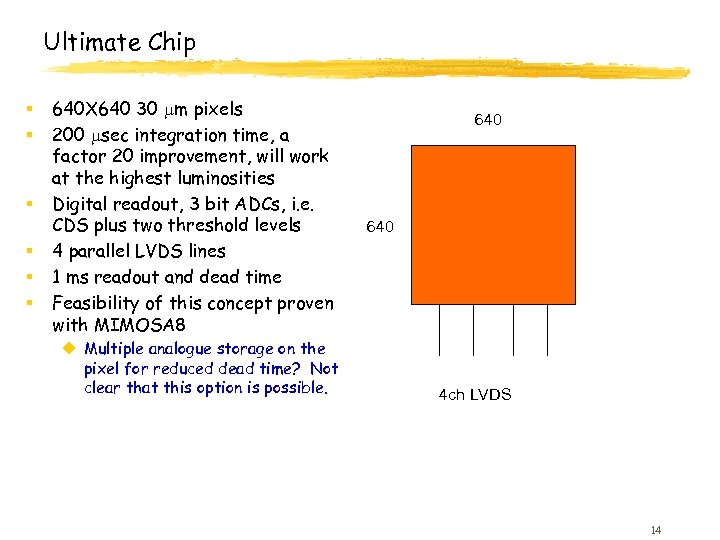

Ultimate Chip § § § 640 X 640 30 m pixels 200 sec integration time, a factor 20 improvement, will work at the highest luminosities Digital readout, 3 bit ADCs, i. e. CDS plus two threshold levels 4 parallel LVDS lines 1 ms readout and dead time Feasibility of this concept proven with MIMOSA 8 u Multiple analogue storage on the pixel for reduced dead time? Not clear that this option is possible. 640 4 ch LVDS 14

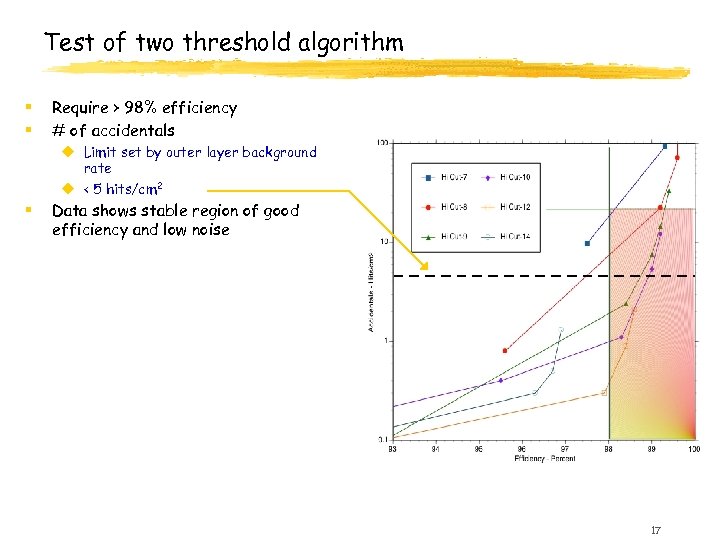

Efficiency vs Accidentals § A critical issue with thin APS CMOS detectors § Can data sparcification be achieved without loss of efficiency? § Following study shows that planned simple high speed algorithm will work 15

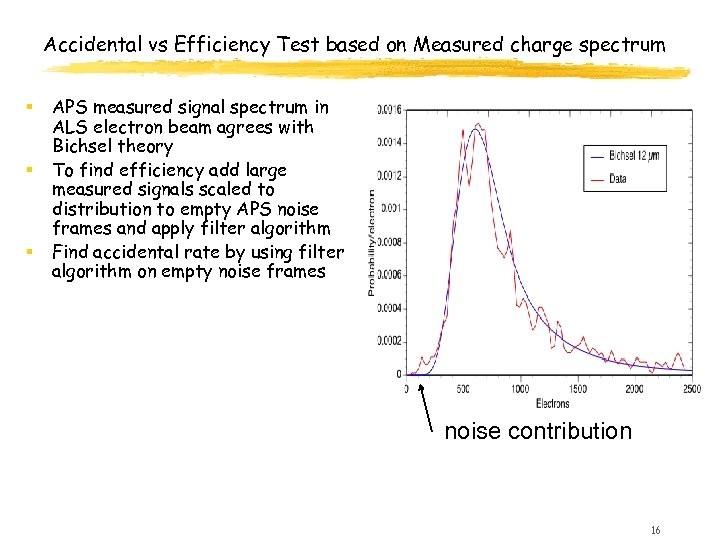

Accidental vs Efficiency Test based on Measured charge spectrum § § § APS measured signal spectrum in ALS electron beam agrees with Bichsel theory To find efficiency add large measured signals scaled to distribution to empty APS noise frames and apply filter algorithm Find accidental rate by using filter algorithm on empty noise frames noise contribution 16

Test of two threshold algorithm § § Require > 98% efficiency # of accidentals u Limit set by outer layer background rate u < 5 hits/cm 2 § Data shows stable region of good efficiency and low noise 17

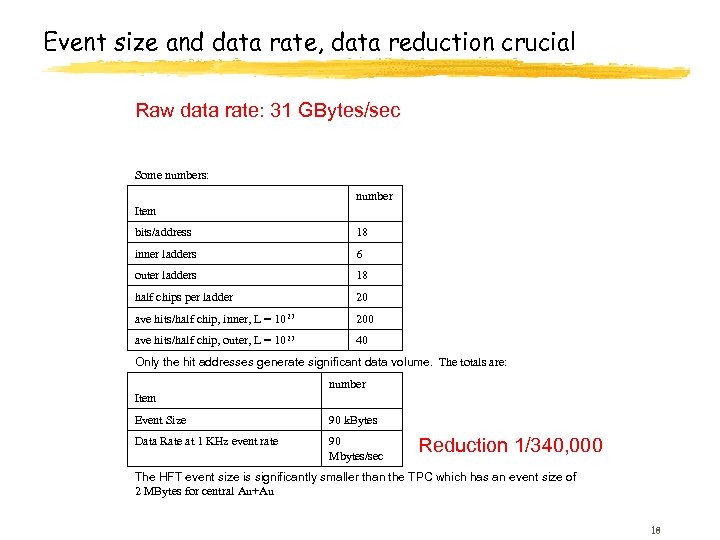

Event size and data rate, data reduction crucial Raw data rate: 31 GBytes/sec Some numbers: number Item bits/address 18 inner ladders 6 outer ladders 18 half chips per ladder 20 ave hits/half chip, inner, L = 10 27 200 ave hits/half chip, outer, L = 10 27 40 Only the hit addresses generate significant data volume. The totals are: number Item Event Size 90 k. Bytes Data Rate at 1 KHz event rate 90 Mbytes/sec Reduction 1/340, 000 The HFT event size is significantly smaller than the TPC which has an event size of 2 MBytes for central Au+Au 18

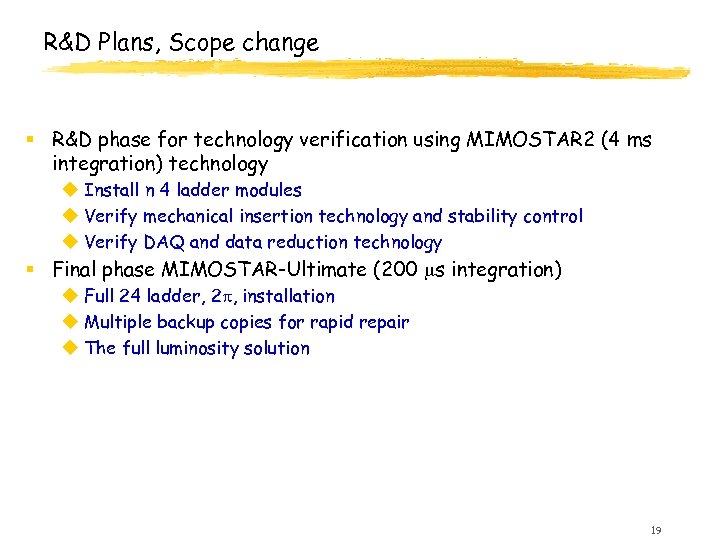

R&D Plans, Scope change § R&D phase for technology verification using MIMOSTAR 2 (4 ms integration) technology u Install n 4 ladder modules u Verify mechanical insertion technology and stability control u Verify DAQ and data reduction technology § Final phase MIMOSTAR-Ultimate (200 s integration) u Full 24 ladder, 2 , installation u Multiple backup copies for rapid repair u The full luminosity solution 19

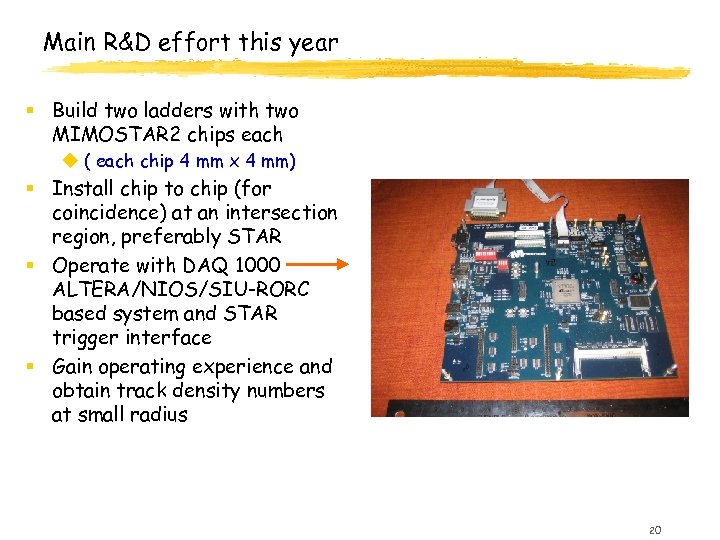

Main R&D effort this year § Build two ladders with two MIMOSTAR 2 chips each u ( each chip 4 mm x 4 mm) § Install chip to chip (for coincidence) at an intersection region, preferably STAR § Operate with DAQ 1000 ALTERA/NIOS/SIU-RORC based system and STAR trigger interface § Gain operating experience and obtain track density numbers at small radius 20

Mechanical § Mechanical support § Beam pipe 21

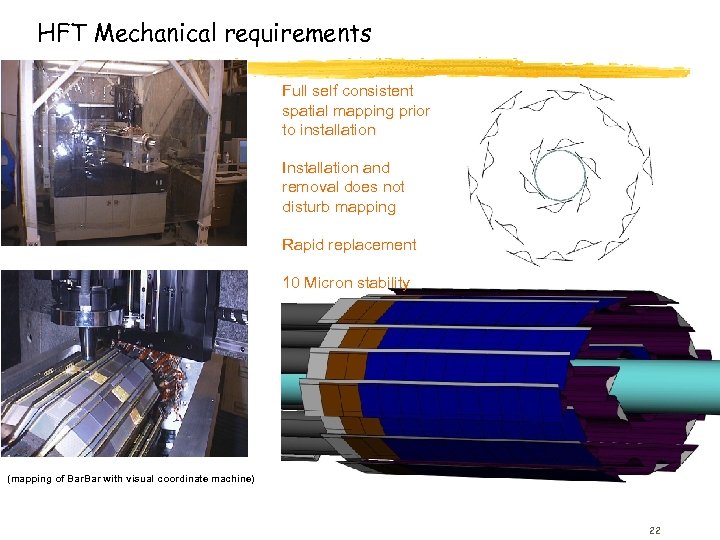

HFT Mechanical requirements Full self consistent spatial mapping prior to installation Installation and removal does not disturb mapping Rapid replacement 10 Micron stability (mapping of Bar with visual coordinate machine) 22

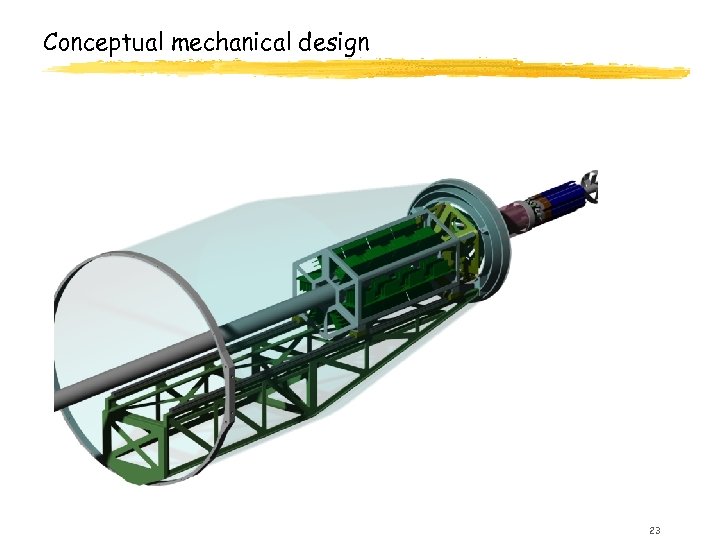

Conceptual mechanical design 23

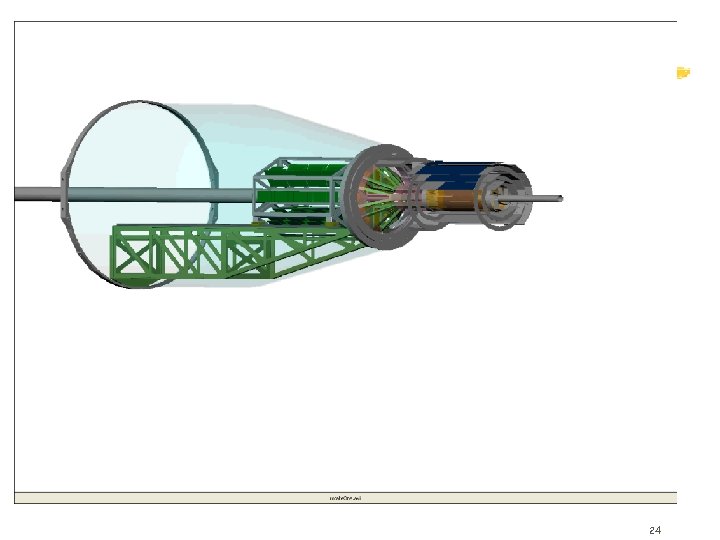

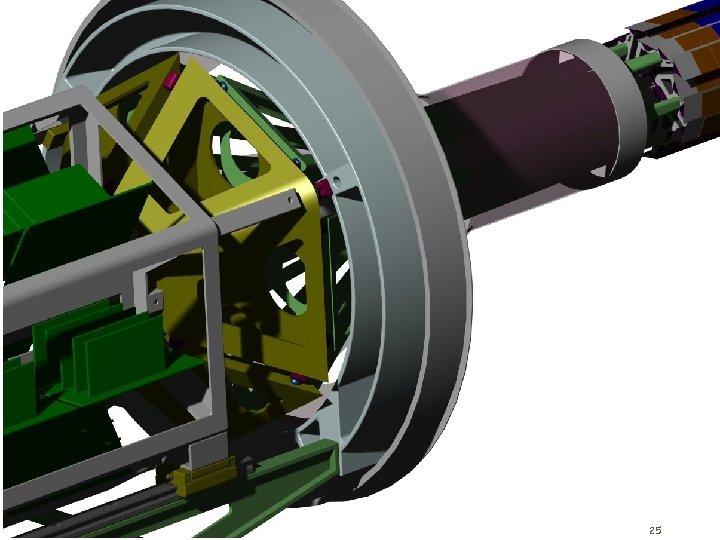

24

25

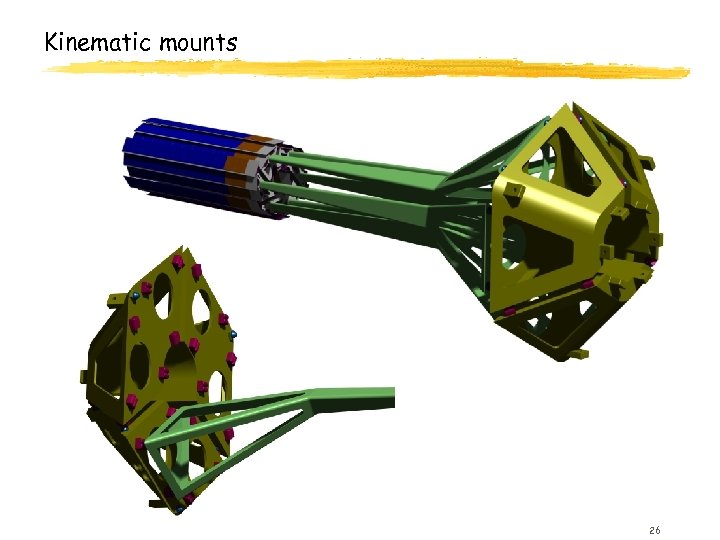

Kinematic mounts 26

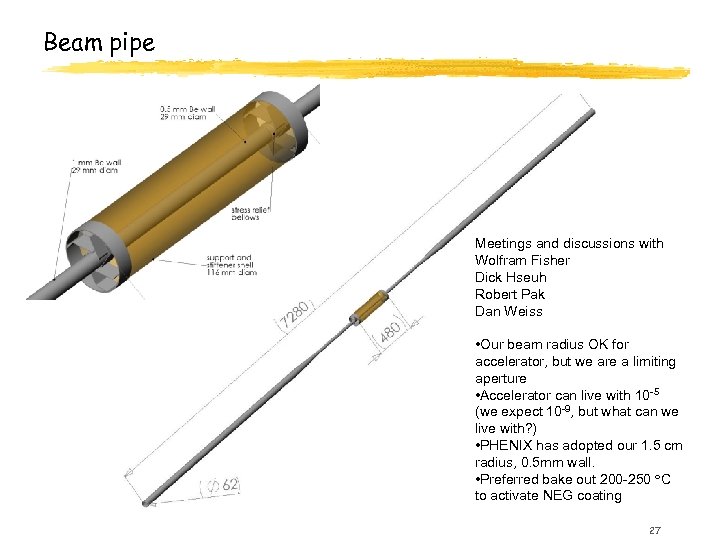

Beam pipe Meetings and discussions with Wolfram Fisher Dick Hseuh Robert Pak Dan Weiss • Our beam radius OK for accelerator, but we are a limiting aperture • Accelerator can live with 10 -5 (we expect 10 -9, but what can we live with? ) • PHENIX has adopted our 1. 5 cm radius, 0. 5 mm wall. • Preferred bake out 200 -250 C to activate NEG coating 27

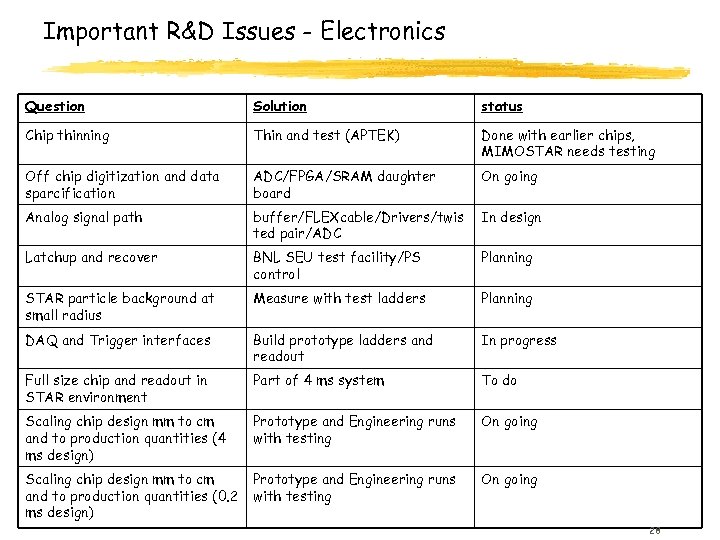

Important R&D Issues - Electronics Question Solution status Chip thinning Thin and test (APTEK) Done with earlier chips, MIMOSTAR needs testing Off chip digitization and data sparcification ADC/FPGA/SRAM daughter board On going Analog signal path buffer/FLEXcable/Drivers/twis ted pair/ADC In design Latchup and recover BNL SEU test facility/PS control Planning STAR particle background at small radius Measure with test ladders Planning DAQ and Trigger interfaces Build prototype ladders and readout In progress Full size chip and readout in STAR environment Part of 4 ms system To do Scaling chip design mm to cm and to production quantities (4 ms design) Prototype and Engineering runs with testing On going Scaling chip design mm to cm and to production quantities (0. 2 ms design) Prototype and Engineering runs with testing On going 28

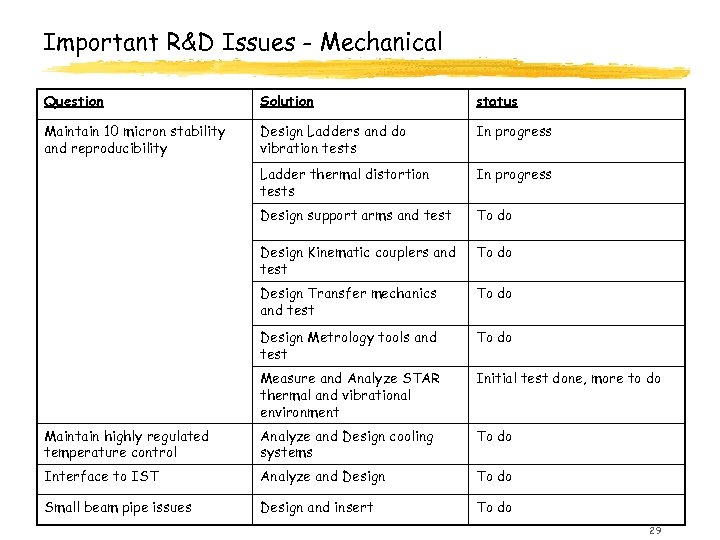

Important R&D Issues - Mechanical Question Solution status Maintain 10 micron stability and reproducibility Design Ladders and do vibration tests In progress Ladder thermal distortion tests In progress Design support arms and test To do Design Kinematic couplers and test To do Design Transfer mechanics and test To do Design Metrology tools and test To do Measure and Analyze STAR thermal and vibrational environment Initial test done, more to do Maintain highly regulated temperature control Analyze and Design cooling systems To do Interface to IST Analyze and Design To do Small beam pipe issues Design and insert To do 29

Conclusion 30

bbfd08659be9379285eceb27686a1819.ppt